An Overview of Recent AI Applications in Combined Heat and Power Systems

Abstract

1. Introduction

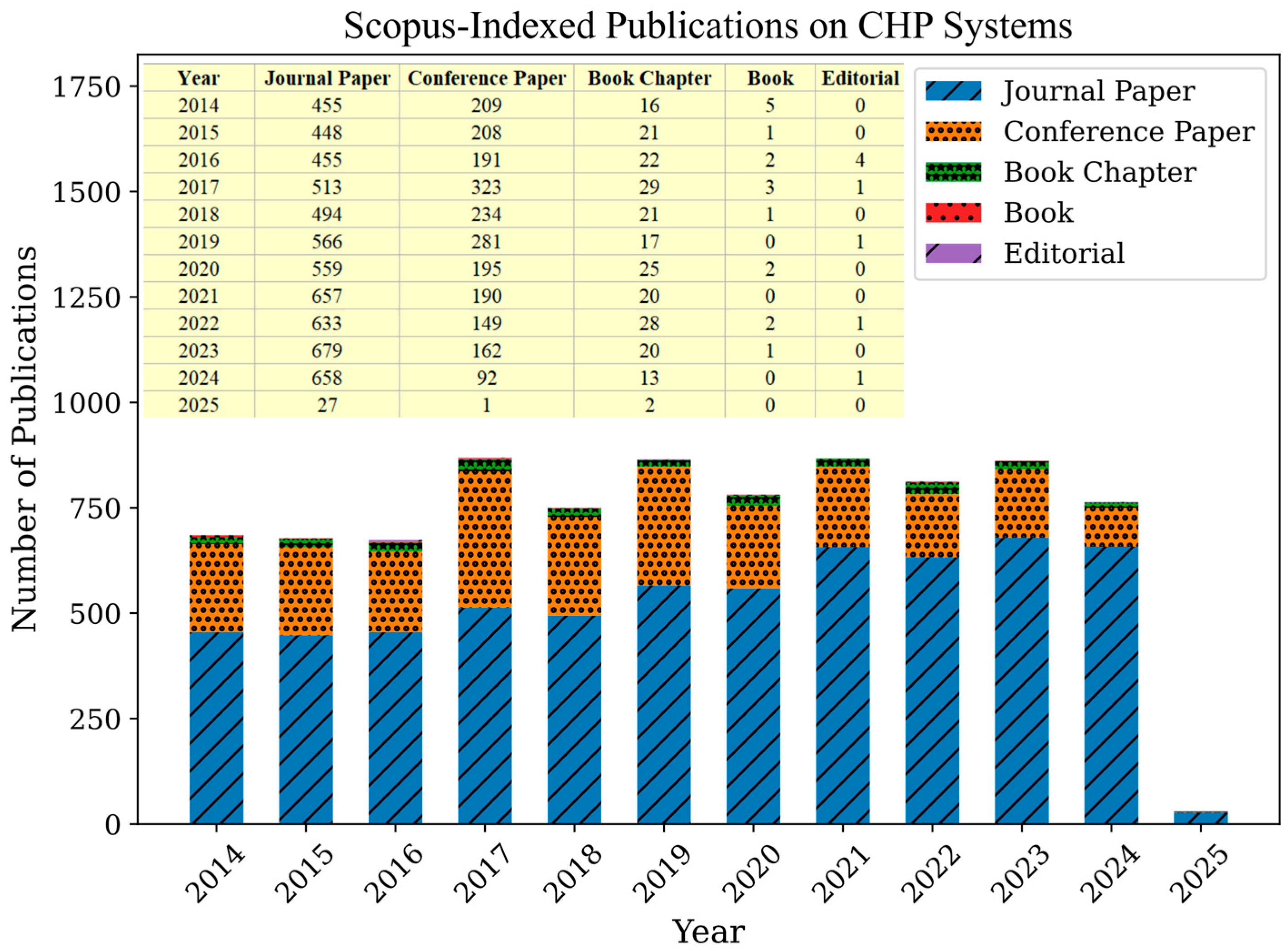

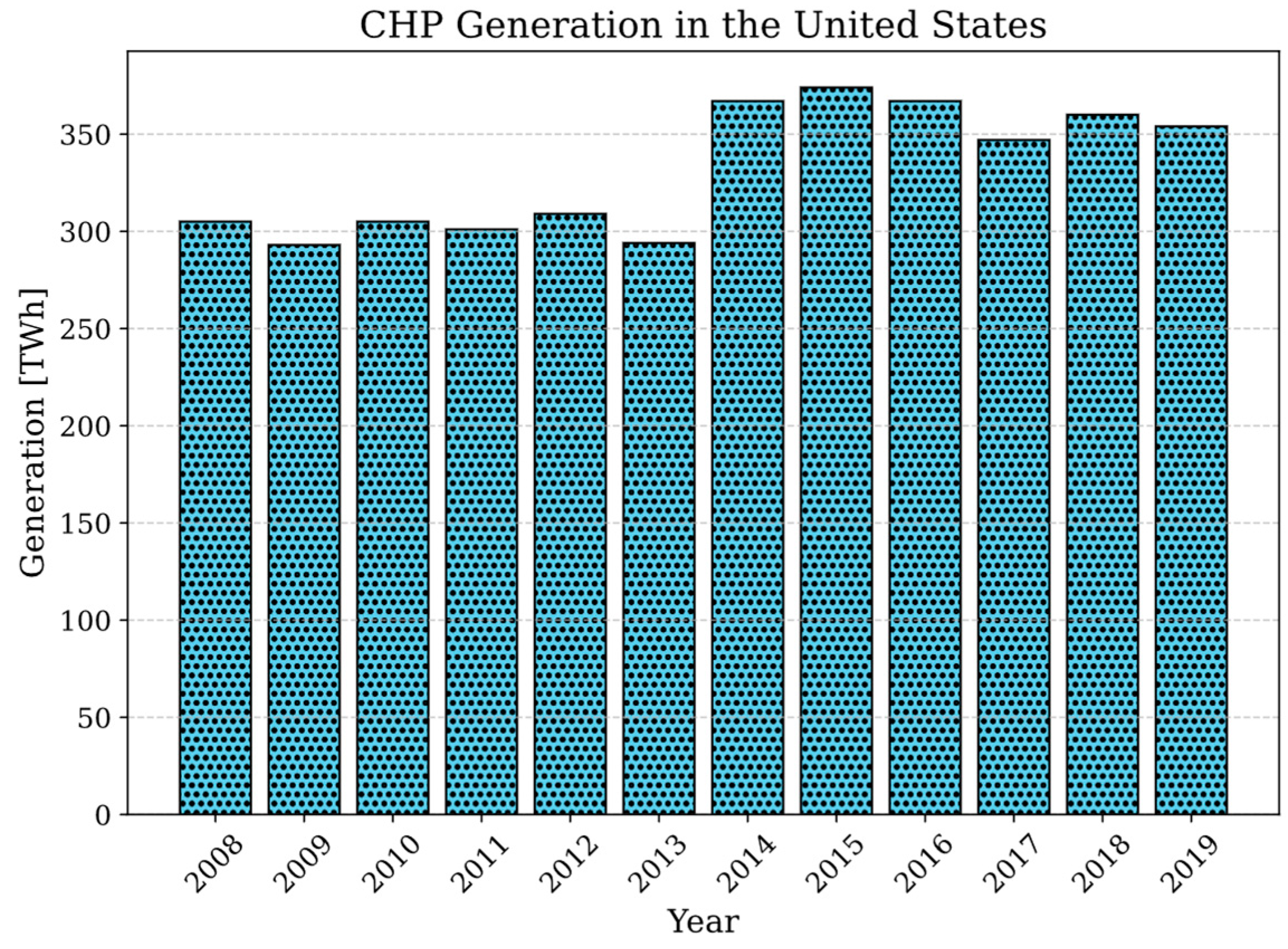

1.1. Background

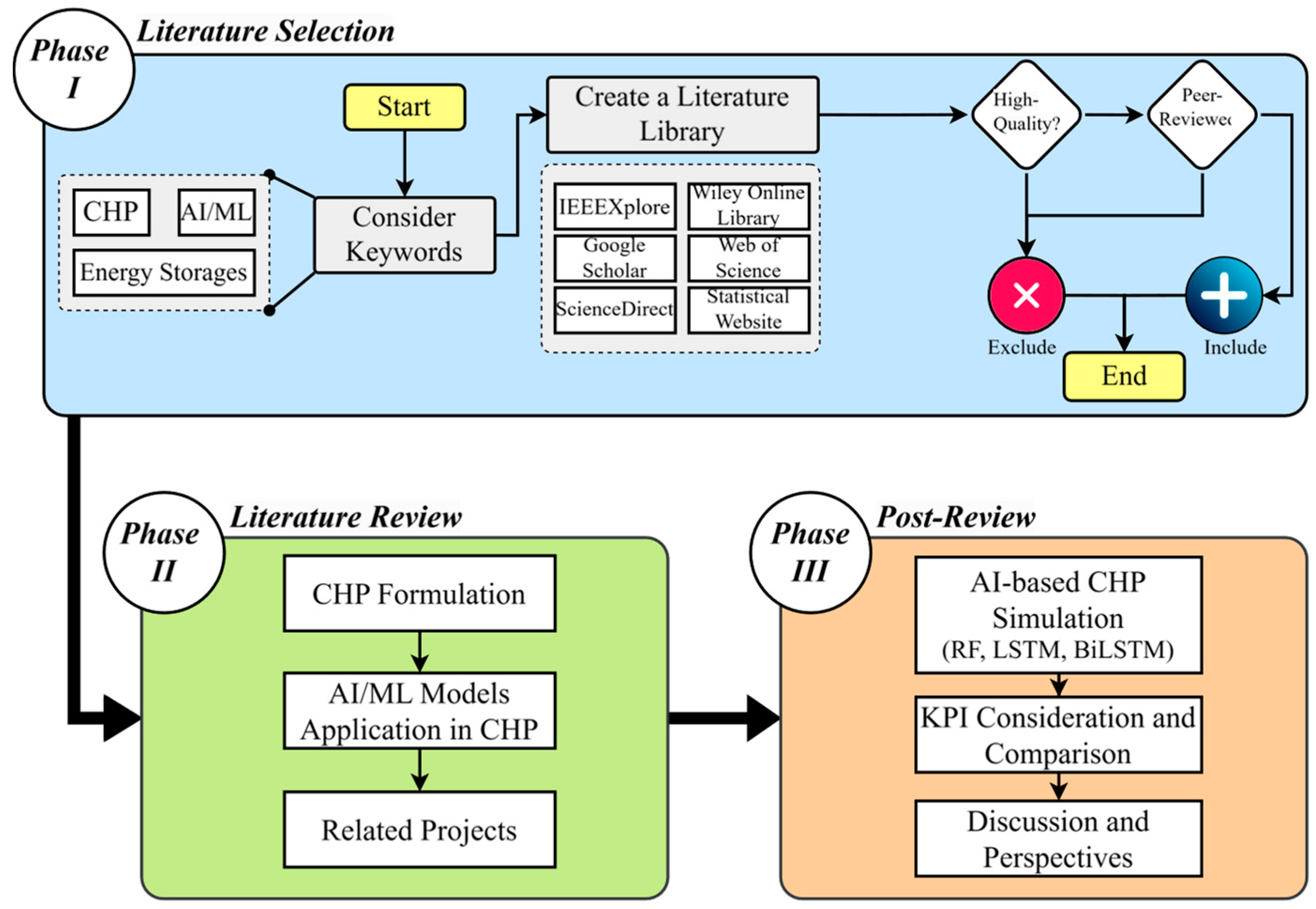

1.2. Review Phases and Search Algorithm

1.3. Contributions

- (1)

