Research on Energy Hierarchical Management and Optimal Control of Compound Power Electric Vehicle

Abstract

1. Preface

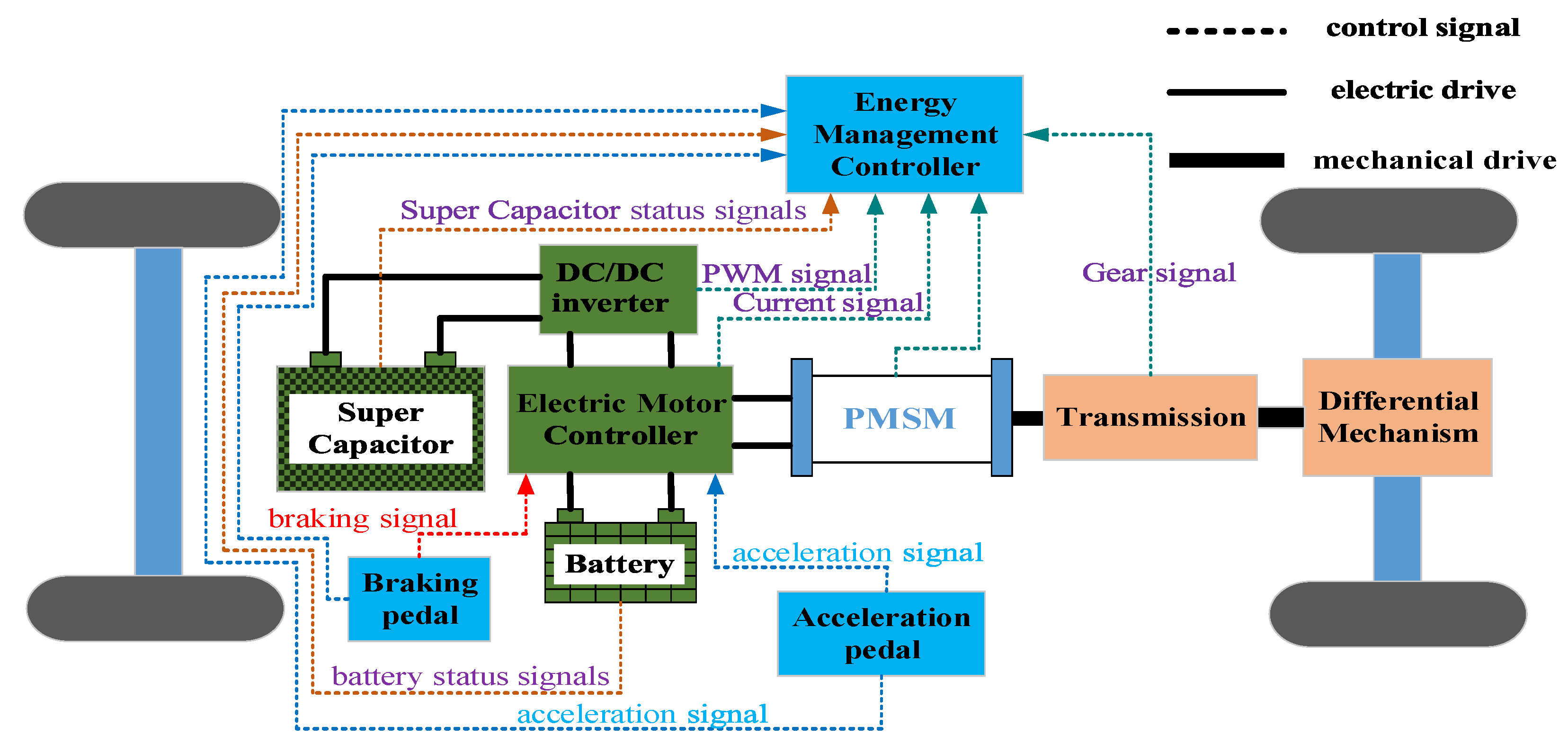

2. Composite Power System Structure

- (1)

- Power battery pack alone drive mode: Utilized during normal driving conditions with low load power, where the power battery operates independently while the super capacitor remains idle.

- (2)

- Super capacitor single drive mode: Employed at vehicle startup or during rapid acceleration to alleviate the load on the power battery. Here, a high-power-density super capacitor serves as the primary power source, while the power battery remains in a standby state.

- (3)

- Co-drive mode of power battery pack and super capacitor: Activated during extended acceleration or steep slope climbing, where load power demand is high. Both the power battery and super capacitor work together to meet power requirements.

- (4)

- Regenerative braking energy recovery mode: Applied during deceleration, downhill driving, or braking to recover braking energy. Super capacitors are primarily used due to their short charging time and high-power density.

- (5)

- Super capacitors balance the chaotic and transient components in the load power: Employed when the vehicle experiences frequent load power fluctuations. Super capacitors help balance the chaotic and transient components, while the power battery handles low-frequency components. This power shunting enhances efficiency and prolongs the power battery’s lifespan.

