Abstract

Industrial robots, like all machines, require energy to operate, which is why energy efficiency in industrial robotics has been a subject of consideration in recent years in many scientific and industrial centers. Interest in the topic is especially noticeable in Industry 4.0. Research on energy efficiency stems from the emergence of new possibilities in terms of making strategic decisions related to manufacturing processes. As energy-efficient production is an essential part of sustainable development, the energy efficiency of industrial robots must be considered. The need to reduce costs while maintaining quality and increasing production efficiency has necessitated the implementation of modern solutions aimed at reducing electricity consumption. The rational use of electrical energy, especially in the industrial sector, significantly reduces production costs and, consequently, contributes to a company’s profits and competitiveness. This article aims to provide an overview of energy efficiency issues based on recently published articles. This article discusses the appropriate selection of robots, their programming, energy-efficient trajectory planning, and the monitoring of the operation of the robotic system to minimize energy consumption. Typical industrial applications of robots are also mentioned and discussed.

Keywords:

energy efficiency; energy consumption; industrial robots; robotics; IIoT; smart monitoring 1. Introduction

The concept of Industry 4.0, which refers to the fourth industrial revolution, is mainly used in Europe. In the USA, it is commonly referred to as the Industrial Internet of Things (IIoT), or simply the “Industrial Internet”. Nevertheless, these terms, in practice, refer to the same concepts, namely, smart manufacturing, which focuses on obtaining real-time information through, among other devices and methods, industrial robots and automatic changes in production methods to achieve optimal resource allocation and to improve energy efficiency [1,2,3,4]. Efficient energy use is one of the strategic goals of the European Union with regard to energy policy. In 2018, EU leaders set a goal to reduce annual energy consumption in the Union by 32.5% by 2030. In March 2023, they agreed on EU targets to reduce primary and final energy consumption by 38% and 40.5% by 2030, respectively. Therefore, energy efficiency is a strategic priority for the EU, which promotes the principle of “energy efficiency first” [5]. Energy efficiency in the industrial sector is a significant factor affecting production costs. Irrational energy use leads to the excessive consumption of energy resources, environmental pollution problems, and excessive CO2 emissions. Therefore, it is evident that by reducing the intensive energy consumption of the production process, a company enhances its competitiveness in the market.

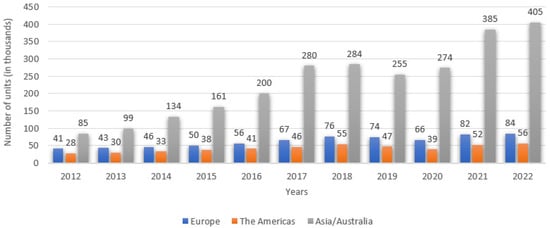

Currently, robotization is one of the main drivers of economic development in industrialized countries. According to the International Federation of Robotics [6], after the global production crisis caused by the COVID-19 pandemic, which paralyzed global production and slowed down investments, a clear revival has occurred. In 2022, the operational stock of industrial robots was computed at 3,903,633 units (+12%). In Asia, there was a 38% increase in the installation of new robots, though it was slightly lower in Europe, where a 24% increase in installation levels was noted compared with the previous year (Figure 1).

Figure 1.

Annual installations of industrial robots [6].

The dynamic development of technology has led to robots being present in almost every branch of industry. Robotization significantly shortens the time required to perform a single operation compared with manual execution. Increasing repeatability and production quality using industrial robots allows for high precision and stable working parameters, and it makes these devices popular for various industrial applications [7,8,9,10]. Every machine needs energy, as without it, it does not operate. However, machines vary in terms of how energy-intensive they are. The increase in the implementation of the number of robots used in the manufacturing process, which has occurred due to the addition of more electricity-consuming devices to production lines, leads to a higher demand for electric energy by the company, thereby increasing production costs. Reducing energy consumption can be achieved through technical means, such as the use of energy-efficient drives or other energy-saving devices. Additionally, improving energy efficiency can be indirectly achieved through organizational measures, such as the optimization of cycle times (operations) [11].

In addition to finding ways to improve the technical parameters of the robot, methods for appropriate trajectory planning are sought. Various proposals for energy-efficient path optimization algorithms, using advanced algorithms, can be found in the literature [12,13,14]. It should be noted, however, that they are usually complex and computationally time-consuming; thus, unfortunately, they are not readily available for general use. For instance, in [15], a multi-objective optimization approach was proposed for generating the energy-saving trajectories of robot manipulators with kinematic constraints, such as velocity limits, acceleration limits, jerk limits, joint angle, and forward kinematics. The sum of the squared joint accelerations was used to measure energy consumption. The proposed method reduced the total energy consumption by 6.1% compared with the energy consumption of the simulation with feasible solutions. To optimize the trajectory within the manipulator’s workspace, a multi-objective method based on the Kalman algorithm was proposed in [16]. The proposed method searches for the optimal solution within the manipulator’s limits, and it maintains the final effector orientation. In [17], a discrete and low-power-consumption motion-planning method for large spaces and the long-time motion of robots was proposed using a quantum computing method called Digital Annealer, developed by Fujitsu. The authors’ simulation results show that the proposed method can reduce the total torque consumption by 10%, and the computation time can be reduced by 77% compared with simple linear motion. Usually, although not always [18], this does not necessarily mean a simultaneous reduction in cycle time. In fact, these are usually two mutually exclusive issues.

As energy efficiency is a key concern in industry, a device’s market success can be determined by its energy consumption. The energy consumption level of production processes is a fundamental criterion for designing the processes and their components. This includes selecting and constructing technological devices, implementing the technological process, and employing production control procedures. Companies aim to reduce energy consumption in the production process by reorganizing the process itself. This can be achieved by replacing worn-out and energy-inefficient machines and equipment with more energy-efficient ones or by installing measurement and monitoring systems for energy and industrial processes. The first step in this process is to determine the level of the energy needs of the implemented technological process. Higher electricity costs lead to increased production costs in plants. The regular analysis of energy usage and costs, in line with production plans, can improve profitability. This approach reduces production costs and increases competitiveness in the market. The implementation of energy efficiency solutions can result in reduced production costs and limited greenhouse gas emissions.

The issue of electricity consumption in robotics is significant, given the increasing global energy consumption trend. By analyzing the market trends for creating automated and robotic production systems, it can be concluded that robotic systems will become increasingly widespread. Like any machine, a robot needs energy to operate. To achieve a balance in energy demand, both globally and in individual countries, it is essential to intensify efforts aimed at the rational use of energy. Raising awareness in society about this issue is also crucial. In addition to the economic aspect, the amount of electricity consumed also has a significant impact on the environment. Therefore, it is important to minimize the energy consumption of tasks performed by robots.

The purpose of this article is to identify and discuss the main factors that influence the energy consumption of robotic systems. Additionally, we will explore current and emerging methods for creating energy-efficient trajectories for robots. To achieve this, we have formulated the following research questions:

- RQ1: What methods are currently used to reduce the energy consumption of industrial robots?

- RQ2: What are the current trends in the development of methods for reducing energy consumption in robotics?

To provide objective answers to these questions, relevant search engine queries were generated using Google, Google Scholar, Bing, and others. We then analyzed the results of these searches in terms of their relevance to our study, which is the subject of this article. In addition to the web searches, we also analyzed selected references in the bibliographies of the articles found.

This article is structured as follows: Section 2 discusses methods for optimizing energy consumption in robotic systems, with a particular focus on energy-efficient trajectory planning. Section 3 examines the primary usage of industrial robot systems in conjunction with state-of-the-art Internet of Things solutions. Section 4 takes a broad approach to the optimization of energy consumption in industrial robots. Section 5 briefly presents the background and discusses contemporary trends in reducing the energy consumption of industrial robots.

2. Fundamentals of Energy Consumption Optimization for Industrial Robots

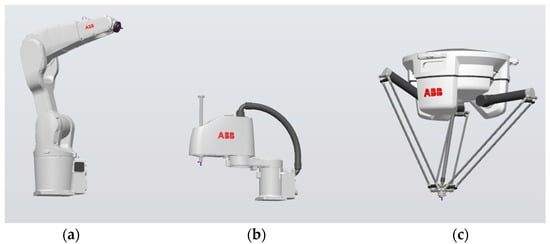

Energy-efficient robotics involves designing, manufacturing, and operating robots with the aim of reducing energy consumption and increasing efficiency [19]. The primary objective is to minimize the environmental impact of industrial robots by optimizing their processes and reducing electricity consumption. When reviewing the literature on industrial robotics, it becomes clear that research on energy efficiency primarily focuses on robots with an anthropomorphic structure, also known as articulated robots (see Figure 2a) [20,21]. These robots are the most implemented in the industry and are designed to perform functions similar to those of the human upper limbs, such as manipulative and articulated functions. Commonly encountered robots in the industry include Cartesian, SCARA (as shown in Figure 2b), and delta (parallel) robots (as shown in Figure 2c). These robots differ in their construction, operating principles, and basic technical parameters.

