Development and Optimization of a Micro-Baffle for the Enhancement of Heat Transfer in Film Boiling

Abstract

1. Introduction

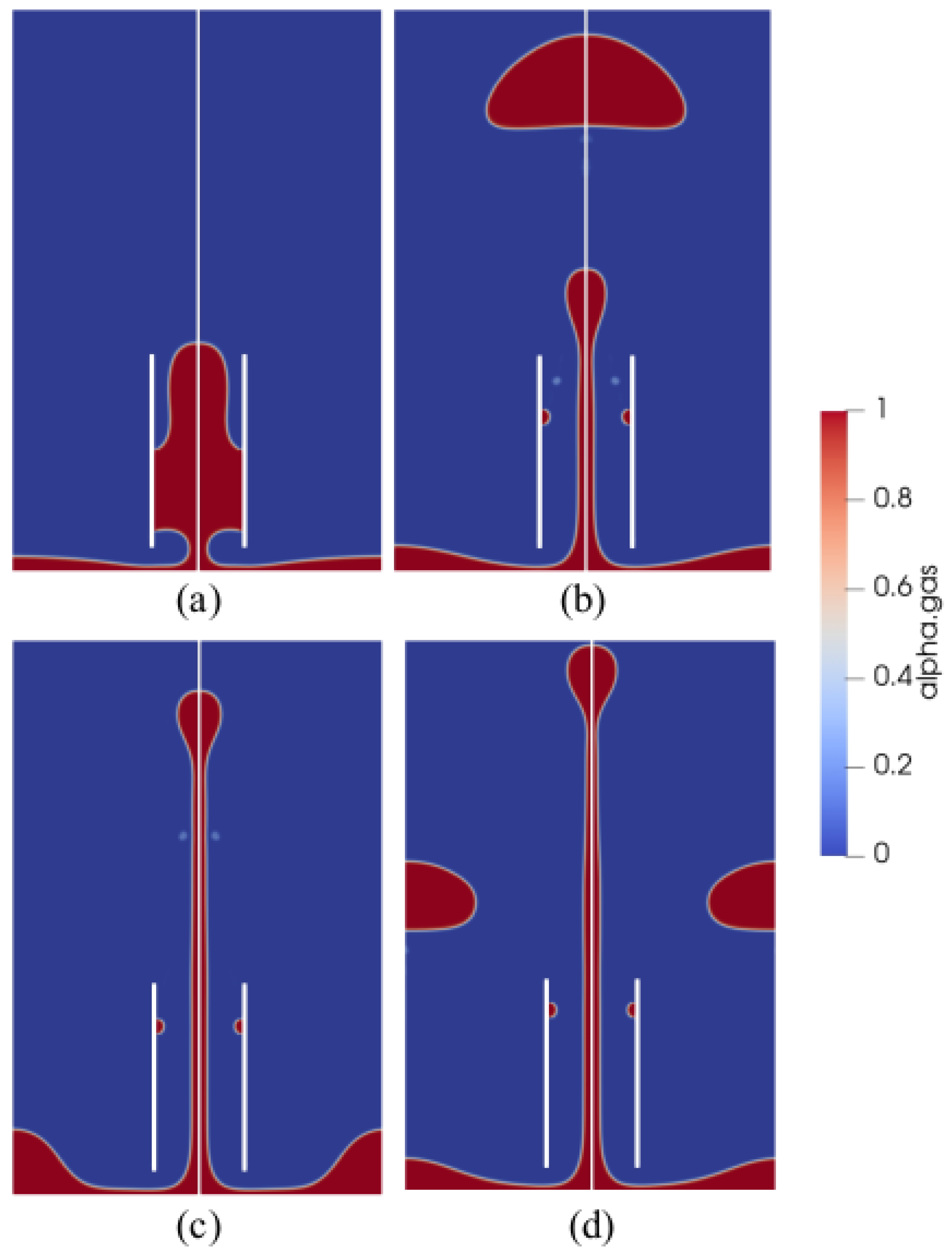

2. Numerical Model and Setup

3. Results and Discussion

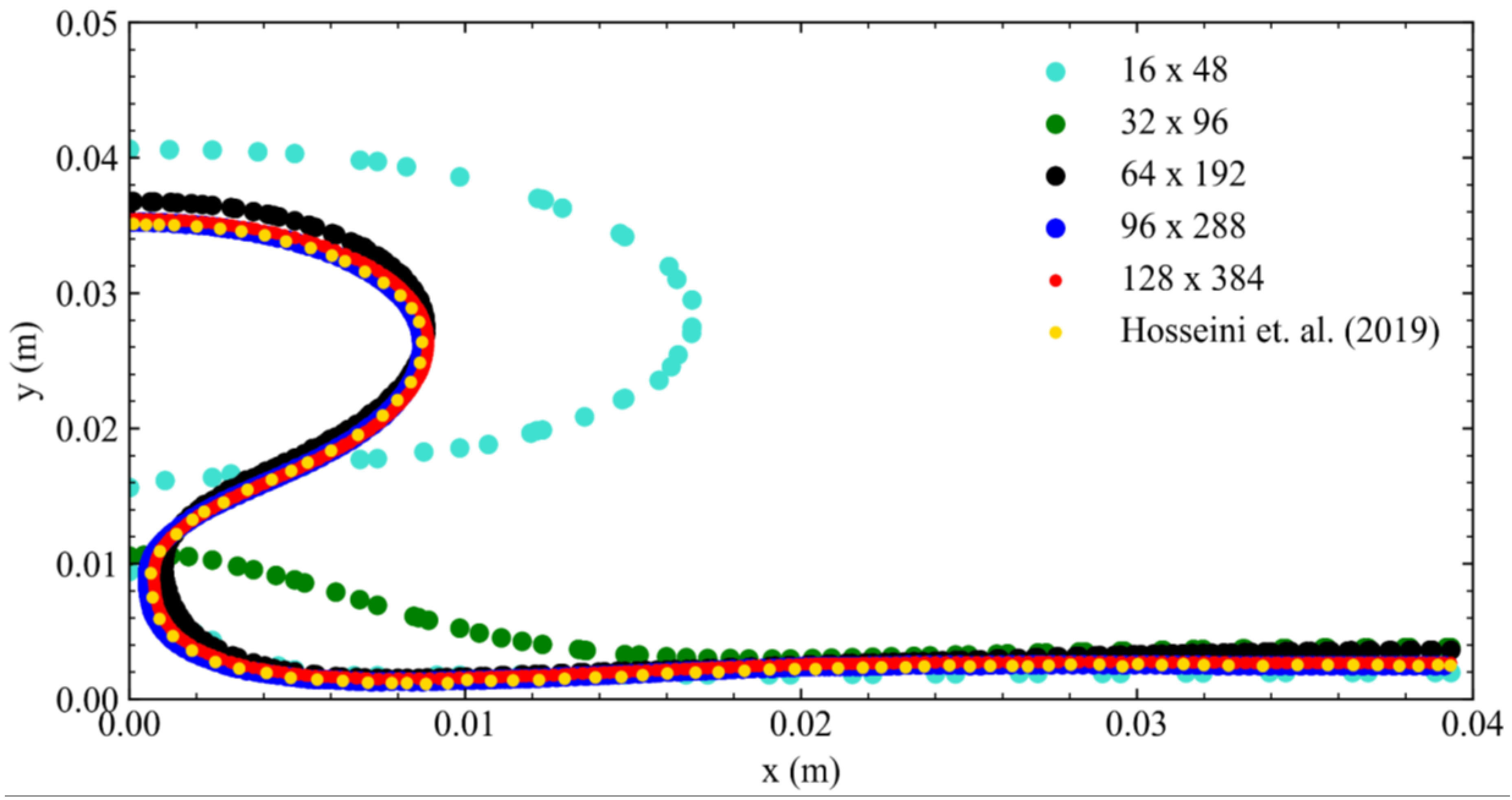

3.1. Validation of the Numerical Model

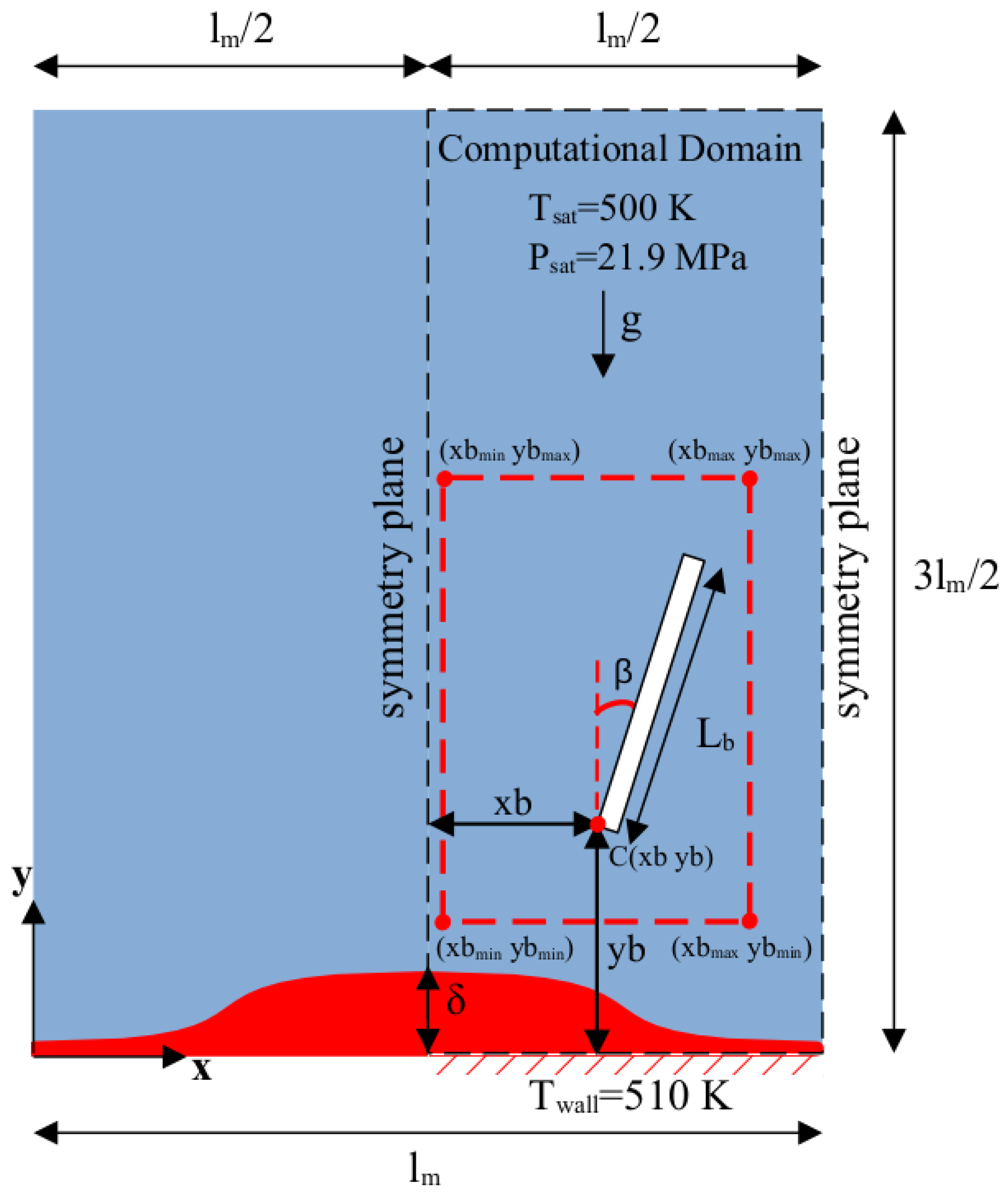

3.2. The Micro-Baffle Design

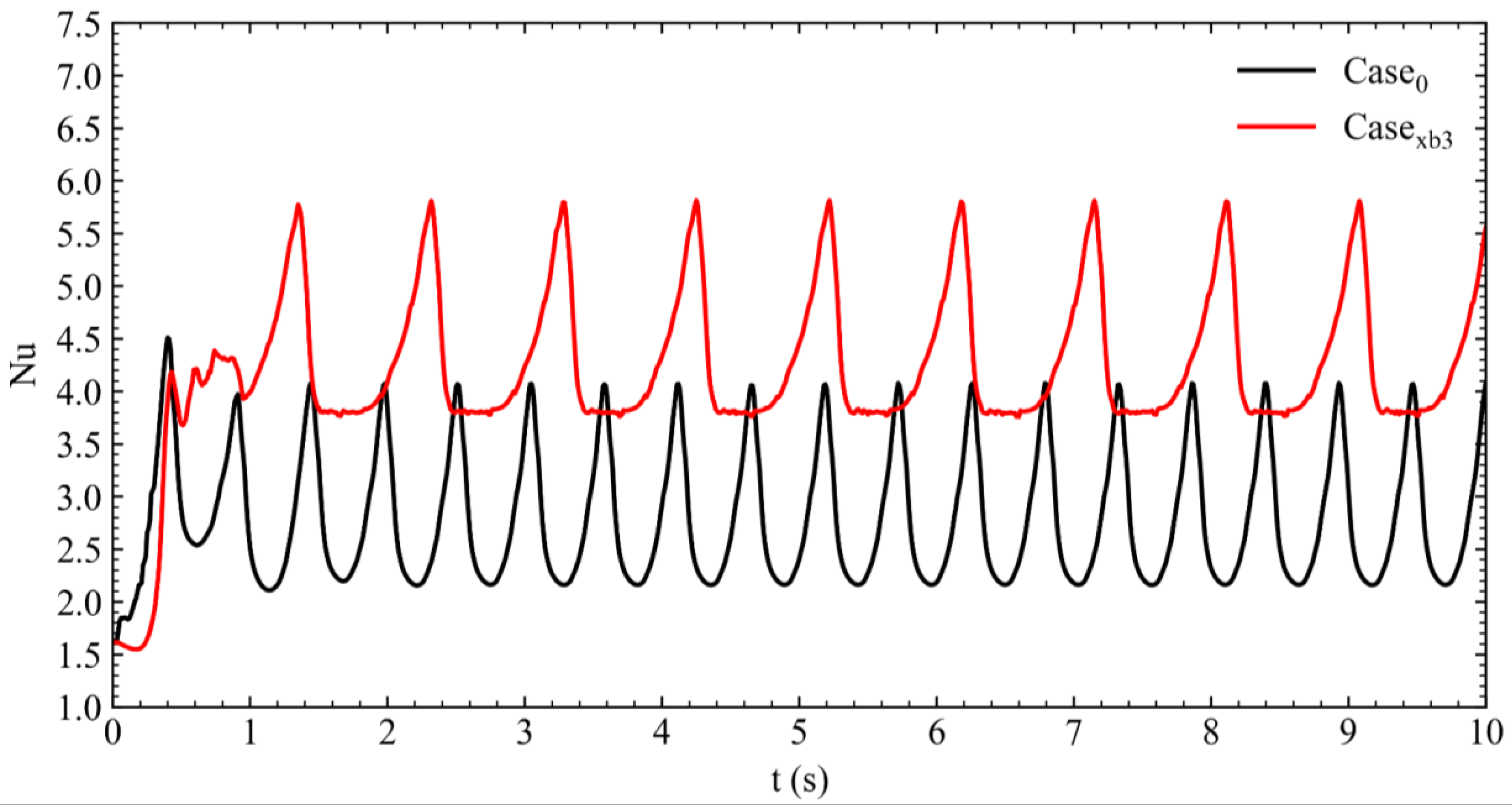

3.3. Influence of the Baffle Location

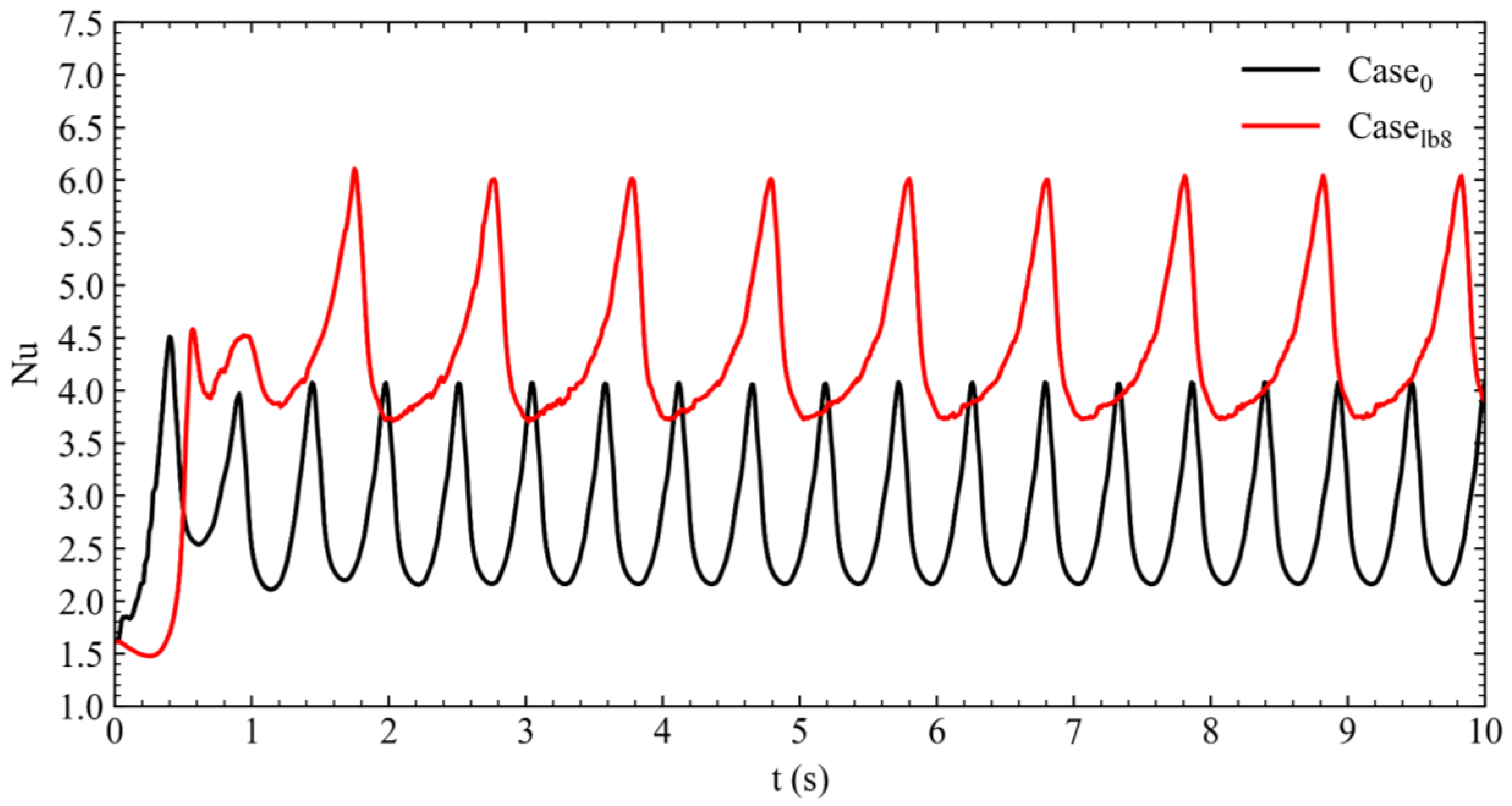

3.4. Influence of the Baffle Length

3.5. Influence of the Baffle Rotation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Area of the vapor column (m2) | |

| Area of the heater surface (m2) | |

| Vapor volume fraction | |

| Liquid volume fraction | |

