The Influence of Addition of Expired Pharmaceuticals on Thermal Behaviour of Selected Types of Biomass

Abstract

1. Introduction

2. Materials and Methods

2.1. Research Objects

2.2. Pyrolysis of Samples in a Tube Furnace

2.3. Spectroscopic Studies of Condensable Pyrolysis Products

2.4. TG/FT-IR Test

2.5. XRD Tests

2.6. SEM Visualization

3. Results and Discussion

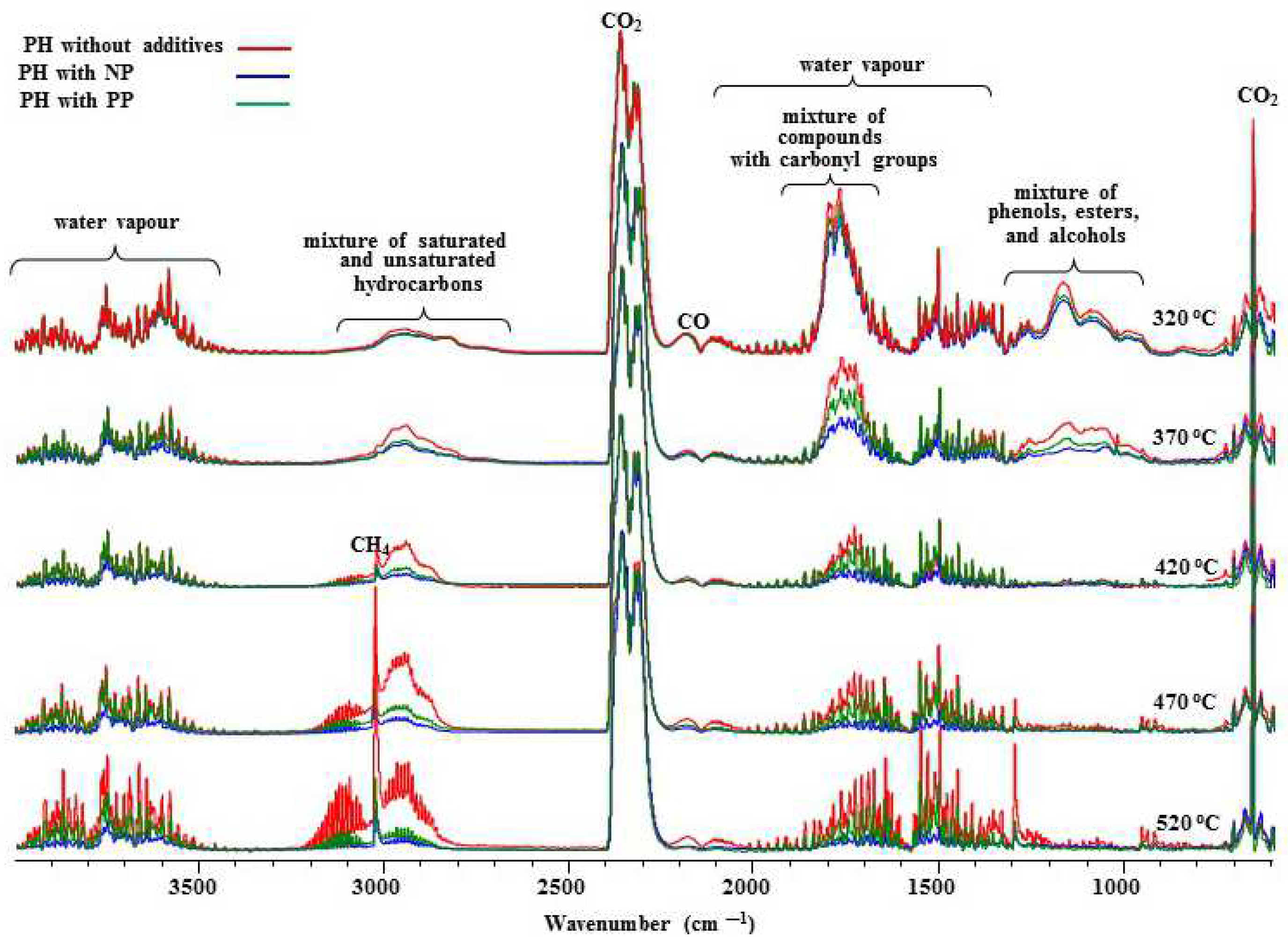

