Abstract

Under the dual imperatives of air pollution control and energy conservation, this study proposes an enhanced optimization framework for combined heat and power (CHP) district heating systems based on bypass thermal storage (BTS). In contrast to conventional centralized tank-based approaches, this method leverages the dynamic hydraulic characteristics of secondary network bypass pipelines to achieve direct sensible heat storage in circulating water, significantly improving system flexibility and energy efficiency. The core innovation lies in addressing the critical yet under-explored issue of control valve dynamic response, which profoundly impacts system operational stability and economic performance. A quality regulation strategy is systematically implemented to stabilize circulation flow rates through temperature modulation by establishing a supply–demand equilibrium model under bypass conditions. To overcome the limitations of traditional feedback control in handling hydraulic transients and heat transfer dynamics in the plate heat exchanger, a Model Predictive Control (MPC) framework is developed, integrating a data-driven valve impedance-opening degree correlation model. This model is rigorously validated against four flow characteristics (linear, equal percentage, quick-opening, and parabolic) and critical impedance parameters (maximum/minimum controllable impedance). This study provides theoretical foundations and technical guidance for optimizing secondary network heating systems, enhancing overall system performance and stability, and promoting energy-efficient development in the heating sector.

1. Introduction

With the intensification of global environmental issues, atmospheric pollution mitigation and energy conservation have become core priorities for the international community. In the energy sector, combined heat and power (CHP) systems have been widely adopted in large-scale district heating projects due to their high energy efficiency [1,2]. Current research on improving the flexibility of heating systems predominantly focuses on external thermal storage devices [3]. For example, Benalcazar et al. developed a Mixed-Integer Linear Programming (MILP) model to jointly optimize thermal storage tank capacity and annual operational scheduling in CHP systems [4]. Wang et al. quantified the flexibility enhancement of CHP systems through a dynamic model integrating heat pumps, analyzing the decoupling effects of electro-thermal strategies [5]. Although these standalone thermal storage methods partially resolve the spatiotemporal conflicts between heat plant operations and heating demands, they involve high hardware investment costs and spatial limitations. The proposed bypass thermal storage (BTS) technology offers a novel pathway for optimizing heating systems. Wang et al. maximized thermal storage benefits by reconfiguring the topology of district heating networks (DHNs), and implementing bypass branches on the primary side of heat exchange stations [6]. This approach directly utilizes the sensible heat of circulating water in pipelines to store surplus thermal energy from power plants, bypassing traditional reliance on standalone tanks. Kouhia et al. further quantified the technical potential of DHNs as short-term thermal storage media, confirming the economic feasibility of BTS in enhancing CHP system flexibility [7]. Compared to conventional solutions, BTS technology actively designs bypass pipelines to store excess heat in the circulating water of heating networks, achieving intraday load shifting without requiring large-scale storage equipment. This reduces the required capacity of peak-shaving heat sources, lowers system construction costs, and improves energy efficiency by shortening heat source operation time. Additionally, BTS reconstructs the operational paradigm of heat exchange stations through hydraulic decoupling: traditional stations suffer from mutual interference due to hydraulic coupling, while bypass pipelines establish pressure buffer interfaces, enabling independent control of each station and enhancing supply–demand balance accuracy [8].

As critical infrastructure, the thermal storage capacity of DHNs depends on parameters such as pipeline water volume and baseline supply/return temperatures [9]. These networks exhibit higher flexibility and environmental adaptability than traditional thermal storage tanks. In large-scale systems, indirect connections typically divide DHNs into primary networks (heat source to exchange stations) and secondary networks (exchange stations to end-users). Secondary networks directly serve users, and their operational characteristics and control strategies significantly impact heating quality and energy efficiency. Although primary network bypass technology improves flexibility through hydraulic decoupling, the high initial investment limits its widespread adoption. Therefore, this study focuses on secondary networks and their key control technologies.

In practical operations, achieving a supply–demand balance at heat exchange stations is essential for maintaining heating quality [10]. However, due to inherent time delays, conventional feedback control struggles to adapt to rapid load variations and thermal source fluctuations. This study proposes a Model Predictive Control (MPC) strategy. MPC enables proactive adjustments by constructing a thermodynamic model to predict disturbance impacts and optimizing valve opening commands using real-time pipeline temperature and user load data. Recent studies have explored similar approaches: Knudsen et al. implemented an MPC-based coordinated thermal storage/discharge control strategy, reducing pressure fluctuations to ±3% and response times to 15 s in a Danish heat exchange station [11]. X et al. developed a lightweight MPC algorithm (delay < 50 MS) integrated with a digital twin platform, improving dynamic response speeds by 40% [12]. Existing research primarily optimizes control methods and operational stability, whereas this study emphasizes valve control performance to enhance supply–demand balance accuracy. Notably, mechanical limitations (e.g., dead zones, hysteresis) cause random fluctuations in the openings of heat exchange control valves and bypass control valves around their setpoints. These fluctuations induce flow deviations and pressure differential variations across bypass control valves, ultimately affecting secondary network supply temperatures and disrupting thermal balance [13].

This study investigates two valves regulating bypass flow and heat exchange flow (specifically the heat exchange control valve and bypass control valve, hereafter collectively termed “control valves”) to analyze their flow characteristics and critical parameters (e.g., maximum/minimum controllable impedance) [14] on the supply–demand balance of thermal substations, with numerical quantification of these effects. The findings will provide theoretical and technical guidance for optimizing secondary network control strategies, advancing the heating industry toward efficient, low-carbon, and stable operations.

