Integrated 3D Geological Modeling, Stress Field Modeling, and Production Simulation for CBM Development Optimization in Zhengzhuang Block, Southern Qinshui Basin

Abstract

1. Introduction

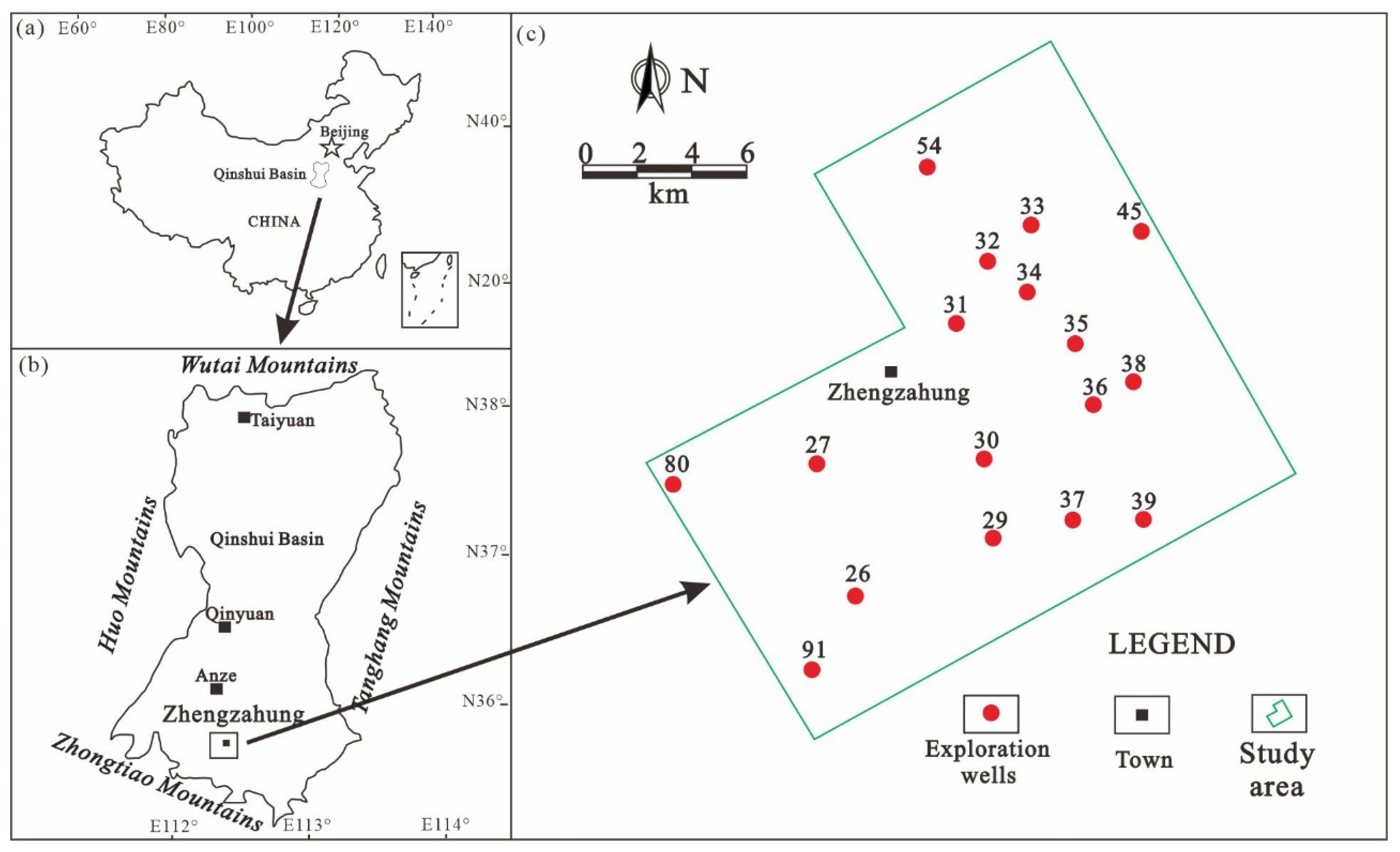

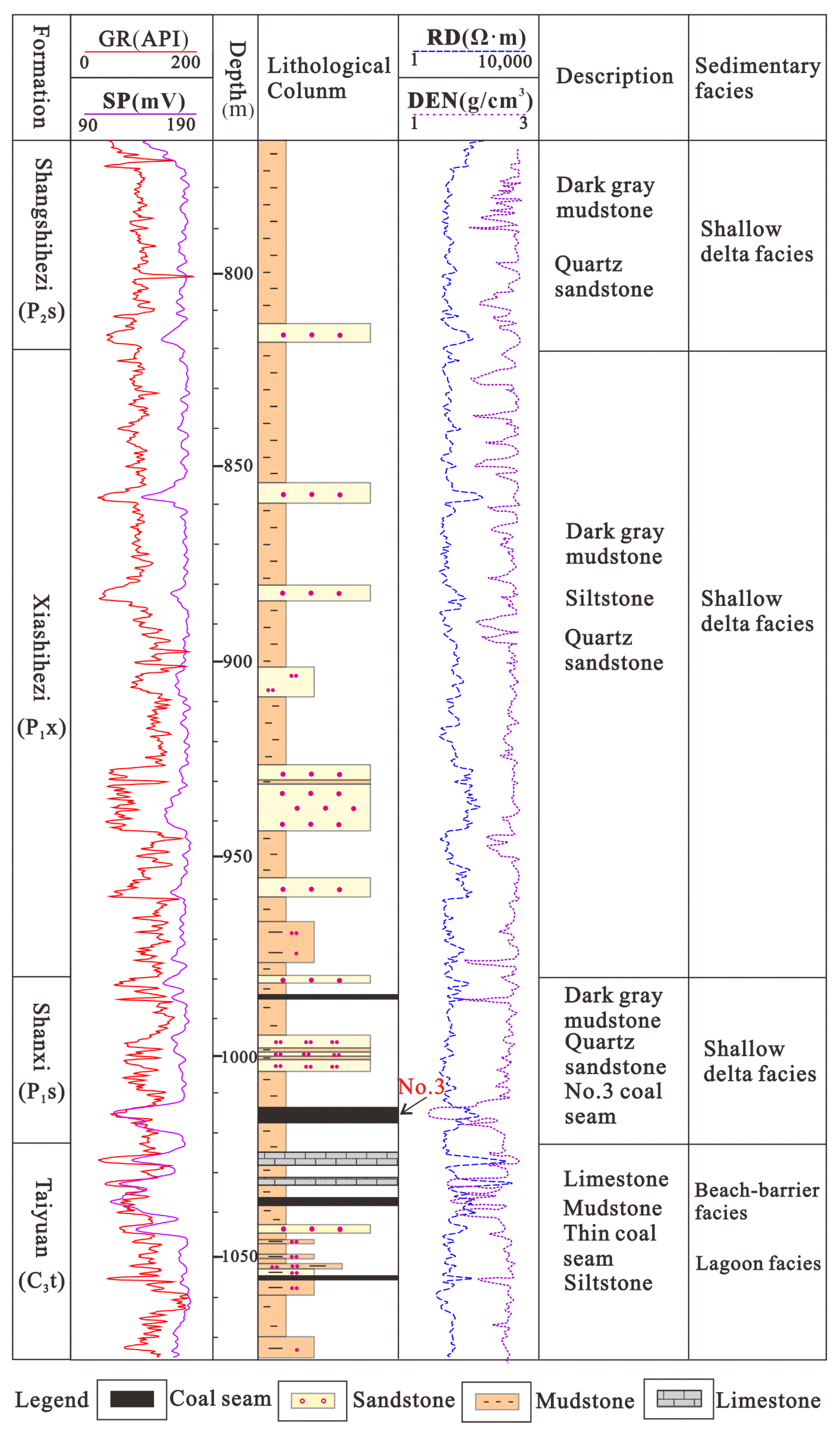

