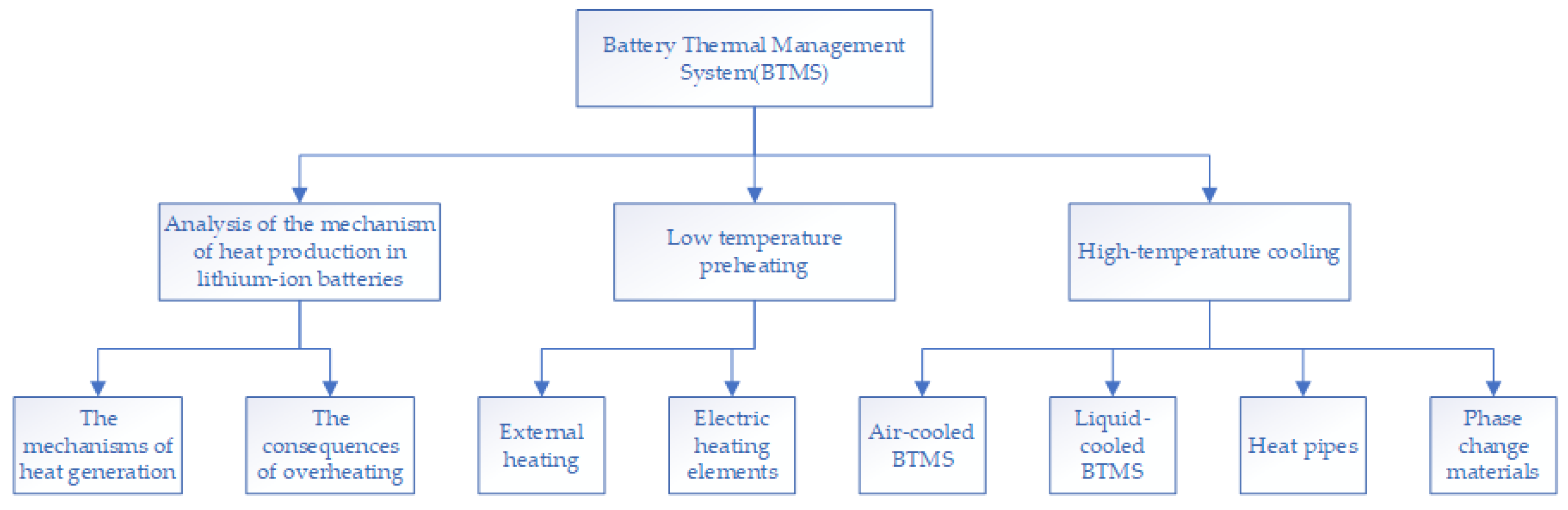

A Review of Thermal Management and Heat Transfer of Lithium-Ion Batteries

Abstract

1. Introduction

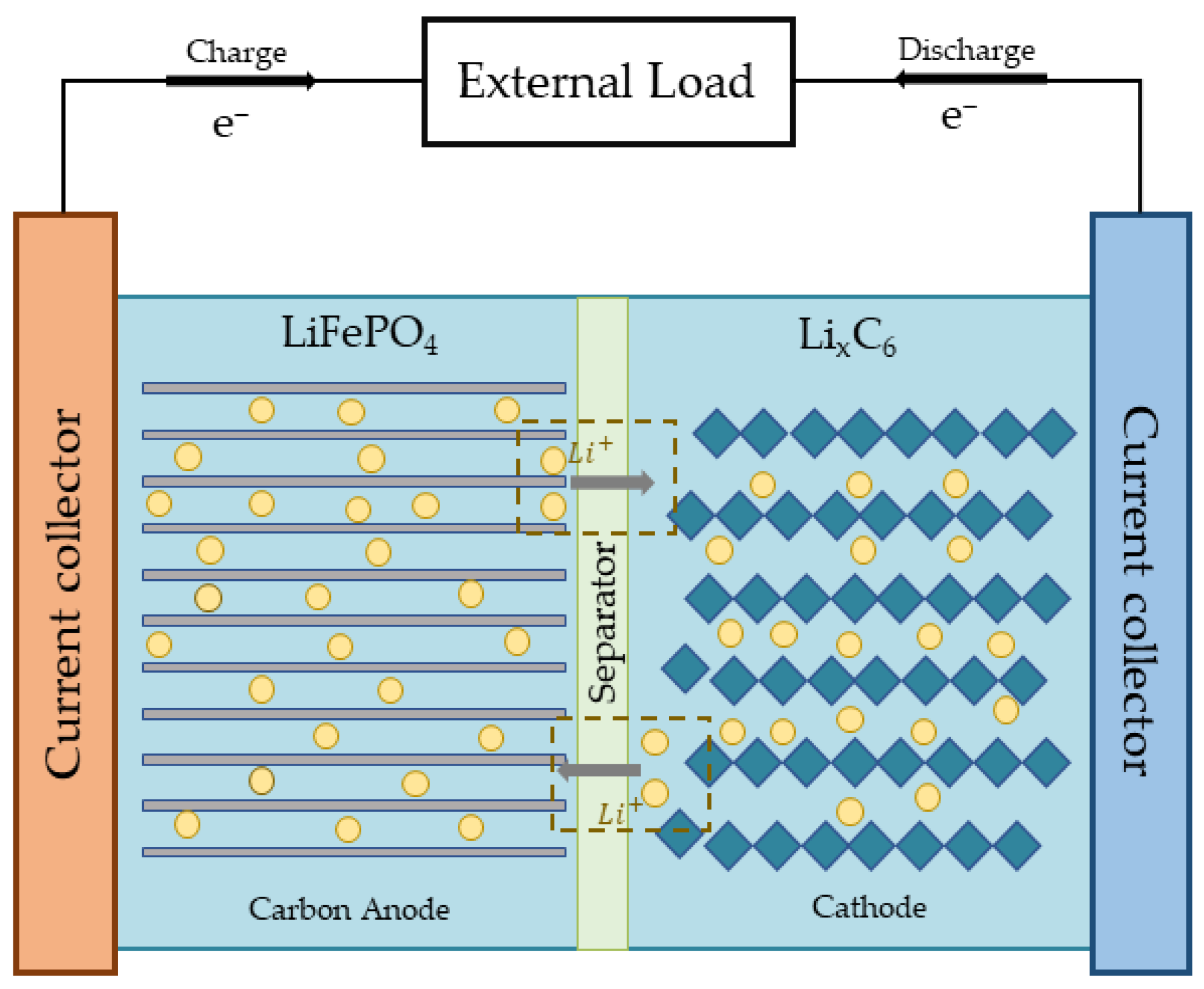

2. Analysis of the Mechanism of Heat Production in Lithium-Ion Batteries

2.1. The Mechanisms of Heat Generation

2.2. The Consequences of Overheating

3. Low-Temperature Preheating

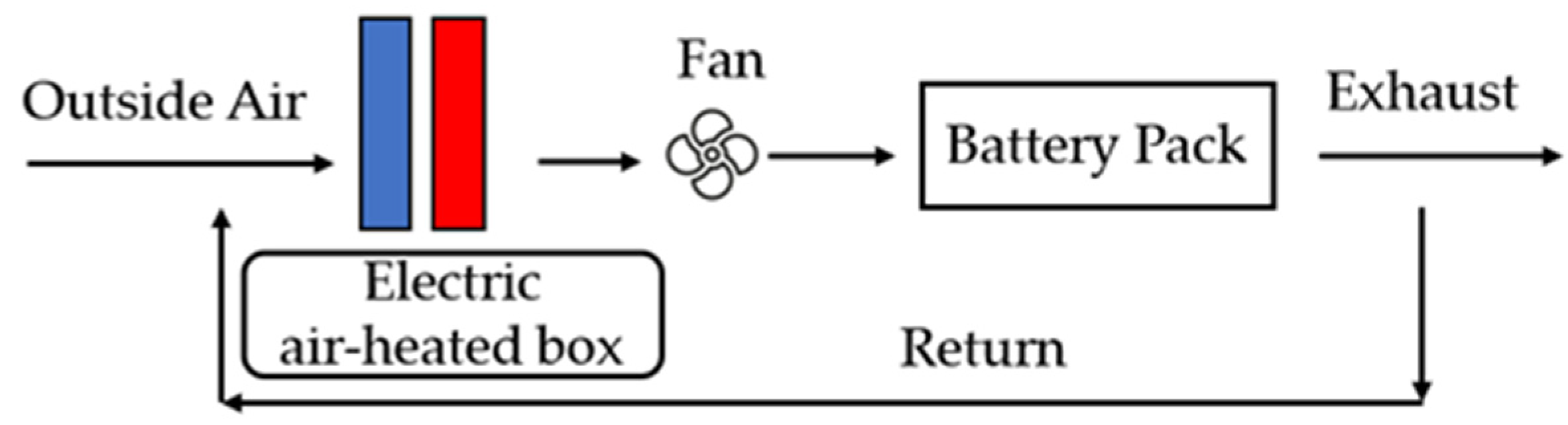

3.1. External Heating

3.1.1. BTMS-Based Technology

3.1.2. Electric Heating Elements

3.2. Internal Heating

3.2.1. Self-Heating Technology

3.2.2. Current Excitation Methods

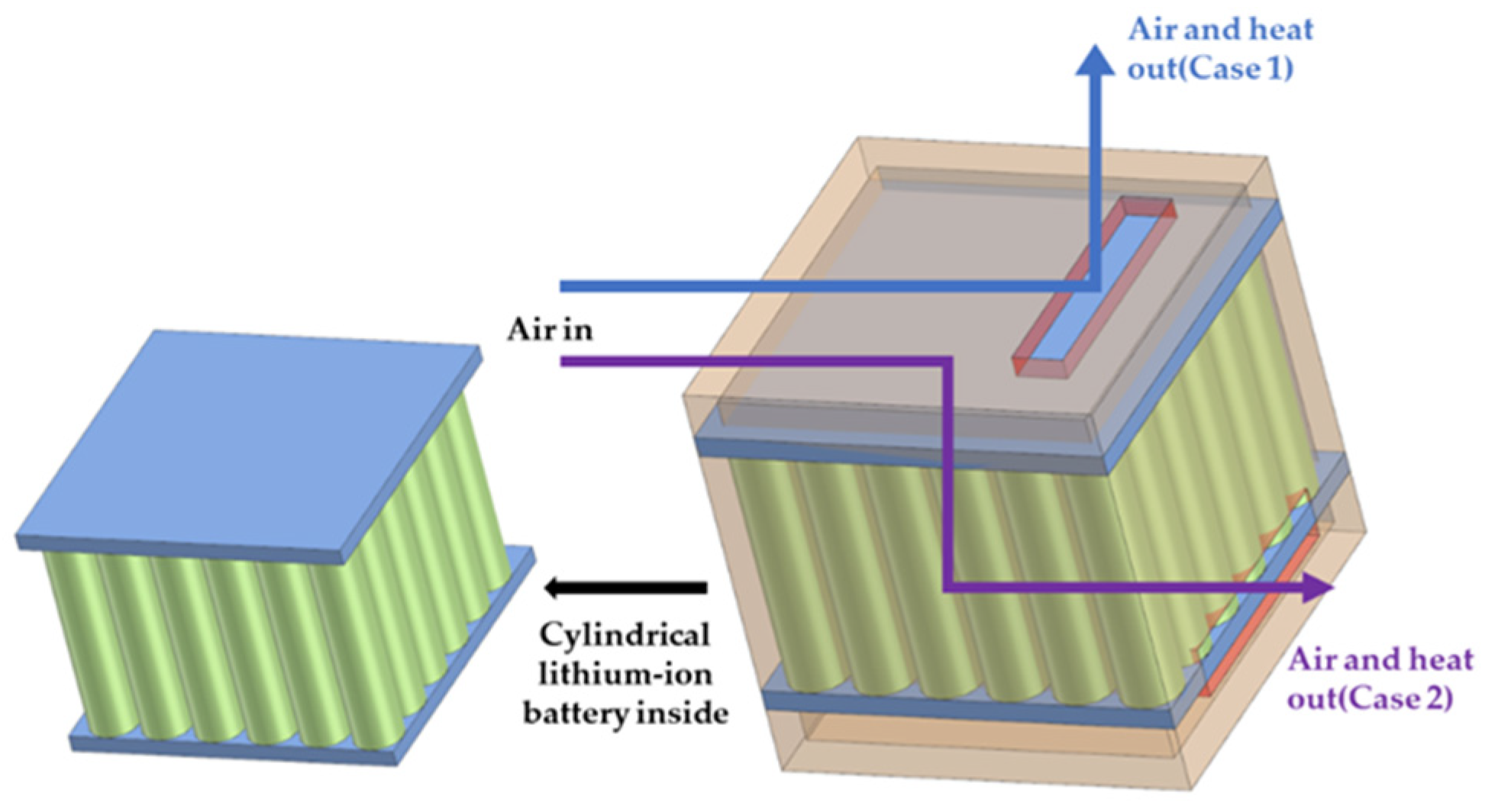

4. Air-Cooled BTMS

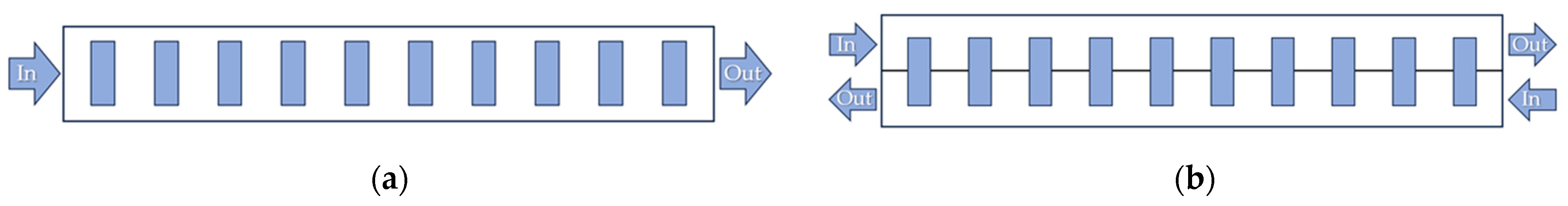

4.1. Battery Array Arrangement

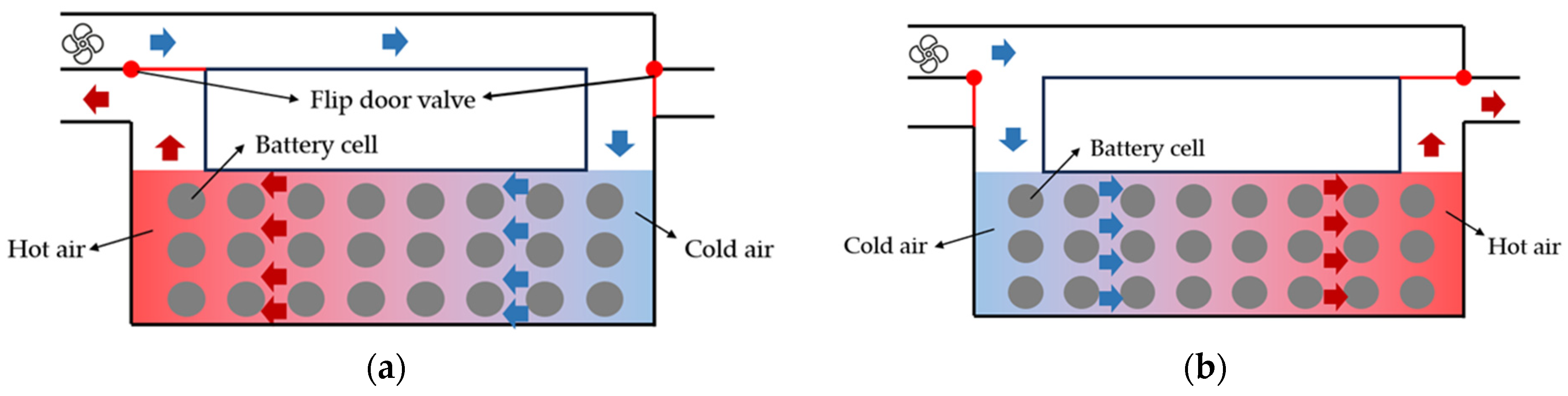

4.2. Airflow Direction Influence

4.3. Influence of the Cooling Channel Structure

4.4. Thermal Conductivity Enhancement Methods

5. Liquid-Cooled BTMS

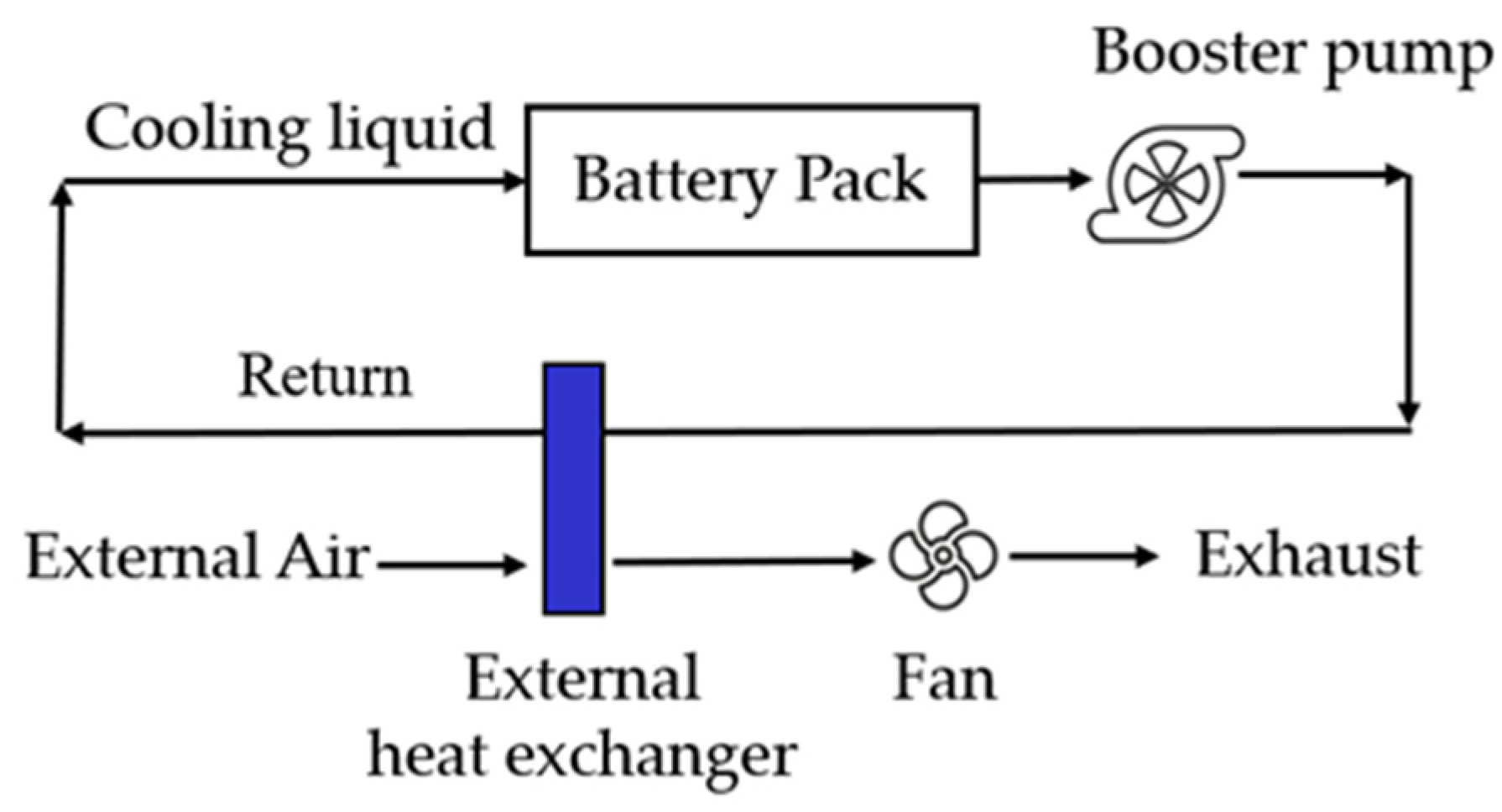

5.1. Direct Cooling

5.2. Indirect Cooling

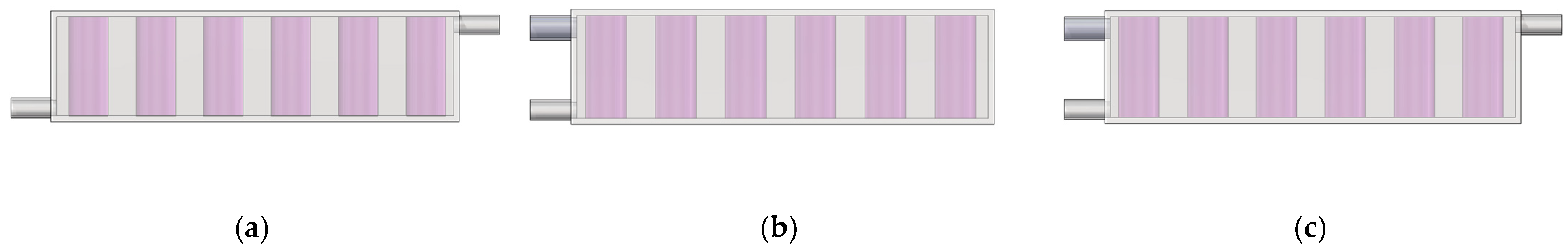

5.2.1. Cold Plate

5.2.2. Thermally Conductive Tubing

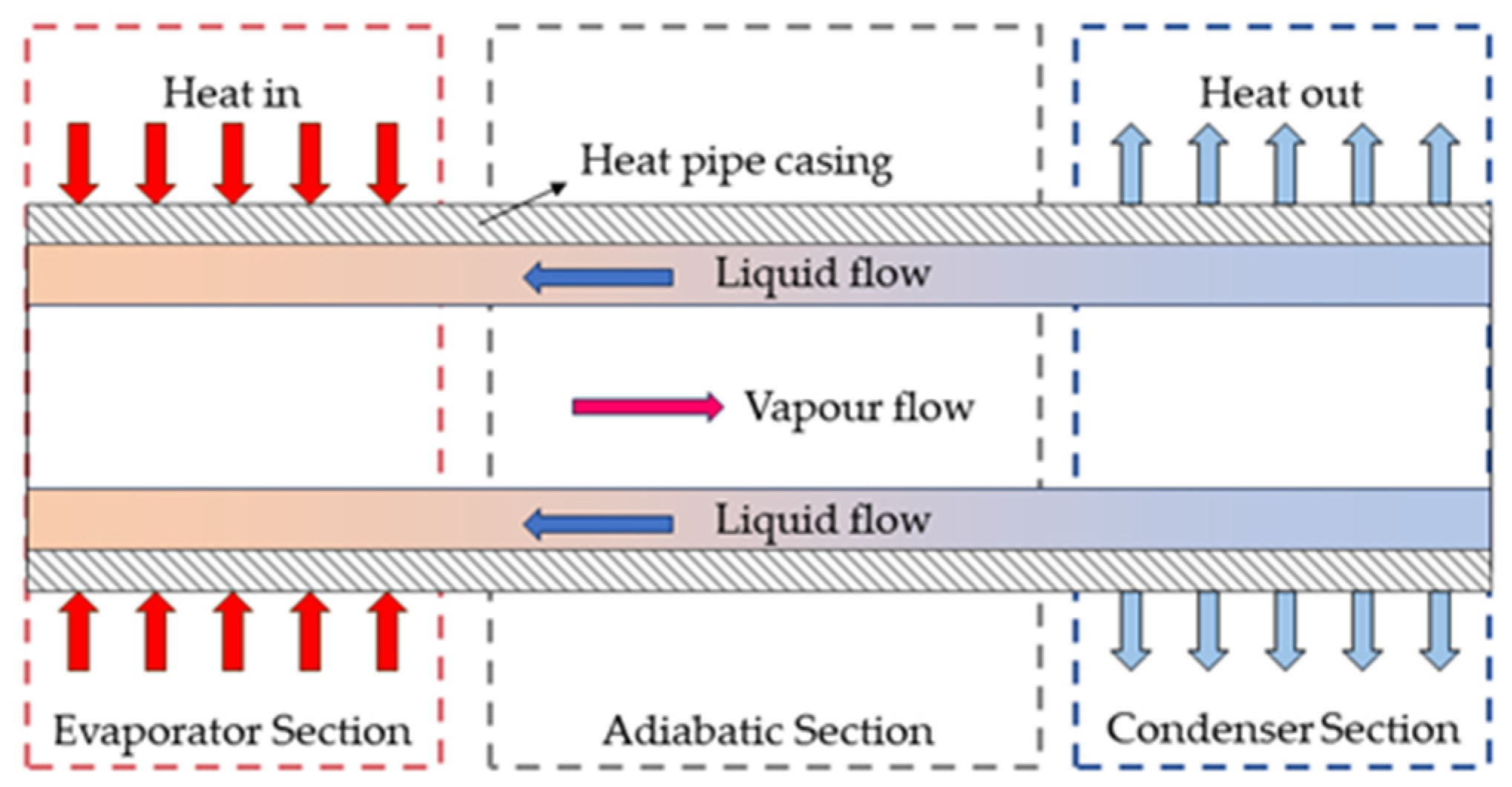

6. Heat Pipes

6.1. Influence of the Working Fluid

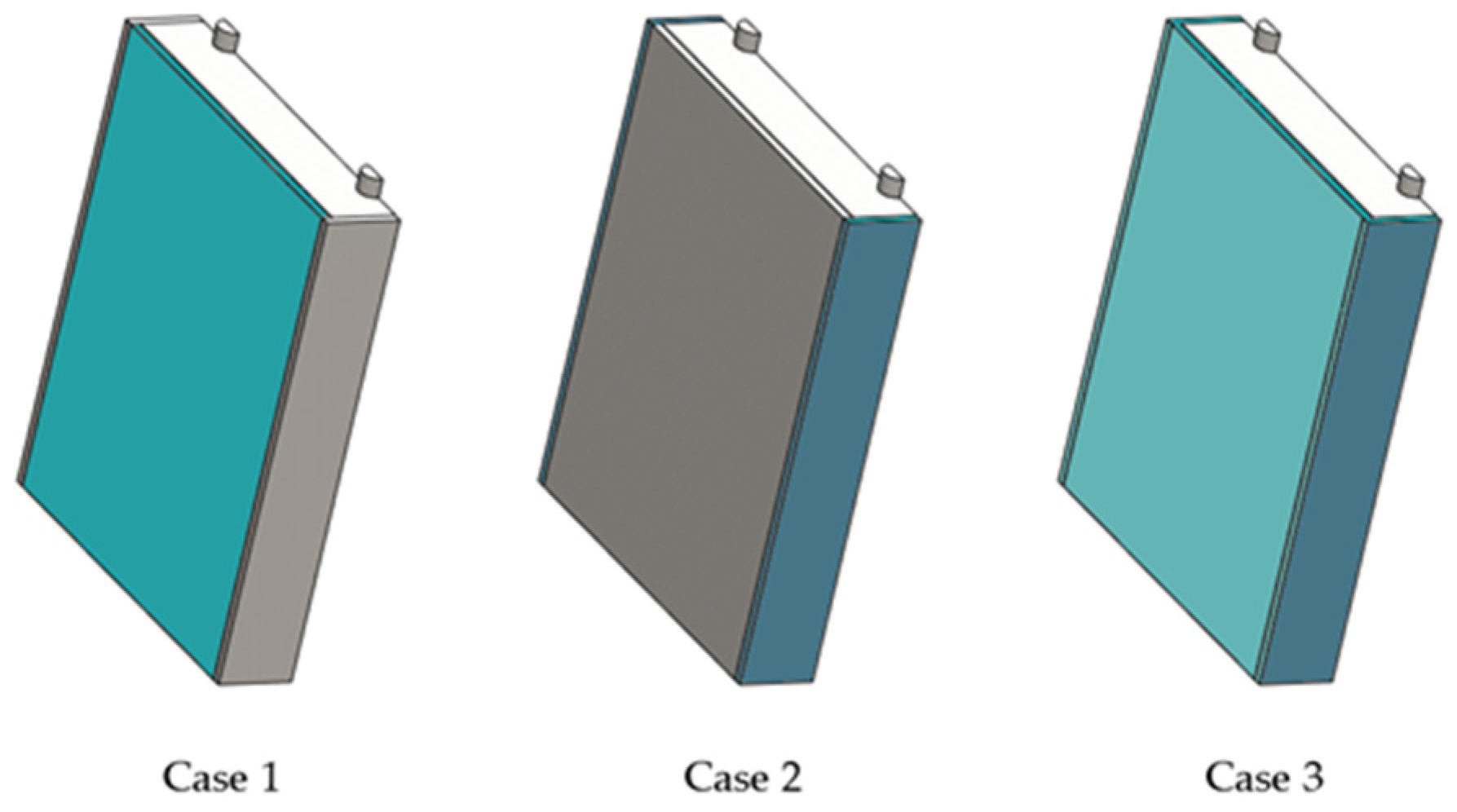

6.2. Influence of the Cooling Method

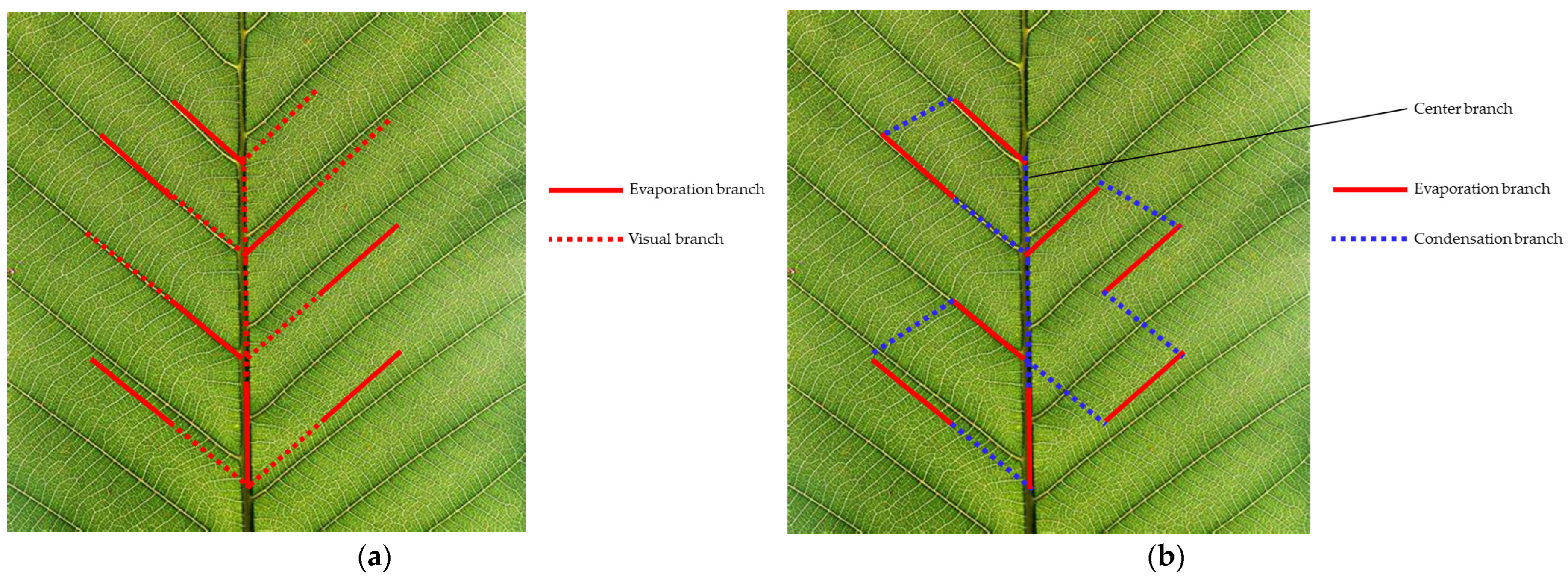

6.3. Structure Optimizations

6.4. Effect of Heat Pipe Configuration

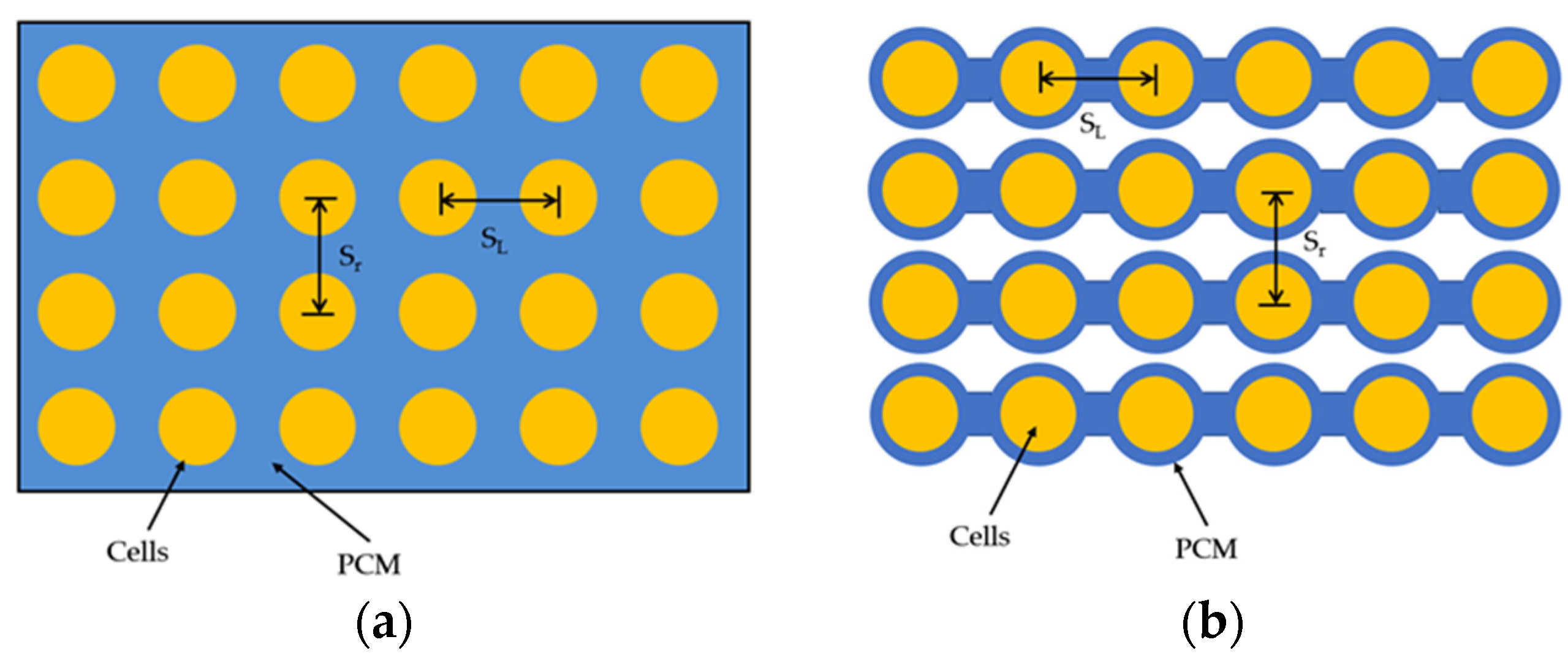

7. Phase Change Materials

7.1. Enhanced Thermal Conductivity

7.1.1. Finning

7.1.2. Incorporation of Thermally Conductive Additives

7.2. Hybrid Cooling Method Based on PCMs

