Abstract

Planning logistical processes supports the managerial processes of an enterprise, including investments such as wind farm construction. The aim of the article is to analyze and assess the time determinant in the logistical process of wind farm planning. The research method involves the analysis of a case study on the investment planning of a wind farm (WF) in Poland from 2008 to 2020. The Critical Path Method (CPM) was applied to the planning and scheduling of projects and logistical planning processes at WF Barwice. As a result of the research efforts, which included the identification of stages, time frames, critical paths, and construction conditions, the outcome is a concept for optimizing the logistical process of wind farm planning. The main problem associated with the planning of this investment was the analysis and evaluation of the environmental factors that would impact upon a positive assessment of the construction of WF Barwice. The outcome is the optimization of the time determinant in the logistical process of wind farm planning from 14 years to 10; however, legal, administrative, and environmental constraints have influenced the achieved result.

1. Introduction

Logistics is an industry consisting of process-oriented enterprises, focusing on the management of the flow of resources, both material and abstract, between the point of origin and the destination. Logistic processes bind all the activities of a company. They are primarily aimed at increasing the exchangeable and utilitarian value of products by adding spatial and temporal attributes. The spatial value means that logistic processes deliver the product to its destination, while the temporal value relates to the specific time of delivery, arising from demand. Logistic processes contribute to the transformation of products and services [1]. Contemporary logistics are based on integrated supply chains (SC). The functioning of the SC significantly influences the quality and efficiency of logistic processes in both large and small enterprises, as well as in wind farm (WF) investments. They enable the planning, coordinating, and controlling of logistic flows related to the movement of materials, finances, and information throughout the entire SC. Typical SC functions in logistics include procurement [2], warehouse management, production planning, sales and distribution, and maintenance and repairs [3]. Planning logistic processes supports the managerial processes of the enterprise, including investments such as wind farms. The improvement and analysis of logistic processes can be characterized by ongoing improvements and/or the perfection of future processes. In improving logistic processes, enterprises may simultaneously apply concepts of project management, process management, and quality management. The article aims to analyze and assess the time determinant in the logistical process of planning a wind farm. The research method is the analysis of a case study of the construction of a WF in Poland in the period 2008–2020. The analysis identified factors determining the investment process, including environmental, spatial, economic, socio-cultural, political, legal-administrative, and technical-technological factors. The article presents manifestations and consequences of the lack of planning of these concepts in optimizing the logistical processes of WF, as well as possible ways of counteracting them.

2. Literature Review

Modern companies operate in conditions of increased market uncertainty and political-legal changes; therefore they must flexibly adapt to the changing conditions of the external environment [4,5]. In an era of economic development based primarily on knowledge and information, the ability to predict certain events and adjust the company’s policy accordingly is especially important. A process, as a sequence of repeatable activities focused on a specific customer (recipient), is considered a logistic process if the distribution, state, and flows of its components require coordination with other processes, due to criteria of location, time, costs, and efficiency in achieving the desired goals of the organization [6,7,8]. All logistic processes in organizations require coordination, but they are mainly focused on activities and information flow. What distinguishes logistic processes from others is the need for coordination of flows, states, and distribution [9]. Logistics processes include not only the flow of goods but also the flow of information and financial resources. Bozarth and Handfield have identified three types of logistic processes [10,11]:

- executive processes comprising activities of high added value performed by the organization, for which the customer is willing to pay,

- supporting processes, comprising necessary activities that do not have added value,

- development processes aimed at improving executive and supporting processes.

The risks of logistic processes refer to the probability of an event that may adversely affect the process of achieving the company’s goals [12,13,14], such as exceeding a deadline. In planning, the systematic identification and analysis of risk affecting logistic processes and their productivity seem necessary to ensure the survival and competitiveness of the company. In addition to achieving goals, risk assessment can also contribute to the improvement of the company’s business processes [15,16,17,18]. Control and improvement of only individual logistic processes and only in selected organizational units (departments, divisions) provide local, not global effects [19].

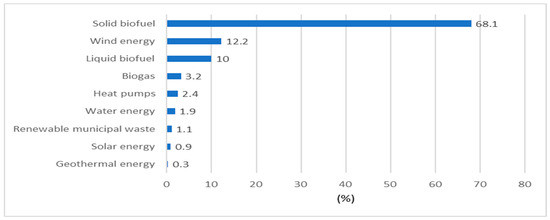

The Polish energy system is primarily based on the use of fossil fuels such as hard coal, lignite, crude oil, and natural gas. Their popularity was due to their low cost, the general availability of the raw material, as well as its high calorific value and well-mastered extraction technology [20]. The armed conflict between Russia and Ukraine, along with the changes imposed by the European Union in obtaining energy from renewable sources (RES), have led to a search for new energy acquisition options. The European Union classifies renewable energy sources as energy produced: (i) from wind on land and at sea, (ii) from the sun, mainly using photovoltaic panels (PV), (iii) from biomass and biogas, and (iv) from water flows and wave motion, as well as sea tides [21,22] (Figure 1).

Figure 1.

Obtaining energy from renewable sources in Poland in 2018 (%) [23].

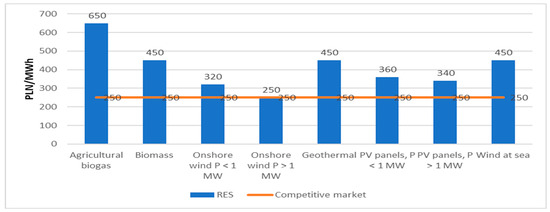

Renewable energy sources (RES), due to their costs, could not appear in a competitive market, hence the need for a system of various kinds of subsidies. An additional stimulus for the development of RES in European Union countries is one of the goals set by the European Commission. The reference prices for energy from RES in relation to the prices for electricity on the exchange in 2020 are presented in Figure 2.

Figure 2.

References princes of energy at RES auctions in 2020 (PLN/MWh) [24].

In 2020, energy produced from RES was to account for 20% of the energy consumed by end users. This target was raised to 30% by 2030, and it can be expected that these goals will increase in the coming decades. The development of renewable sources in Poland depends on the subsidy system. In the first period, from 2005 to 2015, a certificate system was used, whereby the producer of renewable energy from a certified installation introduced any possible amount of energy into the power grid. The introduced energy was sold on the free market or to companies obliged to purchase such energy. Additionally, the RES producer received a green certificate, which was a financial instrument. Electricity trading companies had to acquire green certificates in proportion to their turnover. The prices of energy from RES were 2–2.5 times higher than market prices. Such high prices resulted in rapid investments in RES and an excess of production. According to the Energy Market Agency, the capacity of RES in Poland at the end of June 2023 exceeded 25 GW [25]. This means that RES already accounts for about 40% of the total installed capacity in Poland, which is 63 GW. It is also significant that the total capacity of all renewable sources is now greater than the capacity of all coal-fired power plants in Poland (21.5 GW) [25].