- This is the first updated paper that reviews recent AI/ML models in CHP systems;

- (2)

- It provides modelling of and recent advances in CHP systems;

- (3)

- We conduct a simulation integrating three AI models in CHP systems and compare their performance.

1.4. Paper Structure

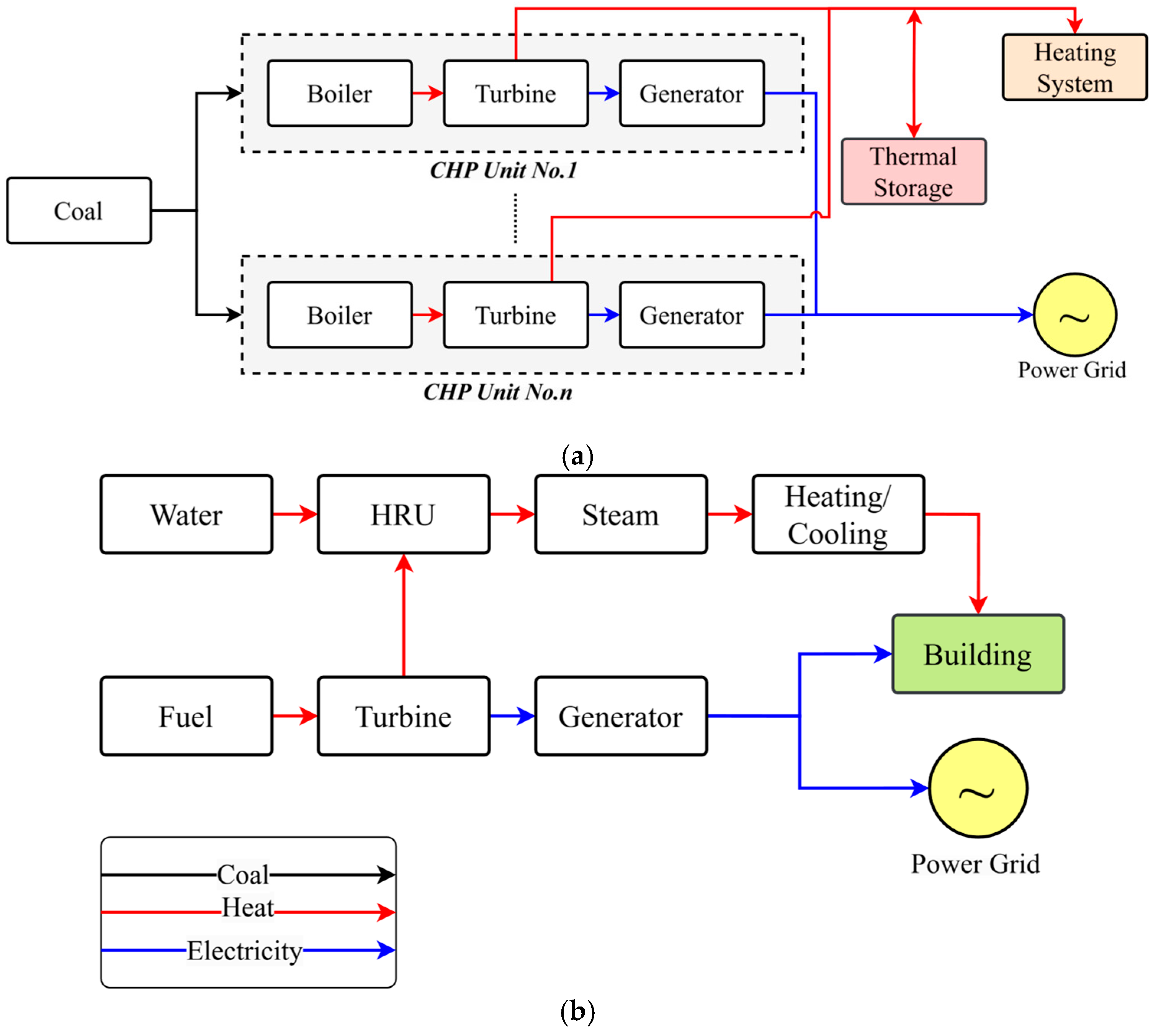

2. CHP General Formulation

3. Advancements and Integrations in CHP Systems

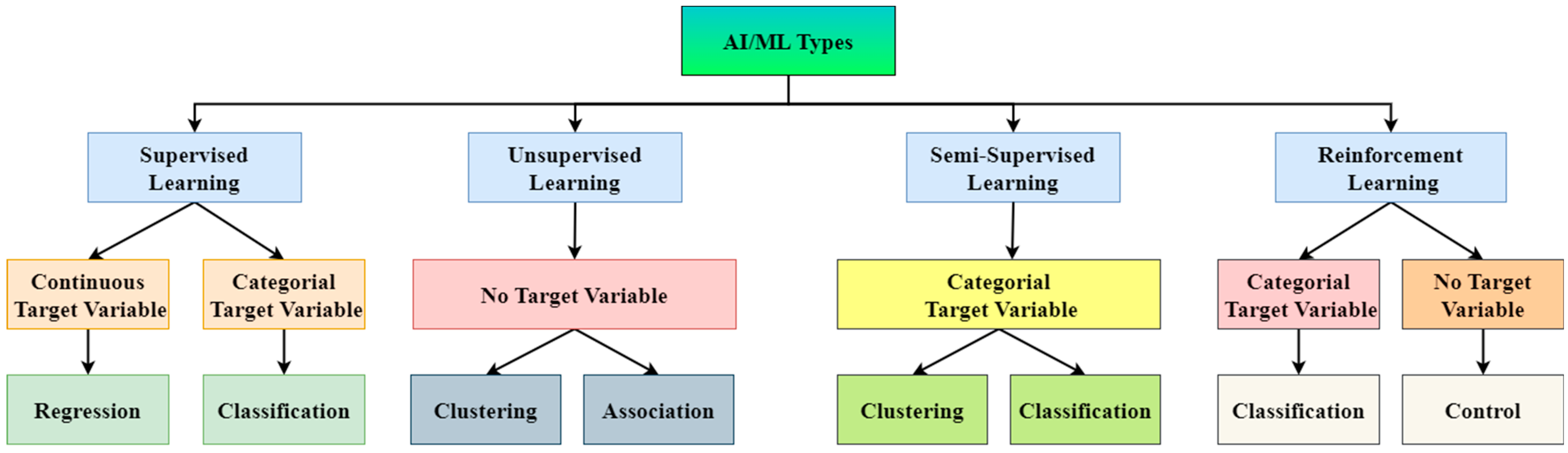

4. Artificial Intelligence Integration

4.1. Overview of Intelligent Model

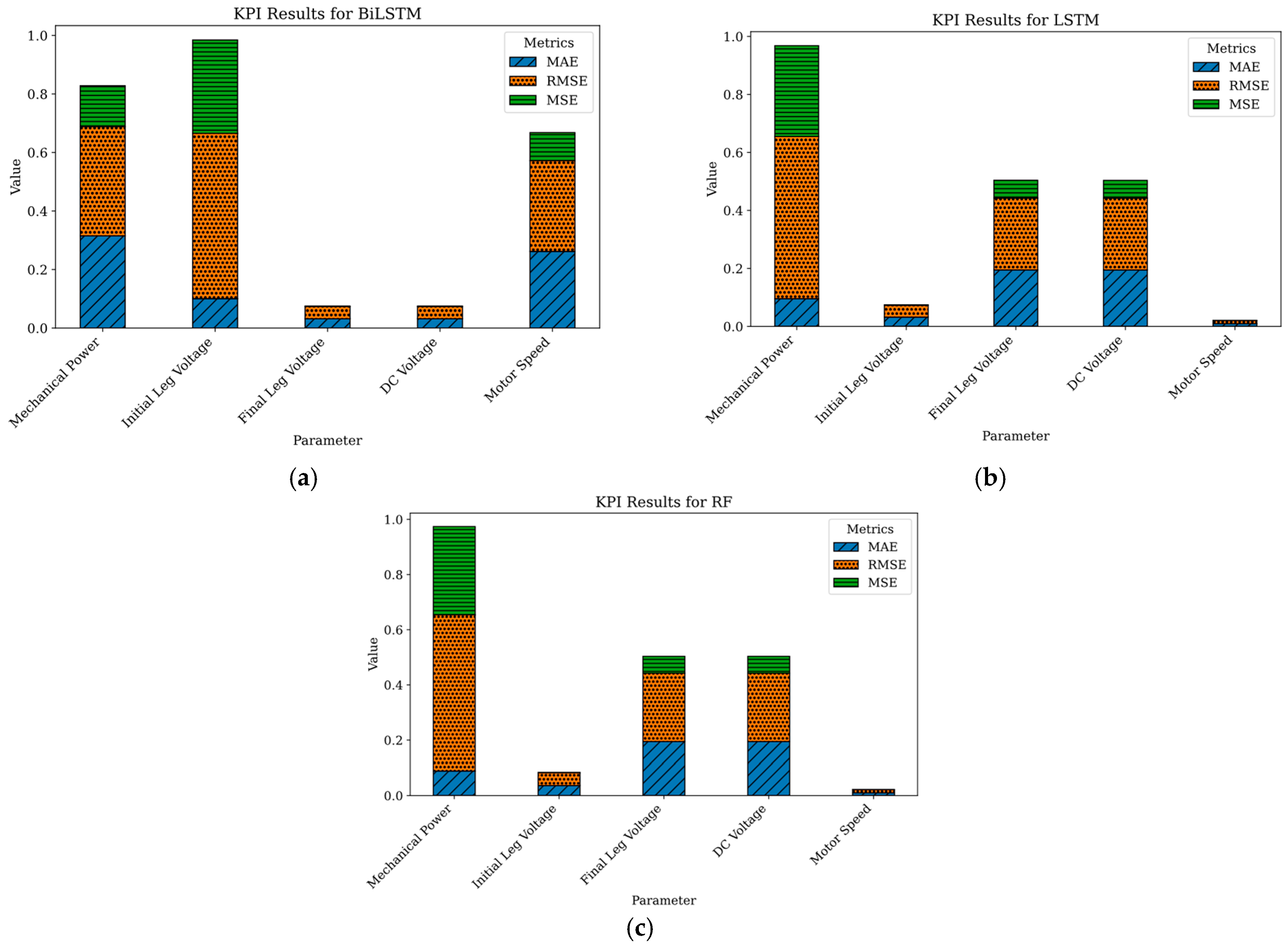

4.2. Key Performance Indicators (KPIs)

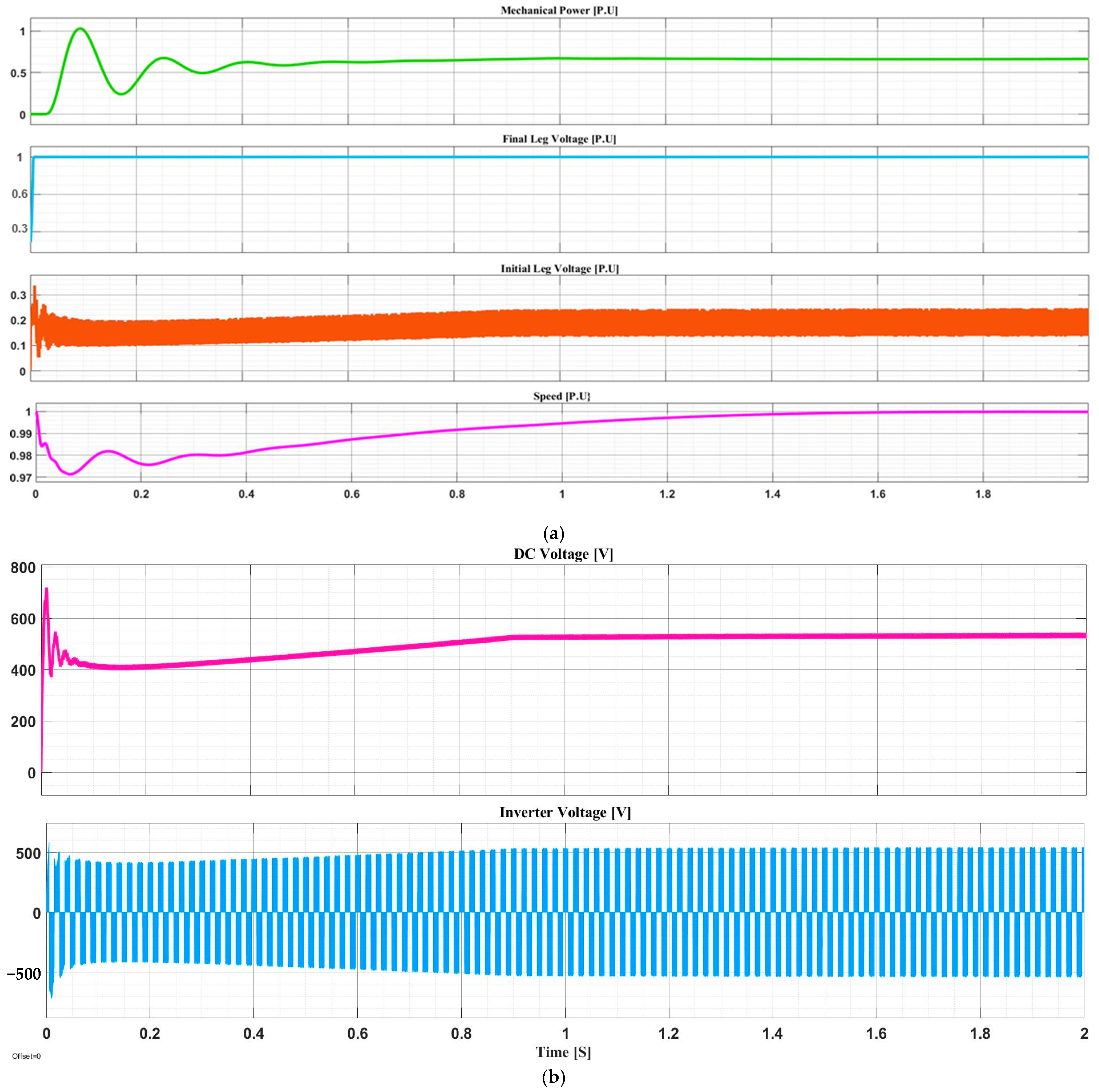

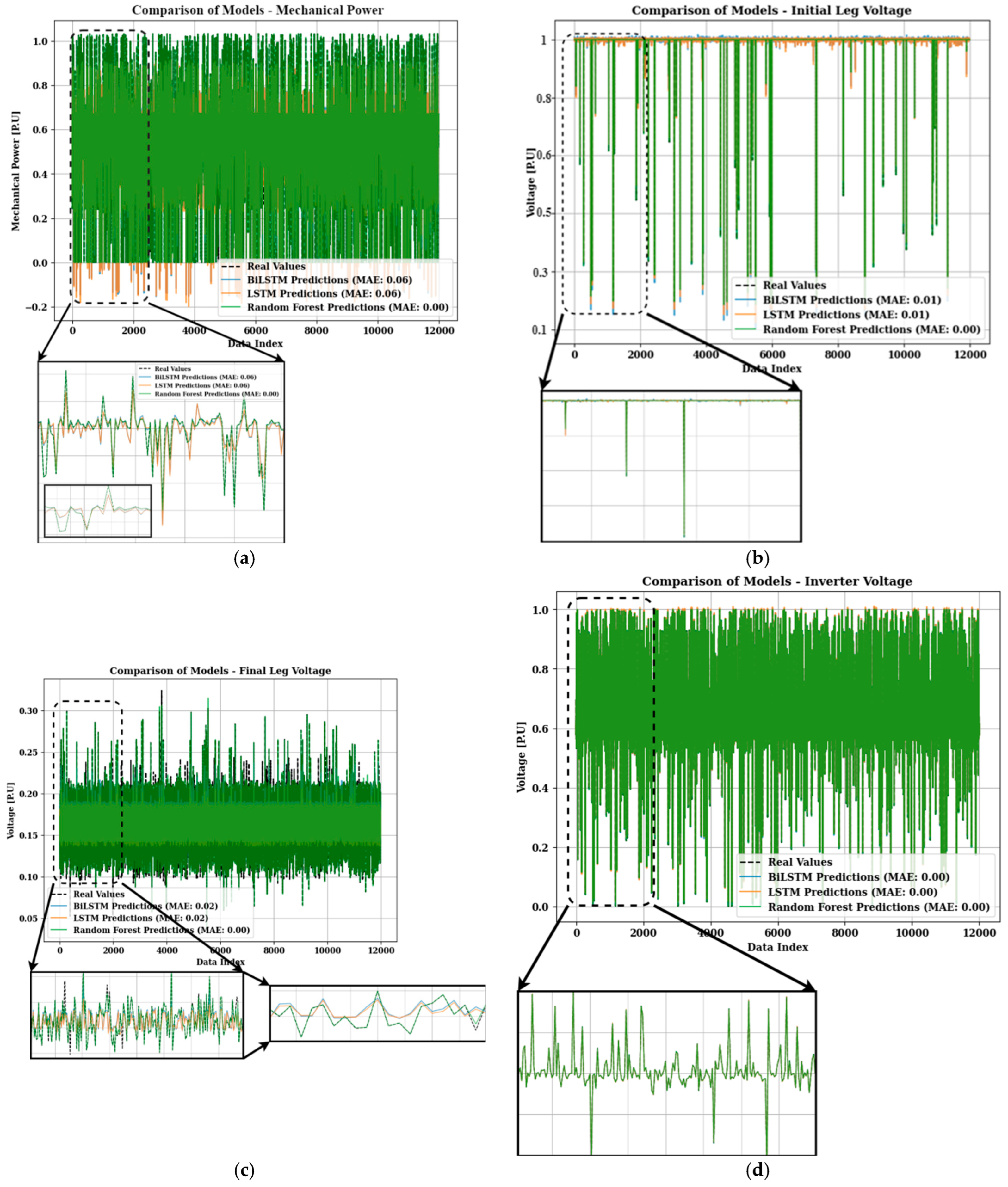

5. Case Study Simulation Review

6. Discussion on Challenges and Future Perspectives

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Boucher, M.J. Accelerating Decentralized Energy Transitions: A Socio-Technical Perspective. Doctoral Dissertation, University of Saskatchewan, Saskatoon, Canada, 2021. [Google Scholar]

- Safari, A.; Oshnoei, A. An Overview of Artificial Intelligence Recent Applications for Combined Heat and Power Systems Optimization in Smart Cities. Authorea, 2024; preprints. [Google Scholar]

- Statista. CHP Generation in the U.S. Statista. Available online: https://www.statista.com/statistics/499578/chp-generation-in-the-us/ (accessed on 22 December 2024).

- European Commission. Eurostat Provides Data in Excel Format on Combined Heat and Power (CHP) for the Period 2005–2019. Eurostat. Available online: https://ec.europa.eu/eurostat/web/energy/database/additional-data#Combined%20heat%20and%20power%20generation%20(CHP) (accessed on 22 December 2024).