2. Technical Methodology

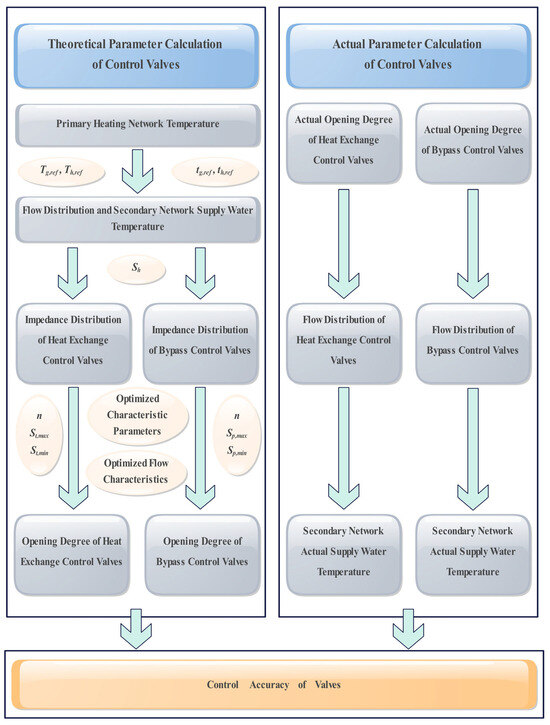

As shown in Figure 1, this figure illustrates the logical flow of the parameter calculation for control valves, with the calculations performed using MATLAB R2022a software. The process is divided into theoretical parameter calculation and actual parameter calculation, followed by an evaluation of the valve control accuracy. Below is a detailed logical description:

Figure 1.

The logical diagram of this article.

2.1. Theoretical Parameter Calculation Section

The theoretical parameter calculation is performed under ideal conditions, assuming that the valves have no dead zone and all parameters can be precisely controlled. This calculation provides benchmark data for evaluating the performance of the valves and the balance state of the network under ideal conditions. Through Formulas (1)–(4), (7), (9), and (12), the theoretical flow distribution, impedance distribution, valve opening degree, and secondary network supply water temperature are calculated, providing a reference for subsequent practical applications.

2.2. Actual Parameter Calculation Section

In practical applications, the valves have a dead zone, causing the actual opening degree to fluctuate near the set value. This directly affects the flow distribution and the secondary network’s supply water temperature. Therefore, the actual parameter calculation, based on the theoretical parameters, takes into account the influence of the dead zone. Through Formulas (13) and (14), the flow distribution is recalibrated, and through Formula (15), the actual supply water temperature of the secondary network is calculated. This process is closer to the real operating environment and can reflect the dynamic balance state of the actual network.

2.3. Comparison and Evaluation

By comparing the results of the theoretical parameter calculation and the actual parameter calculation, the impact of the valve dead zone on the network balance can be quantified [15]. Comparing the flow distribution calculated theoretically and actually, the range of flow fluctuations caused by the dead zone can be assessed. Through Formula (12), the deviation of the secondary network supply water temperature between the theoretical and actual calculations can be evaluated. Based on the comparison results of the theoretical parameter calculation and the actual parameter calculation, the control accuracy of the control valves can be comprehensively evaluated [16]. Through quantitative analysis, the optimal working conditions and applicable range of the valves can be identified, providing a scientific basis for the selection and design of the valves, ensuring that they meet the required performance standards in practical applications. This evaluation process not only helps to improve the control accuracy of the system but also provides valuable data support for subsequent optimization design.

3. Thermal Storage Scheme for Secondary Network Bypass Pipelines

Supply–Demand Balance Regulation of Thermal Substations under Secondary Network Bypass Conditions.

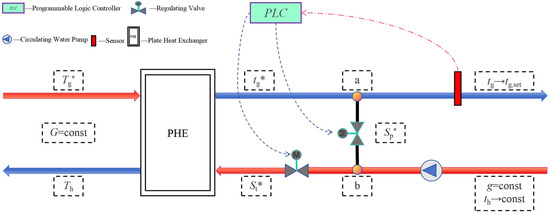

As illustrated in Figure 2, the circulation flow rate on the primary side of the plate heat exchanger (PHE) remains constant, a configuration designed to ensure system stability and operational reliability. Maintaining a steady primary-side flow rate is critical for preserving thermal equilibrium and operational efficiency, thereby mitigating instability and potential equipment damage caused by flow fluctuations [17]. For secondary network regulation, constant flow control (i.e., mass regulation) is implemented, ensuring hydraulic stability by minimizing pressure oscillations and hydraulic imbalances induced by flow variations. This approach guarantees a consistent heating service quality for end-users. Under this control strategy, the secondary network supply temperature exhibits a convergence trend toward the set point, while the return water temperature remains nearly constant, reflecting the thermal inertia of buildings [18]. Furthermore, the PHE’s equivalent impedance in the secondary network is constant, enabling precise prediction and assessment of its hydraulic impacts during system design and commissioning [19].

Figure 2.

Schematic diagram of supply–demand balance regulation for thermal substations under secondary network bypass conditions.

4. Research on Thermal-Hydraulic Parameters and Control Valve Characteristics of PHE

4.1. Thermal-Hydraulic Parameters of PHE

When circulation pumps operate at a fixed frequency, the equivalent impedance between points a and b remains constant, ensuring a stable secondary network circulation flow rate. During pump frequency adjustments, thermal substations dynamically adjust the impedance of the heat exchange control valve and bypass control valve to maintain constant heat transfer power in the plate heat exchanger. Since the heat supply on the demand side remains constant, the set heat supply equals the heat transfer capacity flowing through the heat exchange pipes. The heat flow ratio and heat exchange output temperature are calculated using the Equation (1):

Symbol definitions in Equation (1): cp is specific isobaric heat capacity of water, J/(kg∙°C); g is mass flow rate of heated water through the heat exchange, kg/s; tg,ref is baseline supply temperature of the secondary network, °C; th,ref is baseline return temperature of the secondary network, °C; β is heat exchange flow ratio on the secondary side of the plate heat exchanger (dimensionless); tg* is heat exchange output temperature, °C; B is empirical coefficient (constant value B = 0.3); LMTD is logarithmic mean temperature difference, °C; Tg,ref is baseline supply temperature of the primary network, °C; Th,ref is baseline return temperature of the primary network, °C; Tg* is actual supply temperature of the primary network, °C; Th* is actual return temperature of the primary network, °C.

The logarithmic mean temperature difference (LMTD) is calculated using Equation (2)

Based on Equations (1) and (2), the quantitative expressions for the relative heat transfer coefficient and the adjusted logarithmic mean temperature difference are formulated as Equation (3).