2. Geological Settings

3. Data Sources

4. Results and Discussion

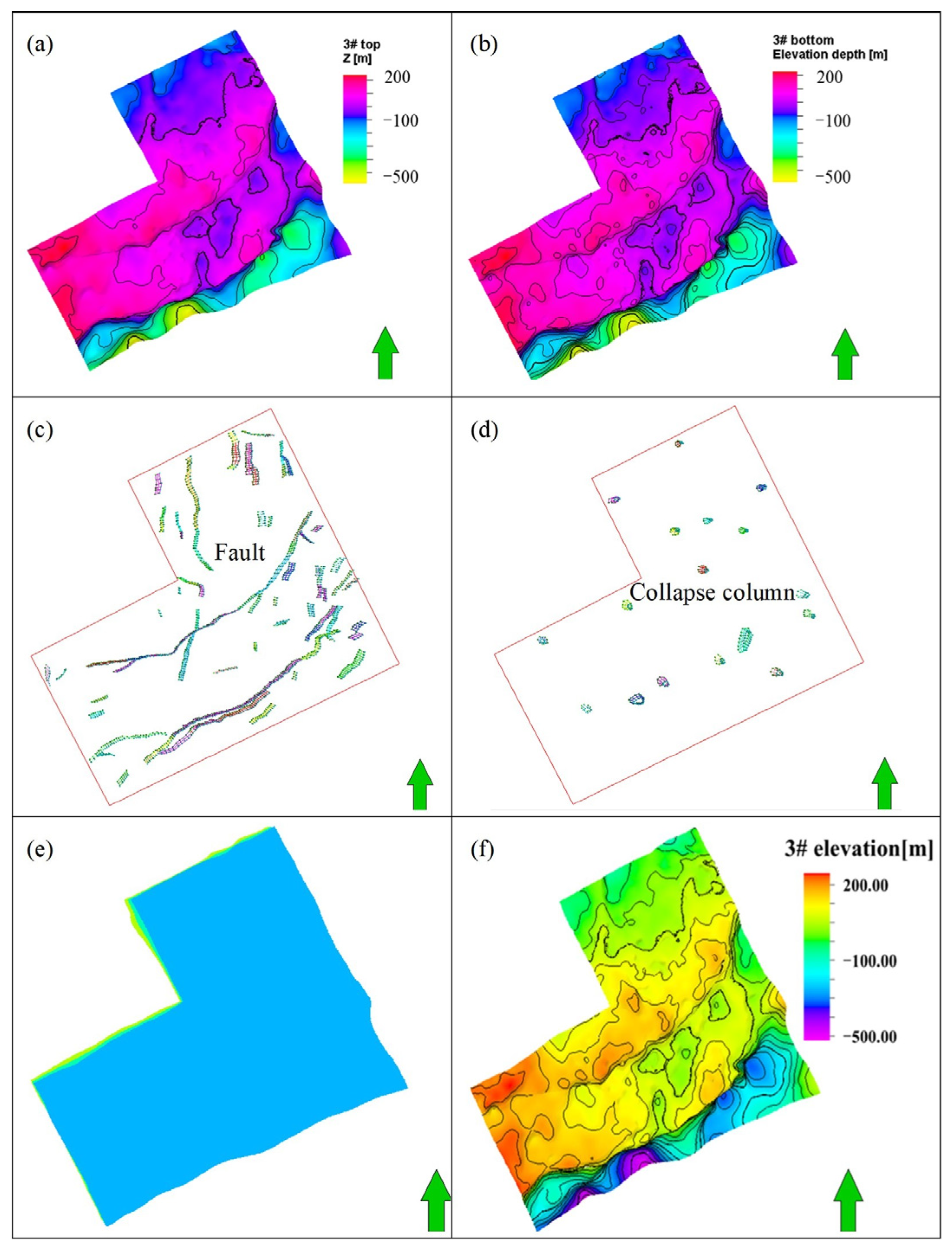

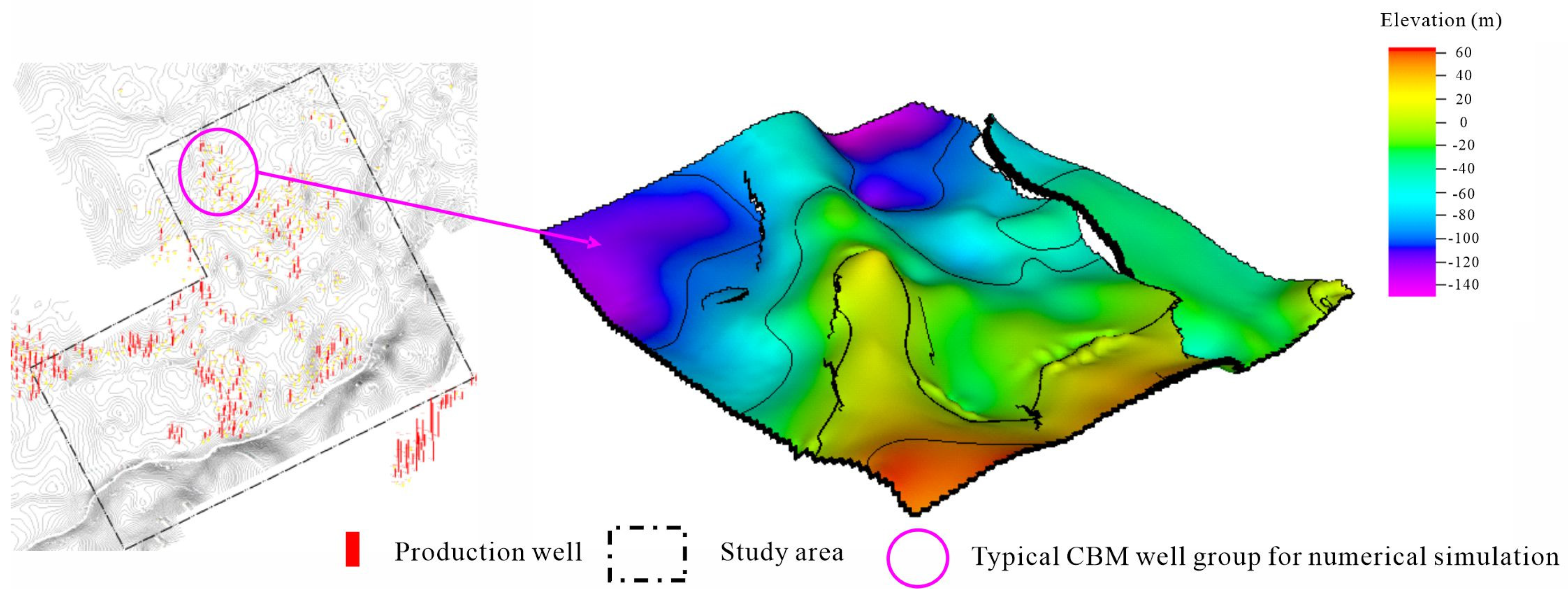

4.1. Three-Dimensional Structural Modeling

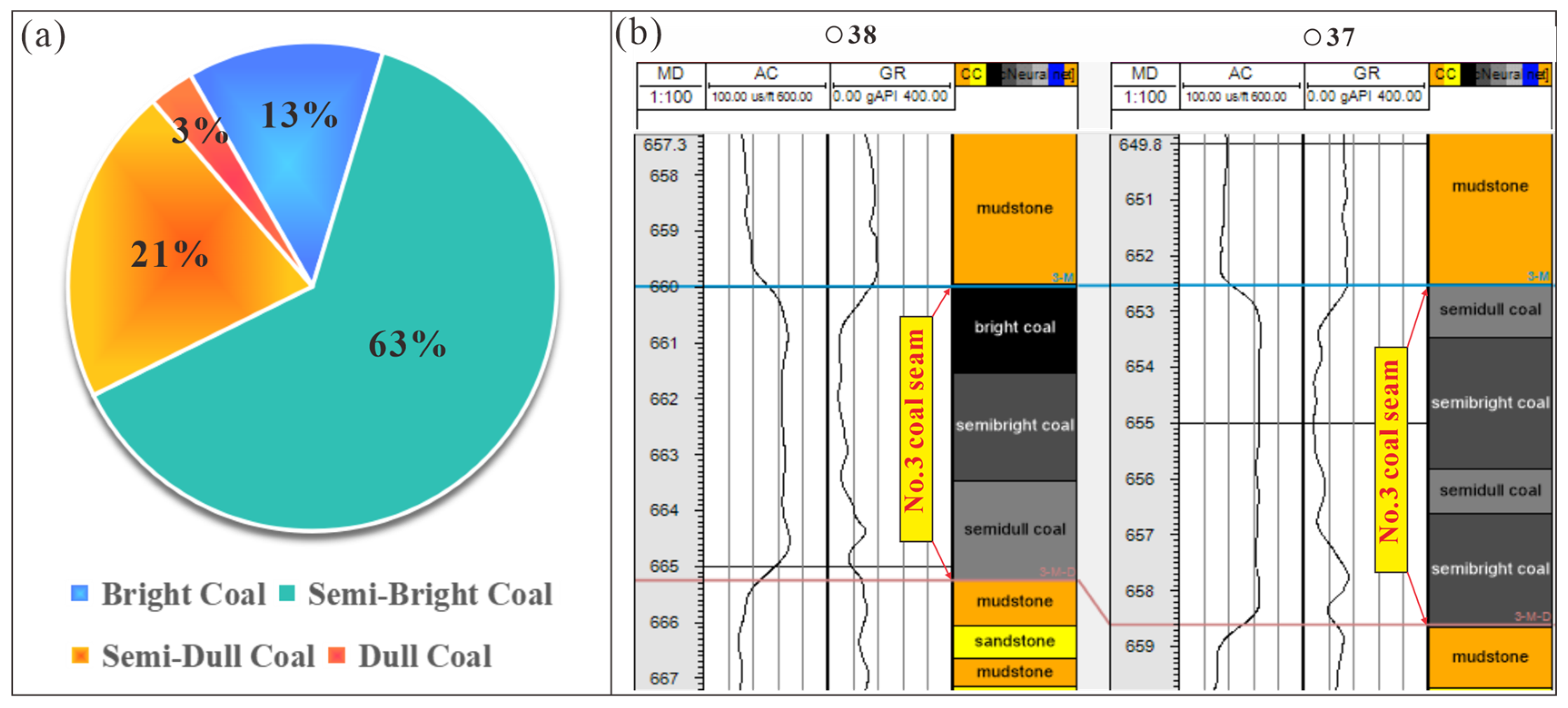