8. Summary and Outlook

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| BTMS | Battery thermal management system |

| SEI | Solid electrolyte interface |

| PCM | Phase change material |

| CPCM | Composite phase change material |

| HGR | Heat generation rate |

| BPNN | Back-propagation neural network |

| HTF | Heat transfer fluid |

| ECM | Equivalent circuit model |

| SHLB | Self-heating lithium-ion battery |

| RLAF | Reverse Layered Air Flow |

| DEC | Direct evaporative cooling |

| SMCHS | Spiral microchannel heat sink |

| VLTs | Vertical layout tubes |

| PTFE | Polytetrafluoroethylene |

| OHPs | Oscillating heat pipes |

| PHP | Pulsating heat pipe |

| CNT | Carbon nanotube |

| EG | Expanded graphite |

References

- Chen, J.; Manivanan, M.; Duque, J.; Kollmeyer, P.; Panchal, S.; Gross, O.; Emadi, A. A Convolutional Neural Network for Estimation of Lithium-Ion Battery State-of-Health during Constant Current Operation. In Proceedings of the 2023 IEEE Transportation Electrification Conference & Expo (ITEC), Detroit, MI, USA, 21–23 June 2023; pp. 1–6. [Google Scholar]

- Lin, S.; Zhou, L. Thermal performance of rectangular serpentine mini-channel cooling system on lithium battery. J. Clean. Prod. 2023, 418, 138125. [Google Scholar] [CrossRef]

- Yu, X.; Chen, R.; Gan, L.; Li, H.; Chen, L. Battery Safety: From Lithium-Ion to Solid-State Batteries. Engineering 2023, 21, 9–14. [Google Scholar] [CrossRef]

- Mu, D.; Ren, H.; Wang, C.; Yue, X.; Du, J.; Ghadimi, P. Structural characteristics and disruption ripple effect in a meso-level electric vehicle Lithium-ion battery supply chain network. Resour. Policy 2023, 80, 103225. [Google Scholar] [CrossRef]