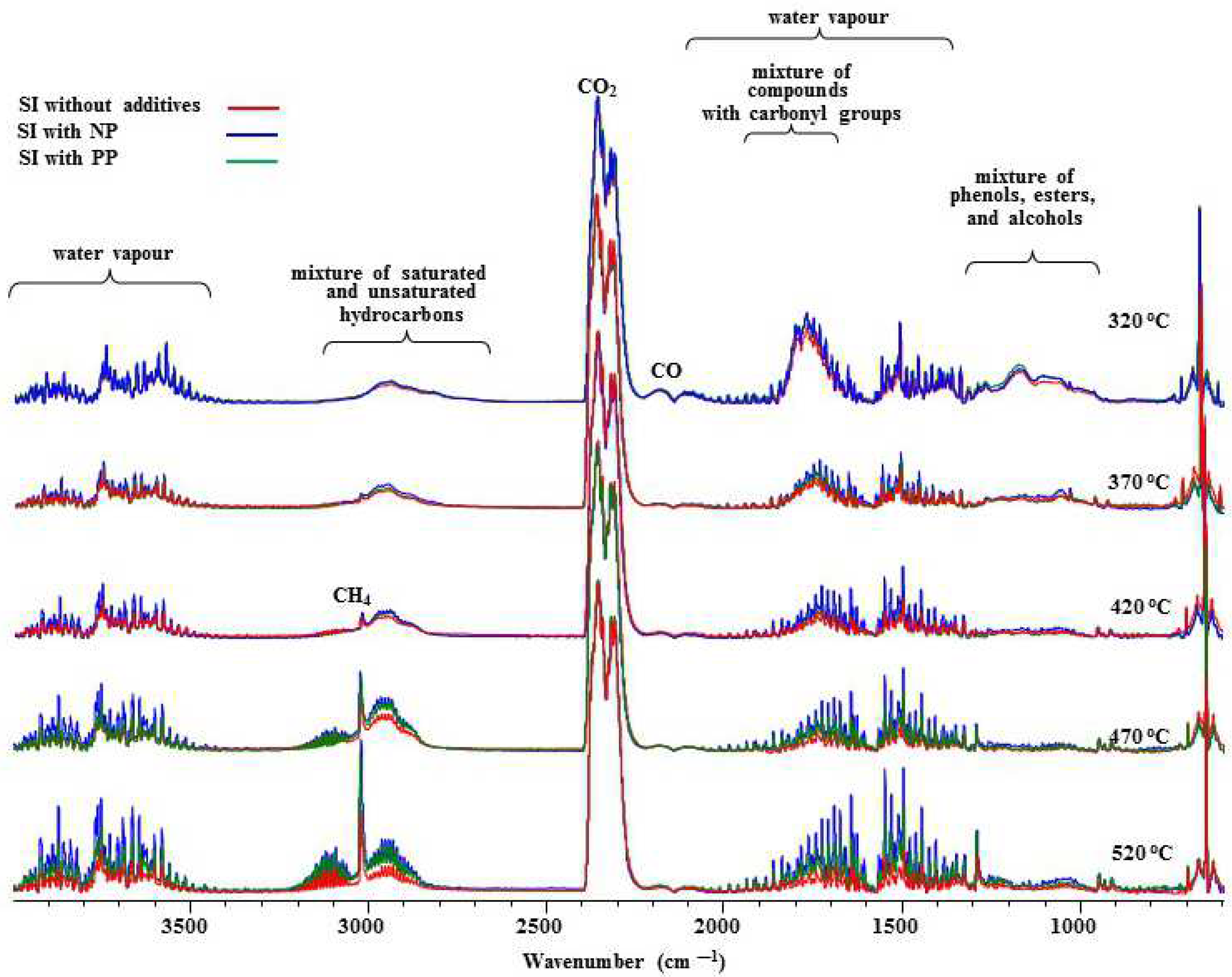

3.1. TG/FT-IR Test

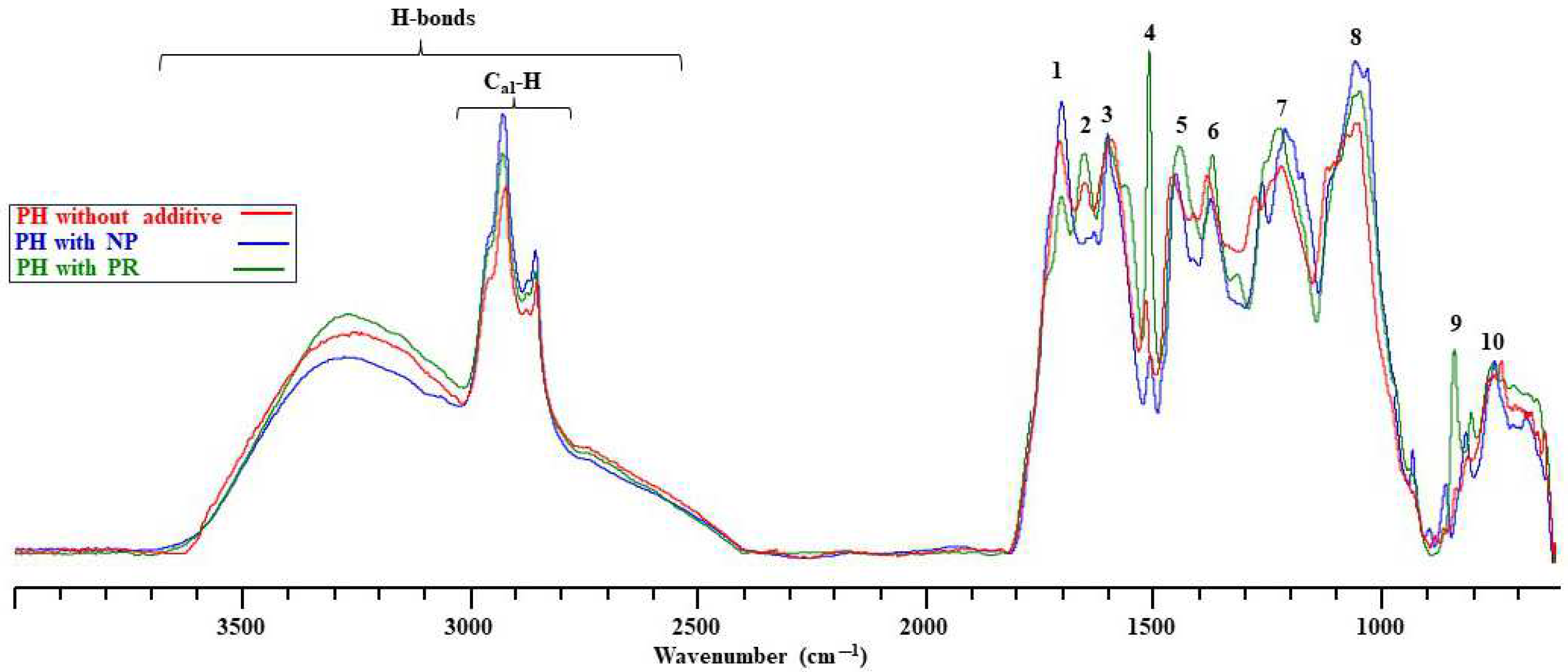

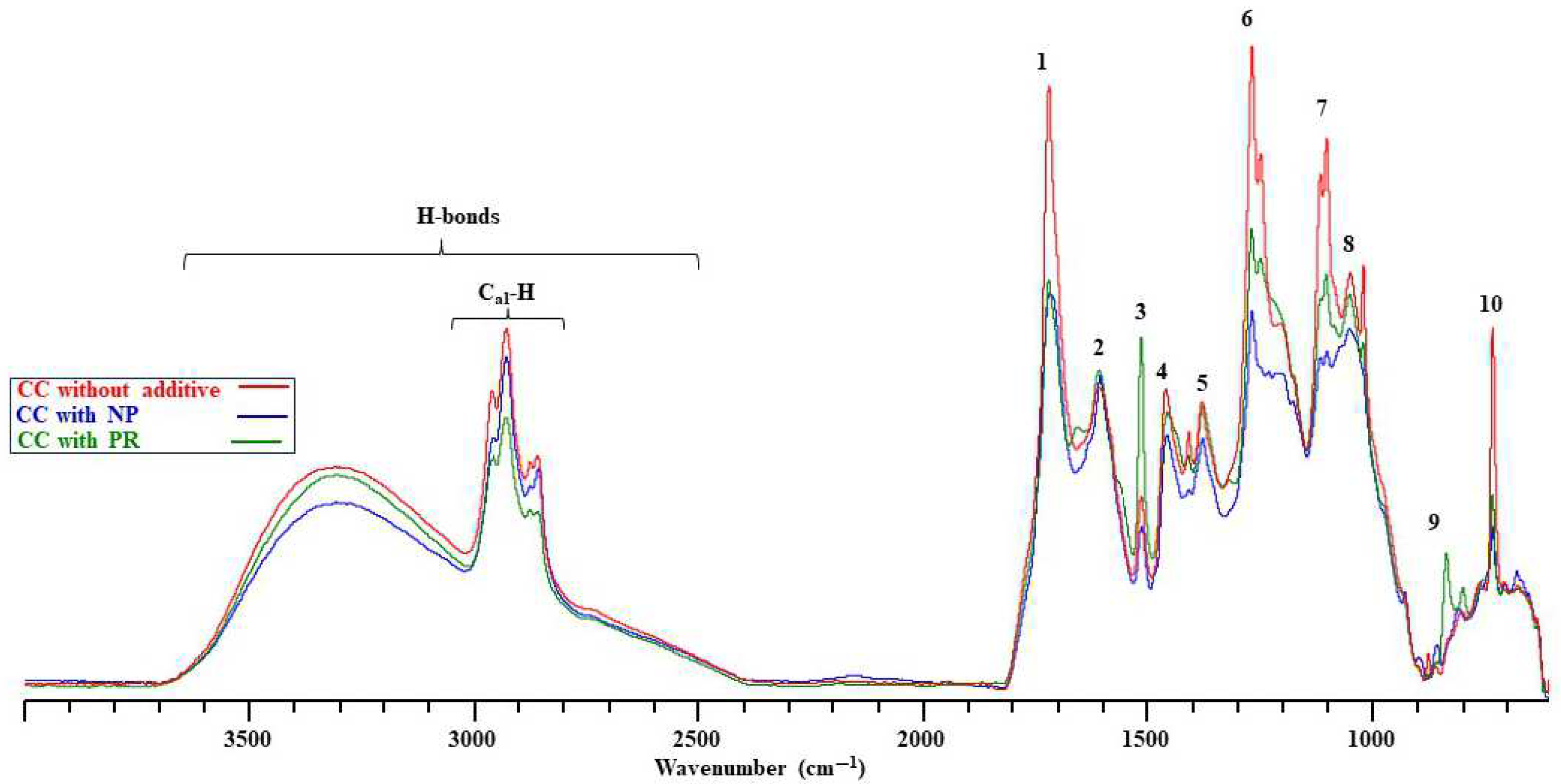

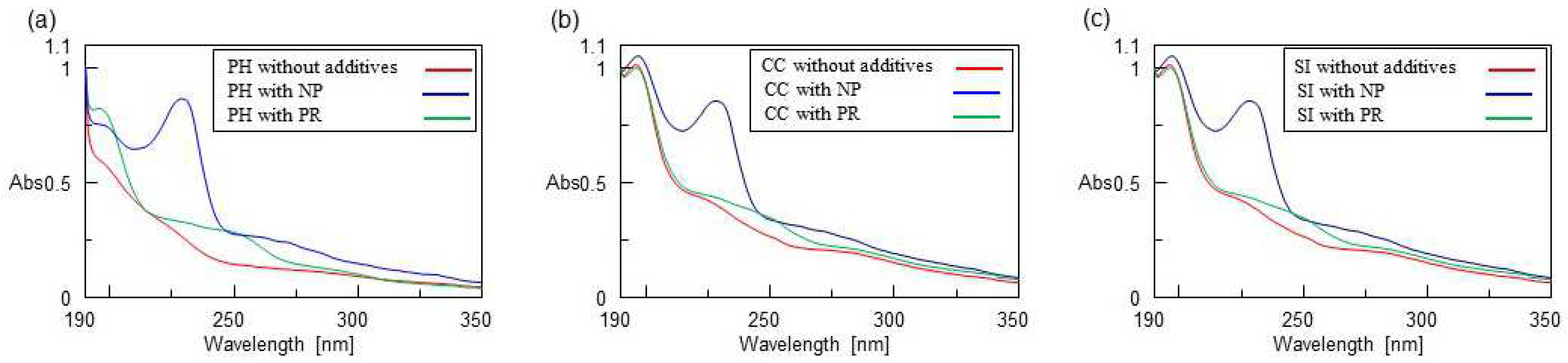

3.2. The Analysis of Influence of Additives on