1. Introduction

In recent years, there has been an increase in interest in new reports on the recovery of valuable raw materials which are often of strategic and critical importance for the economy. The recycling of equipment related to the production of renewable energy is an increasingly important issue in the context of the fight against climate change and sustainable development [

1,

2,

3]. A small-power wind turbine generator is a complex device that uses various metals in its manufacture. In the context of assessing the value of these metals in the assessment of risk in their supply, there are several aspects that should be taken into account, such as the importance of the metals, the availability, supply and value of the metals and forecasts of fluctuations in stock exchange price. Assessing the value of generator metals is important as disruptions in their supply chain can impact the availability and price of these metals [

4,

5].

This article characterizes generators with permanent magnets and describes their construction and possible applications. Then, a methodology for disassembling the generator is presented, allowing for the determination of the shares of strategically important raw materials in it. The next section presents the results of an analysis of the content of selected elements that are important from an economic perspective in the tested neodymium magnet. For the analysed elements, assessments of the risk of the loss of supplies and the degree of substitutability were performed. Based on the adopted prices of elements on world markets, the market value of neodymium magnets was assessed. A simulation of financial benefits showed that the highest values were found for rare earth elements (dysprosium, neodymium, and praseodymium) and cobalt.

2. Permanent Magnet Generator and the Development of Wind Energy in Poland

A permanent magnet generator (PMG) is a type of electrical generator that uses permanent magnets to generate electricity. Unlike conventional generators that use electromagnets to generate a magnetic field, permanent magnet generators use permanent magnets as the source of the magnetic field [

1,

6,

7].

The basic principle of operation of a permanent magnet generator is the principle of electromagnetic induction. When an electric wire crosses magnetic field lines, an electromotive force (EMF) is created in the wire, which leads to the generation of an electric current [

6].

In a permanent magnet generator, the permanent magnets are attached to a rotor that rotates inside a winding stator. The stator winding wires are connected to an external system that consumes the generated electric current. As a result of the movement of the permanent magnet rotor around the stator, the magnetic field lines intersect the stator winding, which generates an electric current in the winding wires [

7,

8,

9].

Permanent magnet generators have many advantages such as high efficiency, low maintenance costs, and a smaller size and weight compared to traditional generators. Moreover, they do not require an external energy source to generate a magnetic field, which makes them more independent and efficient [

10,

11].

The use of permanent magnet generators is broad and includes various applications, such as in the wind power industry, hydropower industry, electric vehicles, industry and emergency systems, where it is necessary to generate electricity reliably and efficiently.

In 2010, approximately 1300 tons of rare earth elements was used worldwide to produce permanent magnets for wind turbines. In an average wind turbine, 250–650 kg of NdFeB magnets is used to generate 1 MW of electricity. In order to spread green energy technology, the installed global wind capacity is expected to increase from 324 GW in 2020 to 578 GW by 2040. The manufacture of generators with neodymium–iron–boron magnets for use in wind turbines requires the use of rare earth elements, especially neodymium and dysprosium. The issue also concerns micro-installations (home wind farms), the popularity of which is systematically growing in Poland and around the world. The draft law regulations prepared in Poland assume an exemption from the obligation to obtain a permit for the construction of free-standing wind installations. The project concerns installations with a total height of 3 to 12 m and a power not exceeding 50 kW. Power plants of this type would only require notification. It is also possible to build installations on the roofs of buildings. In the case of this type of installation, the height of which does not exceed 3 m, no building permit or notification would be required. The suggested solutions will certainly accelerate the construction of new wind micro-installations [

1,

9,

12].

Increased demand may impact the availability and prices of rare earth elements. For this reason, it is important to determine the following market parameters: the risk of the loss of the supply of such elements, their recycling rate and the possibility of their replacement.

