Methodology for Testing Selected Parameters of Low-Current Vacuum Electric Arc

Abstract

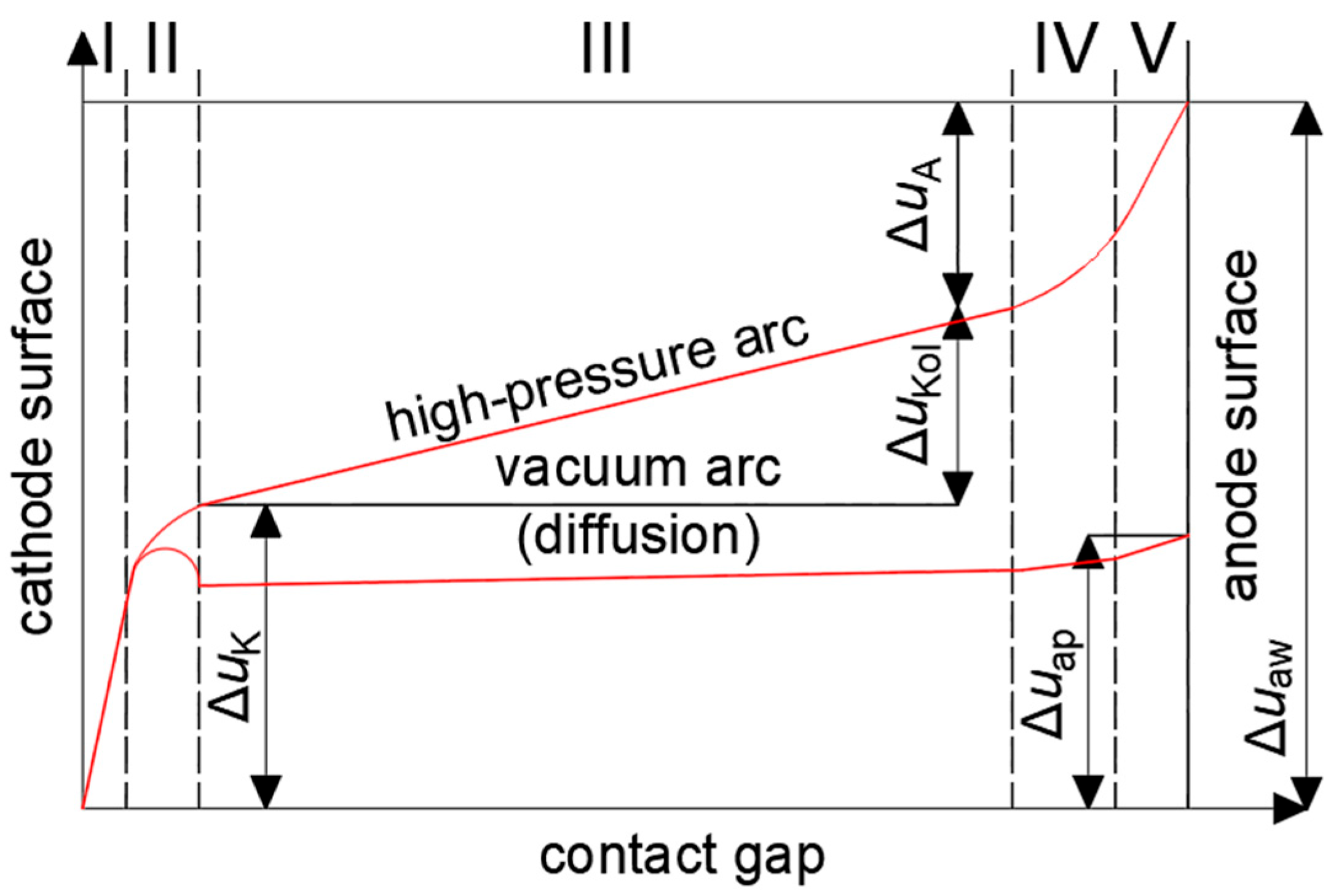

1. Introduction

- the source and type of current carriers;

- concentration and free path of molecules;

- arc voltage;

- the dependence of the form of the discharge on the value of the arc current;

- thermodynamic equilibrium.

