Influence of Excitation by Idling Rotor on Wind Turbine Ultimate Loads in Storm Conditions

Abstract

1. Outlines

2. Simulation Outlines

2.1. Aeroelastic Analysis Method

2.2. Wind Turbine Model

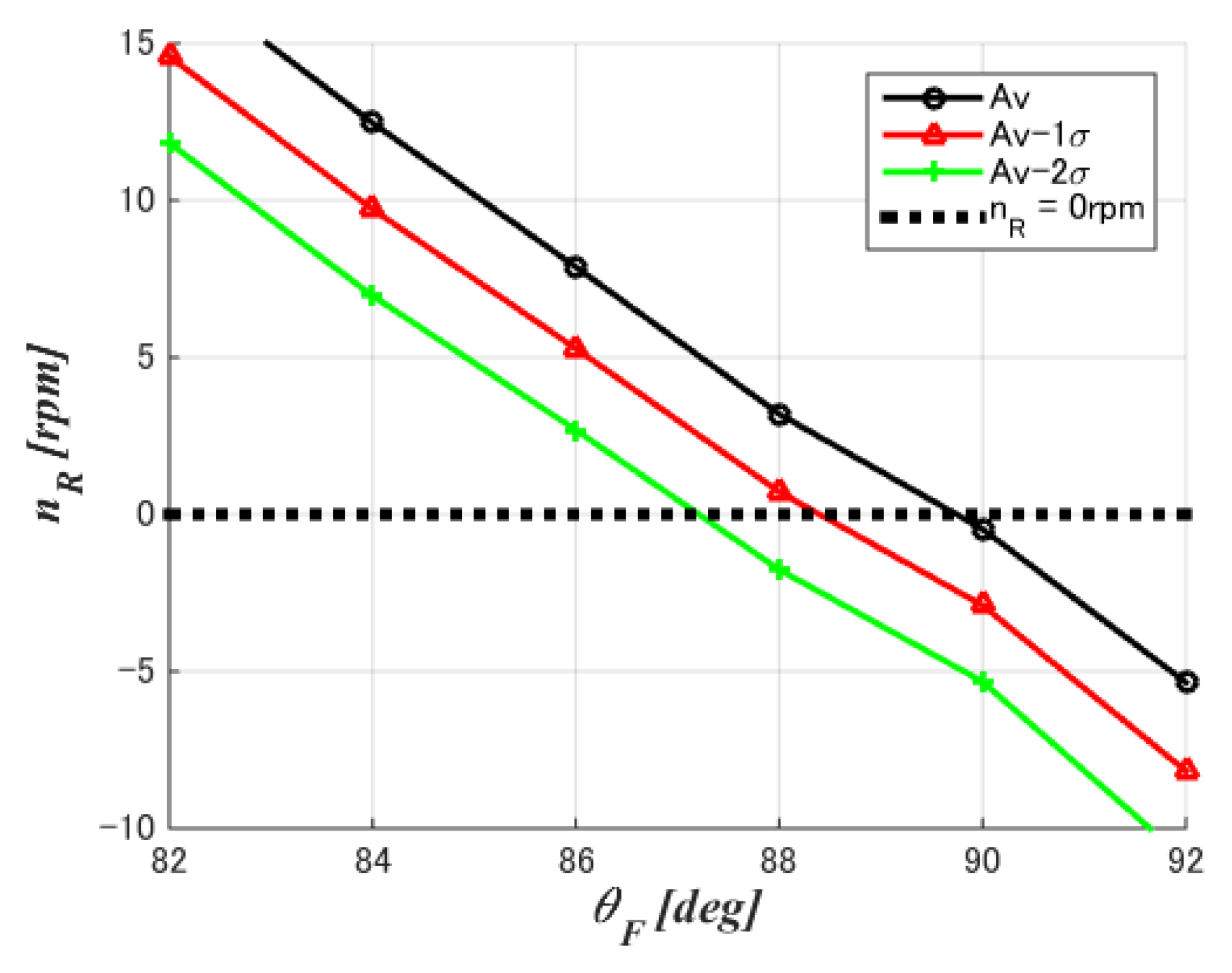

2.3. Full Feather Pitch Angle

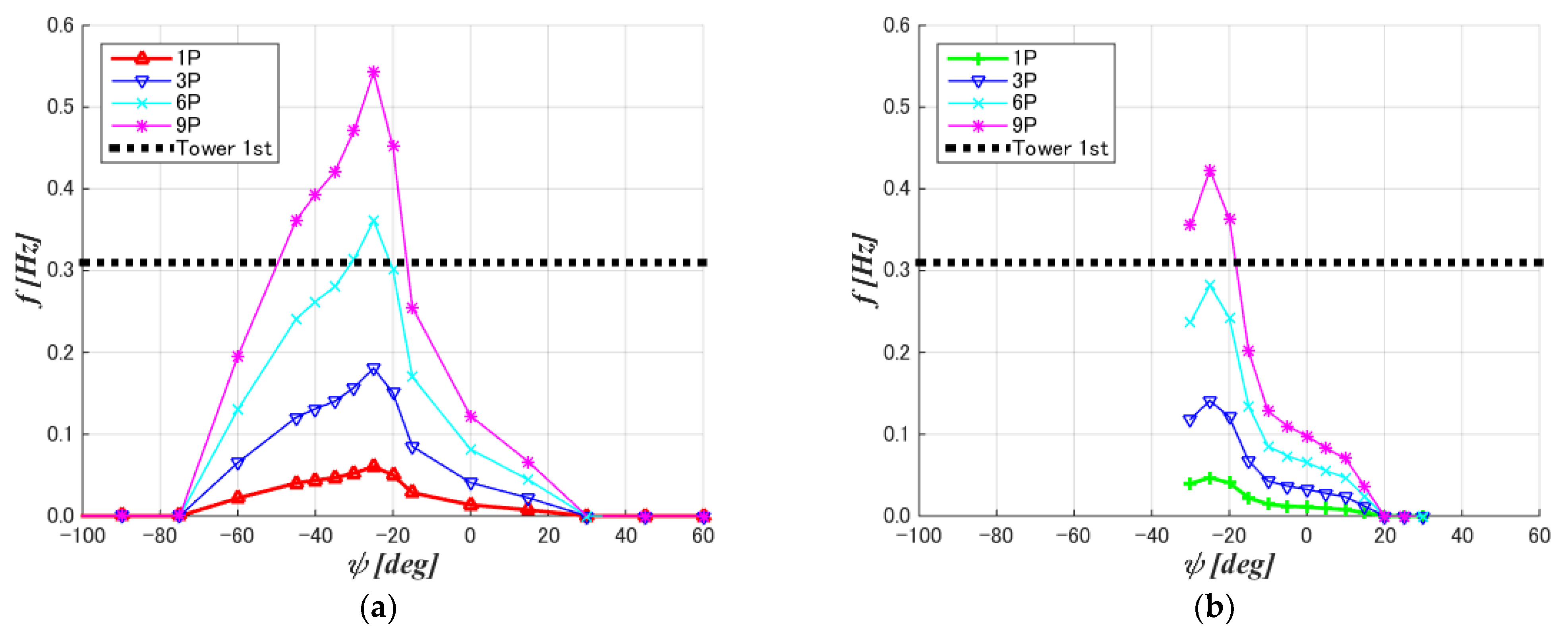