This led to a significant burden for energy consumers. The costs of subsidies for RES, implemented through the mandatory purchase system of green certificates, reached over 5 billion PLN annually [26,27,28,29]. The European Union is committed to the dynamic development of RES and the reduction of coal energy, hence the standards it established were raised in 2018. Within the European Union institution, the PRIMES program is responsible for assessing the impacts of selected energy sector programs. It creates forecasts for the energy mix of member states and determines the level of CO2 emissions. Forecasts for Poland from 2015 to 2050 predict a GDP growth of 87%. PRIMES projects that by 2050, CO2 emissions in Poland will be halved, from 13,000,000 mg/year to 5,000,000 mg/year [30].

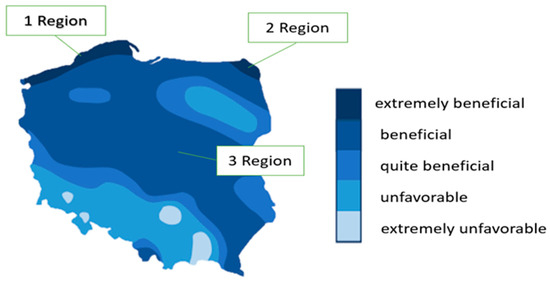

Many articles present an overview of the current state and future trends in WFs worldwide, along with technological challenges, particularly in the planning of WFs and their main components [31,32,33,34,35]. Due to the need for decarbonization of the energy sector, there is a need to replace coal sources with zero-emission sources. WF and offshore wind farms (OWF) are among the sources with the greatest potential [36]. The maximum potential for Polish OWFs is estimated at 28 GW [37]. Wind energy is considered one of the cleanest energy sources, as it does not emit harmful substances into the atmosphere during production. Finding locations with the highest potential for wind energy production is a key factor influencing the locational decision for a new WF. The higher the wind energy production, the greater the potential electricity market sales for WF owners. Regions in Poland with the highest wind energy index include: the Baltic Coast (1 Region), Suwalki Region (2 Region), and the Mazovian Plain (3 Region) (Figure 3).

Figure 3.

Wind energy zones in Poland [38].

However, power system operators value certainty when accepting energy production bids. Due to the stochastic and uncertain nature of wind resources, system operators often reduce the power of WFs, assuming that they will be able to reliably produce only about 10% of their installed capacity [23,39].

A review of the literature on the subject did not reveal the existence of publications strictly concerning the logistical process of constructing a WF. Instead, it indirectly refers to demonstrating the generated powers in various years and countries and their share in the energy mix of various economies. Additionally, some publications only address the profitability of investing in wind farms [40,41].

3. Research Methodology

WFs are becoming an increasingly popular tool for energy production. The potential for energy production in this way, classified as “green energy,” in the Szczecinek district in terms of geography (wind energy zones (Figure 3)) is very optimal (Figure 4). The WF located in the northern part of the commune, between the towns of Barwice, Lubostronie, Ostrowasy, Stary Chwalim, and Gorki, is designated for the siting of wind power plants along with additional development and accompanying infrastructure necessary for their operation.

Figure 4.

WF Barwice on the map of Poland [42],  —location of WF Barwice.

—location of WF Barwice.

—location of WF Barwice.

—location of WF Barwice.

This article is dedicated to the assessment of an existing investment (commissioned for use in 2021) and aims to analyze and evaluate the time determinant in the logistical process of planning the WF Barwice investment. To achieve this goal, a research hypothesis was formulated: It is hypothesized that the time determinant in the logistical process of planning the WF would contribute to a faster realization of the design phase. The outcome of the research, which involved the identification of stages, time frames, critical paths, and construction conditions, will be a concept for optimizing the logistical process of planning the WF. The research problem defined for the study is: To what extent can the logistical process of a WF investment be optimized? The research method employed in this paper is a case study analysis of WF investment planning in Poland from 2008 to 2020.

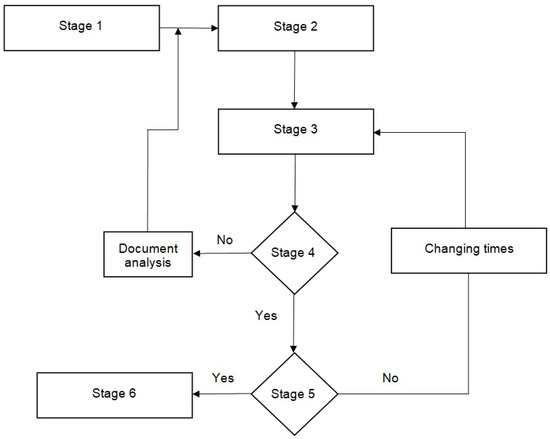

The empirical study was conducted based on the implementation of a multi-stage process, in which six stages were identified, namely:

- Stage 1. Identification of necessary stages in the implementation of wind farm construction investment

- Stage 2. Determination of the sequence of stages in the investment implementation

- Stage 3. Identification of the time required for each stage

- Stage 4. Critical path analysis

- Stage 5. Time optimization in the logistic planning process of the wind farm

- Stage 6. Evaluation of the impact of changes

The research process in a schematic representation and with consideration of dependencies between individual stages is presented in Figure 5.

Figure 5.

The schematic of the research process.

The efficient functioning of logistic processes is possible thanks to the introduction and consistent maintenance of required quality standards, supported by appropriate management concepts [43,44]. Examples of such concepts are standardized quality management systems, which, under conditions conducive to proper implementation and subsequent operation, allow for achieving many tangible benefits in the process of managing a company or the entire SC [45,46], while simultaneously contributing to the elimination of waste, the systematization of processes, increased workflow fluidity, or the reduction of unnecessary actions [47,48,49]. A key aspect in the logistics process is the use of the term “time”, and it does not necessarily mean being the fastest. Quality is of great importance for competitiveness, and replacing speed is not the main goal. The approach based on time compression focuses on how companies use time to provide a lasting and rapid response to customer needs through business processes organized around a strategic emphasis on time [50]. Planning is an activity performed in a project to anticipate existing tasks and conditions by setting goals and tasks to be achieved, and defining executive policies, programs for implementation, schedule and timing, executive and administrative-operational and budgetary procedures, and the power of the source [51]. Several methods can be applied to planning and scheduling projects and logistic processes, one of which is the Critical Path Method (CPM). In the period of ongoing projects, it is known and deterministic that CPM is a useful tool in planning and controlling complex projects like WFs across a wide range of engineering and managerial applications [52]. CPM uses networks to coordinate activities, develop schedules, and monitor project progress. By identifying activities on the critical path, the project planning approach, which divides projects into stages, describes them in diagrams, and then determines the duration of each activity, is applied. The critical path is the path that has the longest duration of all paths from the initial event to the last event on the network activity diagram [53]. CPM can be defined as a sequence of network activities of a project such as WF construction, whose sum is the longest duration. Its sequence regulates the shortest possible project completion time [54], which can be shortened already at the preparation stage. The critical path is a sequence of activities whose total duration is the longest [55]. CPM analysis indicates the shortest possible time for process completion—process time compression. Any delay in an activity on the critical path has a direct impact on the planned completion date of the undertaken actions.