- Chen, M.; Song, W.; Lin, S.; Bai, F.; Feng, Z. Risk evaluation of internal short circuit for lithium-ion battery based on an active protection method. Int. J. Energy Res. 2022, 46, 11879–11891. [Google Scholar] [CrossRef]

- Feng, J.; Cai, F.; Li, H.; Huang, K.; Yin, H. A data-driven prediction model for the remaining useful life prediction of lithium-ion batteries. Process Saf. Environ. Prot. 2023, 180, 601–615. [Google Scholar] [CrossRef]

- Liu, X.; Wu, P.-Y.; Su, C.-Q.; Xiong, X.; Wang, Y.-P. Li-ion battery thermal management and thermal runaway suppression method of combining phase change material and annular thermoelectric cooler. J. Energy Storage 2024, 82, 110564. [Google Scholar] [CrossRef]

- Khan, M.M.; Alkhedher, M.; Ramadan, M.; Ghazal, M. Hybrid PCM-based thermal management for lithium-ion batteries: Trends and challenges. J. Energy Storage 2023, 73, 108775. [Google Scholar] [CrossRef]

- Pu, J.; Huang, Z.; Wu, C.; Liu, S.; Liu, S.; Liu, X.; You, L.; Wang, Q.; Zheng, Y.; Zeng, R.; et al. Boosting the performance enhancement of short-process regenerated Ni-rich cathode via antimony doping and modification. Energy Storage Mater. 2024, 67, 103304. [Google Scholar] [CrossRef]

- Liu, X.; Wang, R.H.; Liu, S.Q.; Pu, J.H.; Xie, H.G.; Wu, M.L.; Liu, D.M.; Li, Y.; Liu, J.W. Organic Eutectic Salts-Assisted Direct Lithium Regeneration for Extremely Low State of Health Ni-Rich Cathodes. Adv. Energy Mater. 2023, 13, 2302987. [Google Scholar] [CrossRef]