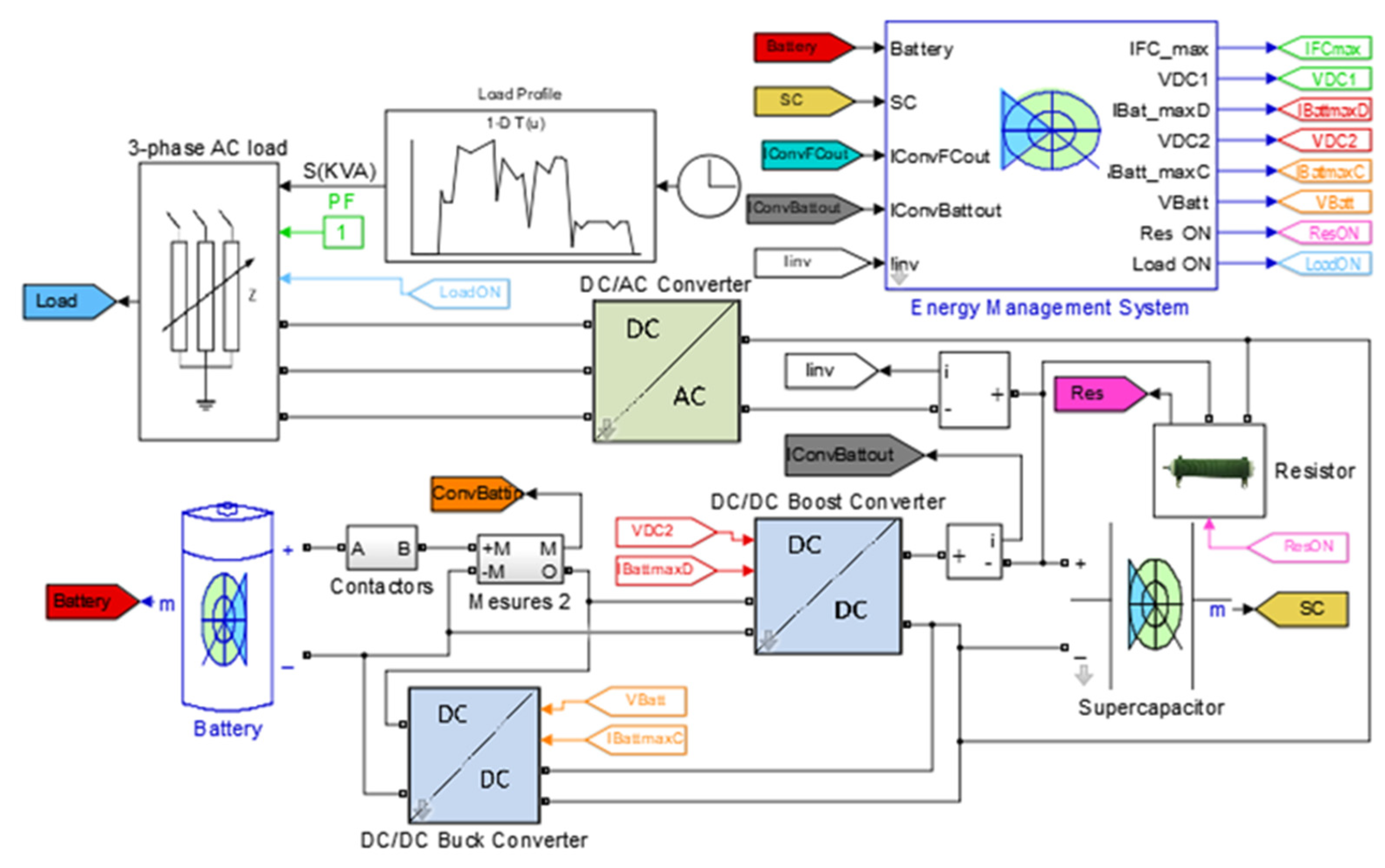

3. Compound Power Simulation Model

3.1. Vehicle Dynamics Model

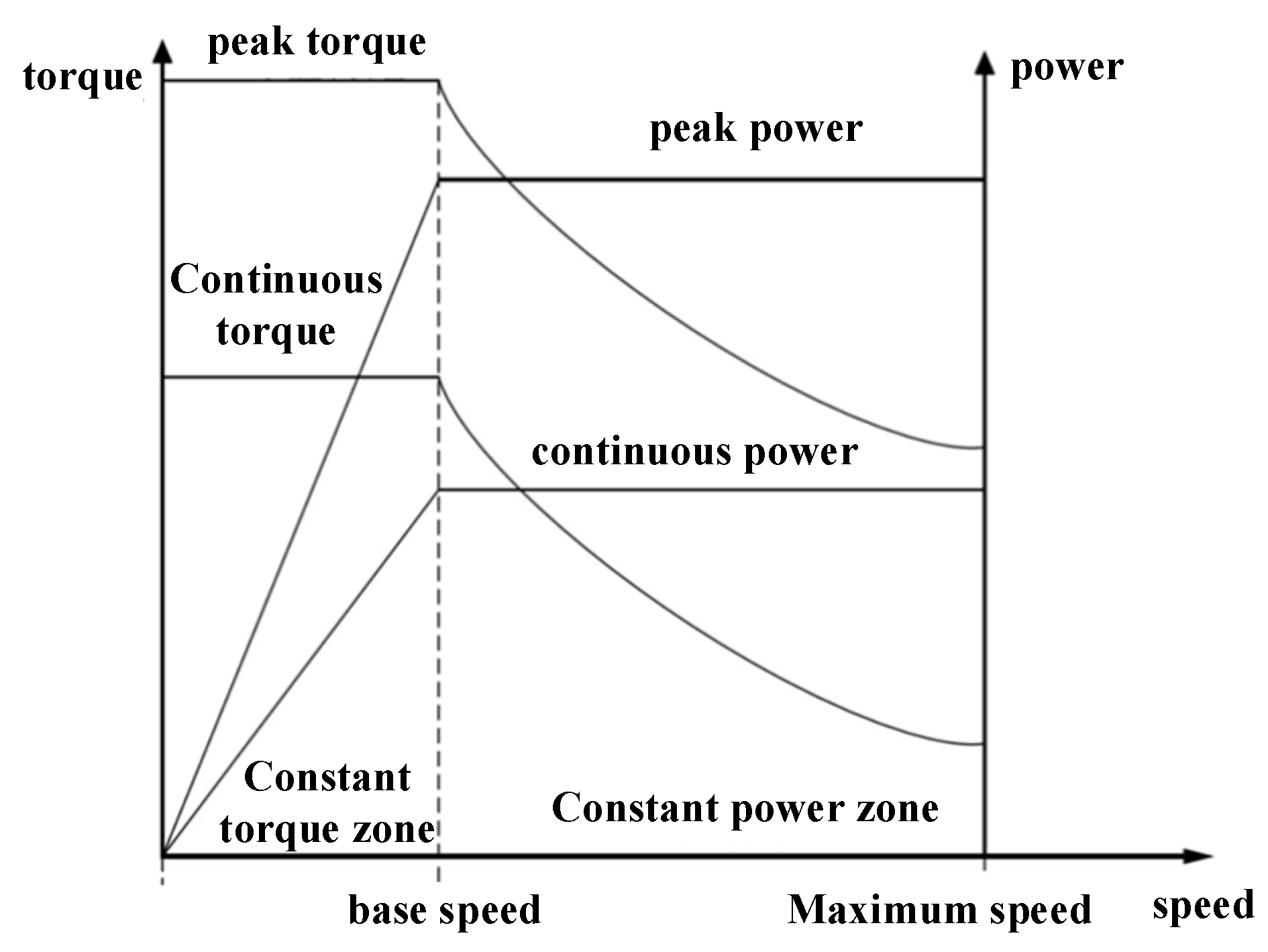

3.2. Calculation of Driving Motor Parameters

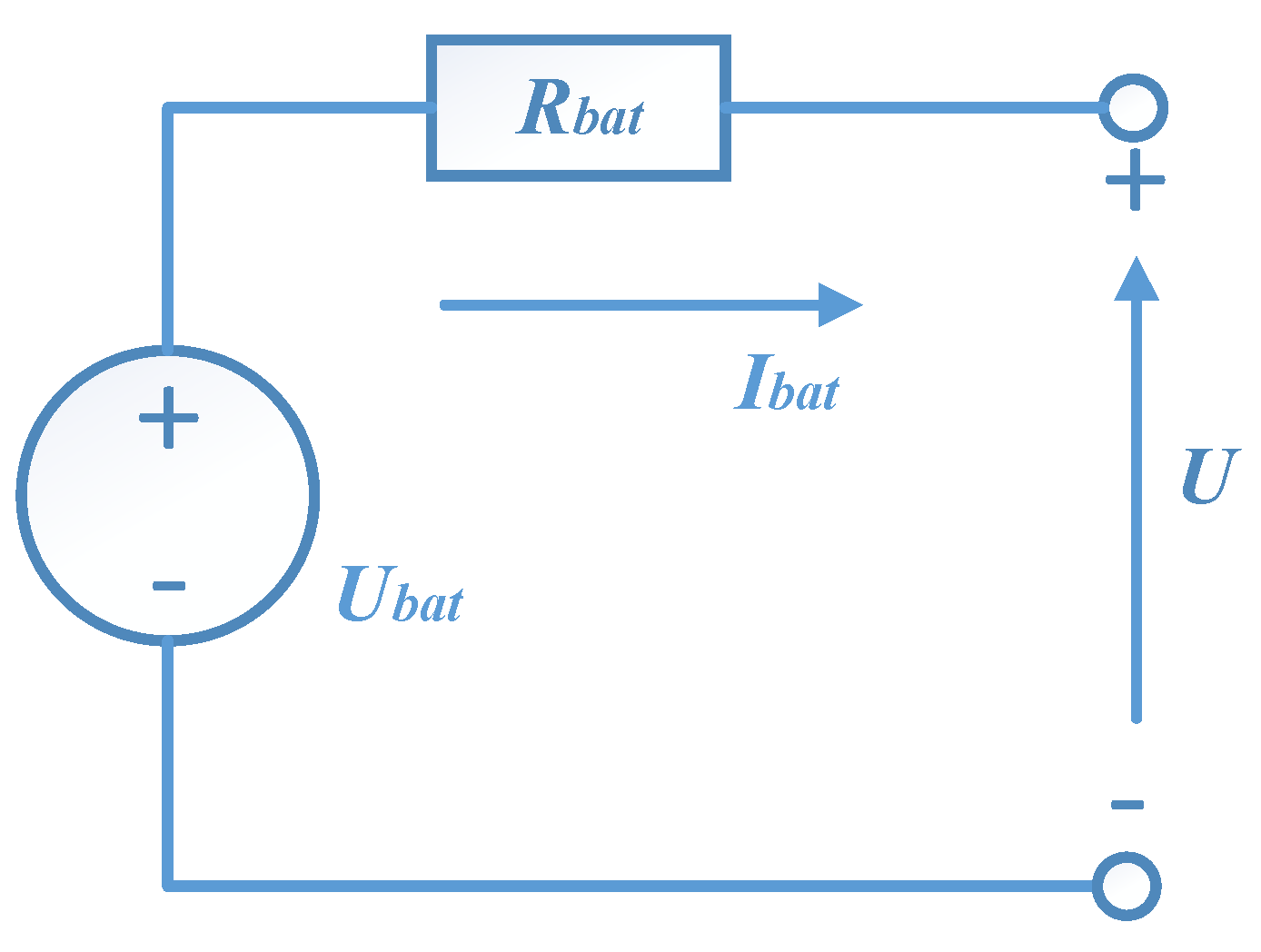

3.3. Power Battery Model

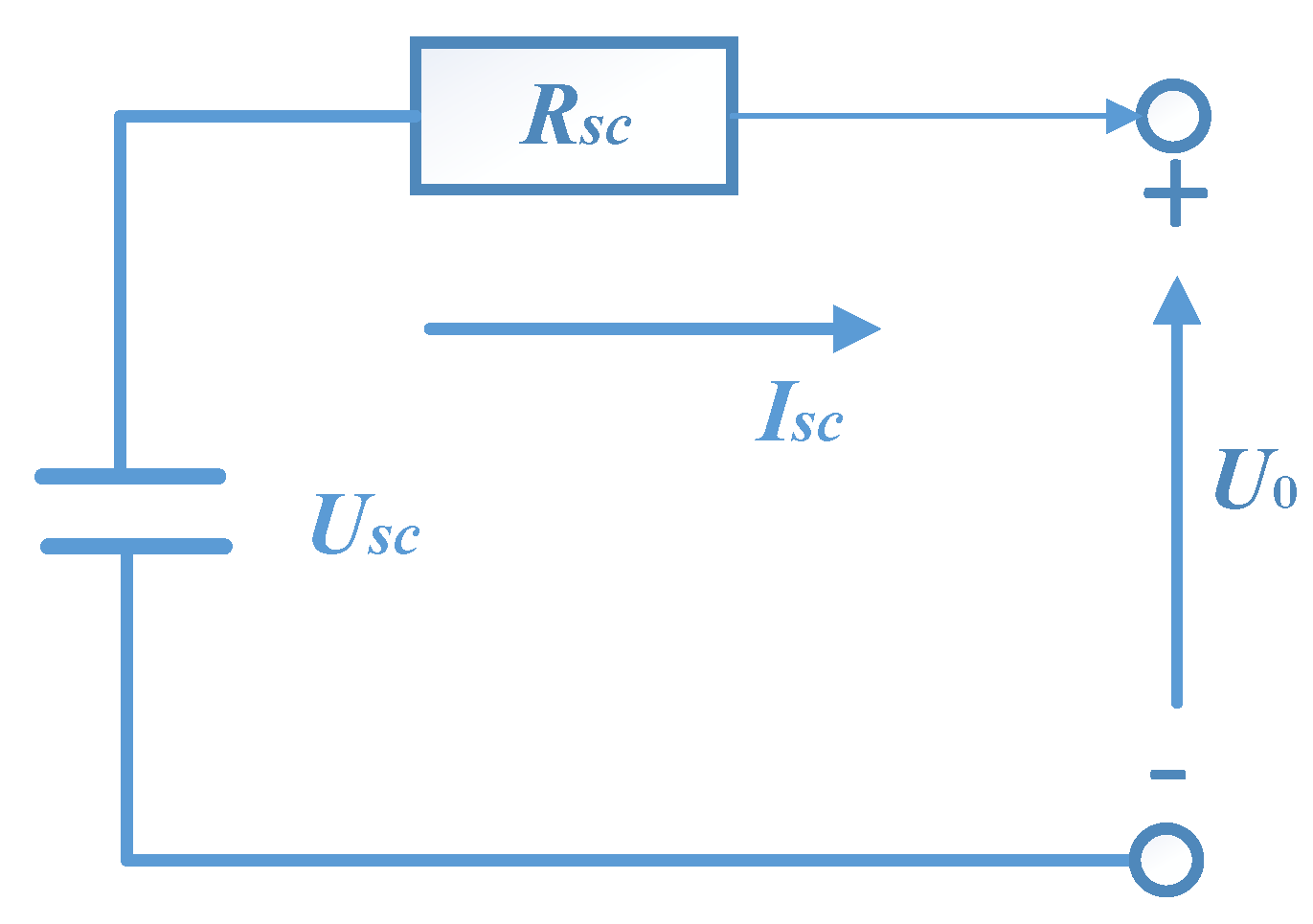

3.4. Super Capacitor Model

3.5. The Main Parameters of the Vehicle