3. Research on the Permanent Magnet Generator

This section provides a comprehensive overview of the methodology employed in the process of dismantling the generator, along with the obtained results detailing the share of each group of materials within the generator. The research conducted in this phase has proven instrumental in discerning the content of strategic raw materials present in the generator, paving the way for a thorough assessment of the associated risks, recycling rates and degree of substitutability. The dismantling methodology involved a systematic approach, meticulously breaking down the generator into its constituent materials. This process enabled the categorization of materials into distinct groups, allowing for a detailed analysis of the composition and distribution of elements within the generator. One of the key achievements of this research study is the quantification of strategic raw materials in the generator. By precisely determining the content of these materials, this study provides valuable insights into potential vulnerabilities related to the supply chain, shedding light on the risk of shortages of critical elements crucial for the generator’s functionality. Furthermore, the assessment of recycling rates was a focal point of the research. By evaluating the efficiency of recycling processes for various materials within the generator, this study contributes to understanding the sustainability and environmental impact of current recycling practices. This evaluation is crucial for identifying areas for improvement and optimizing recycling strategies to enhance resource recovery. The degree of substitutability, another vital aspect explored in this research, helps gauge the extent to which certain materials within the generator can be replaced with alternatives. This information is crucial for devising contingency plans and exploring alternative materials, mitigating the impact of potential supply chain disruptions or shortages of specific raw materials.

3.1. Generator Disassembly

The purpose of disassembling the generator was to determine the share of each material, which is necessary to assess the supply risk. The methodology for disassembling the generator (

Figure 1) was developed based on the authors’ research. They defined the necessary steps related to segregation, allowing for a determination of the shares of strategically important raw materials. The elements of a disassembled three-phase generator containing a permanent magnet of the type PMzg132-8B, manufactured by KOMEL (

Figure 2), were analysed. This type of generator can be used to produce electricity for households, small businesses or other small consumers.

The disassembly of the permanent magnet generator and the development of the disassembly methodology were carried out at the KOMAG Institute of Mining Technology. The generator disassembly methodology included the steps below and a description of the found problems and their elimination.

Schedule of disassembly:

Stage 1: developing the concept of the disassembly sequence.

Stage 2: the preparation of necessary resources and equipment.

Preparation of the workplace:

Stage 1: preparing the place for generator disassembly.

Stage 2: providing the necessary personal protective equipment.

Disassembly of the generator’s connecting components:

Stage 1: the disassembly of bearing disk covers and the terminal box.

Stage 2: the disassembly of the aluminium strips from the extended shaft supporting the NdFeB magnets.

Pulling off the shaft with magnets:

Stage 1: removing the shaft with permanent magnets from the generator stator using pullers.

In this step, a problem was identified with freely pulling the generator shaft out of the generator stator. The problem resulted from the magnetic force of the permanent magnets on the generator shaft. To solve the problem, pullers were used (

Figure 3), enabling the shaft with permanent magnets to be pulled out.

Disassembling the permanent magnets:

Stage 1: the disassembly of the NdFeB magnets using a gas burner.

In this step, the magnetic force of the permanent magnets did not allow for the removal of the magnets from the generator shaft. After removing the aluminium strips that positioned the magnets on the shaft, the magnetic force prevented the magnets from being removed. Thermal processes using a gas burner were used to remove the magnets by reducing their magnetic strength (

Figure 4).

