The Experimental Investigation of the Effects on the Combustion, Performance, and Emission Characteristics of an RCCI Engine Using Methanol/Diesel Fuel

Abstract

1. Introduction

Physical and Chemical Properties of Methanol

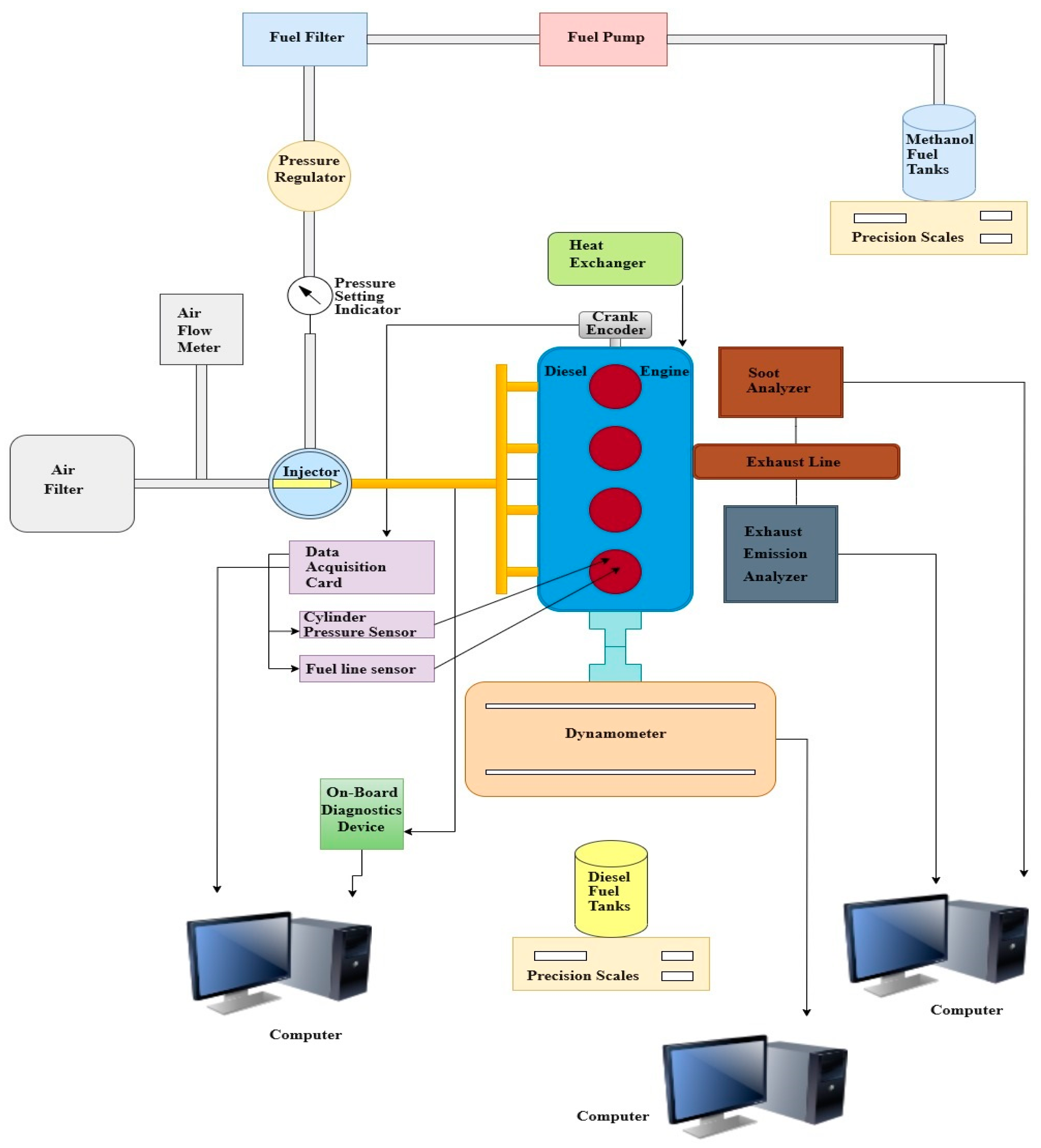

2. Materials and Methods

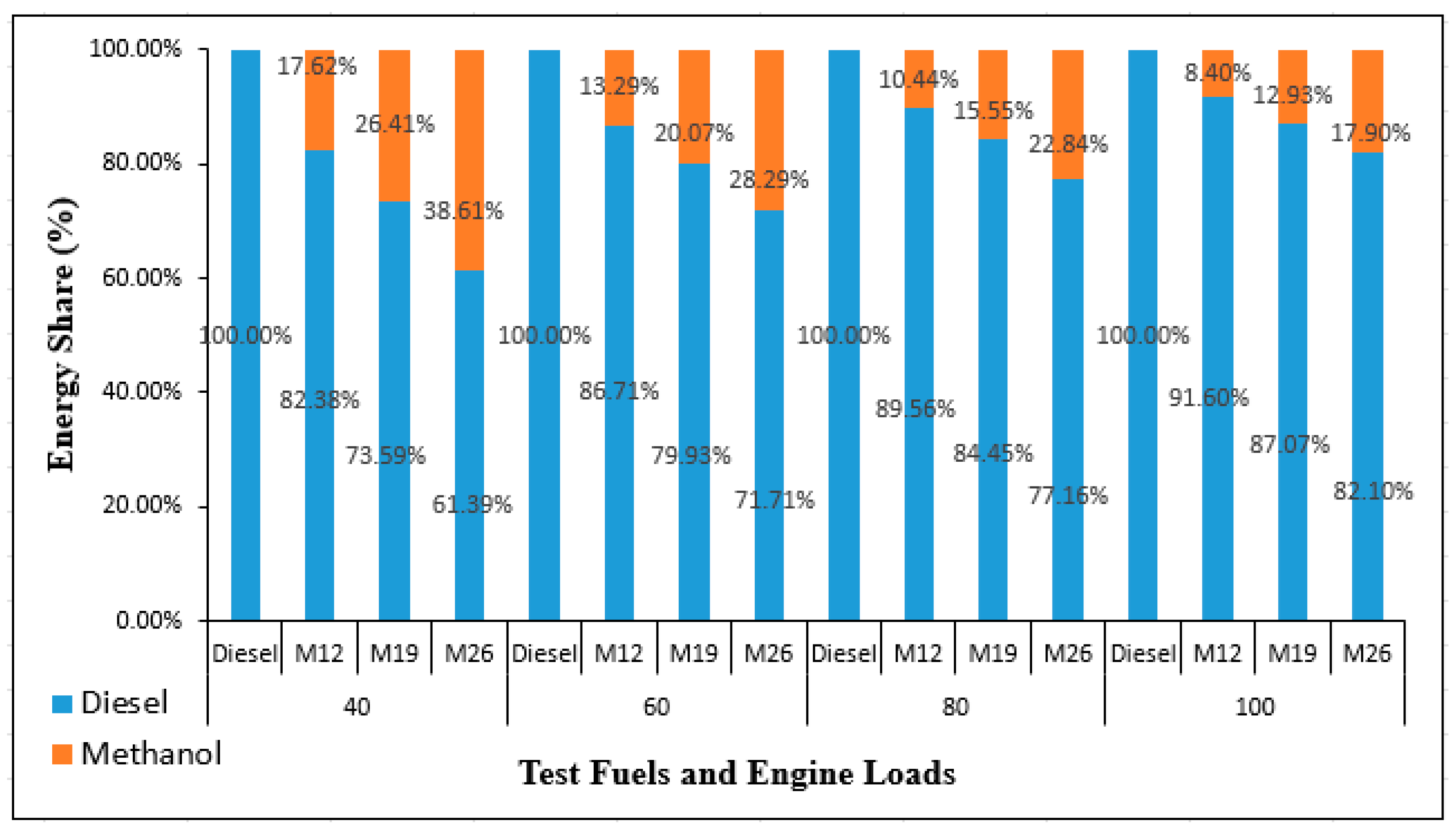

Data Analysis

3. Results

3.1. Combustion Characteristics

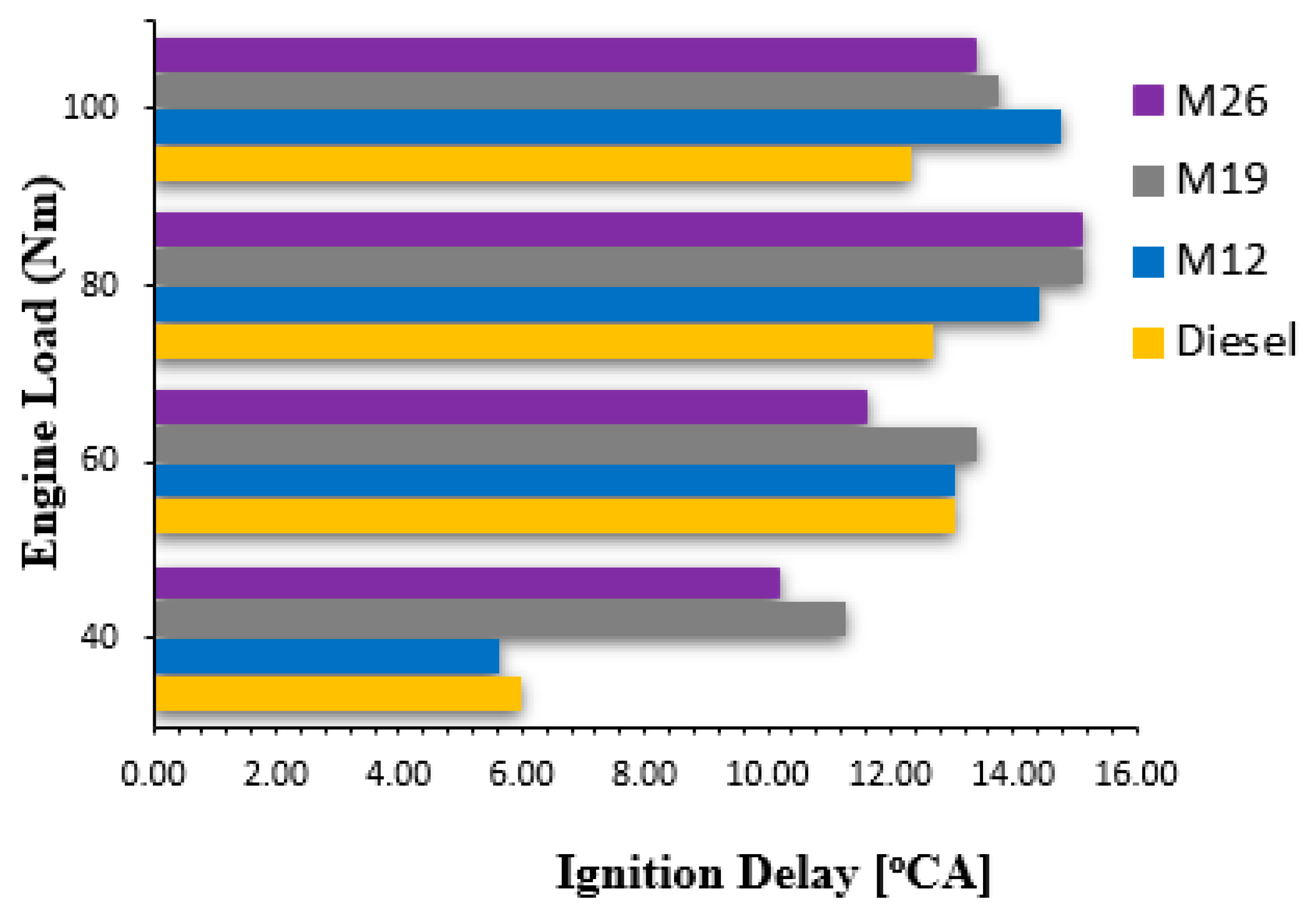

3.1.1. Ignition Delay

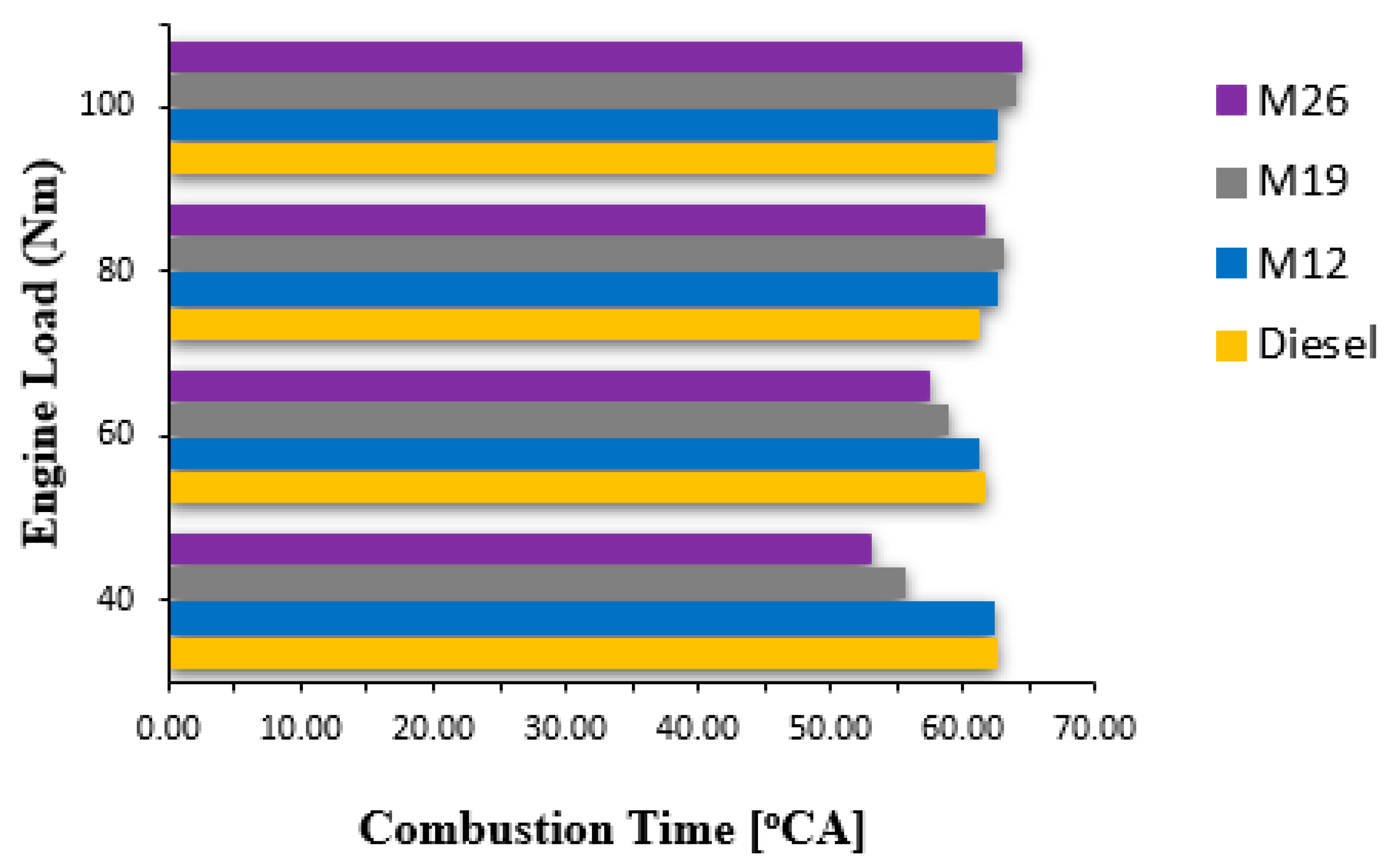

3.1.2. Combustion Duration

3.2. Engine Performance

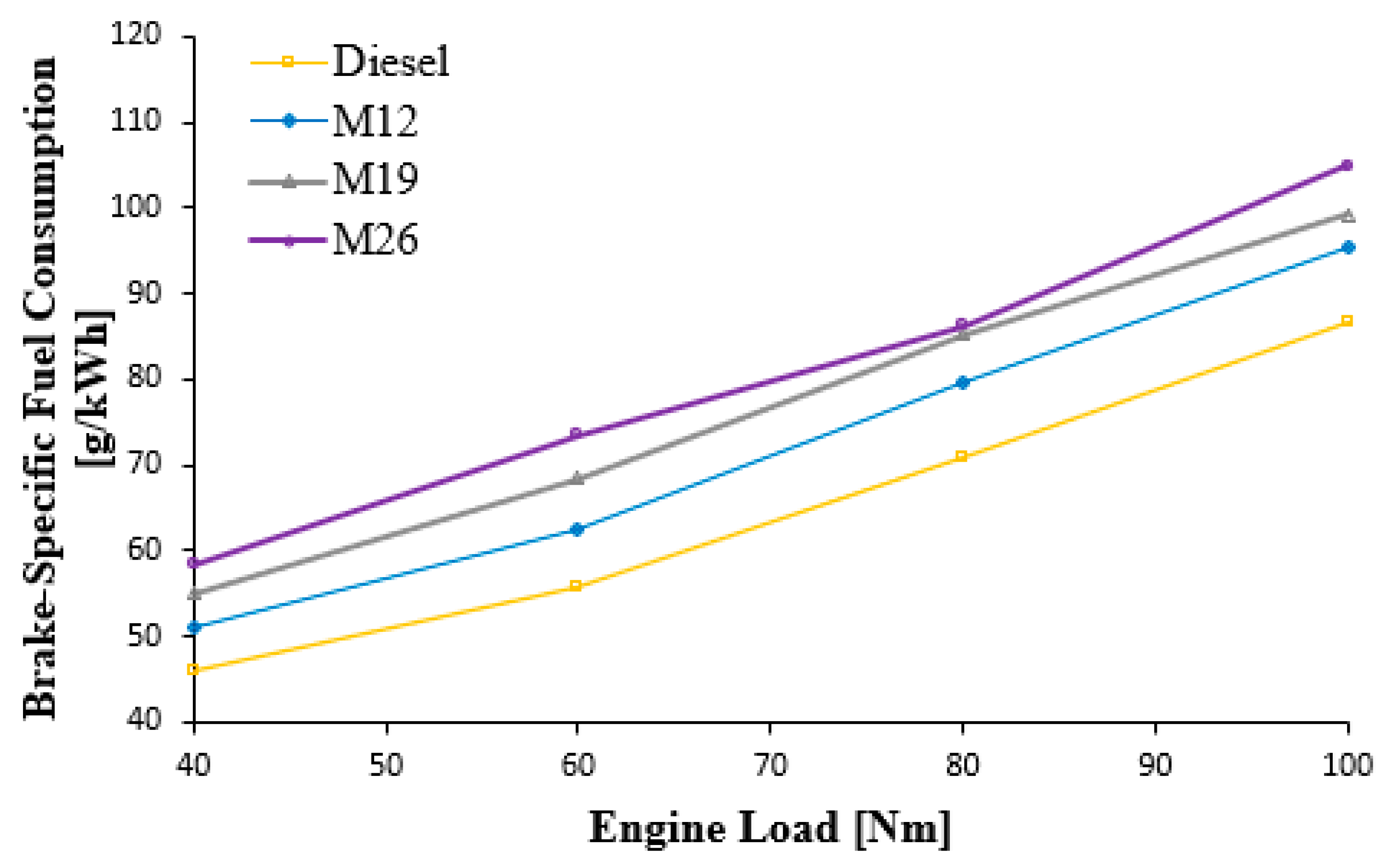

3.2.1. Brake-Specific Fuel Consumption

3.2.2. Brake-Specific Energy Consumption

3.3. Emissions

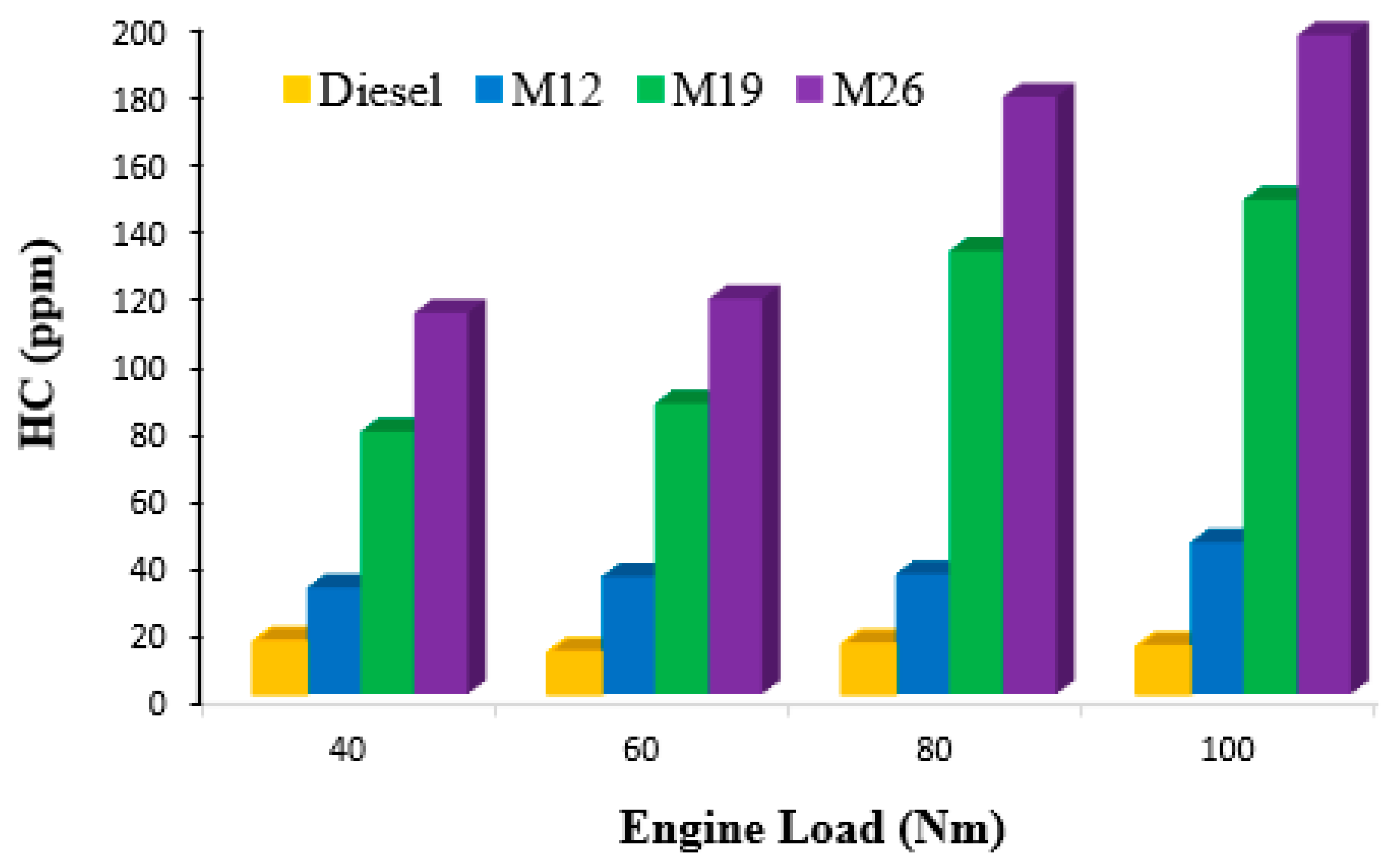