- Erixno, O.; Abd Rahim, N.; Ramadhani, F.; Adzman, N.N. Energy management of renewable energy-based combined heat and power systems: A review. Sustain. Energy Technol. Assess. 2022, 51, 101944. [Google Scholar] [CrossRef]

- Martinez, S.; Michaux, G.; Salagnac, P.; Bouvier, J.L. Micro-combined heat and power systems (micro-CHP) based on renewable energy sources. Energy Convers. Manag. 2017, 154, 262–285. [Google Scholar] [CrossRef]

- Al Moussawi, H.; Fardoun, F.; Louahlia, H. Selection based on differences between cogeneration and trigeneration in various prime mover technologies. Renew. Sustain. Energy Rev. 2017, 74, 491–511. [Google Scholar] [CrossRef]

- Wu, M.; Zhang, H.; Zhao, J.; Wang, F.; Yuan, J. Performance analyzes of an integrated phosphoric acid fuel cell and thermoelectric device system for power and cooling cogeneration. Int. J. Refrig. 2018, 89, 61–69. [Google Scholar] [CrossRef]

- Asensio, F.J.; San Martín, J.I.; Zamora, I.; Oñederra, O. Model for optimal management of the cooling system of a fuel cell-based combined heat and power system for developing optimization control strategies. Appl. Energy 2018, 211, 413–430. [Google Scholar] [CrossRef]

- Salehimaleh, M.; Akbarimajd, A.; Valipour, K.; Dejamkhooy, A. Generalized modeling and optimal management of energy hub based electricity, heat and cooling demands. Energy 2018, 159, 669–685. [Google Scholar] [CrossRef]

- Mytafides, C.K.; Dimoudi, A.; Zoras, S. Transformation of a university building into a zero energy building in Mediterranean climate. Energy Build. 2017, 155, 98–114. [Google Scholar] [CrossRef]

- Lake, A.; Rezaie, B.; Beyerlein, S. Review of district heating and cooling systems for a sustainable future. Renew. Sustain. Energy Rev. 2017, 67, 417–425. [Google Scholar] [CrossRef]

- Kazda, K.; Li, X. A critical review of the modeling and optimization of combined heat and power dispatch. Processes 2020, 8, 441. [Google Scholar] [CrossRef]

- Guo, T.; Henwood, M.I.; Van Ooijen, M. An algorithm for combined heat and power economic dispatch. IEEE Trans. Power Syst. 1996, 11, 1778–1784. [Google Scholar] [CrossRef]

- Rooijers, F.J.; van Amerongen, R.A. Static economic dispatch for co-generation systems. IEEE Trans. Power Syst. 1994, 9, 1392–1398. [Google Scholar] [CrossRef]

- Song, Y.; Chou, C.; Stonham, T. Combined heat and power economic dispatch by improved ant colony search algorithm. Electr. Power Syst. Res. 1999, 52, 115–121. [Google Scholar] [CrossRef]

- Song, Y.; Xuan, Q. Combined heat and power economic dispatch using genetic algorithm based penalty function method. Electr. Mach. Power Syst. 1998, 26, 363–372. [Google Scholar] [CrossRef]

- Su, C.T.; Chiang, C.L. An incorporated algorithm for combined heat and power economic dispatch. Electr. Power Syst. Res. 2004, 69, 187–195. [Google Scholar] [CrossRef]

- Subbaraj, P.; Rengaraj, R.; Salivahanan, S. Enhancement of combined heat and power economic dispatch using self adaptive real-coded genetic algorithm. Appl. Energy 2009, 86, 915–921. [Google Scholar] [CrossRef]

- Vasebi, A.; Fesanghary, M.; Bathaee, S. Combined heat and power economic dispatch by harmony search algorithm. Int. J. Electr. Power Energy Syst. 2007, 29, 713–719. [Google Scholar] [CrossRef]

- Nazari-Heris, M.; Mehdinejad, M.; Mohammadi-Ivatloo, B.; Babamalek-Gharehpetian, G. Combined heat and power economic dispatch problem solution by implementation of whale optimization method. Neural Comput. Appl. 2019, 31, 421–436. [Google Scholar] [CrossRef]

- Murugan, R.; Mohan, M.; Rajan, C.C.A.; Sundari, P.D.; Arunachalam, S. Hybridizing bat algorithm with artificial bee colony for combined heat and power economic dispatch. Appl. Soft. Comput. 2018, 72, 189–217. [Google Scholar] [CrossRef]

- Mohammadi-Ivatloo, B.; Moradi-Dalvand, M.; Rabiee, A. Combined heat and power economic dispatch problem solution using particle swarm optimization with time varying acceleration coefficients. Electr. Power Syst. Res. 2013, 95, 9–18. [Google Scholar] [CrossRef]

- Roy, P.K.; Paul, C.; Sultana, S. Oppositional teaching learning based optimization approach for combined heat and power dispatch. Int. J. Electr. Power Energy Syst. 2014, 57, 392–403. [Google Scholar] [CrossRef]

- Haghrah, A.; Nazari-Heris, M.; Mohammadi-Ivatloo, B. Solving combined heat and power economic dispatch problem using real coded genetic algorithm with improved Mühlenbein mutation. Appl. Therm. Eng. 2016, 99, 465–475. [Google Scholar] [CrossRef]

- Jena, C.; Basu, M.; Panigrahi, C. Differential evolution with Gaussian mutation for combined heat and power economic dispatch. Soft Comput. 2016, 20, 681–688. [Google Scholar] [CrossRef]

- Niknam, T.; Azizipanah-Abarghooee, R.; Roosta, A.; Amiri, B. A new multi-objective reserve constrained combined heat and power dynamic economic emission dispatch. Energy 2012, 42, 530–545. [Google Scholar] [CrossRef]

- Nazari-Heris, M.; Mohammadi-Ivatloo, B.; Gharehpetian, G. A comprehensive review of heuristic optimization algorithms for optimal combined heat and power dispatch from economic and environmental perspectives. Renew. Sustain. Energy Rev. 2018, 81, 2128–2143. [Google Scholar]

- Basu, M. Combined heat and power economic emission dispatch using nondominated sorting genetic algorithm-II. Int. J. Electr. Power Energy Syst. 2013, 53, 135–141. [Google Scholar] [CrossRef]

- Ali Shaabani, Y.; Seifi, A.R.; Kouhanjani, M.J. Stochastic multi-objective optimization of combined heat and power economic/emission dispatch. Energy 2017, 141, 1892–1904. [Google Scholar] [CrossRef]

- Li, Y.; Wang, J.; Zhao, D.; Li, G.; Chen, C. A two-stage approach for combined heat and power economic emission dispatch: Combining multi-objective optimization with integrated decision making. Energy 2018, 162, 237–254. [Google Scholar] [CrossRef]

- Nourianfar, H.; Abdi, H. Solving the multi-objective economic emission dispatch problems using Fast Non-Dominated Sorting TVAC-PSO combined with EMA. Appl. Soft Comput. 2019, 85, 105770. [Google Scholar] [CrossRef]

- Sundaram, A. Combined Heat and Power Economic Emission Dispatch Using Hybrid NSGA II-MOPSO Algorithm Incorporating an Effective Constraint Handling Mechanism. IEEE Access 2020, 8, 13748–13768. [Google Scholar] [CrossRef]

- Tan, P.; Liu, X.; Liu, C.; Feng, J.; Yang, K. Experimental study on heat transfer performance of a series combined microchannel heat dissipation system based on Al2O3 nanofluid. Appl. Therm. Eng. 2024, 240, 122237. [Google Scholar] [CrossRef]

- Hao, Q.; Zhu, L.; Wang, Y.; He, Y.; Zeng, X.; Zhu, J. Achieving near-zero emission and high-efficient combined cooling, heating and power based on biomass gasification coupled with SOFC hybrid system. Fuel 2024, 357, 129751. [Google Scholar] [CrossRef]

- Chang, L.; Li, M.; Qian, L.; de Oliveira, G.G. Developed multi-objective honey badger optimizer: Application to optimize proton exchange membrane fuel cells-based combined cooling, heating, and power system. Int. J. Hydrogen Energy 2024, 50, 592–605. [Google Scholar] [CrossRef]

- Yang, C.; Wu, Z.; Li, X.; Fars, A. Risk-constrained stochastic scheduling for energy hub: Integrating renewables, demand response, and electric vehicles. Energy 2024, 288, 129680. [Google Scholar] [CrossRef]

- Faddouli, A.; Hajji, M.; Fadili, S.; Hartiti, B.; Labrim, H.; Habchi, A. A comprehensive review of solar, thermal, photovoltaic, and thermoelectric hybrid systems for heating and power generation. Int. J. Green Energy 2024, 21, 413–447. [Google Scholar] [CrossRef]

- Jordehi, A.R.; Mansouri, S.A.; Tostado-Véliz, M.; Ahmarinejad, A.; Jurado, F. Resilience-oriented placement of multi-carrier microgrids in power systems with switchable transmission lines. Int. J. Hydrogen Energy 2024, 50, 175–185. [Google Scholar] [CrossRef]

- Nazar, M.S.; Jafarpour, P.; Shafie-khah, M.; Catalão, J.P. Optimal planning of self-healing multi-carriers energy systems considering integration of smart buildings and parking lots energy resources. Energy 2024, 286, 128674. [Google Scholar] [CrossRef]

- Zhao, J.; Li, S.; Tu, Z. Development of practical empirically and statistically-based equations for predicting the temperature characteristics of PEMFC applied in the CCHP system. Int. J. Hydrogen Energy 2024, 52, 894–904. [Google Scholar] [CrossRef]

- Wagle, R.; Sharma, P.; Sharma, C.; Amin, M. Optimal power flow based coordinated reactive and active power control to mitigate voltage violations in smart inverter enriched distribution network. Int. J. Green Energy 2024, 21, 359–375. [Google Scholar] [CrossRef]

- Zhou, Y.; Ma, Z.; Shi, X.; Zou, S. Multi-agent optimal scheduling for integrated energy system considering the global carbon emission constraint. Energy 2024, 288, 129732. [Google Scholar] [CrossRef]

- Fang, X.; Dong, W.; Wang, Y.; Yang, Q. Multi-stage and multi-timescale optimal energy management for hydrogen-based integrated energy systems. Energy 2024, 286, 129576. [Google Scholar] [CrossRef]

