Abstract

The industrial sector dominates global energy usage, accounting for approximately 50% of total energy demand, with process heat representing two-thirds of this consumption. Although renewable energy technologies have become increasingly cost-competitive, industrial users have been hesitant to replace fossil fuels to meet heat generation requirements. This study presents a practical framework for industrial energy transition, proposing a phased approach toward sustainable manufacturing practices, processes, and energy technologies. The framework emphasises that while energy efficiency measures form the foundation, strategic technological investment priorities should target the replacement of fossil fuels with sustainable and renewable energy technologies. The formulation of the three-phased energy technology advancement framework is informed by techno-economic analyses across a range of technical interventions available to plant operators, namely beverage manufacturers. For South African conditions, cost–benefit analyses suggest that the industry will prioritise investments in photovoltaic and battery energy storage systems, driven by attractive returns on investment, which are expected to improve. However, sustainability plans and efforts must extend beyond immediate financial returns, particularly in terms of future space requirements and capital allocation. This more holistic approach will ensure long-term sustainability while meeting increasingly stringent environmental commitments.

1. Introduction

South Africa’s energy transition faces the formidable challenge of reducing its heavy reliance on coal [1]. This fossil fuel has long been the backbone of the country’s energy sector, accounting for approximately 80% of its electricity generation and a significant portion of its industrial process heat [2]. Ongoing dependence on coal contributes substantially to greenhouse gas emissions and poses economic and environmental risks as the world moves towards cleaner energy sources [3].

The urgency of the energy transition is underscored by South Africa’s commitment to the Paris Agreement and its national climate goals [2]. However, the path to decarbonisation is complex, particularly given the country’s unique socio-economic challenges and the deeply entrenched role of coal in its economy [4,5]. While progress is being made in the electricity sector, industrial decarbonisation has lagged, and insufficient action has been taken to date [6,7].

Given the financial benefits of solar photovoltaic (PV) energy, South African industrial and commercial energy users have begun to generate electricity from renewable sources directly or through third parties. The deployment of PV by the private sector is expected to accelerate in the context of sustained above-inflation electricity tariff increases. However, given space constraints, only a portion of the electricity requirements of industrial companies are being met by embedded installations. Other priority energy investments have included installing diesel generators to mitigate the impact of rolling blackouts [8]. However, the high costs of operating diesel generators and the adverse effect on carbon emissions are pushing companies to consider battery energy storage systems.

This study analyses South Africa’s current state of energy transition, focusing on the electricity and processing heat required by industry. It provides a summary of progress made thus far, particularly in the power sector, and the significant challenges, especially in decarbonising industrial process heat. Informed by cost–benefit analyses, this work proposes an operational-level, three-phase technology transition framework for industrial facilities. It provides a practical roadmap for South African industry leaders and stakeholders to navigate the journey towards a low-carbon future. Insights and benchmarks are derived from techno-economic analyses using South African data and the energy demand of typical South African beverage facilities. While explicitly based on South Africa, the outcomes of this work are relevant to industrial sectors such as pulp and paper, chemicals, textiles, and food, which utilise low- to medium-temperature process heat of 200 °C or less, typically supplied from fossil fuels, in regions with high solar irradiation.

2. Materials and Methods

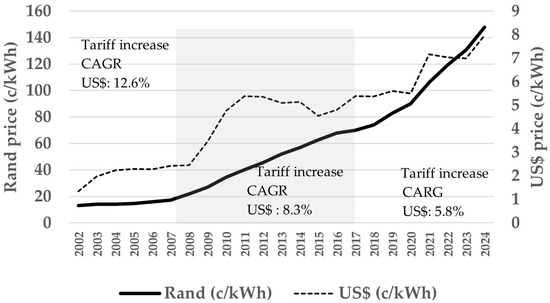

Since the 1960s, the South African national power grid has been managed by Eskom, a single state-owned, vertically integrated utility, responsible for power generation, transmission, and distribution. Before 2010, Eskom generated and transmitted nearly 100% of the country’s electricity [6]. Distribution was and continues to be shared with municipalities [2]. The Independent Power Producer Office was introduced in 2010 to broaden generation capacity, and the South African power network is now evolving towards a traded power sector market, under the oversight of the National Energy Regulator of South Africa [9]. These reforms are occurring alongside increasing electricity costs in South Africa, where tariffs have grown steadily ahead of inflation, as illustrated in Figure 1 by the industrial user electricity tariff compounded annual growth rate (CAGR). Average South African electricity tariffs for industrial users were USD 80/MWh in 2024 or USD 67/MWh in 2020 real terms, which is nearly seven times higher than in 2002 [10]. In addition to the cost of energy, other risks include access to energy, inequalities in society, environmental concerns, and market failure [5].

Figure 1.

Evolution of the South African electricity tariff for industrial users.

South Africa has relatively high irradiation, with global horizontal irradiation ranging from 4.4 to 6.4 kWh/m2 day and an average of 5.6 kWh/m2 day, making investments in solar energy technology attractive [11]. For the most important economic nodes of the country, PV outputs range between 4.5 to 5.5 kWh/kWpeak. It also has a 3000 km coastline favourable for wind energy generation [12]. Recognising this potential, the government has formalised a renewable energy procurement programme enabling the establishment of large-scale project capabilities for electricity generation. Furthermore, the removal of regulatory constraints and ongoing cost reductions in renewable energy solutions have stimulated investment by the private sector [13]. Despite these advancements and the relatively high penetration of solar thermal geysers for domestic use [14], little progress has been made in decarbonising industrial thermal energy systems, with coal continuing to be the primary source of process heat.

This work employs cost–benefit analyses to quantitatively compare investment options that support decarbonisation in industrial sectors utilising low- to medium-temperature process heat. The cost–benefit analyses are derived from energy cost forecasts, the energy requirements of the South African beverage sector (which serves as a case study), and techno-economic analyses on renewable and sustainable energy technologies to compare investment returns.

While PV power plants and battery energy storage system (BESS) capital expenditure and levelised cost of energy (LCOE) are tracked and reported annually, solar thermal energy technologies and heat pump energy costs are less transparent. This study utilises published South African LCOEs for PV and BESS, which are calculated using standard methodology as per the International Renewable Energy Agency recommendation [11,15,16]. Levelised cost of heat (LCOH) is a commonly used cost metric for solar thermal energy and heat pump installations [16,17]. LCOH of solar thermal energy technologies are determined from international benchmark capital costs [3,16] and South African solar irradiation data [18] as described and provided by Saini et al. [19]. The heat pump baseline LCOH is determined using published capital costs [19] and Eskom’s, South Africa’s state-owned power utility, Megaflex variable tariffs (averaged for a 24 h, 7-day operation, which includes ancillary service charges) for a 66–132 kVA direct connection [20]. The historical cost of coal and heavy fuel oil in South Africa was obtained from the IndexMundi data portal [21]. The historical cost of diesel was obtained from the South African Petroleum Industry Association database [22].