Figure 2.

Example manipulators of industrial robots: (a) robot with anthropomorphic structure; (b) SCARA; (c) Delta robot.

When selecting a robot for a specific application, it is crucial to conduct a thorough analysis of the company’s needs. The next step is to establish the goals that the implementation of robotics should achieve. These goals may include increasing efficiency, improving production quality, minimizing the risk of errors, or reducing fixed costs. To achieve sustainable development, it is crucial to design robotic cells that are not only operationally efficient but also energy-efficient. The energy consumption of robotic systems depends on various factors, including the type of robot, programming methods, and the nature of the process being executed [22].

These are introduced below.

The type of robot—The fundamental technical parameters of industrial robots are the number of axes, permissible payload, reach or workspace, maximum working speed, allowable arm load moments, and operation accuracy. Additionally, the weight, mounting method, power supply, and energy consumption are also crucial factors to consider. It is important to note that a robot with a large payload and reach will have different energy requirements than one with a small payload. The proper selection of a robot’s payload and reach for its functions can lead to energy savings. Each type of robot has specific power and energy requirements.

The type of process being performed—The energy consumption of robots during operations is primarily determined by parameters such as the speed, load, and distance covered. It is important to note that a robot with the maximum permissible load may not operate at its highest speed.

The programming method—Efficient programming and the application of advanced control algorithms can contribute to optimizing the energy consumption of robots. Optimal paths, effective motion planning, and intelligent task management can minimize energy consumption. Therefore, the programming of the robot’s trajectory is crucial, particularly with regard to the motion instructions used, specifically those below:

- PTP—Point to Point, also called “Joint”: The TCP (Tool Center Point) moves along the fastest trajectory. The movement is fast and repeatable.

- CP—Continuous Path (Linear or Circular Motion)—The Continuous Path is used when the movement needs to be controlled to precisely follow the programmed path. The TCP is moved along the specified trajectory. The robot controller automatically (at a specified frequency) memorizes the current positions.

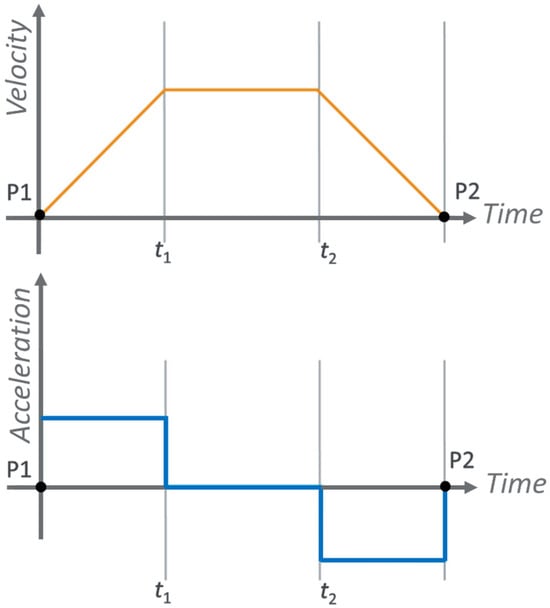

These instructions can also include precise (fine) or coarse positioning, known as approximation. The robot is required to stop at a certain point (target), which causes the motors to slow down. The energy generated by the reduction in speed is transferred to resistors and dissipated as heat. Increasingly, manufacturers are designing robots where the braking energy is recovered and fed back into the electrical grid [21,23]. Figure 3 illustrates the phases in the TCP motion of an industrial robot between points P1 and P2.

Figure 3.

The phases in the motion of the TCP (Tool Center Point) of an industrial robot manipulator between points P1 and P2.

To reduce energy consumption, it is recommended to avoid abrupt changes in speed and the acceleration of motors and other drive components. Trajectory optimization for smooth motion can significantly contribute to this goal. The authors of [24] demonstrated the impact of using Linear motion instructions and Joint-type instructions (PTP—Point to Point) on energy consumption. The authors conducted tests with two points 1.5 m apart and found that Joint-type motion consumes about twice as much energy at the peak moment compared to Linear motion. However, traveling along a trajectory programmed with a Linear instruction takes longer than the time taken with a Joint-type instruction (PTP) and therefore consumes more energy. It is important to optimize robots for energy consumption, both during operation and in standby mode. It is important to note that a robot at rest still consumes energy due to the activated motors that keep the robot arm stationary. However, deactivating the motor power automatically engages the mechanical brakes, resulting in individual kinematic units not drawing energy and a decrease in total consumption. Therefore, it is important to synchronize the operation of each robot in a cell. Programming the cell in a way that minimizes situations where one robot moves rapidly while another waits is crucial [14].

Virtual Programming (Offline)—The offline programming method is a technique that allows the creation, testing, and optimization of robot control programs without the physical presence of the robot on the production line. This method involves creating virtual robotic workstations and programming the trajectories of robot movements, which significantly reduces machine downtime. The ability to design in an offline mode enables the optimization of robot movement trajectories and reduces process cycle times, ultimately shortening the production startup time [25]. Offline environments also allow for the assessment of the impact of different trajectories on energy consumption, enabling the adjustment of robot movements in terms of energy consumption [26].

Work Environment—The energy consumption of a robot can be affected by the environmental conditions in which it operates. For instance, robots working in challenging conditions, such as high or low temperatures, may require additional energy to maintain their performance. High temperatures may cause the overheating of electronic and mechanical components, requiring additional cooling.

Energy-Efficient Components—The implementation of high-efficiency motors, such as brushless motors (BLDC) with permanent magnets, or energy recovery systems, such as regenerative brakes, allows for partial energy recovery. According to [23], energy recovery from braking can result in savings ranging from 8% to 25%. The degree of savings in each case fundamentally depends on the task and the individual motion patterns of the robot.

Monitoring Energy Consumption—Monitoring energy consumption is a crucial aspect of managing energy efficiency in industrial robotics. Continuous tracking and the analysis of the acquired data allow for the introduction of improvements aimed at optimizing the energy efficiency of robots. The essence of monitoring systems is a universal environment, such as cloud-based solutions, enabling direct data exchange, providing access to data, and facilitating various real-time analyses. The real-time monitoring of machine and device operating parameters enables the comprehensive communication of current information throughout the plant. This information is fundamental to making informed decisions to improve energy efficiency and reduce operational costs at all levels of the enterprise. Dedicated monitoring software detects anomalies in equipment operation and notifies the end-user when thresholds are exceeded. For instance, the software verifies the current consumption of individual robot axes, and if energy consumption is significantly higher than usual, it signals the possibility of overload or damage. The software can detect the cause of increased power consumption in individual robot components, such as a damaged gearbox generating high loads, and restore proper energy consumption through service intervention [27].

3. IoT Usage in Industrial Robot Systems

The use of the Internet of Things (IoT) in industrial robot systems is significant for several reasons. IoT allows for the real-time monitoring of industrial robot systems, providing operators and managers with live data on the robot’s performance, status, and other crucial parameters. The application of IoT has a significant impact on monitoring, decision making, preventive maintenance, and prompt issue resolution, thereby enhancing the overall operational efficiency. In the context of energy efficiency, IoT sensors play a crucial role in monitoring and optimizing energy consumption in real time. Energy efficiency is essential for sustainable and cost-effective operations. The Internet of Things (IoT) enables dynamic adjustments in energy usage, leading to reduced operational costs and environmental impacts. In summary, IoT’s significance in industrial robot systems lies in its ability to improve monitoring, control, efficiency, and adaptability. By utilizing IoT technologies, industrial operations can become more data-driven, resilient, and responsive to the dynamic demands of modern manufacturing environments.