- Garud, K.S.; Tai, L.D.; Hwang, S.-G.; Nguyen, N.-H.; Lee, M.-Y. A Review of Advanced Cooling Strategies for Battery Thermal Management Systems in Electric Vehicles. Symmetry 2023, 15, 1322. [Google Scholar] [CrossRef]

- Zhao, Y.; Zou, B.; Zhang, T.; Jiang, Z.; Ding, J.; Ding, Y. A comprehensive review of composite phase change material based thermal management system for lithium-ion batteries. Renew. Sustain. Energy Rev. 2022, 167, 112667. [Google Scholar] [CrossRef]

- Hwang, F.S.; Confrey, T.; Reidy, C.; Picovici, D.; Callaghan, D.; Culliton, D.; Nolan, C. Review of battery thermal management systems in electric vehicles. Renew. Sustain. Energy Rev. 2024, 192, 114171. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, X.; Chen, Z. Low temperature preheating techniques for Lithium-ion batteries: Recent advances and future challenges. Appl. Energy 2022, 313, 118832. [Google Scholar] [CrossRef]

- Liu, J.; Zhou, L.; Zhang, Y.; He, T.; Wang, Z. Thermal stability of lithium-ion battery subjected to inhomogeneous aging. Process Saf. Environ. Prot. 2023, 180, 992–1002. [Google Scholar] [CrossRef]

- Gong, J.; Liu, B.; Lian, H.; Liu, J.; Fu, H.; Miao, Y.; Liu, J. Numerical investigation of suppressing thermal runaway propagation in a lithium-ion battery pack using thermal insulators. Process Saf. Environ. Prot. 2023, 176, 1063–1075. [Google Scholar] [CrossRef]

- Yang, R.; Xie, Y.; Li, K.; Tran, M.K.; Fowler, M.; Panchal, S.; Deng, Z.; Zhang, Y. Comparative Study on the Thermal Characteristics of Solid-State Lithium-Ion Batteries. IEEE Trans. Transp. Electrif. 2024, 10, 1541–1557. [Google Scholar] [CrossRef]

