Hydrodynamic Insights on Floating Bubbling Fluidized Beds: Dynamic Solutions for Mitigating Gas Maldistribution

Abstract

1. Introduction

2. Materials and Methods

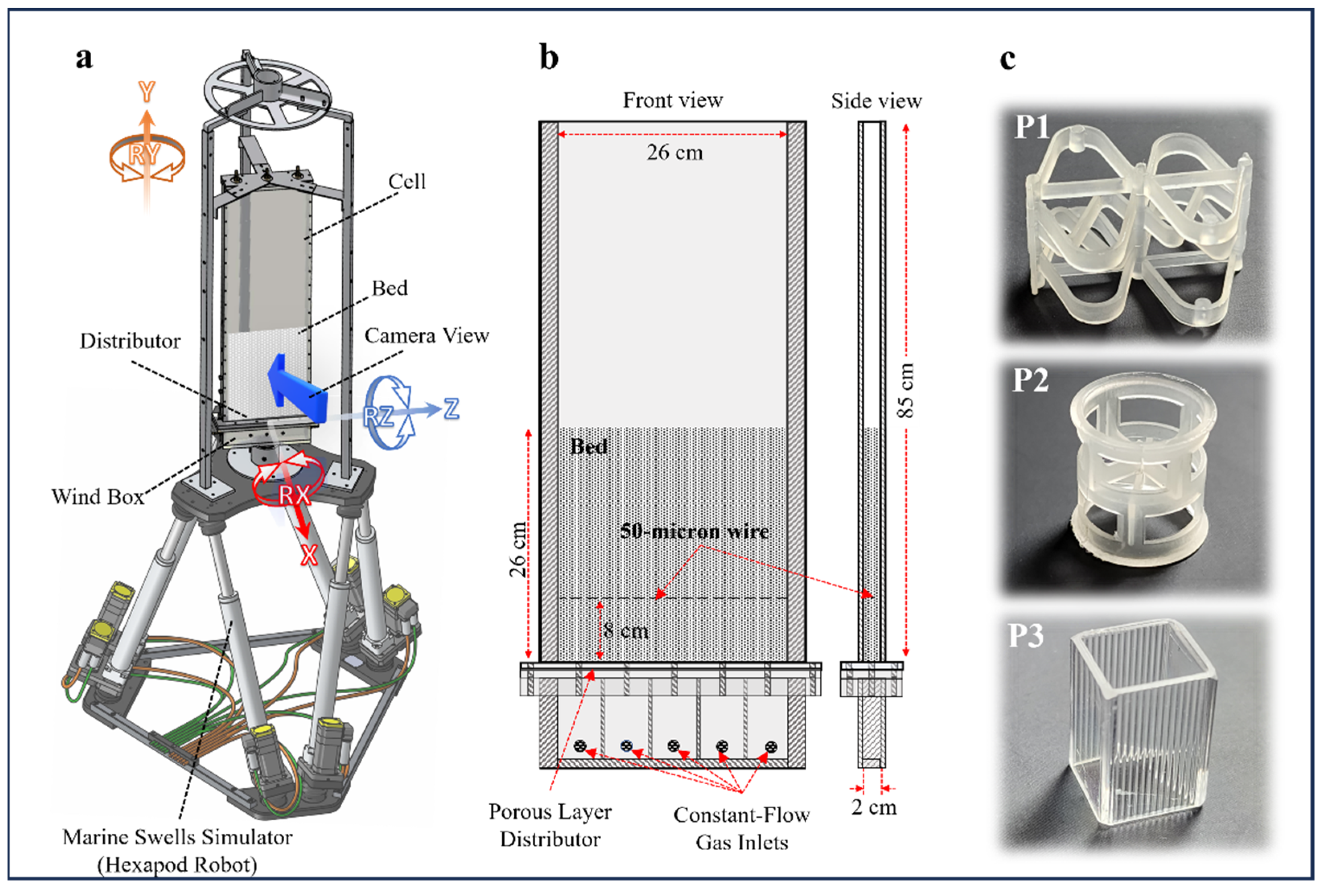

2.1. Setup

2.2. DIA

2.3. PIV

3. Results and Discussion

