Abstract

The DOC (diesel oxidation catalyst), DPF (diesel particulate filter), SCR (selective catalytic reduction), and ASC (ammonia slip catalyst) are widely used in diesel exhaust after-treatment systems. The thermal management of after-treatment systems using DOC, DPF, SCR, and ASC were investigated to improve the efficiency of these devices. This paper aims to identify the challenges of this topic and seek novel methods to control the temperature. Insulation methods and catalysts decrease the energy required for thermal management, which improves the efficiency of thermal management. Thermal insulation decreases the heat loss of the exhaust gas, which can reduce the after-treatment light-off time. The DOC light-off time was reduced by 75% under adiabatic conditions. A 400 W microwave can heat the DPF to the soot oxidation temperature of 873 K at a regeneration time of 150 s. An SCR burner can decrease NOx emissions by 93.5%. Electrically heated catalysts can decrease CO, HC, and NOx emissions by 80%, 80%, and 66%, respectively. Phase-change materials can control the SCR temperature with a two-thirds reduction in NOx emissions. Pt-Pd application in the catalyst can decrease the CO light-off temperature to 113 °C. Approaches of catalysts can enhance the efficiency of the after-treatment systems and reduce the energy consumption of thermal management.

1. Introduction

Due to their efficiency and reliability [1,2], diesel engines are still widely used in transportation for the long term [3,4]. However, the hydrocarbon (HC), carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter (PM) in the exhaust gas of diesel engines seriously threaten human health [5,6]. Governments have successively introduced emission regulations to limit the emissions of diesel engines [7,8]. To meet the emission regulations, diesel oxidation catalysts (DOCs) [9,10], diesel particulate filters (DPFs) [11,12], and selective catalytic reduction (SCR) [13,14] are widely used in diesel exhaust gas after-treatment systems. However, the efficiency of DOC, SCR, and DPF is closely related to temperature [15,16]. The emission is poor [17,18] at a low exhaust temperature [19,20], and DOC and SCR are at a low efficiency level [21,22]. The urea stops injecting when the temperature is below 200 °C [23,24]. A large amount of HC, CO, and NOx will be directly discharged into the atmosphere if the exhaust gas is not treated at this time. Due to the low temperature, PM cannot be eliminated, resulting in blockage in the DPF, which deteriorates the performance of the engine [25,26]. The substrate will melt, and the activity of the catalysts will decrease or even fail, if the temperature is too high [27,28]. Therefore, diesel after-treatment thermal management is crucial for the efficiency of the after-treatment system.

Bai et al. [29] reported that a 15–20% opening of the intake throttle valve could increase the exhaust temperature to more than 200 °C, and the NOx emission under the world harmonized transient cycle (WHTC) could be reduced by 41.5%. They have performed experiments under transient conditions that provide a reference for practical applications. Honardar et al. [30] investigated the effect of post injection timing on exhaust gas temperature and brake-specific fuel consumption (BSFC) on a 1.56 L diesel engine. The exhaust gas temperature increased from 260 °C to 300 °C and the BSFC deteriorated from 530 g/kWh to 620 g/kWh when the post injection timing was postponed from 130 °CA BTDC to −10 °CA BTDC. Brin et al. [31] increased exhaust gas temperature by more than 50 °C with a turbine bypass under the cold federal test procedure (FTP). Turbine bypass might be an optimal thermal management strategy. Salehi et al. [32] optimized the exhaust valve opening (EVO) timing, which reduced the SCR light-off time from 659 s to 500 s, but the fuel consumption increased by 4.1%. Kovacs et al. [33] retarded the intake valve closing timing by 50°, which caused a 20 °C increase in the exhaust temperature and 1.4% reduction in fuel consumption. This research provided a method, intake valve closing timing, that saved fuel and raised the exhaust temperature at the same time.

Hamedi et al. [34] investigated a double-layer exhaust pipe thermal insulation strategy via CFD. The result showed that the DOC inlet temperature increased by 12 °C and the emissions of CO and HC were both reduced by 17%. Burch et al. [35] led to a 52% and 29% reduction in total CO and HC emissions, respectively, via vacuum insulation and phase-change materials (PCMs). Excellent results have been obtained by combining phase-change materials and thermal insulation. Feng et al. [36] increased the SCR inlet temperature by 19.9 °C on average, and improved the NOx conversion efficiency up to 8.0%, with an electrically heated catalyst (EHC). Miao et al. [37] employed a 4.85 kW EH-SCR and a 5.4 kW EH-DOC to shorten the SCR light-off time by 62 s. The dual EHC system presented in that study significantly reduced SCR light-off time. Ma et al. [38] developed an afterburner to reduce the catalytic converter light-off time to below 20 s. Sharp et al. [39] studied the influence of the mini-burner on exhaust gas temperature and fuel consumption. The results showed that SCR reached 200 °C at around 200 s, 400 s faster than baseline, but the fuel consumption increased by 2.6%. They used the burner for SCR and significantly reduced the light-off time. Kurien et al. [40] reported that the DPF with a 400 W microwave achieved a soot light-off temperature of 873 K at a regeneration time of 150 s.

Various methods of diesel engine after-treatment thermal management are listed in this paper. The feature of the study is a focus on non-engine-based after-treatment thermal management technologies, describing thermal management control strategies in detail and summarizing the effects of the various thermal management strategies on exhaust temperature, emission concentrations, and fuel consumption. Some catalysts that help with thermal management are also mentioned. A summary of the relevant literature as well as an identification of deficiencies and challenges are both presented in this paper.

2. Composition and Work Principle of Diesel Engine after-Treatment Systems

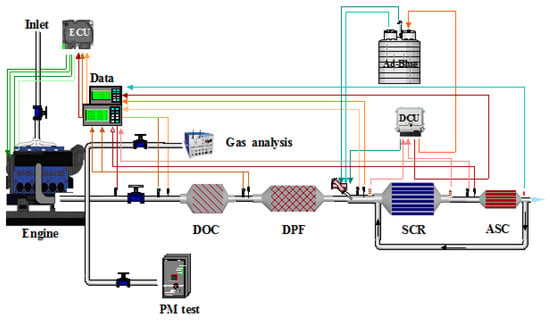

As shown in Figure 1, a typical diesel after-treatment system consists of a DOC, DPF, SCR, and ASC (ammonia slip catalyst) [41].

Figure 1.

Architecture of diesel engine exhaust after-treatment system.

2.1. DOC

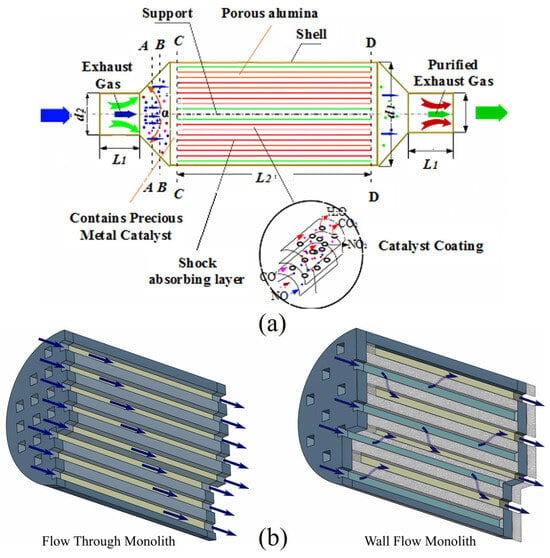

The DOC is the first after-treatment device through which exhaust gas flows [42]. The working principle of the DOC is to oxidize the CO and HC in the exhaust gas [43,44]. The DOC also oxidizes NO to NO2 [45], which increases the ratio of NO2 in NOx. A high ratio of NO2 assists DPF regeneration [46] and improves NOx conversion in SCR [47]. The heat released by the oxidation reaction in the DOC increases the downstream temperature, which assists the DPF light-off [48]. The DOC consists of the shell, the shock-absorbing layer, the substrate, and the catalyst coating [49] (Figure 2a). The substrate of the DOC is a flow-through monolith with a catalyst coating [50] (Figure 2b).

Figure 2.

Structure diagram of catalyst carrier. (a) Schematic diagram of DOC structure [49]. (b) The structures of a flow-through monolith and a wall-flow monolith [50].

The active components in the catalyst reduce the reaction activation energy and promote the oxidation reactions of CO, HC, and NO [51]. CO, HxCy (=HC) and NO enter the DOC, are adsorbed onto the catalyst coating, and react with CO2, NO2, and H2O as follows (reactions (R1)–(R3)) [52]:

2.2. DPF

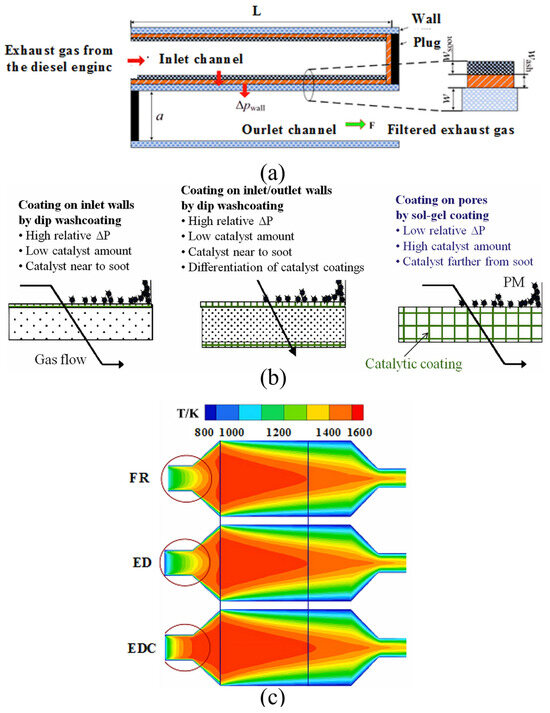

The exhaust gas flows through the wall of the DPF, and then the PM is filtered, which is the working principle of the DPF [53]. The substrate of the wall-flow DPF has a wall-flow monolith, in that the ends of the channels in it are alternately plugged [50] (Figure 3a). The accumulation of PM leads to a back-pressure increase, which leads to a deterioration of the engine performance [54]. The process of removing PM is DPF regeneration. DPF regeneration is classified as active regeneration and passive regeneration [55,56]. Efficient oxidation of PM requires a certain high temperature [57]. Active regeneration is a method that actively injects energy to increase the DPF temperature to the soot light-off temperature. For example, engine-based heating measures [58,59] or microwave-regeneration-based [60,61] active regeneration include post injection in the DOC [62,63] and an extra heating device [64,65]. Passive regeneration includes NO2 oxidation-assisted regeneration [66,67], catalytic diesel particulate filters, (CDPFs) (Figure 3b) [68,69], etc., but requires no energy input. A lot of heat is released during the regeneration (Figure 3c) [70,71], which causes the DPF to age and deteriorates the efficiency of SCR at the downstream side of the DPF [72,73]. Therefore, thermal management is important during regeneration.

Figure 3.

Schematic of the DPF. (a) Side view of adjacent channels [74]. (b) Methods for catalytic coatings on the DPF [75]. (c) Temperature contour of soot combustion reaction [71].