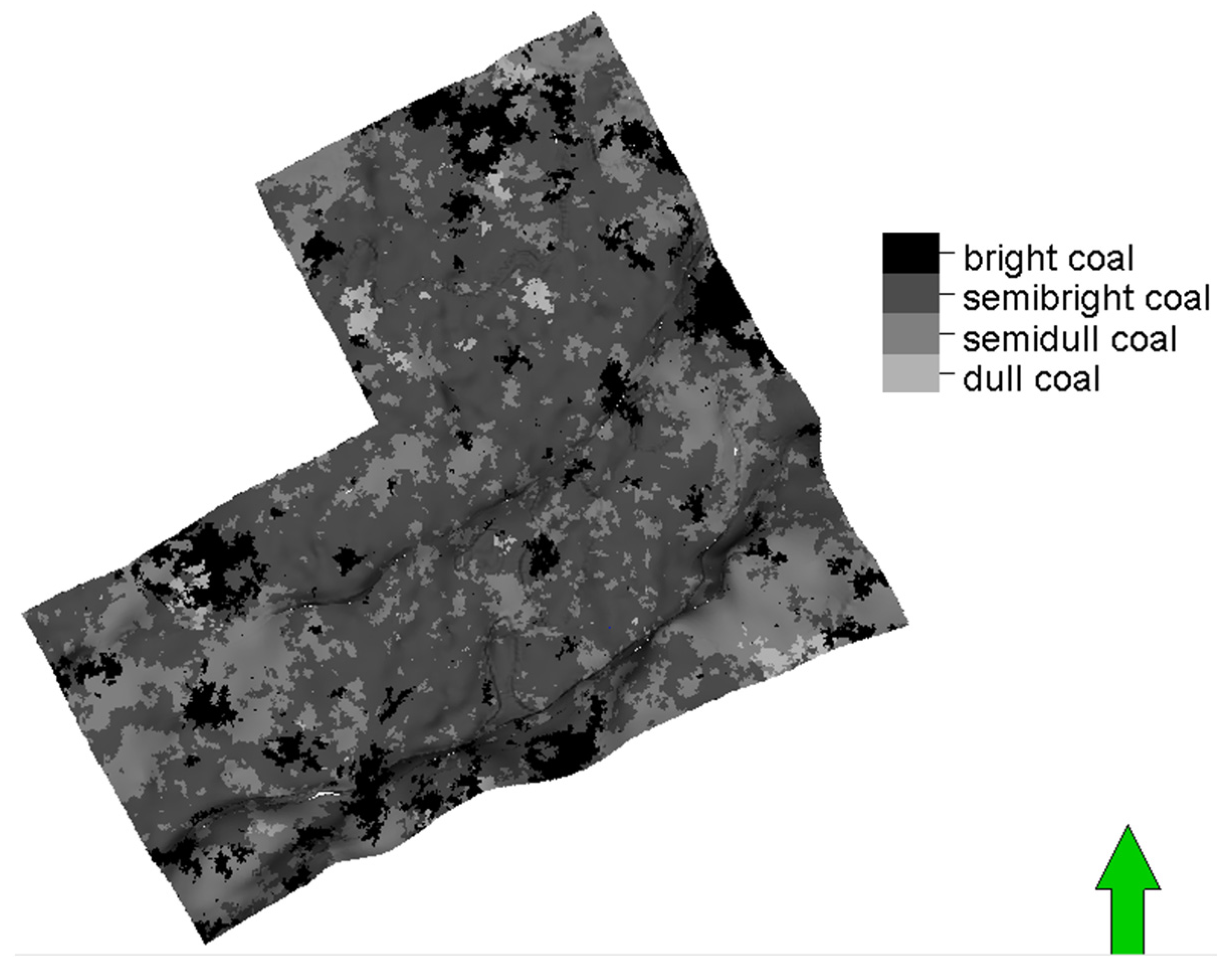

4.2. Modeling of Macroscopic Coal Lithotype

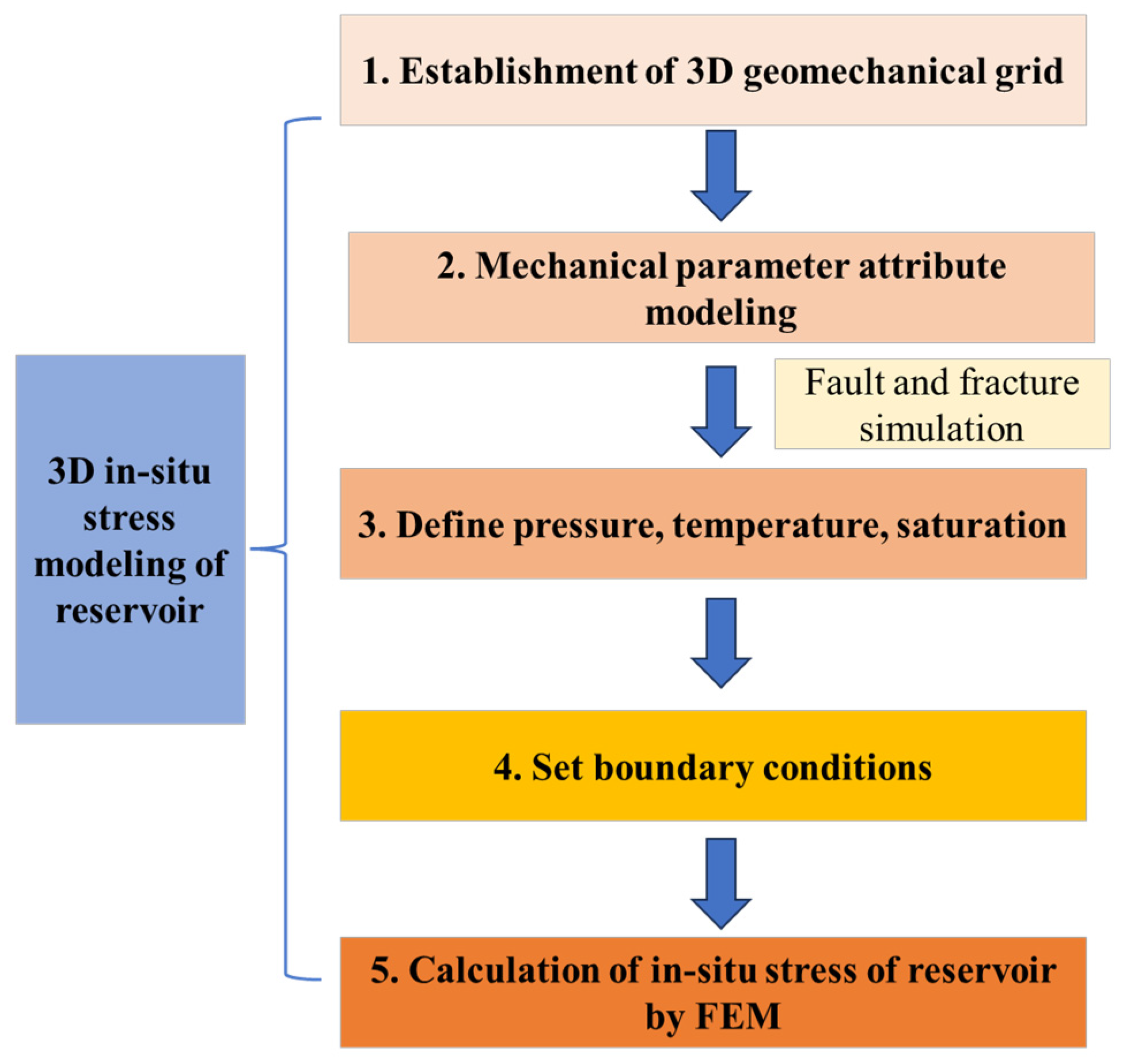

4.3. Modeling of 3D Geomechanical Stress

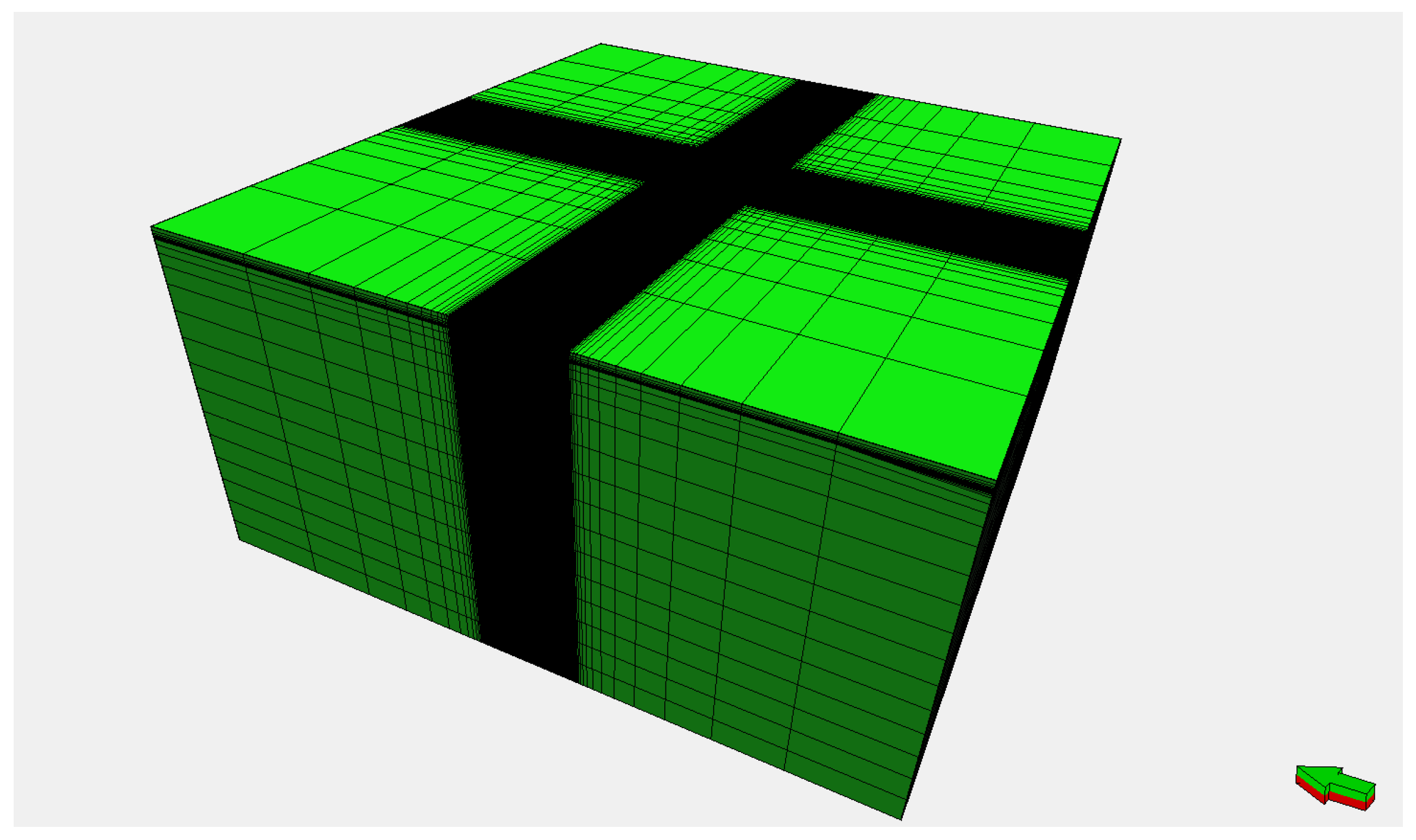

4.3.1. Geomechanical Grid Generation

4.3.2. Mechanical Property Interpolation

- (1)

- Poisson’s Ratio (μ)

- (2)

- Shear Modulus (G)

- (3)

- Young’s Modulus (E)

- (4)

- Bulk Modulus (K)

- (5)

- Compressive Strength ()

- (6)

- Tensile Strength (σt)

- (7)

- Cohesion (τ) and internal friction angle (φ)