- Zhu, C.; Wang, M.; Guo, M.; Deng, J.; Du, Q.; Wei, W.; Zhang, Y.; Mohebbi, A. An innovative process design and multi-criteria study/optimization of a biomass digestion-supercritical carbon dioxide scenario toward boosting a geothermal-driven cogeneration system for power and heat. Energy 2024, 292, 130408. [Google Scholar] [CrossRef]

- Cheng, L.; Guo, Z.; Xia, G. A review on research and technology development of green hydrogen energy systems with thermal management and heat recovery. Heat Transf. Eng. 2024, 45, 300–322. [Google Scholar] [CrossRef]

- Luo, D.; Wu, Z.; Yan, Y.; Cao, J.; Yang, X.; Zhao, Y.; Cao, B. Performance investigation and design optimization of a battery thermal management system with thermoelectric coolers and phase change materials. J. Clean. Prod. 2024, 434, 139834. [Google Scholar] [CrossRef]

- Zhou, L.; Meng, F.; Sun, Y. Numerical study on infrared detectors cooling by multi-stage thermoelectric cooler combined with microchannel heat sink. Appl. Therm. Eng. 2024, 236, 121788. [Google Scholar] [CrossRef]

- Wang, Y.; Dong, P.; Xu, M.; Li, Y.; Zhou, D.; Liu, X. Research on collaborative operation optimization of multi-energy stations in regional integrated energy system considering joint demand response. Int. J. Electr. Power Energy Syst. 2024, 155, 109507. [Google Scholar] [CrossRef]

- Zhou, J.; Alsharif, S.; Alizadeh, A.A.; Ali, M.A.; Goyal, V. Development and analysis of a new method in developments of molten carbonate fuel cell technology, based on hybrid supercritical carbon dioxide for multi objective optimization based on machine learning techniques. Int. J. Hydrogen Energy 2024, 51, 1156–1170. [Google Scholar] [CrossRef]

- Wu, Z.; Li, D.; Xue, Y.; Chen, Y. Gain scheduling design based on active disturbance rejection control for thermal power plant under full operating conditions. In Modeling, Identification, and Control for Cyber-Physical Systems Towards Industry 4.0; Academic Press: Cambridge, MA, USA, 2024; pp. 351–384. [Google Scholar]

- Wang, D.; Ali, M.A.; Alizadeh, A.A.; Singh, P.K.; Almojil, S.F.; Alali, A.F.; Almoalimi, K.T.; Almohana, A.I. Thermoeconomic appraisal of a novel power and hydrogen cogeneration plant with integration of biomass and geothermal energies. Int. J. Hydrogen Energy 2024, 52, 385–400. [Google Scholar] [CrossRef]

- Pivetta, D.; Dall’Armi, C.; Sandrin, P.; Bogar, M.; Taccani, R. The role of hydrogen as enabler of industrial port area decarbonization. Renew. Sustain. Energy Rev. 2024, 189, 113912. [Google Scholar] [CrossRef]

- Wang, S.; Wei, W.; Xie, J.; Wang, W.; Sun, Y.; Li, Z.; Lin, Y.; Huang, C.; Deng, S. Space heating performance analysis of air source heat pump integrated with image gray recognition-based defrosting controller. Appl. Therm. Eng. 2024, 236, 121536. [Google Scholar] [CrossRef]

- Williams, B.; Bishop, D.; Docherty, P. Assessing the energy storage potential of electric hot water cylinders with stochastic model-based control. J. R. Soc. N. Z. 2024, 54, 240–256. [Google Scholar] [CrossRef] [PubMed]

- Chen, K.; Zhang, Z.; Wu, B.; Song, M.; Wu, X. An air-cooled system with a control strategy for efficient battery thermal management. Appl. Therm. Eng. 2024, 236, 121578. [Google Scholar] [CrossRef]

- dos Santos Coelho, L.; Ayala, H.V.; Mariani, V.C. CO and NOx emissions prediction in gas turbine using a novel modeling pipeline based on the combination of deep forest regressor and feature engineering. Fuel 2024, 355, 129366. [Google Scholar] [CrossRef]

- Wang, C.; Song, J. Performance assessment of the novel coal-fired combined heat and power plant integrating with flexibility renovations. Energy 2023, 263, 125886. [Google Scholar] [CrossRef]

- Chen, M.; Lu, H.; Chang, X.; Liao, H. An optimization on an integrated energy system of combined heat and power, carbon capture system and power to gas by considering flexible load. Energy 2023, 273, 127203. [Google Scholar] [CrossRef]

- Castilla, G.M.; Montanés, R.M.; Pallares, D.; Johnsson, F. Dynamics and control of large-scale fluidized bed plants for renewable heat and power generation. Appl. Therm. Eng. 2023, 219, 119591. [Google Scholar] [CrossRef]

- van Veldhuizen, B.N.; van Biert, L.; Amladi, A.; Woudstra, T.; Visser, K.; Aravind, P.V. The effects of fuel type and cathode off-gas recirculation on combined heat and power generation of marine SOFC systems. Energy Convers. Manag. 2023, 276, 116498. [Google Scholar] [CrossRef]

- Yan, R.; Wang, J.; Huo, S.; Zhang, J.; Tang, S.; Yang, M. Comparative study for four technologies on flexibility improvement and renewable energy accommodation of combined heat and power system. Energy 2023, 263, 126056. [Google Scholar] [CrossRef]

- Chen, C.; Ge, Z.; Zhang, Y. Study of combined heat and power plant integration with thermal energy storage for operational flexibility. Appl. Therm. Eng. 2023, 219, 119537. [Google Scholar] [CrossRef]

- Wu, J.; Han, Y. Integration strategy optimization of solar-aided combined heat and power (CHP) system. Energy 2023, 263, 125875. [Google Scholar] [CrossRef]

- Liu, B. Optimal scheduling of combined cooling, heating, and power system-based microgrid coupled with carbon capture storage system. J. Energy Storage 2023, 61, 106746. [Google Scholar] [CrossRef]

- Zhao, P.; Gou, F.; Xu, W.; Shi, H.; Wang, J. Multi-objective optimization of a hybrid system based on combined heat and compressed air energy storage and electrical boiler for wind power penetration and heat-power decoupling purposes. J. Energy Storage 2023, 58, 106353. [Google Scholar] [CrossRef]

- Palys, M.J.; Mitrai, I.; Daoutidis, P. Renewable hydrogen and ammonia for combined heat and power systems in remote locations: Optimal design and scheduling. Optim. Control. Appl. Methods 2023, 44, 719–738. [Google Scholar] [CrossRef]

- Razeghi, M.; Hajinezhad, A.; Naseri, A.; Noorollahi, Y.; Moosavian, S.F. An overview of renewable energy technologies for the simultaneous production of high-performance power and heat. Future Energy 2023, 2, 1–11. [Google Scholar] [CrossRef]

- Zhang, G.; Ge, Y.; Ye, Z.; Al-Bahrani, M. Multi-objective planning of energy hub on economic aspects and resources with heat and power sources, energizable, electric vehicle and hydrogen storage system due to uncertainties and demand response. J. Energy Storage 2023, 57, 106160. [Google Scholar] [CrossRef]

- Perrone, D.; Castiglione, T.; Morrone, P.; Pantano, F.; Bova, S. Numerical and experimental assessment of a micro-combined cooling, heating, and power (CCHP) system based on biomass gasification. Appl. Therm. Eng. 2023, 219, 119600. [Google Scholar] [CrossRef]

- Fan, G.; Yu, B.; Sun, B.; Li, F. Multi-time-space scale optimization for a hydrogen-based regional multi-energy system. Appl. Energy 2024, 371, 123430. [Google Scholar] [CrossRef]

- Pang, K.Y.; Liew, P.Y.; Woon, K.S.; Ho, W.S.; Alwi, S.R.; Klemeš, J.J. Multi-period multi-objective optimisation model for multi-energy urban-industrial symbiosis with heat, cooling, power and hydrogen demands. Energy 2023, 262, 125201. [Google Scholar] [CrossRef]

- Gao, Y.; Matsunami, Y.; Miyata, S.; Akashi, Y. Model predictive control of a building renewable energy system based on a long short-term hybrid model. Sustain. Cities Soc. 2023, 89, 104317. [Google Scholar] [CrossRef]

- Zhao, P.; Xu, W.; He, W.; Wang, J.; Yan, Z. Thermo-economic analysis of a hybrid system based on combined heat-isobaric compressed air energy storage and humidification dehumidification desalination unit. Appl. Therm. Eng. 2023, 219, 119536. [Google Scholar] [CrossRef]

- Zhu, X.; Zhan, X.; Liang, H.; Zheng, X.; Qiu, Y.; Lin, J.; Chen, J.; Meng, C.; Zhao, Y. The optimal design and operation strategy of renewable energy-CCHP coupled system applied in five building objects. Renew. Energy 2020, 146, 2700–2715. [Google Scholar] [CrossRef]

- Assareh, E.; Dejdar, A.; Ershadi, A.; Jafarian, M.; Mansouri, M.; Azish, E.; Saedpanah, E.; Lee, M. Techno-economic analysis of combined cooling, heating, and power (CCHP) system integrated with multiple renewable energy sources and energy storage units. Energy Build. 2023, 278, 112618. [Google Scholar] [CrossRef]

- Assareh, E.; Dejdar, A.; Ershadi, A.; Jafarian, M.; Mansouri, M.; Azish, E.; Saedpanah, E.; Aghajari, M.; Wang, X. Performance analysis of solar-assisted-geothermal combined cooling, heating, and power (CCHP) systems incorporated with a hydrogen generation subsystem. J. Build. Eng. 2023, 65, 105727. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, Q.; Zhang, Z.; Razmjooy, N. A new configuration of autonomous CHP system based on improved version of marine predators algorithm: A case study. Int. Trans. Electr. Energy Syst. 2021, 31, e12806. [Google Scholar] [CrossRef]

- Liu, L.; Wang, R.; Wang, Y.; Li, W.; Sun, J.; Guo, Y.; Qu, W.; Li, W.; Zhao, C. Comprehensive analysis and optimization of combined cooling heating and power system integrated with solar thermal energy and thermal energy storage. Energy Convers. Manag. 2023, 275, 116464. [Google Scholar] [CrossRef]