| δ | Knocker delta |

| μ | Dynamic viscosity (Pa.s) |

| ρ | Density (kg/m3) |

| Vapor density (kg/m3) | |

| Liquid density (kg/m3) | |

| σ | Surface Tension (N/m) |

| Lee model constant | |

| CHF | Critical Heat Flux |

| CFD | Computational Fluid Dynamics |

| CSF | Continuum Surface Force |

| Specific heat (J/kgK) | |

| E | Sensible enthalpy |

| Body Force (Pa) | |

| g | Gravity acceleration (m/s2) |

| h | Heat transfer coefficient (W/m2·K) |

| Latent heat (J/kg) | |

| k | Thermal conductivity (W/mK) |

| l | Liquid volume |

| Critical wavelength | |

| Nu | Nusselt number |

| p | Pressure (Pa) |

| q | Heat Flux (W/m2) |

| Volumetric energy source | |

| Mass source | |

| T | Temperature (K) |

| Surface temperature (K) | |

| Saturation Temperature (K) | |

| Subcooled Temperature (K) | |

| Supply temperature (K) | |

| Wall Temperature (K) | |

| u | Velocity field |

| Critical vapor velocity (m/s) | |

| Vapor volume | |

| w | Width (m) |

References

- Groeneveld, D.C.; Shan, J.Q.; Vasic, A.Z.; Leung, L.K.H.; Durmayaz, A.; Yang, J.; Cheng, S.C.; Tanase, A. The 2006 CHF look-up table. Nucl. Eng. Des. 2007, 237, 1909–1922. [Google Scholar] [CrossRef]

- Tong, L.S.; Weisman, J. Thermal Analysis of Pressurized Water Reactors; American Nuclear Society: Westmont, Il, USA, 1979. [Google Scholar]

- Totten, G.E.; Bates, C.E.; Clinton, N.A. Spray Quenching. In Handbook of Quenchants and Quenching Technology, 1st ed.; Haddad, M.T., Ed.; ASM International: Novelty, OH, USA, 1993. [Google Scholar] [CrossRef]