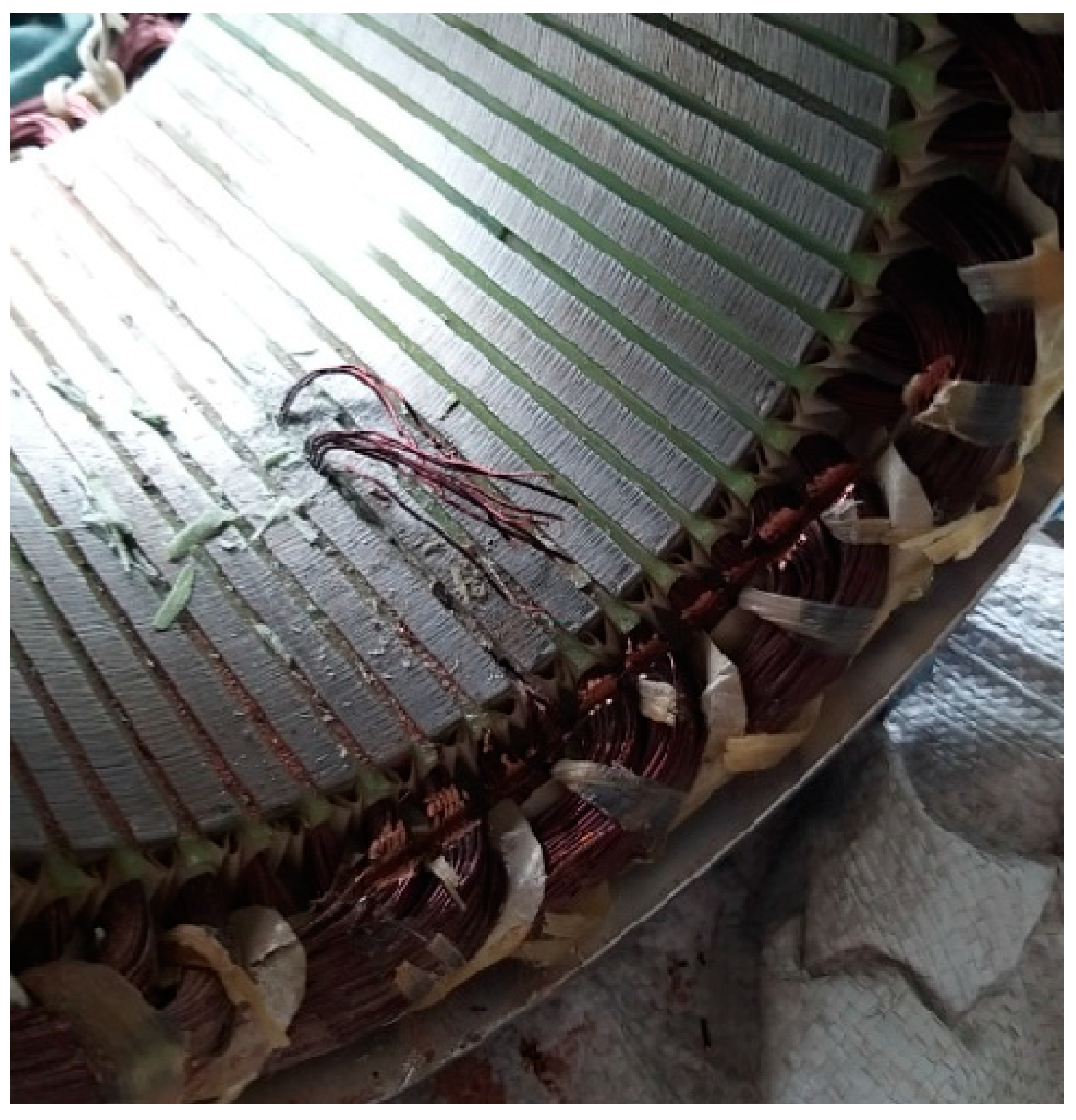

Disassembly of the generator’s integral components and the disassembly of the copper winding:

Stage 1: disassembling the copper winding from the stator grooves and removing the paper lining from the grooves.

Stage 2: removing the laminate from the stator grooves using a special device.

At this stage, it was necessary to remove the laminate from the stator grooves to free the copper winding—a precision device with diamond-tipped drills was used for this purpose (

Figure 5).

Segregation of materials:

Stage 1: the segregation into groups of materials.

Stage 2: determining the material balance of the components included in the disassembled generator.

Documentation:

Stage 1: documenting all elements of the disassembly process, including the problems or incidents (the unforeseen need to purchase pullers).

3.2. Obtained Materials and Their Mass Distribution

As a result of the disassembly, the share of each group of materials of the generator was determined (

Table 1).

As a result of disassembling the generator, the materials were divided into the following 10 groups:

Steel elements including the stator, shaft, connecting components, and bearing cover (

Figure 6);

Aluminium elements—flat bars positioning the permanent magnets and aluminium rings (

Figure 7);

Plastics—covers and generator covers (

Figure 9);

Copper components—generator winding (

Figure 11);

Composite materials—insert in the stator grooves (

Figure 12);

Paper—copper coil insulator in the stator grooves, wrapped between the copper winding (

Figure 13);

Other materials—materials containing adhesives and resins (

Figure 14);

Material resulting from disassembly—a mixture of fine materials (the copper winding, removed laminate) (

Figure 15).