- Esmaeilzadeh, A.; Deal, B.; Yousefi-Koma, A.; Zakerzadeh, M.R. How combination of control methods and renewable energies leads a large commercial building to a zero-emission zone–A case study in US. Energy 2023, 263, 125944. [Google Scholar] [CrossRef]

- Alsagri, A.S.; Alrobaian, A.A. Optimization of Combined Heat and Power Systems by Meta-Heuristic Algorithms: An Overview. Energies 2022, 15, 5977. [Google Scholar] [CrossRef]

- James, G.; Witten, D.; Hastie, T.; Tibshirani, R.; Taylor, J. Linear regression. In An Introduction to Statistical Learning: With Applications in Python; Springer International Publishing: Cham, Switzerland, 2023; pp. 69–134. [Google Scholar]

- Hosmer, D.W., Jr.; Lemeshow, S.; Sturdivant, R.X. Applied Logistic Regression; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Pisner, D.A.; Schnyer, D.M. Support vector machine. In Machine Learning; Academic Press: Cambridge, MA, USA, 2020; pp. 101–121. [Google Scholar]

- Barlow, H.B. Unsupervised learning. Neural Comput. 1989, 1, 295–311. [Google Scholar] [CrossRef]

- Van Engelen, J.E.; Hoos, H.H. A survey on semi-supervised learning. Mach. Learn. 2020, 109, 373–440. [Google Scholar] [CrossRef]

- Ozkaya, B.; Duman, S.; Kahraman, H.T.; Guvenc, U. Optimal solution of the combined heat and power economic dispatch problem by adaptive fitness-distance balance based artificial rabbits optimization algorithm. Expert Syst. Appl. 2024, 238, 122272. [Google Scholar] [CrossRef]

- Yuan, Y.; Chen, L.; Lyu, X.; Ning, W.; Liu, W.; Tao, W.Q. Modeling and optimization of a residential PEMFC-based CHP system under different operating modes. Appl. Energy 2024, 353, 122066. [Google Scholar] [CrossRef]

- Cao, Y.; Zhao, C.; Li, D. Carbon Management for Intelligent Community with Combined Heat and Power Systems. Sustainability 2023, 15, 13257. [Google Scholar] [CrossRef]

- Zhou, S.; Hu, Z.; Gu, W.; Jiang, M.; Chen, M.; Hong, Q.; Booth, C. Combined heat and power system intelligent economic dispatch: A deep reinforcement learning approach. Int. J. Electr. Power Energy Syst. 2020, 120, 106016. [Google Scholar] [CrossRef]

- Facci, A.L.; Ubertini, S. Analysis of a fuel cell combined heat and power plant under realistic smart management scenarios. Appl. Energy 2018, 216, 60–72. [Google Scholar] [CrossRef]

- Patteeuw, D.; Helsen, L. Combined design and control optimization of residential heating systems in a smart-grid context. Energy Build. 2016, 133, 640–657. [Google Scholar] [CrossRef]

- Nuytten, T.; Claessens, B.; Paredis, K.; Van Bael, J.; Six, D. Flexibility of a combined heat and power system with thermal energy storage for district heating. Appl. Energy 2013, 104, 583–591. [Google Scholar] [CrossRef]

- Shaheen, A.M.; Elsayed, A.M.; Elattar, E.E.; El-Sehiemy, R.A.; Ginidi, A.R. An Intelligent Heap-Based Technique with Enhanced Discriminatory Attribute for Large-Scale Combined Heat and Power Economic Dispatch. IEEE Access 2022, 10, 64325–64338. [Google Scholar] [CrossRef]

- Sun, T.; Lu, J.; Li, Z.; Lubkeman, D.L.; Lu, N. Modeling combined heat and power systems for microgrid applications. IEEE Trans. Smart Grid 2017, 9, 4172–4180. [Google Scholar] [CrossRef]

- Olabi, A.G.; Abdelghafar, A.A.; Maghrabie, H.M.; Sayed, E.T.; Rezk, H.; Al Radi, M.; Obaideen, K.; Abdelkareem, M.A. Application of artificial intelligence for prediction, optimization, and control of thermal energy storage systems. Therm. Sci. Eng. Prog. 2023, 39, 101730. [Google Scholar] [CrossRef]

- Xiaodong, Z.; Feng, L.; Jian, L.; Yun, T.; Shengpeng, Y. Research on Optimization Model and Method of a Multi-energy Complementary Combined Heat and Power System. In Proceedings of the 2018 International Conference on Engineering Simulation and Intelligent Control (ESAIC), Changsha, China, 10–11 August 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 206–209. [Google Scholar]

- Matics, J.; Krost, G. Micro combined heat and power home supply: Prospective and adaptive management achieved by computational intelligence techniques. Appl. Therm. Eng. 2008, 28, 2055–2061. [Google Scholar] [CrossRef]

- Zhou, Y.; Zheng, S.; Zhang, G. A review on cooling performance enhancement for phase change materials integrated systems—Flexible design and smart control with machine learning applications. Build. Environ. 2020, 174, 106786. [Google Scholar] [CrossRef]

- Gaska, K.; Generowicz, A.; Gronba-Chyła, A.; Ciuła, J.; Wiewiórska, I.; Kwaśnicki, P.; Mala, M.; Chyła, K. Artificial Intelligence Methods for Analysis and Optimization of CHP Cogeneration Units Based on Landfill Biogas as a Progress in Improving Energy Efficiency and Limiting Climate Change. Energies 2023, 16, 5732. [Google Scholar] [CrossRef]

- Østergaard, J.; Wu, Q.; Garcia-Valle, R. Real time Intelligent Control Laboratory (RT-ICL) of PowerLabDK for smart grid technology development. In Proceedings of the 2012 Complexity in Engineering (COMPENG), Proceedings, Aachen, Germany, 11–13 June 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 1–4. [Google Scholar]

- Jack, M.W.; Suomalainen, K.; Dew, J.J.; Eyers, D. A minimal simulation of the electricity demand of a domestic hot water cylinder for smart control. Appl. Energy 2018, 211, 104–112. [Google Scholar] [CrossRef]

- Gong, M.; Liu, Y.; Sun, J.; Xu, W.; Li, W.; Yan, C.; Fu, W. Intelligent control of district heating system based on RDPG. Eng. Appl. Artif. Intell. 2024, 129, 107672. [Google Scholar] [CrossRef]

- Mertzis, D.; Mitsakis, P.; Tsiakmakis, S.; Manara, P.; Zabaniotou, A.; Samaras, Z. Performance analysis of a small-scale combined heat and power system using agricultural biomass residues: The SMARt-CHP demonstration project. Energy 2014, 64, 367–374. [Google Scholar] [CrossRef]

- Li, D.; Meng, J.; Gao, Z.; Kong, W.; Liu, Z. Study on multi-energy complementary model of coupling system of distribution network and heat pump energy storage. In Proceedings of the 2021 IEEE International Conference on Computer Science, Electronic Information Engineering and Intelligent Control Technology (CEI), Fuzhou, China, 24–26 September 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 785–789. [Google Scholar]

- Wang, A. Optimal control for combined heat and power system using Kuhn-Tucker algorithm. In Proceedings of the 2011 2nd International Conference on Intelligent Control and Information Processing, Bangkok, Thailand, 17–18 July 2011; IEEE: Piscataway, NJ, USA, 2011; Volume 2, pp. 885–888. [Google Scholar]

- Nazari-Heris, M.; Mohammadi-Ivatloo, B.; Asadi, S.; Geem, Z.W. Large-scale combined heat and power economic dispatch using a novel multi-player harmony search method. Appl. Therm. Eng. 2019, 154, 493–504. [Google Scholar] [CrossRef]

- Pattanaik, J.K.; Basu, M.; Dash, D.P. Modified teaching-learning-based optimization for combined heat and power economic dispatch. Int. J. Emerg. Electr. Power Syst. 2017, 18, 20160110. [Google Scholar] [CrossRef]

- Toopshekan, A.; Abedian, A.; Azizi, A.; Ahmadi, E.; Rad, M.A.V. Optimization of a CHP system using a forecasting dispatch and teaching-learning-based optimization algorithm. Energy 2023, 285, 128671. [Google Scholar] [CrossRef]

- Narang, N.; Sharma, E.; Dhillon, J.S. Combined heat and power economic dispatch using integrated civilized swarm optimization and Powell’s pattern search method. Appl. Soft Comput. 2017, 52, 190–202. [Google Scholar] [CrossRef]

- Basu, M. Combined heat and power economic dispatch using opposition-based group search optimization. Int. J. Electr. Power Energy Syst. 2015, 73, 819–829. [Google Scholar] [CrossRef]

- Neyestani, M.; Hatami, M.; Hesari, S. Combined heat and power economic dispatch problem using advanced modified particle swarm optimization. J. Renew. Sustain. Energy 2019, 11, 015302. [Google Scholar] [CrossRef]

- Beigvand, S.D.; Abdi, H.; La Scala, M. Combined heat and power economic dispatch problem using gravitational search algorithm. Electr. Power Syst. Res. 2016, 133, 160–172. [Google Scholar] [CrossRef]

- Basu, M. Bee colony optimization for combined heat and power economic dispatch. Expert Syst. Appl. 2011, 38, 13527–13531. [Google Scholar] [CrossRef]

- Rabiee, A.; Jamadi, M.; Mohammadi-Ivatloo, B.; Ahmadian, A. Optimal non-convex combined heat and power economic dispatch via improved artificial bee colony algorithm. Processes 2020, 8, 1036. [Google Scholar] [CrossRef]

- Van Houdt, G.; Mosquera, C.; Nápoles, G. A review on the long short-term memory model. Artif. Intell. Rev. 2020, 53, 5929–5955. [Google Scholar] [CrossRef]

- Sherstinsky, A. Fundamentals of recurrent neural network (RNN) and long short-term memory (LSTM) network. Phys. D Nonlinear Phenom. 2020, 404, 132306. [Google Scholar] [CrossRef]

- Hameed, Z.; Garcia-Zapirain, B. Sentiment classification using a single-layered BiLSTM model. IEEE Access 2020, 8, 73992–74001. [Google Scholar] [CrossRef]