- Faghri, A.; Zhang, Y. Transport Phenomena in Multiphase Systems, 1st ed.; Academic Press: Cambridge, MA, USA, 2006. [Google Scholar]

- You, S.M.; Kim, J.H.; Kim, K.H. Effect of nanoparticles on critical heat flux of water in pool boiling heat transfer. Appl. Phys. Lett. 2003, 83, 3374–3376. [Google Scholar] [CrossRef]

- Park, S.D.; Lee, S.W.; Kang, S.; Bang, I.C.; Kim, J.H.; Shin, H.S.; Lee, D.W.; Lee, D.W. Effects of nanofluids containing graphene/graphene-oxide nanosheets on critical heat flux. Appl. Phys. Lett. 2010, 97, 023103. [Google Scholar] [CrossRef]

- Mori, S.; Okuyama, K. Enhancement of the critical heat flux in saturated pool boiling using honeycomb porous media. Int. J. Multiph. Flow 2009, 35, 946–951. [Google Scholar] [CrossRef]

- Wang, K.; Gong, H.; Wang, L.; Erkan, N.; Okamoto, K. Effects of a porous honeycomb structure on critical heat flux in downward facing saturated pool boiling. Appl. Therm. Eng. 2020, 170, 115036. [Google Scholar] [CrossRef]

- Hao, W.; Wang, T.; Jiang, Y.-Y.; Guo, C.; Guo, C.H. Pool boiling heat transfer on deformable structures made of shape-memory-alloys. Int. J. Heat Mass Transf. 2017, 112, 236–247. [Google Scholar] [CrossRef]

- Surtaev, A.; Kuznetsov, D.; Serdyukov, V.; Pavlenko, A.; Kalita, V.; Komlev, D.; Ivannikov, A.; Radyuk, A. Structured capillary-porous coatings for enhancement of heat transfer at pool boiling. Appl. Therm. Eng. 2018, 133, 532–542. [Google Scholar] [CrossRef]