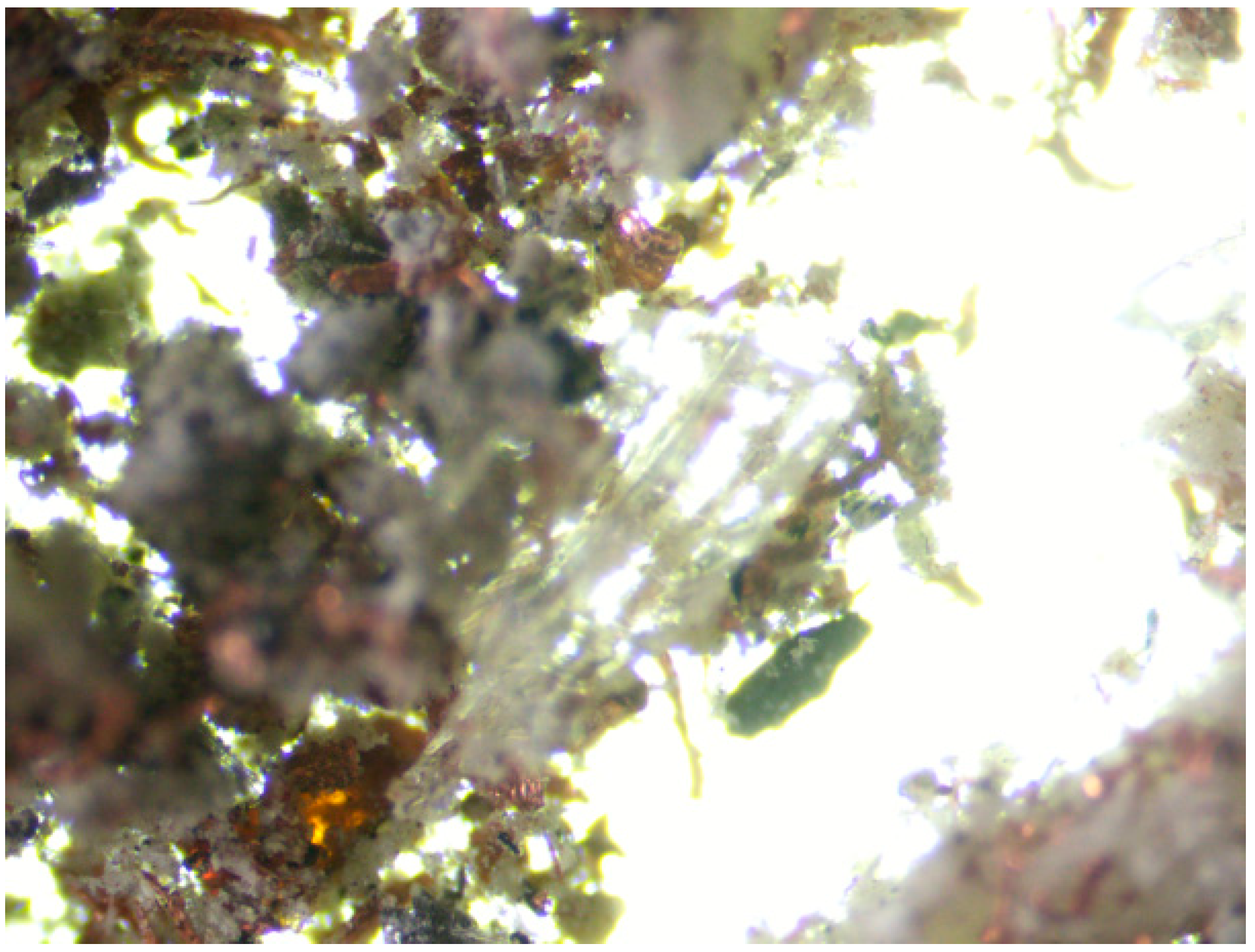

In the next stage of this research work, the share of each component from the mixture of fine materials resulting from disassembly was determined. To identify each material group, a microscopic technique was used (

Figure 16).