Cost projections for all technologies are obtained from a best-fit quadratic regression of generation capacity, coupled with technological learning rates [23], to provide a consistent methodology across solar PV, BESS, solar thermal energy, and heat pumps. Real-term 2020 United States Dollar (2020 USD) values provide a uniform basis of comparison across time frames and publications. The forward-looking range of fossil fuel prices and associated costs of heat is based on the IEA’s pricing scenarios [24,25] and informed by the historical variability of coal and Brent crude oil prices in 2020 US dollars. During the preparation of this manuscript, the authors have used Perplexity AI to help synthesise and simplify the dissertation and conference proceedings materials produced by the authors.

2.1. Renewable Energy Independent Power Producer Procurement Programme (REIPPPP)

The REIPPPP has been a cornerstone of South Africa’s efforts to diversify its energy mix and reduce its reliance on coal. Launched in 2011, the program has faced various challenges, including policy uncertainty and implementation delays [13]. However, it has gained significant momentum in recent years, establishing a thriving local independent power producer sector majority owned by South Africans, demonstrating the country’s commitment to increasing its renewable energy capacity and transformation [26].

As of 2024, the REIPPPP has achieved notable milestones, including the procurement of over 13,422 MW of renewable energy generation capacity, with more than 7335 MW connected to the national grid [13]. The program has attracted over USD 15 billion in investment (ZAR 277 billion), with 25% coming from foreign sources [13]. These achievements highlight the program’s success in stimulating the renewable energy sector despite grid constraints, strict local ownership requirements, and regulatory hurdles.

The REIPPPP has contributed to increasing the share of renewables in South Africa’s energy mix, introducing utility-scale facilities, and has also played a crucial role in reducing the cost of renewable energy technologies in the country. The transparent, managed, and competitive bidding process, overseen by the Independent Power Producer Office of the Department of Electricity and Energy, has driven down prices, with the 2021 bid window 5 of the program achieving the lowest tariffs to date for renewable energy at USD 29/MWh [27]. These costs have made renewable energy increasingly competitive with coal-fired power generation, challenging the traditional economic argument for coal dependence.

In 2011, a power wheeling framework was introduced, paving the way for decentralisation in electricity generation [28]. The lifting of the 1 MW cap on unlicensed power generation in 2021 has since enabled power purchase agreements between commercial and industrial users and large third-party electricity generation companies [29,30]. The national utility, Eskom, and the national regulator continue to provide active oversight over these third-party contracts, though electricity transmission agreements [28].

2.2. Industrial and Commercial PV Deployment

Complementing the utility-scale developments under the REIPPPP, the private sector has played a crucial role in expanding South Africa’s solar capacity following the relaxation of generation regulations. The rapid growth in industrial and commercial PV installations has been driven by several factors, including declining technology costs, the need for energy security amid ongoing power supply challenges, and corporate sustainability goals [26].

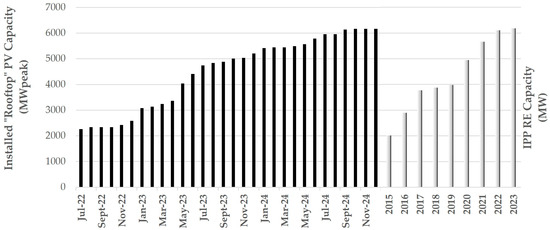

In 2024, South Africa added 961 MW of privately owned solar PV generation capacity, bringing the total to 6.1 GW [31]—an 18% increase from 2023, following sustained month-on-month growth, as shown in Figure 2. Referred to as “Rooftop” PV, privately owned embedded solar energy capacity generation has increased threefold in just over two years, from mid-2022 to the end of 2024, with over 80% of installations being undertaken by the industrial and commercial sectors [31]. By contrast, the policy-driven REIPPPP programme took eight years to increase from 2 GW to 6 GW in solar and wind electricity generation [13].

Figure 2.

Renewable energy evolution in South Africa—Privately owned “Rooftop” PV and REIPPP policy-driven generation capacity [31].

Expanding industrial and commercial PV-embedded generation capacity has several implications for South Africa’s energy transition. It reduces pressure on the national grid, potentially alleviating some of the country’s electricity supply challenges. It provides a model for decentralised energy generation, which could be crucial for future energy system resilience. Furthermore, it creates opportunities for job creation and skills development in the renewable energy sector while enhancing energy security for businesses, reducing their vulnerability to power outages and price fluctuations [26].

However, the rapid growth of privately owned PV installations also presents challenges for grid management, grid integration, and utility business models. Integrating these distributed energy resources into the existing grid infrastructure requires careful planning, new capabilities and investment in smart grid technologies [26].

2.3. The Process Heat Challenge

While progress in the power sector is encouraging, the decarbonisation of industrial process heat remains a significant challenge globally and in South Africa [32]. Process heat represents approximately two-thirds of industrial energy requirements and has seen little advancement in transitioning to cleaner energy sources [33]. Addressing the process heat challenge is crucial for South Africa’s overall decarbonisation strategy. It requires a multifaceted approach considering technological innovations, economic incentives, and policy support. The transition away from coal in the industrial sector is not only an environmental imperative but also a strategic economic necessity, as global markets increasingly demand products with low carbon footprints.

In South Africa, industry accounts for 52% of the national total energy consumption, with 63% coming directly from fossil fuels (when including electricity requirements), primarily coal [34]. This reliance on coal for process heat presents a significant barrier to the country’s overall decarbonisation efforts [4]. The reasons for this persistent dependence are multifaceted. South Africa’s abundant coal reserves have historically provided a cheap and reliable industrial energy source [3]. Many industrial processes are designed around coal-based process heat systems, making transitions to alternative energy sources costly and complex. Additionally, some high-temperature industrial processes are challenging to electrify or transition to alternative fuels.

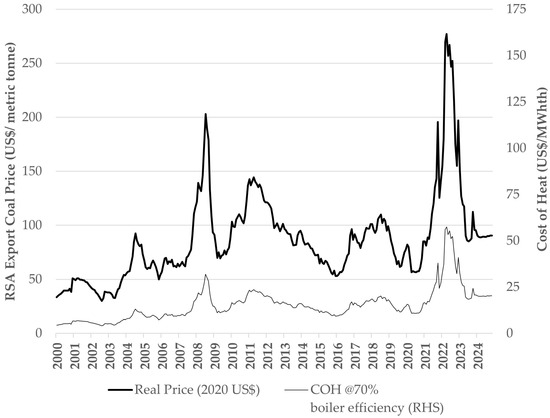

The perceived high costs of transitioning to cleaner technologies often deter industries from making the switch. Real-term or inflation-adjusted export coal prices, presented in Figure 3, show the price recovery following the 2022 European energy crisis [21]. If price volatility had persisted, a greater impetus would have existed to find alternative energy sources to meet process heat requirements. However, that is not the case. While the impact of carbon taxes has been diluted through discounts and allowances, from 2026 onwards, price pressures are expected to intensify, with the differential between European and South African coal prices likely to reduce [35,36].

Figure 3.

Long-term Ex-Richards Bay coal price and resulting cost of heat [21].