- Das, S.; Saha, B.; Bhaumik, S. Experimental study of nucleate pool boiling heat transfer of water by surface functionalization with SiO2 nanostructure. Exp. Therm. Fluid Sci. 2017, 81, 454–465. [Google Scholar] [CrossRef]

- Goswami, N.; Basu, S.; Bhowal, A.; Datta, S. Concentration of solution in cross-flow rotating packed bed contactor. Chem. Eng. Res. Des. 2015, 95, 281–287. [Google Scholar] [CrossRef]

- Quan, X.; Luo, Y.; Qie, S.; Huang, Z.; Liu, C. Mass transfer during falling film evaporation based on new multi-stage flash model. J. Chem. Eng. Jpn. 2015, 48, 528–532. [Google Scholar] [CrossRef]

- Li, H.; Jiang, F.; Qi, G.; Li, X. Investigation of the thermal performance of a novel thermosyphon combined with fluidized bed heat transfer technology. Powder Technol. 2020, 374, 40–48. [Google Scholar] [CrossRef]

- Jiang, F.; Feng, Q.; Qi, G.P.; Jiang, T.; Wang, J.J.; Liang, X.; Li, X.L. Flow boiling in a downflow circulating fluidized bed evaporator. Appl. Therm. Eng. 2019, 156, 359–370. [Google Scholar] [CrossRef]

- Kunkelmann, C. Numerical Modeling and Investigation of Boiling Phenomena. Ph.D. Thesis, Technische Universität Darmstadt, Darmstadt, Germany, 2011. [Google Scholar]

- Ginzburg, I.; Wittum, G. Two-phase flows on interface refined grids modeled with VOF, staggered finite volumes and spline interpolants. J. Comput. Phys. 2001, 166, 302–335. [Google Scholar] [CrossRef]

- Hirt, C.W.; Nichols, B.D. Volume of fluid (VOF) method for the dynamics of free boundary. J. Comput. Phys. 1981, 39, 201–225. [Google Scholar] [CrossRef]

- Yakubov, S.; Cankurt, B.; Maquil, T.; Schiller, P.; Abdel-Maksoud, M.; Rung, T. Euler-Euler and Euler-Lagrange approaches to cavitation modelling in marine applications. CIMNE 2011, 544–555. [Google Scholar] [CrossRef]

- Valizadeh, Z.; Shams, M. Numerical investigation of water-based nanofluid subcooled flow boiling by three-phase Euler–Euler, Euler–Lagrange approach. Heat Mass Transf. 2016, 52, 1501–1514. [Google Scholar] [CrossRef]

- Butaye, E.; Toutant, A.; Mer, S. Euler–Euler Multi-Scale Simulations of Internal Boiling Flow with Conjugated Heat Transfer. Appl. Mech. 2023, 4, 191–209. [Google Scholar] [CrossRef]

- Chen, M.; Liu, M.; Tang, Y. Comparison of Euler-Euler and Euler-Lagrange approaches for simulating gas-solid flows in a multiple-spouted bed. Int. J. Chem. React. Eng. 2019, 17, 20180254. [Google Scholar] [CrossRef]

- Groll, R.; Jakirlić, S.; Tropea, C. Comparative study of Euler/Euler and Euler/Lagrange approaches simulating evaporation in a turbulent gas–liquid flow. Int. J. Numer. Methods Fluids 2009, 59, 873–906. [Google Scholar] [CrossRef]

- Lou, W.; Zhu, M. Numerical simulation of gas and liquid two-phase flow in gas-stirred systems based on Euler–Euler approach. Metall. Mater. Trans. B 2013, 44, 1251–1263. [Google Scholar] [CrossRef]

- Van Sint Annaland, M.; Deen, N.G.; Kuipers, J.A.M. Numerical simulation of gas bubbles behaviour using a three-dimensional volume of fluid method. Chem. Eng. Sci. 2005, 60, 2999–3011. [Google Scholar] [CrossRef]

- Welch, S.W.; Wilson, J. A volume of fluid based method for fluid flows with phase change. J. Comput. Phys. 2000, 160, 662–682. [Google Scholar] [CrossRef]

- Kleefsman, K.M.T.; Fekken, G.; Veldman, A.E.P.; Iwanowski, B.; Buchner, B. A volume-of-fluid based simulation method for wave impact problems. J. Comput. Phys. 2005, 206, 363–393. [Google Scholar] [CrossRef]

- Zeng, Q.; Cai, J.; Yin, H.; Yang, X.; Watanabe, T. Numerical simulation of single bubble condensation in subcooled flow using OpenFOAM. Prog. Nucl. Energy 2015, 83, 336–346. [Google Scholar] [CrossRef]