3.3.1. HC Emissions

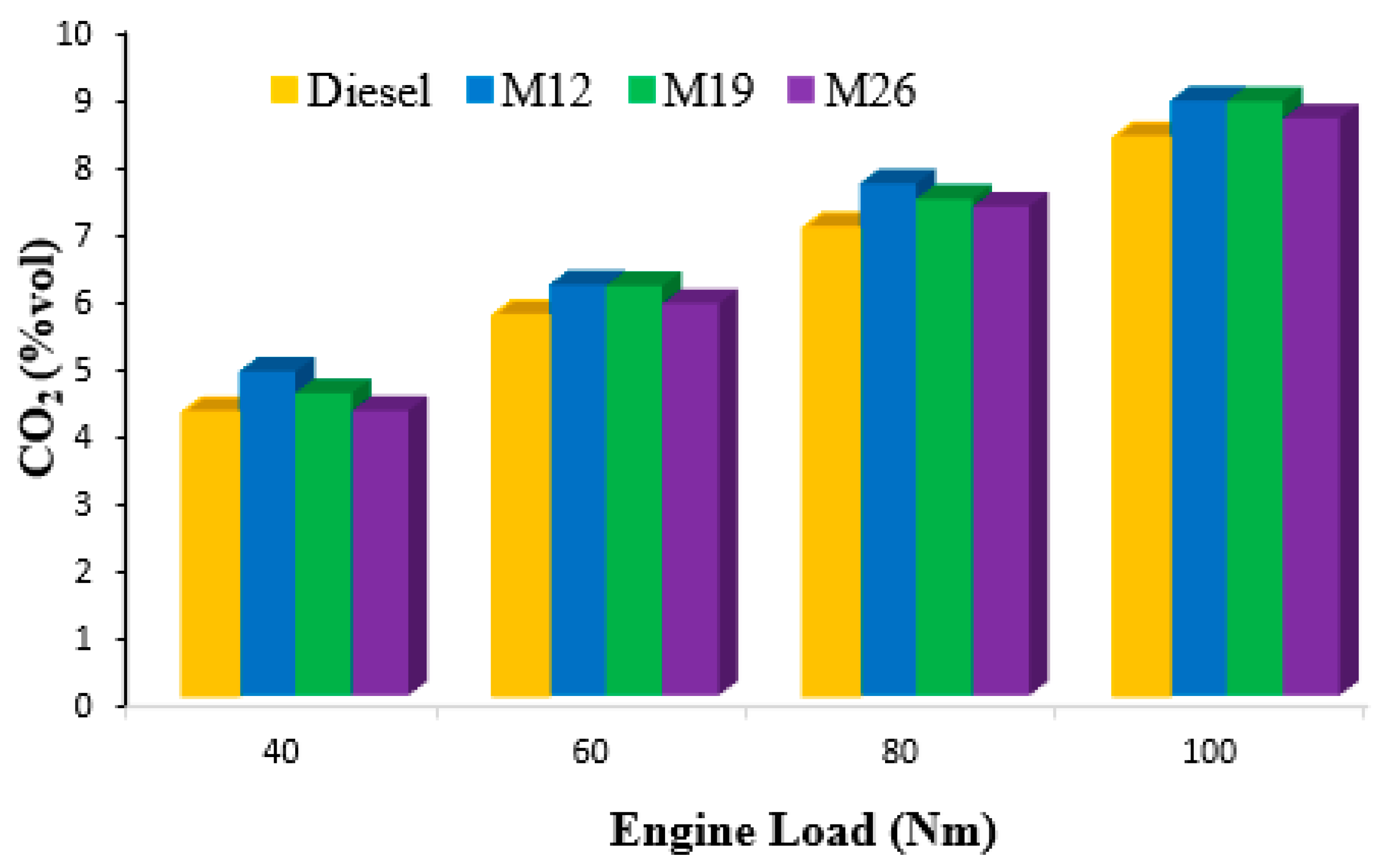

3.3.2. CO2 Emissions

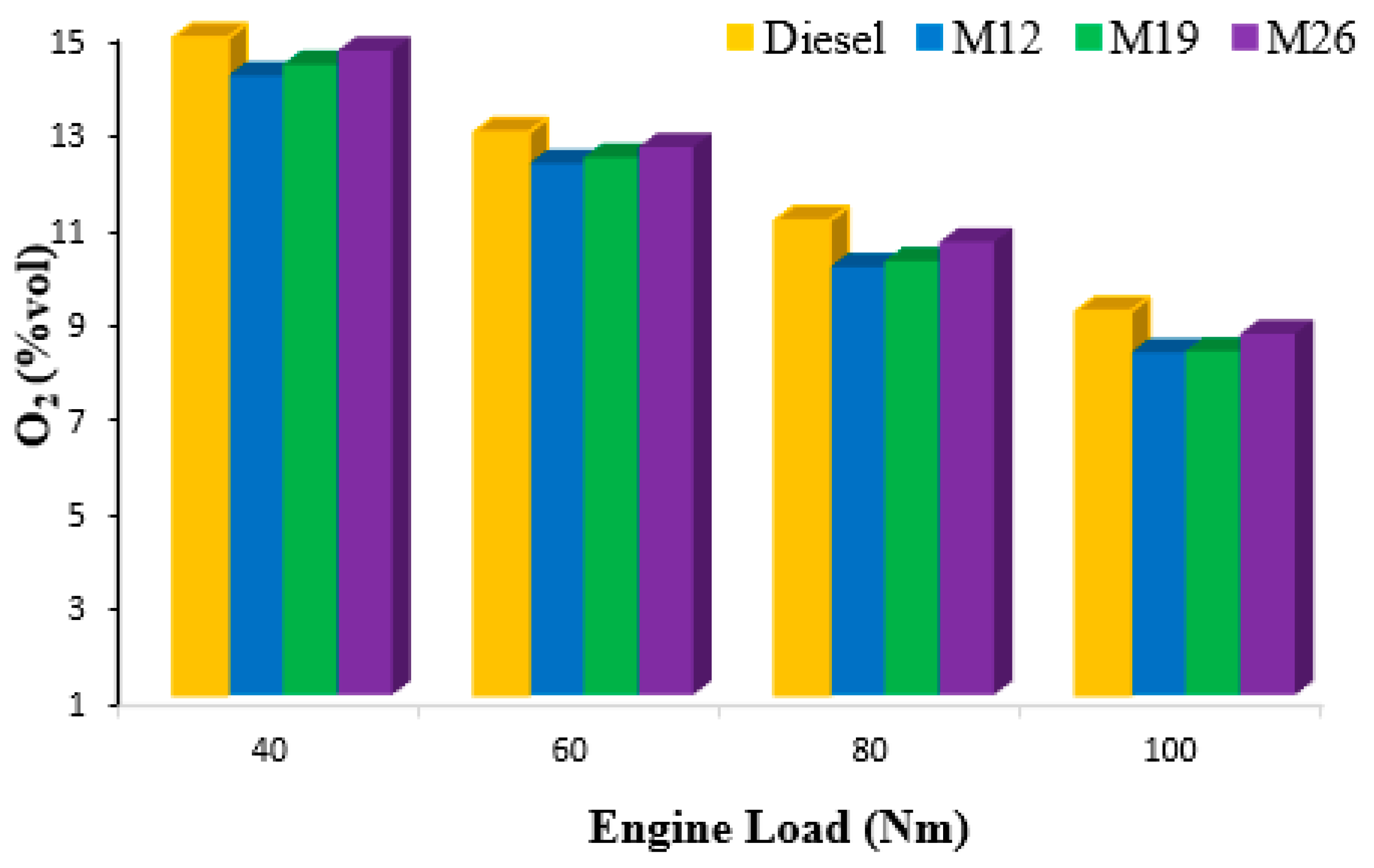

3.3.3. O2 Emissions

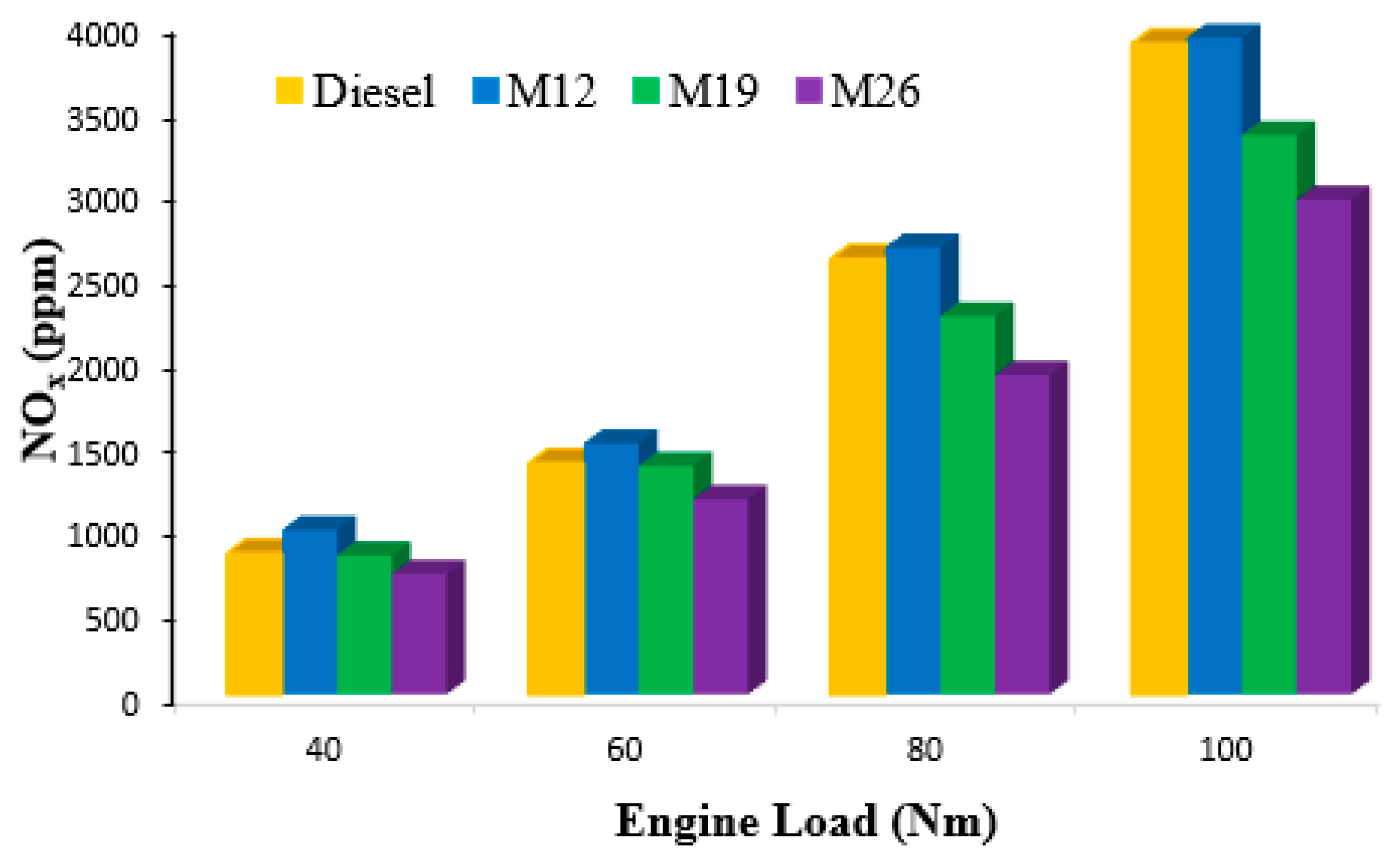

3.3.4. NOx Emissions

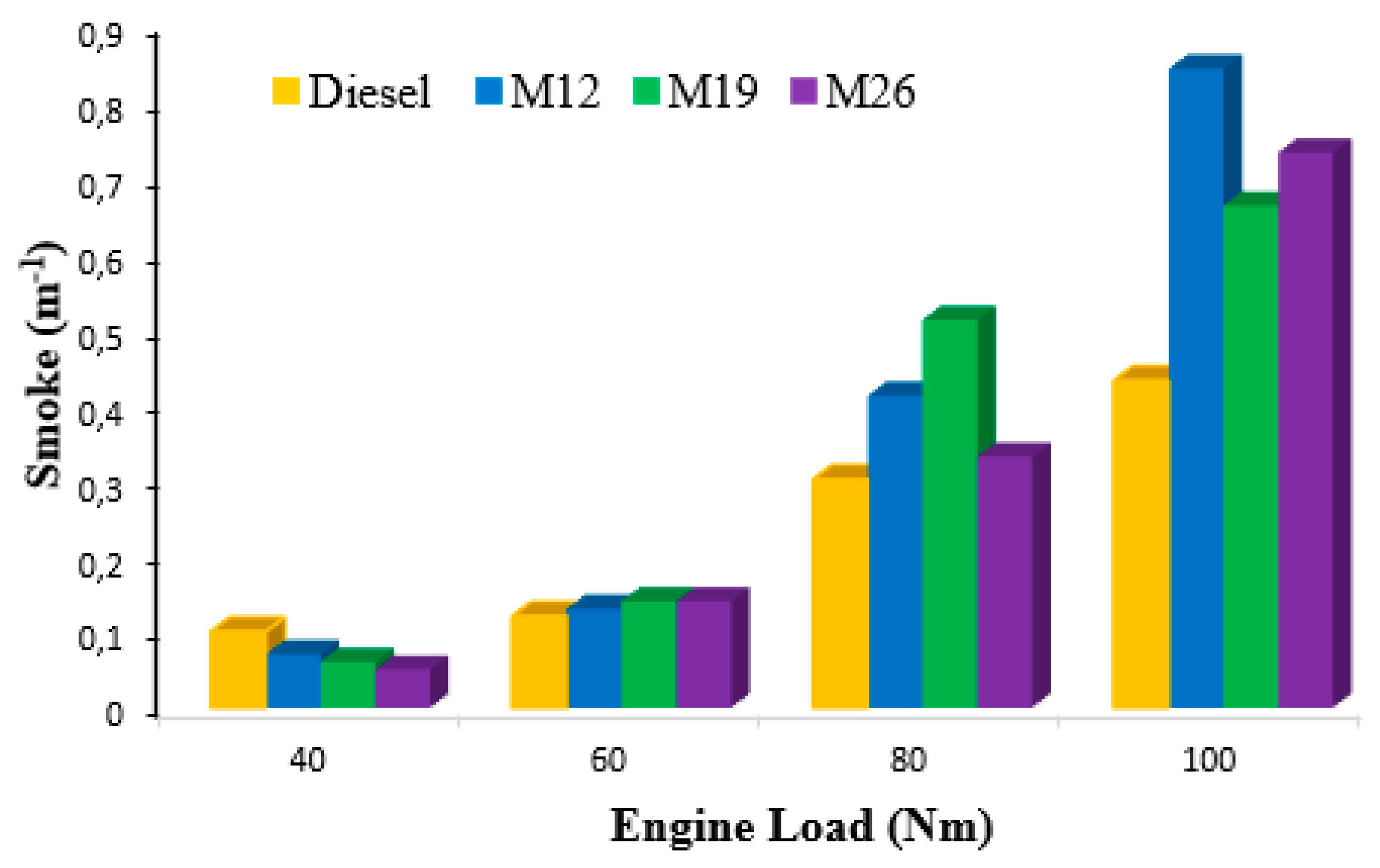

3.3.5. Smoke Emissions

4. Conclusions

- In RCCI mode, as the methanol content increased, the ID also increased. The highest increase was 88.13% in M19 fuel at 40 Nm. It is seen that the ignition delay increases as the load increases. It is seen that ID decreases at high loads of 100 Nm for M19 and M26 fuels. This phenomenon can be attributed to the increase in in-cylinder temperatures resulting from the decrease in the energy fraction of methanol and the lower latent heat of vaporization of diesel compared to methanol.