4. Content of Strategic Raw Materials in the Generator

In 2023, the European Commission published an updated list of critical and strategic raw materials for the European Union economy. These raw materials are crucial for the development of the economy and are widely used in production chains, including in the modern technology industry. The document containing the latest list of critical raw materials is intended to develop activities in the field of scientific and innovative research work, renegotiate trade agreements and implement new projects in the field of new sources of critical raw materials. It also establishes levels of production, processing and recycling, and determines the risk of the loss of supplies of critical raw materials. The list includes the following elements and minerals: antimony, arsenic, bauxite/aluminium, barite, beryllium, bismuth, boron, fluorite, phosphates, phosphorus, gallium, germanium, graphite, hafnium, helium, cobalt, silicon metal, lithium, magnesium, manganese, copper, nickel, niobium, platinum group metals (PGMs), heavy REEs, light REEs, feldspars, scandium, strontium, tantalum, titanium metal, vanadium, coking coal and tungsten [

13,

14].

The analysed generator consisted of raw materials that are critical and of strategic importance for the economy. The generator manufacturer is at risk of losing supplies of critical raw materials, the rare earth raw materials that are necessary for the manufacture of NdFeB magnets. The NdFeB permanent magnets themselves consist of the following elements: iron, neodymium, dysprosium, praseodymium, boron, cobalt, gallium, copper, aluminium and titanium [

15,

16].