To create a schedule for a project with predetermined task completion times, CPM can be used. In this method, the following time characteristics are determined:

- the earliest start time of event j:

- the latest start time of event j:

- the critical time of the project:

- the latest start time of event (i,j):

In CPM, it is necessary to define as the earliest start time of activity , as the earliest finish time of activity , as the latest start, and as the latest finish time of activity . The corresponding calculations for a node involve numbering algorithms, a forward pass (running from the first to the last node in the network), and a backward pass (running from the last node back to the first node in the network):

The forward and backward pass calculations for each activity yield several time values, which include the earliest start time, latest start time, earliest finish time, and latest finish time, respectively. Additionally, their calculations indirectly result in the slack time activity, which is the difference between the earliest and latest execution times of an activity. In effect, the slack time is the maximum time interval in which an activity can be delayed without delaying the completion of the project.

The earliest start time and the earliest finish time for each activity in the planned investment are calculated based on the forward pass, as backward calculations do not meet milestones such as obtaining environmental conditions and winning the ERO auction. The calculations take into account time constraints to minimize time reserves, followed by subtracting the activity duration time .

4. Results

4.1. Identification of the Current State

The WF Barwice, located in Poland in the West Pomeranian Voivodeship, has a total capacity of up to 48 MW. In its initial phase, it consists of a maximum of 21 wind turbines along with access roads, assembly yards, a medium voltage power cable network, telecommunications, and a MPSP power station with an overhead 110 kV line connecting the MPSP to the area ensuring the possibility of using the project—near Barwice, Stary Chwalim, Leknica, Ostrowasy.

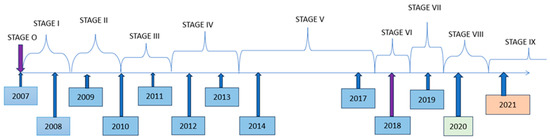

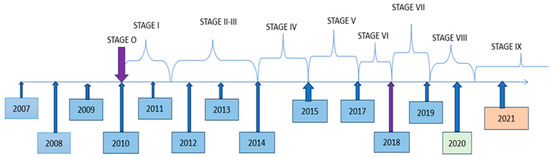

For the purpose of this study, a process was generated based on the identification of time frames for the investment planning of the WF Barwice (Figure 6).

Figure 6.

Stages of the construction process of WF Barwice.

The preliminary phase of preparing documentation for the resolution of the Barwice City Council caused an extension of the time frames in the period 2007–2010.

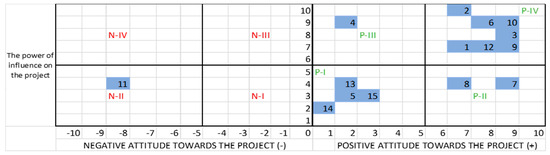

Stage 0—initiation of the logistical process and stakeholder analysis (Figure 7).

Figure 7.

Integrated matrix of stakeholders of wind, legend in Table 1.

Table 1.

Legend from Figure 7.

Table 1.

Legend from Figure 7.

| Number on the Stakeholders’ Map | Stakeholder Group |

|---|---|

| 1 | Top-level State Organization Bodies |

| 2 | Local Government Administration Bodies- Local Governments |

| 3 | Scientific Institutions in the Industry |

| 4 | Investors |

| 5 | Non-Governmental Organizations |

| 6 | Wind Farm Component Manufactures |

| 7 | Companies Providing Logistics and Transportation Services |

| 8 | Cable Installation Companies |

| 9 | Energy Conglomerates—Energy Market Operators |

| 10 | Entities that submitted location applications |

| 11 | Pro–Environmental Entities |

| 12 | Companies involved in the construction and operation process |

| 13 | Residents |

| 14 | Tourists |

| 15 | Media |

- Stage I (2007–2008)

Information about specialists dealing with environmental factors. Gathering information about the natural environment of the WF Barwice power plant location area—querying archival materials, field inspection—eco-physiographic and landscape recognition, vegetation and natural habitats survey, amphibians, reptiles, and mammals (excluding bats) recognition, as well as ornithological and chiropterological monitoring of the planned project location area and its surroundings.

- Stage II (2009–2010)

Implementation, using the expert method, of specialized assessments of the planned project’s impact on the environment, in terms of its effect on noise, electromagnetic radiation, landscape, avifauna and chiropterofauna, as well as on vegetation and natural habitats, i.e., in terms of the main impacts associated with the operation of wind power plants.

- Stage III (2010–2011)

A comprehensive assessment of the project’s impact on the environment, taking into account direct and indirect, secondary and cumulative, short-, medium-, and long-term as well as permanent and temporary effects.

A resolution of the Barwice City Council on the local spatial development plan.

A local spatial development plan for areas located in the Barwice commune, “Construction of wind power plant farms”, was adopted by Resolution No. III/14/2010 of the Barwice City Council on 30 December 2010. The initiation of the preparation of the plan was adopted by Resolution No. XIV/109/19 of the Barwice City Council on 5 December 2009.

Submission of an application for permission to implement the project.

- Stage IV (2012–2013)

Completion of the application regarding environmental conditions, to include: environmental analogy (based on the assumption of the constancy of natural laws); mathematical modeling (noise); diagnosis of the environmental condition based on field mapping as a starting point for future extrapolation; cartographic analyses; and photographic visualization (landscape).

Obtaining a decision approving the construction project and granting permission to build WF Barwice.

- Stage V (2014–2017)

WF project with consideration for oversized transport.

WF Barwice project was carried out by the special purpose company Windfarm Polska II. At the stage of the auction conducted by ERO in November 2018, the owner of this company was the German developer PNE. The plan reduced the number to 14 Siemens SWT-3.0-113 wind turbines with a total nominal capacity of 42 MW. It was anticipated that the WF would be operational by the end of 2019.