The industrial sector’s heavy reliance on gas and coal is particularly pronounced in key industries such as iron and steel, chemicals, and cement production [34]. These sectors consume large amounts of energy and require high-temperature heat that is challenging to provide through renewable sources.

The Food and Beverage, Pulp and Paper, and Textile sectors are also large coal users, with steam boiler-driven process heat used for sterilisation, pasteurisation, raw material preparation, and drying [3]. These low- to medium-temperature process heat sectors offer more technically and financially viable opportunities for renewable energy solutions. Furthermore, the South African beverage sector is largely consolidated and owned by large multinationals committed to reducing carbon emissions [37].

2.4. Corporate Investment Decision Framework

In a comprehensive review of decision-making methods specifically focused on renewable energy projects, Strantzali et al. [38] summarised three main approaches: life-cycle analysis, cost–benefit analysis, and multi-criteria decision aid. While life-cycle analysis examines the environmental impact from cradle to grave, businesses rarely utilise it when making investment decisions [39]. Multi-criterion decision aids allow decision-makers and policymakers to weigh non-monetary impacts and address information uncertainty; however, the level of complexity in the analysis is better suited to countrywide investment programmes or comprehensive investment portfolios [40,41,42]. Given the relatively predictable solar energy yield for PV and solar thermal energy technologies, as well as the relatively stable energy demand from industrial users, a more pragmatic cost-benefit analysis approach was selected for this study. Cost–benefit assessment is, by and large, the preferred approach to investment decision-making used by companies and industrial operators [3]. Elements of irreversibility, the inability to reverse or change course, were also considered in this study, given the 20- to 30-year life span of renewable energy investments [43,44].

The primary investment criterion for companies in free-market environments is to create value through accurate valuation of acquisition targets or project investments using net present value analyses [39]. A positive net present value is obtained when the investment return on capital exceeds the weighted average cost of capital, ensuring that risks and uncertain outcomes are factored into future cash flows [45]. This research presents a simplified Year-1 return on investment to analyse the relative cost-benefits of alternative options. While the insights were obtained from modelling returns at a representative South African beverage facility, using hourly heat demand and irradiation profiles for representative plants located in Johannesburg and Cape Town, decisions were framed more generally to allow a broader group of industrial users to assess renewable energy investment priorities. The decisions were then ranked and ordered to deliver a logical set of choices and associated outcomes, as presented in a decision tree in the discussion section.

2.5. Solar PV and BESS Levelised Cost of Energy

Thanks to substantial reductions in capital costs, the LCOE for PV electricity generation has seen remarkable improvements and is anticipated to continue decreasing [46,47]. For major renewable technologies such as solar PV, cost forecasts obtained from applying historical learning rates to the extrapolation of best-fit capacity regressions are summarised in Table 1 [23]. Predominant technologies during the period analysed were bifacial crystalline PV modules and lithium-ion cell-based battery energy storage systems. While there has yet to be systematic tracking and reporting of the cost of BESS, sufficient information is available to establish a current baseline when combined with large-scale PV installation and extrapolate costs at least to 2030 [23].

Table 1.

LCOE progression and outlook for PV and BESS.

2.6. Solar Thermal Levelised Cost of Heat

Settino et al. [50] comprehensively reviewed technology solutions for producing energy for cooling and heating. Solar thermal energy solutions were estimated to be the most cost-efficient renewable energy technologies for providing heat, especially when combined with thermal storage. The review considers several alternative configurations, including PV with heat pumps and a range of phase change materials suitable for applications below 200 °C. Regarding industrial installations, Solar Payback, in partnership with IRENA, has analysed 241 projects commissioned between 2012 and 2020, with temperatures of up to 400 °C, with average LCOH of USD 61/MWhth, and a mean heat generating capacity of 371 kWth [51]. Since 2019, larger projects (with an average of 1 MWth) have benefited from installed costs of USD 500/kWth or less, generating heat for less than USD40/MWhth [51]. These values correspond with IRENA’s analysis of large Danish and Mexican projects [16]. Furthermore, IRENA highlights that solar thermal energy technology has achieved learning rates of 14–19% on installed costs through the formalisation of project developers and technology suppliers [16].

While flat plate collectors and hybrid PV thermal modules can provide hot water cost-effectively, many industrial systems utilise steam as a process heat transfer medium. The generation of steam from solar irradiation generally requires concentrating collectors, such as linear Fresnel, parabolic troughs, or concentrating dishes. While concentrating collectors are typically more expensive, technical and manufacturing innovations have helped reduce costs in the last five years. For larger projects (greater than 500 kWth), parabolic trough collectors can now be integrated into existing operations for USD 350–400/m2, with an additional USD 50–100/m2 for heat storage [52]. For South Africa, such Capex would result in an LCOH of USD 38–70/MWhth [7]. These capital costs and LCOH are used as the reference in this study for 2020. By combining the expected growth in global capacity over the next three decades with published learning rates for solar thermal heat-generating technologies, costs are expected to decrease by 15–25% by 2030 [37].

2.7. Heat Pump Levelised Cost of Heat

Heat pumps can be used as an alternative or complementary technology to meet thermal energy demand, especially in areas where renewable energy technologies dominate electricity generation. In Europe, policy support for heat pumps has promoted the more efficient utilisation of electricity, thereby reducing carbon emissions. Global installed capacity has increased steadily to reach 1000 GWth (nearly 200 million units) in 2021 [53,54]. High-temperature heat pumps have also become viable options for providing process heat and steam in industry, especially when a waste heat stream is available [55,56]. Saini et al. [19] calculated the LCOH of a typical industrial high-temperature heat pump with a coefficient of performance of 2.5, delivering steam at 140 °C. The estimates used are for heat pumps with a high-capacity factor (>6000 h per annum), considering different utilisation levels (24 h a day, seven days a week, as well as 24 h a day, five days a week) and variable electricity tariffs [19]. The lower Capex value of USD 500/kWth was selected in these analyses, as it represents the cost of larger heat pump systems with a resulting LCOH of USD 45–49/MWh, using 2020 South African electricity tariffs [57]. Using published learning rates of 10–15% [58,59], the resulting heat pump LCOH is expected to decrease by 10–20% by 2030.

2.8. Fossil Fuel Thermal Energy Costs

Due to market disruptions in the fossil fuel industry from 2020 to 2023, the cost of process heat has been volatile. For South Africa, fossil fuel prices and the associated cost of heat for 2017 and 2024 are presented in Table 2, together with the peak values experienced in 2022. The reference Richards Bay export coal prices are in line with reported supply contracts for Gauteng province, given the similar logistical transport costs. Indicatively, long-term coal supply contracts in 2024 for Cape Town were reported to be around USD 150/tonne with a resultant LCOH of USD 28/MWhth, assuming a steam boiler energy conversion efficiency of 70%.

Table 2.

Cost of heat from traditional sources in nominal USD unless specified.