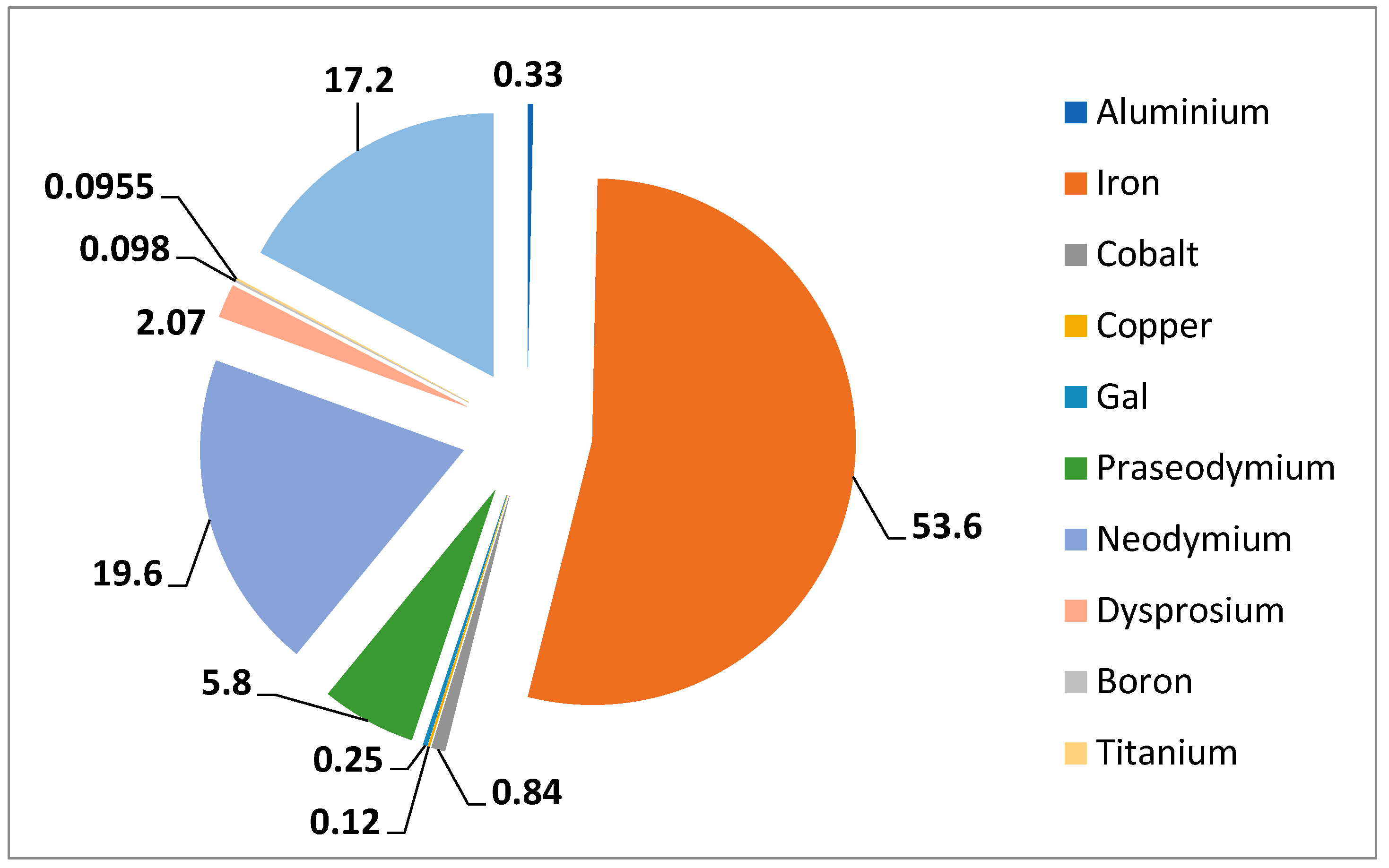

Therefore, the content of elements contained in NdFeB magnets was analysed (

Table 2).

Before determining the content of elements, it was necessary to properly prepare the samples for testing. The magnet from the disassembly of the generator was crushed in a laboratory crusher and then ground in a laboratory grinder.

The milling process produced a finely ground material with a grain size of <0.2 mm, from which a representative five-gram sample was selected.

The fine grain size of the material resulted from the adopted method of element determination. This study was performed using mass spectrometry with ionization in inductively coupled plasma (ICP-MS). The analysis of the element content in the submitted sample was as follows. The laboratory sample was tested for dry matter content and its mineralization. The sample was then mineralized in a closed system, wet, using a microwave mineralizer. The quality of the dissolution of the tested samples was visually assessed to determine if the solution was colourless and clear.

The contents of the specified elements in NdFeB magnets are presented in

Table 2 and

Figure 17.

After the disassembly of the generator and the material analysis, it was shown that the NdFeB magnets in the generator contain eight critical and strategic raw materials.

The share of critical raw materials in the entire generator is 9.84% (NdFeB magnets, aluminium components, copper stator winding and copper wires).

5. Assessment of the Risk of the Loss of Supplies and the Degree of Substitutability

Assessing the risk of the loss of the supply of strategic raw materials and their substitutability is a key element of supply chain management. The elements contained in NdFeB magnets are important from the perspective of economic development. Due to their importance, they were assessed in terms of the risk of the loss of supply, recycling rate and degree of substitutability (

Table 3).

The assessment was based on Royal Society of Chemistry (RSC) tests. RSC tests in the field of chemistry provide, among others information, information on the assessment of the element contents [

17].

Neodymium magnets consist of elements with varying levels of risk of the loss of supply and substitutability. Their recycling rate is crucial for the protection of natural resources and sustainable production.

The risk of the loss of supply is rated on a scale from 1 (very low risk) to 10 (very high risk). It is determined by combining an assessment of abundance in the Earth’s crust, an assessment of the distribution of reserves and an assessment of political stability. The presented analysis shows that cobalt, gallium, praseodymium, neodymium and dysprosium all have a very high (9.5) risk of loss of supply. The lowest risk of loss of supply, not exceeding a value of 5, is found for copper, boron, aluminium and titanium.

The recycling rate determines the share of a given element from the recycled material. In the case of gallium, praseodymium, neodymium and dysprosium, the recycling rate is very low, below 10%. For the remaining analysed elements, this rate exceeds 30%.

The degree of substitutability determines the availability of substitutes for a given element. It is marked on a three-point scale: high (replacement with a substitute is not possible or very difficult), medium (replacement with a substitute is possible but may have a significant impact on the profitability or efficiency of the solution) and low (substitution is possible with little impact on the profitability or efficiency of the solution). In the case of the elements considered, only for copper is the degree of substitution low. For the remaining elements, this degree is medium (aluminium, iron, cobalt, gallium, titanium) or high (praseodymium, neodymium, dysprosium) [

17].