2.3. SCR and ASC

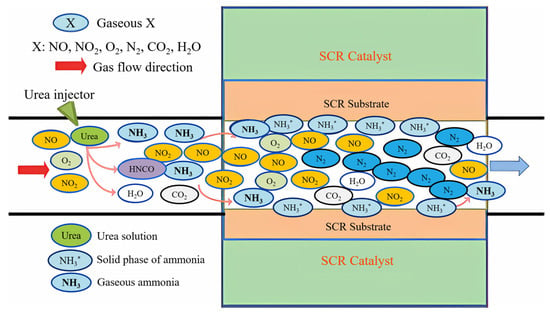

The role of SCR is to reduce NOx to nitrogen (N2) [27]. The exhaust gas contacts the reducing agent in the SCR, and the reducing agent catalytically reduces NOx to N2 (as shown in Figure 4). For reasons of safety and toxicity, an aqueous solution of urea (NH2CONH2) is the preferred selective reducing agent for SCR [76]. NH3 is produced via the hydrolysis of urea injected (reaction (R4)) by the urea solution injector upstream of the SCR [76]. The ASC is installed at the downstream side of the SCR and is used to react the unreacted NH3 [77,78]. The main reactions in SCR and ASC are as follows (reactions (R5)–(R13)) [79,80].

Figure 4.

Principle illustration of urea-based SCR diesel engine after-treatment system [81].

3. After-Treatment Thermal Management Technology

3.1. Exhaust Gas Thermal Management

The high initial exhaust gas temperature can accelerate the after-treatment system to ignite without other heating devices. Taking the DOC as an example, achieving an increase in the initial exhaust temperature under low exhaust temperature conditions helps the DOC to start oxidizing CO and HC earlier, and the exothermic oxidation reaction further increases the temperature. As the engine load gradually increases, the exhaust gas temperature also increases further. Thus, the DOC ignites earlier. The effects of engine control technologies such as variable valve timing technology (VVT) [82,83], injection technology [84], variable geometry turbo technology (VGT) [85], etc. on the exhaust temperature, BSFC, and BTE are listed in Table 1. EEVO, intake throttle, exhaust throttle, and post injection technology can raise the exhaust temperature and reduce the thermal efficiency. VGT and IVC may be the ways to improve thermal efficiency and exhaust gas temperature and effectively solve the trade-off problem between thermal efficiency and exhaust gas temperature. Injection timing slightly affects the exhaust temperature but reduces the BSFC.

Table 1.

Increase or decrease in exhaust temperature, BTE, and BSFC via different thermal management methods.

VVT is a technology that can adjust the open and close timing of the intake and exhaust valves based on engine operating conditions to run the engine in an optimized state [86,87]. Employing VVT also increases the exhaust gas temperature. Robert et al. [82] used a model to predict the effect of early exhaust valve opening (EEVO) on the exhaust gas temperature under a low load condition. The model predicted an approximate 30 °C–100 °C increase in turbine out temperature and a 5% reduction in BTE when the EVO was 90° before nominal. Basaran et al. [83] investigated the effect of early intake valve closing (EIVC) and late intake valve closing (LIVC) on exhaust temperatures. The result showed that both EIVC and LIVC increase the exhaust temperature. The exhaust temperature was higher than 250 °C when the valve timing was earlier than −25 °CA ATDC or later than 115 °CA ATDC. Fuel injection timing affects the heat release rate, and thus, it is related to exhaust temperature and engine thermal efficiency. Bai et al. [84] studied the impacts of the injection advance angle on exhaust temperature and fuel consumption through experiments. When the injection advance angle was postponed from −4 °CA to 7 °CA, the exhaust temperature increased from 225 °C to 253 °C, and the fuel consumption increased by 17 g/(kWh) at a condition of 1300 r/min and 300 N·m. In general, the main injection timing has little effect on exhaust temperature and fuel consumption. The results of the above papers were obtained under steady-state conditions and present us with the thermal management effect of VVT technology, but further transient experiments are needed for practical application.

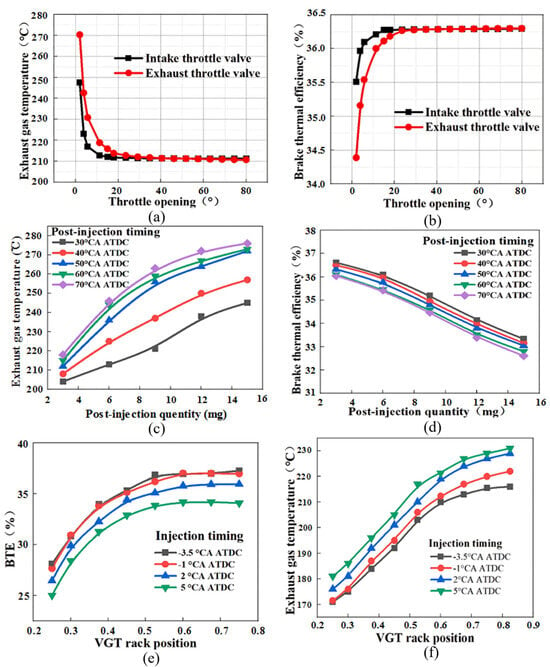

To find ways to improve thermal efficiency and increase exhaust temperature, Wu et al. [85] studied the influence of intake throttle, exhaust throttle, post injection, and VGT on exhaust temperature and BTE. The exhaust gas temperature increased by 40 °C and 60 °C, and the BTE decreased by 1% and 2%, respectively, when the opening of the intake throttle valve and the exhaust throttle valve were sufficiently reduced (Figure 5a,b). The parameters of the post injection quantity and timing had significant effects on the exhaust temperature and thermal efficiency. When the timing was retarded from 30 °CA ATDC to 70 °CA ATDC, the exhaust temperature increased by 50 °C, and the BTE decreased by about 1% at a constant post injection quantity of 9 mg. When the post injection quantity increased from 3 mg to 15 mg, exhaust temperature increased by 50 °C, but the BTE decreased by 3% (Figure 5c,d). As shown in Figure 5e,f, the exhaust temperature increased by about 50 °C and the BTE increased by about 7% with the reduction in the VGT working capacity.

Figure 5.

Effects of different thermal management techniques on exhaust gas temperature and BTE [85]. (a) Relationship between throttle opening and exhaust gas temperature. (b) Relationship between throttle opening and BTE. (c) Effect of post injection on exhaust gas temperature. (d) Effect of post injection on BTE. (e) Effect of VGT on exhaust gas temperature. (f) Effect of VGT on BTE.

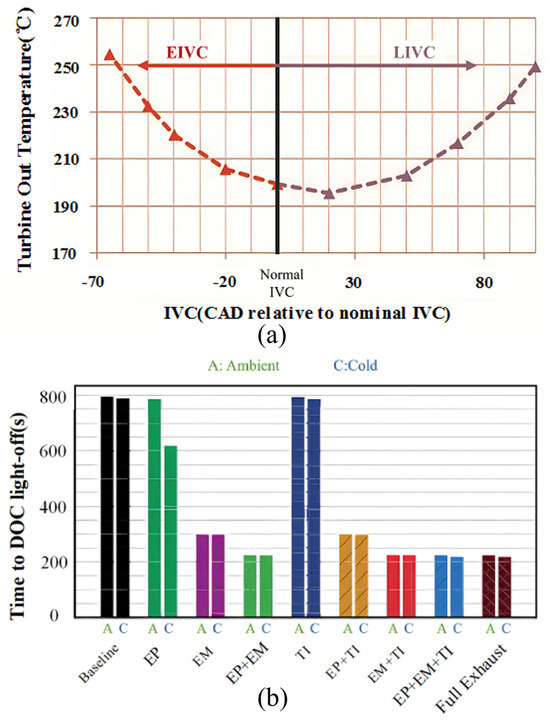

3.2. DOC Thermal Management

The conversion efficiency of the DOC is closely related to temperature because the catalytic activity of catalysts is positively correlated with temperature. Take the common Pt precious metal catalyst as an example. CO conversion reached 100% at a temperature of around 180 °C, while HC conversion reached 40% at a temperature of 270 °C [88]. Ho et al. [89] presented that CO conversion and C3H6 conversion reached 100% at a temperature of around 300 °C, but when the temperature was 150 °C, the CO conversion and C3H6 conversion were 20% and 0%, respectively. A lot of CO and HC will be released into the atmosphere without being treated at low temperatures. Therefore, rapid DOC light-off is crucial [90,91]. High-temperature exhaust gas has a significant effect on DOC light-off. As shown in Figure 6a, Grag et al. [92] increased the exhaust temperature from 195 °C to 255 °C by adjusting the intake valve closing timing. Chuan et al. [93] increased the exhaust temperature from 190 °C to 310 °C, which was higher than the DOC light-off temperature, via cylinder deactivation (CDA) at idle operation. Neely et al. [94] applied intake throttle technology to raise the turbocharger outlet temperature to 230 °C at the condition of 1200 rpm, 1.7 bar BMEP, and 25 °C coolant temperature. Francisco et al. [95] explored exhaust pipe thermal insulation to increase the DOC inlet temperature and accelerate DOC light-off. The adiabatic exhaust port (EP), exhaust manifold (EM), internal surface of the turbine volute (TI), and turbine external housing were simulated under the WTLC. The result is shown in Figure 6b. DOC light-off took 800 s without any insulation, while DOC light-off took only about 200 s when all parts were completely insulated. The exhaust manifold was the part that lost the most heat. The rapid DOC light-off also benefits from external heat sources such as burners and EHCs.

Figure 6.

Data of exhaust temperature and DOC light-off time. (a) Exhaust gas temperatures along EIVC and LIVC sweeps at 1200 RPM, 2.5 bar BMEP [92]. (b) Time to reach the DOC light-off temperature [95].

Zhao et al. [96] added a burner upstream of the DOC. The simulation calculation showed that it took 65 s for the 1.54 kg DOC substrate to reach a temperature of 300 °C at the condition of 79.2 kg/h exhaust flow rate and 25 °C initial temperature. In practical situations, the actual light-off time will increase due to the interference of factors such as heat transfer loss. Paolo et al. [97] employed an EHC to heat the DOC. The DOC employing EHC took about 220 s to reach the peak temperature in driving cycle conditions, and the temperature of the DOC could be maintained at more than 50% of the peak temperature through the on-off control of the electric heater.

3.3. DPF Thermal Management

The soot oxidation light-off temperature of the DPF is higher than the DOC light-off temperature [98,99]. Under the normal operation of diesel vehicles, the exhaust temperature (200–400 °C) cannot meet the continuous oxidation of O2/NO2 to the accumulated PM [100]. Even if the catalyst is applied, high temperatures are required. When the Printex-U load of 3.5 g/L was regenerated at 400 °C, the filtration efficiency of particles showed a value of 86.4% [101]. Tan et al. [102] increased the DOC outlet temperature to 550 °C via a late post injection technology, but raising the DPF inlet temperature in that way was accompanied by worsening fuel consumption [103]. The diesel vaporizer system was to introduce diesel into the DOC to intensify the oxidation heat release of the DOC [104], which enabled the DOC outlet temperature to reach 650 °C rapidly, with a fuel consumption reduction of 50%. Utilizing the HC tailpipe injection could reduce extra fuel consumption. The injection amount is calculated according to the target temperature via Equation (1). This formula is idealized, and its premise is that all fuel is fully oxidized by the DOC to heat the exhaust gas [105]:

where is the mass flow rate of fuel injection, kg/h; is the mass flow rate of the exhaust gas, kg/h; cp is the specific heat of the exhaust gas, kJ/kg/K; is the difference between the target exhaust temperature and the incoming exhaust temperature, K; and H is the lower heating value of the diesel fuel, kJ/kg.