- Deshpande, S.S.; Anumolu, L.; Trujillo, M.F. Evaluating the performance of the two-phase flow solver interFoam. Comput. Sci. Discov. 2012, 5, 014016. [Google Scholar] [CrossRef]

- Sun, D.L.; Xu, J.L.; Wang, L. Development of a vapor–liquid phase change model for volume-of-fluid method in FLUENT. Int. Commun. Heat Mass Transf. 2012, 39, 1101–1106. [Google Scholar] [CrossRef]

- Hosseini, S.A.; Kouhikamali, R. A numerical investigation of various phase change models on simulation of saturated film boiling heat transfer. Heat Transf.-Asian Res. 2019, 48, 2577–2595. [Google Scholar] [CrossRef]

- Samkhaniani, N.; Ansari, M.R. Numerical simulation of bubble condensation using CF-VOF. Prog. Nucl. Energy 2016, 89, 120–131. [Google Scholar] [CrossRef]

- Lee, W.H. A pressure iteration scheme for two-phase flow modeling. In Multiphase Transport Fundamentals, Reactor Safety, Applications, 1st ed.; Veziroglu, T.N., Ed.; Hemisphere Publishing: Washington, DC, USA, 1980. [Google Scholar]

- Chen, G.; Nie, T.; Yan, X. An explicit expression of the empirical factor in a widely used phase change model. Int. J. Heat Mass Transf. 2020, 150, 119279. [Google Scholar] [CrossRef]

- Yang, Z.; Peng, X.F.; Ye, P. Numerical and experimental investigation of two phase flow during boiling in a coiled tube. Int. J. Heat Mass Transf. 2008, 51, 1003–1016. [Google Scholar] [CrossRef]

- Fang, C.; David, M.; Rogacs, A.; Goodson, K. Volume of fluid simulation of boiling two-phase flow in a vapor-venting microchannel. Front. Heat Mass Transf. 2010, 1, 013002. [Google Scholar] [CrossRef]

- Chen, S.; Yang, Z.; Duan, Y.; Chen, Y.; Wu, D. Simulation of condensation flow in a rectangular microchannel. Chem. Eng. Process. Process Intensif. 2014, 76, 60–69. [Google Scholar] [CrossRef]

- Milne-Thomson, L.M. Theoretical Hydrodynamics, 5th ed.; Macmillan: London, UK, 1968; pp. 491–492. [Google Scholar]

- Kendoush, A.A. The virtual mass of an oblate-ellipsoidal bubble. Phys. Lett. A 2007, 366, 253–255. [Google Scholar] [CrossRef]

- Wang, J.; Li, Y.; Wang, L. Numerical study on pool film boiling of liquid hydrogen over horizontal cylinders. Energies 2022, 15, 1044. [Google Scholar] [CrossRef]

- Hassani, M.; Kouhikamali, R. Heat and mass transfer modeling of R-245fa and R1233zd (E) with concurrent boiling and convective evaporation in falling film applications. Int. J. Refrig. 2020, 117, 181–189. [Google Scholar] [CrossRef]

- Wang, J.; Li, Y.; Wang, L.; Xia, S.; Ren, J.; Mao, H.; Xu, Y. Numerical investigation on subcooled pool film boiling of liquid hydrogen in different gravities. Int. J. Hydrogen Energy 2021, 46, 2646–2657. [Google Scholar] [CrossRef]

- Brackbill, J.U.; Kothe, D.B.; Zemach, C. A continuum method for modeling surface tension. J. Comput. Phys. 1992, 100, 335–354. [Google Scholar] [CrossRef]

- Reimann, M.; Grigull, U. Free convection and film boiling heat transfer in the critical region of water and carbon dioxide. Wärme-Stoffübertragung 1975, 8, 229–239. [Google Scholar] [CrossRef]

- Klimenko, V.V. Film boiling on a horizontal plate—New correlation. Int. J. Heat Mass Transf. 1981, 24, 69–79. [Google Scholar] [CrossRef]

- Berenson, P. Film-boiling heat transfer from a horizontal surface. J. Heat Transf. 1961, 83, 351–356. [Google Scholar] [CrossRef]