- analysis of late breakdowns occurring after current interruption in vacuum interrupters [11].

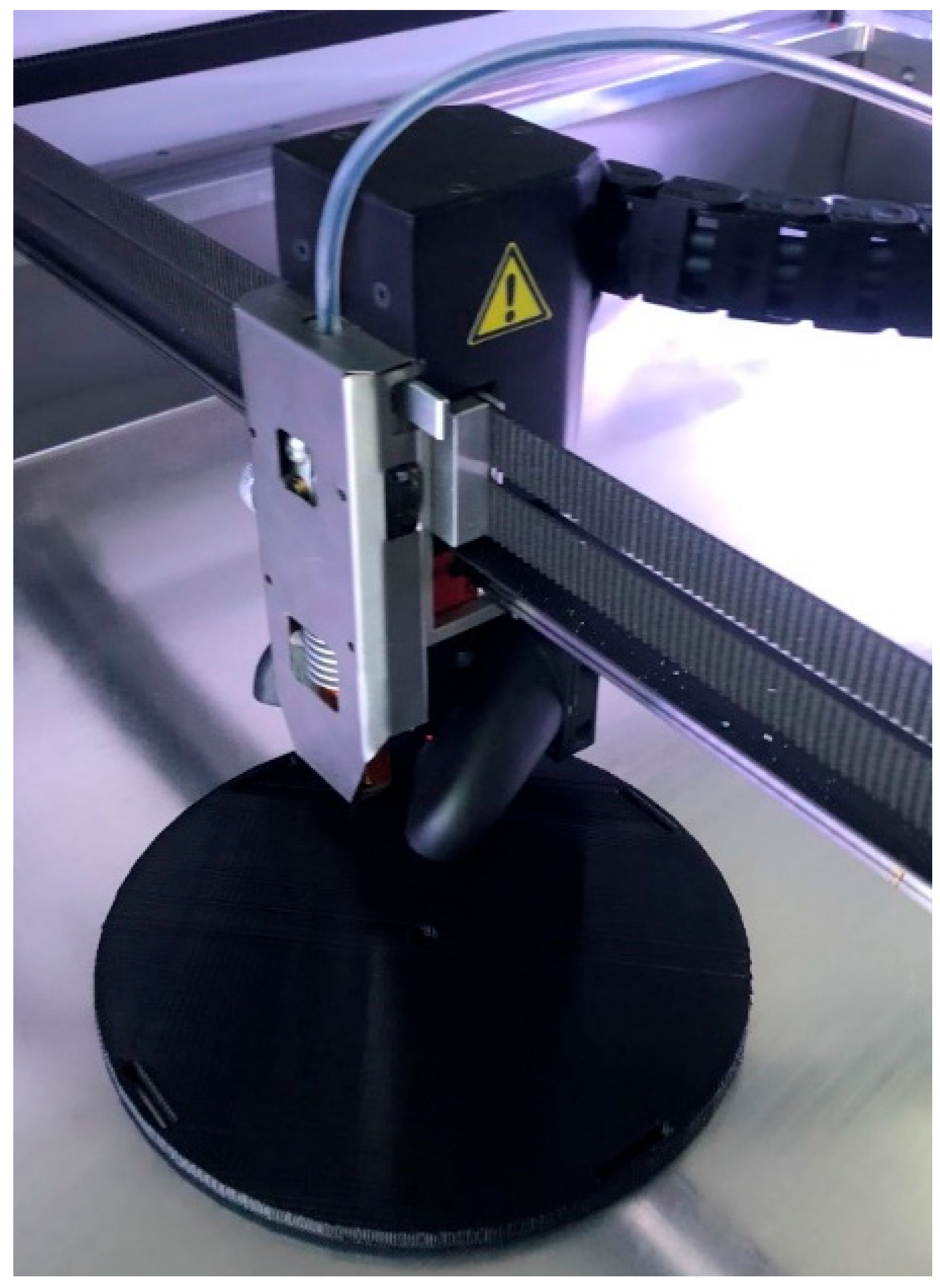

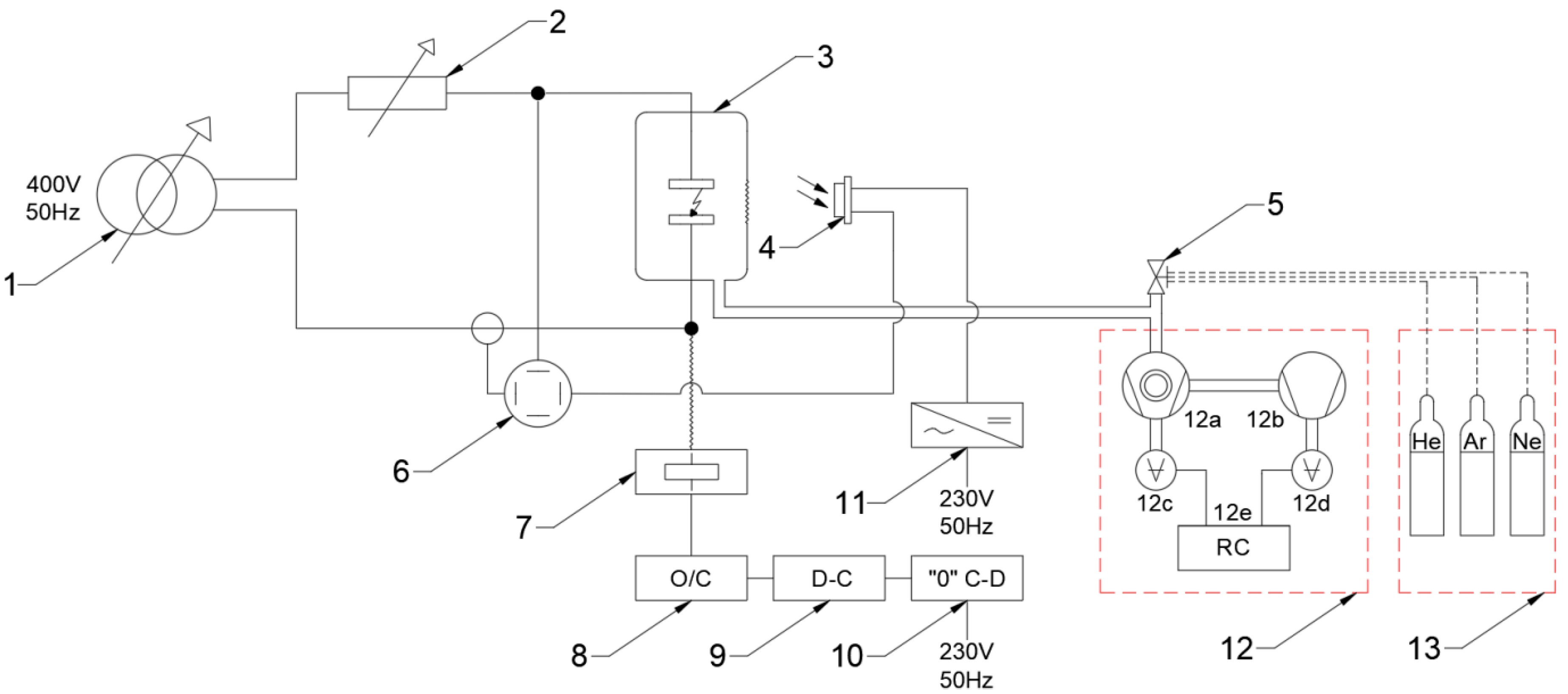

2. Test Stand and Research Object

- Oscilloscope with a set of measuring probes, which makes it possible to measure the current and voltage of the electric arc burning between contacts during switching operations;

- a system based on a photodiode with a wavelength in the 420–675 nm range and a viewing angle of 100°, which was designed and then fabricated to record the burning time of an electric arc between contacts. A schematic of the electronic circuit allowing the signal to be read from the photodiode is shown in Figure 6, while the electrical parameters of the circuit components are shown in Table 2.