Microwaves rapidly heat the DPF to the soot light-off temperature. Kurien et al. [106] utilized microwaves to raise the maximum temperature of the substrate to 800 K and the average temperature to more than 600 K in a regeneration time of 180 s. In [40], the magnetron port power was considered. The DPF reached a soot oxidation temperature of 873 K in a regeneration time of 150 s with a power of 400 W. To minimize microwave energy consumption during DPF regeneration, E et al. [107] developed a microwave energy consumption optimization model and obtained an optimized microwave regeneration power and regeneration heating time. The microwave energy consumption of the four cases was reduced by 5.65%, 5.7%, 10.64%, and 14.64%, respectively. E et al. [108,109] optimized the rotary microwave regeneration performance and obtained a series of optimized regeneration parameter ranges. The optimal parameter ranges of the exhaust temperature, oxygen content, soot mass fraction, and microwave power were 600–750 K, 0.11–1.15, 0.06–0.08, and 800–1200 W, respectively.

Zhao et al. [110] proposed that the field synergy angle could be an index to optimize the temperature distribution of the DPF. Deng et al. [111] concluded that 20–30 g/s was the optimal exhaust mass flow range based on an analysis of the synergy between the vector field and the temperature gradient. Furthermore, wall melting and thermal stress damage could be avoided when the PM load was less than 5 g/L. As shown in Equation (2), the concept of a temperature uniformity coefficient was proposed [112]. The temperature uniformity coefficient describes the temperature distribution of the DPF more accurately. They found that an inlet velocity of 36 m/s and an inlet pressure of 0.08 Mpa were the optimal parameter values based on the formula.

where is the temperature of a position in the wall-flow filter, K; is the wall-flow filter’s average temperature under a certain condition, K; and is the temperature uniformity coefficient.

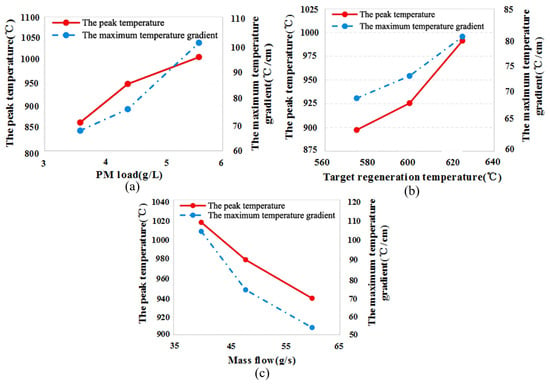

Drop to idle (DTI) is a driving behavior in which the engine rapidly changes from a high-speed condition to an idle condition. The increase in oxygen content and the decrease in exhaust flow lead to an accumulation of heat in the DPF; thus, the temperature rises rapidly during DTI [113,114]. The peak temperature and temperature gradient are a concern. The substrate will crack and melt if the temperature gradient and the peak temperature are too high [115,116]. Wang et al. [117] increased the idle speed via EGR and intake throttling to reduce the oxygen concentration in the exhaust gas, which alleviated the intensity of the oxidation reaction. The presence of EGR and intake throttling reduced the peak temperature by 130 °C at an idle speed of 2200 rpm. Bai et al. [118] raised the idle speed from 700 rpm to 1100 rpm, which resulted in a decrease in the peak temperature from 820 °C to 632 °C and a reduction in the maximum temperature gradient from 30 °C/cm to 10 °C/cm. Tan et al. [119] investigated the effect of PM load, target regeneration temperature, and exhaust mass flow on DPF temperature distribution during DTI. The peak temperature and the maximum temperature gradient of the DPF increased by 17% and 48.6%, respectively, when the PM load was increased from 3.6 g/L to 5.6 h/L (Figure 7a). The increase in the target regeneration temperature from 575 °C to 625 °C was accompanied by a 10.5% increase in the peak temperature and a 15.9% increase in the maximum temperature gradient (Figure 7b). When the exhaust mass flow was increased from 40 g/s to 60 g/s, the peak temperature and the maximum temperature gradient were reduced by 7.75% and 48.17%, respectively (Figure 7c).

Figure 7.

Peak temperature and maximum temperature gradient [119]. (a) The peak temperature and maximum temperature gradient at different PM loads. (b) The peak temperature and maximum temperature gradient at different target regeneration temperatures. (c) The peak temperature and maximum temperature gradient at different mass flows.

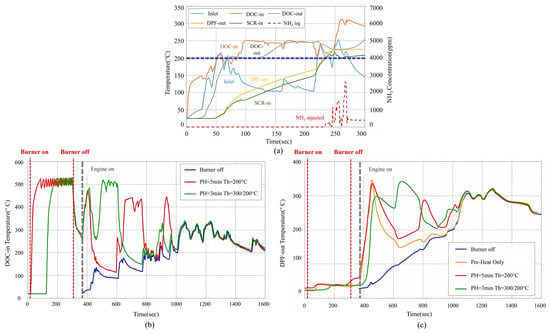

3.4. SCR Thermal Management

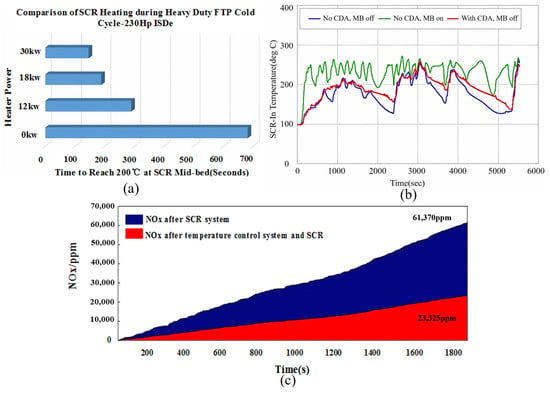

The catalyst in SCR requires a certain temperature range. An iron titanate catalyst showed good activity in a temperature window of 200–350 °C with the NOx conversion above 90% [120]. Nicolo et al. [121] adopted a strategy of VGT and fuel injection timing to advance SCR light-off by 600 s under the cold NEDC for the Euro 6 emission regulations. The fuel consumption of SCR increased by 7.39%. Sung et al. [122] proposed a plasma burner to heat the SCR during cold start conditions (Figure 8a). The SCR surface reached the light-off temperature of 200 °C in only 25 s with the 250 W plasma burner heated. Culbertson et al. [123] studied the impacts of different heating powers on SCR light-off time. SCR reached 200 °C at around 130 s via a 30 kW EHC under the cold FTP, more than 8 min faster than the No EHC case. The catalysts in the SCR have a high conversion efficiency within a specific temperature window [124,125]. SCR will hydrothermally age if exposed to high temperatures for a long time [126,127]. Therefore, the peak temperature of the SCR also needs to be considered. It can be solved using a logic block that was adopted to control the open and close of the burner in [128]. The burner turned off when the maximum set temperature was reached and turned on when it fell below the minimum set temperature. As shown in Figure 8b, the exhaust temperature rose rapidly to 250 °C, and the SCR inlet temperature fluctuated between 200 °C and 250 °C. This indicates that the burner heated up faster and its temperature was relatively stable.

Figure 8.

Figures and data of SCR thermal management. (a) Comparison of times to heat SCR mid-bed to 200 °C [122]. (b) SCR inlet temperature data [128]. (c) The total quantity of NOx elimination with an SCR system only and with an SCR system assisted by a temperature control system [129].

Jiang et al. [129] adopted a PCM to control the temperature of the SCR. After completing the preheating procedure in the European transient cycling (ETC) with a target temperature of 563 K, the fluctuation in the exhaust gas temperature was limited within 30 K. The NOx conversion efficiency was over 90%, and the total NOx emission was reduced by about 2/3 (Figure 8c).

4. After-Treatment Systems Efficiency Enhancement Approaches

4.1. Burner

The burners installed at the upstream side of the catalysts heat the exhaust gas directly, which can effectively reduce the light-off time of the DOC. Alexander et al. [130] employed a burner in a 2 L engine after-treatment system. The emission of HC improved significantly when the preheat time was 0.5 s. When the preheat time was extended to about 20 s, the catalytic converter reached the light-off temperature before the engine turned on. Thomas et al. [131] added a microburner to the engine model. The burner turned on at 4 s under the cold FTP and worked at a constant fuel rate of 0.256 g/s until the end of the cycle. As shown in Figure 9a, the DOC inlet temperature reached 250 °C at 100 s. The late start of the ammonia spray is a limitation.

Figure 9.

Exhaust gas temperature during preheating and the cold-start FTP cycle. (a) Exhaust gas temperatures at various locations within an after-treatment system that includes an in-exhaust burner [131]. (b) DOC-in temperature during preheating and the cold-start FTP cycle [132]. (c) DPF-out temperature during preheating and the cold-start FTP cycle [132].

Two burner control strategies were proposed in [132], as shown in Figure 9b,c. The control strategy represented by the red line was preheating for 5 min after the engine turned on. The DPF outlet temperature was 200 °C as the threshold temperature. (The burner turned off once the temperature was reached.) The control strategy represented by the green line was preheating for 3 min after the engine turned on, which adopted 300 °C as the threshold temperature once, and then reduced the threshold temperature to 200 °C. The DOC and SCR light-off times were less than 50 s and 100 s, respectively, but the DOC temperature could not be maintained above 250 °C all the time. McCarthy et al. [133] utilized an identical two-tier control strategy for SCR. The SCR inlet temperature was maintained at more than 200 °C, and the emission of NOx deceased by 93.5%, but the CO2 emission increased by 9%.

4.2. EHC

EHC is an effective way to improve the efficiency of after-treatment systems. Augusto et al. [134] indicated that nonuniform distribution of the heat generated by the electrical heating device determined the formation of some hot spots inside the catalyst, which promoted the light-off of the reactions at the early cold start condition. Johannes et al. [135] adopted EHC in a hybrid vehicle, which significantly reduced NOx emission levels during urban and short-distance driving. Pfahl et al. [136] utilized a 1 kW EHC to warm up the DOC under the NEDC. An EHC deceased the DOC light-off time by 100 s, while the conversion rates of HC and CO increased by 20% and 60%, respectively. Pace et al. [137] reported that 60% less energy was required for the EHC to reach temperature levels similar to engine-based catalyst heating methods.

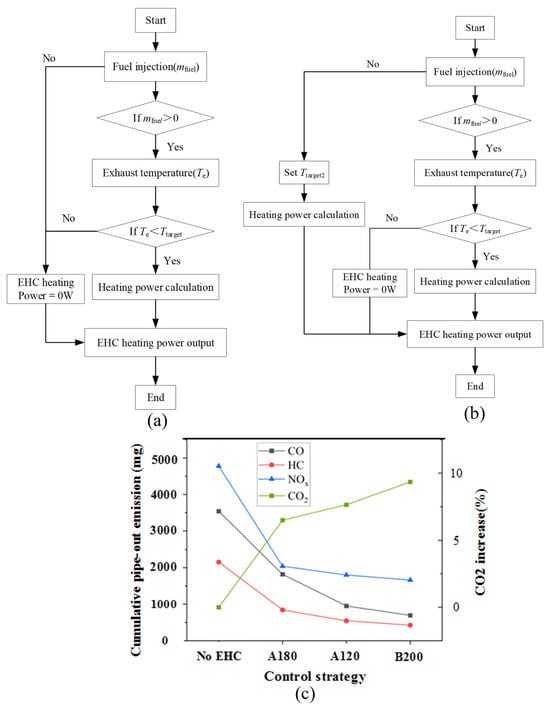

The EHC is a flexible device. Reasonable control strategies can optimize energy consumption, exhaust temperature, catalyst efficiency, and thermal damage to the catalyst. Gao et al. [138] presented two EHC control strategies and investigated their influence on energy consumption and emissions. As displayed in Figure 10a,b, strategy A meant that the EHC turned off when the engine stopped injecting fuel or the exhaust temperature was higher than the target temperature (Ttarget). Strategy B was that the EHC turned off only when the exhaust gas temperature was higher than the target temperature (Ttarget1) and when the engine stopped injecting fuel. A Ttarget2 less than or equal to Ttarget1 was set.