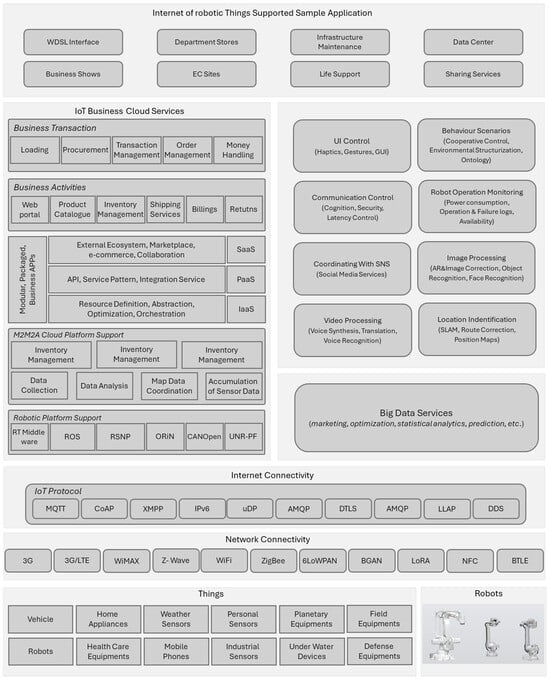

The concept of merging robots and the Internet of Things (IoT) has been labeled as the “Internet of Robotic Things” (IoRT). According to ABI Research, IoRT refers to “intelligent devices that can monitor events, collect data from various sensors, and utilize local and dis-tributed ‘intelligence data’ to determine the best way to operate” [28]. In [29], Figure 4 shows a conceptual diagram of the Internet of Robotic Things architecture.

Figure 4.

Conceptual diagram of Internet of Robotic Things architecture [29].

Existing solutions for IoRT are described in the article by Farnell [30]. It presents the implementation of IoT within Amazon’s order fulfillment warehouses, where robots equipped with special sensors are deployed to transport items to specified locations. These robots are controlled by a central processor through a Wi-Fi network.

In [30], the authors present a method for measuring gas waste using Industrial Internet of Things (IIoT) sensors. The described data collection system was able to determine that 62.1% of the gas used in the soldering process was wasted. This information can be utilized to enhance production efficiency, particularly by minimizing waste in the factory.

Article [31] suggests integrating IoT with mining robots and describes various benefits of using this modern technology. By connecting 24/7-operational IoT sensors, processes such as data collection can be automated, safety can be enhanced, and the development both above and below ground can be balanced.

Article [32] shows how a metal-mechanical company improved by implementing IoT. The data collected before and after the implementation of IoT in the tool machining production process were compared. Enhancements in certain areas of the process were significant, with an increase of over 30%, resulting in improved efficiency and cost-effectiveness. The article discusses the benefits of IoT applications, including communication, automation, control, monitoring, durability, and fewer issues related to temporal resolution. These advantages are further detailed in Table 1, which outlines the general and specific benefits of IoT in the case study. The authors note that a longer observation period is needed to reliably quantify the estimated 60% decrease in paper and ink consumption during the production process, as well as the reduction in energy consumption resulting from shortened production times and error reduction.

Table 1.

The energy consumption per cycle of five-bar linkage mechanisms with and without energy-reducing devices (ERDs) [33].

In their work presented in [34], the authors provide an update on their significant project aimed at achieving the autonomous operation of robots. This autonomy could improve the efficiency and quality of work performed by the robot. The authors also provide a table with an overview of articles related to the concept of IoRT. The table includes a general description of their contents.

Article [35] describes the computational architecture in IoT and its associated issues related to energy consumption. The authors emphasize that most available IoT devices are battery-powered. With the prospect of a significantly large number of sensors in the future [36,37], this could lead to serious issues concerning energy consumption, servicing costs, and device replacements. Improper maintenance and assessment of sensor lifecycles can result in electronic waste. Developing durable and energy-efficient batteries for sensors that can operate throughout their entire lifespan [38,39] is a challenge. Furthermore, determining methods for recycling sensors after their usability has ended is necessary.

A global energy crisis is predicted in the near future. Potential solutions include smart grids (SGs), electrical power system networks (ESNs), and IoT nodes [40]. In [35], the authors describe and analyze IoT protocols in the context of their characteristics and performance in smart grid communication.

Harvesting energy can help increase the efficiency and lifespan of IoT devices [40]. Integrated energy management circuits are essential for reducing battery power consumption, which significantly contributes to prolonging the lifespan of the system [8]. Elahi et al. [41] presented the concept of the Internet of Nano-Things (IoNT), which shows that in the future, IoT devices will use self-powering sources, along with advancements in nanotechnology, to create high-performance nanosystems.

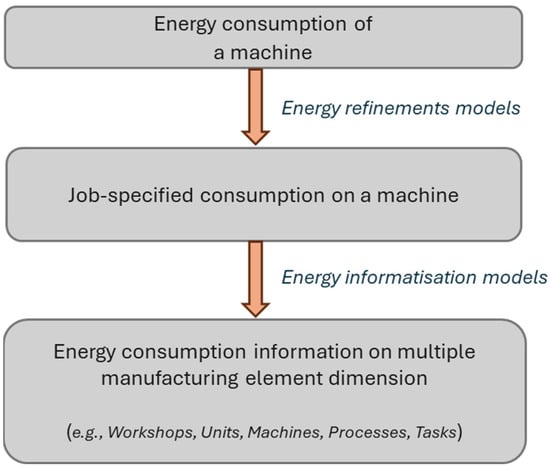

In [38], a method is proposed for modeling energy on the supply side based on existing industrial IoT devices for energy-intensive production systems of aluminum profiles. The system is energy-intensive and has a significant impact on the environment. To gather information on energy consumption, an Industrial Internet of Things (IIoT) data acquisition network was deployed (see Figure 5).

Figure 5.

Energy consumption information mapping [38].

The article presents potential support for improving the quantification of energy consumption for specific workstations, analyzing energy costs, and assessing the environmental impact. IoT sensors and connectivity enable the remote monitoring of robots’ performance and health, allowing for the real-time detection of anomalies or issues and enabling preventive maintenance to minimize downtime. Additionally, IoT data can be analyzed to predict future problems when a robot’s components are likely to fail. This allows for proactive maintenance scheduling, reducing unplanned downtime. Additionally, these sensors can monitor energy consumption in real time, helping organizations optimize robot operations for energy efficiency. Article [39] presents an overview of solutions in the Green Industrial IoT ecosystem in connection with the evolution of the smart industry. It discusses the state of the smart industry in reference to Industry 4.0, technologies related to the IoT and IIoT ecosystem, and the challenges and opportunities offered by Industrial GIIoT for various industrial sectors.

4. Energy Efficiency in Robotics: Reducing Industrial Robots’ Power Consumption

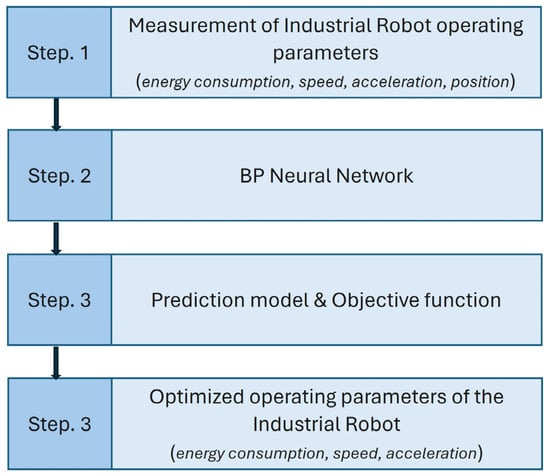

Article [42] presents a method for studying potential energy savings through practical energy consumption optimization. The experiment utilized an artificial neural network to accurately depict the quantitative relationships between operational parameters and energy consumption. A genetic algorithm was then employed to optimize adjustable parameters and minimize energy usage. The study was conducted on an Epson C4 6-DoF industrial robot. The authors demonstrate the effectiveness of the proposed method in assisting parameter selection and energy conservation, as shown in Figure 6.

Figure 6.

Data-driven energy optimization for industrial robots in Industry 4.0 [43].

The authors of [21] present a review of various methodologies and technologies that aim to enhance the energy efficiency of industrial robotic and mechatronic systems, including their classifications and analysis. The available methods were categorized into hardware and software solutions, including several subcategories, as well as hybrid approaches. The participants discussed future perspectives and emerging ideas in the field of robotics.

Hardware solutions in robotics have been categorized into subcategories:

- The robot type;

- Equipment replacement;

- The addition of equipment.

Software improvements have been divided into subcategories as well:

- Trajectory optimization;

- Operation planning.

Article [44] describes a study that aimed to develop an optimal control strategy for industrial robots to minimize energy consumption. The study includes a case study in which two controllers were developed for use in the Mitsubishi RV-2AJ robot arm. According to [44], using an optimal MPC controller can be an effective strategy in manufacturing processes where energy consumption is prioritized over precision, such as pick-and-place production processes, mobile autonomous robots, and underwater inspections.

In [33], a method for reducing the energy consumption of industrial robots is presented. This method involves adding extra devices for energy storage and recovery-compliant elements that are connected in parallel with the axes and regenerative motor drives, resulting in reduced energy consumption. The optimal design of the system was solved analytically. The method was tested using a five-bar linkage mechanism (refer to Table 1) and a SCARA robot (refer to Table 2). The data indicate that the standard, non-optimized trajectory can reduce energy consumption by up to 77.8%. Further optimization of the method may result in even greater reductions in energy consumption.