the Structural-Chemical Parameters of Obtained Condensates

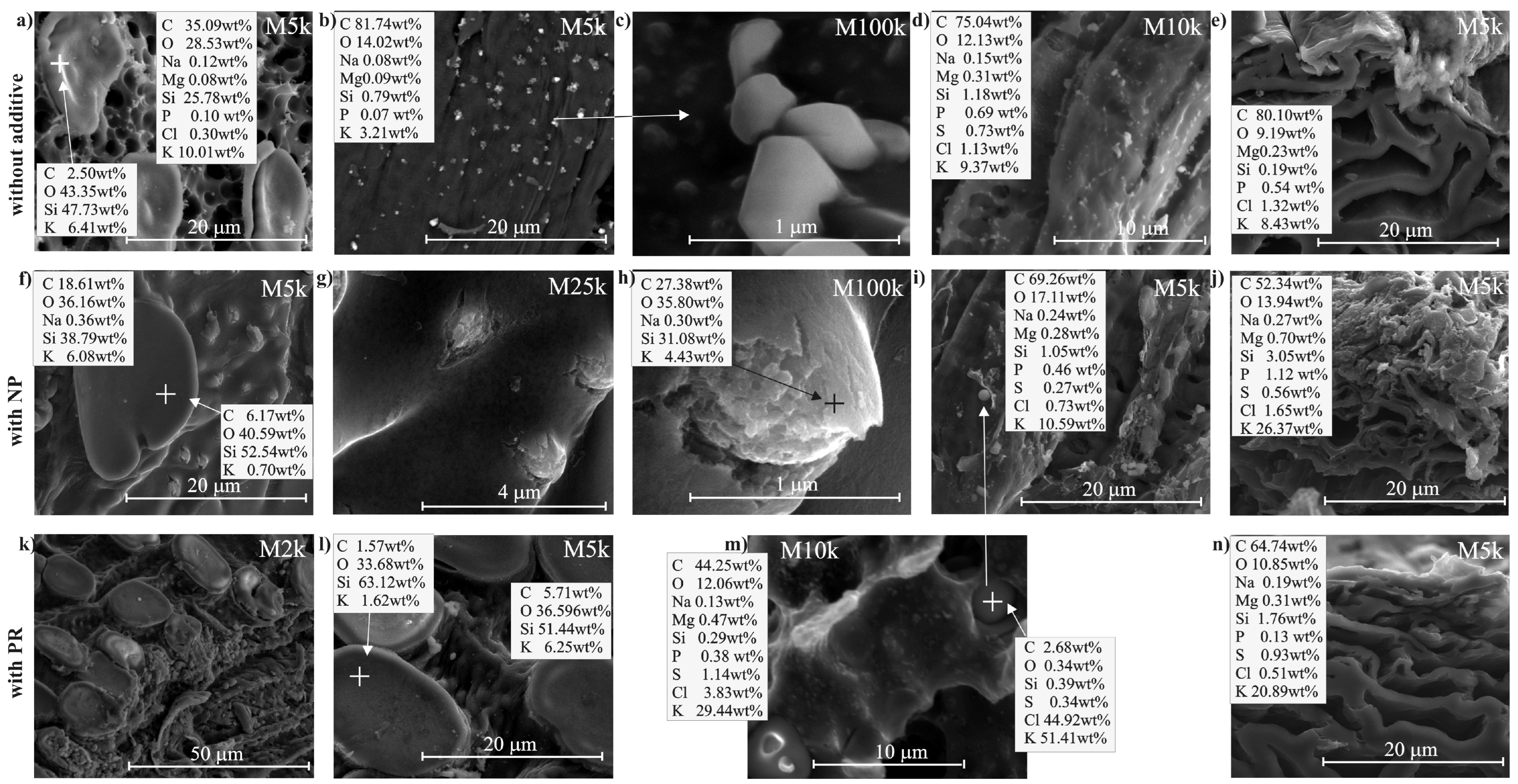

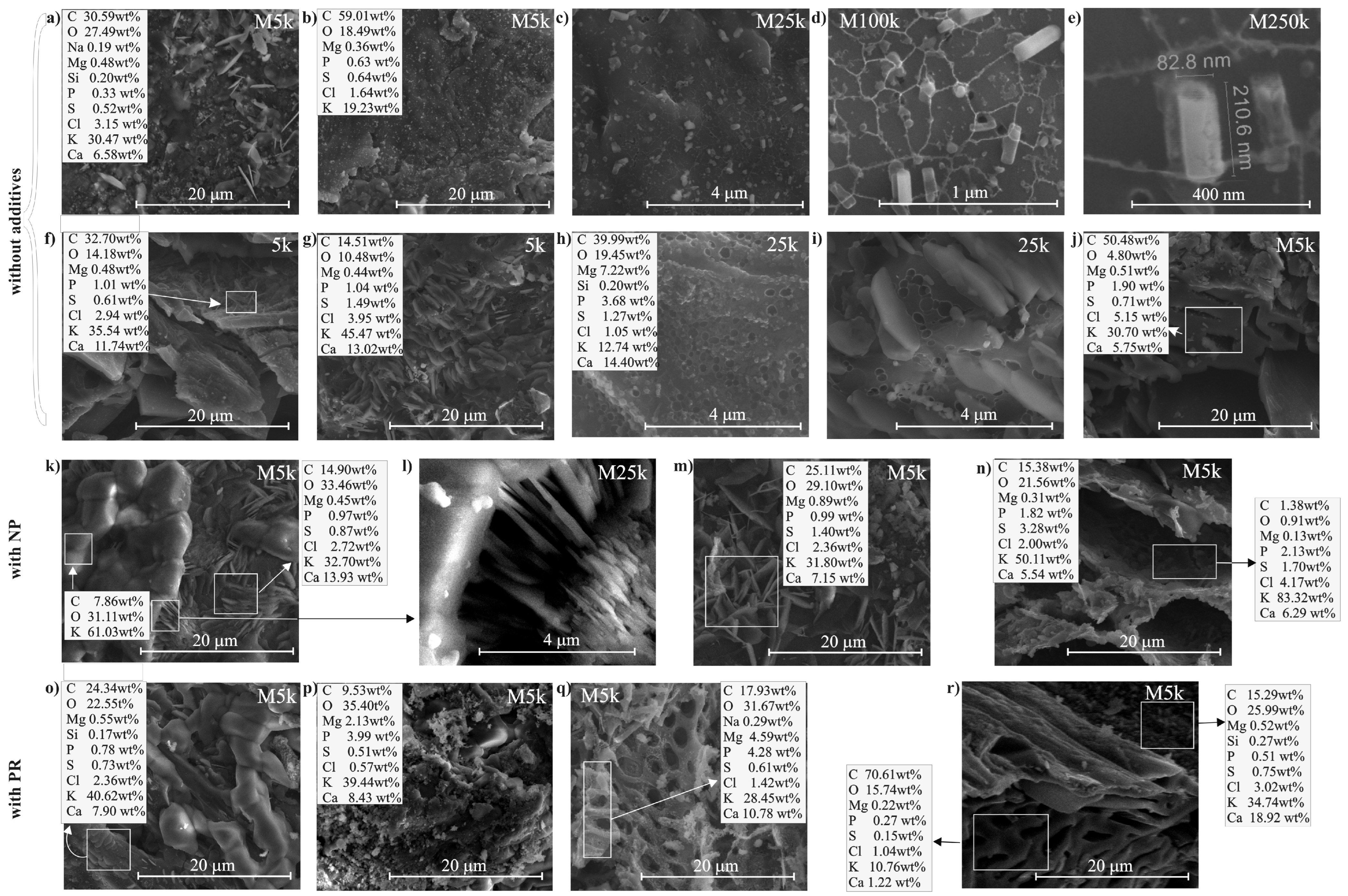

3.3. The Investigation of Chars of PH, CC, and SI Samples and Their Blends with Additives

4. Conclusions

- The influence of the addition of 2 wt.% of expired paracetamol and naproxen on the thermal behaviour of the samples of pea husks, corncobs, and sunflower inflorescences was studied.