- Seo, H.; Bang, I.C. Revisiting the Rayleigh–Taylor instability and critical heat flux with R-123 for different heater sizes and pressures. Int. J. Therm. Sci. 2016, 100, 324–332. [Google Scholar] [CrossRef]

| Properties | Liquid | Gas |

|---|---|---|

| Density (kg/m3) | ||

| Thermal conductivity (W/mK) | ||

| Thermal capacity (J/kgK) | ||

| Viscosity (Pa.s) | ||

| Surface tension (N/m) | - | |

| Enthalpy of vaporization (J/kg) | - |

| Variable | Value (mm) | |

|---|---|---|

| 5 | 1/16 | |

| 20 | 1/4 | |

| 5 | 1/16 | |

| 15 | 3/16 |

| Case | (mm) | (mm) | Numin | Numax | Numean | Enhancement (%) |

|---|---|---|---|---|---|---|

| Casexb1 | 5 | 5 | 2.9 | 4.2 | 3.6 | 13.5 |

| Casexb2 | 7.5 | 5 | 1.8 | 4.8 | 3.3 | 4.1 |

| Casexb3 | 10 | 5 | 3.8 | 5.9 | 4.8 | 53.6 |

| Casexb4 | 12.5 | 5 | 3.4 | 5.7 | 4.5 | 44.5 |

| Casexb5 | 15 | 5 | 3.1 | 5.6 | 4.3 | 37.5 |

| Casexb6 | 17.5 | 5 | 2.4 | 3.6 | 3.0 | −5.9 |

| Casexb7 | 20 | 5 | 2.6 | 3.8 | 3.2 | 0.6 |

| Caseyb1 | 10 | 7.5 | 3.6 | 5.9 | 4.8 | 50.8 |

| Caseyb2 | 10 | 10 | 3.5 | 5.9 | 4.7 | 48.4 |

| Caseyb3 | 10 | 12.5 | 2.5 | 4.3 | 3.4 | 47.9 |

| Caseyb4 | 10 | 15 | 3.4 | 5.9 | 4.6 | 47.6 |

| Case | (mm) | Numin | Numax | Numean | Enhancement (%) |

|---|---|---|---|---|---|

| Caselb1 | 5 | 1.6 | 4.8 | 3.2 | 0.9 |

| Caselb2 | 10 | 1.8 | 5.6 | 3.7 | 46.6 |

| Caselb3 | 15 | 3.8 | 5.8 | 4.8 | 52.8 |

| Caselb4 | 20 | 3.8 | 5.9 | 4.8 | 53.6 |

| Caselb5 | 25 | 3.8 | 5.9 | 4.9 | 54.2 |

| Caselb6 | 30 | 3.8 | 6.0 | 4.9 | 55.2 |

| Caselb7 | 35 | 3.8 | 6.0 | 4.9 | 55.8 |

| Caselb8 | 40 | 3.8 | 6.2 | 5.0 | 57.4 |

| Caselb9 | 45 | 3.8 | 6.2 | 5.0 | 57.5 |

| Caselb10 | 50 | 3.8 | 6.3 | 5.0 | 59.5 |

| Caselb11 | 55 | 3.8 | 6.3 | 5.0 | 59.6 |

| Caselb12 | 60 | 3.8 | 6.3 | 5.1 | 61.0 |

| Case | (°) | Numin | Numax | Numean | Enhancement (%) |

|---|---|---|---|---|---|

| Caseβ1 | 5 | 3.5 | 6.1 | 4.8 | 52.1 |

| Caseβ2 | 10 | 3.2 | 5.9 | 4.6 | 45.5 |

| Caseβ3 | 15 | 3.5 | 4.5 | 4 | 27.2 |

| Caseβ4 | 20 | 3.7 | 4.6 | 4.1 | 31.6 |

| Caseβ5 | 25 | 3.8 | 4.6 | 4.2 | 34.7 |

| Caseβ6 | 30 | 3.8 | 4.5 | 4.2 | 32.6 |

| Caseβ7 | 35 | 3.8 | 3.9 | 3.9 | 23.1 |

| Caseβ8 | 40 | 2.5 | 3.1 | 2.7 | −13.5 |

| Caseβ9 | 45 | 2.3 | 2.6 | 2.5 | −21.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sarikaya, O.M.; Kuzay, M.; Yilmaz, S.; Demirel, E. Development and Optimization of a Micro-Baffle for the Enhancement of Heat Transfer in Film Boiling. Energies 2024, 17, 5224. https://doi.org/10.3390/en17205224

Sarikaya OM, Kuzay M, Yilmaz S, Demirel E. Development and Optimization of a Micro-Baffle for the Enhancement of Heat Transfer in Film Boiling. Energies. 2024; 17(20):5224. https://doi.org/10.3390/en17205224

Chicago/Turabian StyleSarikaya, Onur Muhammed, Mustafa Kuzay, Sibel Yilmaz, and Ender Demirel. 2024. "Development and Optimization of a Micro-Baffle for the Enhancement of Heat Transfer in Film Boiling" Energies 17, no. 20: 5224. https://doi.org/10.3390/en17205224

APA StyleSarikaya, O. M., Kuzay, M., Yilmaz, S., & Demirel, E. (2024). Development and Optimization of a Micro-Baffle for the Enhancement of Heat Transfer in Film Boiling. Energies, 17(20), 5224. https://doi.org/10.3390/en17205224