From the above, it results that the analysed elements are of great importance for the economy, and their lack or insufficient availability may seriously affect the functioning of industrial sectors.

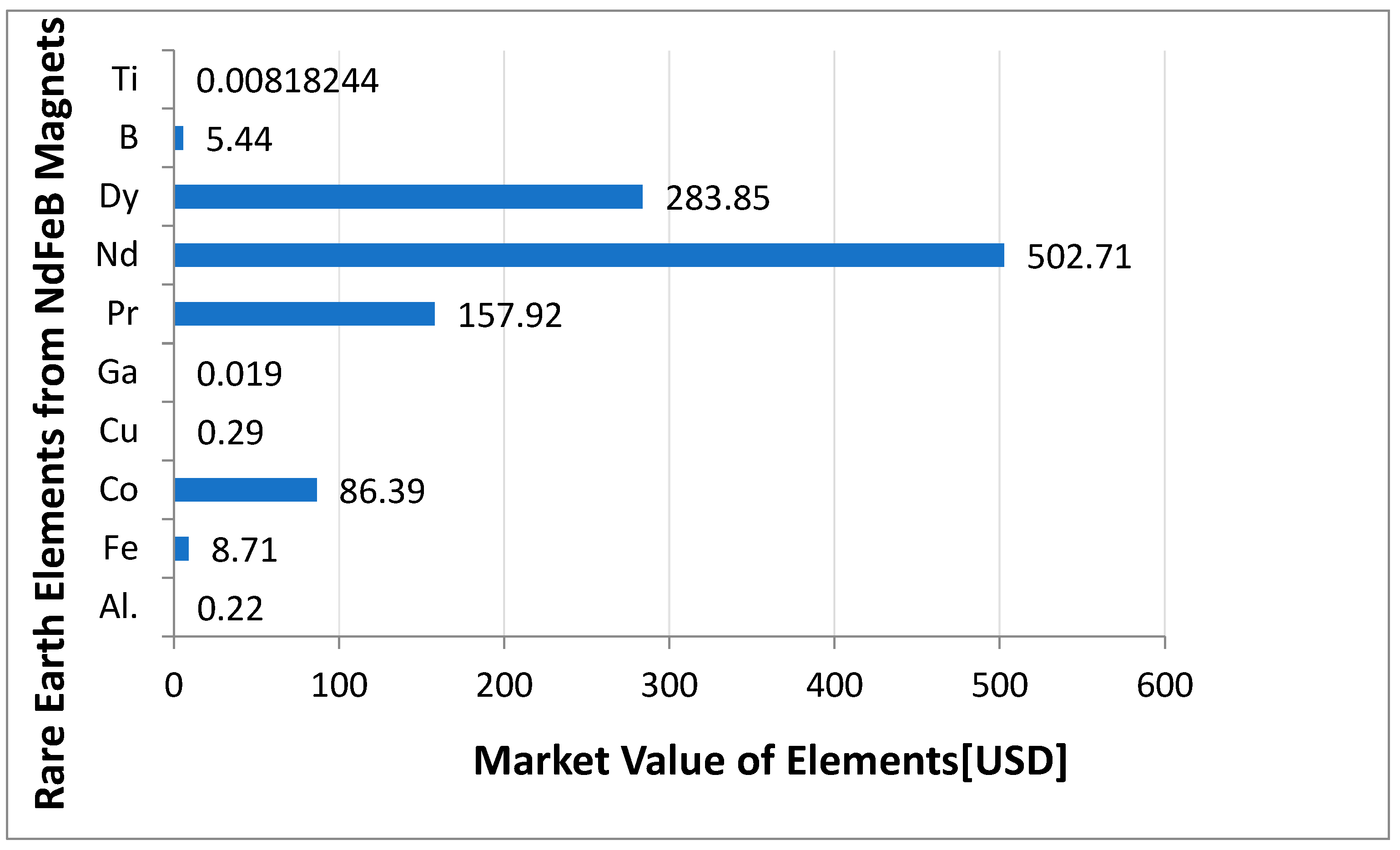

6. Market Value of the Elements in the Neodymium Magnets

Due to the importance of the elements in NdFeB magnets, possible financial benefits from their recycling were calculated based on current stock exchange prices. This analysis enabled a calculation of the value of each element contained in a neodymium magnet (in one generator) (

Figure 18) and their value per 1 ton of generators from which the magnets come (

Figure 19). The calculations are based on the current prices of elements (as of 16 October 2023) on world markets, expressed in US dollars (USD) [

18,

19].