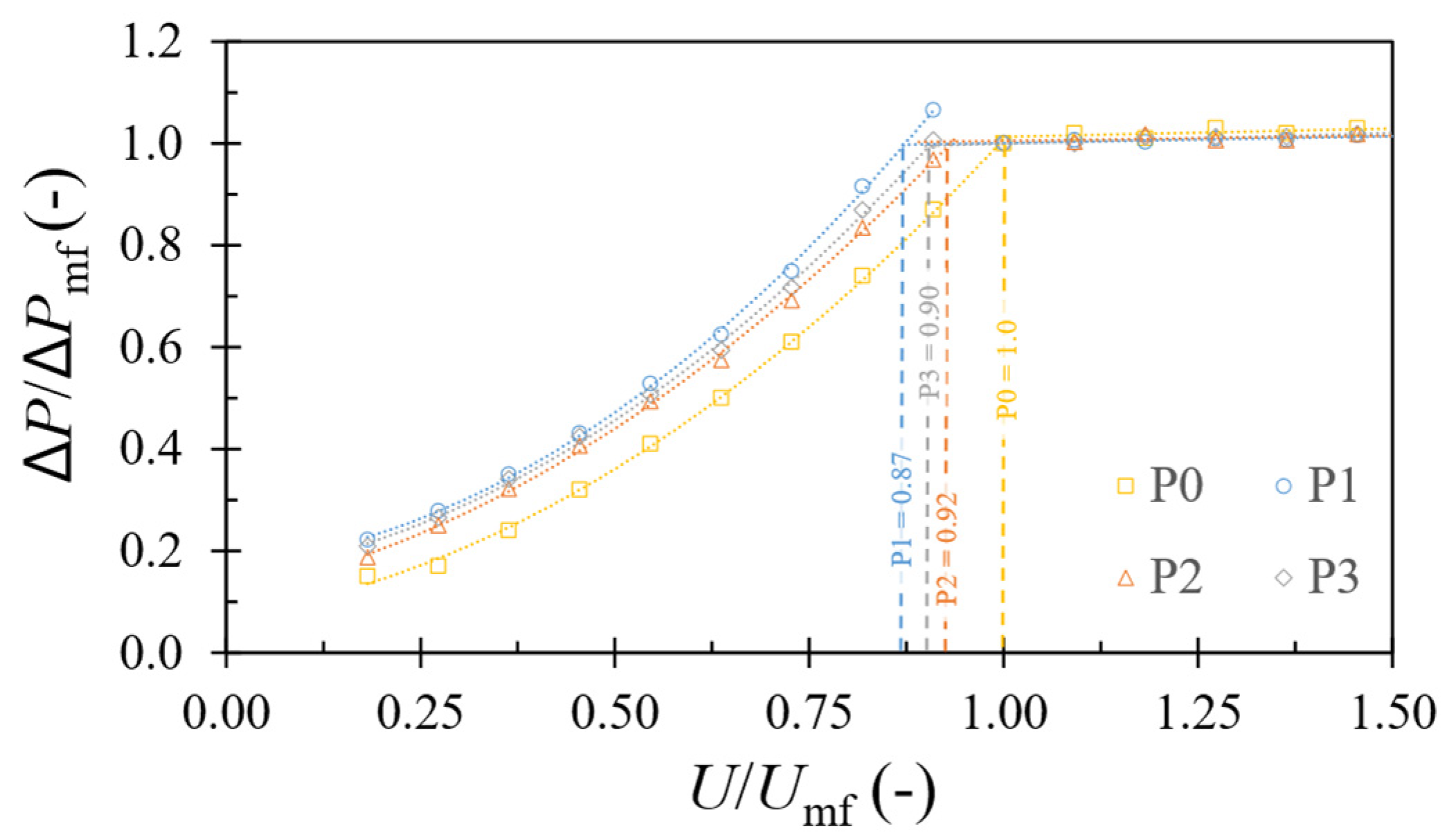

3.1. Pressure Drop and Minimum Fluidization

3.2. Internals and Bubble Coalescence Inhibition

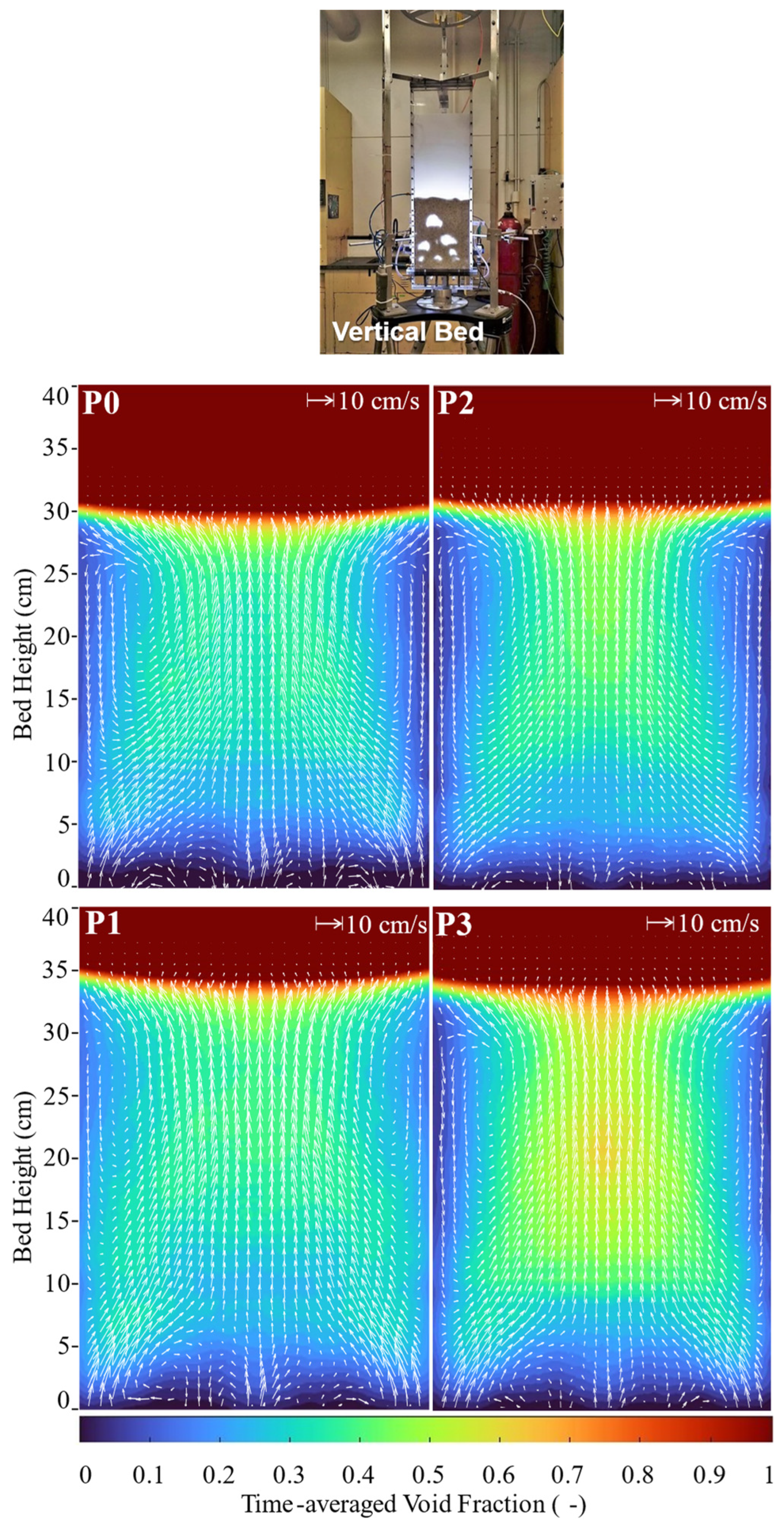

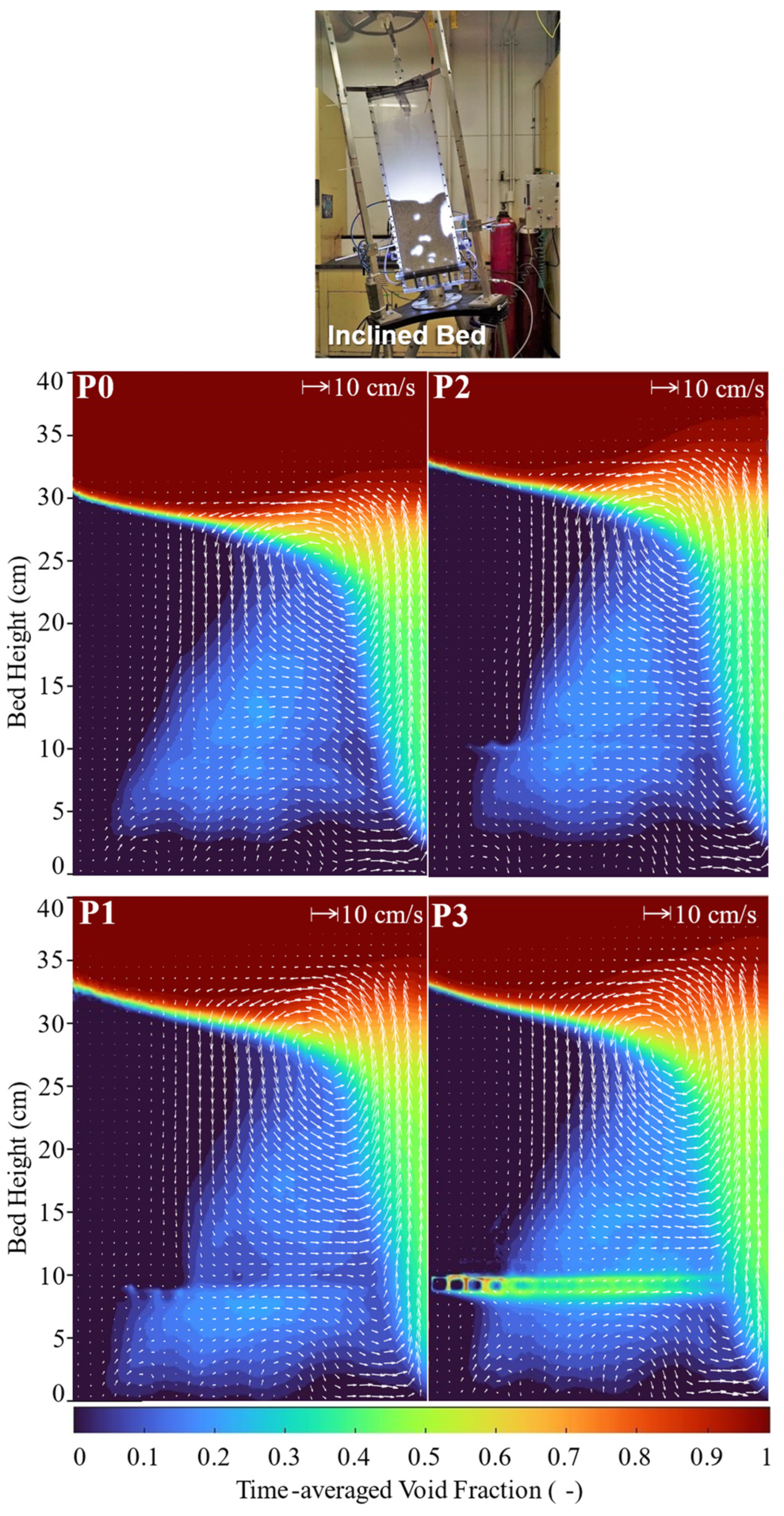

3.3. Time-Average Local Void Fraction/Velocity Field