- Vashisht, S.; Rakshit, D.; Panchal, S.; Fowler, M.; Fraser, R. Thermal behaviour of Li-ion battery: An improved electrothermal model considering the effects of depth of discharge and temperature. J. Energy Storage 2023, 70, 107797. [Google Scholar] [CrossRef]

- Ushak, S.; Song, W.; Marin, P.E.; Milian, Y.; Zhao, D.; Grageda, M.; Lin, W.; Chen, M.; Han, Y. A review on phase change materials employed in Li-ion batteries for thermal management systems. Appl. Mater. Today 2024, 37, 102021. [Google Scholar] [CrossRef]

- Chanthevee, P.; Hirai, S.; Lailuck, V.; Laoonual, Y.; Sriam, P.; Rompho, S.; Chanurai, N.; Masomtob, M. A Simplified Approach for Heat Generation Due to Entropy Change in Cylindrical LCO Battery. In Proceedings of the 2018 IEEE Transportation Electrification Conference and Expo, Asia-Pacific (ITEC Asia-Pacific), Bangkok, Thailand, 6–9 June 2018; pp. 1–5. [Google Scholar]

- Wu, C.; Wu, L.; Qiu, C.; Yang, J.; Yuan, X.; Cai, Y.; Shi, H. Experimental and numerical studies on lithium-ion battery heat generation behaviors. Energy Rep. 2023, 9, 5064–5074. [Google Scholar] [CrossRef]

- Rao, Z.; Wang, S.; Wu, M.; Lin, Z.; Li, F. Experimental investigation on thermal management of electric vehicle battery with heat pipe. Energy Convers. Manag. 2013, 65, 92–97. [Google Scholar] [CrossRef]

- Zhang, G.; Wei, X.; Chen, S.; Wei, G.; Zhu, J.; Wang, X.; Han, G.; Dai, H. Research on the impact of high-temperature aging on the thermal safety of lithium-ion batteries. J. Energy Chem. 2023, 87, 378–389. [Google Scholar] [CrossRef]

- Choudhari, V.G.; Dhoble, D.A.S.; Sathe, T.M. A review on effect of heat generation and various thermal management systems for lithium ion battery used for electric vehicle. J. Energy Storage 2020, 32, 101729. [Google Scholar] [CrossRef]

- Burow, D.; Sergeeva, K.; Calles, S.; Schorb, K.; Börger, A.; Roth, C.; Heitjans, P. Inhomogeneous degradation of graphite anodes in automotive lithium ion batteries under low-temperature pulse cycling conditions. J. Power Sources 2016, 307, 806–814. [Google Scholar] [CrossRef]

- Wang, T.; Li, Y.; Zeng, Y.; Zhang, G.; Zhao, G.; Li, X.; Rao, Z. Investigation on the battery thermal management and thermal safety of battery-powered ship with flame-retardant composite phase change materials. J. Energy Storage 2024, 81, 110228. [Google Scholar] [CrossRef]

- Ji, C.; Liu, D.; Liu, Y.; Wang, S.; Wang, Y.; Zhang, Z.; Wang, B. Effect of low temperature and high-rate cyclic aging on thermal characteristics and safety of lithium-ion batteries. Process Saf. Environ. Prot. 2024, 188, 1514–1526. [Google Scholar] [CrossRef]

- Nagasubramanian, G. Electrical characteristics of 18650 Li-ion cells at low temperatures. J. Appl. Electrochem. 2001, 31, 99–104. [Google Scholar] [CrossRef]

- Ouyang, M.; Chu, Z.; Lu, L.; Li, J.; Han, X.; Feng, X.; Liu, G. Low temperature aging mechanism identification and lithium deposition in a large format lithium iron phosphate battery for different charge profiles. J. Power Sources 2015, 286, 309–320. [Google Scholar] [CrossRef]

- Piao, N.; Gao, X.; Yang, H.; Guo, Z.; Hu, G.; Cheng, H.-M.; Li, F. Challenges and development of lithium-ion batteries for low temperature environments. eTransportation 2022, 11, 100145. [Google Scholar] [CrossRef]

- Qin, P.; Sun, J.; Yang, X.; Wang, Q. Battery thermal management system based on the forced-air convection: A review. etransportation 2021, 7, 100097. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, X.; Meng, H.; Guo, L.; Zhang, Z. Numerical analysis of the thermal performance of a liquid cooling battery module based on the gradient ratio flow velocity and gradient increment tube diameter. Int. J. Heat Mass Transf. 2021, 175, 121338. [Google Scholar] [CrossRef]

- Fan, R.J.; Zhang, C.Z.; Wang, Y.; Ji, C.Z.; Meng, Z.Q.; Xu, L.; Ou, Y.; Chin, C.S. Numerical study on the effects of battery heating in cold climate. J. Energy Storage 2019, 26, 100969. [Google Scholar] [CrossRef]

- Wang, Y.; Rao, Z.; Liu, S.; Li, X.; Li, H.; Xiong, R. Evaluating the performance of liquid immersing preheating system for Lithium-ion battery pack. Appl. Therm. Eng. 2021, 190, 116811. [Google Scholar] [CrossRef]

- E, J.; Qin, Y.; Zhang, B.; Yin, H.; Tan, Y. Effects of heating film and phase change material on preheating performance of the lithium-ion battery pack with large capacity under low temperature environment. Energy 2023, 284, 129280. [Google Scholar] [CrossRef]

- Chen, M.; Li, J. Experimental study on heating performance of pure electric vehicle power battery under low temperature environment. Int. J. Heat Mass Transf. 2021, 172, 121191. [Google Scholar] [CrossRef]

- Liang, L.; Zhao, Y.; Diao, Y.; Ren, R.; Zhu, T.; Li, Y. Experimental investigation of preheating performance of lithium-ion battery modules in electric vehicles enhanced by bending flat micro heat pipe array. Appl. Energy 2023, 337, 120896. [Google Scholar] [CrossRef]

- Moria, H.; Pourhedayat, S.; Dizaji, H.S.; Abusorrah, A.M.; Abu-Hamdeh, N.H.; Wae-hayee, M. Exergoeconomic analysis of a Peltier effect air cooler using experimental data. Appl. Therm. Eng. 2021, 186, 116513. [Google Scholar] [CrossRef]

- Zhang, C.; Jin, X.; Li, J. PTC Self-Heating Experiments and Thermal Modeling of Lithium-Ion Battery Pack in Electric Vehicles. Energies 2017, 10, 572. [Google Scholar] [CrossRef]

- Lei, Z.; Zhang, C.; Li, J.; Fan, G.; Lin, Z. Preheating method of lithium-ion batteries in an electric vehicle. J. Mod. Power Syst. Clean Energy 2015, 3, 289–296. [Google Scholar] [CrossRef]

- Yang, W.; Zhou, F.; Liu, Y.; Chen, X. Preheating Performance by Heating Film for the Safe Application of Cylindrical Lithium-ion Battery at Low Temperature. Fire Technol. 2023, 59, 1115–1135. [Google Scholar] [CrossRef]

- Wang, C.-Y.; Zhang, G.; Ge, S.; Xu, T.; Ji, Y.; Yang, X.-G.; Leng, Y. Lithium-ion battery structure that self-heats at low temperatures. Nature 2016, 529, 515–518. [Google Scholar] [CrossRef]

- Lin, C.; Tao, Z.; Tian, Y. Variable duty cycle heating strategy based online two-dimensional model for self-heating lithium-ion battery. J. Energy Storage 2022, 55, 105572. [Google Scholar] [CrossRef]

- Ji, Y.; Wang, C.Y. Heating strategies for Li-ion batteries operated from subzero temperatures. Electrochim. Acta 2013, 107, 664–674. [Google Scholar] [CrossRef]

- Ruan, H.; Jiang, J.; Sun, B.; Su, X.; He, X.; Zhao, K. An optimal internal-heating strategy for lithium-ion batteries at low temperature considering both heating time and lifetime reduction. Appl. Energy 2019, 256, 113797. [Google Scholar] [CrossRef]

- Stuart, T.A.; Hande, A. HEV battery heating using AC currents. J. Power Sources 2004, 129, 368–378. [Google Scholar] [CrossRef]

- Zhu, J.; Sun, Z.; Wei, X.; Dai, H.; Gu, W. Experimental investigations of an AC pulse heating method for vehicular high power lithium-ion batteries at subzero temperatures. J. Power Sources 2017, 367, 145–157. [Google Scholar] [CrossRef]

- Li, J.; Sun, D.; Chai, Z.; Jiang, H.; Sun, C. Sinusoidal alternating current heating strategy and optimization of lithium-ion batteries with a thermo-electric coupled model. Energy 2019, 186, 115798. [Google Scholar] [CrossRef]

- Zhang, L.; Fan, W.; Wang, Z.; Li, W.; Sauer, D.U. Battery heating for lithium-ion batteries based on multi-stage alternative currents. J. Energy Storage 2020, 32, 101885. [Google Scholar] [CrossRef]

- Li, Y.; Gao, X.; Qin, Y.; Du, J.; Guo, D.; Feng, X.; Lu, L.; Han, X.; Ouyang, M. Drive circuitry of an electric vehicle enabling rapid heating of the battery pack at low temperatures. iScience 2021, 24, 101921. [Google Scholar] [CrossRef]

- Zhao, G.; Wang, X.; Negnevitsky, M.; Zhang, H. A review of air-cooling battery thermal management systems for electric and hybrid electric vehicles. J. Power Sources 2021, 501, 230001. [Google Scholar] [CrossRef]

- Chen, K.; Wang, S.; Song, M.; Chen, L. Configuration optimization of battery pack in parallel air-cooled battery thermal management system using an optimization strategy. Appl. Therm. Eng. 2017, 123, 177–186. [Google Scholar] [CrossRef]

- Fan, Y.; Bao, Y.; Ling, C.; Chu, Y.; Tan, X.; Yang, S. Experimental study on the thermal management performance of air cooling for high energy density cylindrical lithium-ion batteries. Appl. Therm. Eng. 2019, 155, 96–109. [Google Scholar] [CrossRef]

- Du, J.; Tao, H.; Chen, Y.; Yuan, X.; Lian, C.; Liu, H. Thermal Management of Air-Cooling Lithium-Ion Battery Pack. Chin. Phys. Lett. 2021, 38, 118201. [Google Scholar] [CrossRef]