4.2. Control Valve Impedance

In the calculation of heating network impedance, the equivalent impedance between points a and b remains constant. This impedance value corresponds to the original pipeline (i.e., the equivalent impedance of the secondary network without the addition of a bypass pipe). After topological reconstruction, the new equivalent impedance consists of two parts: one is the equivalent impedance of the heat regulation valve and plate heat exchanger in series in the secondary network; the other is the impedance of the bypass control valve. These two parts of the impedance are ultimately combined in parallel to form the reconstructed equivalent impedance.

Impedance Calculation for Heat Exchange and Bypass Control Valves under Different Primary Network Supply Temperatures.

Symbol definitions in Equation (4): Sh is the equivalent impedance of plate heat exchanger in secondary network; St* is impedance of the heat exchange control valve; Sp* is impedance of bypass control valve.

4.3. Valve Opening for Different Flow Characteristics

Control valves play a critical control function in heating systems, where their operation fundamentally relies on precise valve opening adjustments. In practical heating scenarios, the impedance characteristics of control valves significantly influence the fluid flow dynamics within the network [20]. Changes in valve opening directly alter impedance, thereby affecting flow distribution and heat transfer efficiency across the system. To achieve efficient and accurate regulation, it is essential to establish a quantitative relationship between valve impedance and opening.

Control valves exhibit distinct flow characteristic curves, such as linear flow characteristic, equal percentage flow characteristic, quick-opening flow characteristic, and parabolic flow characteristic [21]. By analyzing and comparing valves with different flow characteristics, combined with the specific parameters of the heating system (e.g., temperature range, pressure differentials, and load variations), the most suitable flow characteristic can be selected to optimize system performance [22]. Control valves are defined by two independent parameters: maximum controllable impedance and minimum controllable impedance. Systematic optimization of these parameters ensures the valve meets operational requirements. In real-world applications, deviations between actual valve opening and theoretical valve opening are inevitable. By comparing these values under various operating conditions, error data can be collected and analyzed to identify error distribution patterns and primary influencing factors [23].

4.3.1. Flow Characteristics of Heat Exchange Control Valves

Symbol definitions in Equation (5): is functional expression of relative flow vs. relative opening; R is an adjustable ratio; ξ is relative opening; Sv is valve authority.

By substituting Equation (6) into Equation (5), the quantitative relationship between the opening and impedance of the heat exchange control valve is derived, as shown in Equation (7).

4.3.2. Flow Characteristics of Bypass Control Valves

Symbol definitions in Equation (8): Sp,min is full-open impedance of bypass control valve.

By substituting Equation (8) into Equation (6), the quantitative relationship between the valve opening and impedance of the bypass control valve is derived, as shown in Equation (9).

4.4. Characteristic Parameters

The independent parameters defining the regulation characteristics of a control valve are the maximum controllable impedance and minimum controllable impedance. The impact of each parameter on the regulation performance is analyzed. As shown in Equation (11), an increase in the equivalent impedance of the plate heat exchanger in the secondary network reduces the valve authority, leading to a significant distortion in the valve’s flow characteristics. In practical applications, the valve authority should not be less than 0.3 [24].

Symbol definitions in Equation (10): Qmax is maximum flow rate through the control valve; Qmin is minimum flow rate through the control valve.

The relationship between the valve authority and impedance of the control valve is expressed in the Equation (11).

Symbol definitions in Equation (11): Smin is minimum controllable impedance of the control valve; Sh is equivalent impedance of the plate heat exchanger in the secondary network.

5. Quantitative Analysis of Valve Control Accuracy

Control Accuracy Calculation

Variations in the actual valve opening alter the flow rate and pressure differential across the bypass control valve, thereby affecting the supply–demand balance of the heat exchange station [25]. This metric quantifies the fluctuation amplitude of the secondary network temperature caused by the valve dead zone, with its calculation formula provided in Equation (12).

Symbol definitions in Equation (12): VCA—Valve Control Accuracy; tg′ and tg″ are secondary network supply temperature corresponding to the actual valve opening;

Flow Distribution Formula for Heat Exchange Control Valve Opening in Equation (13).

The relationship between valve opening and flow distribution is expressed as Equation (14):

Based on Equations (1) and (3), the secondary network supply temperature is derived as follows Equation (15):

6. Results and Discussion

6.1. Calculation of Related Parameters

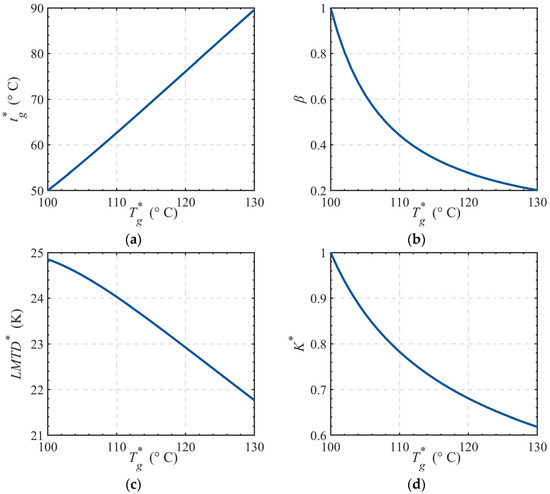

The heat output temperature, heat flow ratio, relative heat transfer coefficient, and adjusted logarithmic mean temperature difference (LMTD), calculated using Equations (1) and (3), vary with the primary network heating temperature as shown in Figure 3.

Figure 3.

Temperature-dependent curves of related parameters. (a) Heat output temperature vs. temperature curves; (b) Heat flow ratio vs. temperature curves; (c) Relative heat transfer coefficient vs. temperature curves; (d) Logarithmic mean temperature difference (LMTD) vs. temperature curves.

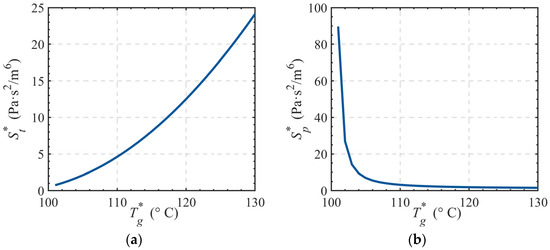

As derived from Equation (4), the impedance of heat exchange and bypass control valves varies with the primary network supply temperature, as shown in Figure 4.