- At low loads (40 and 60 Nm), CD decreases significantly, while at high loads (80 and 100 Nm) CD increases.

- Bsfc and bsec increased as the methanol ratio and engine load increased. As EL increases, Bsfc also increases. The highest increase in bsfc was in M26 fuel at 60 Nm with 31.76%, while the highest increase in bsfc was in M26 fuel at 60 Nm with 12.02%. While the minimum bsfc in conventional diesel fuel was 45.9 g/kWh at 40 Nm, the highest bsfc in M26 fuel was 104.88 g/kWh at 100 Nm. Bsec reached its lowest value at 40 Nm at 1950.58 kJ/kWh on conventional diesel fuel and its highest value at 4034.69 kJ/kWh at 100 Nm on M26 fuel.

- As the methanol ratio increased, HC and O2 emissions increased, while NOx and CO2 emissions decreased. While smoke emission decreased at low loads, it tended to increase at high ELs.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| BMEP | Brake mean effective pressure |

| bsec | Brake-specific energy consumption |

| bsfc | Brake-specific fuel consumption |

| BTE | Brake thermal efficiency |

| CA | Crank angle |

| CO | Carbon monoxide |

| CO2 | Carbon dioxide |

| COHR | Center of heat release |

| CD | Combustion duration |

| CHR | Cumulative heat release |

| CHR | Cumulative heat release |

| CP | Cylinder pressure |

| EGR | Exhaust gas recirculation |

| ES | Energy sharing |

| EL | Engine load |

| HR | Heat release |

| HC | Hydrocarbon |

| HCCI | Homogeneous charge compression ignition |