Figure 10.

Two different EHC control strategies and a graph of emission data [138]. (a) Control strategy A. (b) Control strategy B. (c) Impact of control strategies on emissions.

Strategy A significantly shortened the catalyst light-off time under the cold WLTC. The light-off times were 254 s and 256 s when the target temperature was set to 180 °C and 200 °C (A180 and A200), respectively. Compared with A180, A200 deteriorated the CO2 emission by about 18%, and reduced the CO, HC, and NOx emissions by about 48%, 35%, and 12%, respectively. Compared with the No EHC case, A200 decreased CO, HC, and NOx emissions by about 73%, 75%, and 62%, respectively, while the CO2 emissions increased by 7.64%. In strategy B, when Ttarget1 and Ttarget2 were both set to 200 °C (B200), the CO, HC, and NOx emissions were reduced by about 80%, 80%, and 66%, respectively, while the CO2 increased by 9.35% (as given in Figure 10c). In [139], a pulsating heating strategy with a pulse width of 30 s led to an approximate 70% and 24% reduction in the CO and HC emissions, respectively, under the NEDC. Compared with the typical heating strategy, the pulsating heating strategy increased the CO and HC conversion efficiency by 34% and 31%, respectively. NOX conversion was much lower than that of CO and HC due to the fact that SCR occurs at the end of the after-treatment system and hardly benefits from the heat of the EHC.

Before the engine is turned on, there is no airflow in the exhaust pipe; therefore, when the preheating strategy was adopted, the heat distribution in the after-treatment devices was uneven, and the downstream devices were insufficiently heated. To solve this problem, Bargman et al. [140] installed an air pump upstream of the after-treatment system and utilized the airflow to preheat the downstream after-treatment devices. The results showed that the emission of NOx was reduced by 51% in non-methane organic gas under the cold start condition. Hamedi et al. [139] proposed the method of combining EHC with post injection technology, which reduced the total emission of HC by 79% compared with employing the post injection technology individually. Kim et al. [141] combined EHC and HC injection. The 4.8 kW peak power was applied from the start-up, and then, an appropriate amount of HC injection was applied after 20 s when the EHC temperature reached 250 °C. SCR light-off time was within 100 s. Furthermore, the conversion efficiency of the SCR reached 90% during 100 s to 350 s during the cold FTP75. Matheaus et al. [142] studied the effects of EH combined with CDA on SCR emissions reduction and fuel consumption. Compared with CDA individually, EH (5 kW constant) combined with CDA decreased NOx emissions by 62.5%, and BSFC was increased by 5.7% under the cold FTP. Compared with EH alone, NOx emissions and BSFC decreased by 50% and 2%, respectively.

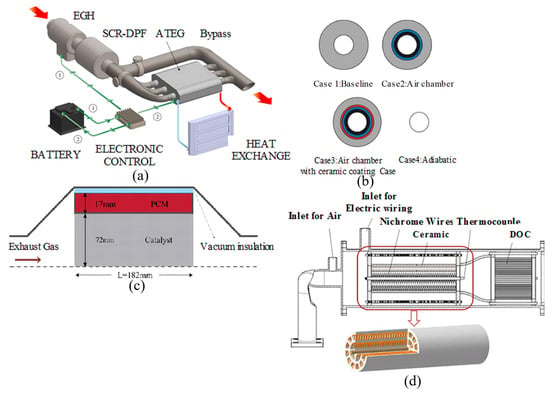

The coupling system of a thermoelectric generator and exhaust gas heater was investigated in [143]. Electric energy was generated by the temperature difference between the exhaust gas and cooling water to compensate for the energy consumption of the electric heater through the coupling system. Ximinis et al. [144] implemented a thermoelectric generator and EH coupling system in the after-treatment system of a diesel engine (Figure 11a). Employing a 5 kW EH powered by a thermoelectric generator alone, they were able to increase the SCR conversion efficiency by 55%.

4.3. Thermal Insulation

Thermal insulation improves catalyst performance by reducing exhaust heat loss during engine warm-up. Broatch et al. [145] simulated the effects of exhaust ports and exhaust manifolds under adiabatic conditions on engine efficiency and after-treatment systems. The exhaust gas temperature slightly increased, and the fuel consumption decreased by 0.5% under the WLTC. Rohil et al. [146] simulated a vacuum-insulated catalytic converter. CO and HC emissions decreased by 26% and 48%, respectively, at real-world driving conditions. Wang et al. [147] applied a layer of 6 mm insulation material to the exhaust pipe in a section between the turbine outlet and the DOC, which reduced NOx emission by 19.5% under the NRTC. Wang et al. [148] increased the in-cylinder temperature by 100–200 K via a thermal barrier coating, which indirectly increased the exhaust gas temperature. Luján et al. [149] investigated the effects of exhaust port insulation and turbocharger insulation on exhaust temperature and fuel consumption. Four cases of exhaust port insulation strategies are shown in Figure 11b. The inlet temperature followed a trend of 4 > 3 > 2 > 1, and the BSFC followed a trend of 1 > 2 ≈ 3 > 4. The thermal insulation strategy of the turbocharger affected insignificantly the inlet temperature of the after-treatment system and BSFC. Thermal insulation methods can improve exhaust temperatures, but they do not provide additional heat. Thus, thermal insulation methods cannot be used as a final solution.

4.4. PCMs and the Heat Recovery System

PCMs release or absorb a large amount of heat during phase change to heat or cool down [150,151]. PCMs can be used to recover waste heat and improve energy utilization. PCMs have been widely implemented in automobiles [152,153]. PCMs are implemented in the after-treatment system to recover heat under high load conditions and then release energy under low load conditions to improve catalyst performance.

Korin et al. [154] embedded a 3.8 kg PCM into the TWC. After the engine turned off, the TWC remained above the light-off temperature for 4 h, which benefited from the heat release of the PCM. If the engine turns on again within 4 h, the emission under cold start conditions will be improved, but the PCM will not work if the engine starts after 4 h. Gaiser et al. [155] adopted a PCM with a phase change temperature higher than the catalytic converter light-off temperature and installed a latent heat storage (LHS) device upstream of the catalytic converter to heat the exhaust gas using the fact that the temperature of the PCM in the LHS did not change when it melted. The catalyst inlet temperature reached 200 °C within 100 s and remained around 200 °C in the following 400 s under the cold start condition. Hamedi et al. [156] developed a thermal energy storage system (TES) based on a PCM to reduce cold start emissions (as shown in Figure 11c). Under the NEDC, the DOC equipped with TES reduced CO and HC emissions by 64% and 34%, respectively.

Jiang et al. [129] limited the temperature fluctuation of SCR to 30 K via PCM. Raznoshinskaia et al. [157] decreased the range of exhaust temperature vibrations by 73.1% with the ternary eutectic mixture of 7NaNO3/40NaNO2/53KNO3. PCMs are a potential way to stabilize the exhaust temperature. Dae et al. [158] developed an engine exhaust heat recovery system (EERS) equipped with secondary combustion. Exhaust gas temperatures increased from 200–350 °C to 350–550 °C due to the combustor, which was installed at the outlet of the exhaust manifold (Figure 11d). The EERS improved thermal efficiency up to 20–25% and decreased CO, NOx, and PM emissions by 80%, 35%, and 90%, respectively. Park et al. [159] adopted the heat storage system of a PCM for a 1.6 L diesel engine. The time to warm up the coolant to 95 °C was reduced by 40.5% under the NEDC, and fuel consumption was reduced by 2.71%. Gumus et al. [160] utilized PCMs to preheat the engine, which improved emissions during cold start. The HC and CO emissions deceased by 17.32% and 28.71%, respectively.

Figure 11.

Structures of exhaust gas after-treatment devices and components in various studies. (a) Structure and energy flow of EGH-ATEG [144]. ① heating stage; ② recovery stage. (b) Representation of exhaust ports thermal insulation cases [149]. (c) PCM model geometry diagram [156]. (d) Schematic diagram of secondary combustor [158].

Table 2 is a summary of the reduction in exhaust emissions by the above after-treatment thermal management technologies.

Table 2.

Performance improvement of exhaust after-treatment systems by different technologies.

4.5. VVT and Post Injection

Arnau et al. [161] investigated the effects of VVT on exhaust temperature, DOC light-off time, and fuel consumption. The combination of an advanced exhaust and a delayed intake obtained a 27 °C increase in DOC inlet temperature, 75 s reduction in DOC light-off time, and 6% deterioration in fuel consumption during the low-speed phase of the worldwide harmonized light vehicles test cycle. Wu et al. [85] combined thermal insulation, post injection, and VGT-RIVCT under cold WHTC to enable the SCR to reach 190 °C at 450 s, which could significantly reduce NOx emission. CDA is achieved by adjusting valve movement and stopping in-cylinder fuel injection. CDA is a technology to reduce fuel consumption [162,163]. The benefit is achieved in part-load operations when the BSFC is higher than in full-load operations [164]. CDA is also an effective method to increase the exhaust temperature [165,166]. Ramesh et al. [167] increased exhaust temperature by 60 °C and improved BTE up to 10% with a three-cylinder strategy at a condition of 800 rpm and 1.3 bar BMEP. A two-cylinder strategy increased the exhaust temperature by 120 °C and improved BTE up to 2%. Allen et al. [168] explored the performance of CDA to maintain warmth for the after-treatment system at an extended idle operation. The result showed that the turbine outlet temperature was maintained above 250 °C with a two-cylinder strategy.

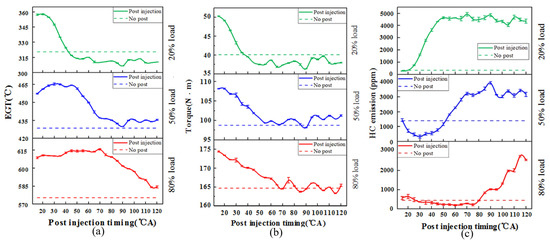

Internal exhaust gas recirculation (IEGR) is achieved with both negative valve overlap (NVO) and reinduction [169]. Joshi et al. [170] confirmed that EEVO/NVO increased the exhaust temperature to more than 255 °C and decreased fuel consumption by 5.7%. Simultaneously, LEVO took the exhaust temperature to above 280 °C with no extra fuel consumption. Wang et al. [171] explored the effects of post injection timing on engine-out HC emission, exhaust temperature, and torque, as displayed in Figure 12a,b.

Figure 12.

Effects of post injection on torque and HC [171]. (a) Effects of post injection on EGT at different loads. (b) Effects of post injection on engine brake torque at different loads. (c) Effects of post injection on HC at different loads.

With the delay in the post injection timing, the exhaust temperature increased and then decreased. The later the post injection timing was, the less fuel participated in the combustion, which resulted in a deterioration in torque. The fuel consumption and the HC entering the exhaust pipe increased (Figure 12c), which intensified the reaction of the DOC and raised the DOC outlet temperature.