3.6. Establishment of a Vehicle Energy Management Model

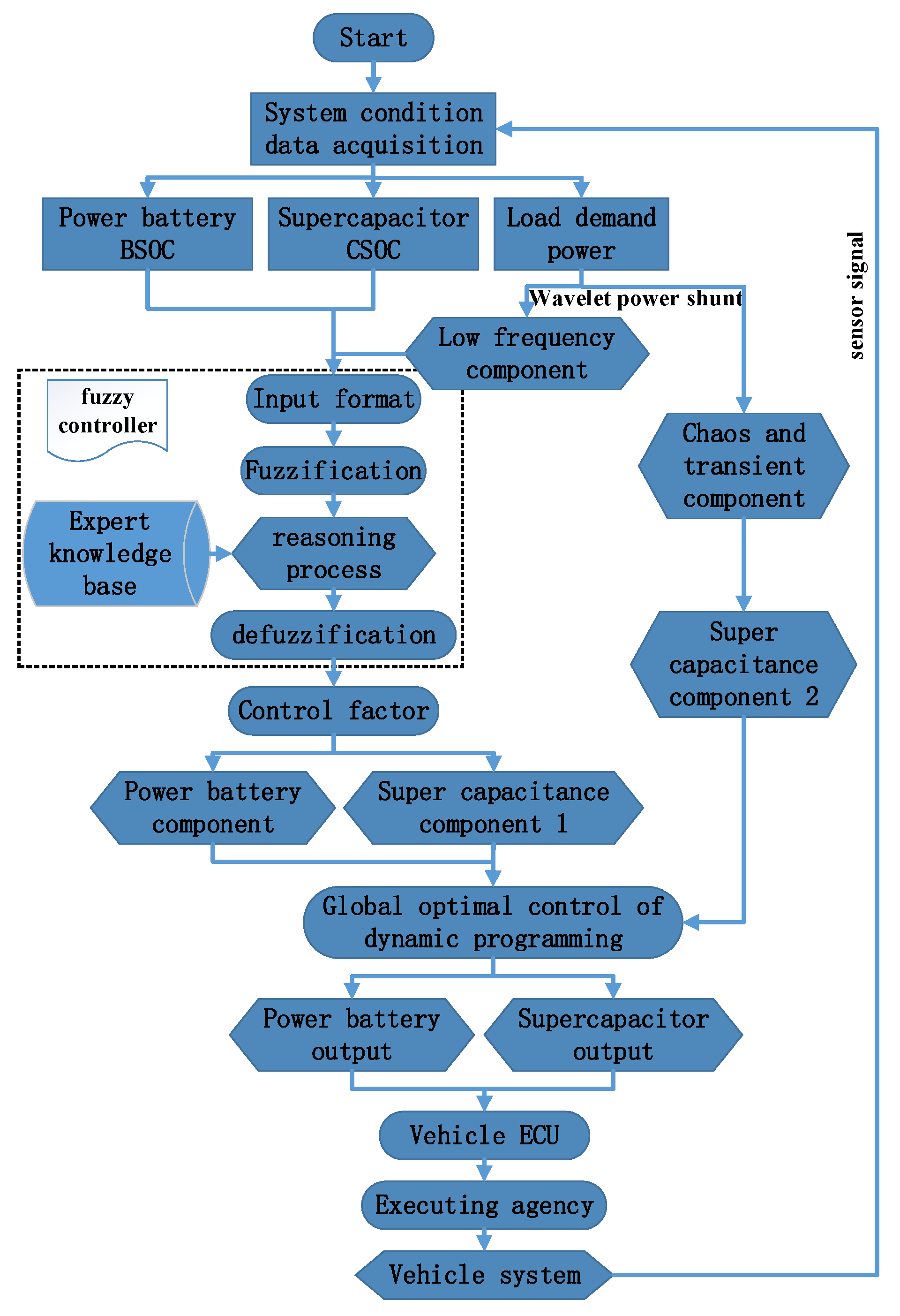

4. Composite Power Energy Management Strategy

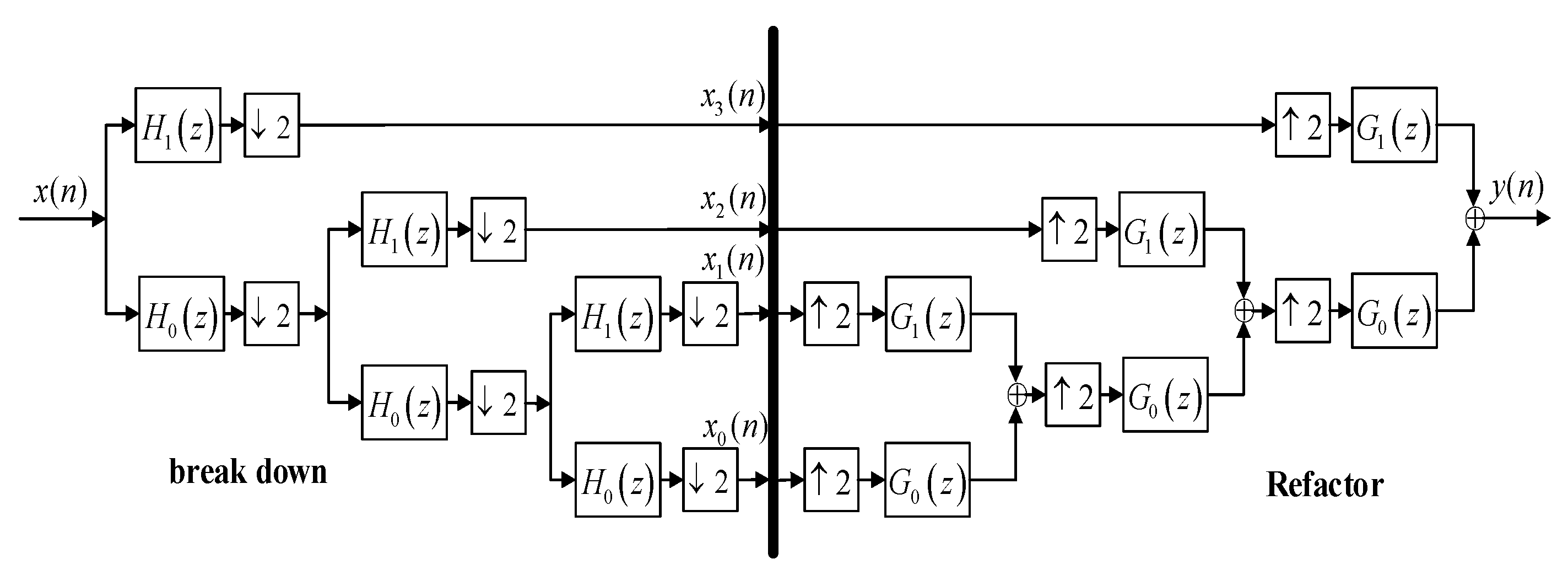

4.1. Power Split Based on Haar Wavelet Theory

4.2. Fuzzy Logic Control Scheme

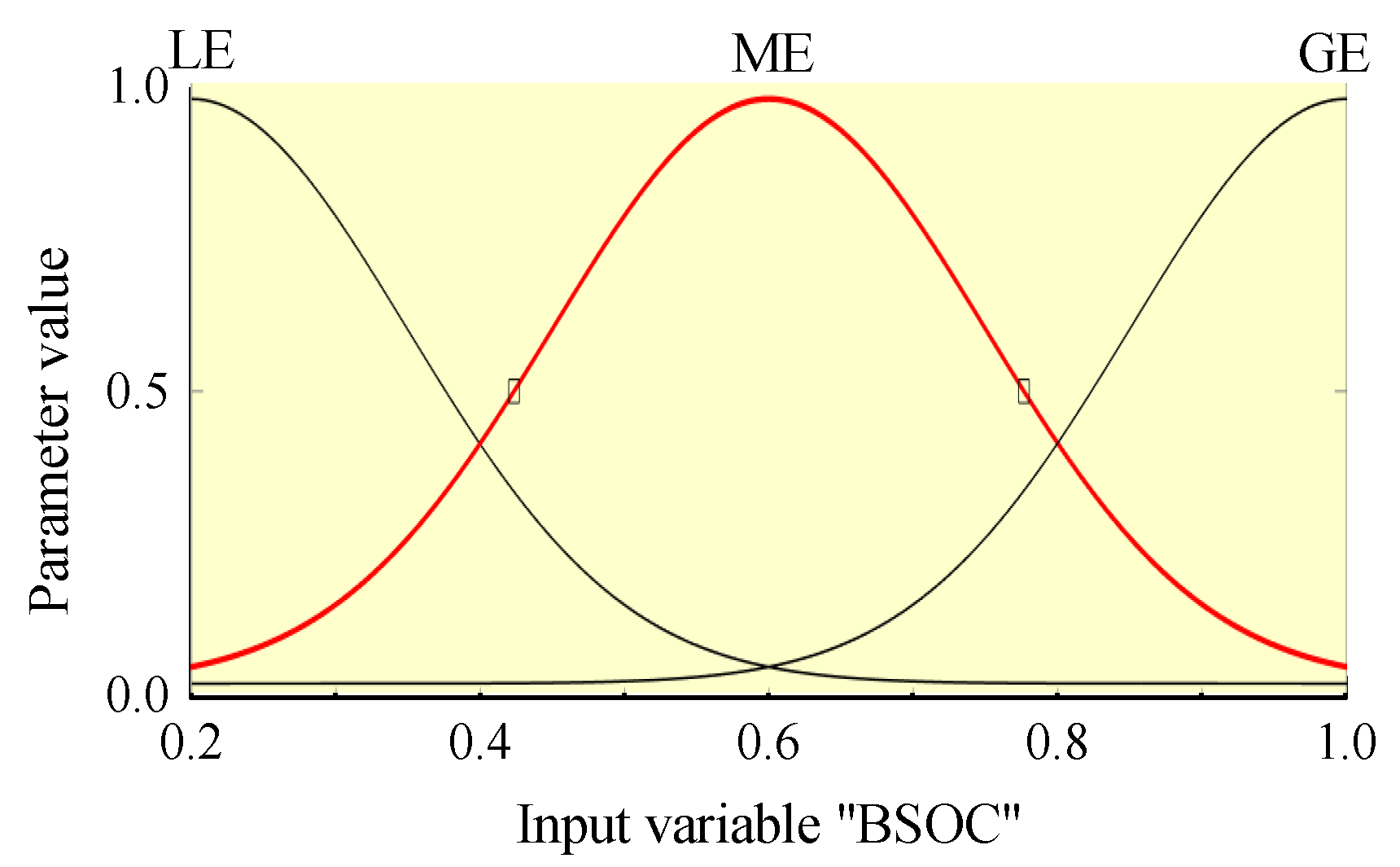

4.3. Fuzzy Controller Design

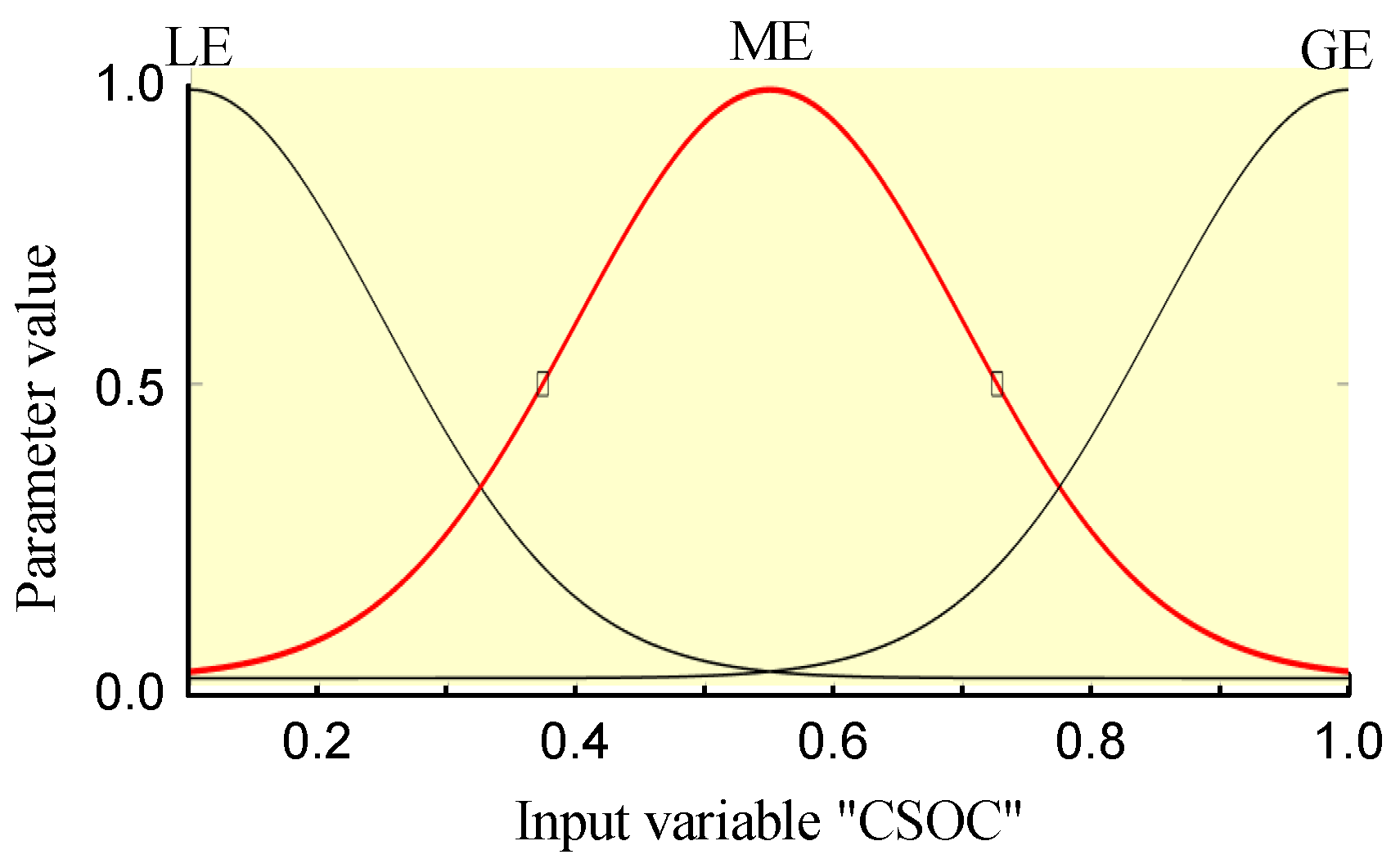

4.3.1. The Domain of Control Variables and the Determination of Fuzzy Subsets

4.3.2. Determination of Membership Function

4.4. Fuzzy Rule Establishment

- (1)

- When the super capacitor CSOC is high, if the BSOC is low and is not very high, the super capacitor solely provides power. If is high, regardless of the power battery BSOC level, both the power battery and the super capacitor provide the power for the vehicle.