| ICE | Internal combustion engine |

| ID | Ignition delay |

| LHV | Lower heating values |

| LTC | Low-temperature combustion |

| NOx | Nitrogen oxide |

| O2 | Oxygen |

| PCCI | Premixed charge compression ignition |

| RCCI | Reactivity-controlled compression ignition |

| ROHR | Rate of heat release |

| ROPR | Rate of pressure rise |

| SOI | Start of ignition |

| V | Volume |

References

- Balki, M.K.; Temur, M.; Erdoğan, S.; Sarıkaya, M.; Sayin, C. The determination of the best operating parameters for a small SI engine fueled with methanol gasoline blends. Sustain. Mater. Technol. 2021, 30, e00340. [Google Scholar] [CrossRef]

- Balki, M.K.; Sayin, C.; Sarıkaya, M. Optimization of the operating parameters based on Taguchi method in an SI engine used pure gasoline, ethanol and methanol. Fuel 2016, 180, 630–637. [Google Scholar] [CrossRef]

- Balki, M.K.; Cavus, V.; Duran, İ.U.; Tuna, R.; Sayin, C. Experimental study and prediction of performance and emission in an SI engine using alternative fuel with artificial neural network. Int. J. Automot. Eng. Technol. 2018, 7, 58–64. [Google Scholar] [CrossRef]

- Verhelst, S.; Turner, J.W.G.; Sileghem, L.; Vancoillie, J. Methanol as a fuel for internal combustion engines. Prog. Energy Combust. Sci. 2019, 70, 43–88. [Google Scholar] [CrossRef]

- Pavlov, G.I.; Nakoryakov, P.V.; Sukhovaya, E.A. Development of silencer for lowpower internal combustion engines. Procedia Eng. 2017, 206, 1690–1695. [Google Scholar] [CrossRef]