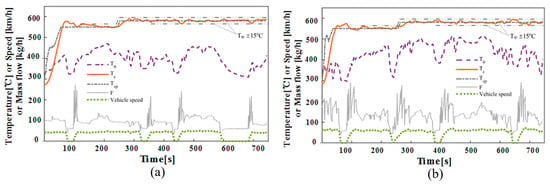

Huang et al. [172] developed a DPF temperature control strategy based on post injection. The control strategy calculated the quantity of post injection based on the target regeneration temperature and amended the quantity via feedback and feedforward compensation methods based on both the exhaust gas temperature and flow rate. As shown in Figure 13a,b, after the DPF inlet temperature reached the target regeneration temperature, its fluctuation was within 15 °C under different urban driving conditions, which proved the robustness of the control strategy.

Figure 13.

Test results of different conditions [172]. (a) Test results under urban driving conditions. (b) Test results under aggressive suburban driving conditions.

4.6. Catalysts

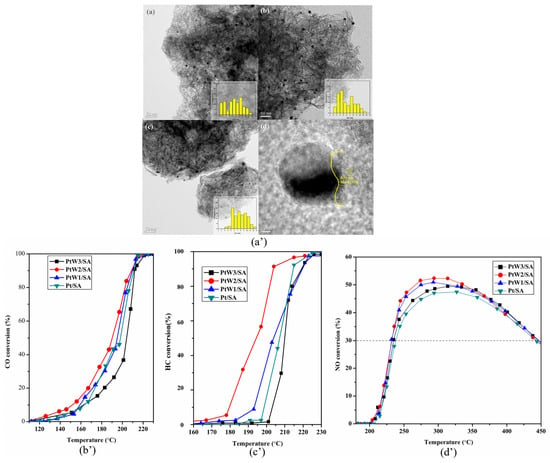

Catalysts with high activity and thermal stability improved the efficiency of the after-treatment system and reduced the energy consumption of the thermal management. Pt-based catalysts are the most widely used catalysts in DOCs [173,174]. Kolli et al. [175] and Boubnov et al. [176] confirmed that Pt/Al2O3 had a high catalytic activity and a poor sulfur resistance. As shown in Figure 14a’, Liang et al. [177] loaded Pt on MnOx, which enhanced the catalytic activity of Pt. The conversions of CO, C3H6, and NOx are given in Figure 14b’–d’. Väliheikki et al. [178] and Gu et al. [179] adopted SiO2-ZrO2 and Ce-Zr-SO42- as supports to improve the sulfur resistance and stability of Pt-based catalysts.

Figure 14.

Conversion of all catalysts (Rx, “x” represents the reaction temperature of manganese oxide reduction) [177]. (a’) TEM images of catalyst: (a) R200, (b) R250, (c) 300, and the corresponding particle size distribution is inserted as a histogram; (d) HRTEM image of R250. (b’) CO conversion of all catalysts. (c’) C3H6 conversion of all catalysts. (d’) NO conversion of all catalysts.

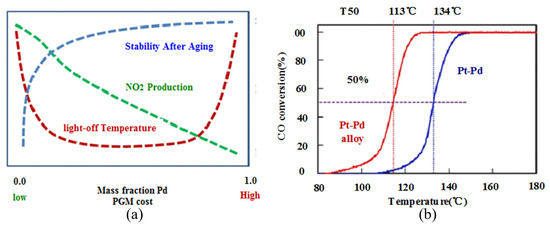

The researchers reported that doping with other metals can enhance the performance of Pt-based catalysts. Liang et al. [180] added 2%wt tungsten trioxide (WO3) to Pt/SiO2-Al2O3, and the light-off temperature of HC and CO was reduced. Kim et al. [181] reported the relationship between the value of Pd/Pt and light-off temperature and the relationship between thermal stability and the value of Pd/Pt (Figure 15a). E et al. [16] indicated that the light-off temperature of the Pt-Pd catalyst was lowest when the Pd was approximately 70%. Huang et al. [182] doped the Pt/Ce-Zr-O catalyst with vanadium (V) (Figure 15b). The CO and HC light-off temperatures of 1Pt-1V/Ce-Zr-O were approximately 195 °C and 190 °C, respectively. Furthermore, the light-off temperature of HC was almost constant, and the light-off temperature of CO increased by 10 °C in an SO2 atmosphere for 70 h.

Figure 15.

Catalytic activity or stability of each series of catalysts. (a) Pt to Pd ratio effect on Pt-based diesel oxidation catalysts [181]. (b) Catalytic activities of CO on the Pt-Pd alloy catalyst and the conventional Pt-Pd catalyst [16].

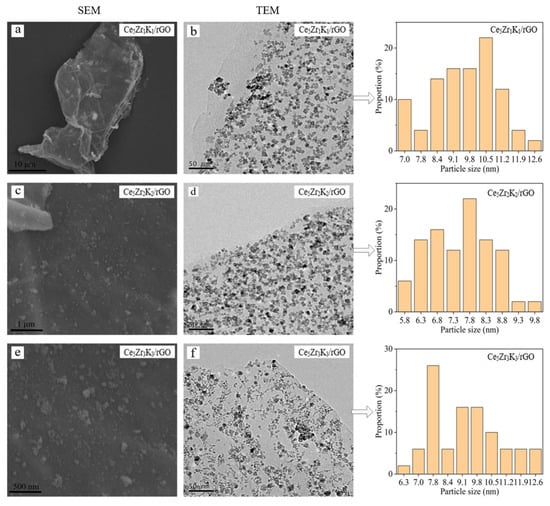

The researchers developed alloy catalysts that were better than conventional catalysts. Dong et al. [183] investigated a Pt (1.0 wt%)-Pd (0.5 wt%) alloy catalyst loaded on SiO2. The activity of the Pt-Pd alloy catalyst was higher than the conventional Pt-Pd catalyst. Franken et al. [184] confirmed that the Mn-Pt alloy catalyst is a sulfur-tolerant catalyst. The conversion of NOx deteriorated by 6% under the 300 ppm SO2 for 70 h, while the pure Pt/Al2O3 catalyst deactivated fully within the first 30 min. Ceria (CeO2) catalysts, which are rare-earth metal catalysts, are widely applied in automotive exhaust after-treatment systems [185,186]. Bueno-López et al. [187] reported that the temperature at which CeO2 reached 50% soot conversion rate was 525 °C. Ce-based catalysts can be doped with rare-earth metals [188,189], noble metals [190,191], transition metals [192,193], alkali metals [194,195], and alkaline earth metals [196]. Yang et al. [197] added Mn to improve the activity of soot oxidation and the thermal stability of Ce-based catalysts. The T10 of the 40% Mn-Ce catalyst was 475 °C, and the T90 was 565 °C. Stability of the 40% Mn-Ce decreased in the third cycle of the thermo-gravimetric analyzer experiment. Atribak et al. [198] revealed that doping zirconium (Zr) improved the thermal stability of Ce-based catalysts. Yang et al. [199] added lanthanum (La) to the CeO2-ZrO2 catalyst and tested the catalytic activity of soluble organics (SOs). The test result indicated that the catalyst was more active and had a slower aging rate after doping with La. Wu et al. [200] studied the catalytic activity of CeZrK/rGo with different doping ratios. The T50 of Ce5Zr1K1/rGO, Ce5Zr2K2/rGO, and Ce5Zr3K3/rGO for soot oxidation were 352 °C, 339 °C, and 358 °C, respectively (Figure 16).

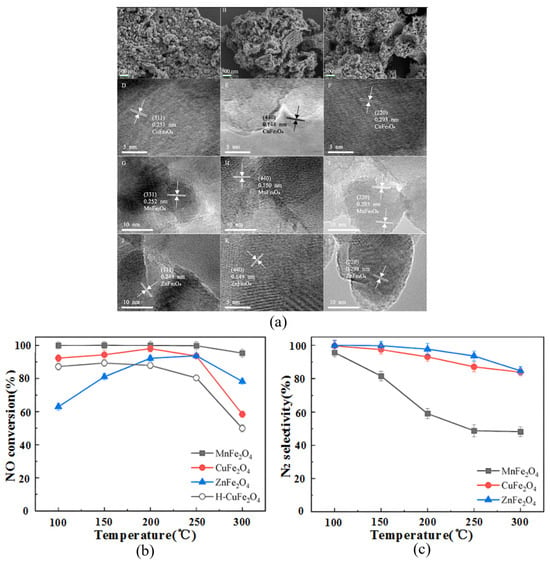

Figure 16.

SEM and TEM images of CeZrK/rGO catalysts ((a,c,e) are SEM images. (b,d,f) are TEM images.) [200].

Sarli et al. [201] added Ag to CeO2, which greatly enhanced the catalytic activity. The T10 of 12% Ag/CeO2 for soot oxidation was 240 °C, and the temperature at maximum conversion was 435 °C. At present, various transition metal catalysts have been investigated. Cheng et al. [202] investigated a series of V2O5/TiO2 catalysts to improve the catalytic performance of NH3-SCR. The results showed that the NO conversion efficiency was above 80% when the 5% V2O5/TiO2 supported on aluminate was at temperatures between 325 °C and 400 °C. Ding et al. [203] prepared the MFe2O4 (M = Cu, Mn, and Zr) (Figure 17a). As shown in Figure 17b,c, MnFe2O4 had the highest activity, and ZnFe2O4 had the highest N2 selectivity, at low temperatures. CuFe2O4 was a balanced catalyst, but its efficient reaction temperature range is narrow. In addition, the catalytic activity of CuFe2O4 decreased by 8% in SO2 atmosphere for about 2 h. Zhang et al. [204] reviewed Mn-based catalysts for NH3-SCR and summarized the advantages and disadvantages of MnOx. MnOx had a high low-temperature activity and played a decisive role in the SCR reaction but had poor thermal stability and a narrow reaction temperature window. It also had an insufficient reaction in the eutrophic environment and weak sulfur resistance.

Figure 17.

Data of MFe2O4 (M = Cu, Mn, and Zn) [200]. (a) SEM of CuFe2O4 (A), MnFe2O4 (B), and ZnFe2O4 (C); HRTEM of CuFe2O4 (D–F), MnFe2O4 (G–I), and ZnFe2O4 (J–L) [203]. (b) NOg conversion vs. temperature (GHSV = 30,000 h−1). (c) N2 selectivity vs. temperature (GHSV = 30,000 h−1).

To reduce the cost and enhance the activity and stability of the catalysts, Tang et al. [205] developed a LaKCoO3/γ-Al2O3/cordierite perovskite catalyst. The results showed the high activity and thermal stability of the LaKCoO3/γ-Al2O3/cordierite. The T10, T50, and T90 of the LaKCoO3/γ-Al2O3/cordierite catalyst for soot oxidation were 186.3 °C, 314.6 °C, and 390.0 °C, respectively.

5. Outlook for Future Research

5.1. Shortcomings of Current Technologies

The engine-based after-treatment management methods increase the exhaust temperature, and the high-temperature flowing exhaust gas heats the after-treatment devices, which can shorten the light-off time of the after-treatment system. These methods do not require additional devices and are relatively simple to implement. However, changing the engine parameters leads to fuel economy penalties. Techniques such as intake and exhaust throttling [85] or EVO timing technology [82] lead to worse combustion and a deterioration in BTE. CDA and IVC timing can increase exhaust temperature and improve fuel consumption [161,167]. The low-flow-rate strategies reduce the exhaust flow rate, and the exhaust gas has a longer contact time with the exhaust pipe, which leads to more heat dissipation to the atmosphere [83,168]. Fuel strategies such as post injection and hydrocarbon injection directly convert the chemical energy of fuel to thermal energy to increase the temperature of the after-treatment system [171,172]. Energy conversion efficiency is a problem that needs to be considered, and these fuel strategies lead to higher fuel consumption [85,171]. Post injection can also lead to oil dilution, affecting the life of the engine [102].