- (2)

- When the super capacitor CSOC is in an intermediate state, if is low, either the power battery or the super capacitor shares the power output. If the BSOC is low and the CSOC is high, the super capacitor supplies energy independently. If is high, then both the power battery and super capacitor together carry out energy output.

- (3)

- When the CSOC is low, irrespective of the level, all energy is supplied by the power battery. When the power demand of the vehicle is small and the power battery has sufficient power, the battery can provide energy to the super capacitor to supplement its necessary power.

- (4)

- When is less than 0, it is the braking energy recovery mode, and the super capacitor is used for braking energy recovery. The control strategy is formulated differently according to the SOC value of the power battery and the SOC value of the super capacitor: if the CSOC is relatively low, the super capacitor recovers the braking energy and charges the power battery after it is fully charged; if the BSOC is low and the CSOC is high, the energy recovered by the super capacitor will charge the power battery; if the BSOC and CSOC are both high, the super capacitor and the power battery are allowed to be appropriate charge.

4.5. Fuzzy Control System Model

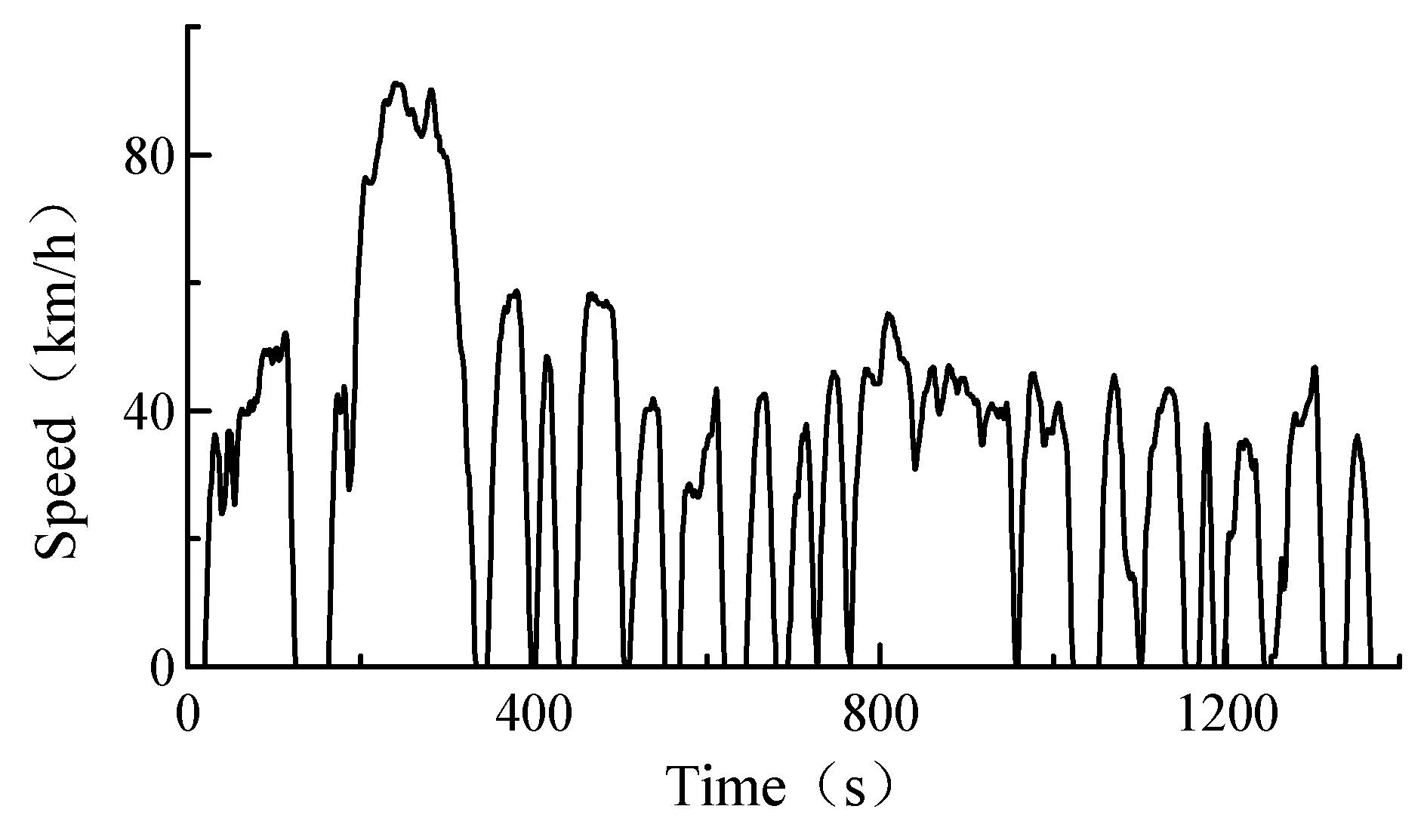

5. Simulation Analysis of Control Strategy

5.1. Wavelet Theory Power Split

5.2. Fuzzy Logic Control Simulation

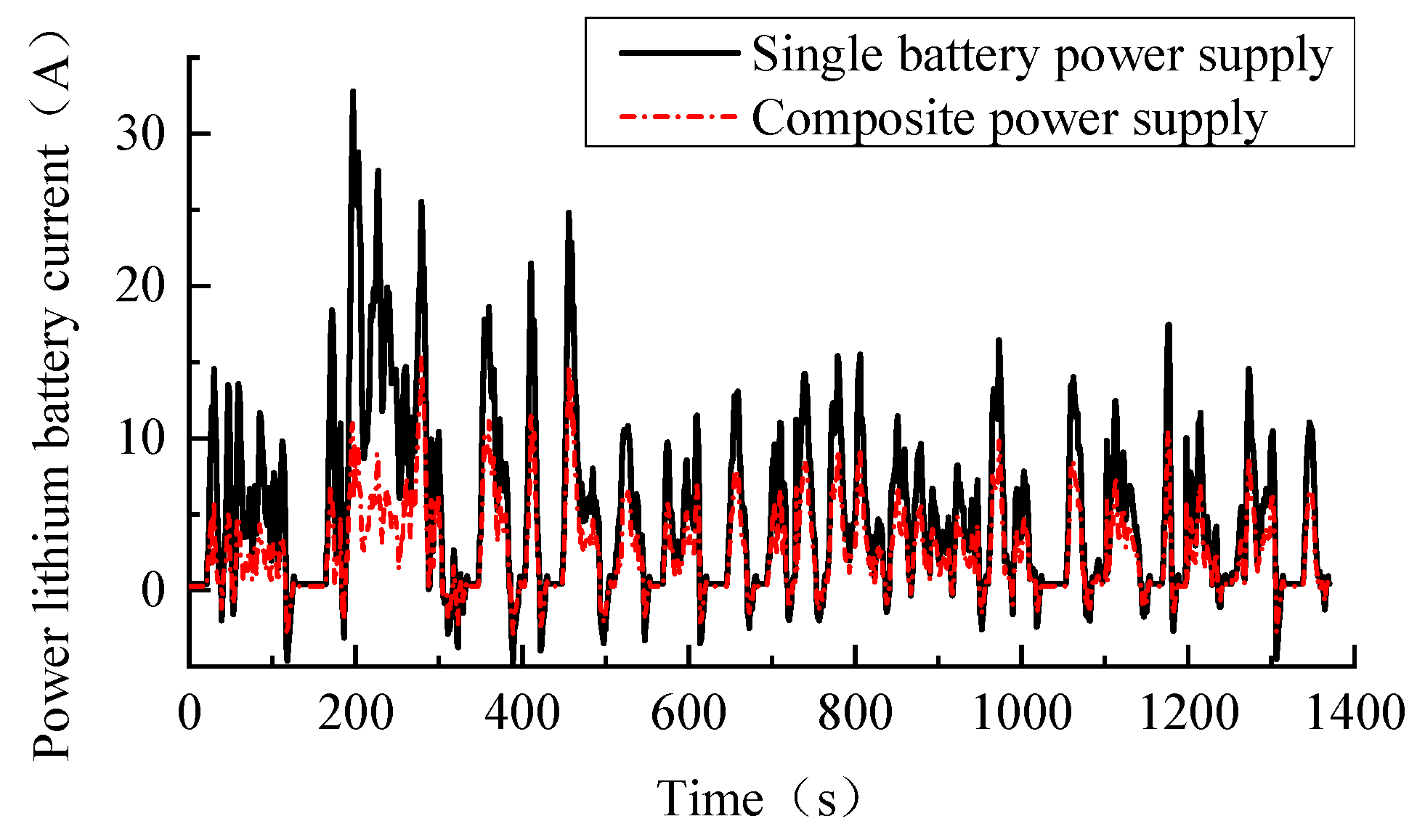

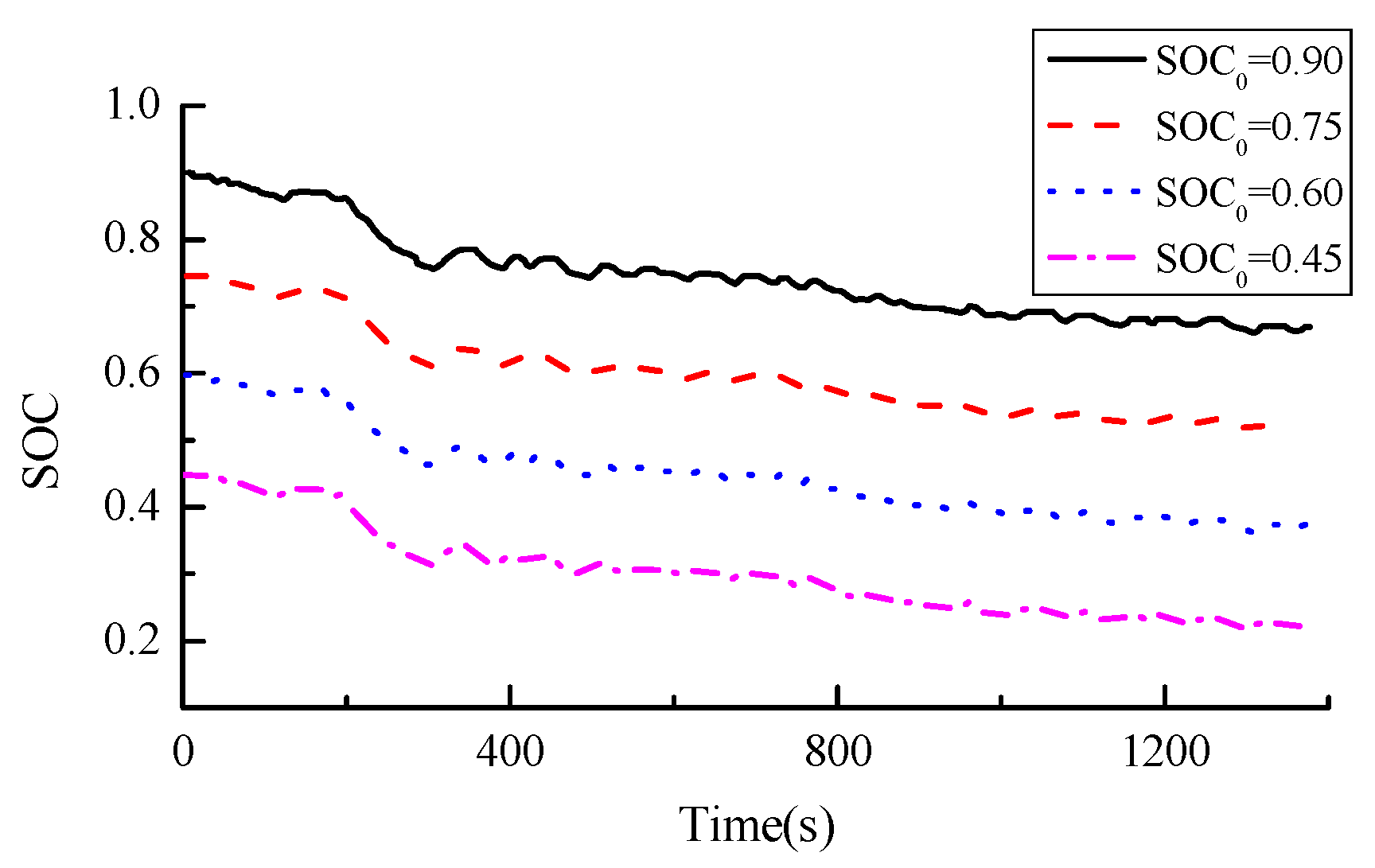

5.2.1. Comparative Analysis of Power Battery SOC and Current Value

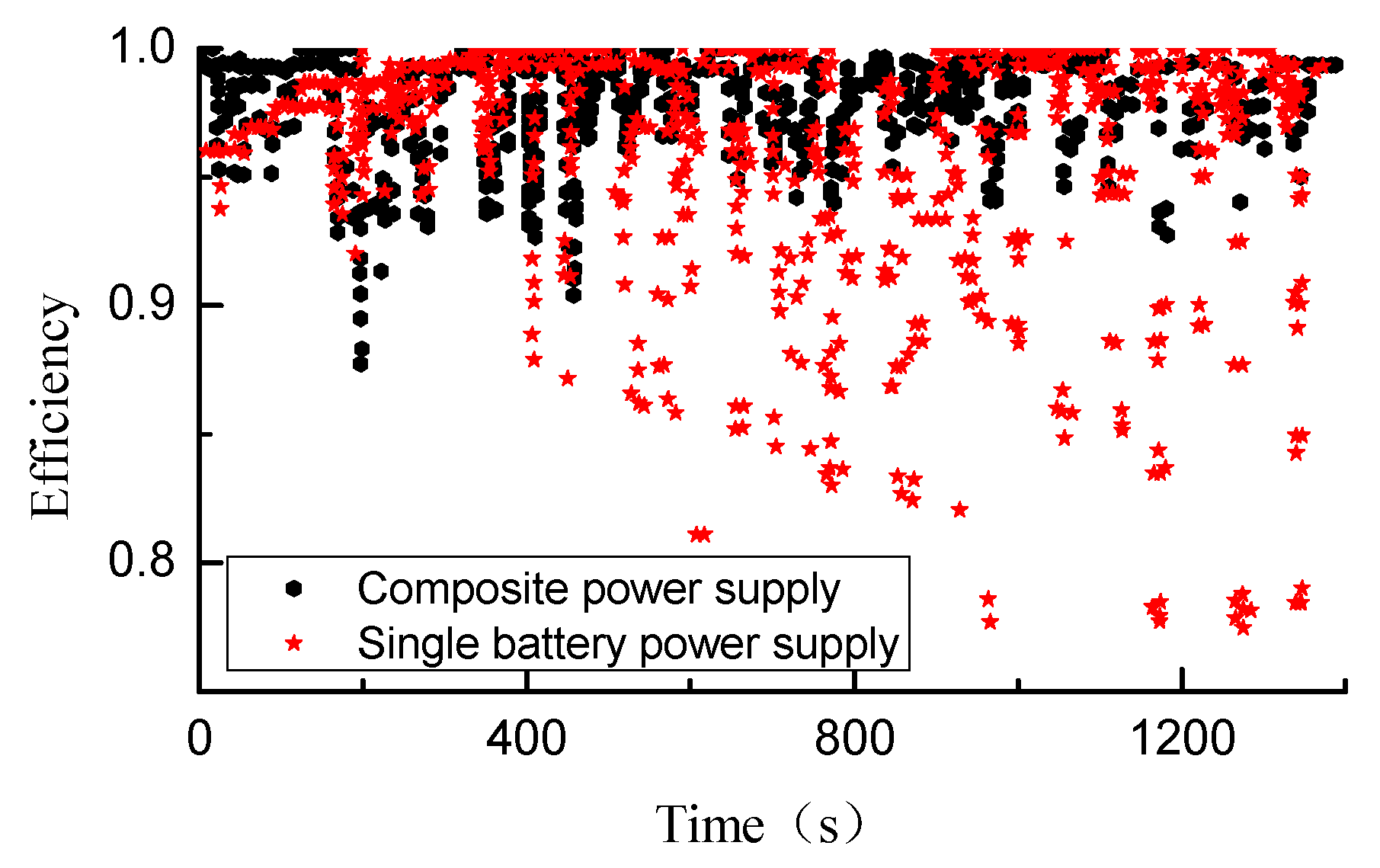

5.2.2. Comparative Analysis of Discharge Efficiency

6. Optimizing the Control Strategy Based on the Dynamic Programming Algorithm

6.1. Optimize the Objective Function

6.2. Optimization Constraint Problems and Solutions

6.3. Comparative Analysis of Optimization Results

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| SOC | State of Charge of the Power Battery |