Figure 4.

Temperature-dependent impedance curves of control valves. (a) Impedance vs. temperature curves for heat exchange control valves; (b) Impedance vs. temperature curves for bypass control valves.

6.2. Heat Exchange Control Valve

In practical applications, the valve authority (Sv) should not be less than 0.3. According to Equation (11), the minimum controllable impedance of the heat exchange control valve must exceed 0.21. The parameter summary of the heat exchange control valve is provided in Table 1.

Table 1.

Summary of parameters for impedance control range of heat exchange control valves.

6.2.1. Impact of Minimum Controllable Impedance

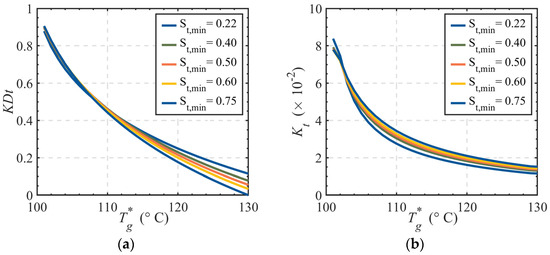

For control valves with equal percentage flow characteristics, the maximum controllable impedance is fixed at 30.29. By varying the minimum controllable impedance, the relationship between valve opening and temperature is analyzed, with results illustrated in Figure 5.

Figure 5.

Control valve opening-temperature curves with varying minimum controllable impedance. (a) Valve opening vs. temperature curves; (b) Slope of valve opening curves.

As shown in Figure 5a, increasing the minimum controllable impedance shifts the entire curve downward in the coordinate system, expanding the valve opening range. For example, at a minimum controllable impedance of 0.75, the valve opening range reaches 0.9001. When the minimum controllable impedance decreases to 0.22, the opening range contracts to 0.7605. This demonstrates a positive correlation between the minimum controllable impedance and the valve opening range within a specific interval: larger minimum controllable impedance increases the operational range of the control valve. A higher minimum controllable impedance indicates that the valve must overcome greater resistance during opening, enabling a broader regulation capability to adapt to varying system demands. Curve (b) illustrates the sensitivity of the valve opening to temperature variations. Across most temperature regions, a higher minimum controllable impedance corresponds to a steeper slope in the curve. This indicates enhanced sensitivity: even minor temperature fluctuations trigger significant adjustments in the valve opening.

6.2.2. Impact of Maximum Controllable Impedance

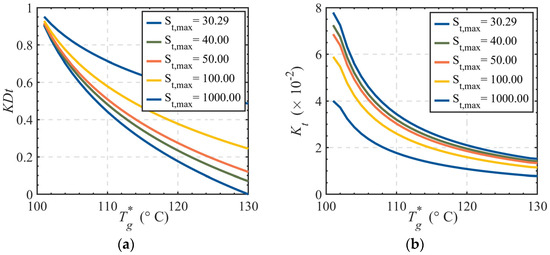

For control valves with equal percentage flow characteristics, the minimum controllable impedance is fixed at 0.75, while the maximum controllable impedance varies starting from 30.29. The relationship between valve opening and temperature under different maximum impedance values is analyzed, with results illustrated in Figure 6.

Figure 6.

Control valve opening-temperature curves with varying maximum controllable impedance. (a) Valve opening vs. temperature curves; (b) Slope of valve opening curves.

As shown in Figure 6a, smaller maximum controllable impedance shifts the overall curve downward in the coordinate system, resulting in a larger valve opening range. For example, at a maximum controllable impedance of 30.29, the valve opening range reaches 0.9057. When the maximum controllable impedance increases to 1000.0, the valve opening range significantly contracts to 0.4656. This indicates a negative correlation between the maximum controllable impedance and the valve opening range within a specific interval: lower maximum controllable impedance expands the operational range of the control valve. The maximum controllable impedance reflects the flow resistance imposed by the fully open valve on fluid dynamics. A smaller maximum controllable impedance implies reduced flow resistance, enabling the valve to operate over a wider opening range to accommodate diverse heating demands. Curve (b) demonstrates that under the same primary network supply water temperature, a smaller maximum controllable impedance corresponds to a steeper slope, indicating higher sensitivity of the control valve opening to temperature variations. This implies that even slight temperature changes will trigger substantial adjustments in valve opening.

6.2.3. Precision Comparison of Heat Exchange Control Valves with Different Flow Characteristics and Metrics

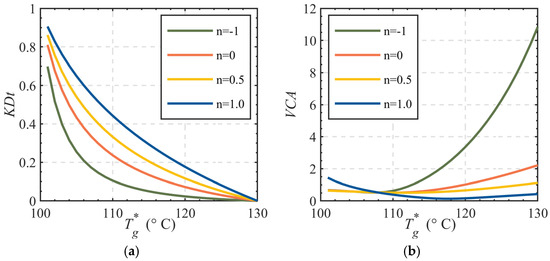

The flow characteristics and control precision of heat exchange control valves play a critical role in ensuring stable system operation and efficient heat supply. Based on previous research, this study selects a set of characteristic parameters with a maximum controllable impedance of 30.29 and a minimum controllable impedance of 0.75. Under these conditions, the valve opening vs. temperature curves for four flow characteristics (linear, equal percentage, quick-opening, and parabolic) are plotted and analyzed, as illustrated in Figure 7.

Figure 7.

Valve opening vs. temperature curves for control valves with four flow characteristics. (a) Valve opening vs. temperature curves; (b) Control accuracy vs. temperature curves.