4.3.3. Modeling of Reservoir Fracture

4.3.4. Boundary Condition Configuration

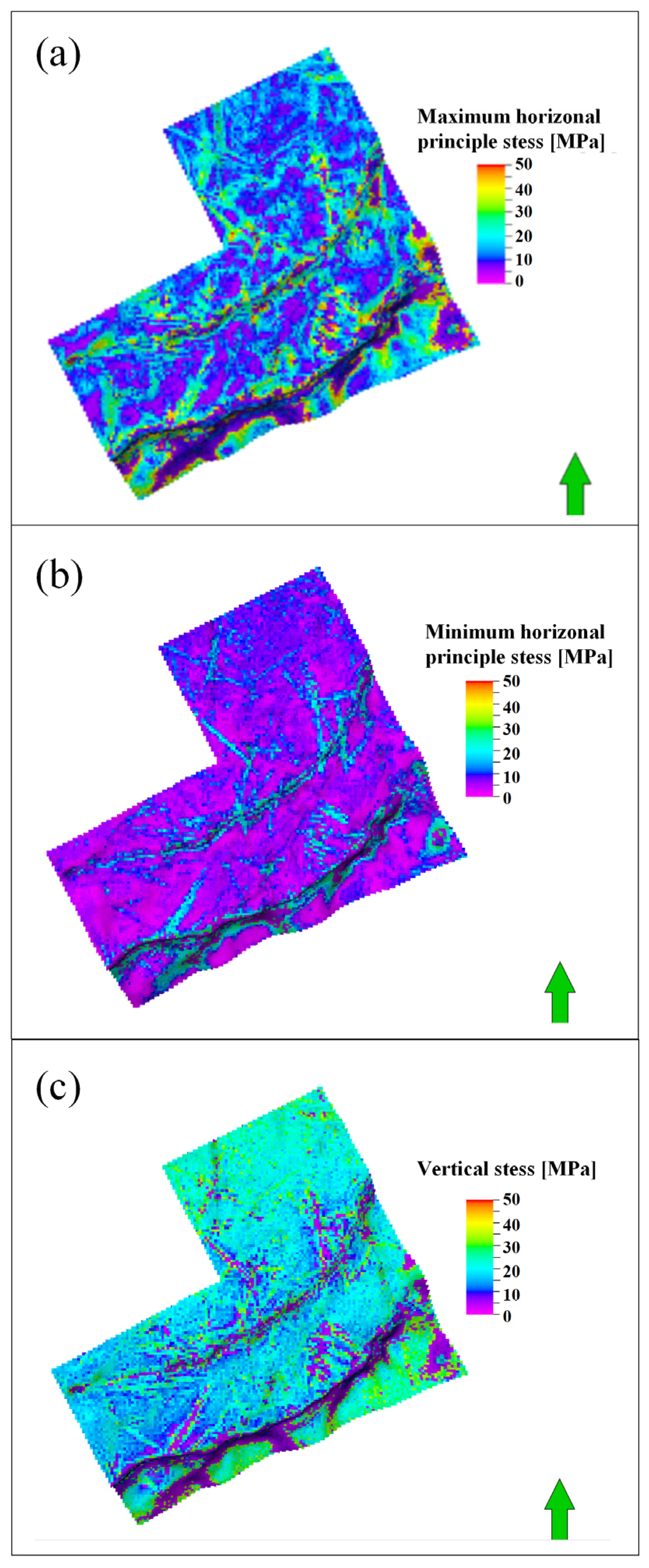

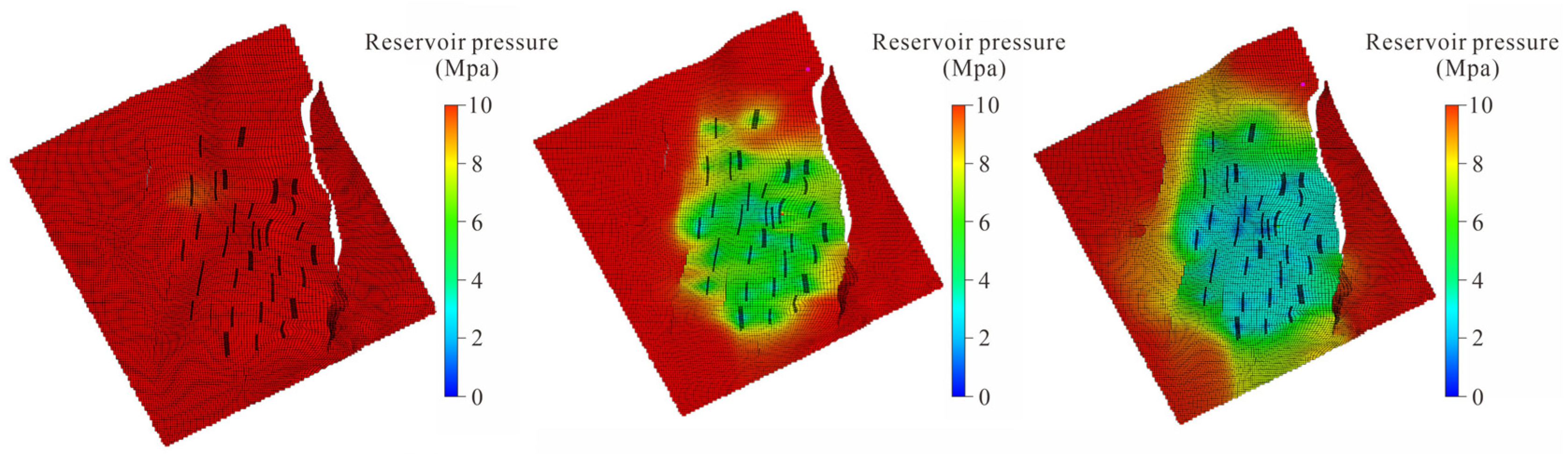

4.3.5. Modeling of In-Site Stress

4.4. Modeling of Reservoir Properties

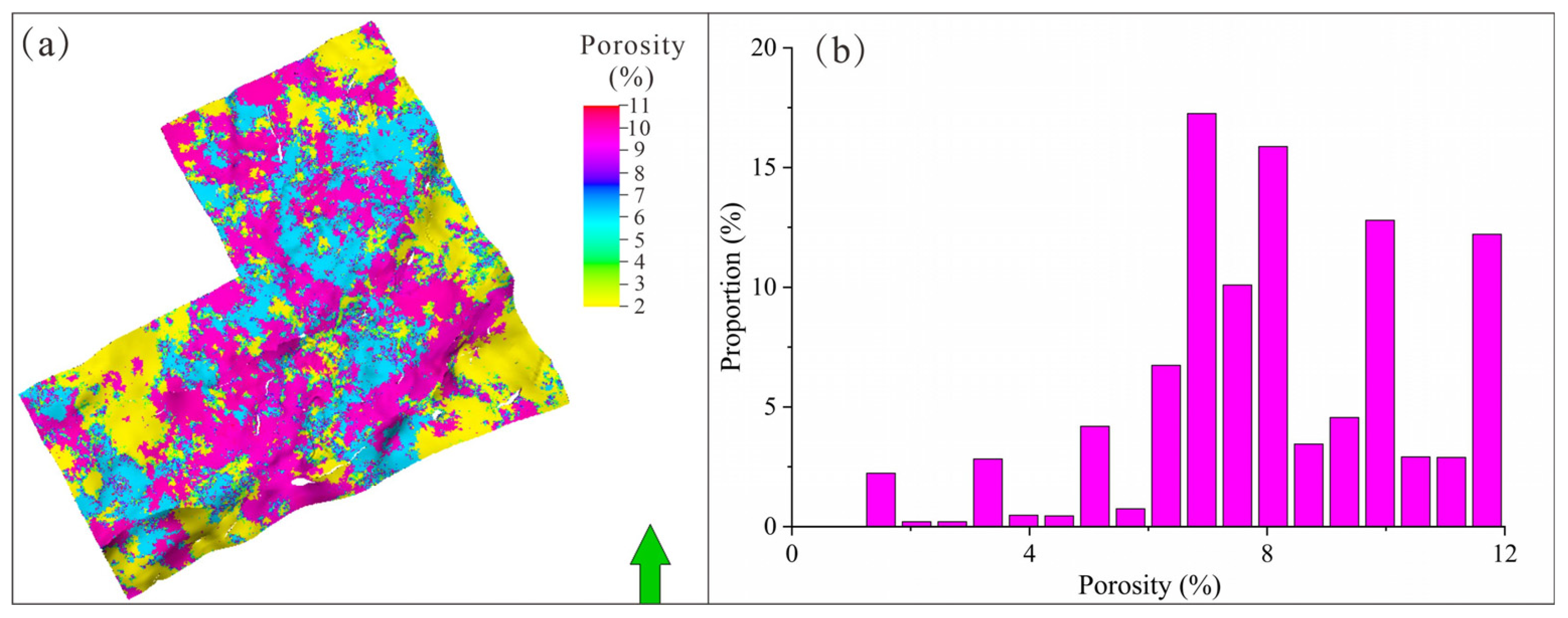

4.4.1. Modeling of Reservoir Porosity

4.4.2. Modeling of Reservoir Permeability

4.4.3. Modeling of Gas Content