| MGs | Microgrids |

| S.E. | Hub Smart Energy Hub |

| IDSM | Integrated Demand Side Management |

| CC | Cloud Computing |

| SC | Super Capacitor |

| NE | Nash Equilibrium |

| DRL | Deep Reinforcement Learning |

| ATSAC | Automatic Tuned Soft Actor-critic |

| HEV | Hybrid Electric Vehicle |

| LiB | Lithium-ion Battery |

| PMSM | Permanent Magnet Synchronous Motor |

| PWM | Pulse Width Modulation |

| BSOC | Battery State of Charge |

| CSOC | Super Capacitor State of Charge |

| UDDS | Urban Dynamometer Driving Schedule |

| DP | Dynamic Programming |

| ECU | Electronic Control Unit |

References

- Lin, Y. Research on Fuzzy Control of Energy Management of Dual Energy Source Pure Electric Vehicles; Chang’an University: Xi’an, China, 2021. [Google Scholar]

- Zhang, C. Research on Matching and Control Theory of Pure Electric Vehicle Composite Power Supply; Jilin University: Changchun, China, 2017. [Google Scholar]

- Liu, T.; Tan, W.; Tang, X.; Zhang, J.; Xing, Y.; Cao, D. Driving Conditions-driven Energy Management Strategies for Hybrid Electric Vehicles: A Review. Renew. Sustain. Energy Rev. 2021, 151, 111521. [Google Scholar] [CrossRef]

- Barresi, M.; Colnago, S.; Ferri, E. Sizing and Energy Management Strategy of a Hybrid Energy Storage System for EVs. In Proceedings of the IEEE Vehicle Power and Propulsion Conference (VPPC), Merced, CA, USA, 1–4 November 2022; pp. 1–6. [Google Scholar]

- Tang, X.; Chen, J.; Liu, T.; Qin, Y.; Cao, D. Distributed Deep Reinforcement Learning-based Energy and Emission Management Strategy for Hybrid Electric Vehicles. IEEE Trans. Veh. Technol. 2021, 70, 9922–9934. [Google Scholar] [CrossRef]

- Sun, H.; Fu, Z.; Tao, F.; Zhu, L.; Si, P. Data-driven Reinforcement-learning-based Hierarchical Energy Management Strategy for Fuel Cell/Battery/Ultracapacitor Hybrid Electric Vehicles. J. Power Sources 2020, 455, 227964. [Google Scholar] [CrossRef]

- Geng, W.; Lou, D.; Wang, C.; Zhang, T. A Cascaded Energy Management Optimization Method of Multimode Power-split Hybrid Electric Vehicles. Energy 2020, 199, 117224. [Google Scholar] [CrossRef]

- Sina, B.; Mehdi, N.; Glareh, A.; Matthew, J.R. The Plugin Hybrid Electric Vehicle Routing Problem: A Power-management Strategy Model. Transp. Res. Part C 2020, 111, 318–333. [Google Scholar]

- Wu, X.; Gu, Y.; Mjia, X. Adaptive Energy Management Strategy for Extended-range Electric Vehicle Based on Micro-trip Identification. IEEE Access 2020, 8, 176555–176564. [Google Scholar] [CrossRef]

- Fakir, C.E.; Idrissi, Z.E.; Lassioui, A.; Fatima, Z.B.; Gaouzi, K.; Fadil, H.E.; Aziz, R. Adaptive Nonlinear Control of Salient-pole PMSM for Hybrid Electric Vehicle Applications: Theory and Experiments. World Electr. Veh. J. 2023, 14, 30. [Google Scholar] [CrossRef]

- Zhang, S.; Zhuan, X. Study on Adaptive Cruise Control Strategy for Battery Electric Vehicle Considering Weight Adjustment. Symmetry 2019, 11, 1516. [Google Scholar] [CrossRef]

- Da Silva, S.F.; Eckert, J.J.; Silva, F.L.; Silva, L.C.; Dedini, F.G. Multi-objective Optimization Design and Control of Plug-in Hybrid Electric Vehicle Powertrain for Minimization of Energy Consumption, Exhaust Emissions and Battery Degradation. Energy Convers. Manag. 2021, 234, 113909. [Google Scholar] [CrossRef]

- Li, J.; Wu, X.; Xu, M.; Liu, Y. A Real-time Optimization Energy Management of Range Extended Electric Vehicles for Battery Lifetime and Energy Consumption. J. Power Sources 2021, 498, 229939. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, T.; Hong, J.; Zhang, H.; Yang, J.; Jia, Q. Double Deep Q-network Guided Energy Management Strategy of a Novel Electric-hydraulic Hybrid Electric Vehicle. Energy 2023, 269, 126858. [Google Scholar] [CrossRef]

- Joud, L.; Da Silva, R.; Chrenko, D.; Kéromnès, A.; Le Moyne, L. Smart Energy Management for Series Hybrid Electric Vehicles Based on Driver Habits Recognition and Prediction. Energies 2020, 13, 2954. [Google Scholar] [CrossRef]

- Zhang, R.; Tao, J.; Zhou, H. Fuzzy Optimal Energy Management for Fuel Cell and Super Capacitor Systems Using Neural Network Based Driving Pattern Recognition. IEEE Trans. Fuzzy Syst. 2019, 27, 45–57. [Google Scholar] [CrossRef]

- Thirugnanam, K.; El Moursi, M.S.; Khadkikar, V. Energy Management of Grid Interconnected Multi-microgrids Based on P2P Energy Exchange: A data driven approach. IEEE Trans. Power Syst. 2020, 36, 1546–1562. [Google Scholar] [CrossRef]

- Sheikhi, A.; Rayati, M.; Bahrami, S. Integrated Demand Side Management Game in Smart Energy Hubs. IEEE Trans. Smart Grid 2015, 6, 675–683. [Google Scholar] [CrossRef]

- Wang, K.; Wang, W.; Wang, L.; Li, L. An Improved SOC Control Strategy for Electric Vehicle Hybrid Energy Storage Systems. Energies 2020, 13, 5297. [Google Scholar] [CrossRef]

- Corinaldesi, C.; Lettner, G.; Schwabeneder, D.; Ajanovic, A.; Auer, H. Impact of Different Charging Strategies for Electric Vehicles in an Austrian Office Site. Energies 2020, 13, 5858. [Google Scholar] [CrossRef]

- Xu, B.; Rathod, D.; Zhang, D.; Yebi, A.; Zhang, X.; Li, X.; Filipi, Z. Parametric Study on Reinforcement Learning Optimized Energy Management Strategy for a Hybrid Electric Vehicle. Appl. Energy 2020, 259, 114200. [Google Scholar] [CrossRef]

- Zhou, W.; Yang, L.; Cai, Y.; Ying, T. Dynamic programming for new energy vehicles based on their work modes Part II: Fuel cell electric vehicles. J. Power Sources 2018, 407, 92–104. [Google Scholar] [CrossRef]

- Yi, F.; Lu, D.; Wang, X.; Pan, C.; Tao, Y.; Zhou, J.; Zhao, C. Energy Management Strategy for Hybrid Energy Storage Electric Vehicles Based on Pontryagin’s Minimum Principle Considering Battery Degradation. Sustainability 2022, 14, 1214. [Google Scholar] [CrossRef]

- Lü, X.; Wu, Y.; Lian, J.; Zhang, Y.; Chen, C.; Wang, P.; Meng, L. Energy management of hybrid electric vehicles: A review of energy optimization of fuel cell hybrid power system based on genetic algorithm. Energy Convers. Manag. 2020, 205, 112474. [Google Scholar] [CrossRef]

- Rezaei, A.; Burl, J.B.; Zhou, B.; Rezaei, M. A new real-time optimal energy management strategy for parallel hybrid electric vehicles. IEEE Trans. Control. Syst. Technol. 2017, 27, 830–837. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, H.; Khajepour, A.; He, H.; Ji, J. Model predictive control power management strategies for HEVs: A review. J. Power Sources 2017, 341, 91–106. [Google Scholar] [CrossRef]

- Li, G.; Gorges, D. Ecological Adaptive Cruise Control and Energy Management Strategy for Hybrid Electric Vehicles Based on Heuristic Dynamic Programming. IEEE Trans. Intell. Transp. Syst. 2019, 20, 3526–3535. [Google Scholar] [CrossRef]