3. Results

For sectors requiring process heat at temperatures of 200 °C or less, where steam boilers are the dominant technology, renewable and sustainable solutions have become viable alternatives to fossil fuels [63,64]. Compared to electro-boilers, heavy fuel oil, or diesel boilers, solar thermal energy systems can provide a more cost-effective alternative across most of South Africa [3]. Where electricity from solar and wind installations can be secured at less than USD 70/MWh via third-party power purchase agreements or even lower from own generation, heat pumps are also viable alternatives [19].

3.1. Solar Thermal Energy (STE)

Solar thermal energy systems offer the potential to reduce fossil fuel usage in industrial processes, particularly for low- to medium-temperature applications. These systems can provide heat for processes up to 400 °C, making them suitable for food and beverage, textiles, and specific chemical processes [64].

However, the economics of STE compared to coal remain challenging in South Africa. In 2020, solar thermal energy systems had a Year-1 return on capital of only 5%, compared to coal at USD 300/tonne. Even with projected improvements by 2030, the return is expected to reach only 10%. This slow progression suggests that STE technology economics may not improve quickly enough to compete with coal without additional incentives, such as those provided by the Austrian Development Agency-funded SOLTRAIN programme, which has offered training to local installers and partly funded the installation of demonstration systems since 2007 [65].

Limitations of STE include high upfront capital costs, intermittency and storage challenges, limited applicability for high-temperature processes, and space requirements. Despite these challenges, STE remains a promising technology for specific industrial and commercial applications, particularly in clinics, hospitals, and hotels where space is limited. The potential for cost reductions through economies of scale and technological improvements could make STE more competitive. Additionally, hybrid systems that combine STE with other renewable technologies or thermal energy storage solutions could address some intermittency and competitiveness issues [66,67].

3.2. Heat Pumps

Heat pumps offer an alternative solution for process heat decarbonisation, providing the potential for significant energy efficiency improvements for both hot water and steam. Recent improvements in High-Temperature Heat Pumps (HTHPS) enable them to meet the heat requirements of industrial processes up to 200 °C [19].

The advantages of HTHPS include high energy efficiency, with coefficients of performance (COP) ranging from 2 to 5, the potential for electrifying heat production, enabling the use of renewable electricity, and flexibility in heat sources, including the ability to upgrade waste heat [68].

However, the viability of HTHPS in South Africa faces several challenges. The viability of heat pumps depends on access to cheap power, which is challenging given South Africa’s high and increasing electricity tariffs [10]. Furthermore, the stubbornly high carbon footprint of the South African power grid, with a CO2e emission rate of approximately 1 tonne per MWh, can be a deterrent for using heat pumps [69]. The economic benefits of HTHPS can be significantly enhanced when waste heat is available, but not all industrial processes produce suitable waste heat streams [70]. Some industrial facilities may lack the space required for HTHP installations and heat storage. The availability of a low-carbon electricity supply is therefore crucial for the operation of HTHPS.

Despite these challenges, HTHPS represent a promising technology for decarbonising specific industrial processes, particularly in conjunction with the increasing availability of renewable electricity from third parties and new developments in thermal storage systems [19]. As renewable and sustainable electricity markets mature and costs continue to decrease, solar- and wind-powered HTHPS could play a significant role in South Africa’s industrial energy transition.

3.3. Year-1 Return on Capital Favouring Photovoltaics and Battery Energy Storage Systems

While opportunities exist for solar thermal systems and HTHP to be readily adopted, Year-1 return on capital estimates presented in Table 3 suggest that corporate capital will first be utilised for PV electricity generation and battery energy storage systems [71]. During the 2020–2025 period, this was further supported by power security and cost concerns when South African operators suffered frequent load-shedding events and high electricity tariff increases. Battery energy storage systems offer an added benefit for time-of-use tariff users, allowing them to avoid the weekday five-hour-a-day peak tariff premium window, which is particularly punitive during the winter months in South Africa from June to August when the cost of electricity more than doubles [20]. Thermal energy systems offer attractive returns when replacing liquid fossil fuel burners; however, against coal, returns are expected to remain unattractive. For a high-temperature heat pump to be attractive against coal, electricity costs would have to be lower than indicative wheeling contract rates of USD 0.07/kWh. An indicative range is provided for 2030 based on expected Capex and energy cost outlooks presented in the Materials and Methods section.

Table 3.

Comparative Year-1 return on capital for renewable electricity and sub-200 °C process heat generation—expanded and adapted table [71].

4. Discussion

To address the complex challenge of transitioning from coal, the South African Presidential Climate Commission has proposed the Just Energy Transition roadmap in 2022 [5]. The roadmap builds on international work on just transitions and proposes policies and principles to democratise, decentralise, and diversify the energy markets in South Africa. The implementation plan includes a breakdown of the investment requirements and sources of funding [72]. Other works on just transitions have modelled scenarios and proposed pathways at a national level [73,74]. The International Energy Agency has also provided a toolbox for the decarbonisation of heavy industries, which provides a range of policies, financing mechanisms, targeted actions, and enabling conditions [75].

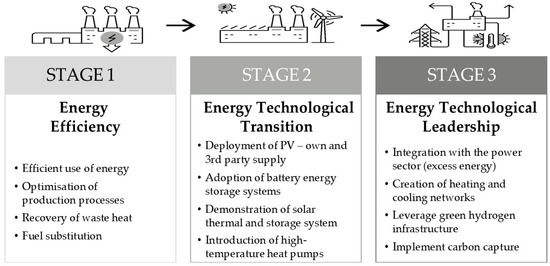

4.1. Proposed Three-Phase Technology Advancement Framework

In contrast to focusing on the national transition agenda or energy-intensive sectors, this work proposes a practical, three-phase approach to technology advancement that guides South Africa’s industrial companies and facilities in navigating and planning their energy transition, balancing immediate actions with long-term, transformative changes. The three-phase framework is presented in Figure 4 [37]. While this framework was developed through analyses focusing on the beverage sector, it has broader applications for industries with low- to medium-process heat. The analyses included techno-economic modelling of solar PV, solar thermal systems, and related technologies, as well as more efficient technologies such as heat pumps. Cost–benefit considerations thus informed intervention priorities.

Figure 4.

Proposed technology advancement three-stage holistic approach to reducing industrial carbon emissions in low- to medium-process heat industrial sectors.

4.1.1. Phase 1: Immediate Energy Efficiency Actions

This phase focuses on laying the groundwork for the transition through energy efficiency improvements, production process optimisation, and fuel switching to lower-carbon alternatives, supported by policy and regulatory reforms. Key actions include implementing energy management systems, conducting energy audits, optimising existing processes, and using energy-efficient technologies. Promoting natural gas as a transitional fuel and encouraging biomass co-firing in existing coal boilers are other important steps [76].

Policy and regulatory reforms during this phase should focus on strengthening the carbon tax and reducing exemptions, introducing incentives or mandatory energy efficiency targets for industries, and developing clear guidelines for power purchase agreements (PPAs) and wheeling. During this phase, focusing on opportunities that can deliver and minimise the energy footprint is a priority while building the foundation and momentum for more fundamental and extensive changes.