For heat-exchange control valves in secondary network bypass configurations, the quick-opening characteristic control valve (Curve a) exhibits distinct segmented behavior. The average slope of its characteristic curve reaches 0.1115 in the low-temperature range (100–105 °C), indicating extreme sensitivity to temperature variations and exceptionally high control accuracy. However, in the mid-to-high temperature range (105–130 °C), the average slope drops significantly to 0.0093, leading to severe degradation of control precision. Curve (b) characterizes the fluctuation of heat exchange control valve errors induced by dead zone effects under varying temperatures. Specifically, a higher vertical coordinate value indicates stronger operational volatility and greater deviations from the preset opening at the corresponding temperature. For valves with quick-opening characteristics, the mean slope of the accuracy curve in the low-temperature region (100–105 °C) is 0.6229, indicating relatively minor fluctuations and errors between the actual and preset valve openings within this range. In contrast, the medium-to-high-temperature region (105–130 °C) exhibits a significantly steeper mean slope of 3.6162, corresponding to amplified operational volatility. Therefore, considering its performance across temperature ranges, the quick-opening valve is optimal for scenarios where primary network supply temperatures fluctuate primarily in the low-temperature zone, leveraging its high-precision regulation in this regime while avoiding precision losses at elevated temperatures.

Replacing the valve with an equal percentage characteristic valve results in a more balanced slope distribution. For equal percentage valves, higher full-open impedance (up to an upper bound) increases the average slope across the entire temperature range, enhancing control accuracy. The equal percentage valve achieves an average slope of 3.17 over 100–130 °C, delivering robust overall control precision. The accuracy curve of the equal percentage-type control valve displays a mean slope of 0.4349 across the full temperature range. This value suggests that within this temperature interval, the actual opening of the valve exhibits minor fluctuations and reduced deviations compared to the preset opening, signifying lower errors. This demonstrates the broad applicability of equal percentage valves in heating systems, providing stable and reliable regulation under diverse thermal conditions.

6.3. Bypass Control Valves

The parameter summary of bypass control valves is presented in Table 2.

Table 2.

Summary of impedance control ranges for bypass control valves.

6.3.1. Impact of Minimum Controllable Impedance

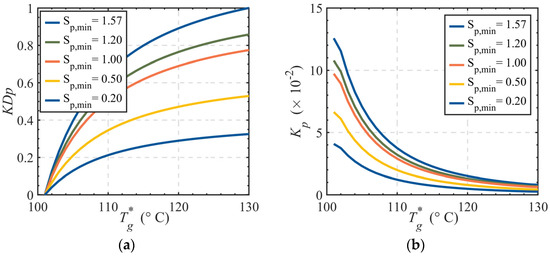

Using control valves with linear flow characteristics as the research subject, the valve opening vs. temperature curves under different minimum controllable impedance values are illustrated in Figure 8, while the maximum controllable impedance is fixed at 89.68.

Figure 8.

Control valve opening-temperature curves with varying minimum controllable impedance. (a) Valve opening vs. temperature; (b) Slope of valve opening curve.

As shown in Curve (a) of Figure 8, increasing the minimum controllable impedance shifts the entire curve upward within the coordinate system. For instance, at a minimum controllable impedance of 1.57, the valve opening range reaches 1.0 (full scale). When the minimum controllable impedance decreases to 0.2, the valve opening range contracts to 0.3252. This demonstrates a positive correlation between the minimum controllable impedance and the valve opening range within a specific interval: larger minimum controllable impedance expands the operational range of the control valve.

6.3.2. Impact of Maximum Controllable Impedance

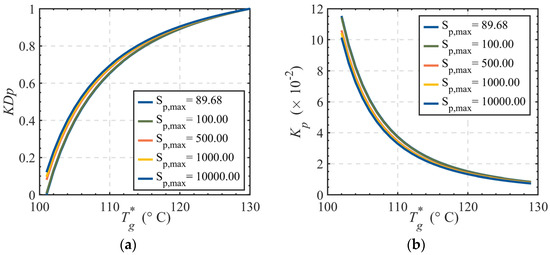

For control valves with linear flow characteristics (fixed minimum controllable impedance at 1.57), the valve opening vs. temperature curves under different maximum controllable impedance values are illustrated in Figure 9.

Figure 9.

Control valve opening-temperature curves with varying maximum controllable impedance. (a) Valve opening vs. temperature; (b) Slope of valve opening curve.

As shown in Figure 9a, smaller maximum controllable impedance shifts the overall curve downward in the coordinate system, resulting in a larger valve opening range. A maximum controllable impedance of 89.68 corresponds to a valve opening range of 1.0 (full scale). When the maximum controllable impedance increases to 10,000, the valve opening range decreases to 0.8837. This demonstrates that the maximum controllable impedance regulates the effective operating range of the valve. Within a specific range, a lower maximum controllable impedance expands the valve opening range.

6.3.3. Precision Comparison of Bypass Control Valves with Different Flow Characteristics and Metrics

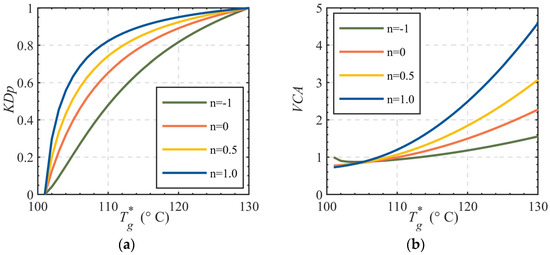

In conclusion, the bypass control valve is selected with a maximum controllable impedance of 89.68 and a minimum controllable impedance of 1.57. The valve opening vs. temperature curves for four flow characteristics (linear, equal percentage, quick-opening, and parabolic) are illustrated in Figure 10.

Figure 10.

Valve opening vs. temperature curves for control valves with four flow characteristics. (a) Valve opening vs. temperature; (b) Control accuracy vs. temperature.