- The additives of expired pharmaceuticals affected the contribution of hydrocarbons in the composition of volatile products of pyrolysis; they decreased this contribution in pea-husk samples, increased it in sunflower inflorescence samples, and did not change in corncob samples.

- Under the influence of both additives, the contribution of the fragments originating from the decomposition of cellulose increased in the condensed material of pea-husk samples, whereas it decreased in corncob samples.

- The addition of paracetamol to every sample promoted the decomposition of lignin and increased the contribution of guaiacyl rings in the condensed material, whereas the addition of naproxen increased the concentration of chromophores in this material, which caused the formation of the peak of absorbance near λ = 260 nm.

- The additives of expired pharmaceuticals changed the morphology and composition of the organic and inorganic parts of the pyrolyzed biomass. These changes caused the alterations in interactions between char and volatiles and modified the course of secondary reactions between the volatile products of pyrolysis.

- The positive effect of the influence of additives on the composition of volatile products of pyrolysis of pea-husk samples and the lack of any effect on the composition of volatiles of corncob samples proved that the paracetamol and naproxen additives can be disposed of with these types of biomass. The exact contribution of additives in the biomass samples will be determined in further studies.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, X.; Liu, J.; Wei, Z.; Chen, Z.; Evrendilek, F.; Huang, W. Oxy-fuel co-combustion dynamics of phytoremediation biomass and textile dyeing sludge: Gas-to-ash pollution abatement. Sci. Total Environ. 2022, 825, 153656. [Google Scholar] [CrossRef] [PubMed]

- Ye, J.L.; Cao, Q.; Zhao, Y.S. Co-pyrolysis of polypropylene and biomass. Energy Sources Part A 2008, 30, 1689–1697. [Google Scholar] [CrossRef]

- Nguyen, Q.V.; Choi, Y.S.; Choi, S.K.; Jeong, Y.W.; Kwon, Y.S. Improvement of bio-crude oil properties via co-pyrolysis of pine sawdust and waste polystyrene foam. J. Environ. Manag. 2019, 237, 24–29. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Rizkiana, J.; Widayanto, W.B.; Karnjanakom, S.; Kaewpanha, M.; Hao, X.; Abudula, A.; Guam, G. Fast co-pyrolysis of low density polyethylene and biomass residue for oil production. Energy Convers. Manag. 2016, 120, 422–429. [Google Scholar] [CrossRef]

- Lu, P.; Huang, Q.; Bourtsalas, A.C.; Chi, Y.; Yan, J. Synergistic effects on char and oil produced by the co-pyrolysis of pine wood, polyethylene and polyvinyl chloride. Fuel 2018, 230, 359–367. [Google Scholar] [CrossRef]

- Tang, Z.; Chen, W.; Chen, Y.; Yang, H.; Chen, H. Co-pyrolysis of microalgae and plastic: Characteristics and interaction effects. Bioresour. Technol. 2019, 274, 145–152. [Google Scholar] [CrossRef] [PubMed]

- Kumagai, S.; Fujita, K.; Kameda, T.; Yoshioka, T. Interactions of beech wood-polyethylene mixtures during co-pyrolysis. J. Anal. Appl. Pyrolysis 2016, 122, 531–540. [Google Scholar] [CrossRef]

- Dewangan, A.; Pradhan, D.; Singh, R.S. Co-pyrolysis of sugarcane bagasse and low-density polyethylene: Influence of plastic on pyrolysis product yield. Fuel 2016, 185, 508–516. [Google Scholar] [CrossRef]

- Jin, W.; Shen, D.; Liu, Q.; Xiao, R. Evaluation of the co-pyrolysis of lignin with plastic polymers by TG-FTIR and Py-GC/MS. Polym. Degrad. Stab. 2016, 133, 65–74. [Google Scholar] [CrossRef]

- Nardella, F.; Bellavia, S.; Mattonai, M.; Ribechini, E. Co-pyrolysis of biomass and plastic: Synergistic effects and estimation of elemental composition of pyrolysis oil by analytical pyrolysis–gas chromatography/mass spectrometry. Bioresour. Technol. 2022, 354, 127170. [Google Scholar] [CrossRef] [PubMed]

- Lin, X.; Kong, L.; Cai, H.; Zhang, Q.; Bi, D.; Yi, W. Effects of alkali and alkaline earth metals on the co-pyrolysis of cellulose and high density polyethylene using TGA and Py-GC/MS. Fuel Process. Technol. 2019, 191, 71–78. [Google Scholar] [CrossRef]

- Bielecki, M.; Zubkova, V.; Strojwas, A. An analysis of the influence of LDPE, novolac, and coal tar pitch additives on the decrease in content of impurities emitted from densified pea husks during the process of their pyrolysis. Energies 2023, 16, 2644. [Google Scholar] [CrossRef]

- Rakowski, A. Leki Przeciwbólowe i Przeciwzapalne (NLPZ)—Czy Mogą Obniżać Odporność? Available online: https://radioklinika.pl/nlpz-niesteroidowe-leki-przeciwzapalne/ (accessed on 4 December 2023).