- Li, T.; Liu, H.; Wang, H.; Yao, Y. Hierarchical predictive control-based economic energy management for fuel cell hybrid construction vehicles. Energy 2020, 198, 117327. [Google Scholar] [CrossRef]

- Yang, C.; Zha, M.; Wang, W.; Liu, K.; Xiang, C. Efficient Energy Management Strategy for Hybrid Electric Vehicles/Plug-in Hybrid Electric Vehicles: Review and Recent Advances under Intelligent Transportation System. IET Intell. Transp. Syst. 2020, 14, 702–711. [Google Scholar] [CrossRef]

- Liu, Z.E.; Li, Y.; Zhou, Q.; Li, Y.; Shuai, B.; Xu, H.; Hua, M.; Tan, G.; Xu, L. Deep Reinforcement Learning based Energy Management for Heavy Duty HEV considering Discrete-Continuous Hybrid Action Space. IEEE Trans. Transp. Electrif. 2024. [Google Scholar] [CrossRef]

- Yan, F.; Wang, J.; Du, C.; Hua, M. Multi-Objective Energy Management Strategy for Hybrid Electric Vehicles Based on TD3 with Non-Parametric Reward Function. Energies 2023, 16, 74. [Google Scholar] [CrossRef]

- Kyriakou, D.G.; Kanellos, F.D.; Ipsakis, D. Multi-agent-based real-time operation of microgrids employing plug-in electric vehicles and building prosumers. Sustain. Energy Grids Netw. 2024, 37, 101229. [Google Scholar] [CrossRef]

- Kanellos, F.D. Optimal scheduling and real-time operation of distribution networks with high penetration of plug-in electric vehicles. IEEE Syst. J. 2020, 15, 3938–3947. [Google Scholar] [CrossRef]

- Randive, V.; Subramanian, S.C.; Thondiyath, A.J.E. Design and Analysis of a Hybrid Electric Powertrain for Military Tracked Vehicles. Energy 2021, 229, 120768. [Google Scholar] [CrossRef]

- Guo, Y.F.; Chen, H.C.; Wang, F.C. The Development of a Hybrid PEMFC Power System. Int. J. Hydrogen Energy 2015, 40, 4630–4640. [Google Scholar] [CrossRef]

- Song, Z.; Hofmann, H.; Li, J.; Han, X.; Zhang, X.; Ouyang, M. A Comparison Study of Different Semi-active Hybrid Energy Storage System Topologies for Electric Vehicles. J. Power Sources 2015, 274, 400–411. [Google Scholar] [CrossRef]

- Muñoz, P.M.; Correa, G.; Gaudiano, M.E.; Fernández, D. Energy Management Control Design for Fuel Cell Hybrid Electric Vehicles Using Neural Networks. Int. J. Hydrogen Energy 2017, 42, 28932–28944. [Google Scholar] [CrossRef]

- Jiang, Y. Research on Optimal Control Strategy of Dual Energy System for Pure Electric Vehicle Based on ADVISOR; Guilin University of Electronic Technology: Guilin, China, 2018. [Google Scholar]

- Snoussi, J.; Ben Elghali, S.; Benbouzid, M.; Mimouni, M.F. Auto-Adaptive Filtering-Based Energy Management Strategy for Fuel Cell Hybrid Electric Vehicles. Energies 2018, 11, 2118. [Google Scholar] [CrossRef]

- Kakouche, K.; Rekioua, T.; Mezani, S.; Oubelaid, A.; Rekioua, D.; Blazek, V.; Prokop, L.; Misak, S.; Bajaj, M.; Ghoneim, S.S.M. Model Predictive Direct Torque Control and Fuzzy Logic Energy Management for Multi Power Source Electric Vehicles. Sensors 2022, 22, 5669. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Chen, W.; Liu, Z.; Li, M. Development of Energy Management System Based on a Power Sharing Strategy for a Fuel Cell-battery-super Capacitor Hybrid Tramway. J. Power Sources 2015, 279, 267–280. [Google Scholar] [CrossRef]

- Kakouche, K.; Oubelaid, A.; Mezani, S.; Rekioua, D.; Rekioua, T. Different Control Techniques of Permanent Magnet Synchronous Motor with Fuzzy Logic for Electric Vehicles: Analysis, Modelling, and Comparison. Energies 2023, 16, 3116. [Google Scholar] [CrossRef]

- Mehmet-Ugras, C.; Tahsin, K. A Comprehensive Review on Estimation Strategies Used in Hybrid and Battery Electric Vehicles. Renew. Sustain. Energy Rev. 2015, 42, 517–531. [Google Scholar]

- De Nunzio, G.; Gharbia, I.B.; Sciarretta, A. A General Constrained Optimization Framework for the Eco-routing Problem: Comparison and Analysis of Solution Strategies for Hybrid Electric Vehicles. Transp. Res. Part C 2021, 123, 102935. [Google Scholar] [CrossRef]

- Ou, K.; Yuan, W.W.; Choi, M.; Yang, S.; Jung, S.; Kim, Y.B. Optimized Power Management Based on Adaptive-PMP Algorithm for Stationary PEM Fuel Cell/Battery Hybrid System. Int. J. Hydrogen Energy 2018, 43, 15433–15444. [Google Scholar] [CrossRef]

| Parameter Type | Parameter Name | Parameter |

|---|---|---|

| Whole vehicle | Curb weight/kg | 1200 |

| Windward area/m2 | 1.9 | |

| Dynamic | maximum speed (km/h) | 180 |

| Maximum grade (20 km/h) | 30% | |

| 0–50 km/h acceleration time/s | 8 | |

| Economical | Recharge mileage/km | 200 |

| Motor (power device) | Working voltage/V | 300 |

| Peak power/Kw | 83 | |

| Rated power/kW | 46 | |

| Maximum torque/(Nc·m) | 264 | |

| Rated torque/(N·m) | 88 | |

| Power battery (power device) | Number of batteries | 72 × 2 |

| Single rated capacity/Ah | 60 | |

| Battery pack voltage | 302.4 | |

| Super capacitor (power device) | Quantity | 52 |

| Single rated voltage | 2.7 | |

| capacity/Ah | 55 | |

| Other parameters | Tire size | 175/70 R14 |

| Level | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|

| fuzzy language | NB | NM | NS | ZE | PS | PM | PB |

| Level | 1 | 2 | 3 |

|---|---|---|---|

| fuzzy language | LE | ME | GE |

| Level | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| fuzzy language | LE | ML | ME | MB | GE |

| NB | NM | NS | ZE | PS | PM | PB | ||

|---|---|---|---|---|---|---|---|---|

| BSOC (CSOC = LE) | LE | ME | ME | ML | LE | MB | MB | MB |

| ME | ML | ML | LE | LE | GE | GE | MB | |

| GE | LE | LE | LE | LE | GE | GE | GE | |

| BSOC (CSOC = ME) | LE | MB | ME | ML | LE | ML | LE | ML |

| ME | ME | ML | LE | LE | ML | ME | MB | |

| GE | LE | LE | LE | LE | MB | GE | GE | |

| BSOC (CSOC = GE) | LE | GE | GE | GE | LE | LE | LE | ML |

| ME | MB | ML | ML | LE | LE | ML | ME | |

| GE | ML | LE | LE | LE | LE | ME | MB | |

| Initial Value of SOC | Electricity Consumption per Hundred Kilometers (kWh/100 km) | Comparison Result | |

|---|---|---|---|

| Fuzzy Control of Composite Power Supply | Dynamic Planning of Composite Power Supply | ||

| SOC = 0.90 | 11.101 | 9.469 | decrease 1.632 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Tang, J.; Zhang, J.; Zhang, T. Research on Energy Hierarchical Management and Optimal Control of Compound Power Electric Vehicle. Energies 2024, 17, 1359. https://doi.org/10.3390/en17061359

Zhang Z, Tang J, Zhang J, Zhang T. Research on Energy Hierarchical Management and Optimal Control of Compound Power Electric Vehicle. Energies. 2024; 17(6):1359. https://doi.org/10.3390/en17061359

Chicago/Turabian StyleZhang, Zhiwen, Jie Tang, Jiyuan Zhang, and Tianci Zhang. 2024. "Research on Energy Hierarchical Management and Optimal Control of Compound Power Electric Vehicle" Energies 17, no. 6: 1359. https://doi.org/10.3390/en17061359

APA StyleZhang, Z., Tang, J., Zhang, J., & Zhang, T. (2024). Research on Energy Hierarchical Management and Optimal Control of Compound Power Electric Vehicle. Energies, 17(6), 1359. https://doi.org/10.3390/en17061359