3.3.1. Vertical Bed

3.3.2. Inclined Bed

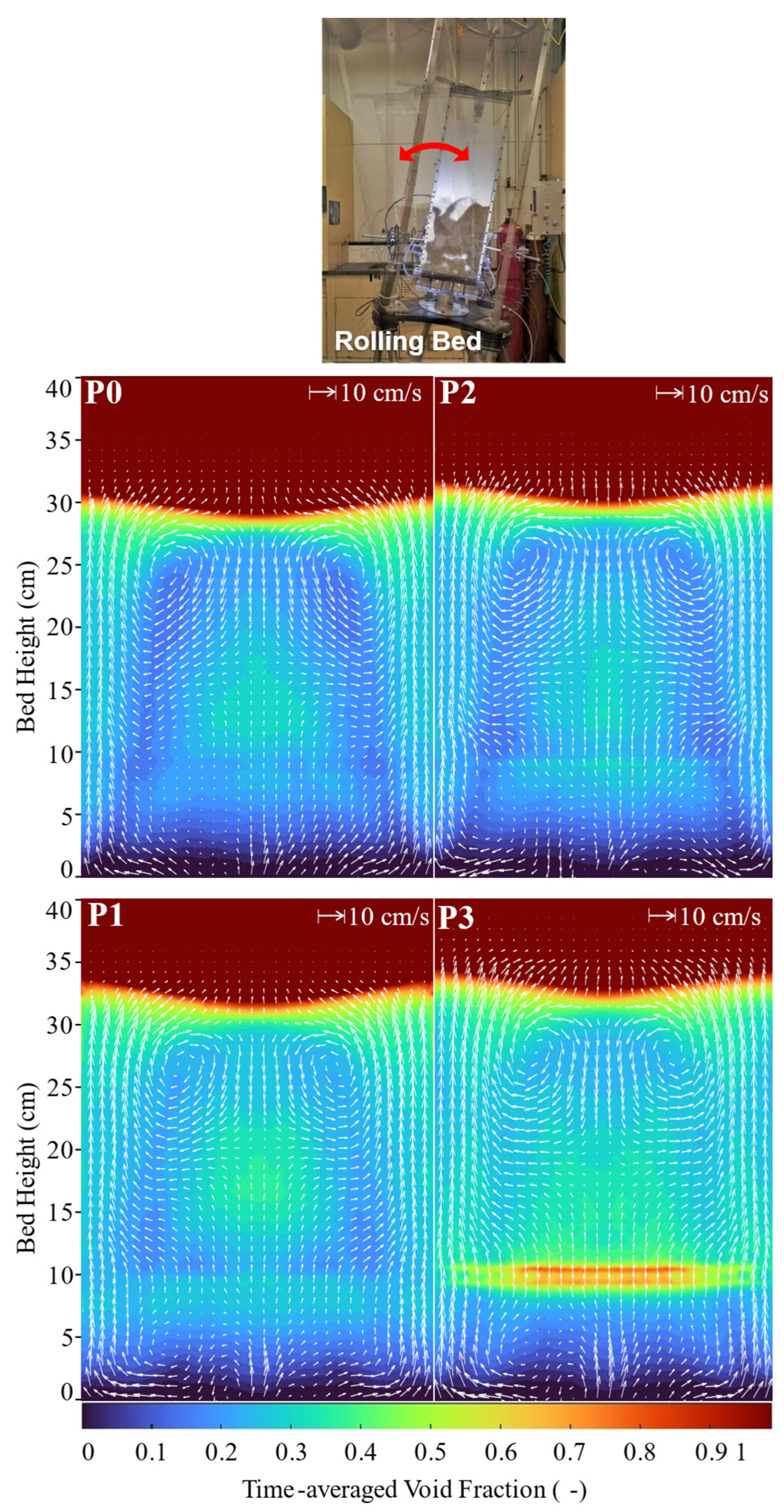

3.3.3. Rolling Bed

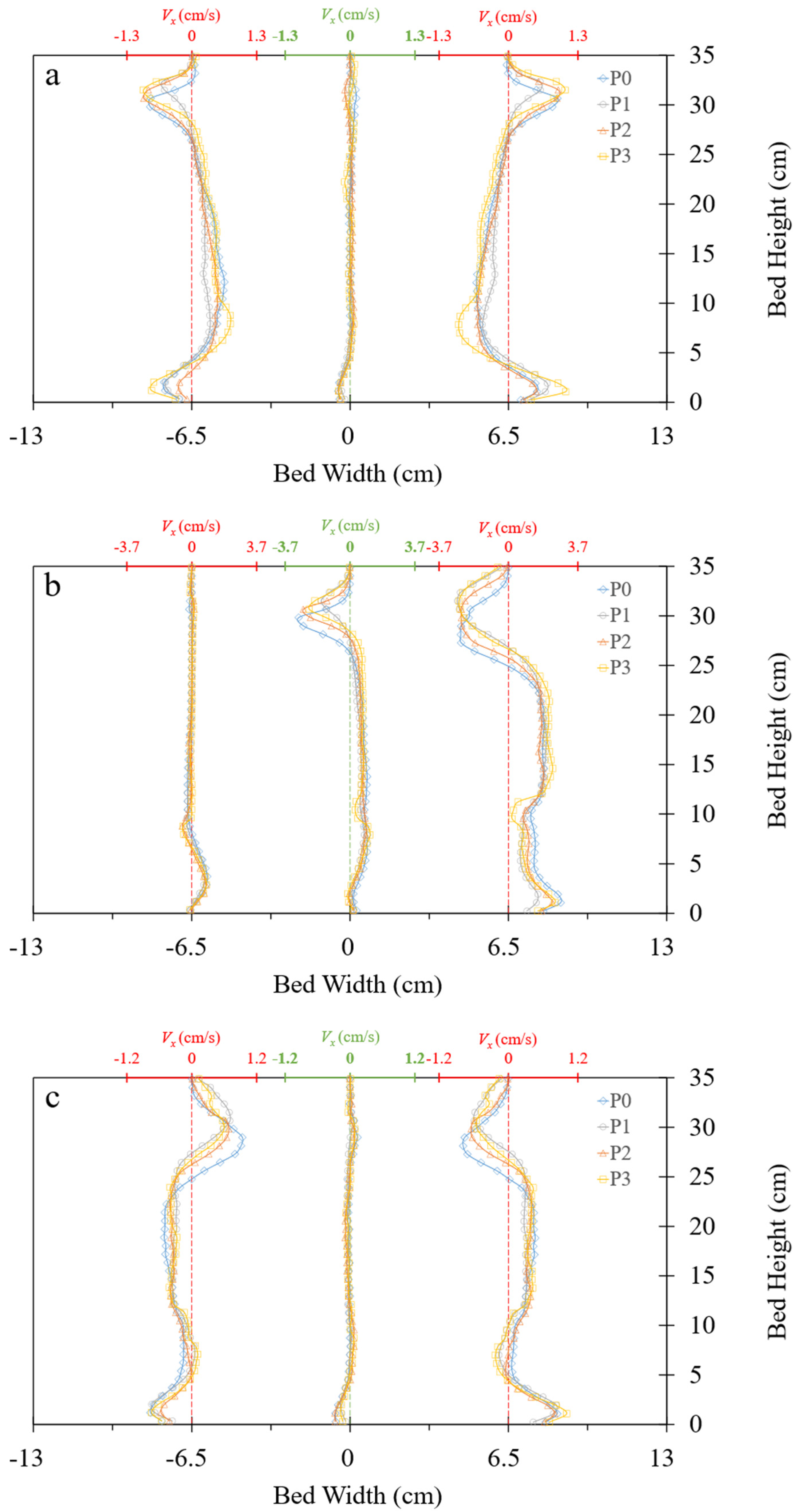

3.4. Velocity Components of Granular Phase

4. Conclusions

- Vertical bed: The introduction of P1 internals had a significantly increased bed height and improved bubble distribution efficiency. This was in contrast with the moderate changes caused by P2 and the less efficient changes caused by P3 internals, highlighting the increased operability of P1 due to its unique geometry that favored the maintenance of smaller bubble sizes.

- Inclined bed (9°): In this case, the P1 internals were found to be superior to the other internals. Nevertheless, the drastic maldistribution conditions imposed by a static bed inclination could not be corrected by adding internals to the bed.