4.5. Production Numerical Simulation of Typical Well Group

4.5.1. Numerical Model Setup

4.5.2. History Matching

4.5.3. Residual Gas Content of Reservoir

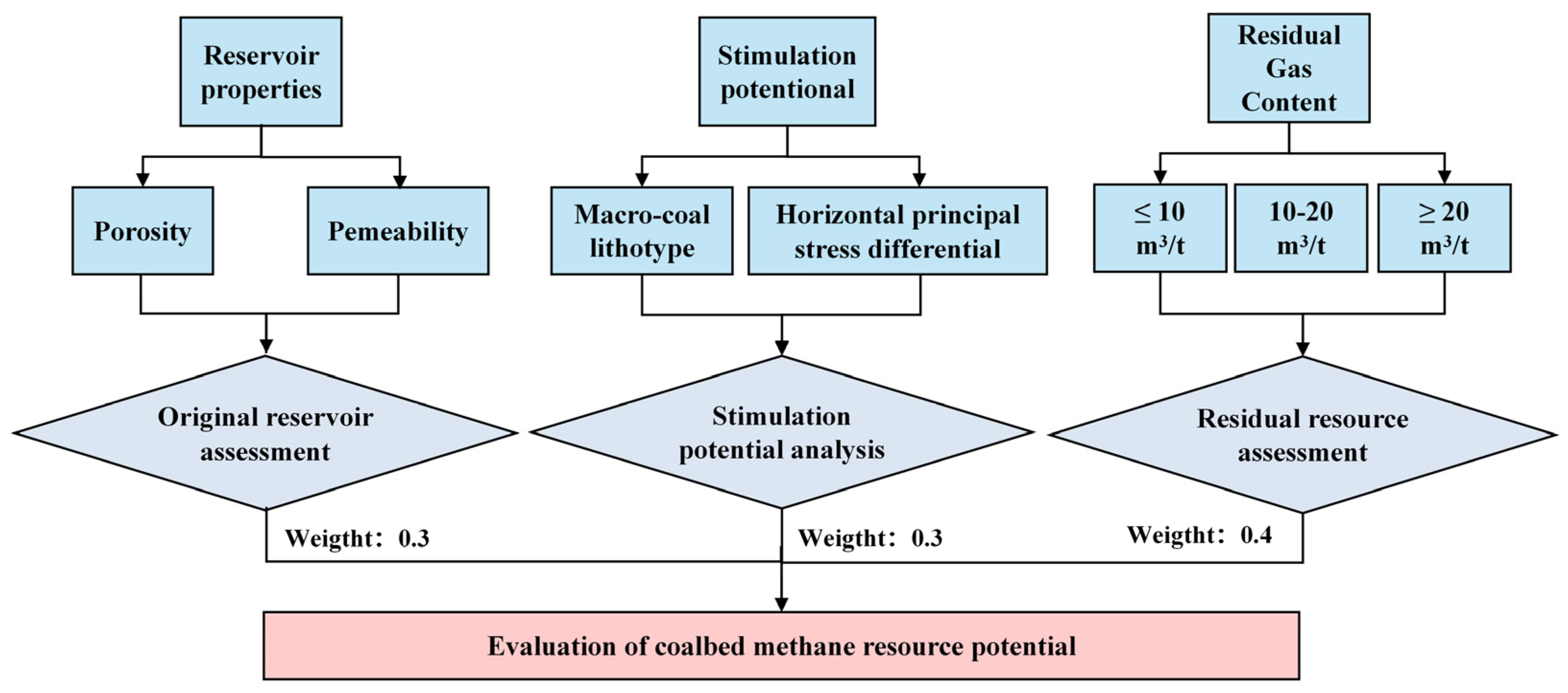

4.6. Potential Evaluation of CBM Resources

4.6.1. Residual Resources Assessment

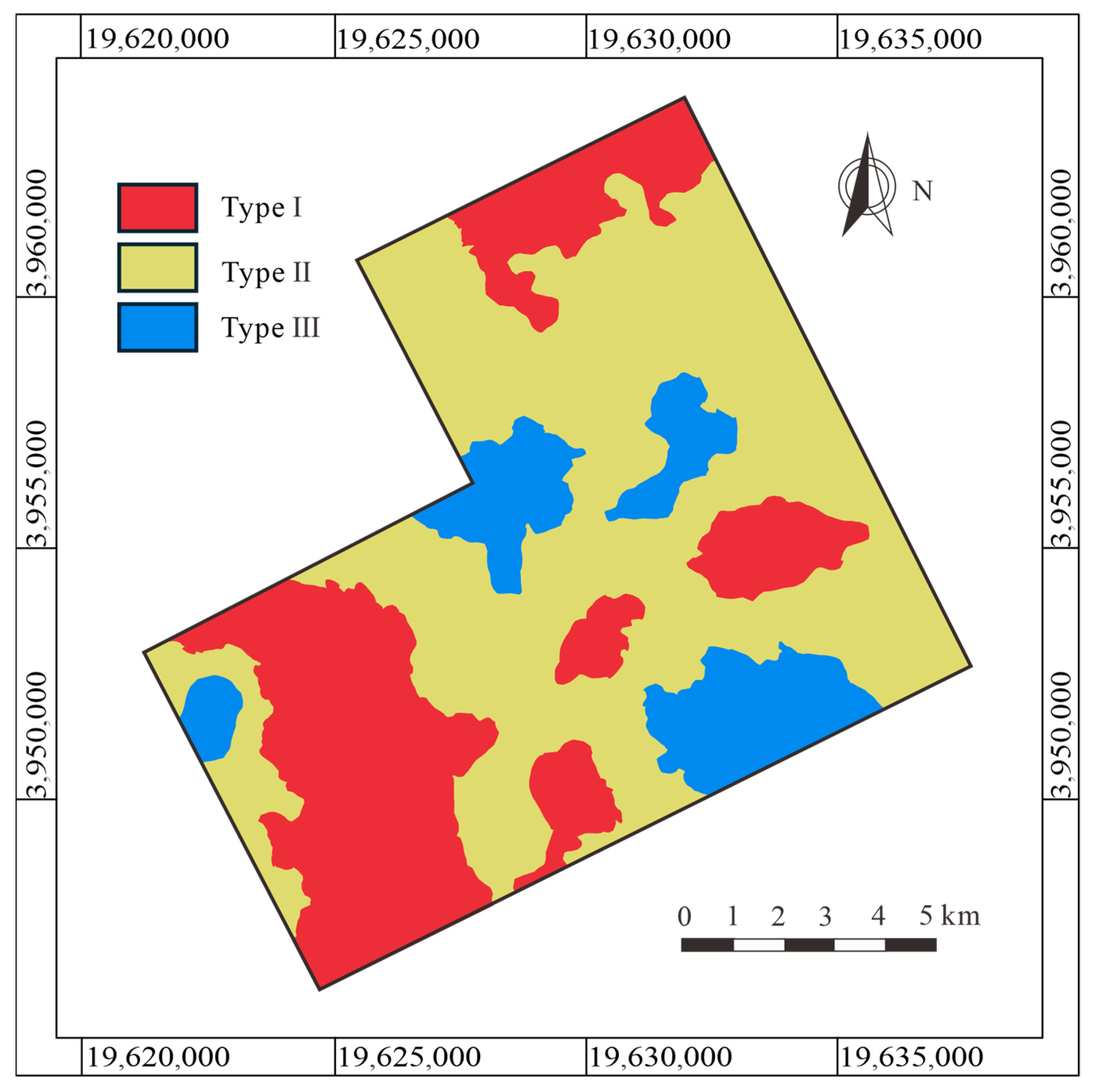

4.6.2. Evaluation of CBM Resource Potential

5. Conclusions

- (1)