- Parmar, A.; Katariya, R.; Patel, V. A review on random forest: An ensemble classifier. In Proceedings of the International Conference on Intelligent Data Communication Technologies and Internet of Things (ICICI), Coimbatore, India, 7–8 August 2018; Springer International Publishing: Cham, Switzerland, 2019; pp. 758–763. [Google Scholar]

- De Ville, B. Decision trees. Wiley Interdiscip. Rev. Comput. Stat. 2013, 5, 448–455. [Google Scholar] [CrossRef]

- Hochreiter, S. Long Short-term Memory. In Neural Computation; MIT Press: Cambridge, MA, USA, 1997. [Google Scholar]

- Schuster, M.; Paliwal, K.K. Bidirectional recurrent neural networks. IEEE Trans. Signal Process. 1997, 45, 2673–2681. [Google Scholar] [CrossRef]

- Breiman, L. Random forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Safari, A.; Ghavifekr, A. Use case of artificial intelligence, and neural networks in energy consumption markets, and industrial demand response. In Industrial Demand Response: Methods, Best Practices, Case Studies, and Applications; IET: London, UK, 2022. [Google Scholar] [CrossRef]

- Safari, A.; Kharrati, H.; Rahimi, A. Multi-Term Electrical Load Forecasting of Smart Cities Using a New Hybrid Highly Accurate Neural Network-Based Predictive Model. Smart Grids Sustain. Energy 2023, 9, 8. [Google Scholar] [CrossRef]

- Safari, A.; Daneshvar, M.; Anvari-Moghaddam, A. Energy Intelligence: A Systematic Review of Artificial Intelligence for Energy Management. Appl. Sci. 2024, 14, 11112. [Google Scholar] [CrossRef]

- Safari, A.; Hashemzadeh, F.; Zare, K. DeepEMS: Multimodal optimal energy management of microgrid systems based on a hybrid multi-stage machine learning model. J. Eng. 2024, 2024, e70012. [Google Scholar] [CrossRef]

| Parameters | Insights | Unit |

|---|---|---|

| CHP operational cost, heat/power-only units | [$] | |

| CHP emissions, heat/power-only units | [Kg] | |

| Objective functions of the system | [$, Kg] | |

| Heat-only cost coefficients | [] | |

| Power-only cost coefficients | [] | |

| Power-only emission coefficients | [] | |

| CHP cost coefficients | [] | |

| Emission coefficients for CHP and heat only | [] | |

| Power loss coefficient between unit i and j | [] | |

| Power loss coefficient of unit i | – | |

| Constant power loss | [MW] | |

| pl | System total power loss | [MW] |

| HP demand | [MW] | |

| Power-only minimum/maximum power output | [MW] | |

| Heat-only minimum/maximum power output | [MW] | |

| CHP heat output and heat-only unit | [MW] | |

| CHP power output and power-only unit | [MW] | |

| Minimum/maximum CHP unit heat output | [MW] |

| Ref. No | CCHP/CHP Systems | Biomass | Solar Energy | Geothermal Energy | Fuel Cells | Key Findings |

|---|---|---|---|---|---|---|

| [34] | ✗ | ✗ | ✗ | ✗ | ✗ | Improved performance with microchannel heat sinks and energy efficiency. |

| [35] | ✗ | ✓ | ✗ | ✗ | ✓ | High electrical efficiency, low CO2 emissions, and economic viability. |

| [36] | ✓ | ✗ | ✗ | ✗ | ✓ | Improved efficiency, reduced greenhouse gas emissions, and optimized importance. |

| [37] | ✗ | ✗ | ✗ | ✗ | ✗ | Reduction in operational costs and emissions; effective energy management. |

| [38] | ✗ | ✗ | ✓ | ✗ | ✗ | Review of solar hybrid systems and insights into recent developments. |

| [39] | ✗ | ✗ | ✗ | ✗ | ✗ | Strategy for enhancing power system resilience; 52% improvement in ELNS. |

| [40] | ✗ | ✗ | ✗ | ✗ | ✗ | Reduction in aggregated system costs; effective optimal planning. |

| [41] | ✓ | ✗ | ✗ | ✗ | ✓ | Analysis of functional relationships; a reliable method for determining suitable operating temperatures. |

| [42] | ✗ | ✗ | ✗ | ✗ | ✗ | Improved multi-agent coordination, decreased system operation costs, and reduced carbon emissions. |

| [43] | ✗ | ✗ | ✗ | ✗ | ✗ | Flexibility and improved energy utilization; effectiveness confirmed on IEEE 33-bus test network. |

| [44] | ✗ | ✓ | ✗ | ✓ | ✗ | System efficiency and combined cycle heating and cooling optimization using multi-objective GWO. |

| [45] | ✗ | ✗ | ✗ | ✗ | ✗ | Overview of GH2 energy systems with a focus on thermal management and process optimization. |

| [46] | ✗ | ✗ | ✗ | ✗ | ✗ | Adjustable TEC input, length, and thickness affect temperature reduction; optimal battery thermal management. |

| [47] | ✗ | ✗ | ✗ | ✗ | ✗ | Integration of SWIR detectors with multi-stage TECs and MHS; best performance and minimum volume. |

| [48] | ✗ | ✗ | ✗ | ✗ | ✗ | A two-way programming optimization model reduced system operating costs and carbon emissions. |

| [49] | ✗ | ✓ | ✗ | ✗ | ✓ | Optimization of design variables and balance between efficiency, emission reduction, and economic viability. |

| [50] | ✗ | ✗ | ✗ | ✗ | ✗ | Safe operations under full conditions, improved power tracking, and disturbance rejection. |

| [51] | ✗ | ✓ | ✗ | ✓ | ✗ | Technical, environmental, and economic evaluation; bi-objective optimization for efficiency and cost. |

| [52] | ✗ | ✗ | ✗ | ✗ | ✗ | Review of decarbonization strategies; focus on GH2, onshore power supply, challenges, and potential. |

| [53] | ✗ | ✗ | ✗ | ✗ | ✗ | Image gray recognition-based defrosting control; improved accuracy and COP. |

| [54] | ✗ | ✗ | ✗ | ✗ | ✗ | Comparison of temperature control methods, thermal storage capacity assessment, and peak-shaving potential. |

| [55] | ✗ | ✗ | ✗ | ✗ | ✗ | Parallel air-cooled system for battery packs; efficient thermal management for varying conditions. |

| [56] | ✗ | ✗ | ✗ | ✗ | ✗ | Predictive modelling for CO and NOx emissions; DFR model for higher prediction potential. |

| [57] | ✓ | ✗ | ✗ | ✗ | ✗ | Comparison of HBP and LZPO renovations; improved peak-shaving, heating capacity, and efficiency. |

| [58] | ✓ | ✗ | ✗ | ✗ | ✗ | Low-carbon model with flexible load, CHP, CCS, and P2G; reduced transaction and operating costs. |

| [59] | ✓ | ✗ | ✗ | ✗ | ✗ | Dynamic model for fluidized bed combustion, control strategies for load changes, and decoupling. |

| [60] | ✗ | ✗ | ✗ | ✗ | ✓ | High efficiency, low emissions, fuel flexibility for marine applications, and methane as an efficient fuel. |

| [61] | ✓ | ✗ | ✗ | ✗ | ✗ | Integration technologies for improved flexibility; increased heat–electricity ratio. |

| [62] | ✓ | ✗ | ✗ | ✗ | ✗ | Molten salt TES integration for flexibility, increased thermal and exergy efficiency. |

| [63] | ✓ | ✗ | ✓ | ✗ | ✗ | Solar-aided CHP integration, advantages in efficiency and economics. |

| [64] | ✓ | ✗ | ✗ | ✗ | ✗ | Multi-objective optimization for cost and CO2 reduction in microgrid scenarios. |

| [65] | ✓ | ✗ | ✗ | ✗ | ✗ | A hybrid system with wind power, improved efficiencies, and reduced environmental impact. |

| [66] | ✓ | ✗ | ✗ | ✗ | ✗ | Economic competitiveness of renewable NH3-enabled CHP systems, even with high energy prices. |

| [67] | ✓ | ✓ | ✗ | ✗ | ✗ | Exploration of renewable CHP technologies and potential reduction in biomass consumption. |

| [68] | ✗ | ✗ | ✗ | ✗ | ✗ | Optimal planning in microgrids, demand-side management, reduced costs, and pollution. |

| [69] | ✓ | ✓ | ✗ | ✗ | ✗ | Innovative micro-CCHP system with woody biomass gasification, high efficiency, and economic feasibility. |

| [70] | ✗ | ✗ | ✗ | ✗ | ✗ | Integration of DHN flow control, increased wind energy adaptation, and warning against excessive flows. |

| [71] | ✗ | ✗ | ✗ | ✗ | ✗ | Role of H2 in decarbonization, economic viability, and optimal planning for RMESs. |

| [72] | ✗ | ✗ | ✓ | ✗ | ✗ | Improved battery safety, 81.6% enhancement in battery safety, and 36.4% in CHP operation. |

| [73] | ✓ | ✗ | ✗ | ✗ | ✗ | Hybrid CH-ICAES and HDH desalination, competitive economic performance, and GOR of 2.0678. |

| [74] | ✓ | ✗ | ✗ | ✓ | ✗ | Geothermal-based CCHP with Kalina cycle; improved thermal efficiency and economic feasibility. |

| [75] | ✓ | ✗ | ✗ | ✗ | ✗ | Optimal design of CCHP system for five buildings under two optimization scenarios. |

| [76] | ✓ | ✗ | ✓ | ✓ | ✓ | Solar and geothermal CCHP with steam turbines, PV/T, improved efficiency, and reduced costs. |

| [77] | ✗ | ✗ | ✗ | ✗ | ✗ | Control of sCO2 systems with a PI controller; better controllability for larger tank volumes. |

| [78] | ✓ | ✗ | ✗ | ✗ | ✗ | Optimal CHP configuration using the IMPA model, minimizing total annual cost. |

| [79] | ✓ | ✗ | ✓ | ✗ | ✗ | HVAC retrofit with BIPV and CCHP, reduced CO2 emissions, and improved comfort. |

| [80] | ✓ | ✗ | ✗ | ✗ | ✗ | Overview of CHP metaheuristic optimization and comparison of optimization methods. |

| [81] | ✗ | ✗ | ✗ | ✗ | ✗ | Industrial energy hubs, mobile storage, demand response, and reduced residual load. |