Technologies such as burners, EHCs, and microwave heating have proven to be effective thermal management measures that are flexible and easy to control, but the control strategy cannot coordinate the entire after-treatment system [131,138]. For example, when the burner and EHC are installed upstream of the after-treatment system, the heat produced has a relatively weak effect on the SCR downstream of the after-treatment system. The conversion rate of NOx is lower compared with HC and CO [131,138]. The DPF outlet temperature can be considered the SCR threshold temperature while ignoring the DOC [131,133].

The heat recovery system based on the PCM for the after-treatment system thermal management can solve the trade-off problem of exhaust gas temperature and carbon dioxide emission, but the PCMs are effective only when the engine is turned on again before the PCM heat is exhausted [156]. PCMs are a potential method to stabilize exhaust temperatures [157]. The thermoelectric generator recovers a part of the electric energy through the exhaust heat and compensates for the EHC. The thermoelectric generator increases the complexity of the after-treatment system, which can increase the back pressure [143,144].

Simulation research under adiabatic conditions has confirmed that the thermal insulation methods are able to shorten the light-off time of the after-treatment system, but the currently developed thermal insulation methods still have a certain gap in the adiabatic case. The developed catalysts have high activity at low temperatures [174,183]. The reaction temperature window is narrow for SCR [203,204]. The anti-deterioration performance is still a challenge (anti-sulfur, phosphorus, etc.) [49,204].

5.2. Outlook for Future Technologies

As described in the previous section, there are limitations in the separate technical methods, and multiple technologies need to be combined to improve the efficiency of after-treatment thermal management technology. Future technologies can be further explored from the following aspects:

- (1)

- To optimize CO2 emissions and exhaust temperatures, control strategies for the EHC and post injection coupled methods are investigated [137].

- (2)

- The active and passive thermal management technologies are combined [85,156].

- (3)

- Further control strategies for EHC [138,139], burners [132,133], and late post injection [168], based on the entire after-treatment system, are applied.

- (4)

- Materials are used with lower thermal conductivity and different insulation methods to approach adiabatic conditions [145,149] for better PCM development [156,157].

- (5)

- The inexpensive catalysts’ improvement is developed widely to explore catalysts with excellent degradation resistance [204,205].

6. Conclusions

Although combustion technology [206,207] and alternative fuels [208,209] are constantly improving, increasingly stringent emission regulations promote the development of advanced technologies in the after-treatment systems of internal combustion engines [210,211]. After-treatment systems still have the shortcoming that they require strict temperature conditions to efficiently convert pollutants [212,213]. At too low or too high a temperature, the after-treatment devices are at a low conversion efficiency level [214,215]. This thermal heat can be converted into electrical energy, as shown in the latest research [216,217]. The investigation of diesel after-treatment thermal management is summarized. After-treatment thermal management can improve the efficiency of after-treatment devices and reduce emissions, but the trade-off problem between thermal efficiency and exhaust gas temperature is still a challenge. The technical advantages and application potential of after-treatment thermal management are valuable to carry out in-depth research. The main conclusions of this study are as follows.

- (1)

- SCR burners can decrease NOx emissions by 93.5%. EHC can decrease CO, HC, and NOx emissions by 80%, 80%, and 66%, respectively. PCMs can control the temperature of SCR, resulting in a 2/3 reduction in NOx emissions.

- (2)

- Thermal insulation decreases the heat loss of the exhaust gas, which can reduce the after-treatment light-off time. DOC light-off time was reduced by 75% under adiabatic conditions. Microwave is an effective method for DPF regeneration. A 400 W microwave can heat the DPF to the soot oxidation temperature of 873 K at a regeneration time of 150 s.

- (3)

- Catalysts can enhance the efficiency of the after-treatment system and reduce the thermal management energy consumption. Pt-Pd application in the catalyst can decrease the CO light-off temperature to 113 °C. The LaKCoO3/γ-Al2O3/cordierite catalyst with a T50 of 314.6 °C for soot oxidation can reduce the regeneration target temperature.

- (4)

- The future research trends focus on integration of engine-based and non-engine-based thermal management methods, control strategies of EHCs, insulation methods with low thermal conductivity, catalysts with excellent degradation resistance, and the implementation of these thermal management methods under transient operating conditions.

Funding

This work is supported by the National Natural Science Foundation of China (Grant No. 51976016), the Young Scientists Fund of the National Natural Science Foundation of China (Grant No. 52106151), and the Natural Science Foundation of Hunan Province, China (Grant No. 2020JJ4616).

Conflicts of Interest

Authors Tao Ling, Xuejun Peng, Zhilai Su were employed by the company China Railway Wuju Group First Engineering Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Nomenclature

| Compounds | |

| Al2O3 | Alumina |

| CO | Carbon monoxide |

| CO2 | Carbon dioxide |

| CeO2 | Cerium dioxide |

| HC | Hydrocarbon |

| H2O | Water |

| MnOx | Manganese oxides |

| N2 | Nitrogen |

| NOx | Nitrogen oxides |

| NO2 | Nitrogen dioxide |

| NO | Nitric oxide |

| N2O | Nitrous oxide |

| NH2CONH2 | Urea |

| NH3 | Ammonia gas |

| O2 | Oxygen |

| PM | Particulate matter |

| SOs | Soluble organics |

| SO42− | Sulfate |

| SiO2 | Silicon dioxide |

| TiO2 | Titanium oxide |

| V2O5 | Vanadium oxide |

| WO3 | Tungsten oxide |

| ZrO2 | Zirconium dioxide |

| Abbreviations | |

| ASC | Ammonia slip catalyst |

| ATDC | After top dead center |

| ATEG | Automotive thermoelectric generator |

| BMEP | Brake mean effective pressure |

| BSFC | Brake-specific fuel consumption |

| BTDC | Before top dead center |

| BTE | Brake thermal efficiency |

| CA | Crank angle |

| CDA | Cylinder deactivation |

| CFD | Computational fluid dynamics |

| CDPF | Catalytic diesel particulate filter |

| DOC | Diesel oxidation catalyst |

| DPF | Diesel particulate filter |

| DTI | Drop to idle |

| EEHRS | Engine exhaust heat recovery system |

| EEVO | Early exhaust valve opening |

| EGR | Exhaust gas recirculation |

| EGT | Exhaust gas temperature |

| EHC | Electrically heated catalyst |

| EH | Electric heating |

| EIVC | Early intake valve closing |

| EM | Exhaust manifold |

| EP | Exhaust port |

| ETC | European transient cycling |

| EVO | Exhaust valve opening |

| FTP | Federal test procedure |

| FTP75 | Environmental Protection Agency Federal Test Procedure |

| IEGR | Internal exhaust gas recirculation |

| IVC | Intake valve closing |

| LEVO | Late exhaust valve opening |

| LHS | Latent heat storage |

| LIVC | Late intake valve closing |

| LLC | Low load cycle |

| NEDC | New European driving cycle |

| NRTC | Non-road transient cycle |

| NVO | Negative valve overlap |

| PCM | Phase-change material |

| RIVCT | Retarded intake valve closing timing technology |

| RDPF | Rotary diesel particulate filter |

| SCR | Selective catalytic reduction |

| SEM | Scanning electron microscopy |

| TEM | Transmission electron microscopy |

| TESS | Thermal energy storage system |

| TI | Internal surface of the turbine volute |

| TWC | Three-way catalyst |

| VGT | Variable geometry turbine |

| VVT | Variable valve timing |

| WHTC | World harmonized transient cycle |

| WLTC | World light vehicle test cycle |

| Symbols | |

| cp | Specific heat of the exhaust gas, kJ/kg/K |

| H | Lower heating value of the diesel fuel, kJ/kg |

| exhaust | Mass flow rate of the exhaust gas, kg/h |

| RTU | Temperature uniformity coefficient |

| ΔTexhaust | Difference between target exhaust temperature and incoming exhaust temperature, K |

| Tj | Temperature of a position in the wall-flow filter, K |

| The wall-flow filter’s average temperature under a certain condition, K |

References

- Jiaqiang, E.; Zuo, W.; Gao, J.; Peng, Q.; Zhang, Z.; Hieu, P.M. Effect analysis on pressure drop of the continuous regeneration-diesel particulate filter based on NO2 assisted regeneration. Appl. Therm. Eng. 2016, 100, 356–366. [Google Scholar]

- Jiaqiang, E.; Zhao, X.; Qiu, L.; Wei, K.; Zhang, Z.; Deng, Y.; Han, D.; Liu, G. Experimental investigation on performance and economy characteristics of a diesel engine with variable nozzle turbocharger and its application in urban bus. Energy Convers. Manag. 2019, 193, 149–161. [Google Scholar]

- Serrano, J.R. Imagining the future of the internal combustion engine for ground transport in the current context. Appl. Sci. 2017, 7, 1001. [Google Scholar] [CrossRef]

- Backhaus, R. We still need diesel engines. MTZ Worldw. 2019, 80, 6–7. [Google Scholar] [CrossRef]

- Reşitoğlu, İ.A.; Altinişik, K.; Keskin, A. The pollutant emissions from diesel-engine vehicles and exhaust after-treatment systems. Clean Technol. Environ. Policy 2015, 17, 15–27. [Google Scholar] [CrossRef]

- Di Natale, F.; Carotenuto, C. Particulate matter in marine diesel engines exhausts: Emissions and control strategies. Transp. Res. Part D Transp. Environ. 2015, 40, 166–191. [Google Scholar] [CrossRef]

- Kim, Y.S.; Han, E.J.; Sohn, S.Y. Demand forecasting for heavy-duty diesel engines considering emission regulations. Sustainability 2017, 9, 166. [Google Scholar] [CrossRef]

- Rubio, F.; Llopis-Albert, C.; Valero, F.; Besa, A.J. Sustainability and optimization in the automotive sector for adaptation to government vehicle pollutant emission regulations. J. Bus. Res. 2020, 112, 561–566. [Google Scholar] [CrossRef]

- Russell, A.; Epling, W.S. Diesel oxidation catalysts. Catal. Rev.-Sci. Eng. 2011, 53, 337–423. [Google Scholar] [CrossRef]

- Zhang, Z.; Cheung, C.; Chan, T.; Yao, C. Emission reduction from diesel engine using fumigation methanol and diesel oxidation catalyst. Sci. Total Environ. 2009, 407, 4497–4505. [Google Scholar] [CrossRef]

- Yang, S.; Deng, C.; Gao, Y.; He, Y. Diesel particulate filter design simulation: A review. Adv. Mech. Eng. 2016, 8, 1–14. [Google Scholar] [CrossRef]

- Li, J.; Ge, Y.; Wang, H.; Yu, C.; Yan, X.; Hao, L.; Tan, J. Effects of different diesel particulate filter on emission characteristics of in-use diesel vehicles. Energy Sources Part A-Recovery Util. Environ. Eff. 2019, 41, 2989–3000. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, H.; Haller, G.; Li, Y. Recent advances in the selective catalytic reduction of NOx with NH3 on Cu-Chabazite catalysts. Appl. Catal. B Environ. 2017, 202, 346–354. [Google Scholar] [CrossRef]

- Zhang, R.; Quan, X.; Yang, F.; Chung, J.S. Selective catalytic reduction of NO with NH3 on wire mesh honeycomb. Chin. J. Catal. 2002, 23, 46–50. [Google Scholar]

- Gao, J.; Tian, G.; Sorniotti, A.; Karci, A.E.; Di Palo, R. Review of thermal management of catalytic converters to decrease engine emissions during cold start and warm up. Appl. Therm. Eng. 2019, 147, 177–187. [Google Scholar] [CrossRef]