- Stage VI (2018)

The investor participated in and won the ERO auction held in November 2018 and was in a position to start construction. However, after winning the auction, just a few weeks after the successful bid in the Polish tender for wind energy projects, the Barwice project was sold to an investor at the end of 2018, and the owner of the company and the investment it carried out became Wirtgen Invest Energy GmbH.

- Stage VII (2019)

Start of construction of WF Barwice.

On 12 March 2019, construction of the wind farm began. The plan concerning the initiation of the preparation of the local spatial development plan for the areas located in the Barwice commune was adopted.

- Stage VIII (2020–2021)

Construction of the wind farm

The towers for these wind turbines were produced by GSG Towers, a company belonging to the Gdansk Shipyard, under a contract worth 5 million euros. The contract for the construction of WF Barwice was won by a consortium of companies including Erbud, PBDI, and Electrum, with a net value of 41.35 million PLN. The scope of the order for the consortium involving Erbud, PBDI, and Electrum was valued at 11.85 million PLN. Sevivon participated in the construction process from July 2019 as the construction management company. The investment was scheduled to be completed by the end of February 2020. The sale of electricity for WF Barwice was also secured by Sevivon. Wirtgen Invest Energy GmbH ordered wind towers from a Polish supplier, and Siemens Gamesa strengthened its extensive local SC. Siemens Gamesa sources components and purchases services related to wind turbines from Polish suppliers for projects both in the country and across Europe. In the local SC, the company acquires blades, power units, elements of turbine nacelles, and various plastic and metal parts used in turbine assembly. Data for the transportation of wind turbines in the logistical process:

- rotor diameter: 113.0 m; rotor area: 10,000.0 m2; number of blades: 3

- mass/weights: rotor weight: 67.0 t; nacelle weight: 78.0 t; tower weight, max.: 75.0 t; total weight: 220.0 t.

- Stage IX (2021–2051)

Exploitation of a WF

- Siemens Gamesa Renewable Energy entrusted the supply of spare parts for the serviced wind turbines to the distribution center operated by Schenker Deutschland AG in the German municipality of Gallin.

- To handle diverse loads and peak logistic periods, intralogistics consultants from STILL optimized the task-oriented fleet and short-term rental service.

4.2. Identification of Factors Determining the Planning Process

For the assessment of the time compression process in the logistical planning of WF construction, the authors defined and identified the main determinants of the planning process. The primary issues related to obtaining consent involve the analysis and assessment of environmental factors that favor a positive evaluation of the construction of WF Barwice.

The following general types of factors in wind farm energy production, which should be considered in the logistical process, can be distinguished:

- Environmental factors relate to the natural environment resources needed for economic activities, such as mineral resources and others, climatic conditions, landscape conditions, and availability of water, soils, etc. Regulations prohibit the construction of wind turbines within a distance of less than 10 H (10 times the height of the turbine) from nature protection forms—national and landscape parks, reserves, Natura 2000 areas, and promotional forest complexes (Table 2).

Table 2. Environmental factors considered in the process of constructing a WF in the vicinity of Barwice.

Table 2. Environmental factors considered in the process of constructing a WF in the vicinity of Barwice. - Spatial factors, which include terrain configuration, distances relative to other locations, available surfaces, and the shape and characteristics of the land. Individual turbines should be located within the boundaries of land properties no. 383, 371/5, 369, 311, 58, 18, 15, 13, 465/17, 477, 59 (rotor location), 372/1 (rotor location), and 384 (rotor location) within the Stary Chwalin area, no. 287/1, 287/2, 285, 2/1, and 2/2 (rotor location) within the Ostrowasy area, and no. 236/22, 236/21 (rotor location), and 235/52 within the Leknica area. The scope of change involves supplementing the Study of Conditions and Directions of Spatial Development of the city and commune of Barwice with individual provisions for parts of the commune affected by this change, i.e., for the areas.

- Economic factors, which include the country’s economic situation. The amendment assumes that the investor will offer at least 10% of the installed capacity of WF to the residents of the commune, who would use the electricity as virtual prosumers. Each resident of this commune will be able to take a share not larger than 2 kW and receive electricity at a price resulting from the calculation of the maximum construction cost. The ecological investment as the latest WF to be built in Barwice will produce electricity at half the cost compared to the newest coal-fired power plants. The realization of the investment also means several hundred thousand PLN of annual tax, which will contribute to the commune’s budget. The construction of the wind farm brings a series of benefits for the Barwice commune. During the implementation of this investment, a county road on the section of 2.3 km from Barwice to Lubostron will be rebuilt, the road will be widened to 6 m, and its carrying capacity will also increase.

- Socio-cultural factors, which include the population’s attitude towards a given activity, i.e., acceptance of the proximity of a particular investment and readiness to use its products and services. The amendment stipulates that new wind turbines can only be located based on a local spatial development plan (LSDP). The basis for determining the minimum distance—between 10 H and 700 m for residential buildings—will include, among others, the results of a strategic environmental assessment (SEA) conducted as part of the LSDP. The SEA analyzes, among others, the impact of noise emissions on the environment and the health of residents. The municipal authorities will not be able to deviate from conducting an SEA for an LSDP project that includes a wind power plant. The current law prohibits the construction of wind turbines at a distance less than 10 times the height of the tower and rotor blade in its highest position from residential buildings. The prohibition also applies to building constructions at a distance less than 10 H from a wind turbine. The maximum sound power level set for wind turbines is 108.5 dB.

- Political factors, which refer to the attitude of public authorities towards a given activity, both at the state level and at various levels of local government. The Act of 9 March 2023, amending the Act on investments in the field of wind power plants and some other laws (Journal of Laws, item 553), came into force 30 days after the date of announcement, except for the provisions concerning the inclusion of the residents of the commune where the WF is to be located in the catalog of virtual prosumers, which will come into effect on 2 July 2024.

- Legal and administrative factors, which are largely a derivative of political factors. They include legal regulations, such as the transparency of regulations, the amount and complexity of taxes, restrictions on capital transfer, or equality in the treatment of entities. Administrative factors are regulations concerning, among others, the attractiveness of conditions for starting and conducting business, especially the number, complexity, and resource intensity of procedures.

- Technical and technological factors, including the processes of creating and improving technologies, work tools, organization of production, and management of processes such as production, supply, and distribution.