Table 2.

The energy consumed per cycle when using energy-reducing devices (ERDs) for a SCARA robot, as described in [33].

Article [45] presents an energy analysis of a 4-DOF parallel manipulator. The study estimated the energy efficiency of the robot during pick-and-place operations along a linear path. To achieve this, the study implemented electromechanical and dynamic models of the manipulator to estimate the energy consumption of the robot’s actuators during motion. The study also adopted energy consumption maps as guidelines for optimal robot positioning and provided numerical results from the models. The results presented can enhance energy efficiency in industrial settings.

Another publication [42] analyzed the energy parameters of an industrial manipulator. The impact of trajectory planning on the total energy consumption of the manipulator in a pick-and-place task was examined. An electromechanical model of the actuators and an inverse dynamic model of the robot were developed to estimate the energy consumption during the basic motion task. The results were presented in energy consumption maps, illustrating how the task’s location in the robot’s workspace affects its energy efficiency.

In [46], the energy consumption of two types of robots was compared: those operating autonomously without human interaction and lightweight robots collaborating with humans. The study examined various configurations and analyzed their impact on the energy consumption of the UR3e Cobot. The variables used in the configuration included motion commands, speed and acceleration constraints, stopping position, time scaling, and joint temperatures. The study compared the energy consumption of UR3e with that of other industrial robots in the literature. The results showed that UR3e’s electronic components consume more energy, while mechanical energy consumption is higher in industrial robots compared to their electronic components. The article proposes optimization strategies for reducing the energy consumption of UR3e, focusing on efficient electronic design and task distribution among system resources. It deems the strategy for energy consumption reduction through motion planning less significant.

The authors of [47] present research on the energy consumption of industrial robots in the automotive industry. The study conducted three experiments in a simulated environment, testing various values of variables and program parameters, such as the robot payload, acceleration, and connection speed. The first experiment’s results focused on energy consumption during the robot’s idle time. They showed the significance of selecting an energy-efficient robot position and choosing an appropriate timer value responsible for turning off servo motors. The second experiment involved studying the robot during motion. Avoiding low speeds and selecting maximum continuous stops at intermediate points proved to be crucial parameters. The third experiment analyzed the impact of friction in the robot joint on energy consumption. It was found that at high motor speeds, low temperatures increase energy consumption. The study analyzed parameters such as the load, temperature, and speed.

The work described in [48] aimed to present the possibilities for saving electrical energy in contemporary industrial robots. Practical examples related to programming and positioning robots were demonstrated using the industrial robot IRB 1600. Four tests were performed to determine the optimal trajectories, vary tool masses, identify the optimal position of the processed object, and determine the optimal working speed. The results of these tests yielded significant energy savings. It was concluded that greater energy efficiency can be achieved through the proper installation and tuning of the robot.

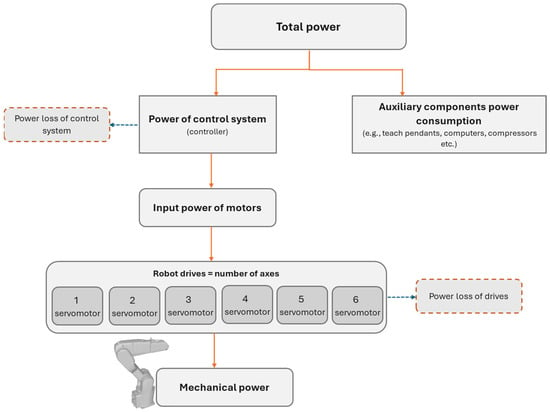

In [26], an analysis was presented on the characteristics and modeling of energy consumption by industrial robots (Figure 7). The modeling of energy consumption considered parameters such as inertia and friction using simulated power data. The analysis examined the relationship between the robot’s speed and energy consumption.

Figure 7.

The energy flow of the industrial robot [26].

The objective of this study was to model the energy consumption of the motor, which varies with the robot’s trajectory, using the ABB IRB 1200 program. The energy consumption model of the robot was obtained through parameter identification. The analysis of the relationship between the robot’s speed and its energy consumption led to the conclusion that optimal energy consumption is achieved when the speed is neither too high nor too low.

Article [26] analyzed energy consumption using a six-axis industrial robot and validated a dynamic model. The study examined the impact of parameters such as the payload and speed on energy consumption. The results of simulations and experiments show that the operational parameters of the robot significantly affect energy consumption. A higher payload and speed increase the power required by the robot. The analysis was conducted under various working conditions. A simulation tool was used to analyze energy consumption, and the results were verified with experiments conducted on a real robot. The study demonstrated a slight difference between the experimental and simulation results.

In [49], a simulation tool (Delmia Robotics environment) was presented. This tool collaborates with offline robot programming tools, allowing for a reduction in robot energy consumption. The simulation tool enables the automatic calculation of energetically optimal motion parameters. Experimental studies conducted on the KUKA Quantec KR210 R2700 Prime industrial robot, widely used in the automotive industry on assembly lines, confirmed the effectiveness of the demonstrated method.

Article [50] presents the hardware tools used in experiments to measure the energy consumption of industrial robots. The experiments involved studying the robot with the simultaneous motion of all joints or the motion of the robot’s first axis. The experimental data have been made available as an open research dataset. The presented tests show that in certain scenarios, energy savings of over 50% are possible. The tests were conducted using the KUKA KR210 R2700 Prime robot. The study evaluated the impact of the oil temperature in the gearbox on energy consumption, assessed the significance of viscous losses in the robot’s power flow, and measured the variability in energy consumption based on programmed speed and acceleration parameters.

In [51], an optimization algorithm was proposed that, in experiments, saved between 18% and 45% of the energy consumed by an industrial multi-robot system. This effect was achieved without altering the total cycle time or original paths. The algorithms are based on a nonlinear model used to optimize the sequence of operations and motion trajectories.

Methods for optimizing energy consumption by robots in the whole-system planning model are presented in [52]. The optimal plan for energy efficiency was determined by solving a mixed-integer nonlinear programming problem. Each operation was modeled and parameterized in terms of energy consumption. The authors of [53] present a combined analysis of the energy consumption and expected lifespan of a robotic system, providing an assessment and trade-off between lifecycle and energy consumption optimization. The models were examined in terms of load criteria on wear and fatigue occurring in gear joints.

A method for optimizing energy consumption during robot movement is presented in [13]. An optimization module was developed using Matlab to solve the inverse kinematics of the robot and find possible joint configurations required to perform the task. The next step involved analyzing the moments and forces applied to each joint and link of the robot by solving its inverse dynamics. At each step, the energy consumption was calculated, and configurations were optimized. The results were then transmitted to the robot controller. Experiments showed that optimizing the path’s destination location can reduce energy consumption. The presented module reduces energy consumption by selecting optimal configurations for different tasks.

The authors of [54] present methods to reduce energy consumption in multi-robot assembly lines in the automotive industry. The proposed methods resulted in energy savings of up to 10.6%. These methods involve calculating the motion trajectories of robots and releasing the actuator brake earlier when the robots are stationary. The simulations were based on real-time production in a factory and showed that the execution time of robot tasks is often suboptimally synchronized with other tasks, which can be exploited to reduce energy consumption. According to the authors, the proposed methods can be easily implemented in existing systems with minor modifications to robot programs.

In [55], the authors introduce an energy-semantic model that analyzes the energy consumption of industrial robots. They proposed and implemented four performance experiments for the UR3e robot. The experiments revealed that energy consumption is influenced by various parameters, including trajectory planning, acceleration and speed constraints, motion commands, payload, configuration, and joint temperature.

In [56], methods for optimizing the energy consumption of medium- and large-payload industrial robots are presented. The article discusses various methods for reducing energy consumption in robots, including intelligent brake management, temporary storage of kinetic energy, energy exchange between controllers, robot selection, idle-time shutdown, and transitioning between different standby modes.

Additionally, the authors of [57] presented a method for reducing energy consumption without the need for equipment replacement. The article also describes methods for optimizing the energy consumption of pick-and-place manipulators for TCP position profiles. Time scaling was used to calculate the optimal energy trajectories. The proposed method was evaluated through two simulated case studies.

Energy savings in the automotive industry through robotized assembly lines are described in [58]. The methods presented for reducing energy consumption involve optimizing trajectories through time scaling and releasing actuator brakes earlier when robots are stationary. Simulation results demonstrate that energy consumption can be reduced without negatively impacting production time. The energy savings achieved are 12.1% for a single industrial robot and 7.3% for the entire cell.