2.4. Conditions for Major Excitation Sources

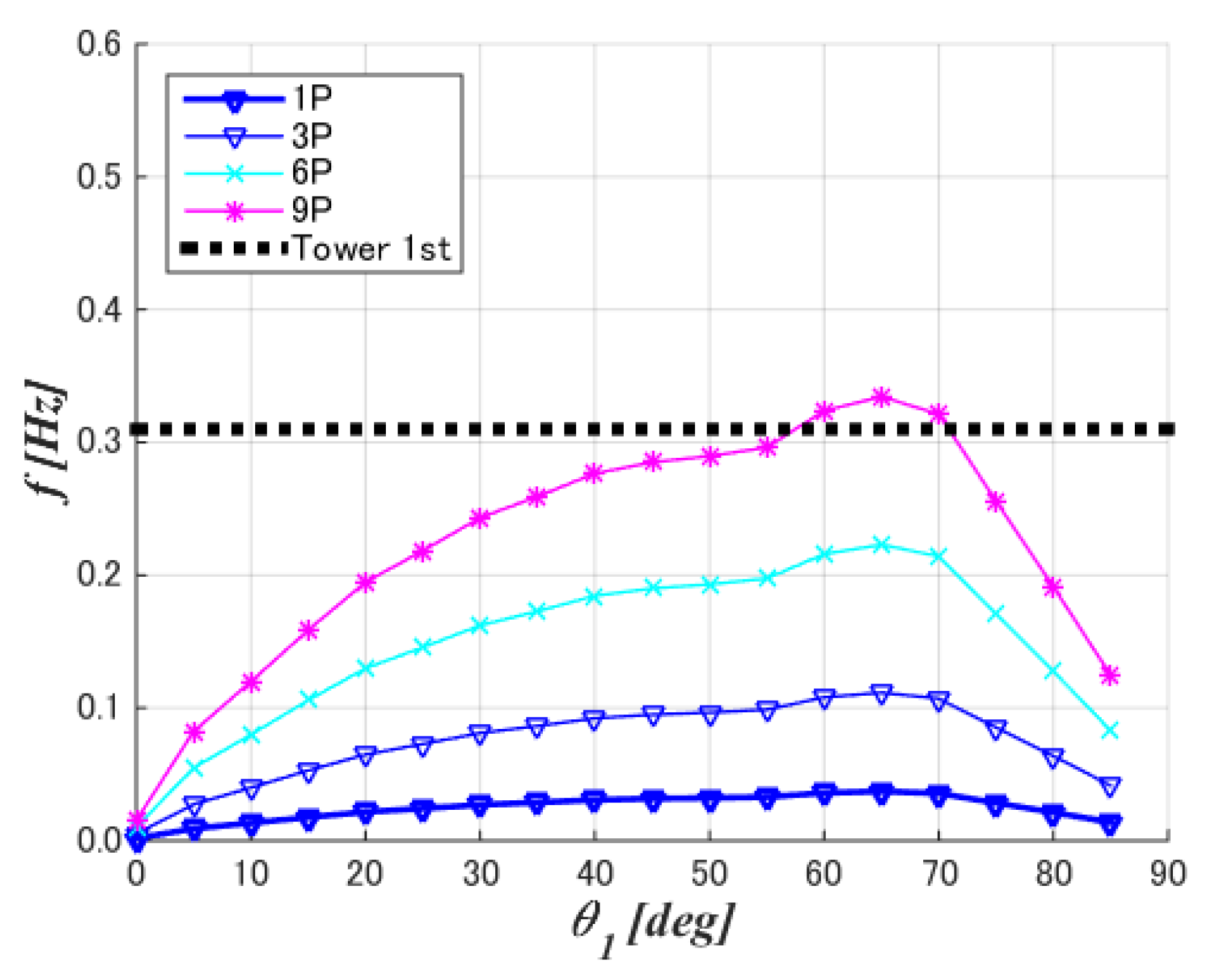

2.4.1. Rotor Aerodynamic Imbalance

2.4.2. Rotor Mass Imbalance

2.4.3. Blade–Tower Aerodynamic Interaction

2.5. Analysis Conditions

3. Simulation Results of Steady Extreme Wind Conditions

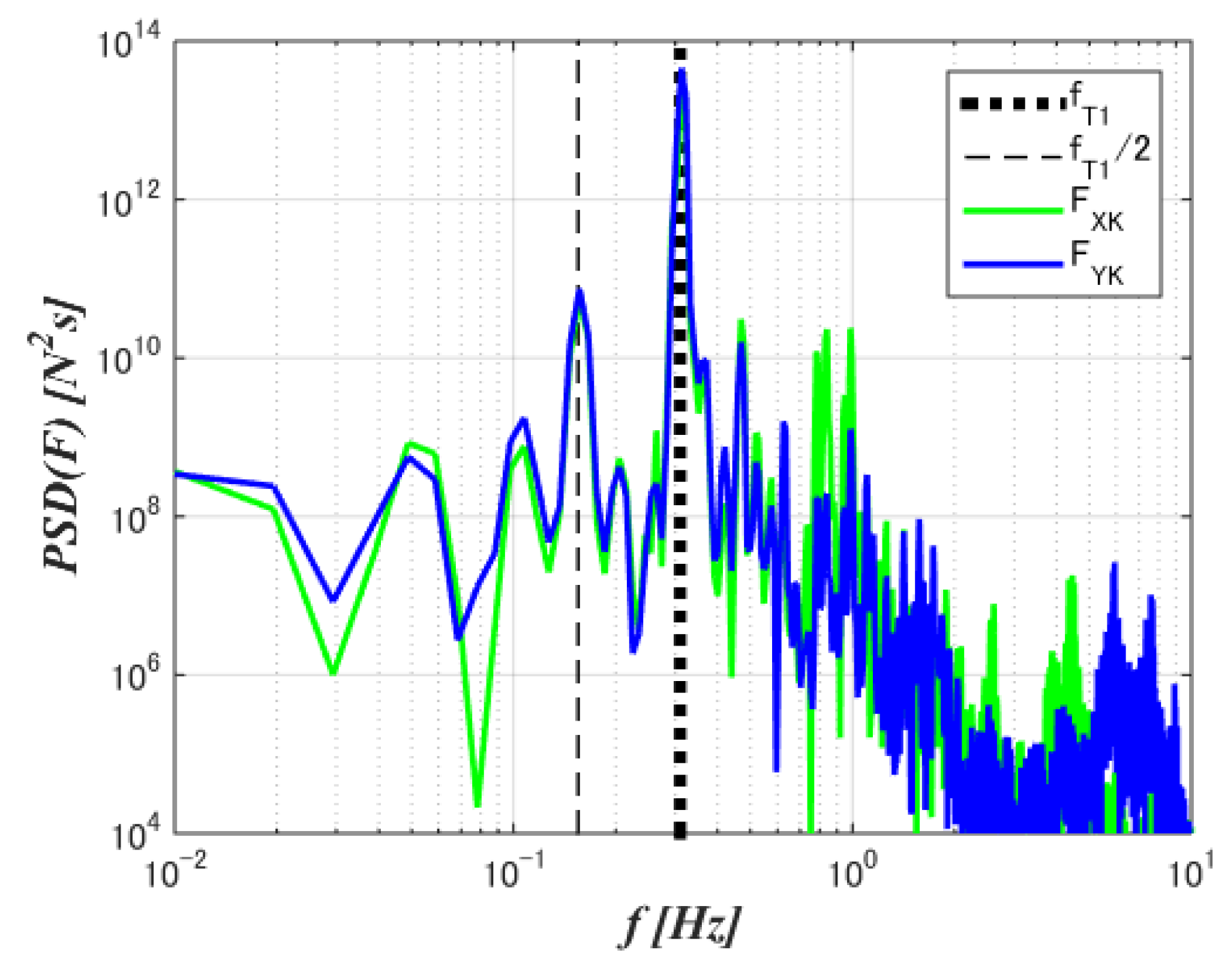

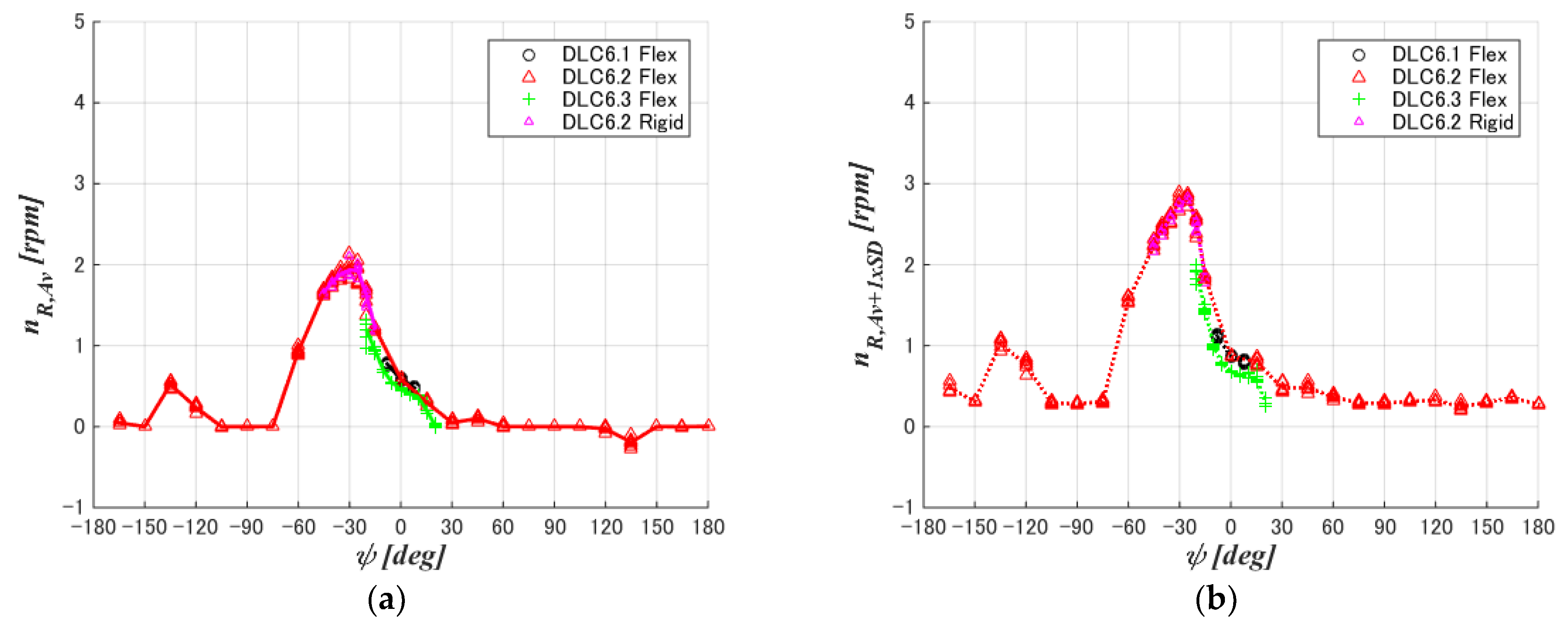