4.3. Concept of Possible Changes

Scheduling in logistic process planning is a key factor in effective management. If information is presented effectively, it can aid future investors in WFs in understanding the multitude of activities and the interconnections between them. In this regard, graphical representation of schedules from serial to parallel-serial can greatly facilitate the understanding of a large amount of information, instead of reviewing a large set of data tables and information. This goal can be achieved by using logistic networks. In logistic network models, based on the duration of the critical path, it is possible to determine the time compression needed for the construction of a wind farm.

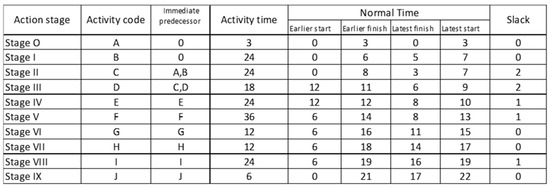

Step 1: the initial activity will be numbered as 0.

Step 2: the next number will be assigned to any unnumbered activity whose previous activities are already numbered. Step 2 will be repeated until all actions are numbered (Figure 8).

Figure 8.

The time determinant in the logistical process of a WF in the CPM network model.

The forward pass is used to determine the earliest possible start time and finish time for each activity in the network. During calculations, time constraints on completion are considered by recognizing the minimum finish time, and then subtracting the duration of the activity (). Moreover, for all, the earliest start is by default day 0 of the phase. In the next step, the earliest finish time of each activity is determined.

- Step 1:

- Step 2: (where n is the last activity),

- Step 3:

Backward pass calculations follow a procedure similar to the forward pass, but instead focus on the last phase time and start from the last time. In calculating the latest finish time in backward pass mode, it is determined that the latest start time is consistent with the precedence constraint regarding the start times of activities. Therefore, the calculations include minimizing all activities that have as their predecessor. Also at this point, the feasibility of the scheduled activity can be checked and imposed. The rule is that a scheduled activity is not feasible if the late start time is shorter than the early start time.

- Step 1: Let equal the required completion time of the project

- Note: must equal/exceed

- Step 2: For

- Step 3:

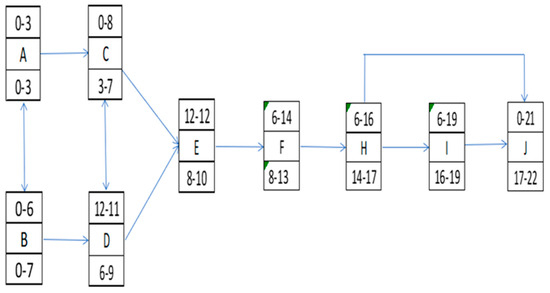

In the case of the logistical process of planning a WF, the optimal critical path was chosen, which allows for the completion of construction in 2020 and its operation (Figure 9).

Figure 9.

Time compression of the logistic process of wind farm construction in the CPM network model.

Additionally, the construction of the wind farm could have started from November 2018 (winning the ERO auction). In CPM, activities A-B and C-D were planned in parallel, and E and F were shortened (Figure 10).

Figure 10.

The concept of optimizing time in the planning process of the logistical investment for WF Barwice.

The first of these is to ensure that logistic processes such as design, operation, and project development are conducted in a way that meets the needs of end-users—the energy consumers. The second is managing the logistic process in a dynamic commercial environment, which makes managing the process and SC a demanding reality. The simplicity and clarity of the approach to time optimization encompassing not only the boundaries of a single company but the entire network of connections and functionalities, provide a good platform to meet these challenges. CPM modeling in scheduling and control are the main tasks in the construction of a WF. Effective logistic process management techniques are important to ensure the successful completion of any project. In this regard, the present study applied a case study method to analyze and evaluate the optimization of the logistical planning process for WF using the CPM method with MIDAS NFX STR software. Critical paths and defined actions covered the entire planning and construction time of the WF, including the latest start time, earliest and latest times of reduction, ultimately resulting in the compression of the time in the logistical process. Forward and backward pass calculations for each activity directly yield several activity time values, which include the earliest start time, the latest start time, the earliest finish time, and the latest finish time. Moreover, their calculations indirectly result in buffer time activities, which have been eliminated or shortened to a period of 1 month. A 1-year delay was eliminated, but the planned completion period and the quarter of 2019 were not achievable. The application of CPM can improve the future logistical planning process of WF investments compared to those built earlier. Furthermore, time optimization analysis in the logistical process can be applied to general practical cases of WF.

4.4. Discussion

After conducting a time analysis, it must additionally be assumed that time compression of the logistical process would have increased the profitability of this investment. However, the mentioned costs required the engagement of additionally high initial capital, which could have ended in failure. The problems were legal, administrative, and environmental limitations, as well as initial refusal to connect to the network. Initially, Poland had the most restrictive legal regulations concerning wind power, which slowed down the development of investments. Investments in wind power plants yield a profit of 12% to 16% per annum. With current electricity prices on the stock exchange, the rate of return can reach 16% per annum. The expected operational period of modern wind power plants is about 25–30 years. It is currently unknown whether, after this time, WF Barwice will be decommissioned or replaced with new structures. For example, in some European countries, one can apply for an environmental decision and building permit as part of a single application, and the authorities coordinate the subsequent steps among themselves. This gives the investor greater certainty about the duration of this procedure. Looking to the future, companies building and operating WFs must be flexible to meet at least two possible key challenges.

To ensure the safety of achieving the project objectives of the investment, the technical service of WF Barwice will be conducted by energy consult GmbH (part of the PNE group), which manages technically about 800 wind turbines across Europe with a total installed capacity of over 1.6 GW. WF Barwice is the first WF in the Polish market to be serviced by energy consult GmbH. The company indicated that without winning the auction for energy sales, it would not be able to start the investment. Following another auction win by PNE AG for energy sales, conducted in December 2019, the company outlined its development path in the Polish market. The analysis considered factors (described in Section 4.2) limiting the planning process and obtaining approval for the WF. These factors cannot be eliminated from planning and should be prepared in advance by collaborating with the authorities responsible for issuing environmental permits. Early consultations with residents, presenting the benefits and potential risks of the investment, are also necessary. The method of assessing the impact of the planned project on ornithofauna and other environmental factors is outlined in a report prepared for the General Directorate for Environmental Protection [45]. It should be emphasized that in the current situation, planning future possibilities for obtaining certificates is challenging, significantly increasing the risk and uncertainty not only regarding the conditions of operation but also the WF analysis. The presented solutions may require a reassessment of assumptions regarding WF projects, and as a result, some may not allow for the application of time compression in the logistical process. This could lead to the lack of profitability in certain investments.