- The 3D geological model effectively characterized spatial heterogeneity of the No. 3 coal seam, identifying semi-bright coal as dominant, with porosity (1.3–12%) and permeability (0.01–1 mD) variations controlled by fracture networks.

- (2)

- Stress field modeling revealed significant stress anisotropy (σH/σh gradients: 0.0344/0.0215 MPa/m), delineating stimulation-favorable zones in southwestern structural compartments.

- (3)

- Numerical simulations revealed that 84.8% of cumulative gas production and 88.4% of water production were matched historically, with residual gas content (14–33.5 m3/t) concentrated in structurally elevated western and southeastern regions.

- (4)

- A multi-criteria evaluation framework categorized resources into three tiers: Type I, Type II, and Type III, among which Type I areas are prioritized for future development. This integrated approach establishes a technical basis for optimizing well patterns, improving hydraulic fracturing efficiency, and enhancing residual gas recovery in heterogeneous CBM reservoirs.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pashin, J.C. Geology of North American coalbed methane reservoirs. In Coal Bed Methane (Second Edition): Theory and Applications; Elsevier Inc.: Amsterdam, The Netherlands, 2020. [Google Scholar] [CrossRef]

- Cai, Y.; Liu, D.; Yao, Y.; Li, J.; Qiu, Y. Geological Controls on Prediction of Coalbed Methane of No.3 Coal Seam in Southern Qinshui Basin, North China. Int. J. Coal Geol. 2011, 88, 101–112. [Google Scholar] [CrossRef]

- Ma, X.; Zhou, A.; Cheng, X.; Cheng, C.; Zhao, W. Multi-Field Coupling Models of Coal and Gas and Their Engineering Applications to CBM in Deep Seams: A Review. Energies 2024, 17, 6221. [Google Scholar] [CrossRef]

- Wei, C.; Qin, Y.; Wang, G.; Jiang, B.; Zhang, Z. Simulation Study on Rvolution of Coalbed Methane Reservoir in Qinshui Basin, China. Int. J. Coal Geol. 2007, 72, 53–69. [Google Scholar] [CrossRef]

- Li, C.; Sun, L.; Zhao, Z.; Zhang, J.; Li, Y.; Meng, Y.; Wang, L. A Method for Evaluating Coalbed Methane Reservoir Productivity Considering Drilling Fluid Damage. Energies 2024, 17, 1686. [Google Scholar] [CrossRef]

- Leng, K.; Guan, B.; Liu, W.; Jiang, C.; Cong, S.; Xin, Y. Research Progress of Coalbed Methane Extraction. Energy Rep. 2024, 12, 5728–5746. [Google Scholar] [CrossRef]

- Mondalt, D.; Sang, S.; Han, S.; Zhou, X.; Zhao, F.; Zhang, J.; Gao, W. Coalbed Methane Reservoir Properties Assessment and 3D Static Modeling for Sweet-spot Prediction in Dahebian Block, Liupanshui Coal field, Guizhou Province, Southwestern China. Heliyon 2024, 10, e35481. [Google Scholar] [CrossRef]

- Cao, L.; Yao, Y.; Liu, D.; Yang, Y.; Wang, Y.; Cai, Y. Application of Seismic Curvature Attributes in the Delineation of Coal Texture and Deformation in Zhengzhuang Field, Southern Qinshui Basin. AAPG Bull. 2020, 104, 1143–1166. [Google Scholar] [CrossRef]

- Chen, S.; Chen, P.; Tang, D.; Tao, S.; Zhang, T. Identification of Thin-layer Coal Texture Using Geophysical Logging Data: Investigation by Wavelet Transform and Linear Discrimination Analysis. Int. J. Coal Geol. 2021, 239, 103727. [Google Scholar] [CrossRef]

- Liu, D.; Yao, Y.; Wang, H. Structural Compartmentalization and Its Relationships with Gas Accumulation and Gas Production in the Zhengzhuang Field, Southern Qinshui Basin. Int. J. Coal Geol. 2022, 259, 104055. [Google Scholar] [CrossRef]

- Di, C.; Wei, Z.; Wang, K.; Deng, P.; Chen, B.; Shen, L.; Chen, Z. The impact of pressurization-induced decrease of capillary pressure and residual saturation on geological carbon dioxide storage. J. Clean. Prod. 2025, 486, 144573. [Google Scholar] [CrossRef]

- Chen, Y.; Tang, D.; Xu, H.; Li, Y.; Meng, Y. Structural Controls on Coalbed Methane Accumulation and High Production Models in the Eastern Margin of Ordos Basin, China. J. Nat. Gas Sci. Eng. 2015, 23, 524–537. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, Q.; Qu, Z.; Zhang, Y. South Anze Structure and Its Control on Coalbed Methane Aggregation in the Qinshui Basin and the Mechanism of Syncline Gas Enrichment in the Qinshui Basin. Energies 2023, 16, 4521. [Google Scholar] [CrossRef]

- Huang, S.; Liu, D.; Gomez-Rivas, E.; Griera, A.; Gan, Q.; Wang, M.; Xing, Y.; Zhao, Y. Experimental Insights into the Nucleation and Propagation of Hydraulic Fractures in Anthracite Coalbed Methane Reservoirs. Earth Energy Sci. 2025; in press. [Google Scholar] [CrossRef]

- Zhou, F.D.; Yao, G.Q.; Tyson, S. Impact of Geological Modeling Processes on Spatial Coalbed Methane Resource Estimation. Int. J. Coal Geol. 2015, 146, 14–27. [Google Scholar] [CrossRef]

- Zhang, B.; Deng, Z.; Fu, X.; Yin, K. A Study on Three-Phase Gas Content in Coal Reservoirs and Coalbed Methane-Water Differential Distribution in the Western Fukang Mining Area, Xinjiang, China. ACS Omega 2021, 6, 3999–4012. [Google Scholar] [CrossRef]

- Yue, P.; Qu, S.; Zhang, Y.; Tu, J.; Ning, W.; Duan, J. Numerical Simulation Study of the Upper Aquifer Impact on the Coalbed Methane Production. Front. Energy Res. 2022, 9, 789021. [Google Scholar] [CrossRef]

- Quan, F.; Wei, C.; Feng, S.; Hu, Y. Physical Experiment and Numerical Simulation of the Depressurization Rate for Coalbed Methane Production. ACS Omega 2020, 5, 22661–22673. [Google Scholar] [CrossRef] [PubMed]

- Rahman, M.K.; Suarez, Y.; Chen, Z.; Rahman, S.S. Unsuccessful Hydraulic Fracturing Cases in Australia: Investigation into Causes of Failures and Their Remedies. J. Pet. Sci. Eng. 2007, 55, 213–227. [Google Scholar] [CrossRef]