- Hai, T.; Abidi, A.; Sajadi, S.M.; Zain, J.M.; Malekshah, E.H.; Aybar, H.Ş. Simultaneous cooling of plate and cylindrical batteries in an air-cooled lithium battery thermal management system, by changing the distances of the batteries from each other and the pack wall. J. Taiwan Inst. Chem. Eng. 2023, 148, 104931. [Google Scholar] [CrossRef]

- Kirad, K.; Chaudhari, M. Design of cell spacing in lithium-ion battery module for improvement in cooling performance of the battery thermal management system. J. Power Sources 2021, 481, 229016. [Google Scholar] [CrossRef]

- Liao, X.; Ma, C.; Peng, X.; Garg, A.; Bao, N. Temperature Distribution Optimization of an Air-Cooling Lithium-Ion Battery Pack in Electric Vehicles Based on the Response Surface Method. J. Electrochem. Energy Convers. Storage 2019, 16, 041002. [Google Scholar] [CrossRef]

- Peng, X.; Ma, C.; Garg, A.; Bao, N.; Liao, X. Thermal performance investigation of an air-cooled lithium-ion battery pack considering the inconsistency of battery cells. Appl. Therm. Eng. 2019, 153, 596–603. [Google Scholar] [CrossRef]

- Wang, Y.-W.; Jiang, J.-M.; Chung, Y.-H.; Chen, W.-C.; Shu, C.-M. Forced-air cooling system for large-scale lithium-ion battery modules during charge and discharge processes. J. Therm. Anal. Calorim. 2019, 135, 2891–2901. [Google Scholar] [CrossRef]

- Pan, S.; Ji, C.; Wang, S.; Wang, B. Study on the Performance of Parallel Air-Cooled Structure and Optimized Design for Lithium-Ion Battery Module. Fire Technol. 2020, 56, 2623–2647. [Google Scholar] [CrossRef]

- Mahamud, R.; Park, C. Reciprocating air flow for Li-ion battery thermal management to improve temperature uniformity. J. Power Sources 2011, 196, 5685–5696. [Google Scholar] [CrossRef]

- Yu, K.; Yang, X.; Cheng, Y.; Li, C. Thermal analysis and two-directional air flow thermal management for lithium-ion battery pack. J. Power Sources 2014, 270, 193–200. [Google Scholar] [CrossRef]

- Wang, C.; Xu, J.; Wang, M.; Xi, H. Experimental investigation on reciprocating air-cooling strategy of battery thermal management system. J. Energy Storage 2023, 58, 106406. [Google Scholar] [CrossRef]

- Wang, H.; Ma, L. Thermal management of a large prismatic battery pack based on reciprocating flow and active control. Int. J. Heat Mass Transf. 2017, 115, 296–303. [Google Scholar] [CrossRef]

- Na, X.; Kang, H.; Wang, T.; Wang, Y. Reverse layered air flow for Li-ion battery thermal management. Appl. Therm. Eng. 2018, 143, 257–262. [Google Scholar] [CrossRef]

- Wang, S.; Li, K.; Tian, Y.; Wang, J.; Wu, Y.; Ji, S. Improved thermal performance of a large laminated lithium-ion power battery by reciprocating air flow. Appl. Therm. Eng. 2019, 152, 445–454. [Google Scholar] [CrossRef]

- Zhao, R.; Liu, J.; Gu, J.; Zhai, L.; Ma, F. Experimental study of a direct evaporative cooling approach for Li-ion battery thermal management. Int. J. Energy Res. 2020, 44, 6660–6673. [Google Scholar] [CrossRef]

- Xi, Y.; Feng, Y.; Xiao, Y.; He, G. Novel Z-Shaped Structure of Lithium-Ion Battery Packs and Optimization for Thermal Management. J. Energy Eng. 2020, 146, 04019035. [Google Scholar] [CrossRef]

- Wang, N.; Li, C.; Li, W.; Huang, M.; Qi, D. Effect analysis on performance enhancement of a novel air cooling battery thermal management system with spoilers. Appl. Therm. Eng. 2021, 192, 116932. [Google Scholar] [CrossRef]

- Zhang, F.; Liu, P.; He, Y.; Li, S. Cooling performance optimization of air cooling lithium-ion battery thermal management system based on multiple secondary outlets and baffle. J. Energy Storage 2022, 52, 104678. [Google Scholar] [CrossRef]

- Chen, K.; Song, M.; Wei, W.; Wang, S. Structure optimization of parallel air-cooled battery thermal management system with U-type flow for cooling efficiency improvement. Energy 2018, 145, 603–613. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, J. Design a J-type air-based battery thermal management system through surrogate-based optimization. Appl. Energy 2019, 252, 113426. [Google Scholar] [CrossRef]

- Luo, L.; Liu, Y.; Liao, Z.; Zhong, J. Optimal structure design and heat transfer characteristic analysis of X-type air-cooled battery thermal management system. J. Energy Storage 2023, 67, 107681. [Google Scholar] [CrossRef]

- Mohammadian, S.K.; Rassoulinejad-Mousavi, S.M.; Zhang, Y. Thermal management improvement of an air-cooled high-power lithium-ion battery by embedding metal foam. J. Power Sources 2015, 296, 305–313. [Google Scholar] [CrossRef]

- Saw, L.H.; Ye, Y.; Yew, M.C.; Chong, W.T.; Yew, M.K.; Ng, T.C. Computational fluid dynamics simulation on open cell aluminium foams for Li-ion battery cooling system. Appl. Energy 2017, 204, 1489–1499. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, Y.; Jing, Z.; Wang, C.; Zhou, G.; Zhao, W. Thermal performance of lithium-ion batteries applying forced air cooling with an improved aluminium foam heat sink design. Int. J. Heat Mass Transf. 2021, 167, 120827. [Google Scholar] [CrossRef]

- Mohammadian, S.K.; Zhang, Y. Thermal management optimization of an air-cooled Li-ion battery module using pin-fin heat sinks for hybrid electric vehicles. J. Power Sources 2015, 273, 431–439. [Google Scholar] [CrossRef]

- Chen, K.-H.; Han, T.; Khalighi, B.; Klaus, P. Air Cooling Concepts for Li-Ion Battery Pack in Cell Level. In Proceedings of the ASME 2017 Heat Transfer Summer Conference, Bellevue, WA, USA, 9–12 July 2017. [Google Scholar]

- Cheng, L.; Garg, A.; Jishnu, A.K.; Gao, L. Surrogate based multi-objective design optimization of lithium-ion battery air-cooled system in electric vehicles. J. Energy Storage 2020, 31, 101645. [Google Scholar] [CrossRef]

- Li, C.; Li, Y.; Gao, L.; Garg, A.; Li, W. Surrogate model-based heat dissipation optimization of air-cooling battery packs involving herringbone fins. Int. J. Energy Res. 2021, 45, 8508–8523. [Google Scholar] [CrossRef]

- Shi, Z.; Chen, G.; Zhu, L.; Li, J.; Xia, Y. Sandwich Structure Design of a Cooling Fin for Battery Modules Against Impact Loads. Automot. Innov. 2020, 3, 260–269. [Google Scholar] [CrossRef]

- Subhedar, D.; Chauhan, K.V.; Panchal, S.; Bais, A. Numerical investigation of performance for liquid-cooled cylindrical electrical vehicle battery pack using Al2O3/EG-water nano coolant. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Dubey, P.; Pulugundla, G.; Srouji, A.K. Direct Comparison of Immersion and Cold-Plate Based Cooling for Automotive Li-Ion Battery Modules. Energies 2021, 14, 1259. [Google Scholar] [CrossRef]

- Tan, X.; Lyu, P.; Fan, Y.; Rao, J.; Ouyang, K. Numerical investigation of the direct liquid cooling of a fast-charging lithium-ion battery pack in hydrofluoroether. Appl. Therm. Eng. 2021, 196, 117279. [Google Scholar] [CrossRef]

- Le, Q.; Shi, Q.; Liu, Q.; Yao, X.; Ju, X.; Xu, C. Numerical investigation on manifold immersion cooling scheme for lithium ion battery thermal management application. Int. J. Heat Mass Transf. 2022, 190, 122750. [Google Scholar] [CrossRef]

- Larrañaga-Ezeiza, M.; Vertiz, G.; Arroiabe, P.F.; Martinez-Agirre, M.; Berasategi, J. A novel direct liquid cooling strategy for electric vehicles focused on pouch type battery cells. Appl. Therm. Eng. 2022, 216, 118869. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, R.; Wang, S.; Huang, D. Heat transfer characteristics and influencing factors of immersion coupled direct cooling for battery thermal management. J. Energy Storage 2023, 62, 106821. [Google Scholar] [CrossRef]

- Wu, N.; Ye, X.; Yao, J.; Zhang, X.; Zhou, X.; Yu, B. Efficient thermal management of the large-format pouch lithium-ion cell via the boiling-cooling system operated with intermittent flow. Int. J. Heat Mass Transf. 2021, 170, 121018. [Google Scholar] [CrossRef]

- Wang, Y.-F.; Wu, J.-T. Thermal performance predictions for an HFE-7000 direct flow boiling cooled battery thermal management system for electric vehicles. Energy Convers. Manag. 2020, 207, 112569. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, H.; Yang, C.; Zhao, J. Simulation study of lithium-ion battery thermal management system based on a variable flow velocity method with liquid metal. Appl. Therm. Eng. 2020, 179, 115578. [Google Scholar] [CrossRef]

- Imran, A.A.; Mahmoud, N.S.; Jaffal, H.M. Numerical and experimental investigation of heat transfer in liquid cooling serpentine mini-channel heat sink with different new configuration models. Therm. Sci. Eng. Prog. 2018, 6, 128–139. [Google Scholar] [CrossRef]

- Wang, J.; Liu, X.; Liu, F.; Liu, Y.; Wang, F.; Yang, N. Numerical optimization of the cooling effect of the bionic spider-web channel cold plate on a pouch lithium-ion battery. Case Stud. Therm. Eng. 2021, 26, 101124. [Google Scholar] [CrossRef]

- Huo, Y.; Rao, Z.; Liu, X.; Zhao, J. Investigation of power battery thermal management by using mini-channel cold plate. Energy Convers. Manag. 2015, 89, 387–395. [Google Scholar] [CrossRef]

- Sameer Mahmoud, N.; Mohammad Jaffal, H.; Abdulnabi Imran, A. Performance evaluation of serpentine and multi-channel heat sinks based on energy and exergy analyses. Appl. Therm. Eng. 2021, 186, 116475. [Google Scholar] [CrossRef]