Problems and solutions related to limiting robot energy consumption are presented in [59]. The problem of reducing energy consumption involves a compromise between energy reduction and productivity. It is a planning problem that determines when it is possible to extend the robot’s movement time without affecting productivity. The problem is defined as a stochastic optimization problem, and energy consumption reduction is achieved by finding optimal execution times and operation sequences. The presented heuristic method reduces energy consumption under conditions that the authors believe apply in practice to many types of robot stations.

A method for reducing the energy consumption of pick-and-place robots in both long- and short-term picking operations is investigated in [60]. The method involves the intelligent control of robot joints and the selection of the appropriate joint configuration for placing objects. The methodology falls within the scope of reinforcement learning problems in robotics, inverse statics, progressive kinematics, and inverse kinematics. The study utilized MATLAB/Simulink models and developed a neural-network-based controller for the IRB1600 robot. Five permissible joint configurations were compared, revealing potential power consumption savings of up to 18%. The holding force accounted for the majority of the robot’s total power consumption.

In [61], the authors make predictions about the future electricity consumption of robots until 2025. The estimated range for the forecast is between 0.5% and 0.8% of the total electricity demand in the USA, as shown in Table 3 and Table 4.

Table 3.

Energy usage assumptions of industrial robots [61].

Table 4.

Electricity consumption of industrial robots in the reference scenario [61].

Table 5 compiles selected publications on energy optimization methods and outlines the solution approaches proposed by the respective authors.

Table 5.

This table summarizes how other authors have assessed and optimized robot energy consumption.

We evaluated the advantages and disadvantages of the methods for measuring and optimizing energy usage, as shown in Table 5, and the results are summarized in Table 6.

Table 6.

The advantages and disadvantages of methods for measuring and optimizing energy usage.

In general, the success of these methods depends on the specific context, the complexity of the system, and the trade-offs between accuracy and computational cost. It is often beneficial to combine multiple methods to create a comprehensive energy optimization strategy.

5. Trends in Robotics Energy Consumption

The current industrial era is characterized by the quest for the full automation of industrial processes. The adoption of Industry 4.0/5.0 principles entails a gradual rise in the use of robotic systems while also considering the limits on energy consumption imposed by growing ecological awareness. It is clear that, in addition to carbon dioxide emission taxation and investments in renewable energy sources, there are increased costs associated with acquiring electrical energy. Price uncertainty is exacerbated by unpredictable market fluctuations. In recent years, these have been influenced by pandemics and armed conflicts. To ensure stable growth in the implementation of robotic systems, it is crucial to minimize their energy consumption. The automotive industry provides a good example, where robots account for 8% of the total energy consumption throughout the vehicle’s lifecycle [62].

Shaping trends related to energy consumption in robotics is an interesting issue from both technical and sociological perspectives. The common belief is that the implementation of robotic systems intensifies energy consumption and increases the carbon footprint. However, Obgemhe et al. [63] argue that robots consume electrical energy, but savings can be found in areas such as industrial hall lighting (robots do not require bright space illumination) and heating. The authors of different publications do not have a unanimous opinion on the energy consumption of industrial robots and their direct impact on a company’s carbon footprint. Yao et al. [64] propose the introduction of intelligent optimization in connection with the automation and robotization of production. This issue is also addressed by Wang et al. [65], who highlight the relationship between the energy consumption of robots and production efficiency. They argue that increasing the number of robots involved in the process will increase electrical energy consumption. However, the application of robotic systems enhances production efficiency. According to Soori et al. [22], it is crucial to establish the correlation between efficiency and energy consumption in robotized production.

The authors provide a thorough review of current methods for optimizing the energy consumption of industrial robots, with a focus on the production process. They also discuss the selection of a suitable industrial robot for the task at hand. Over-sized robots consume more energy due to inertial effects caused by the weight of components. However, Paryanto et al. [66] identify three areas for reducing a robot’s energy consumption:

- Efficient motion planning is the primary focus, with an emphasis on smooth and optimally timed trajectories;

- Optimizing the operational parameters of industrial robots can be achieved through an experimental approach and computer modeling and simulation;

- Planning tasks for industrial robots involves optimizing the sequence of movements and minimizing the number of starts and stops. This includes various factors that need to be considered, such as the efficiency of the robot’s movements and the time required to complete the task.

The authors assess the potential for reducing energy consumption during the implementation of industrial robots. They suggest that the most effective results can be achieved during the production planning stage by selecting energy-efficient robots and implementing proper operational planning. The startup process offers fewer opportunities, with efforts mainly focused on reducing downtime and eliminating unnecessary stops. However, it is important to consider limitations that may arise from planned production efficiency. The least effective actions are at the level of the operating production process, where it is only possible to influence the trajectory shape. Unfortunately, at this stage, there is no possibility of changing the equipment or the production line cycle time. The authors mention that simulation programs, such as ABB’s RobotStudio and Siemens’ Tecnomatix, allow for creating virtual models of robotic environments and conducting virtual startups. This opens up new possibilities, as it enables appropriate reactions and corrections to be made before the actual equipment and production line or cell startup. The authors also note that these software environments introduced the prediction of the energy consumption of industrial robots.

Regarding the concerns raised in [66], specifically the optimization of operational parameters for industrial robots, Meike et al. [58] conducted a simulation experiment. They used parameters obtained from measurements taken in a real robotic cell operating in a car factory and found that robots experience significant idle time after completing tasks. Through the use of simulation methods, potential energy savings of 12.1% for a single robot and 7.3% for the analyzed cell were achieved [58].

The International Federation of Robotics analyzed the automation and robotics market in 2023 and identified five leading trends that will shape robot production in the near and distant future [67]. The first trend is the continued growth of the robot market, both in manufacturing applications and in other industries. The remaining trends are as follows:

- Increased energy efficiency: Methods for recovering electrical energy resulting from kinetic energy transformation will be developed, and smart-power-saving modes will be introduced to increase energy efficiency. Energy monitoring will become standard.

- Reshoring aims to shorten the distance between the manufacturer and the recipient of components needed for production: This leads to the increased implementation of robotic systems by expanding companies, as many things can be produced on-site without the need for long-distance transport.

- Ease of use: Technologies that lower the entry threshold in terms of robot programming, such as “low code” or “no code” techniques, will be implemented to improve ease of use. Emphasis will be placed on solution flexibility and easy configuration. For example, it will be possible to equip a heavy industrial robot with sensors and software that enable collaborative work.

- Utilization of artificial intelligence: AI development will primarily support the optimization of robotic processes, enabling better management of variable or unpredictable events.

- Second life of industrial robots: The ability to repair and upgrade used industrial robots is environmentally friendly and cost-effective. Modernization can also contribute to reducing the energy consumption of refurbished robots.

Based on the analysis presented, it is evident that energy efficiency will play a significant role in shaping the industrial robot market. The combination of electrical energy recovery with the repair and modernization of used robots has the potential to greatly impact the achievement of environmental protection and sustainable development goals. This concept is in line with Evjemo et al.’s considerations [68] regarding the development of Smart Factories and Smart Manufacturing, where humans will share spaces with machines, including robots. This implies, among other things, the absence of barriers and the relatively free movement of employees around the production hall. The authors propose that robotic systems will have the ability to switch between different levels of operation and apply safety procedures as needed. This means that a single robot could operate in a fully automatic cycle and, upon detecting the presence of a human, switch to collaborative mode and share the workspace with people. This aligns with the trends formulated by IFR [67] and the assumptions of Industry 4.0 and 5.0. However, from an energy efficiency standpoint, estimating the consequences of this approach may be challenging due to the robot’s switching between operating modes in response to a human presence. Artificial intelligence methods can be applied in this situation to optimize processes with high variability or actions under uncertain conditions.

Izagirre et al. [69] provide an interesting example of using artificial intelligence to reduce the energy consumption of industrial robots. The authors suggest that the robot’s electrical energy consumption and joint loads can be significantly reduced by properly positioning manipulator arms while waiting to start a task. To determine the optimal position, the authors implemented a genetic algorithm to minimize the total torque. The study demonstrated that, for a heavy industrial robot with a high payload, the torque in the non-optimized position is over three times greater than that in the optimized position. The authors achieved a reduction in the total torque of over 30% for the ABB IRB 6400r robot operating in real industrial conditions. A lower torque in the waiting position not only results in lower energy consumption but also reduces the temperature of motors and gears, thereby extending their operational life.

A trend in energy-saving methods for robotic systems is the use of a digital twin. Vatankhah Barenji et al. [70] propose a real-time, agent-based structure for optimizing energy consumption. The agent responsible for trajectory generation collaborates with the trajectory dynamic assessment agent to choose the optimal path while avoiding collisions. The third sub-agent assesses energy consumption concerning the generated paths, estimating the required torque of the motors. The evaluation is performed in two stages: one for each joint and one for the entire manipulator arm of the robot. The decision-making process is based on negotiations between three agents and occurs in real time.