- Zhang, Y.P.; Yang, Y.H.; Shao, G.L.; Chen, L.W.; Wei, N.; Zhang, L.W. Problems and Countermeasures in the Exploitation of High Coal Rank CBM Horizontal Wells in Fanzhuang–Zhengzhuang Area of Qinshui Basin. Nat. Gas Ind. 2017, 37, 46–54. [Google Scholar] [CrossRef]

- Su, X.; Lin, X.; Liu, S.; Zhao, M.; Song, Y. Geology of Coalbed Methane Reservoirs in the Southeast Qinshui Basin of China. Int. J. Coal Geol. 2005, 62, 197–210. [Google Scholar] [CrossRef]

- Yang, X.; Tang, S.; Xi, Z.; Zhang, S.; Zhang, Q.; Zhang, K. Dynamic Evolution and Differential Enrichment of Deep Coalbed Methane: A Case Study in Qinshui Basin. Int. J. Coal Geol. 2025, 299, 104696. [Google Scholar] [CrossRef]

- Wang, H.; Yao, Y.; Huang, C.; Liu, D.; Cai, Y. Fault Development Characteristics and Their Effects on Current Gas Content and Productivity of No. 3 Coal Seam in the Zhengzhuang Field, Southern Qinshui Basin, North China. Energy Fuel 2021, 35, 2268–2281. [Google Scholar] [CrossRef]

- Qin, Y.; Jiang, B.; Wang, J.; Wu, C.; Ju, Y. Coupling Control of Tectonic Dynamical Conditions to Coalbed Methane Reservoir Formation in the Qinshui Basin, Shanxi, China. Acta Geolog. Sin. 2008, 82, 1355–1362. [Google Scholar]

- Shao, L.; Wang, X.; Wang, D.; Li, M.; Wang, S.; Li, Y.; Shao, K.; Zhang, C.; Gao, C.; Dong, D.; et al. Sequence Stratigraphy, Paleogeography, and Coal Accumulation Regularity of Major Coal-Accumulating Periods in China. Int. J. Coal Sci. Technol. 2020, 7, 240–262. [Google Scholar] [CrossRef]

- Wang, H.; Yao, Y.; Liu, D.; Pan, Z.J.; Yang, Y.; Cai, Y. Fault-sealing Capability and Its Impact on Coalbed Methane Distribution in the Zhengzhuang Field, Southern Qinshui Basin, North China. J. Nat. Gas Sci. Eng. 2016, 28, 613–625. [Google Scholar] [CrossRef]

- Allawi, R.H. Geomechanical Model of Ratawi Shale Reservoir. Int. J. Coal Sci. Technol. 2024, 35, 1–16. [Google Scholar] [CrossRef]

- Huang, S.; Liu, D.; Yao, Y.; Gan, Q.; Cai, Y.; Xu, L. Natural Fractures Initiation and Fracture Type Prediction in Coal Reservoir under Different In-situ Stresses during Hydraulic Fracturing. J. Nat. Gas Sci. Eng. 2017, 43, 69–80. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, J.; Yu, Z.; Liu, Z.; Yin, P. WOA (Whale Optimization Algorithm) Optimizes Elman Neural Network Model to Predict Porosity Value in Well Logging Curve. Energies 2022, 15, 4456. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, D.; Cai, Y.; Yao, Y.; Pan, Z. Constraining coalbed methane reservoir petrophysical and mechanical properties through a new coal structure index in the southern Qinshui Basin, northern China: Implications for hydraulic fracturing. AAPG Bull. 2020, 104, 1817–1842. [Google Scholar] [CrossRef]

| Well | Depth (m) | Top Elevation (m) | (Mpa) | (Mpa) | (Mpa) |

|---|---|---|---|---|---|

| 14 | 1122.3 | 919.11 | 42.72 | 26.40 | 27.50 |

| 15 | 896.71 | 815.74 | 26.23 | 16.87 | 21.97 |

| 19 | 559.85 | 746.89 | 26.86 | 15.98 | 13.72 |

| 27 | 747.05 | 885.91 | 22.95 | 14.77 | 18.30 |

| 30 | 638.5 | 633.99 | 14.75 | 10.51 | 15.64 |

| 31 | 601.25 | 674.06 | 20.78 | 13.21 | 14.73 |

| 38 | 659.95 | 693.19 | 30.79 | 18.87 | 16.17 |

| 39 | 992.9 | 597.72 | 27.24 | 18.92 | 24.33 |

| 64 | 1242.4 | 826.31 | 44.77 | 27.65 | 30.44 |

| 67 | 1269.7 | 924 | 46.86 | 29.09 | 31.11 |

| 69 | 1187.25 | 1127 | 29.16 | 19.19 | 29.09 |

| 76 | 515.4 | 904.4 | 28.45 | 15.97 | 12.63 |

| 78 | 702.8 | 1000 | 20.17 | 11.88 | 17.22 |

| 80 | 752.1 | 941 | 21.37 | 13.45 | 18.43 |

| 82 | 703.8 | 937 | 21.09 | 13.08 | 17.24 |

| 89 | 521.6 | 737 | 22.75 | 13.47 | 12.78 |

| 102 | 1102.4 | 869.4 | 42.64 | 25.99 | 27.01 |

| Input Parameters | Value |

|---|---|

| Initial reservoir pressure (Mpa) | 4.76–10.89 |

| Permeability (mD) | 0.012–1 |

| Porosity (%) | 0.0129–0.10 |

| Gas content (m3/t) | 14.1–31.8 |

| Water saturation (%) | 100 |

| Assessment Projects | Reservoir Parameters | Better | Good | Bad |

|---|---|---|---|---|

| Reservoir properties | Porosity | ≥8% | 4–8% | ≤4% |

| Permeability | ≥0.8 mD | 0.5–0.8 mD | ≤0.5 mD | |

| Stimulation potential | Macro-coal lithotype | Bright coal | Semi-bright coal | Semi-dull coal and dull coal |

| Horizontal principal stress differential | ≥10 MPa | 5–10 MPa | ≤5 MPa | |

| Residual resource assessment | Residual gas content | ≥20 m3/t | 10–20 m3/t | ≤10 m3/t |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Wang, H.; Lu, X.; Zhang, Q.; Yang, Y.; Zhang, T.; Zhang, C.; Wang, Z. Integrated 3D Geological Modeling, Stress Field Modeling, and Production Simulation for CBM Development Optimization in Zhengzhuang Block, Southern Qinshui Basin. Energies 2025, 18, 2617. https://doi.org/10.3390/en18102617

Liu Z, Wang H, Lu X, Zhang Q, Yang Y, Zhang T, Zhang C, Wang Z. Integrated 3D Geological Modeling, Stress Field Modeling, and Production Simulation for CBM Development Optimization in Zhengzhuang Block, Southern Qinshui Basin. Energies. 2025; 18(10):2617. https://doi.org/10.3390/en18102617

Chicago/Turabian StyleLiu, Zhong, Hui Wang, Xiuqin Lu, Qianqian Zhang, Yanhui Yang, Tao Zhang, Chen Zhang, and Zihan Wang. 2025. "Integrated 3D Geological Modeling, Stress Field Modeling, and Production Simulation for CBM Development Optimization in Zhengzhuang Block, Southern Qinshui Basin" Energies 18, no. 10: 2617. https://doi.org/10.3390/en18102617

APA StyleLiu, Z., Wang, H., Lu, X., Zhang, Q., Yang, Y., Zhang, T., Zhang, C., & Wang, Z. (2025). Integrated 3D Geological Modeling, Stress Field Modeling, and Production Simulation for CBM Development Optimization in Zhengzhuang Block, Southern Qinshui Basin. Energies, 18(10), 2617. https://doi.org/10.3390/en18102617