4.1.2. Phase 2: Medium-Term Energy Technological Transition

The medium-term phase, spanning the 2020–2040 time horizon, emphasises scaling up renewable energy integration and advancing heat pump technologies. Industry has embraced PV systems for self-generation of electricity to reduce costs and started to adopt BESS to mitigate load shedding and high peak tariff windows. The expectation is for investment to continue and possibly intensify. Solar thermal energy demonstration systems have also been commissioned, although primarily for hot water applications.

Expanding REIPPPP to include dedicated allocations for industrial users, supporting third-party renewable energy generation capacity investments at or lower than USD 70/MWh, and implementing smart-grid technologies to manage the integration of variable renewable energy into the national grid are key steps in scaling up the transition going forward [77,78]. Encouraging the development of energy storage solutions, both electrical and thermal, will also be crucial.

Advancing heat pump technologies involves investing in research and development for high-temperature heat pumps, piloting large-scale HTHP projects in key industrial sectors, creating financial mechanisms to support the adoption of HTHP, and expanding local manufacturing capabilities for heat pump technologies. Specifically, where meaningful streams of waste heat are available, further analyses have shown that heat pumps can provide financially viable solutions even against coal.

This phase focuses on accelerating the deployment of proven technologies while investing in the development and demonstration of emerging solutions. Creating a supportive ecosystem for innovation and technology adoption, including research partnerships, skills development programs, and financial incentives, will be crucial.

4.1.3. Phase 3: Long-Term Energy Technological Leadership

The final phase involves fully deploying renewables in the power and industrial process heat sectors, developing a green hydrogen economy, and implementing carbon capture [79]. This includes developing and deploying a mix of solar and wind electricity generation capacity wheeled over an improved power transmission network supported by market trading mechanisms, creating industrial and commercial symbiosis networks to maximise waste heat utilisation, integrating renewable heat and cooling solutions with smart-energy management systems (as is being done in European advanced district heating and cooling networks) and retrofitting existing industrial processes to use hydrogen as a fuel and feedstock [56,79,80].

Developing green hydrogen infrastructure involves establishing pilot projects for green hydrogen production, developing hydrogen storage and transportation infrastructure, creating a regulatory framework for hydrogen use in industry, and fostering international partnerships for the transfer of hydrogen technology [79].

Carbon capture and utilisation efforts should focus on implementing carbon capture technologies in remaining hard-to-abate sectors, developing markets and applications for captured carbon, integrating carbon capture with green hydrogen production for synthetic fuels, and exploring negative emissions technologies such as direct air capture [24].

This long-term phase focuses on achieving deep decarbonisation across all industrial sectors. It requires sustained investment in the research, development, and deployment of advanced technologies, as well as the creation of new markets and business models for low-carbon industrial products [24].

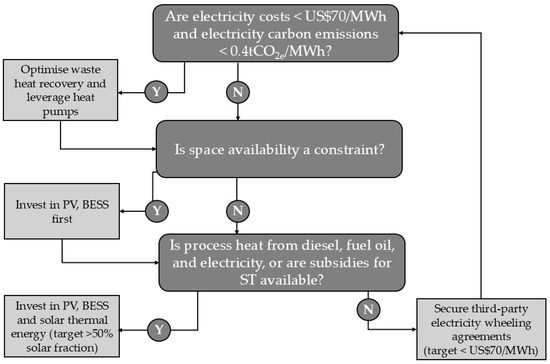

4.2. Critical Metrics and Enablers

To assist industry decision-makers, critical metrics are presented in Figure 5 as part of a logical decision tree. These key decision points and triggers were developed for the beverage sector and are suitable for other sectors that use low- to medium-temperature process heat. Critical enablers to decarbonising the industrial sector would be the availability of electricity at rates of less than USD 70/MWh with carbon emissions of less than 0.4 tCO2e/MWh, enabling greater adoption of heat pumps. Consideration should also be given to restricting the combustion of liquid fossil fuels for steam and hot water generation, as well as constraining or taxing the installation of new coal boilers.

Figure 5.

Simplified decision tree with power grid and process parameters.

4.3. Policy and Financial Mechanisms

Robust policy and financial mechanisms are crucial to supporting this transition framework. These include strengthening carbon pricing through an enhanced carbon tax and cap-and-trade system, developing green finance mechanisms such as green bonds or investment subsidy mechanisms, investing in skills development programs, leveraging international cooperation and climate finance, implementing regulatory reforms, and increasing support for research and development in clean energy technologies.

In South Africa, carbon taxes have had a minimal impact, given the large allowances and discounts [36]. With the European Union strengthening the carbon tax mechanism and associated reporting from 2026, South Africa’s most important trading market will intensify the impetus to move away from fossil fuels.

The REIPPP has provided a platform for investment funds, both local and international, to support the implementation of projects, especially those involving large-scale generation (tens to hundreds of megawatts). With over a decade of experience, international firms and local ventures have acquired the competence to plan, execute, and operationalise projects across solar and wind energy generation.

Regarding solar heat generation, incentive schemes and building regulations have established a baseline of capabilities, specifically around hot water domestic applications, namely with the Eskom Solar Water Heating programme in 2008–2015 or the existing SANS 10400:XA new building hot water requirement stipulating that at least 50% of water heating needs come from non-grid electricity [81].

However, changing the coal-dominated, human resource-intensive South African power generation system has also raised important socio-economic challenges, as experienced around shut-down power stations such as Komati [82]. Much work is, therefore, being done on the just energy transition, which is critical to ensuring livelihoods and social stability.

4.4. Limitations

The analyses and insights shared in this work were derived from the beverage sector in South Africa, and efforts were made to broaden their applicability to other industrial sectors, specifically those where hot water and steam are used as process heat fluids. These industrial sectors would use process heat temperatures of less than 200 °C. For the sake of simplicity, comparative cost–benefit analyses were performed on steam systems and average costs, and operating parameters were used. Detailed variation and sensitivity analyses can be found in the cited materials [7,19,68]. Energy-intensive and industrial facilities operating at high conversion temperatures face distinct challenges, and the proposed framework and decision parameters are likely to vary significantly.

The South African energy sector, market dynamics, and policies are evolving under a set of specific regulations overseen by the national energy regulator. Other countries would have different regulations, incentives, environmental priorities, and market dynamics, which would influence the national, provincial, and corporate agendas. Despite global trade and global pressures to reduce carbon emissions, industry investment priorities may differ by country. This would be further influenced by existing and required capabilities and human capital challenges.

While comparative cost–benefit analysis results were presented as simplified Year-1 return on investment, detailed techno-economic analyses and modelling systems under different boundary conditions are essential to developing investment proposals for specific situations. This work generalised findings from case studies to facilitate high-level comparison and derive implications. The specific energy mix of a facility needs to be considered and analysed. Most importantly, future electricity and fuel costs will create a dynamic environment in which investment options will need to be revisited, particularly given the growing importance of carbon tax mechanisms in the years to come. Finally, the quadratic regression methodology used to extrapolate generation capacity and costs, need to be updated regularly to ensure anomalies are taken into consideration and forecasts refreshed every three to five years as recommended by the authors [23]; hence, this analysis was limited to 2030.