- Fortune Business Insights. NSAIDs Market to Reach USD 24.35 Billion by 2027; Surging Research on Selective Cyclooxygenase-2 Inhibitors to Boost Growth. 2020. Available online: https://www.globenewswire.com/news-release/2020/05/28/2040374/0/en/NSAIDs-Market-to-Reach-USD-24-35-Billion-by-2027-Surging-Research-on-Selective-Cyclooxygenase-2-Inhibitors-to-Boost-Growth-Fortune-Business-Insights.html#:~:text=Filings%20Media%20Partners-,NSAIDs%20Market%20to%20Reach%20USD%2024.35%20Billion%20by%202027%3B%20Surging,Growth%3A%20Fortune%20Business%20Insights%E2%84%A2 (accessed on 13 October 2020).

- Non-Steroidal Anti-Inflammatory Drugs Market Size, Share & Trends Analysis Report by Disease Indication (Arthritis, Migraine, Ophthalmic Diseases), by Route of Administration, by Distribution Channel, by Region, and Segment Forecasts, 2022–2030. Available online: https://www.grandviewresearch.com/industry-analysis/non-steroidal-anti-inflammatory-drugs-market-report (accessed on 12 December 2023).

- Lipiec, A. Polacy Kochają Leki Bez Recepty. Available online: https://www.medonet.pl/narodowy-test-zdrowia-polakow/zyj-zdrowiej,polacy-kochaja-leki-bez-recepty--po-jakie-sieg (accessed on 4 December 2023).

- Zubkova, V.; Strojwas, A.; Kaniewskij, M.; Jany, B. The influence of the additives of expired paracetamol (PR) and naproxen (NP) on the thermal behaviour of high volatile bituminous coal (HVBC) and the composition of material extracted from the zones of its plastic layer. Fuel 2020, 273, 117752. [Google Scholar] [CrossRef]

- Zubkova, V.; Strojwas, A.; Bielecki, M.; Kieush, L.; Koverya, A. Comparative study of pyrolytic behavior of the biomass wastes originating in the Ukraine and potential application of such biomass. Part 1. Analysis of the course of pyrolysis process and the composition of formed products. Fuel 2019, 254, 115688. [Google Scholar] [CrossRef]

- Yang, H.; Yan, R.; Chen, H.; Lee, D.H.; Zheng, C. Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 2007, 86, 1781–1788. [Google Scholar] [CrossRef]

- Giudicianni, P.; Cardone, G.; Ragucci, R. Cellulose, hemicellulose and lignin slow steam pyrolysis: Thermal decomposition of biomass components mixtures. J. Anal. Appl. Pyrolysis 2013, 100, 213–222. [Google Scholar] [CrossRef]

- Eom, I.Y.; Kim, J.Y.; Kim, T.S.; Lee, S.M.; Choi, D.; Choi, I.G.; Choi, J.W. Effect of essential inorganic metals on primary thermal degradation of lignocellulosic biomass. Bioresour. Technol. 2012, 104, 687–694. [Google Scholar] [CrossRef] [PubMed]

- Guo, F.; Liu, Y.; Wang, Y.; Li, X.; Li, T.; Guo, C. Pyrolysis kinetics and behavior of potassium-impregnated pine wood in TGA and a fixed-bed reactor. Energy Convers. Manag. 2016, 130, 184–191. [Google Scholar] [CrossRef]

- Chen, X.; Li, S.; Liu, Z.; Chen, Y.; Yang, H.; Wang, X.; Che, Q.; Chen, W.; Chen, H. Pyrolysis characteristics of lignocellulosic biomass components in the presence of CaO. Bioresour. Technol. 2019, 287, 121493. [Google Scholar] [CrossRef] [PubMed]

- Hu, S.; Jing, L.; Wang, Y.; Su, S.; Sun, L.; Xu, B.; He, L.; Xiang, J. Effects of inherent alkali and alkaline earth metallic species on biomass pyrolysis at different temperatures. Bioresour. Technol. 2015, 192, 23–30. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Che, Q.; Li, S.; Liu, Z.; Yang, H.; Chen, Y.; Wang, X.; Shao, J.; Chen, H. Recent developments in lignocellulosic biomass catalytic fast pyrolysis: Strategies for the optimization of bio-oil quality and yield. Fuel Proc. Technol. 2019, 196, 106180. [Google Scholar] [CrossRef]

- Usino, D.O.; Supriyanto, S.; Ylitervo, P.; Pettersson, A.; Richards, T. Influence of temperature and time on initial pyrolysis of cellulose and xylan. J. Anal. Appl. Pyrolysis 2020, 147, 104782. [Google Scholar] [CrossRef]

- Traoré, M.; Kaal, J.; Matínez Cortizas, A. Application of FTIR spectroscopy to the characterization of archeological wood. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2016, 153, 63–70. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.-B. Peracetic acid pretreatment of sugarcane bagasse for enzymatic hydrolysis: A continued work. J. Chem. Technol. Biotechnol. 2008, 6, 950–956. [Google Scholar] [CrossRef]