- E, J.; Luo, J.; Han, D.; Tan, Y.; Feng, C.; Deng, Y. Effects of different catalysts on light-off temperature of volatile organic components in the rotary diesel particulate filter during the regeneration. Fuel 2022, 310, 122451. [Google Scholar]

- Zare, A.; Nabi, M.N.; Bodisco, T.A.; Hossain, F.M.; Rahman, M.M.; Van, T.C.; Ristovski, Z.D.; Brown, R.J. Diesel engine emissions with oxygenated fuels: A comparative study into cold-start and hot-start operation. J. Clean. Prod. 2017, 162, 997–1008. [Google Scholar] [CrossRef]

- Chaichan, M.T.; Maroon, O.K.; Abaas, K.I. The effect of diesel engine cold start period on the emitted emissions. Int. J. Sci. Eng. Res. 2016, 7, 749–753. [Google Scholar]

- Deng, Y.; Liu, H.; Zhao, X.; Jiaqiang, E.; Chen, J. Effects of cold start control strategy on cold start performance of the diesel engine based on a comprehensive preheat diesel engine model. Appl. Energy 2018, 210, 279–287. [Google Scholar] [CrossRef]

- Robinson, K.; Ye, S.; Yap, Y.; Kolaczkowski, S.T. Application of a methodology to assess the performance of a full-scale diesel oxidation catalyst during cold and hot start NEDC drive cycles. Chem. Eng. Res. Des. 2013, 91, 1292–1306. [Google Scholar] [CrossRef]

- Maus, W.; Brück, R.; Konieczny, R.; Scheeder, A. Electrically heated catalyst for thermal management in modern vehicle applications. MTZ Worldw. 2010, 71, 34–39. [Google Scholar] [CrossRef]

- Mera, Z.; Fonseca, N.; Casanova, J.; López, J.M. Influence of exhaust gas temperature and air-fuel ratio on NOx after-treatment performance of five large passenger cars. Atmos. Environ. 2021, 244, 117878. [Google Scholar] [CrossRef]

- Birkhold, F.; Meingast, U.; Wassermann, P.; Deutschmann, O. Modeling and simulation of the injection of urea-water-solution for automotive SCR DeNOx-systems. Appl. Catal. B Environ. 2007, 70, 119–127. [Google Scholar] [CrossRef]

- Kim, H.J.; Jo, S.; Kwon, S.; Lee, J.T.; Park, S. NOx emission analysis according to after-treatment devices (SCR, LNT + SCR, SDPF), and control strategies in Euro-6 light-duty diesel vehicles. Fuel 2022, 310, 122297. [Google Scholar] [CrossRef]

- Prasad, R.; Singh, S.V. A review on catalytic oxidation of soot emitted from diesel fuelled engines. J. Environ. Chem. Eng. 2020, 8, 103945. [Google Scholar]

- Orihuela, M.P.; Chacartegui, R.; Gómez-Martín, A.; Ramírez-Rico, J.; Villanueva, J.A.B. Performance trends in wall-flow diesel particulate filters: Comparative analysis of their filtration efficiency and pressure drop. J. Clean. Prod. 2020, 260, 120863. [Google Scholar] [CrossRef]

- Han, L.; Cai, S.; Gao, M.; Hasegawa, J.Y.; Wang, P.; Zhang, J.; Shi, L.; Zhang, D. Selective catalytic reduction of NO x with NH3 by using novel catalysts: State of the art and future prospects. Chem. Rev. 2019, 119, 10916–10976. [Google Scholar] [CrossRef]

- Zhong, F.; Zhong, Y.; Xiao, Y.; Cai, G.; Wei, K. Effect of Si-doping on thermal stability and diesel oxidation activity of Pt supported porous γ-Al2O3 monolithic catalyst. Catal. Lett. 2011, 141, 1828–1837. [Google Scholar] [CrossRef]

- Bai, S.; Han, J.; Liu, M.; Qin, S.; Wang, G.; Li, G. Experimental investigation of exhaust thermal management on NOx emissions of heavy-duty diesel engine under the world Harmonized transient cycle (WHTC). Appl. Therm. Eng. 2018, 142, 421–432. [Google Scholar] [CrossRef]

- Honardar, S.; Busch, H.; Schnorbus, T.; Severin, C.; Kolbeck, A.F.; Korfer, T. Exhaust temperature management for diesel engines assessment of engine concepts and calibration strategies with regard to fuel penalty. In Proceedings of the 10th International Conference on Engines & Vehicles, Naples, Italy, 10–14 September 2023. [Google Scholar]

- Brin, J.W.; Keim, J.A.; Christensen, E.T.; Holman, R.S. Applying a driven turbocharger with turbine bypass to improve after-treatment warm-up and diesel nitrous oxides conversion. SAE Int. J. Commer. Veh. 2021, 14, 391–407. [Google Scholar] [CrossRef]

- Salehi, R.; Stefanopoulou, A.G. Optimal exhaust valve opening control for fast after-treatment warm up in diesel engines. In Proceedings of the ASME 2018 Dynamic Systems and Control Conference, Atlanta, GA, USA, 30 September–3 October 2018. [Google Scholar]

- Kovacs, D.; Rauch, H.; Rezaei, R.; Huang, Y.; Harris, T. Modeling heavy-duty engine thermal management technologies to meet future cold start requirements. In Proceedings of the WCX SAE World Congress Experience, Detroit, MI, USA, 9–11 April 2019. [Google Scholar]

- Hamedi, M.; Tsolakis, A.; Herreros, J.M. Thermal Performance of Diesel After-treatment: Material and Insulation CFD Analysis. In Proceedings of the SAE 2014 International Powertrain, Fuels & Lubricants Meeting, Birmingham, UK, 20–22 October 2014. [Google Scholar]

- Burch, S.D.; Potter, T.F.; Keyser, M.A.; Brady, M.J.; Michaels, K.F. Reducing cold-start emissions by catalytic converter thermal management. In SAE Transactions; National Renewable Energy Laboratory: Golden, CO, USA, 1995; pp. 348–353. [Google Scholar]

- Feng, X.; Ge, Y.; Tan, J.; Li, J.; Zhang, Y.; Yu, C. Effects of electrically heated catalyst on the low temperature performance of vanadium-based SCR catalyst on diesel engine. In Proceedings of the SAE 2014 World Congress & Exhibition, Detroit, MI, USA, 8–10 April 2014. [Google Scholar]

- Miao, Y.; Chen, L.-D.; He, Y.; Kuo, T.-W. Study of SCR cold-start by energy method. Chem. Eng. J. 2009, 155, 260–265. [Google Scholar] [CrossRef]

- Ma, T.; Collings, N.; Hands, T. Exhaust gas ignition (EGI)-a new concept for rapid light-off of automotive exhaust catalyst. SAE Trans. 1992, 101, 595–599. [Google Scholar]

- Sharp, C.; Webb, C.C.; Neely, G.; Carter, M.; Yoon, S.; Henry, C. Achieving ultra-low NOx emissions levels with a 2017 heavy-duty on-highway TC diesel engine and an advanced technology emissions system-thermal management strategies. SAE Int. J. Engines 2017, 10, 1697–1712. [Google Scholar] [CrossRef]

- Kurien, C.; Srivastava, A.K.; Lesbats, S. Experimental and computational study on the microwave energy-based regeneration in diesel particulate filter for exhaust emission control. J. Energy Inst. 2020, 93, 2133–2147. [Google Scholar] [CrossRef]

- Yang, W.; Gong, J.; Wang, X.; Bao, Z.; Guo, Y.; Wu, Z. A Review on the Impact of SO2 on the Oxidation of NO, Hydrocarbons, and CO in Diesel Emission Control Catalysis. ACS Catal. 2021, 11, 12446–12468. [Google Scholar] [CrossRef]

- Hoang, S.; Lu, X.; Tang, W.; Wang, S.; Du, S.; Nam, C.-Y.; Ding, Y.; Vinluan, R.D.; Zheng, J.; Gao, P.-X. High performance diesel oxidation catalysts using ultra-low Pt loading on titania nanowire array integrated cordierite honeycombs. Catal. Today 2019, 320, 2–10. [Google Scholar] [CrossRef]

- Nadanakumar, V.; Muthiya, S.J.; Prudhvi, T.; Induja, S.; Sathyamurthy, R.; Dharmaraj, V. Experimental investigation to control HC, CO & NOx emissions from diesel engines using diesel oxidation catalyst. Mater. Today Proc. 2021, 43, 434–440. [Google Scholar]

- Zervas, E. Impact of different configurations of a diesel oxidation catalyst on the CO and HC tail-pipe emissions of a Euro4 passenger car. Appl. Therm. Eng. 2008, 28, 962–966. [Google Scholar] [CrossRef]

- Gimenez-Manogil, J.; Bueno-Lopez, A.; Garcia-Garcia, A. Preparation, characterisation and testing of CuO/Ce0.8Zr0.2O2 catalysts for NO oxidation to NO2 and mild temperature diesel soot combustion. Appl. Catal. B Environ. 2014, 152, 99–107. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, W.; Chen, Z.; Jiang, Q. Mechanism of accelerating soot oxidation by NO2 from diesel engine exhaust. Environ. Pollut. 2020, 264, 114708. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Herreros, J.M.; Tsolakis, A.; York, A.P. Increased NO2 concentration in the diesel engine exhaust for improved Ag/Al2O3 catalyst NH3-SCR activity. Chem. Eng. J. 2015, 270, 582–589. [Google Scholar] [CrossRef]

- Tang, T.; Cao, D.; Zhang, J.; Zhao, Y.-G.; Shuai, S.-J. Experimental study of catalyzed diesel particulate filter with exhaust fuel injection system for heavy-duty diesel engines. In Proceedings of the SAE 2014 World Congress & Exhibition, Detroit, MI, USA, 8–10 April 2014. [Google Scholar]

- Zhang, Z.; Tian, J.; Li, J.; Cao, C.; Wang, S.; Lv, J.; Zheng, W.; Tan, D. The development of diesel oxidation catalysts and the effect of sulfur dioxide on catalysts of metal-based diesel oxidation catalysts: A review. Fuel Process. Technol. 2022, 233, 107317. [Google Scholar] [CrossRef]

- Lao, C.T.; Akroyd, J.; Eaves, N.; Smith, A.; Morgan, N.; Nurkowski, D.; Bhave, A.; Kraft, M. Investigation of the impact of the configuration of exhaust after-treatment system for diesel engines. Appl. Energy 2020, 267, 114844. [Google Scholar] [CrossRef]

- Salomons, S.; Votsmeier, M.; Hayes, R.; Drochner, A.; Vogel, H.; Gieshof, J. CO and H2 oxidation on a platinum monolith diesel oxidation catalyst. Catal. Today 2006, 117, 491–497. [Google Scholar] [CrossRef]

- Stadlbauer, S.; Waschl, H.; Schilling, A.; del Re, L. DOC temperature control for low temperature operating ranges with post and main injection actuation. In Proceedings of the SAE 2013 World Congress & Exhibition, Detroit, MI, USA, 16–18 April 2013. [Google Scholar]

- Guan, B.; Zhan, R.; Lin, H.; Huang, Z. Review of the state-of-the-art of exhaust particulate filter technology in internal combustion engines. J. Environ. Manag. 2015, 154, 225–258. [Google Scholar] [CrossRef]

- Deng, Y.; Zheng, W.; Jiaqiang, E.; Zhang, B.; Zhao, X.; Zuo, Q.; Zhang, Z.; Han, D. Influence of geometric characteristics of a diesel particulate filter on its behavior in equilibrium state. Appl. Therm. Eng. 2017, 123, 61–73. [Google Scholar] [CrossRef]