- Rolling bed: Once again, the effectiveness of the P1 internals was evident, with a notable 10% increase in the bed void rate due to the presence of smaller bubbles and the inhibition of bubble coalescence, surpassing the improvements achieved by the P2 and P3 internals. This underscores the versatility of the P1 internals in the dynamic environment of rolling fluidized beds.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| dp | Particle diameter (cm) |

| FI | In-plane missing particles |

| FO | Out-of-plane missing particles |

| FT | Particle shape |

| ft | Tracer fraction factor |

| FΔ | Velocity distribution |

| M | Pixel-to-millimeter conversion factor (mm−1) |

| N | Total number of particles |

| NI | Particle count in interrogation window |

| P0 | No internal |

| P1 | Super Raschig ring |

| P2 | Pall ring |

| P3 | Square ring |

| RD | Particle displacement (m) |

| Umf | Minimum fluidization gas velocity (cm/s) |

| VX | Particle transverse velocity component (cm/s) |

| VY | Particle longitudinal velocity component (cm/s) |

| ΔP | Bed pressure drop (psi) |

| ΔPmf | Minimum fluidization pressure drop (psi) |

| Acronyms | |

| 2D | Two dimensional |

| DIA | Digital image analysis |

| ECA | Emission control area |

| EGCS | Exhaust gas cleaning system |

| EPS | Expandable polystyrene |

| IMO | International Maritime Organization |

| MARPOL | International Convention for the Prevention of Pollution from Ships |

| PIV | Particle image velocimetry |

References

- Eyring, V.; Isaksen, I.S.A.; Berntsen, T.; Collins, W.J.; Corbett, J.J.; Endresen, O.; Grainger, R.G.; Moldanova, J.; Schlager, H.; Stevenson, D.S. Transport impacts on atmosphere and climate: Shipping. Atmos. Environ. 2010, 44, 4735–4771. [Google Scholar] [CrossRef]

- Motamed Dashliborun, A.; Zhang, J.; Taghavi, S.M.; Larachi, F. 110th anniversary: Marinization of multiphase reactors through the prism of chemical Engineers. Ind. Eng. Chem. Res. 2019, 58, 2607–2630. [Google Scholar] [CrossRef]

- Sarbanha, A.-A.; Larachi, F.C.A.; Taghavi, S.-M.; Thiboutot-Rioux, M.; Boudreau, A.; Dugas, G. Mitigation of Ship Emissions: Overview of Recent Trends. Ind. Eng. Chem. Res. 2023, 62, 1707–1724. [Google Scholar] [CrossRef]

- Fitzmaurice, M.; Borg, S.; Attard, F.G.; Vella de Fremeaux, P.M. Research Handbook on Ocean Governance Law. In Chapter 6: The International Convention for the Prevention of Pollution from Ships (MARPOL); Edward Elgar Publishing: Northampton, MA, USA, 2023; pp. 91–108. [Google Scholar]

- Zannis, T.C.; Katsanis, J.S.; Christopoulos, G.P.; Yfantis, E.A.; Papagiannakis, R.G.; Pariotis, E.G.; Rakopoulos, D.C.; Rakopoulos, C.D.; Vallis, A.G. Marine Exhaust Gas Treatment Systems for Compliance with the IMO 2020 Global Sulfur Cap and Tier III NOx Limits: A Review. Energies 2022, 15, 3638. [Google Scholar] [CrossRef]

- Papadopoulos, C.; Kourtelesis, M.; Moschovi, A.M.; Sakkas, K.M.; Yakoumis, I. Selected Techniques for Cutting SOx Emissions in Maritime Industry. Technologies 2022, 10, 99. [Google Scholar] [CrossRef]

- Joung, T.-H.; Kang, S.-G.; Lee, J.-K.; Ahn, J. The IMO initial strategy for reducing Greenhouse Gas(GHG) emissions, and its follow-up actions towards 2050. J. Int. Marit. Saf. Environ. Aff. Ship. 2020, 4, 1–7. [Google Scholar] [CrossRef]

- Chong, Y.O.; Leung, L.S.; Nguyen, T.H.; Teo, C.S. Inclined Fluidized Bed, AIChE Symposium Series; Department of Chemical Engineering, University of Queensland: St. Lucia, Australia, 1984; p. 241. [Google Scholar]

- O’dea, D.; Rudolph, V.; Chong, Y.; Leung, L. The effect of inclination on fluidized beds. Powder Technol. 1990, 63, 169–178. [Google Scholar] [CrossRef]

- Liang, J.D.; Hsu, C.Y.; Hung, T.C.; Chiang, Y.C.; Chen, S.L. Geometrical parameters analysis of improved circulating inclined fluidized beds for general HVAC duct systems. Appl. Energy 2018, 230, 784–793. [Google Scholar] [CrossRef]

- Chiang, Y.C.; Chen, C.H.; Chiang, Y.C.; Chen, S.L. Circulating inclined fluidized beds with application for desiccant dehumidification systems. Appl. Energy 2016, 175, 199–211. [Google Scholar] [CrossRef]

- Yasui, T.; Nakayama, T.; Yoshida, K. Heat-transfer characteristics in a rocking fluidized bed. Int. Commun. Heat Mass Transf. 1984, 11, 477–488. [Google Scholar] [CrossRef]

- Mutsers, S.M.P.; Rietema, K. The effect of interparticle forces on the expansion of a homogeneous gas-fluidized bed. Powder Technol. 1977, 18, 239–248. [Google Scholar] [CrossRef]

- Gilbertson, M.A.; Yates, J.G. The tilting fluidized bed: A re-examination. Powder Technol. 1996, 89, 26–36. [Google Scholar] [CrossRef]