Yan et al. [71] developed a digital twin of a physical robot to serve as a foundation for future research. The digital model of the robot was created and calibrated to enable real-time energy consumption monitoring and consumption prediction through simulation. The digital twin system utilizes the open-source Robot Operating System (ROS) for visualization and virtual robot simulation. The flexibility of the ROS enables rapid changes to the robot and the creation of new simulations without the need for cumbersome modeling.

Similarly, Stan et al. [72] employed a digital twin in their work. They present a robotic system designed for deburring the edges of large machined parts, focusing on processing only parts requiring improvement after prior machining. A vision system is used for this purpose, with the robot inspecting the machined surface. During program execution, energy consumption is monitored. However, the authors note that data obtained solely from simulations may be somewhat underestimated due to the specifics of the kinematic unit, such as friction in kinematic pairs.

Braking energy recovery systems are commonly used to reduce robot energy consumption [22,67]. Furthermore, mechanical components are employed to store energy temporarily or balance forces during movement [33,73]. These components typically consist of carefully selected springs. This is a direct intervention in the kinematic chain of the manipulator. The solution is implemented for manipulators moving along a predefined trajectory, carried out cyclically, such as pick-and-place tasks. This approach can lead to significant energy savings. For instance, in [73], a reduction in energy consumption of 77.8% was achieved during the execution of a typical, non-optimized trajectory by the robot. The solution’s applicability is limited to selecting mechanical element characteristics for a specific path, making it suitable for cases with a repeatable trajectory and infrequent retooling of the robotic system.

Currently, the increase in the energy efficiency of robots and robotic systems mainly relies on well-known and frequently used energy recovery systems. Another common solution is path optimization using advanced AI algorithms. The implementation of Industry 4.0/5.0 and the development of Smart Factory/Smart Manufacturing concepts offer new opportunities for achieving energy savings through the use of advanced robot monitoring systems (including IIoT), intelligent systems based on artificial intelligence (including data processing and Deep Learning), and advanced simulation systems and digital twins. A significant trend in robotization’s impact on the environment is the adoption of a holistic approach that considers not only energy efficiency but also the relationship with greenhouse gas emissions. This is influenced by the entire life cycle of the product, from production to disposal [74,75,76].

6. Conclusions

The integration of modern manufacturing processes with advanced technologies, such as industrial robots, is crucial [77]. Industry 4.0 utilizes technology to achieve significant benefits, including energy efficiency. Efficient energy management in the industry primarily involves investing in solutions that reduce electrical energy consumption, such as intelligent energy management, energy saving, and storage for later use. Market trend analysis indicates the dynamic development of robotization, particularly after the global crisis related to the COVID-19 pandemic. The rise in the number of installed robots, especially in Asia, highlights the growing interest in automating and robotizing manufacturing processes. This article analyzes the impact of various factors on energy consumption in industrial robotics and identifies key factors that influence it, such as the selection of the appropriate type of robot, programming, and the real-time monitoring of energy consumption.

This article also discusses trends in reducing energy consumption, with solutions that involve energy recovery during manipulator braking still dominating. However, the widespread adoption of Industry 4.0/5.0 has led to an increase in the implementation of artificial intelligence and advanced simulation systems. There is also a growing focus on the impact of robotics on the environment, including energy consumption and greenhouse gas emissions associated with the entire life cycle of the industrial robot product. In this context, it is important to consider the trend of renewing and modernizing old units.

In summary, implementing strategies related to energy efficiency in industrial robotics contributes to reducing production costs and promoting sustainable development by minimizing waste. Therefore, developing innovative solutions for energy efficiency is a crucial direction for the industry’s future.

Author Contributions

Conceptualization, A.S., K.F., T.B. and G.K.; methodology, A.S., T.B. and K.F.; investigation, A.S., K.F. and T.B.; resources, A.S., T.B., K.F. and G.K.; writing—original draft preparation, A.S., K.F. and T.B.; writing—review and editing, A.S., K.F., T.B. and G.K.; visualization, A.S., K.F., T.B. and G.K.; supervision, A.S., K.F., T.B. and G.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflicts of interest.

Nomenclature

| AR | Augmented reality |

| CCTV | Closed-circuit television |

| EC | Electronic commerce |

| GUI | Graphical user interface |

| IoT | Internet of Things |

| IIoT | Industrial Internet of Things/Industrial Internet |

| IoRT | Internet of Robotic Things |

| SCARA | Selective Compliance Assembly Robot Arms |

| SLAM | Simultaneous localization and mapping |

| SNS | Social networking services |

| UI | User interface |

| VR | Virtual reality |

| WSDL | Web service description language |

References

- Ghobakhloo, M.; Fathi, M.; Iranmanesh, M.; Maroufkhani, P.; Morales, M.E. Industry 4.0 Ten Years On: A Bibliometric and Systematic Review of Concepts, Sustainability Value Drivers, and Success Determinants. J. Clean. Prod. 2021, 302, 127052. [Google Scholar] [CrossRef]

- Suleiman, Z.; Shaikholla, S.; Dikhanbayeva, D.; Shehab, E.; Turkyilmaz, A. Industry 4.0: Clustering of Concepts and Characteristics. Cogent. Eng. 2022, 9, 2034264. [Google Scholar] [CrossRef]

- Alcácer, V.; Cruz-Machado, V. Scanning the Industry 4.0: A Literature Review on Technologies for Manufacturing Systems. Eng. Sci. Technol. Int. J. 2019, 22, 899–919. [Google Scholar] [CrossRef]

- Aoun, A.; Ilinca, A.; Ghandour, M.; Ibrahim, H. A Review of Industry 4.0 Characteristics and Challenges, with Potential Improvements Using Blockchain Technology. Computers 2021, 162, 107746. [Google Scholar] [CrossRef]

- European Parliament. Available online: https://www.europarl.europa.eu/ (accessed on 8 September 2023).

- International Federation of Robotics. Executive Summary World Robotics 2023 Industrial Robots. IFR 2023. Available online: https://ifr.org/free-downloads/ (accessed on 16 October 2023).

- Borys, S.; Kaczmarek, W.; Laskowski, D.; Polak, R. Experimental Study of the Vibration of the Spot Welding Gun at a Robotic Station. Appl. Sci. 2022, 12, 12209. [Google Scholar] [CrossRef]

- Guo, Q.; Su, Z. The Application of Industrial Robot and the High-Quality Development of Manufacturing Industry: From a Sustainability Perspective. Sustainability 2023, 15, 12621. [Google Scholar] [CrossRef]

- Singh, G.; Banga, V.K. Robots and Its Types for Industrial Applications. Mater. Today Proc. 2022, 60, 1779–1786. [Google Scholar] [CrossRef]

- Kaczmarek, W.; Borys, S.; Panasiuk, J.; Siwek, M.; Prusaczyk, P. Experimental Study of the Vibrations of a Roller Shutter Gripper. Appl. Sci. 2022, 12, 9996. [Google Scholar] [CrossRef]

- Herrmann, C.; Thiede, S.; Zein, A.; Ihlenfeldt, S.; Blau, P. Energy Efficiency of Machine Tools: Extending the Perspective. In Proceedings of the 42nd CIRP International Conference on Manufacturing Systems, Grenoble, France, 3–5 June 2009. [Google Scholar]

- Pellegrinelli, S.; Borgia, S.; Pedrocchi, N.; Villagrossi, E.; Bianchi, G.; Tosatti, L.M. Minimization of the Energy Consumption in Motion Planning for Single-Robot Tasks. Procedia CIRP 2015, 29, 354–359. [Google Scholar] [CrossRef]

- Mohammed, A.; Schmidt, B.; Wang, L.; Gao, L. Minimizing Energy Consumption for Robot Arm Movement. Procedia CIRP 2015, 29, 354–359. [Google Scholar] [CrossRef]

- Chemnitz, M.; Schreck, G.; Krüger, J. Analyzing Energy Consumption of Industrial Robots. In Proceedings of the IEEE Conference on Emerging Technologies & Factory Automation, Toulouse, France, 5–9 September 2011; pp. 1–4. [Google Scholar] [CrossRef]

- Liu, S.; Wang, Y.; Wang, X.V.; Wang, L. Energy-Efficient Trajectory Planning for an Industrial Robot Using a Multi-Objective Optimization Approach. Procedia Manuf. 2018, 25, 517–525. [Google Scholar] [CrossRef]

- Garriz, C.; Domingo, R. Trajectory Optimization in Terms of Energy and Performance of an Industrial Robot in the Manufacturing Industry. Sensors 2022, 22, 7538. [Google Scholar] [CrossRef] [PubMed]