- Bai, S.-Z.; Tang, J.; Wang, G.-H.; Li, G.-X. Soot loading estimation model and passive regeneration characteristics of DPF system for heavy-duty engine. Appl. Therm. Eng. 2016, 100, 1292–1298. [Google Scholar] [CrossRef]

- Meng, Z.; Chen, Z.; Tan, J.; Wang, W.; Zhang, Z.; Huang, J.; Fang, J. Regeneration performance and particulate emission characteristics during active regeneration process of GPF with ash loading. Chem. Eng. Sci. 2022, 248, 117114. [Google Scholar] [CrossRef]

- Corro, G.; Pal, U.; Ayala, E.; Vidal, E. Diesel soot oxidation over silver-loaded SiO2 catalysts. Catal. Today 2013, 212, 63–69. [Google Scholar] [CrossRef]

- Gehrke, S.; Kovács, D.; Eilts, P.; Rempel, A.; Eckert, P. Investigation of VVA-based exhaust management strategies by means of a HD single cylinder research engine and rapid prototyping systems. SAE Int. J. Commer. Veh. 2013, 6, 47–61. [Google Scholar] [CrossRef]

- Guan, W.; Zhao, H.; Ban, Z.; Lin, T. Exploring alternative combustion control strategies for low-load exhaust gas temperature management of a heavy-duty diesel engine. Int. J. Engine Res. 2019, 20, 381–392. [Google Scholar] [CrossRef]

- Jiaqiang, E.; Liu, M.; Deng, Y.; Zhu, H.; Gong, J. Influence analysis of monolith structure on regeneration temperature in the process of microwave regeneration in the diesel particulate filter. Can. J. Chem. Eng. 2015, 1, 168–174. [Google Scholar]

- Pallavkar, S.; Kim, T.-H.; Rutman, D.; Lin, J.; Ho, T. Active regeneration of diesel particulate filter employing microwave heating. Ind. Eng. Chem. Res. 2009, 48, 69–79. [Google Scholar] [CrossRef]

- Chen, P.; Wangm, J. Control-oriented model for integrated diesel engine and after-treatment systems thermal management. Control Eng. Pract. 2014, 22, 81–93. [Google Scholar] [CrossRef]

- Parks, J.; Huff, S.; Kass, M.; Storey, J. Characterization of in-cylinder techniques for thermal management of diesel after-treatment. In Proceedings of the Powertrain & Fluid Systems Conference and Exhibition, Rosemont, IL, USA, 29 October–1 November 2007. [Google Scholar]

- Lee, D.H.; Kim, H.; Song, Y.H.; Kim, K.T. Plasma burner for active regeneration of diesel particulate filter. Plasma Chem. Plasma Process. 2014, 34, 159–173. [Google Scholar] [CrossRef]

- Fang, X.; Mastbergen, D.; Paterson, C. Diesel particulate filter burner system modeling, control and diagnosis. In Proceedings of the Commercial Vehicle Engineering Congress, Rosemont, IL, USA, 13–14 September 2011. [Google Scholar]

- Li, Z.; Cai, D.; He, L.; Cao, L.; Li, Z.; Meng, Y. NO2-Assisted Regeneration Performance Enhancement of Catalyzed Diesel Particulate Filters. Environ. Eng. Sci. 2019, 36, 922–936. [Google Scholar] [CrossRef]

- Jiaqiang, E.; Xie, L.; Zuo, Q.; Zhang, G. Effect analysis on regeneration speed of continuous regeneration-diesel particulate filter based on NO2-assisted regeneration. Atmos. Pollut. Res. 2016, 7, 9–17. [Google Scholar]

- Wu, G.; Li, Z.; Abubakar, S.; Li, Y.; Li, Y. Numerical study on effects of key factors on performance of CeO2-based catalyzed diesel particulate filter. J. Therm. Sci. 2020, 29, 1398–1409. [Google Scholar] [CrossRef]

- Li, Z.; Li, Y.; Liu, Z.; Wu, G.; Huang, J. Multi-objective optimization of composite regeneration performance of a CeO2-based catalyzed diesel particulate filter. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 1–16. [Google Scholar] [CrossRef]

- Zhao, X.; Jiaqiang, E.; Liao, G.; Zhang, F.; Chen, J.; Deng, Y. Numerical simulation study on soot continuous regeneration combustion model of diesel particulate filter under exhaust gas heavy load. Fuel 2021, 290, 119795. [Google Scholar] [CrossRef]

- Chen, K.; Martirosyan, K.; Luss, D. Transient temperature rise during regeneration of diesel particulate filters. Chem. Eng. J. 2011, 176, 144–150. [Google Scholar] [CrossRef]

- Zhang, B.; Jiaqiang, E.; Gong, J.; Yuan, W.; Zhao, X.; Hu, W. Influence of structural and operating factors on performance degradation of the diesel particulate filter based on composite regeneration. Appl. Therm. Eng. 2017, 121, 838–852. [Google Scholar] [CrossRef]

- Wei, Y.; Liang, P.; Li, Y.; Zhao, Y.; Min, X.; Tao, P.; Hu, J.; Sun, T. Modification of Mn-Fe mixed oxide catalysts for low-temperature NH3-SCR of NO from marine diesel exhausts. J. Environ. Chem. Eng. 2022, 10, 107772. [Google Scholar] [CrossRef]

- Zhang, B.; Jiaqiang, E.; Gong, J.; Yuan, W.; Zuo, W.; Li, Y.; Fu, J. Multidisciplinary design optimization of the diesel particulate filter in the composite regeneration process. Appl. Energy 2016, 181, 14–28. [Google Scholar] [CrossRef]

- Maunula, T. Intensification of catalytic after-treatments systems for mobile applications. In Proceedings of the SAE 2013 World Congress & Exhibition, Detroit, MI, USA, 16–18 April 2013. [Google Scholar]

- Guan, B.; Zhan, R.; Lin, H.; Huang, Z. Review of state of the art technologies of selective catalytic reduction of NOx from diesel engine exhaust. Appl. Therm. Eng. 2014, 66, 395–414. [Google Scholar] [CrossRef]

- Shrestha, S.; Harold, M.P.; Kamasamudram, K.; Kumar, A.; Olsson, L.; Leistner, K. Selective oxidation of ammonia to nitrogen on bi-functional Cu–SSZ-13 and Pt/Al2O3 monolith catalyst. Catal. Today 2016, 267, 130–144. [Google Scholar] [CrossRef]

- Maunula, T.; Tuikka, M.; Wolff, T. The reactions and role of ammonia slip catalysts in modern urea-SCR Systems. Emiss. Control Sci. Technol. 2020, 6, 390–401. [Google Scholar] [CrossRef]

- Pârvulescu, V.I.; Grange, P.; Delmon, B. Catalytic removal of NO. Catal. Today 1998, 46, 233–316. [Google Scholar] [CrossRef]

- Scheuer, A.; Hauptmann, W.; Drochner, A.; Gieshoff, J.; Vogel, H.; Votsmeier, M. Dual layer automotive ammonia oxidation catalysts: Experiments and computer simulation. Appl. Catal. B Environ. 2012, 111, 445–455. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, J. Adaptive sliding-mode observer design for a selective catalytic reduction system of ground-vehicle diesel engines. IEEE/ASME Trans. Mechatron. 2016, 21, 2027–2038. [Google Scholar] [CrossRef]

- Roberts, L.; Magee, M.; Shaver, G.; Garg, A.; McCarthy, J.; Koeberlein, E.; Holloway, E.; Shute, R.; Koeberlein, D.; Nielsen, D. Modeling the impact of early exhaust valve opening on exhaust after-treatment thermal management and efficiency for compression ignition engines. Int. J. Engine Res. 2015, 16, 773–794. [Google Scholar] [CrossRef]

- Basaran, H.U.; Ozsoysal, O.A. Effects of application of variable valve timing on the exhaust gas temperature improvement in a low-loaded diesel engine. Appl. Therm. Eng. 2017, 122, 758–767. [Google Scholar] [CrossRef]

- Bai, S.; Chen, G.; Sun, Q.; Wang, G.; Li, G.-X. Influence of active control strategies on exhaust thermal management for diesel particular filter active regeneration. Appl. Therm. Eng. 2017, 119, 297–303. [Google Scholar] [CrossRef]

- Wu, B.; Jia, Z.; Li, Z.G.; Liu, G.Y.; Zhong, X.L. Different exhaust temperature management technologies for heavy-duty diesel engines with regard to thermal efficiency. Appl. Therm. Eng. 2021, 186, 116495. [Google Scholar] [CrossRef]

- Xu, G.; Jia, M.; Li, Y.; Chang, Y.; Liu, H.; Wang, T. Evaluation of variable compression ratio (VCR) and variable valve timing (VVT) strategies in a heavy-duty diesel engine with reactivity controlled compression ignition (RCCI) combustion under a wide load range. Fuel 2019, 253, 114–128. [Google Scholar] [CrossRef]

- Hong, H.; Parvate-Patil, G.B.; Gordon, B. Review and analysis of variable valve timing strategies—Eight ways to approach. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2004, 218, 1179–1200. [Google Scholar] [CrossRef]

- Zhao, X.; Jiang, J.; Zuo, H.; Mao, Z. Performance analysis of diesel particulate filter thermoelectric conversion mobile energy storage system under engine conditions of low-speed and light-load. Energy 2023, 282, 128411. [Google Scholar] [CrossRef]

- Ho, P.H.; Woo, J.W.; Feizie Ilmasani, R.; Han, J.; Olsson, L. The role of Pd–Pt Interactions in the Oxidation and Sulfur Resistance of Bimetallic Pd–Pt/γ-Al2O3 Diesel Oxidation Catalysts. Ind. Eng. Chem. Res. 2021, 60, 6596–6612. [Google Scholar] [CrossRef]

- Farhan, S.M.; Wang, P. Post-injection strategies for performance improvement and emissions reduction in DI diesel engines—A review. Fuel Process. Technol. 2022, 228, 107145. [Google Scholar] [CrossRef]

- Zhang, J.; Lou, D.; Sun, Y.; Tan, P.; Hu, Z.; Huang, C. Effects of DOC and CDPF catalyst composition on emission characteristics of light-duty diesel engine with DOC + CDPF + SCR system. In Proceedings of the WCX World Congress Experience, Detroit, MI, USA, 10–12 April 2018. [Google Scholar]

- Garg, A.; Magee, M.; Ding, C.; Roberts, L.; Shaver, G.; Koeberlein, E.; Shute, R.; Koeberlein, D.; McCarthy, J.J.; Nielsen, D. Fuel-efficient exhaust thermal management using cylinder throttling via intake valve closing timing modulation. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2016, 230, 470–478. [Google Scholar] [CrossRef]

- Ding, C.; Roberts, L.; Fain, D.J.; Ramesh, A.K.; Shaver, G.M.; McCarthy, J.J.; Ruth, M.; Koeberlein, E.; Holloway, E.A.; Nielsen, D. Fuel efficient exhaust thermal management for compression ignition engines during idle via cylinder deactivation and flexible valve actuation. Int. J. Engine Res. 2016, 17, 619–630. [Google Scholar] [CrossRef]

- Neely, G.D.; Sarlashkar, J.V.; Mehta, D. Diesel cold-start emission control research for 2015–2025 LEV III emissions. SAE Int. J. Engines 2013, 6, 1009–1020. [Google Scholar] [CrossRef]