- Hamahira, S.M.Y.; Yutani, S.; Hashimoto, Y. Experimental Research of Fluidized Bed Combustion for Marine Application. J. Mar. Eng. Soc. Jpn. 1984, 18, 856–866. [Google Scholar] [CrossRef][Green Version]

- Murata, H.; Oka, H.; Adachi, M.; Harumi, K. Effects of the ship motion on gas–solid flow and heat transfer in a circulating fluidized bed. Powder Technol. 2012, 231, 7–17. [Google Scholar] [CrossRef]

- Sarbanha, A.A.; Larachi, F.; Taghavi, S.M. Bubble and particle dynamics in a thin rectangular bubbling fluidized bed under emulated marine instabilities. Chem. Eng. Sci. 2023, 280, 119041. [Google Scholar] [CrossRef]

- Sarbanha, A.A.; Larachi, F.; Taghavi, S.M. Solids Mixing in Marinized Bubbling Fluidized Beds: Gas Distribution Study. Ind. Eng. Chem. Res. 2023, 62, 18879–18891. [Google Scholar] [CrossRef]

- Zhao, T.; Ding, X.; Wang, Z.; Zhang, Y.; Liu, K. Dynamic control method of particle distribution uniformity in the rolling circulating fluidized bed (RCFB). Eng. Appl. Comput. Fluid Mech. 2021, 15, 210–221. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, T.; Yao, J.; Liu, K.; Takei, M. Influence of particle size on the exit effect of a full-scale rolling circulating fluidized bed. Partic. Sci. Technol. 2018, 36, 541–551. [Google Scholar] [CrossRef]

- Zhao, T.; Nakamura, Y.; Liu, K.; Murata, H.; Takei, M. The effect of rolling amplitude and period on particle distribution behavior in a rolling circulating fluidized bed. Powder Technol. 2016, 294, 484–492. [Google Scholar] [CrossRef]

- Fu, Z.; Zhu, J. Characterization of the Effective Density for the Separation of Immersed Objects in the Gas–Solid Fluidized Bed Coal Beneficiator. Ind. Eng. Chem. Res. 2023, 62, 17236–17242. [Google Scholar] [CrossRef]

- Utomo, M.S.K.T.S.; Yohana, I.E.; Krisna, B.; Dwinanda, M.F.; Tauviqirrahman, M.; Choi, K.-H. Effect of ring baffle on erosion in circulating fluidized bed boiler. Cogent Eng. 2023, 10, 2274534. [Google Scholar] [CrossRef]

- Huang, Y.; Bao, X.; Duan, Y.; Li, L.; Fang, D.; Wang, Y.; Duan, L. Heat transfer behavior of an immersed tube with sCO2 working fluid in a hot fluidized bed at high pressure. Fuel 2023, 333, 126457. [Google Scholar] [CrossRef]

- Nemati, N.; Filiu Moreno, P.; Rydén, M. Investigation of the hydrodynamics of packed-fluidized beds: Characterization of solids flux. Fuel 2023, 335, 127010. [Google Scholar] [CrossRef]

- Bouhamri, N.; Zelmat, M.E.; Tilmatine, A. Micronized plastic waste recycling using two-disc tribo-electrostatic separation process. Adv. Powder Technol. 2019, 30, 625–631. [Google Scholar] [CrossRef]

- Uemoto, K.; Narita, S.; Harada, S.; Sakamoto, Y.; Tsuji, T.; Oshitani, J.; Kajiwara, H.; Matsuoka, K. Wireless measurement of Float-Sink motion of Variously-shaped objects in Gas-Solid fluidized bed. Adv. Powder Technol. 2023, 34, 104111. [Google Scholar] [CrossRef]

- Gallucci, F. 4-Fluidized bed membrane reactors. In Current Trends and Future Developments on (Bio)Membranes; Basile, A., Gallucci, F., Eds.; Elsevier: Amsterdam, The Netherlands, 2023; pp. 77–93. [Google Scholar]

- Liu, W.; Larachi, F.; Chu, G.-W.; Luo, Y.; Taghavi, S.M. Spreading of point-source liquid spills in a thin rectangular packed bed under simulated marine conditions. AIChE J. 2023, 69, e17424. [Google Scholar] [CrossRef]

- Grace, J.R.; Bi, X.; Ellis, N. Essentials of Fluidization Technology; John Wiley & Sons: Hoboken, NJ, USA, 2020. [Google Scholar]

- Antistatic Agent for Expanded Polystyrene (EPS) and Expanded Polypropylene (EPP) (MECOSTAT®-3/549); MEK GmbH: Allensbach, Germany, 2022.