For bypass control valves with equal percentage flow characteristics in secondary network bypass systems, Curve (a) shows an average slope of 9.85 in the low-temperature range (100–106 °C), achieving exceptional control accuracy. In the mid-to-high temperature range (106–130 °C), the average slope decreases to 1.68, resulting in significant degradation of control precision. The accuracy curve of the equal percentage flow characteristic control valve exhibits a mean slope of 0.8090 in the low-temperature region (100–106 °C), indicating minor fluctuations and reduced deviations between the actual and preset valve openings within this range. In contrast, the mean slope increases significantly to 2.4378 in the medium-to-high-temperature region (106–130 °C), corresponding to amplified fluctuations and diminished control precision. Consequently, when evaluating the performance of the equal percentage flow characteristic bypass control valve across different temperature intervals, it is better suited for scenarios where the primary network supply temperature predominantly fluctuates within the low-temperature range. Under such conditions, the valve leverages its high-precision regulation advantage in the low-temperature region while mitigating the inherent limitations of reduced accuracy in high-temperature operations.

When replacing the bypass control valve with a quick-opening flow characteristic valve, Curve (a) demonstrates more balanced slope distribution across the entire temperature range. For quick-opening heat exchange control valves, higher full-open impedance (up to an upper bound) correlates with increased average slope values, enhancing control accuracy. Specifically, the average slope across the full temperature range reaches 3.49, indicating robust overall control performance. The accuracy curve of the quick-opening characteristic control valve exhibits a mean slope of 1.1114 across the full temperature range, indicating minor fluctuations and reduced deviations between the actual opening and preset opening within this interval. In summary, the equal percentage characteristic valve demonstrates broad applicability in heating systems, delivering stable and reliable regulation performance under varying temperature conditions.

7. Optimization Verification Based on Real Heating Network

7.1. Basic Information of the Heating System

The centralized heating system is located in Zhangjiakou City, Hebei Province. The heating period lasts 141 days (from 1 November to 31 March of the following year). The design heat load was calculated using the climate correction method, with baseline parameters under −13.6 °C temperature conditions. The heating radius is approximately 11.4 km, covering a total heating area of 11.5 million m², and the total design heat load reaches 350 MW. The system comprises one heat source (an extraction condensing turbine cogeneration unit) and 51 heating stations. All heating stations have undergone network topology reconstruction, with bypass branches added to the original pipeline structure.

7.2. Model Control Strategy

This study adopts a Model Predictive Control (MPC) strategy, which integrates historical meteorological data and real-time forecasting information to achieve a 6-h-ahead precise prediction of heat load demand. Based on these predictions, the system dynamically generates reference temperatures as control input parameters. Utilizing a Programmable Logic Controller (PLC), the system flexibly adjusts the opening degrees of heat exchange control valves and bypass control valves, thereby enabling refined control of the district heating network.

7.3. Verification Method

During the 2024–2025 heating season, our team selected 16 heating stations with similar operating conditions from the Zhangjiakou Flexible Heating Network Project. Each station was configured with different control valve types as outlined in Table 3.

Table 3.

The valve configuration of the heat station.

Based on the actual measurement data of each heat station, the stability of the secondary network supply temperature when the primary network supply temperature changes between 70 and 100 °C is observed. If the average deviation between the secondary network supply temperature and the set supply temperature is too large, then the valve configuration is unreasonable; otherwise, the configuration is reasonable.

7.4. Engineering Data Analysis

The average temperature deviation of the secondary network supply for each heat station is shown in Table 4:

Table 4.

The heat exchange flow fluctuates.

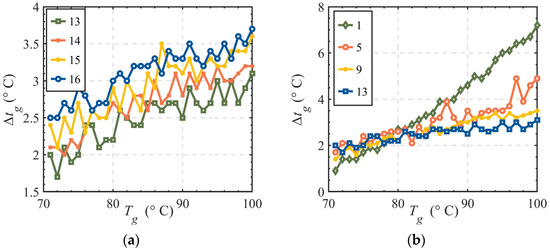

From the figure above, it can be seen that the 13th heating substation has the smallest average temperature deviation, only 2.5 °C. The experimental validation section constructed 16 combination scenarios through pairing four characteristic types of heat exchange control valves with four characteristic types of bypass control valves. From 55 heating stations, 16 typical stations with complete operational data were selected for comparative analysis. Based on the research conclusion—minimum temperature deviation fluctuation occurs when using equal percentage heat exchange control valves paired with quick-opening bypass control valves—the following two contrast groups were specifically chosen:

Group 1 (Numbers 13, 14, 15, 16): The heat exchange control valves are fixed as equal percentage type, with bypass control valve configurations covering various characteristics such as linear and parabolic, to validate the stability advantages of equal percentage heat exchange control valves in diverse bypass scenarios.

Group 2 (Numbers 1, 5, 9, 13): The bypass control valves are fixed as quick-opening type, with heat exchange control valves covering various characteristics such as linear and parabolic, to quantify the enhancement effect of quick-opening bypass control valves on the system’s disturbance rejection capability.

The control valve configurations of each heating substation are shown in Table 5.

Table 5.

Valve configuration of the selected heat exchange stations.

As shown in Figure 11a, where all heat exchange control valves are equal percentage type control valves, it can be seen that when the bypass control valves are quick-opening type control valves, the fluctuation of the secondary network supply temperature is lower. In Figure 11b, where all bypass control valves are quick-opening type control valves, it is observed that when the heat exchange control valves are equal percentage type control valves, the fluctuation of the secondary network supply temperature is also lower. The above observed data can intuitively validate the correctness of the conclusion of this paper.

Figure 11.

(a) The comparison for Heat Substations Nos 13, 14, 15, and 16. (b) The comparison for Heat Substations Nos 1, 5, 9, and 13.

8. Conclusions

This study focuses on a heating network system based on BTS technology, establishing a theoretical framework for valve selection and control strategies with engineering significance through quantitative analysis of dynamic regulation performance under specific operating conditions. By overcoming the limitations of traditional single-performance-index evaluation, the research reveals the intrinsic mechanism between valve control impedance characteristics and supply–demand balance from a system coupling perspective, providing new cognitive dimensions for heating system optimization.

8.1. System Impact Mechanism of Control Impedance Characteristics

This study demonstrates that when the controllable impedance range of control valves covers system operational requirements, a combination of higher minimum control impedance and lower maximum control impedance significantly enhances the regulation stability of heat exchange stations. This is manifested in smoother valve opening adjustments, stabilized dynamic responses in heat exchange processes, and effective suppression of overload phenomena and oscillation effects during regulation. Notably, the minimum control impedance is constrained by a critical threshold of valve authority. When valve authority falls below the theoretical optimal range, nonlinear distortion occurs in valve operating characteristics, leading to systemic attenuation of regulation accuracy.