- Lähdetie, A.; Liitiä, T.; Tamminen, T.; Jääskeläinena, A.-S. Reflectance UV-Vis and UV resonance raman spectroscopy in characterization of kraft pulps. BioResources 2009, 4, 1600–1619. [Google Scholar] [CrossRef]

- Albinsson, B.; Li, S.; Lundquist, K.; Stomberg, R. The origin of lignin fluorescence. J. Mol. Struct. 1999, 508, 19–27. [Google Scholar] [CrossRef]

- Bielecki, M.; Zubkova, V.; Strojwas, A. Influence of densification on the pyrolytic behavior of Agricultural Biomass waste and the characteristics of pyrolysis products. Energies 2022, 15, 4257. [Google Scholar] [CrossRef]

- Huang, Y.; Liu, H.; Yuan, H.; Lv, X.; Xu, B.; Li, W.; Uttaruean, J.; Yin, X.; Wu, C. Migration and speciation transformation of K and Cl caused by interaction of KCl with organics during devolatilization of KCl-loaded model biomass compounds. Fuel 2020, 277, 118205. [Google Scholar] [CrossRef]

- Anca-Couce, A.; Sommersacher, P.; Hochenauer, C.; Scharler, R. Multi-stage model for the release of potassium in single particle biomass combustion. Fuel 2020, 280, 118569. [Google Scholar] [CrossRef]

- Huang, S.; Liu, J.; Chen, S.; Wang, J.; Chen, Z.; Evrendilek, F.; Chen, T.; Huang, W.; Xie, W.; Sun, S. Converting and valorizing heavy metal-laden post-harvest hyperaccumulator (Pteris vittate L.) into biofuel via acid-pretreated pyrolysis and gasification. Chem. Eng. J. 2023, 468, 143490. [Google Scholar] [CrossRef]

| Main Characteristics | PH | CC | SI |

|---|---|---|---|

| Cd [%] | 40.99 ± 0.21 | 44.75 ± 0.20 | 39.46 ± 0.12 |

| Hd [%] | 5.77 ± 0.24 | 6.12 ± 0.01 | 5.59 ± 0.06 |

| Nd [%] | 0.03 ± 0.00 | 0 | 0.02 ± 0.00 |

| Sd [%] | 0 | 0 | 0 |

| Ad [%] | 9.59 ± 0.46 | 4.89 ± 0.73 | 13.9 ± 0.27 |

| Oad [%] | 43.62 ± 0.23 | 44.24 ± 0.31 | 41.03 ± 0.11 |

| HHVb [MJ·kg−1] | 16.40 ± 0.16 | 18.15 ± 0.31 | 19.49 ± 0.11 |

| Si [mg·kg−1] | 4210 ± 233 | 5521 ± 219 | 4009 ± 345 |

| P [mg·kg−1] | 233 ± 94 | 189 ± 79 | 1395 ± 172 |

| S [mg·kg−1] | 1628 ± 75 | 1172 ± 61 | 3292 ± 133 |

| Cl [mg·kg−1] | 475 ± 27 | 3176 ± 41 | 5995 ± 80 |

| K [mg·kg−1] | 475 ± 27 | 6684 ± 99 | 52,218 ± 325 |

| Ca [mg·kg−1] | 15,052 ± 331 | 6684 ± 99 | 18,636 ± 486 |

| Sample | PH | CC | SI |

|---|---|---|---|

| without additives | 1.121 ± 0.019 | 1.016 ± 0.022 | 1.094 ± 0.015 |

| with 2wt.% NP | 1.068 ± 0.021 | 0.968 ± 0.033 | 1.042 ± 0.028 |

| with 2wt.% PR | 1.057 ± 0.024 | 0.959 ± 0.025 | 1.033 ± 0.031 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Strojwas, A.; Zubkova, V.; Banas, D.; Stabrawa, I. The Influence of Addition of Expired Pharmaceuticals on Thermal Behaviour of Selected Types of Biomass. Energies 2024, 17, 2809. https://doi.org/10.3390/en17122809

Strojwas A, Zubkova V, Banas D, Stabrawa I. The Influence of Addition of Expired Pharmaceuticals on Thermal Behaviour of Selected Types of Biomass. Energies. 2024; 17(12):2809. https://doi.org/10.3390/en17122809

Chicago/Turabian StyleStrojwas, Andrzej, Valentina Zubkova, Dariusz Banas, and Ilona Stabrawa. 2024. "The Influence of Addition of Expired Pharmaceuticals on Thermal Behaviour of Selected Types of Biomass" Energies 17, no. 12: 2809. https://doi.org/10.3390/en17122809

APA StyleStrojwas, A., Zubkova, V., Banas, D., & Stabrawa, I. (2024). The Influence of Addition of Expired Pharmaceuticals on Thermal Behaviour of Selected Types of Biomass. Energies, 17(12), 2809. https://doi.org/10.3390/en17122809