- Valera, H.; Agarwal, A.K. Methanol as an Alternative Fuel for Diesel Engines. In Methanol and the Alternate Fuel Economy; Energy, Environment, and Sustainability; Springer: Singapore, 2017; pp. 9–33. [Google Scholar] [CrossRef]

- Moon, C.S. Estimations of the lethal and exposure doses for representative methanol symptoms in humans. Moon Ann. Occup. Environ. Med. 2017, 29, 44. [Google Scholar] [CrossRef]

- Sayin, C. Engine performance and exhaust gas emissions of methanol and ethanol–diesel Blends. Fuel 2010, 89, 3410–3415. [Google Scholar] [CrossRef]

- Yin, X.; Yue, G.; Liu, J.; Duan, H.; Duan, Q.; Kou, H.; Wang, Y.; Yang, B.; Zeng, K. Investigation into the operating range of a dual-direct injection engine fueled with methanol and diesel. Energy 2023, 267, 126625. [Google Scholar] [CrossRef]

- Feng, H.; Chen, X.; Sun, L.; Ma, R.; Zhang, X.; Zhu, L.; Yang, C. The effect of methanol/diesel fuel blends with co-solvent on diesel engine combustion based on experiment and exergy analysis. Energy 2023, 282, 128792. [Google Scholar] [CrossRef]

- Ning, L.; Duan, Q.; Chen, Z.; Kou, H.; Liu, B.; Yang, B.; Zeng, K. A comparative study on the combustion and emissions of a non-road common rail diesel engine fueled with primary alcohol fuels (methanol, ethanol, and n-butanol)/diesel dual fuel. Fuel 2020, 266, 117034. [Google Scholar] [CrossRef]

- Li, Y.; Ming, J.; Chan, Y.; Liu, Y.; Xie, M.; Wang, T.; Zhou, L. Parametric study and optimization of a RCCI (reactivity controlled compression ignition) engine fueled with methanol and diesel. Energy 2013, 65, 319–332. [Google Scholar] [CrossRef]

- Li, J.; Yang, W.; Zhou, D. Review on the management of RCCI engines. Renew. Sustain. Energy Rev. 2016, 69, 65–79. [Google Scholar] [CrossRef]

- Reitz, R.D.; Duraisamy, G. Review of high efficiency and clean reactivity controlled compression ignition (RCCI) combustion in internal combustion engines. Prog. Energy Combust. Sci. 2014, 46, 12–71. [Google Scholar] [CrossRef]

- Kokjohn, S.L.; Hanson, R.M.; Splitter, D.A.; Reitz, R.D. Fuel reactivity controlled compression ignition (RCCI): A pathway to controlled high-efficiency clean combustion. Int. J. Engine Res. 2011, 12, 209–226. [Google Scholar] [CrossRef]

- Kokjohn, S.L.; Reitz, R.D. Reactivity controlled compression ignition and conventional diesel combustion: A comparison of methods to meet light-duty NOx and fuel economy targets. Intern. J. Engine Res. 2013, 14, 452–468. [Google Scholar] [CrossRef]

- Panda, K.; Ramesh, A. Parametric investigations to establish the potential of methanol based RCCI engine and comparison with the conventional dual fuel mode. Fuel 2021, 308, 122025. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Kumar, V.; Jena, A.; Kalwar, A. Fuel injection strategy optimization and experimental performance and emissions evaluation of diesel displacement by port fuel injected methanol in a retrofitted mid-size genset engine prototype. Energy 2022, 248, 123593. [Google Scholar] [CrossRef]

- Duraisamy, G.; Rangasamy, M.; Govindan, N. A Govindan, Comparative study on methanol/diesel and methanol/PODE dual fuel RCCI combustion in an automotive diesel engine. Renew. Energy 2020, 145, 542–546. [Google Scholar] [CrossRef]

- Hassan, Q.H.; Ridha, G.S.A.; Hafedh KA, H.; Alalwan, H.A. The impact of Methanol-Diesel compound on the performance of a Four-Stroke CI engine. Mater. Today Proc. 2021, 42, 1993–1999. [Google Scholar] [CrossRef]

- Huang, F.; Li, L.; Zhou, M.; Wan, M.; Shen, L.; Lei, J. Effect of EGR on performance and emissions of a methanol–diesel reactivity controlled compression ignition (RCCI) engine. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 440. [Google Scholar] [CrossRef]

- Liu, J.; Wu, P.; Ji, Q.; Sun, P.; Wang, P.; Meng, Z.; Ma, H. Experimental study on effects of pilot injection strategy on combustion and emission characteristics of diesel/methanol dual-fuel engine under low load. Energy 2022, 242, 123464. [Google Scholar] [CrossRef]

- Singh, V.S.; Jain, S.; Karn, A.; Dwivedi, G.; Alam, T.; Kumar, A. Experimental Assessment of Variation in Open Area Ratio on Thermohydraulic Performance of Parallel Flow Solar Air Heater. Arab. J. Sci. Eng. 2023, 48, 11695–11711. [Google Scholar] [CrossRef]

- Sandalcı, T.; Karagoz, Y. Experimental investigation of the combustion characteristics, emissions and performance of hydrogen port fuel injection in a diesel engine. Int. J. Hydrogen Energy 2014, 39, 18480–18489. [Google Scholar] [CrossRef]

- Zangana, L.M.K.; Yaseen, A.H.; Hassan, Q.H.; Mohammed, M.M.; Mohammed, M.F.; Alalwan, H.A. Investigated kerosene-diesel fuel performance in internal combustion engine. Clean. Eng. Technol. 2023, 12, 100591. [Google Scholar] [CrossRef]

- Qi, D.H.; Geng, L.M.; Chen, H.; Bian, Y.Z.; Liu, J.; Ren, X.C. Combustion and performance evaluation of a diesel engine fueled with biodiesel produced from soybean crude oil. Renew. Energy 2009, 34, 2706–2713. [Google Scholar] [CrossRef]

- Wang, S.; Viswanathan, K.; Esakkimuthu, S.; Azad, K. Experimental investigation of high alcohol low viscous renewable fuel in DI diesel engine. Environ. Energy Manag. Res. 2021, 28, 12026–12040. [Google Scholar] [CrossRef]

- Wei, J.; He, C.; Lv, G.; Zhuang, Y.; Qian, Y.İ.; Pan, S. The combustion, performance and emissions investigation of a dual fuel diesel engine using silicon dioxide nanoparticle additives to methanol. Energy 2021, 230, 120734. [Google Scholar] [CrossRef]

- Gao, Z.; Curran, S.J.; Parks, J.E., II; Smith, D.E.; Wagner, R.M.; Daw, C.S.; Edwards, K.D.; Thomas, J.F. Drive cycle simulation of high efficiency combustions on fuel economy and exhaust properties in light-duty vehicles. Appl. Energy 2015, 157, 762–776. [Google Scholar] [CrossRef]

- Imtenan, S.; Varman, M.; Masjuki, H.H.; Kalam, M.A.; Sajjad, H.; Fattah, M.I.A.I.M.R. Impact of low temperature combustion attaining strategies on diesel engine emissions for diesel and biodiesels. Energy Convers. Manag. 2014, 80, 329–356. [Google Scholar] [CrossRef]