In the case study discussed, from 1 January to 31 December 2019, the Mayor of Barwice issued two negative decisions on determining building conditions, which concerned single-family residential construction (construction and reconstruction of single-family buildings along with necessary infrastructure). The refusal concerned the impact of the subject investment (WF Barwice).

It should be noted, as indicated in this study, that cost minimization will generally occur as a direct result of reducing stages or compressing time that does not add value. Such time compression can result in a series of savings related to the removal of fixed and variable overhead costs, direct costs, and the involved working capital. Additionally, the biggest challenge for investors in such a variable and demanding Polish energy market is the need to obtain the necessary permits for the realization of the investment. Another important issue is the difficulties in running parallel decision-making proceedings (e.g., environmental), which significantly affect the investment planning process. This means that until the proceedings for considering the application for approval of the project (environmental conditions) are completed, there is no chance of submitting an application for a building permit. The entire logistical process is prolonged in the phase of document preparation and design.

5. Conclusions

Due to problems related to social acceptance of building onshore WFs and the lengthy planning process, a solution seems to be energy based on OWFs. Investors are eager to finance such projects, resulting in an increasing number of such farms being built each year in the North and Baltic Seas. The construction costs of OWFs are much higher than their land-based counterparts, but it is a much more efficient investment, due to greater stability in raw material supplies, stronger wind force, and lack of technological limitations. The preparation time for these investments is half as short due to different environmental factors. The cost of building an OWF is about 30–50% higher compared to land-based power plants. A capital-intensive factor is the need to conduct a series of environmental studies, adapt the location to shipping and fishing routes, and greater difficulties associated with the transport and assembly of individual elements. Better wind energy resources make the investment rational despite the more complicated and expensive construction and operation. An additional advantage of locating OWFs is the absence of variable terrain forms (terrain obstacles, forested areas, buildings) and a lower level of velocity fluctuation (turbulence) in front of the turbine, resulting in more stabilized inflow conditions. OWFs do not have limitations in the form of minimum distance from the nearest buildings and are not as bothersome as land turbines, as they are built far from residential areas, hence the logistic process is shorter. Not every investment in a WF is successful; according to the report from the president of the Energy Regulatory Office (URE), in the years 2021–2022, the Office received over 9000 notifications of refusals to connect a renewable energy source (RES) facility to the network. The main reason is the too slow modernization of the network and the wave of connections made in previous years. An essential consideration is the variability in the load of the power system. Challenges in balancing the available power from wind farms and conventional power plants, which must remain operational to ensure the system’s safe operation, apply to hypothetical scenarios with a realistic probability of occurrence estimated at 100–200 h per year. Consequently, power grids must be integrated into a unified system.

5.1. Limitations

Generally, it can be stated that in the analyzed logistic processes, the need to increase the reliability of the entire project is emphasized. Therefore, there is a need for a more precise definition of concepts such as: reliability of completion within a specified deadline, overall task quality, execution safety, or the risk of process failure at stage VI. This also requires the development of new or modified models of logistic process reliability and the logistics system as a whole, and an analysis of the possibilities of using these models to describe existing real solutions. There is also a lack of specified methods of measurement besides time, which makes it difficult or even impossible to compare the results of financial-time analysis with each other. The lack of access to financial data at stages VII–IX and contracts with subsequent changes related to delays prevents the conduct of a full CPM-COST analysis. An additional constraint in obtaining permits and conducting the investment was the COVID-19 pandemic. The planning of a WF is significantly dependent on its distance from the point of connection to the power grid (PCPG) and its integration into the power network. Therefore, particular attention should be given to the parameters of the energy infrastructure at the selected location, as this should be defined in the early stages of planning.

5.2. Observations

The application of CPM can improve the schedules that were used previously. Furthermore, the calculation times used in solving general practical cases of logistic process projects are encouraging. The priority issue for any venture implemented over a long period, such as the construction of a WF, is primarily to determine how time affects the risk of not realizing a given project and can impact the operation, process, organization, and what actions should be taken to eliminate or at least reduce this risk to an acceptable level. For time compression in the logistic process to bring the expected results, it should be implemented after proper familiarization with the factors mentioned in the publication above, which directly affect its occurrence in logistic processes.

5.3. Recommendations

The results of our research have expanded the theoretical basis regarding methods for identifying the time necessary to plan the construction of wind farms. The study fills the scientific gap regarding the analysis of the implementation of such investments in energy enterprises, and in particular the planning process. Based on our research, we have identified good practices that can be used in other similar investments by entities building wind farms in Poland and abroad. A key business implication of the study is that other similar companies can potentially benefit from utilizing our research results. It is recommended for stakeholders and investors to use the CPM model in conjunction with cost analysis for, among others, the construction of offshore wind farms and PV farms. In this way, they can reduce the level of investment risk (extension of the period), which will directly translate into the profitability and payback period of the investment. Optimizing the planning process can also positively impact the organization’s (investor’s) image. This is crucial because a vital stage in planning the implementation of such investments involves obtaining necessary permits and consents from institutions, especially the local community.

Author Contributions

Conceptualisation, N.C-G., J.A.D. and M.O.; methodology, N.C-G., J.A.D., M.O. and W.W.; software, N.C-G., J.A.D., M.O. and W.W.; validation, N.C.-G., R.S. and W.W.; formal analysis, N.C.-G., R.S. and W.W.; investigation, N.C-G., J.A.D., M.O. and W.W.; resources, N.C-G., J.A.D. and M.O.; data curation, J.A.D., M.O. and N.C.-G.; writing—original draft preparation, N.C-G., J.A.D. and M.O.; writing—review and editing, R.S., N.C.-G. and W.W.; visualisation, J.A.D. and M.O.; supervision, N.C.-G., R.S. and W.W.; project administration, W.W. and N.C.-G.; funding acquisition, W.W. and R.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Publicly available datasets were analyzed in this study. This data can be found here: (-) the documents are available in hard copy at the Szczecinek District Office (decision no. 398/2012/2013) and Barwice Municipality (document IOS. 6220.1.2011), (-) investor documentation Windfarm Polska II in Koszalin, (-) Regional Directorate for Environmental Protection in Szczecin (environmental impact report).