| Ref. | Algorithm | Bench System | Purpose |

|---|---|---|---|

| [87] | Adaptive Fitness-Distance Balance-Based Artificial Rabbits Optimization (AFDB-ARO) | CHP System | Optimal Solution of CHP Economic Dispatch |

| [88] | ANN | PEMFC-Based CHP | Modelling/Optimization |

| [89] | Resource Allocation-Energy Sharing Algorithm | Intelligent Community With CHP Systems | Carbon Management |

| [90] | Deep RL | CHP System | Intelligent Solution of Economic Dispatch |

| [91] | Multi-Scenario Analysis | Fuel Cell-Integrated CHP | Primary Energy Consumption Minimization |

| [92] | Multi-Scenario Analysis And Control | Residential Heating System | Emissions and Costs |

| [93] | Data-Driven Analysis | TESS-Integrated CHP | District Heating |

| [94] | Heap-Based Technique With Enhanced Discriminatory Attribute | LSCHP | Optimal Solution of Economic Dispatch |

| [95] | Isochronous Governor Control Strategy Integrated With OPAL-RT | CHP | Zero-Steady-State-Error Frequency Regulation |

| [96] | Different AI Models | TESSs | Classifications, Roles, and Optimizing Design of TESSs |

| [97] | Dynamic-Objective Method (DOM) | Multi-Energy Complementary CHP System | Economic and Environmental Benefits and the Cogeneration System Source Side Load |

| [98] | Adaptive Control | Residential Micro CHP | Energy Cost Minimization |

| [99] | ML | Phase-Change Material Integrated Systems | Cooling Performance Enhancement |

| [100] | AI-Supervisory Control and Data Acquisition (SCADA) | CHP Cogeneration Units Based on Landfill Biogas | Some AI-based Diagnostic Tools by Multithreaded Polymorphic Models, Integrated with SCADA Systems |

| [101] | Real-Time Intelligent Control Laboratory (RT-ICL) | PoewrLabDK | Smart Grid Technology Development |

| [102] | Data-Driven Method Achieves Reasonable Fidelity With Monitored Demand | Domestic Hot Water Cylinder | Minimal Solution |

| [103] | Recurrent Deterministic Policy Gradient (RDPG) | District Heating System | HTR and the Stable Control Performance |

| [104] | Mobile Gasification Unit (MGU) | Small-Scale CHP | Performance Analysis |

| [105] | Multi-Energy Complementary Model (MECM) | Coupling System of Distribution Network and HPES | Utilization Rate of RES; Shifting/Filling Peaks/Valleys to Economic Analysis |

| [106] | Kuhn–Tucker | CHP | Optimal Solution and Control |

| [107] | Multi-Player Harmony Search Method (MPHS) | CHP | Optimal Solution of Economic Dispatch |

| [108] | Modified Teaching-Learning-Based Optimization (MTLBO) | CHP | Optimal Solution of Economic Dispatch |

| [109] | Oppositional Teaching Learning-Based Optimization (OTLBO) | CHP | Optimal Solution of Economic Dispatch |

| [110] | Civilized Swarm Optimization and Powell’s Pattern Search (CSO-PPS) | CHP | Optimal Solution of Economic Dispatch |

| [111] | Opposition-Based Group Search Optimization (OGSO) | CHP | Optimal Solution of Economic Dispatch |

| [112] | Advanced Modified Particle Swarm Optimization (AMPSO) | CHP | Optimal Solution of Economic Dispatch |

| [113] | Gravitational Search Algorithm | CHP | Optimal Solution of Economic Dispatch |

| [114] | Bee Colony Optimization (BCO) | CHP | Optimal Solution of Economic Dispatch |

| [115] | Improved Artificial Bee Colony (IABC) | CHP | Optimal Solution of Economic Dispatch |

| [116] | Different AI Model | Heat and Power Incorporated Networks | Optimal Solution of Economic Dispatch |

| Model | LSTM | BiLSTM | RF |

|---|---|---|---|

| First Introduced in Ref. | [121] | [122] | [123] |

| Advantages/ Disadvantages | Handles sequential data and captures long-term dependencies. Vanishing gradient issue and high training time. | Bidirectional context and improved performance in time-series data. Higher computational complexity and requires more resources. | Robust to noise; simple and interpretable. May overfit and less effective for time-series data. |

| Applications in CHP Systems | Predicting load demand and optimizing energy distribution | Fault detection and dynamic state prediction. | Anomaly detection in system operations and feature selection. |

| Dynamics Dependency | ✪ ✪ ✪ | ✪ ✪ ✪ | ✪ ✪ ✪ |

| Data Dependency | ✪ ✪ ✪ | ✪ ✪ ✪ | ✪ ✪ ✪ |

| Computational Complexity | ✪ ✪ ✪ | ✪ ✪ ✪ | ✪ ✪ ✪ |

| Structural Complexity | ✪ ✪ ✪ | ✪ ✪ ✪ | ✪ ✪ ✪ |

| Metric | Formulation | Insights in CHPs | Best Value | Worst Value |

|---|---|---|---|---|

| MAE | Reflects the average absolute error between actual and predicted values in energy generation, heat output, or other operational parameters, providing a straightforward measure of prediction accuracy. | 0 | ||

| MSE | Penalizing larger deviations more heavily, which is important in CHP systems for avoiding large operational errors and having reliable system outputs. | 0 | ||

| RMSE | Useful for understanding the typical magnitude of prediction errors in key CHP metrics such as power and heat efficiency. | 0 |

| Mechanical Power | Initial Leg Voltage | Final Leg Voltage | Motor Speed | DC Voltage | Inverter Voltage | |

|---|---|---|---|---|---|---|

| Mean [P.U] | 0.625453 | 0.998333 | 0.172192 | 0.991734 | 498.5686 | 498.5686 |

| Variance | 0.016934 | 0.03189 | 0.000822 | 6.72 × 10−5 | 2223.683 | 2223.683 |

| Amount of Data | 102,124 | 102,124 | 102,124 | 102,124 | 1,021,232 | 1,021,232 |

| BiLSTM | |||

|---|---|---|---|

| Parameter | MAE | RMSE | MSE |

| Mechanical Power | 0.315146 | 0.373435 | 0.139454 |

| Initial Leg Voltage | 0.10045 | 0.564845 | 0.31905 |

| Final Leg Voltage | 0.031708 | 0.041718 | 0.00174 |

| DC Voltage | 0.031708 | 0.041718 | 0.00174 |

| Motor Speed | 0.261886 | 0.309942 | 0.096064 |

| LSTM | |||

| Parameter | MAE | RMSE | MSE |

| Mechanical Power | 0.095493 | 0.559512 | 0.313054 |

| Initial Leg Voltage | 0.032234 | 0.040584 | 0.001647 |

| Final Leg Voltage | 0.194758 | 0.247855 | 0.061432 |

| DC Voltage | 0.194656 | 0.247679 | 0.061345 |

| Motor Speed | 0.009416 | 0.01119 | 0.000125 |

| Random Forest | |||

| Parameter | MAE | RMSE | MSE |

| Mechanical Power | 0.088961 | 0.565373 | 0.319646 |

| Initial Leg Voltage | 0.036392 | 0.045858 | 0.002103 |

| Final Leg Voltage | 0.194664 | 0.247636 | 0.061324 |

| DC Voltage | 0.194664 | 0.247636 | 0.061324 |

| Motor Speed | 0.010003 | 0.011923 | 0.000142 |

| Challenge | Impact Area | Stakeholders Involved | Technology Enablers | Future Work/Prospective Solutions |

|---|---|---|---|---|

| Data Availability | Data Quality | Utilities and Researchers | Open Data Platforms and APIs | Establish open-access datasets and collaborative platforms for high-quality CHP data; incentivize utilities and stakeholders to contribute. |

| Data Integration | Interoperability | System Integrators and Manufacturers | IoT and Data Standards | Develop standardized data protocols and adopt IoT frameworks to ensure seamless, unified data acquisition and communication. |

| Real-Time Data Processing | Operational Efficiency | Engineers and IT Teams | Edge Computing and AI Accelerators | Leverage edge computing and advanced AI algorithms for real-time analytics; utilize cloud infrastructure for scalable data processing. |

| System Complexity | System Design | Researchers and Software Developers | Hybrid Modelling and Simulation Tools | Employ hybrid modelling approaches that combine physics-based and AI-driven techniques; design modular architectures for system simplification. |

| Uncertainty and Nonlinearity | Model Reliability | AI Developers and Operators | Probabilistic Models, RL, and Ensemble Learning | Use robust AI methods to manage uncertainty and complex dynamics. |

| Scalability Issues | Deployment | System Designers and Utilities | Distributed Computing and Multi-Agent Systems | Enhance AI algorithms for distributed/cloud-based deployment; implement scalable multi-agent control systems for large-scale CHP networks. |

| Generalization Across Systems | Transferability | Researchers and AI Modellers | Transfer Learning and Meta-Learning | Train models on diverse datasets to improve adaptability; apply transfer learning for efficient deployment. |

| Real-Time Control | Decision Making | Control Engineers and Operators | Reinforcement Learning and MPC | Apply RL and predictive control strategies for adaptive real-time decision making. |

| Cybersecurity Vulnerabilities | System Security | IT Security Teams and Regulators | Blockchain and Intrusion Detection Systems | Integrate AI-powered intrusion detection and blockchain technologies to secure communication and data integrity. |

| Data Privacy Concerns | Compliance | Data Officers and Legal Teams | Federated Learning and Differential Privacy | Adopt privacy-preserving AI approaches to protect sensitive data during model training. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Safari, A.; Oshnoei, A. An Overview of Recent AI Applications in Combined Heat and Power Systems. Energies 2025, 18, 2891. https://doi.org/10.3390/en18112891

Safari A, Oshnoei A. An Overview of Recent AI Applications in Combined Heat and Power Systems. Energies. 2025; 18(11):2891. https://doi.org/10.3390/en18112891

Chicago/Turabian StyleSafari, Ashkan, and Arman Oshnoei. 2025. "An Overview of Recent AI Applications in Combined Heat and Power Systems" Energies 18, no. 11: 2891. https://doi.org/10.3390/en18112891

APA StyleSafari, A., & Oshnoei, A. (2025). An Overview of Recent AI Applications in Combined Heat and Power Systems. Energies, 18(11), 2891. https://doi.org/10.3390/en18112891