5. Conclusions

South Africa’s transition from coal requires a comprehensive, phased approach that addresses both the power sector and industrial process heat. While progress is measurable across the power sector, insufficient action is being taken in the industrial sector. The proposed practical three-phase energy technology framework provides a roadmap for the transition required by industry, balancing immediate energy efficiency actions with long-term technological changes. By implementing this framework alongside supportive policy and financial mechanisms, South African companies can overcome the economic and technical barriers to decarbonisation, ultimately achieving a sustainable and competitive industrial sector powered by clean energy.

The success of this transition will depend on the private sector’s commitment and international support to decarbonise both electricity consumption and process heat generation. As South Africa’s corporates navigate this complex journey, they can become leaders in industrial decarbonisation by leveraging favourable solar and wind energy resources and associated renewable and sustainable energy solutions. This work has demonstrated that the adoption of PV electricity generation is starting to have an impact. However, more needs to be done to avoid burning liquid fossil fuels using backup electricity generators or steam burners, where both BESS and solar thermal energy systems can offer attractive returns on investments. The path ahead is challenging, but the potential benefits are substantial. The return on investment in PV, BESS, and solar thermal technologies, now ranging from 20–30%, is improving rapidly.

Furthermore, heat pumps driven by renewable energy can also yield immediate benefits when waste heat streams and lower-cost green electricity are available. However, financially viable solutions to coal remain challenging and will necessitate the right policies, subsidies, and carbon tax mechanisms. A successful transition away from coal will contribute to global efforts to mitigate climate change and position South Africa’s industry for long-term competitiveness in a carbon-constrained world. It can create new economic opportunities, improve energy security, and stimulate local manufacturing and skills development.

While this phased transition would likely apply elsewhere than in South Africa, national priorities, specific country regulations, environmental and societal pressures, and risks will have influence over industry agendas.

As the world moves towards a low-carbon future, South Africa’s ability to withdraw from its coal addiction will be crucial for its economic resilience, social transformation, and environmental sustainability. The proposed energy technology transition framework and accompanying policy measures provide a starting point for initiating this vital transition within the industrial sector. However, their success will ultimately depend on the collective efforts of the government, industry, society, and international partners.

Author Contributions

Conceptualization, F.R. and C.M.; methodology, F.R.; validation, F.R. and M.O.; formal analysis, F.R.; investigation, F.R.; writing—original draft preparation, F.R.; writing—review and editing, C.M. and M.O.; visualization, F.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Analyses data available on request.

Acknowledgments

During the preparation of this manuscript, the authors used Perplexity to help synthesise the dissertation and conference proceeding materials produced by the authors. The authors have reviewed and edited the output and take full responsibility for the content of this publication.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| BESS | Battery energy storage system(s) |

| CO2e | Carbon dioxide equivalent |

| COP | Coefficient of Performance |

| CAGR | Compounded Annual Growth Rate |

| HTHP | High temperature heat pump(s) |

| LCOE | Levelised cost of energy |

| LCOH | Levelised cost of heat |

| PV | Photovoltaic(s) |

| REIPPPP | Renewable Energy Independent Power Producer Procurement Programme |

| STE | Solar thermal energy |

References

- Burton, J.; Caetano, T.; Mccall, B.; Sartor, O. Coal Transition in South Africa—Understanding the Implications of a 2 °C-Compatible Coal Phase-out for South Africa; IDDRI & Climate Strategies: Saint-Guillaume, Paris, 2018. [Google Scholar]

- Department of Energy. South Africa Integrated Resource Plan; Department of Energy: Washington, DC, USA, 2019. [Google Scholar]

- Solar Payback Solar Heat for Industry—South Africa; 2019. Available online: https://www.solarthermalworld.org/sites/default/files/news/file/2019-03-02/ship_south_africa_february_2019.pdf (accessed on 14 May 2021).

- Montmasson-Clair, G. A Policy Toolbox for Just Transitions; Trade & Industrial Policy Strategies (TIPS): Pretoria, South Africa, 2021. [Google Scholar]

- Presidential Climate Commission. Framework for a Just Transition in South Africa; Draft for Public Comment; Presidential Climate Commission: Johannesburg, South Africa, 2022. [Google Scholar]

- Terblanche, U.; Botha, C.; Louw, C.; Radmore, J. Large-Scale Renewable Energy Report; IEA: Paris, France, 2024. [Google Scholar]

- Rozon, F.; Koke, J.; McGregor, C.; Owen, M. Techno-Economic Analyses of Solar Thermal Process Heat Integration at South African Beverage Producers. Sol. Compass 2023, 8, 100063. [Google Scholar] [CrossRef]

- Thango, B.A.; Obokoh, L. Techno-Economic Analysis of Hybrid Renewable Energy Systems for Power Interruptions: A Systematic Review. Eng 2024, 5, 2108–2156. [Google Scholar] [CrossRef]

- South African Department Mineral Resources and Energy Renewable. Energy Independent Power Producer Procurement Bid Window 6; South African Department Mineral Resources and Energy Renewable: Pretoria, South Africa, 2022. [Google Scholar]

- Eskom Tariff History. Available online: https://www.eskom.co.za/distribution/tariffs-and-charges/tariff-history/ (accessed on 16 April 2024).

- World Bank. Global Photovoltaic Power Potential; World Bank: Washington, DC, USA, 2022. [Google Scholar]

- Department of Mineral Resources and Energy. REIPPPP Focus on Wind; Department of Mineral Resources and Energy: Pretoria, South Africa, 2020. [Google Scholar]

- Department of Mineral Resources and Energy. Independent Power Producer—An Overview; Department of Mineral Resources and Energy: Pretoria, South Africa, 2024. [Google Scholar]

- Naidoo, A. The Socio-Economic Impacts of Solar Water Heaters Compared across Two Communities: A Case Study of Cato Manor. Renew. Sustain. Energy Rev. 2020, 119, 109525. [Google Scholar] [CrossRef]

- GreenCape. The Business Case for Solar PV in South Africa; GreenCape: Cape Town, South Africa, 2020. [Google Scholar]

- International Renewable Energy Agency. Renewable Power Generation Costs in 2020; International Renewable Energy Agency: Masdar City, United Arab Emirates, 2021. [Google Scholar]

- Nian, V.; Sun, Q.; Li, H. A Comparative Cost Assessment of Energy Production from Central Heating Plant or Combined Heat and Power Plant. Energy Procedia 2016, 104, 556–561. [Google Scholar] [CrossRef]

- National Aeronautics and Space Administration. Prediction of Worldwide Energy Resources; National Aeronautics and Space Administration: Washington, DC, USA, 2021. [Google Scholar]

- Saini, P.; Ghasemi, M.; Arpagaus, C.; Bless, F.; Bertsch, S.; Zhang, X. Techno-Economic Comparative Analysis of Solar Thermal Collectors and High-Temperature Heat Pumps for Industrial Steam Generation. Energy Convers. Manag. 2023, 277, 116623. [Google Scholar] [CrossRef]

- Eskom. Schedule of Eskom Tariffs 2020/21; Eskom: Sandton, South Africa, 2020. [Google Scholar]

- IndexMundi Commodities. Available online: https://www.indexmundi.com/commodities/ (accessed on 10 February 2025).