8.2. Valve Type Selection

Comparative analysis demonstrates that selecting equal percentage valves for heat exchange regulation and quick-opening valves for bypass regulation achieves optimal control performance with minimal variation, enabling control valves to deliver their maximum regulatory efficiency. Experimental verification in practical engineering applications confirms that this configuration attains the most stable supply–demand equilibrium in thermal stations. Critical implementation requires explicit consideration of the operational temperature range in the primary network water supply. For bypass regulation valves, quick-opening valves exhibit enhanced control capability in low-temperature regimes (100–106 °C), while equal percentage valves demonstrate superior control performance in high-temperature ranges (106–130 °C).

8.3. Practical Implications

The research outcomes hold significant real-world applicability. For instance, urban heating network decarbonization retrofits can implement closed-loop control strategies integrating “peak-shifting heat storage—dynamic allocation—energy efficiency optimization”, directly improving energy utilization rates and heating service quality. Additionally, bypass pipeline heat storage technology enhances the peak-shaving capacity of combined heat and power (CHP) units, addressing the core challenge of renewable energy (e.g., wind and solar power) intermittency and volatility, thereby promoting renewable energy integration.

8.4. Research Boundaries and Knowledge Expansion Pathways

Current research is constrained by regional engineering data limitations (Zhangjiakou flexible heating network), leaving theoretical gaps in:

- 1.

- Universal applicability validation under extreme cold/humid–hot climates;

- 2.

- Nonlinear dynamic modeling of multi-valve coupling in complex networks;

- 3.

- Long-term material aging effects on valve characteristics.

Future research will expand along three dimensions:

- 1.

- Cross-scale data validation: Establish multi-climate zone data collection networks covering frigid regions (e.g., Shenyang) and hot summer/cold winter zones (e.g., Shanghai), developing GIS-based model parameter correction mechanisms.

- 2.

- Complex system modeling: Introduce fluid network theory and Nash equilibrium models to construct impedance distribution optimization models considering multi-valve coupling effects, achieving optimal energy flow allocation through equilibrium solutions.

- 3.

- Long-term performance evolution: Implement a 5-year tracking observation program for the Zhangjiakou project, developing time-varying prediction models for valve characteristic degradation and optimizing lifecycle-based control strategies.

Author Contributions

J.Y.: Writing—original draft, Conceptualization, Data Curation, Visualization. J.W.: Supervision, Writing—review and editing, Software, Funding Acquisition. P.Z.: Conceptualization, Data Curation, Visualization. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by the National Natural Science Foundation of China (No. 52208104) and the Hebei Natural Science Foundation (No. E2024202065).

Data Availability Statement

The original contributions presented in this study are included in this article, further inquiries can be directed to the corresponding author.

Acknowledgments

We would like to thank the Hebei Gongda Keya Group Co., Ltd. for providing the necessary data and field study platform. Jinda Wang would like to thank the support from Initial Research Funding of Hebei University of Technology.

Conflicts of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| CHP | Combined Heat and Power |

| BTS | Bypass Thermal Storage |

| LMTD | Logarithmic Mean Temperature Difference |

| PHE | Plate Heat Exchanger |

| MPC | Model Predictive Control |

| VCA | Valve Control Accuracy |

Nomenclature

The following nomenclature is used in this manuscript:

| Symbol | Significance Represented | Symbol | Significance Represented |

| Tg,ref | reference supply water temperature of the primary network, K | Sp* | Impedance distribution of the secondary side bypass control valves of the heat substation, Pa·s2/m6 |

| Th,ref | reference return water temperature of the primary temperature, K | LMTDref | reference LMTD of PHE, K |

| tg,ref | reference supply water temperature of the secondary network, K | LMTD * | LMTD of PHE after throttling regulation, K |

| th,ref | reference return water temperature of secondary network, K | ξ | relative opening of the control valve |

| Cp | constant-pressure specific heat of the heat medium, | ξt* | relative opening of the heat exchange control valve |

| n | Characteristic curve exponent | ξp* | relative opening of the bypass control valve |

| β | proportion of the bypass control valve cost in the total cost of the bypass branch | tg′, tg″ | secondary-side supply temperature corresponding to the actual valve opening |

| Tg*, Th* | design supply and return water temperatures of the primary network, K | R | rangeability |

| Sv | Valve authority | Rt | rangeability of heat exchange control valves |

| tg*, th* | design supply and return water temperatures of the secondary network, K | Rp | rangeability of bypass control valves |

| B | empirical parameters to characterize the convective heat transfer intensity of radiators | Sp,min | minimum impedance of bypass regulating on the secondary side of the heat substation, Pa·s2/m6 |

| K | overall heat transfer coefficient of PHE regulation, W/(m2·K) | Sp,max | maximum impedance of bypass regulating on the secondary side of the heat substation, Pa·s2/m6 |

| Sh | equivalent impedance of plate heat exchanger in the secondary network, Pa·s2/m6 | St,min | minimum impedance of heat-exchange regulating on the secondary side of the heat substation, Pa·s2/m6 |

| St* | impedance of the secondary side heat exchange regulating of the heat substation, Pa·s2/m6 | St,max | maximum impedance of heat-exchange regulating on the secondary side of the heat substation, Pa·s2/m6 |

| KDt | relative opening of the valve | Kt | slope of the primary network supply water temperature curve about valve opening |

References

- Barco-Burgos, J.; Bruno, J.C.; Eicker, U.; Saldaña-Robles, A.L.; Alcántar-Camarena, V. Review on the integration of high-temperature heat pumps in district heating and cooling networks. Energy 2022, 239, 122378. [Google Scholar] [CrossRef]

- Ma, M.; Tang, X.; Shi, C.; Wang, M.; Li, X.; Luo, P.; Zhang, B. Roadmap towards clean and low-carbon heating to 2060: The case of northern urban region in China. Energy 2023, 284, 129181. [Google Scholar] [CrossRef]