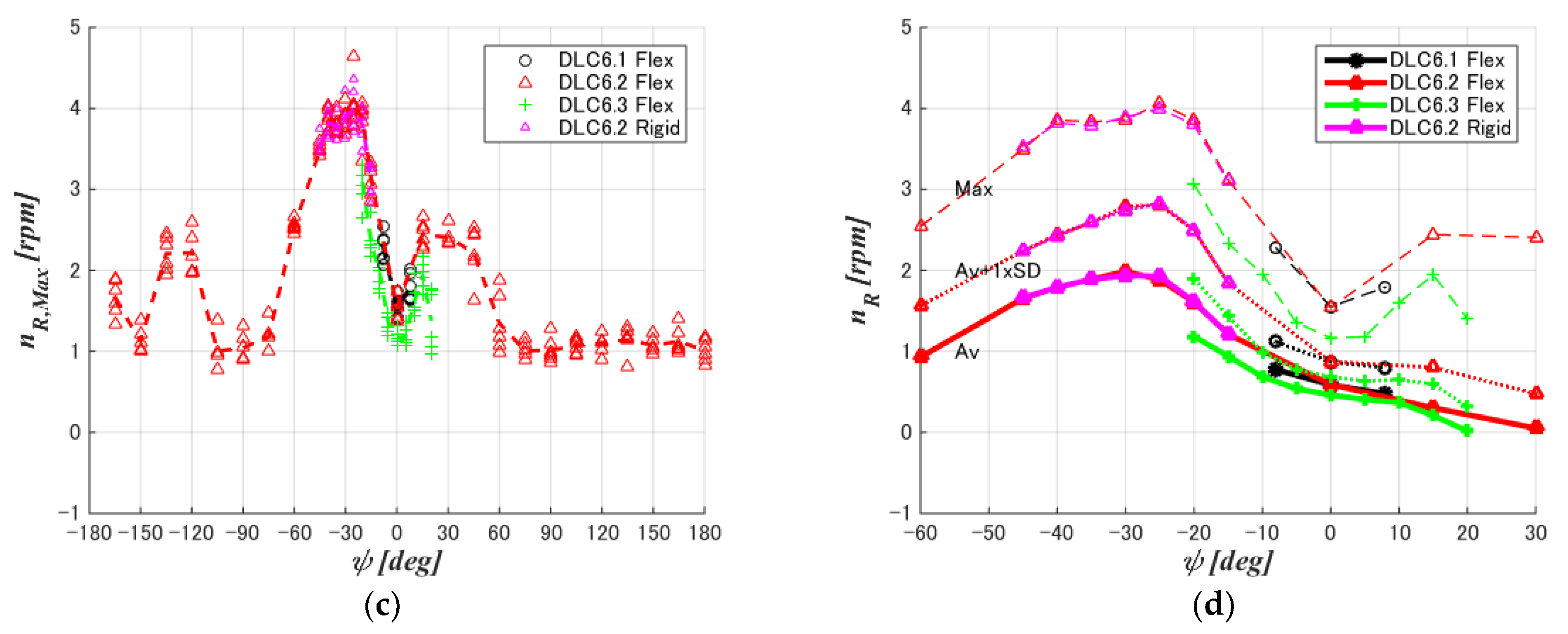

3.1. Rotor Speed

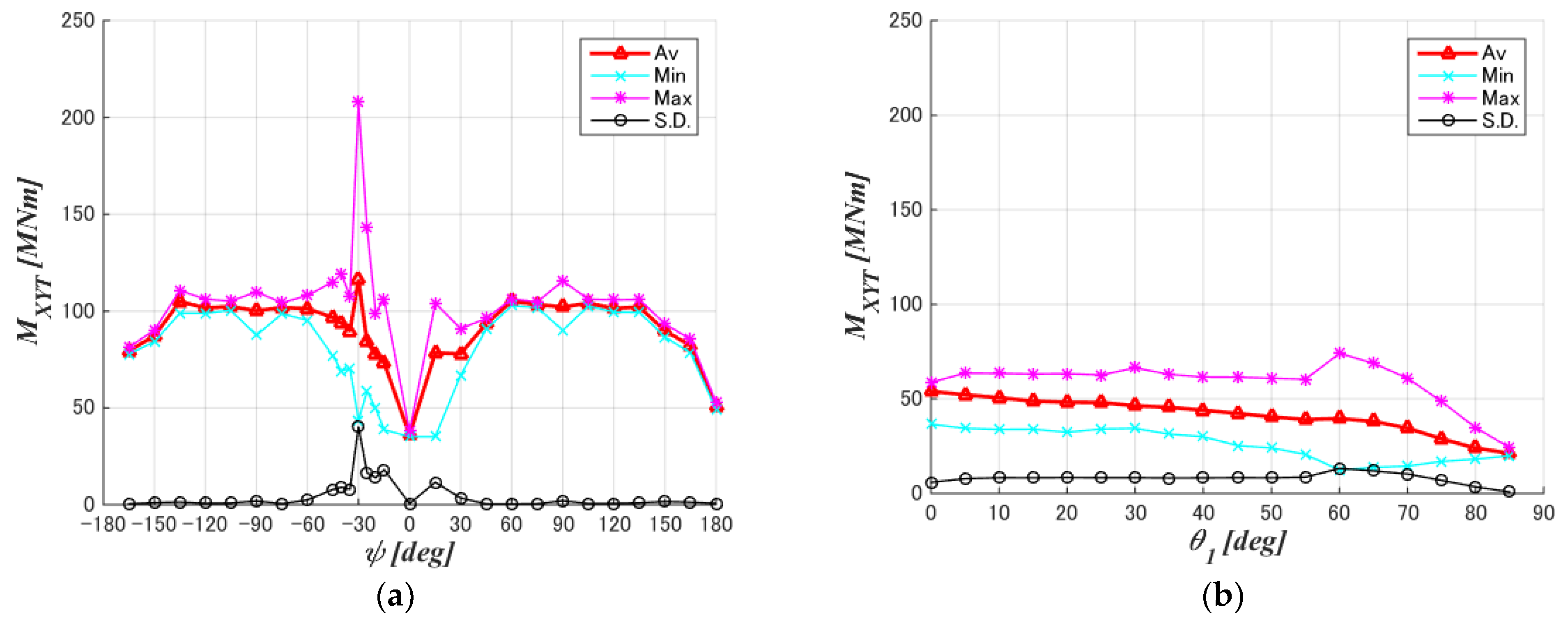

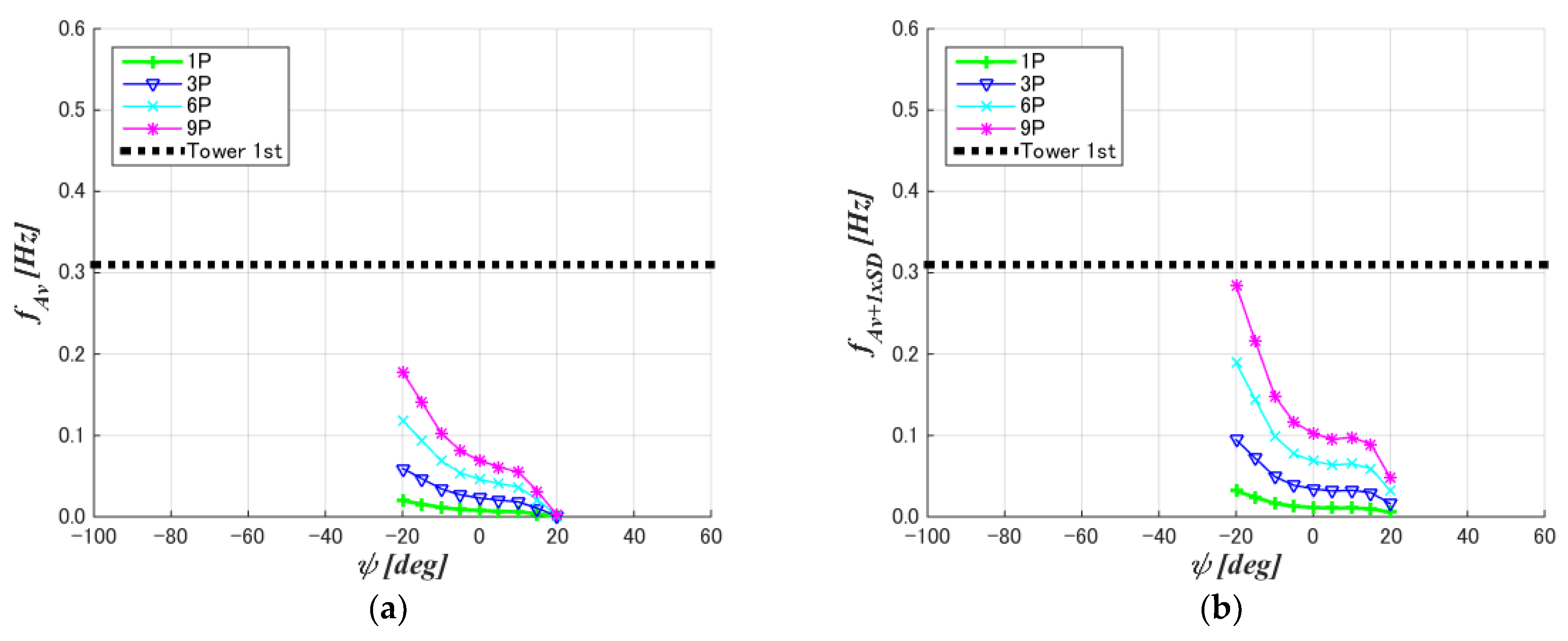

3.2. Tower Base Bending Moment

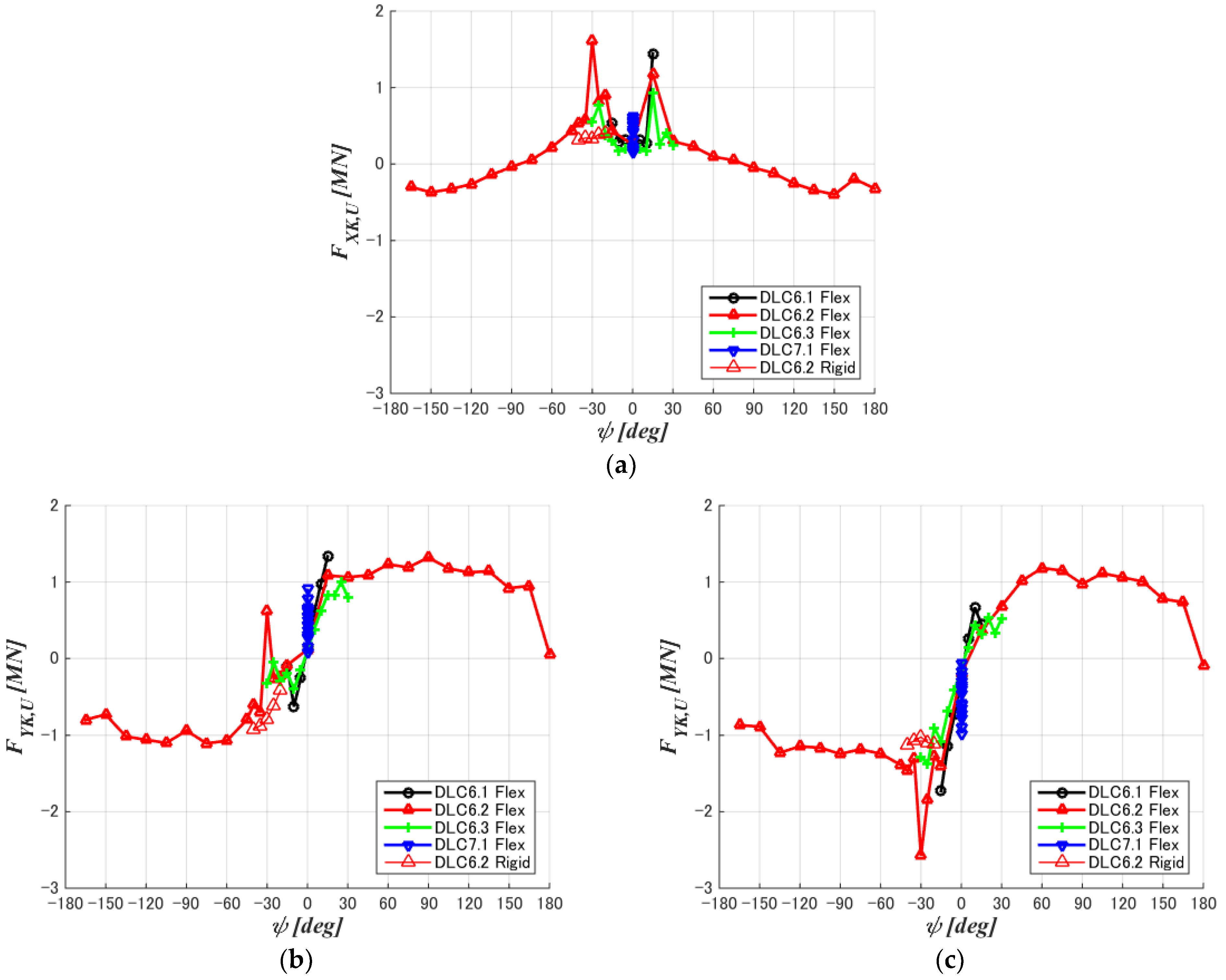

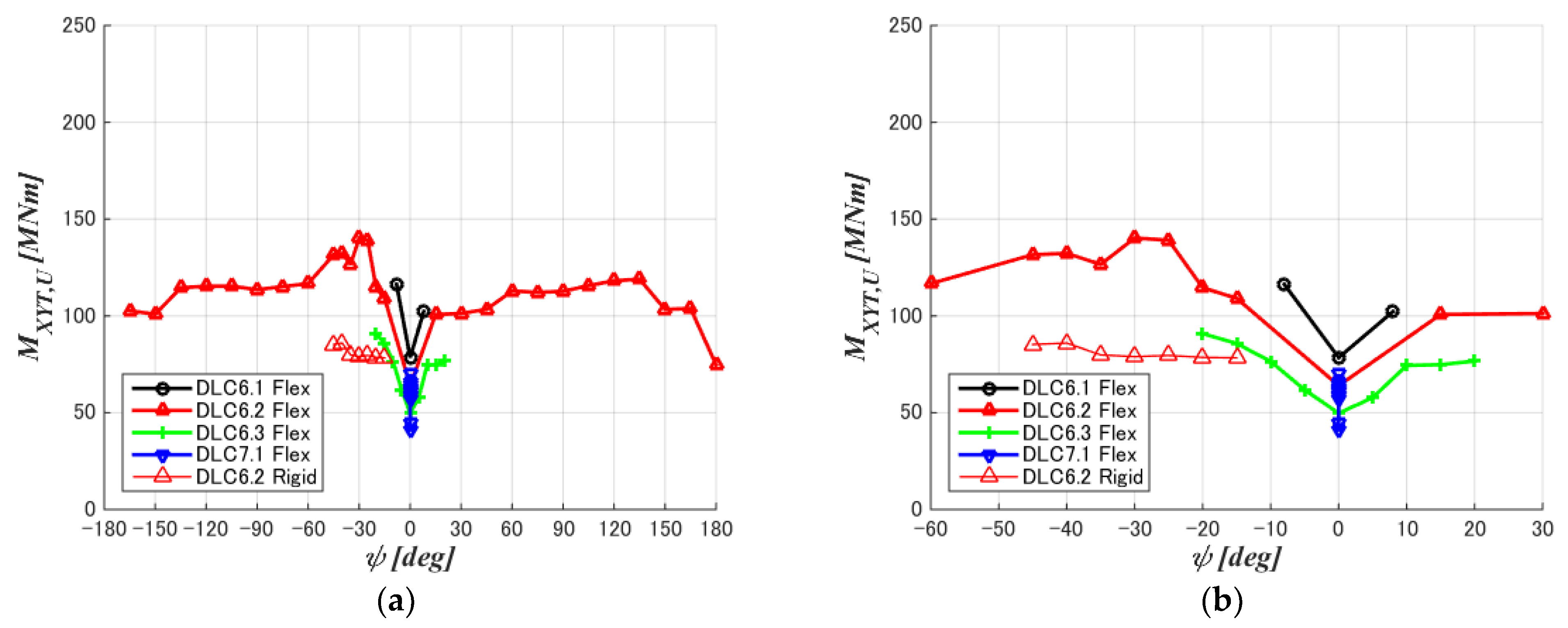

3.3. Yaw Center Shear Force

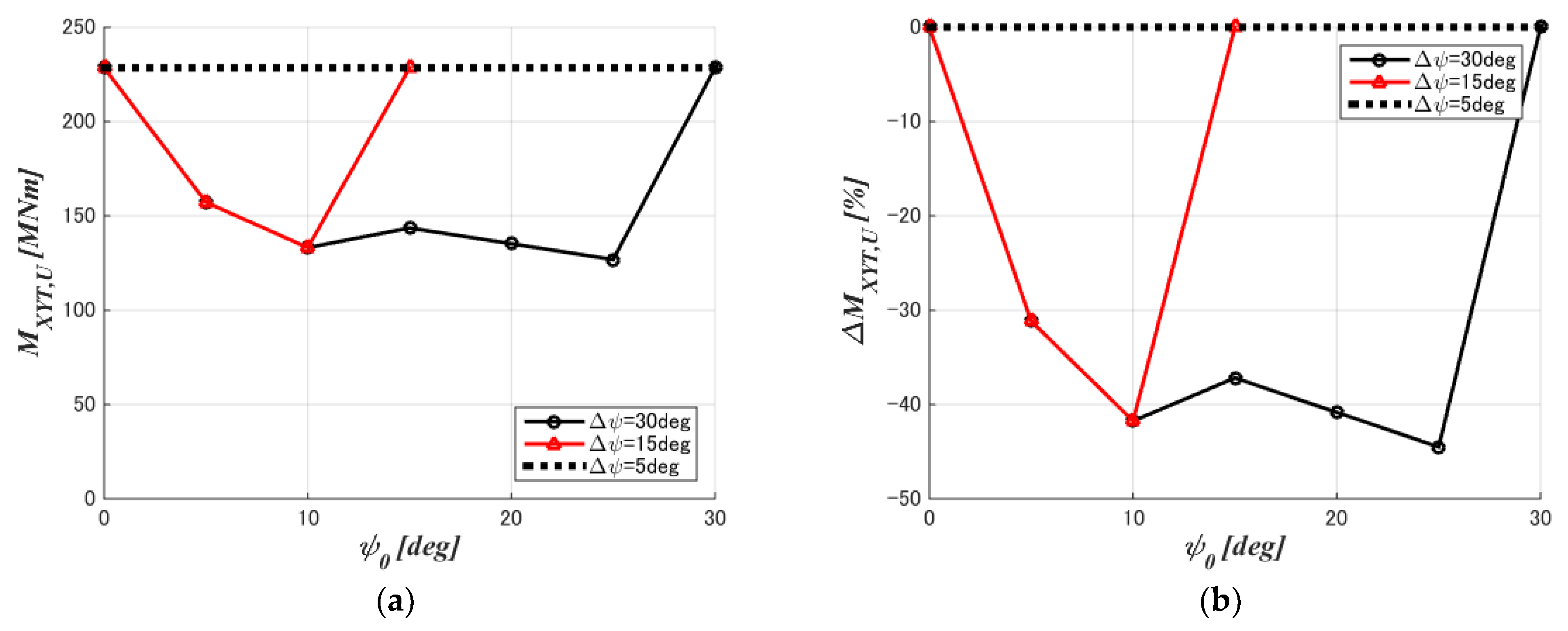

3.4. Effect of Analysis Conditions

4. Simulation Results of Turbulent Extreme Wind Conditions

4.1. Rotor Speed

4.2. Tower Base Bending Moment

4.3. Yaw Center Shear Force

4.4. Effect of Analysis Conditions

5. Conclusions

- (1)

- The results of the analysis under steady extreme wind conditions showed that the rotor speed is high at around −30 degrees of yaw error in DLC6.2, and the first-mode tower bending frequency is excited at twice the blade passing frequency (6P). In addition, under the conditions in DLC7.1 with one blade fixed, the rotor speed cannot reach a high enough speed to considerably excite the tower.

- (2)

- A similar trend was observed under turbulent extreme wind conditions, although the influence was not as pronounced compared with that under steady extreme wind conditions.

- (3)

- We confirmed that, unless the average yaw error is analyzed with an appropriate resolution, the excitation due to rotor rotation is not captured, and the ultimate load used in the design is therefore optimistic. In particular, the influence is stronger under steady extreme wind conditions. This result showed that analysis with sufficient resolution is necessary when twice the blade passing frequency during free rotation (6P) exceeds the first-mode tower bending frequency.