- South African Petroleum Industry Association Old Fuel Prices. Available online: https://fuelsindustry.org.za/ (accessed on 30 August 2022).

- Rozon, F.; McGregor, C.; Owen, M. Long-Term Forecasting Framework for Renewable Energy Technologies’ Installed Capacity and Costs for 2050. Energies 2023, 16, 6874. [Google Scholar] [CrossRef]

- International Energy Agency. Net Zero by 2050: A Roadmap for the Global Energy Sector; International Energy Agency: Paris, France, 2021. [Google Scholar]

- International Energy Agency. World Energy Outlook; International Energy Agency: Paris, France, 2022. [Google Scholar]

- Poorun, A.; Terblanche, U.; Radmore, A. Energy Services Market Intelligence Report; GreenCape: Cape Town, South Africa, 2024. [Google Scholar]

- New Development Bank Renewable Energy Sector. Project Performance Evaluation; The New Development Bank: Sandton, South Africa, 2024. [Google Scholar]

- National Energy Regulator of South Africa. Regulatory Rules on Network Charges for Third-Party Transportation of Energy; National Energy Regulator of South Africa: Pretoria, South Africa, 2011; pp. 1–20. [Google Scholar]

- Department of Mineral Resources and Energy. Amended Schedule 2 of the Electricity Regulation Act 4 of 2006; Department of Mineral Resources and Energy: Pretoria, South Africa, 2021. [Google Scholar]

- Eskom. Tariffs and Charges Booklet 2023/2024; Eskom: Sandton, South Africa, 2023. [Google Scholar]

- Eskom. Eskom Weekly Status Report; Eskom: Sandton, South Africa, 2024. [Google Scholar]

- Weiss, W.; Spörk-Dür, M. Solar Heat World—Global Market Development and Trends 2021; 2022. Available online: https://www.iea-shc.org/Data/Sites/1/publications/Solar-Heat-Worldwide-2021.pdf (accessed on 17 June 2022).

- International Energy Agency. Solar Heating and Cooling Programme Projects (Tasks). Available online: https://www.iea-shc.org/tasks (accessed on 1 September 2023).

- Ratshomo, K.; Nembahe, R. The South African Energy Sector Report; Stanford University: Stanford, CA, USA, 2019. [Google Scholar]

- International Monetary Fund. South Africa Carbon Pricing and Climate; International Monetary Fund: Washington, DC, USA, 2023. [Google Scholar]

- Boingotlo, G.K.; Makrelov Shanthessa, R. Carbon Taxation in South Africa and the Risks of Carbon Border Adjustment Mechanisms: OBEN 2401*—September 2023; Research Department South African Reserve Bank: Pretoria, South Africa, 2023. [Google Scholar]

- Rozon, F.; McGregor, C.; Owen, M. An Outlook on the Energy Mix at South African Beverage Manufacturers and Opportunities for Greater Adoption of Renewable Energy Solutions. Ph.D. Thesis, Stellenbosch University, Stellenbosch, South Africa, 2024. [Google Scholar]

- Strantzali, E.; Aravossis, K. Decision Making in Renewable Energy Investments: A Review. Renew. Sustain. Energy Rev. 2016, 55, 885–898. [Google Scholar] [CrossRef]

- Copeland, T.; Koller, T.; Murrin, J. Valuation: Measuring and Managing the Value of Companies; John Wiley & Sons: Hoboken, NJ, USA, 1990. [Google Scholar]

- Masini, A.; Menichetti, E. The Impact of Behavioural Factors in the Renewable Energy Investment Decision Making Process: Conceptual Framework and Empirical Findings. Energy Policy 2012, 40, 28–38. [Google Scholar] [CrossRef]

- Cayir, B.; Evren, R.; Delen, D. A Multi-Objective Decision-Making Approach for Sustainable Energy Investment Planning. Renew. Energy 2018, 126, 387–402. [Google Scholar] [CrossRef]

- Korzenowski, L.; Alves, R.; Freitas, D.; Paulo, E. Stochastic Model to Aid Decision Making on Investments in Renewable Energy Generation: Portfolio Diffusion and Investor Risk Aversion. Renew. Energy 2020, 162, 1161–1176. [Google Scholar] [CrossRef]

- Henry, C. Investment Decisions under Uncertainty: The “Irreversibility Effect”. Am. Econ. Rev. 1974, 64, 1006–1012. [Google Scholar]

- Hildebrandt, P.; Knoke, T. Forest Policy and Economics Investment Decisions under Uncertainty—A Methodological Review on Forest Science Studies. For. Policy Econ. 2011, 13, 1–15. [Google Scholar] [CrossRef]

- Maurice, C.; Thomas, C.; Smithson, C. Managerial Economics, 4th ed.; Irwin: Huntersville, NC, USA, 1992. [Google Scholar]

- Kost, C.; Shammugam, S.; Fluri, V.; Peper, D.; Memar, A.D.; Schlegel, T. Levelized Cost of Electricity- Renewable Energy Technologies; Fraunhofer Institute: München, Germany, 2021. [Google Scholar]

- Tsiropoulos, I.; Tarvydas, D.; Zucker, A. Cost Development of Low Carbon Energy Technologies—Scenario-Based Cost Trajectories to 2050, 2017 Edition; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Mkhize, M. Rad 2022 Large-Scale Renewable Energy Market Intelligence Report; GreenCape: Cape Town, South Africa, 2022. [Google Scholar]

- National Renewable Energy Laboratory Annual Technology Baseline. Available online: https://atb.nrel.gov/electricity/2022/index (accessed on 21 July 2022).

- Settino, J.; Sant, T.; Micallef, C.; Farrugia, M.; Staines, C.S.; Licari, J.; Micallef, A. Overview of Solar Technologies for Electricity, Heating and Cooling Production. Renew. Sustain. Energy Rev. 2018, 90, 892–909. [Google Scholar] [CrossRef]

- Epp, B.; Oropeza, M.; Taylor, M. Cost Trends of Solar Energy for Heat in Industry. 2021. Available online: https://www.solar-payback.com/ (accessed on 22 June 2022).

- Fraunhofer Solar Payback Online Calculator. Available online: https://iki.ise.fraunhofer.de (accessed on 21 October 2022).