- Otani, T.; Nakamura, M.; Kimura, K.; Takanishi, A. Energy Efficient Path and Trajectory Optimization of Manipulators with Task Deadline Constraints. IEEE Access 2023, 11, 107441–107450. [Google Scholar] [CrossRef]

- Paes, K.; Dewulf, W.; Vander Elst, K.; Kellens, K.; Slaets, P. Energy Efficient Trajectories for an Industrial ABB Robot. Procedia CIRP 2014, 15, 105–110. [Google Scholar] [CrossRef]

- Peta, K.; Wlodarczyk, J.; Maniak, M. Analysis of Trajectory and Motion Parameters of an Industrial Robot Cooperating with Numerically Controlled Machine Tools. J. Manuf. Process. 2023, 101, 1332–1342. [Google Scholar] [CrossRef]

- Paryanto, P.M.B.; Kohl, J.; Merhof, J.; Spreng, S.; Franke, J. Energy Consumption and Dynamic Behavior Analysis of a Six-Axis Industrial Robot in an Assembly System. Procedia CIRP 2014, 23, 131–136. [Google Scholar] [CrossRef]

- Carabin, G.; Wehrle, E.; Vidoni, R. A Review on Energy-Saving Optimization Methods for Robotic and Automatic Systems. Robotics 2017, 6, 39. [Google Scholar] [CrossRef]

- Soori, M.; Arezoo, B.; Dastres, R. Optimization of Energy Consumption in Industrial Robots, a Review. Cogn. Robot. 2023, 3, 142–157. [Google Scholar] [CrossRef]

- Yaskawa Robotics. Available online: https://www.yaskawa.eu.com/products/robot (accessed on 3 November 2023).

- Uhlmann, E.; Reinkober, S.; Hollerbach, T. Energy Efficient Usage of Industrial Robots for Machining Processes. Procedia CIRP 2016, 48, 206–211. [Google Scholar] [CrossRef]

- Sekala, A.; Kost, G.; Banas, W.; Gwiazda, A.; Grabowik, C. Modelling and Simulation of Robotic Production Systems. J. Phys. Conf. Ser. 2022, 2198, 012065. [Google Scholar] [CrossRef]

- Liu, A.; Liu, H.; Yao, B.; Xu, W.; Yang, M. Energy consumption modeling of industrial robot based on simulated power data and parameter identification. Adv. Mech. Eng. 2018, 10, 1–11. [Google Scholar] [CrossRef]

- Pollak, A.; Temich, S.; Ptasiński, W.; Kucharczyk, J.; Gąsiorek, D. Prediction of Belt Drive Faults in Case of Predictive Maintenance in Industry 4.0 Platform. Appl. Sci. 2021, 11, 10307. [Google Scholar] [CrossRef]

- Farnell. Amazon—A Prime Example of an IoT Implementation; Farnell: Chicago, IL, USA, 2017; Available online: https://pl.farnell.com/amazon-a-prime-example-of-an-iot-implementation (accessed on 16 October 2023).

- Ray, P.P. Internet of Robotic Things: Concept, Technologies, and Challenges. IEEE Access 2017, 4, 9489–9500. [Google Scholar] [CrossRef]

- Waters, M.; Waszczuk, P.; Ayre, R.; Dreze, A.; McGlinchey, D.; Alkali, B.; Morison, G. Open Source IIoT Solution for Gas Waste Monitoring in Smart Factory. Sensors 2022, 22, 2972. [Google Scholar] [CrossRef]

- Cropp, C. Technological Trends Driving Advances in the Mining Industry. 2021. Available online: https://info.vercator.com/blog/technological-advancements-in-mining-industry (accessed on 3 July 2023).

- Cañizares, E.; Valero, F.A. Analyzing the Effects of Applying IoT to a Metal-Mechanical Company. J. Ind. Eng. Manag. 2018, 11, 308–317. [Google Scholar] [CrossRef]

- Palomba, I.; Wehrle, E.; Carabin, G.; Vidoni, R. Minimization of the Energy Consumption in Industrial Robots through Regenerative Drives and Optimally Designed Compliant Elements. Appl. Sci. 2020, 10, 7475. [Google Scholar] [CrossRef]

- Krejčí, J.; Babiuch, M.; Babjak, J.; Suder, J.; Wierbica, R. Implementation of an Embedded System into the Internet of Robotic Things. Micromachines 2023, 14, 113. [Google Scholar] [CrossRef]

- Wójcicki, K.; Biegańska, M.; Paliwoda, B.; Górna, J. Internet of Things in Industry: Research Profiling, Application, Challenges and Opportunities—A Review. Energies 2022, 15, 1806. [Google Scholar] [CrossRef]

- Farhan, L.; Shukur, S.T.; Alissa, A.E.; Alrweg, M.; Raza, U.; Kharel, R. A survey on the challenges and opportunities of the Internet of Things (IoT). In Proceedings of the 2017 Eleventh International Conference on Sensing Technology (ICST), Sydney, Australia, 4–6 December 2017; pp. 1–5. [Google Scholar]

- Chen, Y. Challenges and opportunities of internet of things. In Proceedings of the 17th Asia and South Pacific Design Automation Conference, Sydney, Australia, 30 January–2 February 2012; pp. 383–388. [Google Scholar]

- Peng, C.; Peng, T.; Liu, Y.; Geissdoerfer, M.; Evans, S.; Tang, R. Industrial Internet of Things enabled supply-side energy modelling for refined energy management in aluminium extrusions manufacturing. J. Clean. Prod. 2021, 301, 126882. [Google Scholar] [CrossRef]

- Tabaa, M.; Monteiro, F.; Bensag, H.; Dandache, A. Green Industrial Internet of Things from a smart industry perspectives. Energy Rep. 2020, 6, 430–446. [Google Scholar] [CrossRef]

- Kumar, N.M.; Chand, A.A.; Malvoni, M.; Prasad, K.A.; Mamun, K.A.; Islam, F.; Chopra, S.S. Distributed energy resources and the application of AI, IoT, and blockchain in smart grids. Energies 2020, 13, 5739. [Google Scholar] [CrossRef]

- Elahi, H.; Munir, K.; Eugeni, M.; Atek, S.; Gaudenzi, P. Energy Harvesting towards Self-Powered IoT Devices. Energies 2020, 13, 5528. [Google Scholar] [CrossRef]

- Boscariol, P.; Scalera, L.; Gasparetto, A. Task-Dependent Energetic Analysis of a 3 dof Industrial Manipulator. In Proceedings of the International Conference on Robotics in Alpe-Adria Danube Region, Kaiserslautern, Germany, 19–21 June 2019; pp. 162–169. Available online: https://www.academia.edu/39317276/Task_dependent_energetic_analysis_of_a_3_d_o_f_industrial_manipulator (accessed on 17 October 2023).

- Zhang, M.; Yan, J. A data-driven method for optimizing the energy consumption of industrial robots. J. Clean. Prod. 2021, 285, 124862. [Google Scholar] [CrossRef]

- Benotsmane, R.; Kovács, G. Optimization of Energy Consumption of Industrial Robots Using Classical PID and MPC Controllers. Energies 2023, 16, 3499. [Google Scholar] [CrossRef]

- Scalera, L.; Boscariol, P.; Carabin, G.; Vidoni, R.; Gasparetto, A. Enhancing Energy Efficiency of a 4-DOF Parallel Robot Through Task-Related Analysis. Machines 2020, 8, 10. [Google Scholar] [CrossRef]

- Heredia, J.; Schlette, C.; Kjærgaard, M.B. Breaking Down the Energy Consumption of Industrial and Collaborative Robots: A Comparative Study. In Proceedings of the 2023 IEEE 28th International Conference on Emerging Technologies and Factory Automation (ETFA), Sinaia, Romania, 12–15 September 2023; pp. 1–8. [Google Scholar]

- Garcia, R.R.; Bittencourt, A.C.; Villani, E. Relevant Factors for the Energy Consumption of Industrial Robots. J Braz. Soc. Mech. Sci. Eng. 2018, 40, 464. [Google Scholar] [CrossRef]

- Rassõlkin, A.; Hõimoja, H.; Teemets, R. Energy Saving Possibilities in the Industrial Robot IRB 1600 Control. In Proceedings of the 2011 7th International Conference-Workshop Compatibility and Power Electronics (CPE), Tallinn, Estonia, 1–3 June 2011; pp. 226–229. [Google Scholar]

- Gadaleta, M.; Pellicciari, M.; Berselli, G. Optimization of the Energy Consumption of Industrial Robots for Automatic Code Generation. Robot. Comput. Integr. Manuf. 2019, 57, 452–464. [Google Scholar] [CrossRef]