- Al-Zareer, M.; Dincer, I.; Rosen, M.A. Development and analysis of a new tube based cylindrical battery cooling system with liquid to vapor phase change. Int. J. Refrig. 2019, 108, 163–173. [Google Scholar] [CrossRef]

- Basu, S.; Hariharan, K.S.; Kolake, S.M.; Song, T.; Sohn, D.K.; Yeo, T. Coupled electrochemical thermal modelling of a novel Li-ion battery pack thermal management system. Appl. Energy 2016, 181, 1–13. [Google Scholar] [CrossRef]

- Du, X.; Qian, Z.; Chen, Z.; Rao, Z. Experimental investigation on mini-channel cooling–based thermal management for Li-ion battery module under different cooling schemes. Int. J. Energy Res. 2018, 42, 2781–2788. [Google Scholar] [CrossRef]

- Jang, D.S.; Ham, S.H.; Kim, J.; Kim, Y. Thermal and aging performance characteristics of pouch-type lithium-ion battery using heat pipes under nonuniform heating conditions. Appl. Therm. Eng. 2024, 236, 121891. [Google Scholar] [CrossRef]

- Wu, W.; Wang, S.; Wu, W.; Chen, K.; Hong, S.; Lai, Y. A critical review of battery thermal performance and liquid based battery thermal management. Energy Convers. Manag. 2019, 182, 262–281. [Google Scholar] [CrossRef]

- Hao, T.; Ma, H.; Ma, X. Heat transfer performance of polytetrafluoroethylene oscillating heat pipe with water, ethanol, and acetone as working fluids. Int. J. Heat Mass Transfer 2019, 131, 109–120. [Google Scholar] [CrossRef]

- Nasir, F.M.; Abdullah, M.Z.; Majid, M.F.M.A.; Ismail, M.A. Nanofluid-filled heat pipes in managing the temperature of EV lithium-ion batteries. J. Phys. Conf. Ser. 2019, 1349, 012123. [Google Scholar] [CrossRef]

- Chen, M.; Li, J. Nanofluid-based pulsating heat pipe for thermal management of lithium-ion batteries for electric vehicles. J. Energy Storage 2020, 32, 101715. [Google Scholar] [CrossRef]

- Zhou, Z.; Lv, Y.; Qu, J.; Sun, Q.; Grachev, D. Performance evaluation of hybrid oscillating heat pipe with carbon nanotube nanofluids for electric vehicle battery cooling. Appl. Therm. Eng. 2021, 196, 117300. [Google Scholar] [CrossRef]

- Behi, H.; Behi, M.; Karimi, D.; Jaguemont, J.; Ghanbarpour, M.; Behnia, M.; Berecibar, M.; Van Mierlo, J. Heat pipe air-cooled thermal management system for lithium-ion batteries: High power applications. Appl. Therm. Eng. 2021, 183, 116240. [Google Scholar] [CrossRef]

- Zhao, R.; Gu, J.; Liu, J. An experimental study of heat pipe thermal management system with wet cooling method for lithium ion batteries. J. Power Sources 2015, 273, 1089–1097. [Google Scholar] [CrossRef]

- Wang, Q.; Jiang, B.; Xue, Q.F.; Sun, H.L.; Li, B.; Zou, H.M.; Yan, Y.Y. Experimental investigation on EV battery cooling and heating by heat pipes. Appl. Therm. Eng. 2015, 88, 54–60. [Google Scholar] [CrossRef]

- Yue, Q.L.; He, C.X.; Jiang, H.R.; Wu, M.C.; Zhao, T.S. A hybrid battery thermal management system for electric vehicles under dynamic working conditions. Int. J. Heat Mass Transf. 2021, 164, 120528. [Google Scholar] [CrossRef]

- Ling, Y.-Z.; Zhang, X.-S.; Wang, F.; She, X.-H. Performance study of phase change materials coupled with three-dimensional oscillating heat pipes with different structures for electronic cooling. Renew. Energy 2020, 154, 636–649. [Google Scholar] [CrossRef]

- Kang, Z.; Shou, D.; Fan, J. Numerical study of a novel Single-loop pulsating heat pipe with separating walls within the flow channel. Appl. Therm. Eng. 2021, 196, 117246. [Google Scholar] [CrossRef]

- Chi, R.G.; Rhi, S.H. Oscillating Heat Pipe Cooling System of Electric Vehicle’s Li-Ion Batteries with Direct Contact Bottom Cooling Mode. Energies 2019, 12, 1698. [Google Scholar] [CrossRef]

- Zhao, J.; Rao, Z.; Liu, C.; Li, Y. Experiment study of oscillating heat pipe and phase change materials coupled for thermal energy storage and thermal management. Int. J. Heat Mass Transf. 2016, 99, 252–260. [Google Scholar] [CrossRef]

- Qu, J.; Wang, C.; Li, X.; Wang, H. Heat transfer performance of flexible oscillating heat pipes for electric/hybrid-electric vehicle battery thermal management. Appl. Therm. Eng. 2018, 135, 1–9. [Google Scholar] [CrossRef]

- Grimonia, E.; Andhika, M.R.C.; Aulady, M.F.N.; Rubi, R.V.C.; Hamidah, N.L. Thermal Management System Using Phase Change Material for Lithium-ion Battery. J. Phys. Conf. Ser. 2021, 2117, 012005. [Google Scholar] [CrossRef]

- Joshi, A.K.; Kakati, P.; Dandotiya, D.; Pandiyan, P.S.; Patil, N.G.; Panchal, S. Computational analysis of preheating cylindrical lithium-ion batteries with fin-assisted phase change material. Int. J. Mod. Phys. C (IJMPC) 2024, 35, 1–16. [Google Scholar] [CrossRef]

- Zare, P.; Perera, N.; Lahr, J.; Hasan, R. Solid-liquid phase change materials for the battery thermal management systems in electric vehicles and hybrid electric vehicles—A systematic review. J. Energy Storage 2022, 52, 105026. [Google Scholar] [CrossRef]

- Jani, H.K.; Modi, K.V. Experimental performance evaluation of single basin dual slope solar still with circular and square cross-sectional hollow fins. Sol. Energy 2019, 179, 186–194. [Google Scholar] [CrossRef]

- Huang, Y.; Stonehouse, A.; Abeykoon, C. Encapsulation methods for phase change materials—A critical review. Int. J. Heat Mass Transf. 2023, 200, 123458. [Google Scholar] [CrossRef]

- Garg, N.; Khaudiyal, S.; Kumar, S.; Kumar Das, S. Research trends in phase change materials (PCM) for high-performance sustainable construction. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Dai, X.; Kong, D.; Du, J.; Zhang, Y.; Ping, P. Investigation on effect of phase change material on the thermal runaway of lithium-ion battery and exploration of flame retardancy improvement. Process Saf. Environ. Prot. 2022, 159, 232–242. [Google Scholar] [CrossRef]

- Liu, C.; Xu, D.; Weng, J.; Zhou, S.; Li, W.; Wan, Y.; Jiang, S.; Zhou, D.; Wang, J.; Huang, Q. Phase Change Materials Application in Battery Thermal Management System: A Review. Materials 2020, 13, 4622. [Google Scholar] [CrossRef] [PubMed]

- Yu, K.; Liu, Y.; Yang, Y. Review on form-stable inorganic hydrated salt phase change materials: Preparation, characterization and effect on the thermophysical properties. Appl. Energy 2021, 292, 116845. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, C.; Fang, G. Encapsulation of inorganic phase change thermal storage materials and its effect on thermophysical properties: A review. Sol. Energy Mater. Sol. Cells 2022, 241, 111747. [Google Scholar] [CrossRef]

- Galazutdinova, Y.; Ushak, S.; Farid, M.; Al-Hallaj, S.; Grágeda, M. Development of the inorganic composite phase change materials for passive thermal management of Li-ion batteries: Application. J. Power Sources 2021, 491, 229624. [Google Scholar] [CrossRef]

- Ling, Z.; Li, S.; Cai, C.; Lin, S.; Fang, X.; Zhang, Z. Battery thermal management based on multiscale encapsulated inorganic phase change material of high stability. Appl. Therm. Eng. 2021, 193, 117002. [Google Scholar] [CrossRef]

- Kharabati, S.; Saedodin, S. A systematic review of thermal management techniques for electric vehicle batteries. J. Energy Storage 2024, 75, 109586. [Google Scholar] [CrossRef]

- Tian, L.-L.; Liu, X.; Chen, S.; Shen, Z.-G. Effect of fin material on PCM melting in a rectangular enclosure. Appl. Therm. Eng. 2020, 167, 114764. [Google Scholar] [CrossRef]

- Saedodin, S.; Zaboli, M.; Rostamian, S.H.; Kharabati, S. Statistical analysis and shape optimization of a finned corrugated heat exchanger using RSM. Chem. Eng. Commun. 2023, 210, 716–739. [Google Scholar] [CrossRef]

- Jiang, K.; Liao, G.; E, J.; Zhang, F.; Chen, J.; Leng, E. Thermal management technology of power lithium-ion batteries based on the phase transition of materials: A review. J. Energy Storage 2020, 32, 101816. [Google Scholar] [CrossRef]

- Weng, J.; Ouyang, D.; Yang, X.; Chen, M.; Zhang, G.; Wang, J. Optimization of the internal fin in a phase-change-material module for battery thermal management. Appl. Therm. Eng. 2020, 167, 114698. [Google Scholar] [CrossRef]

- Choudhari, V.G.; Dhoble, A.S.; Panchal, S. Numerical analysis of different fin structures in phase change material module for battery thermal management system and its optimization. Int. J. Heat Mass Transf. 2020, 163, 120434. [Google Scholar] [CrossRef]

- Zhang, F.; Zhai, L.; Zhang, L.; Yi, M.; Du, B.; Li, S. A novel hybrid battery thermal management system with fins added on and between liquid cooling channels in composite phase change materials. Appl. Therm. Eng. 2022, 207, 118198. [Google Scholar] [CrossRef]

- Fan, R.; Zheng, N.; Sun, Z. Evaluation of fin intensified phase change material systems for thermal management of Li-ion battery modules. Int. J. Heat Mass Transf. 2021, 166, 120753. [Google Scholar] [CrossRef]

- Zheng, N.; Fan, R.; Sun, Z.; Zhou, T. Thermal management performance of a fin-enhanced phase change material system for the lithium-ion battery. Int. J. Energy Res. 2020, 44, 7617–7629. [Google Scholar] [CrossRef]