The recycling of metals has high benefits, both environmental and financial. A simulation of the financial benefits resulting from the market value of the elements included in permanent magnets shows that the highest value is represented by rare earth elements (dysprosium, neodymium, praseodymium) and cobalt.

Based on the current prices of elements (16 October 2023), it was estimated that the market value of the elements in the NdFeB magnets from the generator is USD 73.02. Converting the value of the analysed elements into 1 ton of generators, their market value is USD 1045.56.

7. Discussion

The research topic undertaken and the work involved in its implementation were carried out using the knowledge, experience and research infrastructure of ITG KOMAG in Gliwice and the Silesian University of Technology in Gliwice.

The realisation of this research study, the results of which are presented in the above article, allowed the following thoughts to be formulated:

The assessment of the risk of the loss of supply is a key element of supply chain management in various industries. The results of research on this issue can bring important information on how to minimise risk and improve the efficiency of the entire supply system.

The results of research on the degree of substitutability of materials can contribute to the identification of potential benefits, challenges and developments that will affect sustainable and efficient production in different sectors of the economy.

Research on recycling rates is key to understanding the effectiveness of waste management activities and sustainable resource management.

In the course of this endeavour, a comprehensive methodology was meticulously devised for the disassembly of generators containing NdFeB magnets. This method encompasses a systematic breakdown of the generator, with a particular focus on the separation of components, thereby facilitating the precise quantification of strategically significant raw materials. Each step in this segregation process was meticulously outlined, ensuring a thorough analysis of the proportion of vital resources. Following the successful segregation phase, specific raw materials were meticulously prepared for experimentation at the ICPMS station. The outcomes of these tests not only validated the feasibility of the process but also elucidated the economic advantages arising from the recovery of valuable elements. The subsequent phase of our research endeavour will delve into the development of innovative technologies for the efficient recycling of rare earth elements extracted from permanent magnets within generators. Furthermore, our future research trajectory encompasses a broader scope wherein we aim to investigate additional facets such as the determination of environmental parameters, including the assessment of the carbon footprint associated with the entire life cycle of this type of generator. This holistic approach reflects our commitment to sustainable practices and underscores the multifaceted impact of our research on both economic and environmental fronts. As we embark on the next phase of our scientific inquiry, the objective remains to contribute significantly to the advancement of green technologies and the responsible utilization of critical raw materials.

8. Conclusions

The adopted methodology of disassembling the generator presented in this article allowed for the determination of the share of each component included in it.

Material analyses show that permanent magnet generators are at risk of losing supplies of critical raw materials. Based on the disassembly, it was shown that the NdFeB magnets alone contain eight critical raw materials. The total content of critical raw materials in the generator is 9.84%. An analysis of the elements contained in the magnets showed a very high risk of the loss of supplies, i.e., for cobalt, gallium, praseodymium, neodymium and dysprosium. An assessment of the recycling rates for gallium, praseodymium, neodymium and dysprosium showed a very low recycling level (below 10%). Among the analysed economic parameters of permanent magnets, the best-rated replacement rate was based on Royal Society of Chemistry (RSC) tests.

Only in the case of copper is the degree of substitutability low (

Table 3), while for the remaining elements, it is medium or high.

The estimated market value (

Figure 18 and

Figure 19), resulting primarily from the share and value of neodymium, dysprosium and cobalt, is significant. The simulation shows that recycling metals from NdFeB magnets can bring both environmental and economic benefits. Exact financial benefits may vary depending on current market conditions. The price of each rare earth element may change for various reasons, such as supply and demand on the global market, the economic policy of China, which is the main producer of REEs, and technological progress affecting mining and production processes.

The presented research methodology and analysis of the results allow us to conclude that the shortage of critical materials on the market and problems with the supply chain of raw materials, mainly from China, necessitate the further development of work in the described direction.