- Wang, H.; Yin, W.; Abdollahi, E.; Lahdelma, R.; Jiao, W. Modelling and optimization of CHP-based district heating system with renewable energy production and energy storage. Appl. Energy 2015, 159, 401–421. [Google Scholar] [CrossRef]

- Benalcazar, P. Optimal sizing of thermal energy storage systems for CHP plants considering specific investment costs: A case study. Energy 2021, 234, 121323. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, S.; Fu, Y.; Liu, M.; Liu, J.; Yan, J. Heat–power decoupling for the CHP unit by utilizing heat storage in the district heating system integrated with heat pumps: Dynamic modeling and performance analysis. Energy 2024, 306, 132485. [Google Scholar] [CrossRef]

- Wang, J.; Pan, B.; Rong, L.; Sun, C.; Qi, C. Topology reconstruction of the district heating network for maximizing comprehensive benefits of thermal storage. Energy 2024, 313, 134065. [Google Scholar] [CrossRef]

- Kouhia, M.; Laukkanen, T.; Holmberg, H.; Ahtila, P. District heat network as a short-term energy storage. Energy 2019, 177, 293–303. [Google Scholar] [CrossRef]

- Jiang, Y.; Wan, C.; Botterud, A.; Song, Y.; Xia, S. Exploiting Flexibility of District Heating Networks in Combined Heat and Power Dispatch. IEEE Trans. Sustain. Energy 2020, 11, 2174–2188. [Google Scholar] [CrossRef]

- Vivian, J.; Quaggiotto, D.; Zarrella, A. Increasing the energy flexibility of existing district heating networks through flow rate variations. Appl. Energy 2020, 275, 115411. [Google Scholar] [CrossRef]

- Deng, W.; Yao, J.; Ma, D. Robust adaptive precision motion control of hydraulic actuators with valve dead-zone compensation. ISA Trans. 2017, 70, 269–278. [Google Scholar] [CrossRef]

- Knudsen, B.R.; Rohde, D.; Kauko, H. Thermal energy storage sizing for industrial waste-heat utilization in district heating: A model predictive control approach. Energy 2021, 234, 121200. [Google Scholar] [CrossRef]

- Zheng, X.; Shi, Z.; Wang, Y.; Zhang, H.; Tang, Z. Digital twin modeling for district heating network based on hydraulic resistance identification and heat load prediction. Energy 2024, 288, 129726. [Google Scholar] [CrossRef]

- Xu, B.; Su, Q.; Zhang, J.; Lu, Z. Analysis and compensation for the cascade dead-zones in the proportional control valve. ISA Trans. 2017, 66, 393–403. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Wang, Y.; Fang, L.; Wang, Z.; Li, Y. Numerical study on cavity-vortex evolution in cavitation flow in nuclear control valves with different openings and structural parameters. Ann. Nucl. Energy 2025, 211, 110880. [Google Scholar] [CrossRef]

- Lee, J.; Moon, G.; Lee, J.; Jun, C.; Choi, J. Evaluation of Methods for Estimating Long-Term Flow Fluctuations Using Frequency Characteristics from Wavelet Analysis. Water 2023, 15, 2968. [Google Scholar] [CrossRef]

- Damarla, S.K.; Sun, X.; Xu, F.W.; Shah, A.; Huang, B.A.; IEEE. A Sigmoid Function based Method for Detection of Stiction in Control Valves. In Proceedings of the 7th IEEE International Symposium on Advanced Control of Industrial Processes (AdCONIP), Univ British Columbia, Vancouver, BC, Canada, 7–9 August 2022; pp. 210–215. [Google Scholar]

- Xuan, W.C.; Xu, C.T.; Qian, C.Y.; Wang, J.X.; Jiang, Z.K.; Ma, R.X.; Yu, B.B.; Shi, J.Y.; Chen, J.P. Numerical simulation and thermodynamic test analysis of plate heat exchanger based on topology optimization. Appl. Therm. Eng. 2024, 255, 17. [Google Scholar] [CrossRef]

- Soret, G.M.; Vacca, P.; Tignard, J.; Hidalgo, J.P.; Maluk, C.; Aitchison, M.; Torero, J.L. Thermal inertia as an integrative parameter for building performance. J. Build. Eng. 2021, 33, 101623. [Google Scholar] [CrossRef]

- Bordin, C.; Gordini, A.; Vigo, D. An optimization approach for district heating strategic network design. Eur. J. Oper. Res. 2016, 252, 296–307. [Google Scholar] [CrossRef]

- Li, S.X.; Yu, M.Y.; Wu, H.L.; Hu, Y.G.; Ma, T.Q.; Liu, B.C. Optimization of V-shaped regulating ball valve profile based on proxy optimization algorithm. Eng. Comput. 2023, 40, 1723–1748. [Google Scholar] [CrossRef]

- Fan, Y.; Wang, J.; Lei, Y.; Huang, J.; Peng, L.; Xu, X. Study on flow field and flow control characteristics of pressure independent control valve. Fluid Mach. 2022, 50, 68–74. [Google Scholar]

- Blizard, A.; Stockar, S. A Graph-Based Technique for the Automated Control-Oriented Modeling of District Heating Networks. J. Dyn. Syst. Meas. Control-Trans. ASME 2024, 146, 12. [Google Scholar] [CrossRef]

- Daneshwar, M.A.; Noh, N.M. Identification of a process with control valve stiction using a fuzzy system: A data-driven approach. J. Process Control 2014, 24, 249–260. [Google Scholar] [CrossRef]

- Muniak, D.P. Control Valve with a Constant Inner Authority Value. J. Therm. Sci. 2018, 27, 487–495. [Google Scholar] [CrossRef]

- Nguyen, Q.K.; Jung, K.H.; Lee, G.N.; Park, S.B.; Kim, J.M.; Suh, S.B.; Lee, J. Experimental study on pressure characteristics and flow coefficient of butterfly valve. Int. J. Nav. Archit. Ocean. Eng. 2023, 15, 100495. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).