- International Energy Agency. The Future of Heat Pumps; International Energy Agency: Paris, France, 2022. [Google Scholar]

- Rosenow, J.; Gibb, D.; Nowak, T.; Lowes, R. Heating up the Global Heat Pump Market. Nat. Energy 2022, 7, 901–904. [Google Scholar] [CrossRef]

- Lund, H.; Østergaard, P.A.; Chang, M.; Werner, S.; Svendsen, S.; Sorknæs, P.; Thorsen, J.E.; Hvelplund, F.; Mortensen, B.O.G.; Mathiesen, B.V.; et al. The Status of 4th Generation District Heating: Research and Results. Energy 2018, 164, 147–159. [Google Scholar] [CrossRef]

- Meyers, S.; Schmitt, B.; Vajen, K. Renewable Process Heat from Solar Thermal and Photovoltaics: The Development and Application of a Universal Methodology to Determine the More Economical Technology. Appl. Energy 2018, 212, 1537–1552. [Google Scholar] [CrossRef]

- Meyers, S.; Schmitt, B.; Vajen, K. The Future of Low Carbon Industrial Process Heat: A Comparison between Solar Thermal and Heat Pumps. Sol. Energy 2018, 173, 893–904. [Google Scholar] [CrossRef]

- Louwen, A.; Junginger, M.; Krishnan, A. Technological Learning in Energy Modelling: Experience Curves; Technische Universität Dresden: Dresden, Germany, 2018. [Google Scholar]

- Kiss, B.; Neij, L.; Jakob, M. Heat Pumps: A Comparative Assessment of Innovation and Diffusion Policies in Sweden and Switzerland; Lunds Universitet: Lund, Sweden, 2011; ISBN 9781139150880. [Google Scholar]

- Nedbank Monthly Average Exchange Rates. Available online: https://www.nedbank.co.za/content/dam/nedbank/site-assets/AboutUs/Economics_Unit/Forecast_and_data/Daily_Rates/Monthly_Average_Exchange_Rates.pdf (accessed on 16 May 2024).

- Braun, M. Fleetwatch Truck Operated Benchmarks. Available online: http://fleetwatch.co.za/e-mag/fw/issue64/index.html?page=53 (accessed on 7 November 2022).

- Federal Reserve Bank of St Louis Economic Data. Available online: https://fred.stlouisfed.org (accessed on 30 May 2024).

- McMillan, C.; Schoeneberger, C.; Zhang, J. Opportunities for Solar Industrial Process Heat in the United States; NREL: Lakewood, CO, USA, 2021. [Google Scholar]

- Schoeneberger, C.A.; McMillan, C.A.; Kurup, P.; Akar, S.; Margolis, R.; Masanet, E. Solar for Industrial Process Heat: A Review of Technologies, Analysis Approaches, and Potential Applications in the United States. Energy 2020, 206, 118083. [Google Scholar] [CrossRef]

- AEE INTEC Soltrain. Available online: https://www.soltrain.org/ (accessed on 18 November 2024).

- Jesper, M.; Pag, F.; Vajen, K.; Jordan, U. Hybrid Solar Thermal and Heat Pump Systems in Industry: Model Based Development of Globally Applicable Design Guidelines. Sol. Energy Adv. 2023, 3, 100034. [Google Scholar] [CrossRef]

- Rosales-pérez, J.F.; Villarruel-jaramillo, A.; Pérez-garcía, M.; Cardemil, J.M.; Escobar, R. Techno-Economic Analysis of Hybrid Solar Thermal Systems with Flat Plate and Parabolic Trough Collectors in Industrial Applications ST. Alex. Eng. J. 2024, 86, 98–119. [Google Scholar] [CrossRef]

- Koke, J.; Rozon, F.; McGregor, C. Analyzing the Techno-Economic Viability of Different Solar Heating Systems in South African Beverage Plants. In Proceedings of the International Sustainable Energy Conference—Proceedings, Graz, Austria, 10–11 April 2024. [Google Scholar]

- Eskom. 2020 Carbon Footprint Report; Eskom: Sandton, South Africa, 2021; Volume 4. [Google Scholar]

- Sadjjadi, B.S.; Gerdes, J.N.; Sauer, A. Energy Flexible Heat Pumps in Industrial Energy Systems: A Review. Energy Rep. 2023, 9, 386–394. [Google Scholar] [CrossRef]

- Rozon, F.; McGregor, C.; Owen, M. An Outlook on the Adoption of Renewable Energy Solutions at South African Beverage Manufacturers. In Proceedings of the ISEC 2024—3rd International Sustainable Energy Conference Proceedings, Graz, Austria, 10–11 April 2024. [Google Scholar] [CrossRef]

- The Presidency: Republic of South Africa. Just Energy Transition Implementation Plan 2023–2027; The Presidency: Republic of South Africa: Pretoria, South Africa, 2023. [Google Scholar]

- Lawrenz, L.; Xiong, B.; Lorenz, L.; Krumm, A.; Hosenfeld, H.; Burandt, T.; Löffler, K.; Oei, P.Y.; Von Hirschhausen, C. Exploring Energy Pathways for the Low-Carbon Transformation in India—A Model-Based Analysis. Energies 2018, 11, 3001. [Google Scholar] [CrossRef]

- Bartholdsen, H.K.; Eidens, A.; Löffler, K.; Seehaus, F.; Wejda, F.; Burandt, T.; Oei, P.Y.; Kemfert, C.; von Hirschhausen, C. Pathways for Germany’s Low-Carbon Energy Transformation towards 2050. Energies 2019, 14, 2988. [Google Scholar] [CrossRef]

- International Energy Agency Policy. Toolbox for Industrial Decarbonisation; International Energy Agency Policy: Paris, France, 2025. [Google Scholar]

- Rehfeldt, M.; Fleiter, T.; Herbst, A.; Eidelloth, S. Fuel Switching as an Option for Medium-Term Emission Reduction—A Model-Based Analysis of Reactions to Price Signals and Regulatory Action in German Industry. Energy Policy 2020, 147, 111889. [Google Scholar] [CrossRef]

- Zahid, H.; Altamimi, A.; Kazmi, S.A.A.; Khan, Z.A. Multi-Phase Techno-Economic Framework for Energy Wheeling via Generation Capacity Design of Microgrids and Virtual Power Plants. Energy Rep. 2022, 8, 5412–5429. [Google Scholar] [CrossRef]

- Erasmus, S.; Esterhuysen, N.; Maritz, J. Campus Microgrids within the South African Context: A Case Study to Illustrate Unique Design, Control Challenges, and Hybrid Dispatch Strategies. Energies 2023, 16, 1519. [Google Scholar] [CrossRef]

- Bataille, C.; Åhman, M.; Neuhoff, K.; Nilsson, L.J.; Fischedick, M.; Lechtenböhmer, S.; Solano-Rodriquez, B.; Denis-Ryan, A.; Stiebert, S.; Waisman, H.; et al. A Review of Technology and Policy Deep Decarbonization Pathway Options for Making Energy-Intensive Industry Production Consistent with the Paris Agreement. J. Clean. Prod. 2018, 187, 960–973. [Google Scholar] [CrossRef]

- Lund, H.; Østergaard, P.A.; Connolly, D.; Mathiesen, B.V. Smart Energy and Smart Energy Systems. Energy 2017, 137, 556–565. [Google Scholar] [CrossRef]

- SANS 10400-XA:2021; The Application of the National Building Regulations. South African Bureau of Standards the National Building Regulations: Pretoria, South Africa, 2011.

- Tladi, B.; Kambule, N.; Modley, L.A. Assessing the Social and Environmental Impacts of the Just Energy Transition in Komati, Mpumalanga Province, South Africa. Energy Res. Soc. Sci. 2024, 111, 103489. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).