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviation

List of abbreviations used in the article.

| Abbreviation | Abbreviation Extension |

| CPM | Critical Path Method |

| EF | earliest finish |

| ERO | Energy Regulatory Office |

| ES | earliest start |

| GDP | Gross domestic product |

| GW | Giga Watt |

| kW | kilo Watt |

| LF | latest finish |

| LS | latest start |

| LSDP | local spatial development plan |

| MPSP | Main Power Supply Point |

| OWF | offshore wind farm |

| PCPG | Point of Connection to the Power Grid |

| PRIMES | Price-Induced Market Equilibrium System |

| PV | photovoltaic panel |

| REI | Renewable Energy Institute |

| RES | Renewable Energy Source |

| SEA | strategic environmental assessment |

| SC | supply chain |

| WF | wind farm |

| PLN | Polish zloty |

References

- Christopher, M. New directions in logistics. In Global Logistics and Distribution Planning; Routledge: New York, NY, USA, 2018; pp. 27–38. [Google Scholar]

- Lin, C.Y.; Ho, Y.H. Determinants of green practice adoption for logistics companies in China. J. Bus. Ethics 2011, 98, 67–83. [Google Scholar] [CrossRef]

- Kuhlang, P.; Edtmayr, T.; Sihn, W. Methodical approach to increase productivity and reduce lead time in assembly and production-logistic processes. CIRP J. Manuf. Sci. Technol. 2011, 4, 24–32. [Google Scholar] [CrossRef]

- Barmutaa, K.; Rusakovab, N.; Malkhasyan, A. Improving the method of analyzing risks of the company’s logistics processes. Transp. Res. Procedia 2022, 63, 737–745. [Google Scholar] [CrossRef]

- Olkiewicz, M. Knowledge management as a determinant of innovation in enterprises. In Proceedings of the 9th International Management Conference Management and Innovation for Competitive Advantage, Bucharest, Romania, 5–6 November 2015; pp. 399–409. [Google Scholar]

- Nowosielski, S. Projekty jako narzędzie doskonalenia procesów logistycznych przedsiębiorstwa. Zesz. Nauk. Organ. I Zarządzanie/Politech. Śląska 2016, 1068, 333. [Google Scholar]

- Reshetnikova, O.; Dyczkowska, J.A.; Olkiewicz, M.; Paszkowska, D. Promoting Pro-ecological Behavior with Logistics Operators in Poland and Ukraine. Rocz. Ochr. Sr. 2021, 23, 642–654. [Google Scholar] [CrossRef]

- Olkiewicz, M.; Olkiewicz, A.; Wolniak, R.; Wyszomirski, A. Effects of Pro-Ecological Investments on an Example of the Heating Industry—Case Study. Energies 2021, 18, 5959. [Google Scholar] [CrossRef]

- Gębczyńska, A. Pomiar efektywności procesów logistycznych. Zesz. Nauk. Wyższej Szkoły Bank. We Wrocławiu 2012, 32, 211–220. [Google Scholar]

- Handfield, R.B.; Graham, G.; Burns, L. Corona virus, tariffs, trade wars and supply chain evolutionary design. Int. J. Oper. Prod. Manag. 2020, 40, 1649–1660. [Google Scholar] [CrossRef]

- Handfield, R.B.; Aitken, J.; Turner, N.; Boehme, T.; Bozarth, C. Assessing adoption factors for additive manufacturing: Insights from case studies. Logistics 2022, 6, 36. [Google Scholar] [CrossRef]

- Kostin, K.; Kozhukhina, K. Problems of the improvement of risk management in business. Econ. Environ. Manag. 2019, 1, 171–180. [Google Scholar] [CrossRef]

- George, C. The essence of risk identification in project risk management: An overview. Int. J. Sci. Res. 2020, 9, 1553–1557. [Google Scholar] [CrossRef]

- Dyczkowska, J.A.; Reshetnikova, O. Logistics Centers in Ukraine: Analysis of the Logistics Center in Lviv. Energies 2022, 21, 7975. [Google Scholar] [CrossRef]

- Mesjasz-Lech, A. Logistics performance and management of logistics system safety. Syst. Saf. Hum. Tech. Facil. Environ. 2019, 1, 730–737. [Google Scholar] [CrossRef]

- Borisenko, I.; Panasenko, N.; Ganzhur, M.; Shatamirov, I.; Prokopaylo, A. Risk analysis managerial structures. AIP Conf. Proc. 2019, 2188, 050024. [Google Scholar] [CrossRef]

- Wu, P.J.; Chaipiyaphan, P. Diagnosis of delivery vulnerability in a logistics system for logistics risk management. Int. J. Logist. Manag. 2020, 31, 43–58. [Google Scholar] [CrossRef]

- Barmuta, K.; Tuguz, N. Organizational and managerial mechanism for risk management of agricultural enterprises. E3S Web Conf. 2021, 273, 08005. [Google Scholar] [CrossRef]

- Facchini, F.; Oleśków-Szłapka, J.; Ranieri, L.; Urbinati, A. A maturity model for logistics 4.0: An empirical analysis and a roadmap for future research. Sustainability 2019, 12, 86. [Google Scholar] [CrossRef]

- Dobrzycki, A.; Wodnicki, G. Analiza techniczno-ekonomiczna budowy morskiej farmy wiatrowej w warunkach Polski. Pozn. Univ. Technol. Acad. J. Electr. Eng. 2018, 94, 73–86. [Google Scholar] [CrossRef]

- Mielczarski, W. Odnawialne źródła energii jako element Nowego Zielonego Ładu. ACADEMIA-Mag. Pol. Akad. Nauk. 2021, 1/65, 84–87. [Google Scholar] [CrossRef]

- Olczak, K. Odnawialne źródła energii jako przesłanka prawna bezpieczeństwa energetycznego. Stud. Prawno-Ekon. 2020, 117, 115–128. [Google Scholar] [CrossRef]

- Li, Z.; Tian, G.; El-Shafay, A. Statistical-analytical study on world development trend in offshore wind energy production capacity focusing on Great Britain with the aim of MCDA based offshore wind farm siting. J. Clean Prod. 2022, 363, 132326. [Google Scholar] [CrossRef]

- Energy from Renewable Source in 2022, Statistical Poland, Warsaw 2022. Available online: https://stat.gov.pl/obszary-tematyczne/srodowisko-energia/energia/energia-ze-zrodel-odnawialnych-w-2022-roku,3,17.html (accessed on 10 January 2024).

- Available online: https://www.rynekelektryczny.pl/moc-zainstalowana-oze-w-polsce/#:~:text=Moc%20zainstalowana%20OZE%20przekroczy%C5%82a%2025%20gigawat%C3%B3w%2010%2F08%2F2023%20Na,jest%20obecnie%20s%C5%82o%C5%84ce.%20Na%20drugim%20miejscu%20jest%20wiatr (accessed on 20 February 2024).