- Cheng, C.H.; Cheung, C.S.; Chana, T.L.; Lee, S.C.; Yao, C.D. Experimental investigation on the performance, gaseous and particulate emissions of a methanol fumigated diesel engine. Sci. Total Environ. 2008, 389, 115–124. [Google Scholar] [CrossRef]

- Gonca, G.; Hocaoglu, M.F. Emission and in-cylinder combustion characteristics of a spark ignition engine operated on binary mixtures of gas and liquid fuels. Int. J. Hydrog. Energy 2023, 52, 1502–1518. [Google Scholar] [CrossRef]

- Sayin, C.; Uslu, K.; Canakci, M. Influence of injection timing on the exhaust emissions of a dual-fuel CI engine. Renew. Energy 2008, 3, 1314–1323. [Google Scholar] [CrossRef]

- Benajes, J.; Molina, S.; García, A.; Belarte, E.; Vanvolsem, M. An investigation on RCCI combustion in a heavy duty diesel engine using in cylinder blending of diesel and gasoline fuels. Appl. Therm. Eng. 2014, 63, 66–76. [Google Scholar] [CrossRef]

- Pilusa, T.J.; Mollagee, M.M.; Muzenda, E. Reduction of vehicle exhaust emissions from diesel engines using the whale concept filter. Aerosol Air Qual. Res. 2012, 12, 994–1006. [Google Scholar] [CrossRef]

- Papagiannakis, R.G.; Rakopoulos, C.D.; Hountalas, D.T.; Rakopoulos, D.C. Emission characteristics of high speed, dual fuel, compression ignition engine operating in a wide range of natural gas/diesel fuel proportions. Fuel 2010, 89, 1397–1406. [Google Scholar] [CrossRef]

| Fuel Specifications | Diesel | Methanol |

|---|---|---|

| Chemical formula | C12H24 | CH3OH |

| Density (kg/m3 293 °K) | 847 | 795 |

| Ignition temperature (°K) | 483–523 | 743 |

| Lower calorific value (MJ/kg) | 42.5 | 20.1 |

| Latent heat of vaporization (kJ/kg) | 260 | 1100 |

| Cetane number | 51 | <5 |

| Octane number | 17 | 111 |

| Latent burning speed (cm/s) | - | 523 |

| Stoichiometric air/fuel ratio | 14.3 | 6.5 |

| Viscosity (mm2/s 313 K) | 2.72 | 0.58 |

| Boiling point (°C) | 180–360 | 64.5 |

| Engine Specifications | |

|---|---|

| Type | In-line, turbocharged |

| Number of cylinders | 4 |

| Bore | 76 mm |

| Stroke | 80.5 mm |

| Number of valves | 8 |

| Cylinder volume | 1461 cm3 |

| Compression ratio | 18.25:1 |

| Maximum power (4000 rpm) | 48 kW (65 hp) |

| Maximum torque (1750 rpm) | 160 Nm |

| Fuel injection | Common-rail |

| Type | In-line, turbocharged |

| Features | Measuring Range | Sensibility |

|---|---|---|

| Hydrocarbon (HC) | 0–10,000 ppm | 1 ppm |

| Oxygen (O2) | 0–22% vol. | 0.01% vol |

| Nitrogen oxide (NOx) | 0–5000 ppm | 1 ppm |

| Carbon dioxide (CO2) | 0–18% vol. | 0.01% vol |

| Air excess coefficient | 0.5–1.8 | 0.001 |

| Absorption coefficient (K) | 0–10 m−1 | 0.01 m−1 |

| Parameter | Device | Accuracy |

|---|---|---|

| Engine torque | Load cell | ±0.25% |

| Engine speed | Crank encoder | ±0.1% |

| Cylinder pressure | Oprand 32288GPA | ±0.5% |

| Fuel pressure | Kistler, 4067 | ±0.05% |

| EL | Parameter | Unit | Diesel | M12 | M19 | M26 |

|---|---|---|---|---|---|---|

| 40 Nm | SOI | °CA | 339.26 | 339.26 | 345.94 | 348.05 |

| J/°CA | 0.87 | 0.27 | 0.24 | 0.35 | ||

| Maximum CP | °CA | 364.57 | 365.63 | 366.33 | 368.44 | |

| MPa/°CA | 83.48 | 86.56 | 87.24 | 89.55 | ||

| ID | °CA | 5.98 | 5.63 | 11.25 | 10.20 | |

| CD | °CA | 62.58 | 62.23 | 55.55 | 53.09 | |

| 60 Nm | SOI | °CA | 342.07 | 342.42 | 344.53 | 345.59 |

| J/°CA | 0.01 | 0.27 | 0.36 | 0.38 | ||

| Maximum CP | °CA | 364.92 | 365.27 | 365.98 | 366.33 | |

| MPa/°CA | 88.97 | 93.45 | 95.03 | 99.29 | ||

| ID | °CA | 13.01 | 13.01 | 13.36 | 11.60 | |

| CD | °CA | 61.52 | 61.17 | 58.71 | 57.30 | |

| 80 Nm | SOI | °CA | 340.66 | 341.02 | 342.07 | 343.83 |

| J/°CA | 0.30 | 0.55 | 0.36 | 0.62 | ||

| Maximum CP | °CA | 377.58 | 366.68 | 365.98 | 365.63 | |

| MPa/°CA | 105.57 | 103.27 | 105.33 | 109.56 | ||

| ID | °CA | 12.66 | 14.41 | 15.12 | 15.12 | |

| CD | °CA | 61.17 | 62.58 | 62.93 | 61.52 | |

| 100 Nm | SOI | °CA | 338.91 | 339.26 | 340.31 | 340.66 |

| J/°CA | 0.38 | 0.27 | 0.11 | 0.33 | ||

| Maximum CP | °CA | 377.23 | 375.82 | 375.47 | 371.25 | |

| MPa/°CA | 117.97 | 114.86 | 116.31 | 117.89 | ||

| ID | °CA | 12.30 | 14.77 | 13.71 | 13.36 | |

| CD | °CA | 62.23 | 62.58 | 63.98 | 64.34 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Temur, M.; Sayin, C.; Yilmaz, I.T. The Experimental Investigation of the Effects on the Combustion, Performance, and Emission Characteristics of an RCCI Engine Using Methanol/Diesel Fuel. Energies 2024, 17, 1436. https://doi.org/10.3390/en17061436

Temur M, Sayin C, Yilmaz IT. The Experimental Investigation of the Effects on the Combustion, Performance, and Emission Characteristics of an RCCI Engine Using Methanol/Diesel Fuel. Energies. 2024; 17(6):1436. https://doi.org/10.3390/en17061436

Chicago/Turabian StyleTemur, Mustafa, Cenk Sayin, and Ilker Turgut Yilmaz. 2024. "The Experimental Investigation of the Effects on the Combustion, Performance, and Emission Characteristics of an RCCI Engine Using Methanol/Diesel Fuel" Energies 17, no. 6: 1436. https://doi.org/10.3390/en17061436

APA StyleTemur, M., Sayin, C., & Yilmaz, I. T. (2024). The Experimental Investigation of the Effects on the Combustion, Performance, and Emission Characteristics of an RCCI Engine Using Methanol/Diesel Fuel. Energies, 17(6), 1436. https://doi.org/10.3390/en17061436