- Gadaleta, M.; Berselli, G.; Pellicciari, M.; Grassia, F. Extensive Experimental Investigation for the Optimization of the Energy Consumption of a High Payload Industrial Robot with Open Research Dataset. Robot. Comput. Integr. Manuf. 2021, 68, 102046. [Google Scholar] [CrossRef]

- Riazi, S.; Bengtsson, K.; Wigström, O.; Vidarsson, E.; Lennartson, B. Energy Optimization of Multi-Robot Systems. In Proceedings of the 2015 IEEE International Conference on Automation Science and Engineering (CASE), Gothenburg, Sweden, 24–28 August 2015; pp. 1345–1350. [Google Scholar]

- Vergnano, A.; Thorstensson, C.; Lennartson, B.; Falkman, P.; Pellicciari, M.; Yuan, C.; Biller, S.; Leali, F. Embedding Detailed Robot Energy Optimization into High-Level Scheduling. In Proceedings of the 2010 IEEE International Conference on Automation Science and Engineering, Auckland, New Zealand, 26–30 August 2010; pp. 386–392. [Google Scholar]

- Stuhlenmiller, F.; Jungblut, J.; Clever, D.; Rinderknecht, S. Combined Analysis of Energy Consumption and Expected Service Life of a Robotic System. In Proceedings of the 2020 6th International Conference on Mechatronics and Robotics Engineering (ICMRE), Barcelona, Spain, 12–15 February 2020; pp. 53–57. [Google Scholar]

- Meike, D.; Pellicciari, M.; Berselli, G.; Vergnano, A.; Ribickis, L. Increasing the Energy Efficiency of Multi-Robot Production Lines in the Automotive Industry. In Proceedings of the 2012 IEEE International Conference on Automation Science and Engineering (CASE), Seoul, Republic of Korea, 20–24 August 2012; pp. 700–705. [Google Scholar]

- Heredia, J.; Schlette, C.; Kjargaard, M.B. Sizing up Energy Consumption in Lightweight Robots: A Comprehensive Assessment. In Proceedings of the 2023 7th International Conference on Automation, Control and Robots (ICACR), Kuala Lumpur, Malaysia, 4–6 August 2023; pp. 31–38. [Google Scholar]

- Meike, D.; Ribickis, L. Energy Efficient Use of Robotics in the Automobile Industry. In Proceedings of the 2011 15th International Conference on Advanced Robotics (ICAR), Tallinn, Estonia, 20–23 June 2011; pp. 507–511. [Google Scholar]

- Pellicciari, M.; Berselli, G.; Leali, F.; Vergnano, A. A Method for Reducing the Energy Consumption of Pick-and-Place Industrial Robots. Mechatronics 2013, 23, 326–334. [Google Scholar] [CrossRef]

- Meike, D.; Pellicciari, M.; Berselli, G. Energy Efficient Use of Multirobot Production Lines in the Automotive Industry: Detailed System Modeling and Optimization. IEEE Trans. Automat. Sci. Eng. 2014, 11, 798–809. [Google Scholar] [CrossRef]

- Hovgard, M.; Lennartson, B.; Bengtsson, K. Energy reduction of stochastic time-constrained robot stations. Robot. Comput. Integr. Manuf. 2023, 81, 102511. [Google Scholar] [CrossRef]

- Vodovozov, V.; Raud, Z.; Petlenkov, E. Intelligent Control of Robots with Minimal Power Consumption in Pick-and-Place Operations. Energies 2023, 16, 7418. [Google Scholar] [CrossRef]

- Barnett, N.; Costenaro, D.; Rohmund, I. Direct and indirect impacts of robots on future electricity load. In Proceedings of the ACEEE Summer Study on Energy Efficiency in Industry, Denver, CO, USA, 15–18 August 2017; pp. 1–9. Available online: https://www.aceee.org/files/proceedings/2017/data/polopoly_fs/1.3687904.1501159084!/fileserver/file/790278/filename/0036_0053_000029.pdf (accessed on 17 October 2023).

- 3 Trends in Robotics Energy Consumption. Robotics Tomorrow. Available online: https://roboticstomorrow.com/story/2021/03/3-trends-in-robotics-energy-consumption/16385/ (accessed on 3 October 2023).

- Ogbemhe, J.; Mpofu, K.; Tlale, N.S. Achieving Sustainability in Manufacturing Using Robotic Methodologies. Procedia Manuf. 2017, 8, 440–446. [Google Scholar] [CrossRef]

- Yao, M.; Shao, Z.; Zhao, Y. Review on Energy Consumption Optimization Methods of Typical Discrete Manufacturing Equipment. In Intelligent Robotics and Applications; Liu, X.-J., Nie, Z., Yu, J., Xie, F., Song, R., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 48–58. [Google Scholar]

- Wang, E.-Z.; Lee, C.-C.; Li, Y. Assessing the Impact of Industrial Robots on Manufacturing Energy Intensity in 38 Countries. Energy Econ. 2022, 105, 105748. [Google Scholar] [CrossRef]

- Paryanto; Brossog, M.; Bornschlegl, M.; Franke, J. Reducing the Energy Consumption of Industrial Robots in Manufacturing Systems. Int. J. Adv. Manuf. Technol. 2015, 78, 1315–1328. [Google Scholar] [CrossRef]

- Vavra, C. Five Robot Trends for 2023. Available online: https://www.controleng.com/articles/five-robot-trends-for-2023/ (accessed on 25 October 2023).

- Evjemo, L.D.; Gjerstad, T.; Grøtli, E.I.; Sziebig, G. Trends in Smart Manufacturing: Role of Humans and Industrial Robots in Smart Factories. Curr. Robot. Rep. 2020, 1, 35–41. [Google Scholar] [CrossRef]

- Izagirre, U.; Arcin, G.; Andonegui, I.; Eciolaza, L.; Zurutuza, U. Torque-Based Methodology and Experimental Implementation for Industrial Robot Standby Pose Optimization. Int. J. Adv. Manuf. Technol. 2020, 111, 2065–2072. [Google Scholar] [CrossRef]

- Vatankhah Barenji, A.; Liu, X.; Guo, H.; Li, Z. A Digital Twin-Driven Approach towards Smart Manufacturing: Reduced Energy Consumption for a Robotic Cell. Int. J. Comput. Integr. Manuf. 2021, 34, 844–859. [Google Scholar] [CrossRef]

- Yan, K.; Xu, W.; Yao, B.; Zhou, Z.; Pham, D.T. Digital Twin-Based Energy Modeling of Industrial Robots. In Methods and Applications for Modeling and Simulation of Complex Systems; Li, L., Hasegawa, K., Tanaka, S., Eds.; Springer: Singapore, 2018; pp. 333–348. [Google Scholar]

- Stan, L.; Nicolescu, A.F.; Pupăză, C.; Jiga, G. Digital Twin and Web Services for Robotic Deburring in Intelligent Manufacturing. J. Intell. Manuf. 2023, 34, 2765–2781. [Google Scholar] [CrossRef]

- Barreto, J.P.; Schöler, F.J.-F.; Corves, B. The Concept of Natural Motion for Pick and Place Operations. In New Advances in Mechanisms, Mechanical Transmissions and Robotics; Corves, B., Lovasz, E.-C., Hüsing, M., Maniu, I., Gruescu, C., Eds.; Springer International Publishing: Cham, Switzerland, 2017; Volume 46, pp. 89–98. ISBN 9783319454498. [Google Scholar]

- Stuhlenmiller, F.; Weyand, S.; Jungblut, J.; Schebek, L.; Clever, D.; Rinderknecht, S. Impact of Cycle Time and Payload of an Industrial Robot on Resource Efficiency. Robotics 2021, 10, 33. [Google Scholar] [CrossRef]

- Lv, H.; Shi, B.; Li, N.; Kang, R. Intelligent Manufacturing and Carbon Emissions Reduction: Evidence from the Use of Industrial Robots in China. Int. J. Environ. Res. Public Health 2022, 19, 15538. [Google Scholar] [CrossRef] [PubMed]

- Yu, L.; Wang, Y.; Wei, X.; Zeng, C. Towards Low-Carbon Development: The Role of Industrial Robots in Decarbonization in Chinese Cities. J. Environ. Manag. 2023, 330, 117216. [Google Scholar] [CrossRef] [PubMed]

- Weidemann, C.; Mandischer, N.; van Kerkom, F.; Corves, B.; Hüsing, M.; Kraus, T.; Garus, C. Literature Review on Recent Trends and Perspectives of Collaborative Robotics in Work 4.0. Robotics 2023, 12, 84. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).