- Choudhari, V.G.; Dhoble, A.S.; Panchal, S.; Fowler, M.; Fraser, R. Numerical investigation on thermal behaviour of 5 × 5 cell configured battery pack using phase change material and fin structure layout. J. Energy Storage 2021, 43, 103234. [Google Scholar] [CrossRef]

- Lee, Y.S.; Lee, S.-Y.; Kim, K.S.; Noda, S.; Shim, S.E.; Yang, C.-M. Effective Heat Transfer Pathways of Thermally Conductive Networks Formed by One-Dimensional Carbon Materials with Different Sizes. Polymers 2019, 11, 1661. [Google Scholar] [CrossRef]

- Taherian, R. Experimental and analytical model for the electrical conductivity of polymer-based nanocomposites. Compos. Sci. Technol. 2016, 123, 17–31. [Google Scholar] [CrossRef]

- Wu, W.; Wu, W.; Wang, S. Thermal management optimization of a prismatic battery with shape-stabilized phase change material. Int. J. Heat Mass Transf. 2018, 121, 967–977. [Google Scholar] [CrossRef]

- Zhang, W.; Ling, G.; Zhuang, L.; Liang, Z. The effect of reducing the thermal contact resistance on the performance of battery thermal management system. Int. J. Energy Res. 2021, 45, 9970–9982. [Google Scholar] [CrossRef]

- Mahdi, J.M.; Mohammed, H.I.; Talebizadehsardari, P.; Ghalambaz, M.; Majdi, H.S.; Yaïci, W.; Giddings, D. Simultaneous and consecutive charging and discharging of a PCM-based domestic air heater with metal foam. Appl. Therm. Eng. 2021, 197, 117408. [Google Scholar] [CrossRef]

- Li, W.Q.; Guo, S.J.; Tan, L.; Liu, L.L.; Ao, W. Heat transfer enhancement of nano-encapsulated phase change material (NEPCM) using metal foam for thermal energy storage. Int. J. Heat Mass Transf. 2021, 166, 120737. [Google Scholar] [CrossRef]

- Li, H.; Hu, C.; He, Y.; Tang, D.; Wang, K.; Hu, X. Visualized-experimental investigation on the energy storage performance of PCM infiltrated in the metal foam with varying pore densities. Energy 2021, 237, 121540. [Google Scholar] [CrossRef]

- Heyhat, M.M.; Mousavi, S.; Siavashi, M. Battery thermal management with thermal energy storage composites of PCM, metal foam, fin and nanoparticle. J. Energy Storage 2020, 28, 101235. [Google Scholar] [CrossRef]

- Kharabati, S.; Saedodin, S.; Rostamian, S.H. Experimental investigation of thermal and rheological behavior of silica/soybean oil nano lubricant in low-temperature performance of internal combustion engine. Energy Sources Part A 2021, 1–15. [Google Scholar] [CrossRef]

- Mousavi, S.; Siavashi, M.; Heyhat, M.M. Numerical melting performance analysis of a cylindrical thermal energy storage unit using nano-enhanced PCM and multiple horizontal fins. Numer. Heat Transf. Part A Appl. 2019, 75, 560–577. [Google Scholar] [CrossRef]

- Jilte, R.; Afzal, A.; Panchal, S. A novel battery thermal management system using nano-enhanced phase change materials. Energy 2021, 219, 119564. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, L.; Zhan, W.; Chen, Y.; Chen, M. Flame retardant composite phase change materials with MXene for lithium-ion battery thermal management systems. J. Energy Storage 2024, 86, 111293. [Google Scholar] [CrossRef]

- Mehrabi-Kermani, M.; Houshfar, E.; Ashjaee, M. A novel hybrid thermal management for Li-ion batteries using phase change materials embedded in copper foams combined with forced-air convection. Int. J. Therm. Sci. 2019, 141, 47–61. [Google Scholar] [CrossRef]

- Chen, G.; Shi, Y.; Ye, H.; Kang, H. Experimental study on phase change material based thermal management design with adjustable fins for lithium-ion battery. Appl. Therm. Eng. 2023, 221, 119808. [Google Scholar] [CrossRef]

- Jilte, R.D.; Kumar, R.; Ahmadi, M.H.; Chen, L. Battery thermal management system employing phase change material with cell-to-cell air cooling. Appl. Therm. Eng. 2019, 161, 114199. [Google Scholar] [CrossRef]

- Qin, P.; Liao, M.; Zhang, D.; Liu, Y.; Sun, J.; Wang, Q. Experimental and numerical study on a novel hybrid battery thermal management system integrated forced-air convection and phase change material. Energy Convers. Manag. 2019, 195, 1371–1381. [Google Scholar] [CrossRef]

- Chen, S.; Garg, A.; Gao, L.; Wei, X. An experimental investigation for a hybrid phase change material-liquid cooling strategy to achieve high-temperature uniformity of Li-ion battery module under fast charging. Int. J. Energy Res. 2021, 45, 6198–6212. [Google Scholar] [CrossRef]

- An, Z.; Zhang, C.; Luo, Y.; Zhang, J. Cooling and preheating behavior of compact power Lithium-ion battery thermal management system. Appl. Therm. Eng. 2023, 226, 120238. [Google Scholar] [CrossRef]

- Pakrouh, R.; Ranjbar, A.A.; Hosseini, M.J.; Rahimi, M. Thermal management analysis of new liquid cooling of a battery system based on phase change material and thermoelectric cooler. Appl. Therm. Eng. 2023, 231, 120925. [Google Scholar] [CrossRef]

- Kong, D.; Peng, R.; Ping, P.; Du, J.; Chen, G.; Wen, J. A novel battery thermal management system coupling with PCM and optimized controllable liquid cooling for different ambient temperatures. Energy Convers. Manag. 2020, 204, 112280. [Google Scholar] [CrossRef]

- Wang, J.; Mei, W.; Mao, B.; Wang, Q. Investigation on the temperature control performance and optimization strategy of a battery thermal management system combining phase change and liquid cooling. Appl. Therm. Eng. 2023, 232, 121080. [Google Scholar] [CrossRef]

- Yang, W.; Zhou, F.; Liu, Y.; Xu, S.; Chen, X. Thermal performance of honeycomb-like battery thermal management system with bionic liquid mini-channel and phase change materials for cylindrical lithium-ion battery. Appl. Therm. Eng. 2021, 188, 116649. [Google Scholar] [CrossRef]

- Zhang, W.; Liang, Z.; Yin, X.; Ling, G. Avoiding thermal runaway propagation of lithium-ion battery modules by using hybrid phase change material and liquid cooling. Appl. Therm. Eng. 2021, 184, 116380. [Google Scholar] [CrossRef]

- Qu, J.; Ke, Z.; Zuo, A.; Rao, Z. Experimental investigation on thermal performance of phase change material coupled with three-dimensional oscillating heat pipe (PCM/3D-OHP) for thermal management application. Int. J. Heat Mass Transf. 2019, 129, 773–782. [Google Scholar] [CrossRef]

- Leng, Z.; Yuan, Y.; Cao, X.; Zhong, W.; Zeng, C. Heat pipe/phase change material coupled thermal management in Li-ion battery packs: Optimization and energy-saving assessment. Appl. Therm. Eng. 2022, 208, 118211. [Google Scholar] [CrossRef]

- Peng, P.; Wang, Y.; Jiang, F. Numerical study of PCM thermal behavior of a novel PCM-heat pipe combined system for Li-ion battery thermal management. Appl. Therm. Eng. 2022, 209, 118293. [Google Scholar] [CrossRef]

- Gurra, E.; Iasiello, M.; Naso, V.; Chiu, W.K.S. Numerical Prediction and Correlations of Effective Thermal Conductivity in a Drilled-Hollow-Sphere Architected Foam. J. Therm. Sci. Eng. Appl. 2023, 15, 041002. [Google Scholar] [CrossRef]

- Min, R.; Wang, Z.; Yang, H.; Bao, R.; Zhang, N. Heat transfer characterization of waste heat recovery heat exchanger based on flexible hybrid triply periodic minimal surfaces (TPMS). Int. Commun. Heat Mass Transf. 2024, 157, 107760. [Google Scholar] [CrossRef]

- Bianco, N.; Cherella, N.; Fragnito, A.; Iasiello, M.; Mauro, G.M. Multi-material topology optimization of innovative microchannel heat sinks equipped with metal foams. Int. J. Heat Mass Transf. 2024, 222, 125201. [Google Scholar] [CrossRef]

| BTMS | Advantages | Disadvantages |

|---|---|---|

| Air-based | Direct contact | Low specific heat |

| Lightweight | Poor temperature uniformity | |

| Small size | Noise generation | |

| Low price | ||

| Simple operation and maintenance | ||

| Liquid-based | High specific heat | Exorbitant |

| Good temperature uniformity | Risk of fluid leakage | |

| Large cooling area | Structural complexity | |

| Space-intensive | ||

| Heat-pipe-based | Small volume | Complex structure |

| Low energy consumption | High cost | |

| Relatively good thermal performance | Difficult to maintain | |

| Long life cycle | ||

| PCM-based | High latent heat | Extra insulation for leak prevention |

| Uniform temperature distribution | Limited temperature range | |

| Compatible with extreme environments | ||

| Low cost | ||

| Low energy consumption for passive operation | ||

| Hybrid | Uniform temperature distribution | Excessive complexity |

| High thermal management efficiency | Increased costs | |

| High adaptability | Difficult to maintain | |

| Energy saving and consumption reduction | Complex control strategy | |

| Flexible space utilization |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, L.; Wang, S.; Xi, L.; Li, Y.; Gao, J. A Review of Thermal Management and Heat Transfer of Lithium-Ion Batteries. Energies 2024, 17, 3873. https://doi.org/10.3390/en17163873

Xu L, Wang S, Xi L, Li Y, Gao J. A Review of Thermal Management and Heat Transfer of Lithium-Ion Batteries. Energies. 2024; 17(16):3873. https://doi.org/10.3390/en17163873

Chicago/Turabian StyleXu, Liang, Shanyi Wang, Lei Xi, Yunlong Li, and Jianmin Gao. 2024. "A Review of Thermal Management and Heat Transfer of Lithium-Ion Batteries" Energies 17, no. 16: 3873. https://doi.org/10.3390/en17163873

APA StyleXu, L., Wang, S., Xi, L., Li, Y., & Gao, J. (2024). A Review of Thermal Management and Heat Transfer of Lithium-Ion Batteries. Energies, 17(16), 3873. https://doi.org/10.3390/en17163873