- Xiao, D.; Dong, X.; Hu, S.; Liu, X. Coupling particle image velocimetry and digital image analysis to characterize cluster dynamics in a fast fluidized bed. Powder Technol. 2024, 434, 119267. [Google Scholar] [CrossRef]

- Yuan, Z.; Huang, Z.; Ma, S.; Zhao, G.; Yang, H.; Yue, G. Experimental investigation on the effect of superficial gas velocity on bubble dynamics properties of B particles in gas–solid fluidized bed reactor using digital image analysis technique. Fuel 2023, 348, 128617. [Google Scholar] [CrossRef]

- Zhu, X.; Liu, Y.; Li, Y.; Wang, H.; Wang, Z. Bubble behaviors of geldart B particle in a pseudo two-dimensional pressurized fluidized bed. Particuology 2023, 79, 121–132. [Google Scholar] [CrossRef]

- Hou, J.; Grace, J.R.; Bi, X. Effect of gas properties on particle charging and wall fouling in gas-solids fluidized beds. Powder Technol. 2023, 421, 118419. [Google Scholar] [CrossRef]

- Westerweel, J. Fundamentals of digital particle image velocimetry. Meas. Sci. Technol. 1997, 8, 1379–1392. [Google Scholar] [CrossRef]

- Sarbanha, A.A.; Movahedirad, S.; Ehsani, M. On the hydrodynamics of a pseudo two-dimensional two-zone gas-solid fluidized bed. Chem. Eng. J. 2018, 350, 971–981. [Google Scholar] [CrossRef]

- Jahandar Lashaki, M.; Sarbanha, A.A.; Movahedirad, S. Overall particles flow pattern in a two-zone gas-solid fluidized bed with a secondary-gas stream. Chem. Eng. Res. Des. 2022, 187, 570–583. [Google Scholar] [CrossRef]

- Helmi, A.; Campos Velarde, I.; Gallucci, F.; van Sint Annaland, M. Hydrodynamics of dense gas-solid fluidized beds with immersed vertical membranes using an endoscopic-laser PIV/DIA technique. Chem. Eng. Sci. 2018, 182, 146–161. [Google Scholar] [CrossRef]

- Campos Velarde, I.; Gallucci, F.; van Sint Annaland, M. Development of an endoscopic-laser PIV/DIA technique for high-temperaturegas–solid fluidized beds. Chem. Eng. Sci. 2016, 143, 351–363. [Google Scholar] [CrossRef]

- Carlos Varas, A.E.; Peters, E.A.J.F.; Kuipers, J.A.M. Experimental study of fullfield riser hydrodynamics by PIV/DIA coupling. Powder Technol. 2017, 313, 402–416. [Google Scholar] [CrossRef]

- Julián, I.; Gallucci, F.; Van Sint Annaland, M.; Herguido, J.; Menéndez, M. Hydrodynamic study of a Two-Section Two-Zone Fluidized Bed Reactor with an immersed tube bank via PIV/DIA. Chem. Eng. Sci. 2015, 134, 238–250. [Google Scholar] [CrossRef]

- Julián, A.I.; Gallucci, F.; van Sint Annaland, M.; Herguido, J.; Menéndez, M. Coupled PIV/DIA for fluid dynamics studies on a Two-Section Two-Zone Fluidized Bed Reactor. Chem. Eng. J. 2012, 207–208, 122–132. [Google Scholar] [CrossRef]

- Roghair, I. Development of an Experimental Method to Investigate the Hydrodynamics in a Fluidized Bed Using PIV and DIA; University of Twente: Enschede, The Netherlands, 2007. [Google Scholar]

- Sugii, Y.; Nishio, S.; Okuno, T.; Okamoto, K. A highly accurate iterative PIV technique using a gradient method. Meas. Sci. Technol. 2000, 11, 1666–1673. [Google Scholar] [CrossRef]

- Adrian, R. Dynamic ranges of velocity and spatial resolution of particle image velocimetry. Meas. Sci. Technol. 1997, 8, 1393–1398. [Google Scholar] [CrossRef]

- Keane, R.; Adrian, R. Optimization of particle image velocimeters: II. Multiple pulsed systems. Meas. Sci. Technol. 1991, 2, 963–974. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sarbanha, A.A.; Larachi, F.; Taghavi, S.M. Hydrodynamic Insights on Floating Bubbling Fluidized Beds: Dynamic Solutions for Mitigating Gas Maldistribution. Energies 2024, 17, 672. https://doi.org/10.3390/en17030672

Sarbanha AA, Larachi F, Taghavi SM. Hydrodynamic Insights on Floating Bubbling Fluidized Beds: Dynamic Solutions for Mitigating Gas Maldistribution. Energies. 2024; 17(3):672. https://doi.org/10.3390/en17030672

Chicago/Turabian StyleSarbanha, Ali Akbar, Faïçal Larachi, and Seyed Mohammad Taghavi. 2024. "Hydrodynamic Insights on Floating Bubbling Fluidized Beds: Dynamic Solutions for Mitigating Gas Maldistribution" Energies 17, no. 3: 672. https://doi.org/10.3390/en17030672

APA StyleSarbanha, A. A., Larachi, F., & Taghavi, S. M. (2024). Hydrodynamic Insights on Floating Bubbling Fluidized Beds: Dynamic Solutions for Mitigating Gas Maldistribution. Energies, 17(3), 672. https://doi.org/10.3390/en17030672