- Seroka, A. Odnawialne źródła energii jako element zarządzania bezpieczeństwem energetycznym państwa. Zesz. Nauk. Politech. Częstochowskiej Zarządzanie 2022, 46, 88–100. [Google Scholar] [CrossRef]

- Tomaszewski, K.; Sekściński, A. Odnawialne źródła energii w Polsce–perspektywa lokalna i regionalna. Rynek Energii 2020, 149, 10–19. [Google Scholar]

- Kaznowski, R.; Sztafrowski, D. System elektroenergetyczny oparty o odnawialne źródła energii-możliwości i bariery rozwoju. Przegląd Elektrotechniczny 2023, 99, 186–189. [Google Scholar] [CrossRef]

- Tokarski, S. Transformacja energetyczna–zapotrzebowanie na źródła energii pierwotnej w perspektywie 2040r. Co się zmieni po wybuchu wojny na Ukrainie? Nowa Energ. 2022, 2, 10–16. [Google Scholar]

- Klimat Dla Polski, Polska Dla Klimatu. 2022. Available online: https://ios.edu.pl/wp-content/uploads/2019/03/Klimat-dla-Polski-Polska-dla-Klimatu_PL-1.pdf (accessed on 12 August 2023).

- Díaz, H.; Soares, C.G. Review of the current status, technology and future trends of offshore wind farms. Ocean. Eng. 2020, 209, 107381. [Google Scholar] [CrossRef]

- Porté-Agel, F.; Bastankhah, M.; Shamsoddin, S. Wind-turbine and wind-farm flows: A review. Bound.-Layer Meteorol. 2020, 174, 1–59. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Yu, Y.; Cao, S.; Zhang, X.; Gao, S. A review of applications of artificial intelligent algorithms in wind farms. Artif. Intell. Rev. 2020, 53, 3447–3500. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, D.; Li, Z.; Han, X.; Liu, H.; Dong, C.; Wang, J.; Liu, C.; Xia, Y. Power prediction of a wind farm cluster based on spatiotemporal correlations. Appl. Energy 2021, 302, 117568. [Google Scholar] [CrossRef]

- Maienza, C.; Avossa, A.M.; Ricciardelli, F.; Coiro, D.; Troise, G.; Georgakis, C.T. A life cycle cost model for floating offshore wind farms. Appl. Energy 2020, 266, 114716. [Google Scholar] [CrossRef]

- Dobrzycki, A.; Roman, J. Correlation between the Production of Electricity by Offshore Wind Farms and the Demand for Electricity in Polish Conditions. Energies 2022, 15, 3669. [Google Scholar] [CrossRef]

- Wind Europe 11/2019. Our Energy, Our Future. In How Offshore Wind Will Help Europe Go Carbon-Neutral; Wind Europe: Brussels, Belgium, 2019; Available online: https://windeurope.org/wp-content/uploads/files/about-wind/reports/WindEurope-Our-Energy-Our-Future.pdf (accessed on 12 August 2023).

- Wiśniewski, G.; Michałowska-Knap, K.; Koć, S. Energetyka Wiatrowa—Stan Aktualny i Perspektywy Rozwoju w Polsce; PWN: Warszawa, Poland, 2012; p. 7. [Google Scholar]

- Latinopoulos, D.; Kechagia, K. A GIS-based multi-criteria evaluation for wind farm site selection. A regional scale application in Greece. Renew. Energy 2015, 78, 550–560. [Google Scholar] [CrossRef]

- Wiśniewska, M.P.; Pusz, A.; Rogalski, D. Rozwój odnawialnych źródeł energii (OZE) w Unii Europejskiej i w Polsce. Pol. J. Sustain. Dev. 2020, 24, 101–112. [Google Scholar] [CrossRef]

- Azlan, F.; Kurnia, J.C.; Tan, B.T.; Ismadi, M.Z. Review on optimization methods of wind farm array under three classical wind condition problems. Renew. Sustain. Energy Rev. 2021, 135, 110047. [Google Scholar] [CrossRef]

- Available online: https://www.edukacja-dzieci.pl/wp-content/uploads/2021/04/szablony-mapa-polski.pdf (accessed on 21 February 2024).

- Olkiewicz, M. Management systems as a guarantee of quality assurance. Zesz. Nauk. Organ. I Zarządzanie Politech. Śląska 2018, 128, 317–332. [Google Scholar] [CrossRef]

- Malindžák, D. The basic principle of logistic theory. Appl. Mech. Mater. 2015, 708, 47–52. [Google Scholar] [CrossRef]

- Zimon, D.; Kawalec, A. Wpływ systemu zarządzania jakością na doskonalenie wybranych procesów logistycznych w dużym przedsiębiorstwie produkcyjnym. Nauk. O Zarządzaniu 2015, 3, 165–174. [Google Scholar]

- Olkiewicz, M. Quality improvement through foresight methodology as a direction to increase the effectiveness of an organization. Contemp. Econ. 2018, 12, 69–80. [Google Scholar]

- Fonseca, L.M. From quality gurus and TQM to ISO 9001: 2015: A review of several quality paths. Int. J. Qual. Res. 2015, 1, 167–180. [Google Scholar]

- Wolniak, R.; Sułkowski, M. Motywy wdrażania certyfikowanych systemów zarządzania jakością. Probl. Jakości 2015, 9, 7–9. [Google Scholar] [CrossRef]

- Wyszomirski, A.; Olkiewicz, M. Environmental corporate social responsibility as a tool for creating the future of environmental protection. Rocz. Ochr. Sr. 2020, 22, 1145–1161. [Google Scholar]

- Beesley, A. Time compression in the supply chain. In Global Logistics and Distribution Planning; Christopher, M., Ed.; Routledge: New York, NY, USA, 2018; p. 72. [Google Scholar]

- Atin, S.; Lubis, R. Implementation of critical path method in project planning and scheduling. IOP Conf. Ser. Mater. Sci. Eng. 2019, 662, 022031. [Google Scholar] [CrossRef]

- Shih-Pin, C.; Yi-Ju, H. A simple approach to fuzzy critical path analysis in project networks. Appl. Math. Model. 2008, 32, 1289–1297. [Google Scholar] [CrossRef]

- Kusumadarma, I.A.; Pratami, D.; Yasa, I.P.; Tripiawan, W. Developing project schedule in telecommunication projects using critical path method (CPM). Int. J. Integr. Eng. 2020, 12, 60–67. [Google Scholar]

- Cynthia, O.U. Implementation of Project Evaluation and Review Technique (PERT) and Critical Path Method (CPM): A Comparative Study. Int. J. Ind. Oper. Res. 2020, 3, 1–9. [Google Scholar] [CrossRef]

- Bishnoi, N. Critical path method (CPM): A coordinating tool. Int. Res. J. Manag. Sci. Technol. 2018, 9, 459–467. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).