- (4)

- We recommend the resolution of yaw misalignment to be fine enough (5 degrees around the maximum idling speed in this study) to catch the resonance even in storm conditions with large yaw error, such as DLC6.2. This is not stated in design standards and design guidelines, nor considered carefully in the present design of wind turbines. This concern is more important for large offshore wind turbines designed for high wind speed and low turbulence conditions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- International Electrotechnical Commission. Wind Energy Generation Systems—Part 1: Design Requirements, 4th ed.; IEC614001; IEC: Sydney, Australia, 2016. [Google Scholar]

- Totsuka, Y.; Imamura, H.; Yde, A. Dynamic Behavior of Parked Wind Turbine at Extreme Wind Speed. In Proceedings of the 1st International Symposium on Flutter and Its Application, Tokyo, Japan, 15–17 May 2016. [Google Scholar]

- Wang, K.; Riziotis, V.A.; Voutsinas, S.G. Aeroelastic Stability of Idling Wind Turbines. Wind Energy Sci. 2017, 2, 415–437. [Google Scholar] [CrossRef]

- Bangga, G.; Carrion, M.; Collier, W.; Parkinson, S. Technical Modeling Challenges for Large Idling Wind Turbines. J. Phys. Conf. Ser. 2023, 2626, 012026. [Google Scholar] [CrossRef]

- Lian, J.; Zhou, H.; Dong, X. A Theoretical Approach for Resonance Analysis of Wind Turbines under 1P/3P Loads. Energies 2022, 15, 5787. [Google Scholar] [CrossRef]

- Tibaldi, C.; Kim, T.; Larsen, T.J.; de Rocca Serra, R.; Sanz, F. An Investigation on Wind Turbine Resonant Vibrations. Wind Energy 2016, 19, 847–859. [Google Scholar] [CrossRef]

- Yoshida, S. In-plane Self-excitation of Two-bladed Horizontal Axis Wind Turbine Rotors Due to Blade Elasticity and Gravity. Wind Eng. 2016, 40, 343–359. [Google Scholar] [CrossRef]

- DNV. Wind Turbine Design Software-Bladed, version 4.7.066; DNV: Bærum, Norway, 2015.

- Germanischer Lloyd. Rules and Guidelines IV Guideline for the Certification of Wind Turbines, Edition 2010; Germanischer Lloyd: Hamburg, Germany, 2010. [Google Scholar]

- Yoshida, S.; Kiyoki, S. Load Equivalent Tower Shadow Modeling for Downwind Turbines. JSME 2007, 73, 1273–1279. [Google Scholar] [CrossRef]

| Rotor Position | Upwind |

| Rated Power | 5 MW |

| Rotor Diameter | 118 m |

| Hub Height | 80 m |

| Number of Blades | 3 |

| Tilt Angle | 4 degrees |

| Coning Angle | 0 degree |

| Rotor Speed | 7.5–13.9 rpm |

| Tower Diameter | 4.4–6.0 m |

| Rotor Mass | 92 t |

| RNA Mass | 342 t |

| Tower First-mode Frequency | 0.31 Hz |

| Rotor Mass Imbalance | 264 kgm |

| Pitch Error | 0, −0.3, +0.3 degrees |

| DLC6.1 | DLC6.2 | DLC6.3 | DLC7.1 | |

|---|---|---|---|---|

| WT Condition | Normal | Grid loss | Normal | Fault |

| Wind Speed | 70 m/s | 70 m/s | 56 m/s | 56 m/s |

| Average Yaw Error | −15–+15 degrees | −180–+180 degrees | −30–+30 degrees | 0 degree |

| Turbulence Intensity | – | – | – | – |

| Turbulence Seed | – | – | – | – |

| Average Wind Shear | 0.11 | 0.11 | 0.11 | 0.11 |

| Average Inclination | 0 degree | 0 degree | 0 degree | 0 degree |

| Pitch Blade 1 | 87.0 degrees | 87.0 degrees | 87.0 degrees | 0.0–85.0 degrees |

| Pitch Blade 2 | 86.7 degrees | 86.7 degrees | 86.7 degrees | 86.7 degrees |

| Pitch Blade 3 | 87.3 degrees | 87.3 degrees | 87.3 degrees | 87.3 degrees |

| Rotor | Idling | Idling | Idling | Idling |

| PSFL | 1.35 | 1.1 | 1.35 | 1.1 |

| DLC6.1 | DLC6.2 | DLC6.3 | DLC7.1 | |

|---|---|---|---|---|

| WT Condition | Normal | Grid loss | Normal | Fault |

| Wind Speed | 50 m/s | 50 m/s | 40 m/s | 40 m/s |

| Average Yaw Error | −8–+8 degrees | −180–+180 degrees | −20–+20 degrees | 0 degree |

| Turbulence Intensity | 0.11 | 0.11 | 0.11 | 0.11 |

| Turbulence Seed | 6 | 6 | 6 | 6 |

| Average Wind Shear | 0.11 | 0.11 | 0.11 | 0.11 |

| Average Inclination | 0 degree | 0 degree | 0 degree | 0 degree |

| Pitch Blade 1 | 87.0 degrees | 87.0 degrees | 87.0 degrees | 0.0–85.0 degrees |

| Pitch Blade 2 | 86.7 degrees | 86.7 degrees | 86.7 degrees | 86.7 degrees |

| Pitch Blade 3 | 87.3 degrees | 87.3 degrees | 87.3 degrees | 87.3 degrees |

| Rotor | Idling | Idling | Idling | Idling |

| PSFL | 1.35 | 1.1 | 1.35 | 1.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoshida, S.; Fekry, M. Influence of Excitation by Idling Rotor on Wind Turbine Ultimate Loads in Storm Conditions. Energies 2024, 17, 1030. https://doi.org/10.3390/en17051030

Yoshida S, Fekry M. Influence of Excitation by Idling Rotor on Wind Turbine Ultimate Loads in Storm Conditions. Energies. 2024; 17(5):1030. https://doi.org/10.3390/en17051030

Chicago/Turabian StyleYoshida, Shigeo, and M. Fekry. 2024. "Influence of Excitation by Idling Rotor on Wind Turbine Ultimate Loads in Storm Conditions" Energies 17, no. 5: 1030. https://doi.org/10.3390/en17051030

APA StyleYoshida, S., & Fekry, M. (2024). Influence of Excitation by Idling Rotor on Wind Turbine Ultimate Loads in Storm Conditions. Energies, 17(5), 1030. https://doi.org/10.3390/en17051030