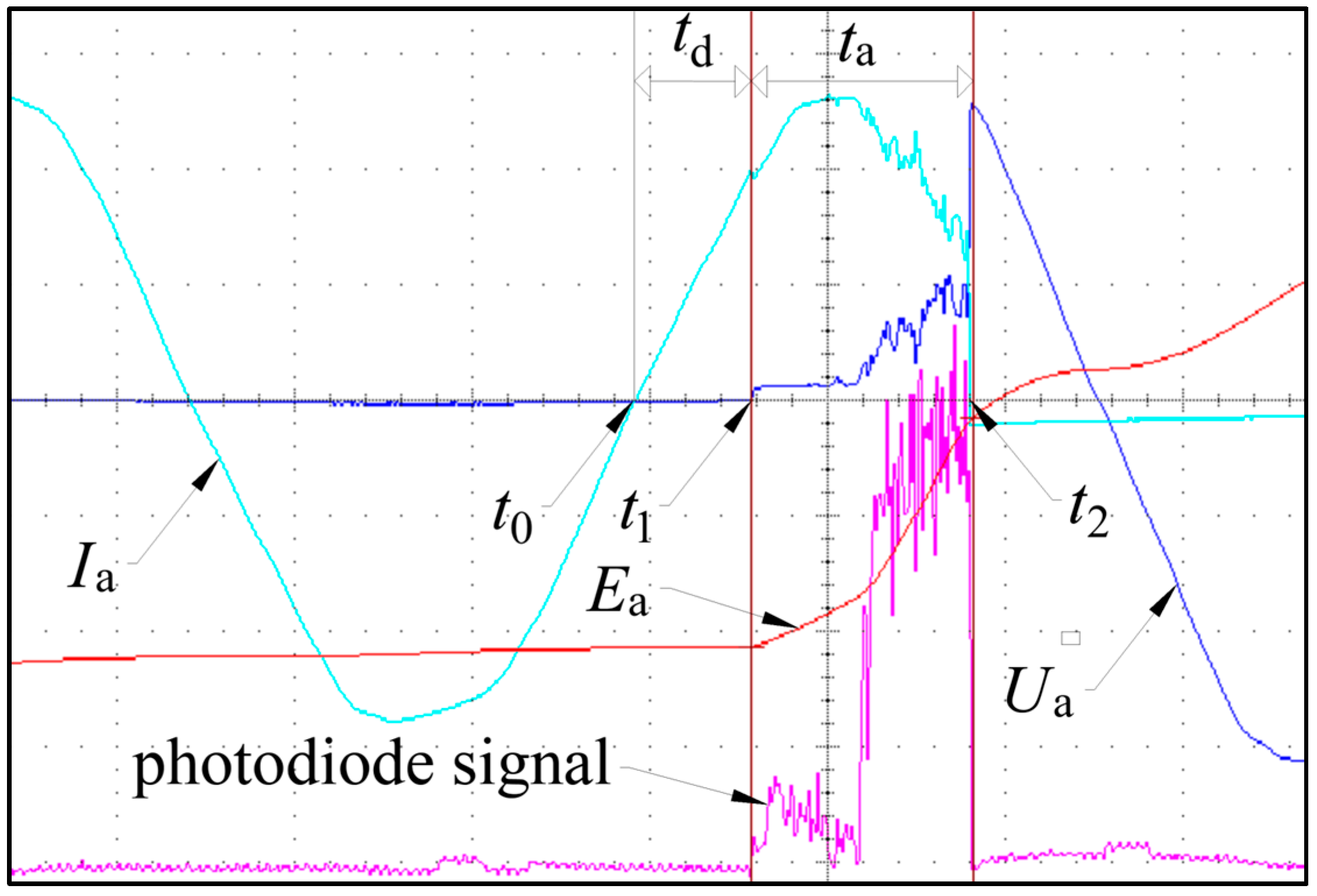

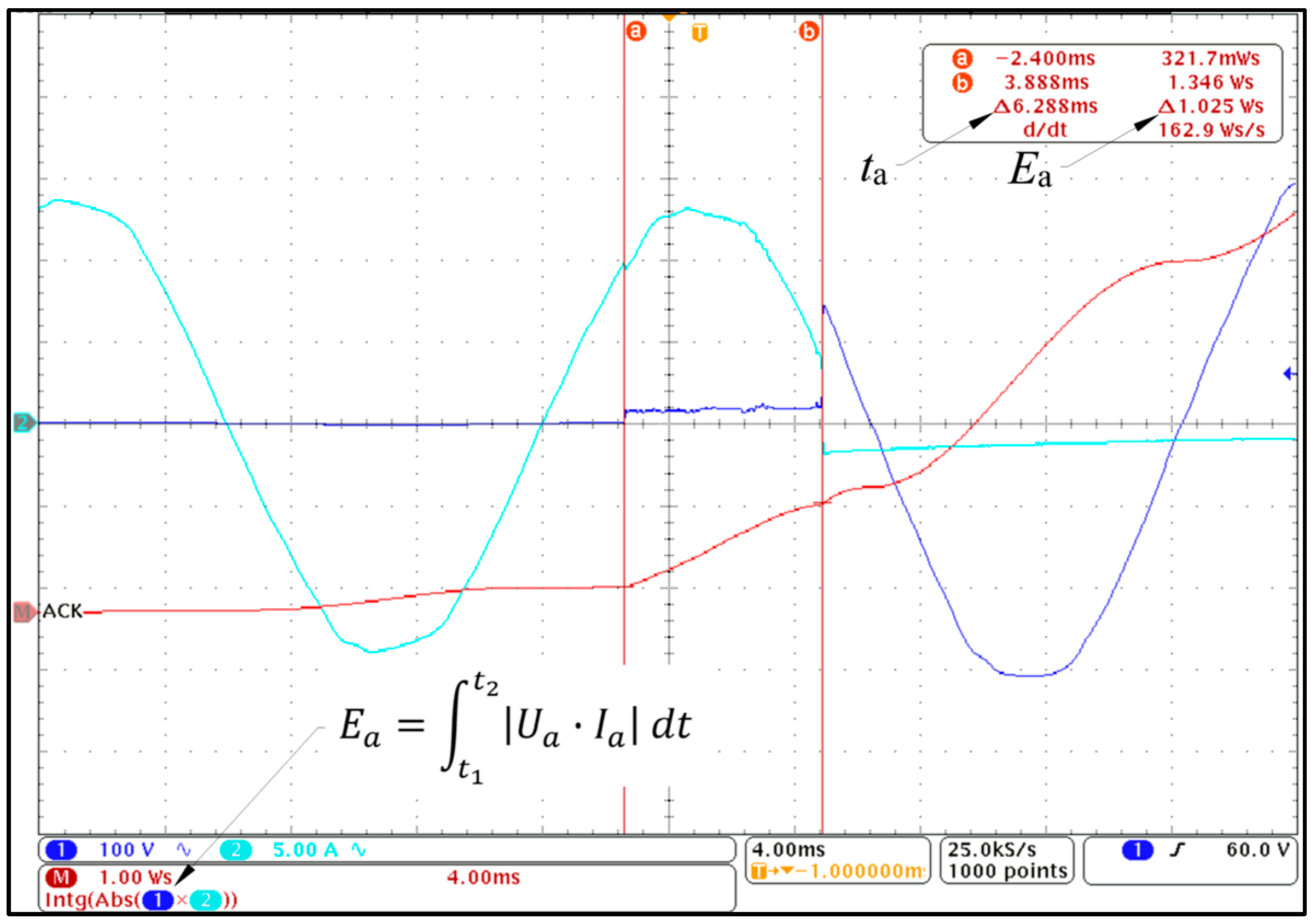

3. Research Methodology

- arc energy Ea;

- arc burning time ta.

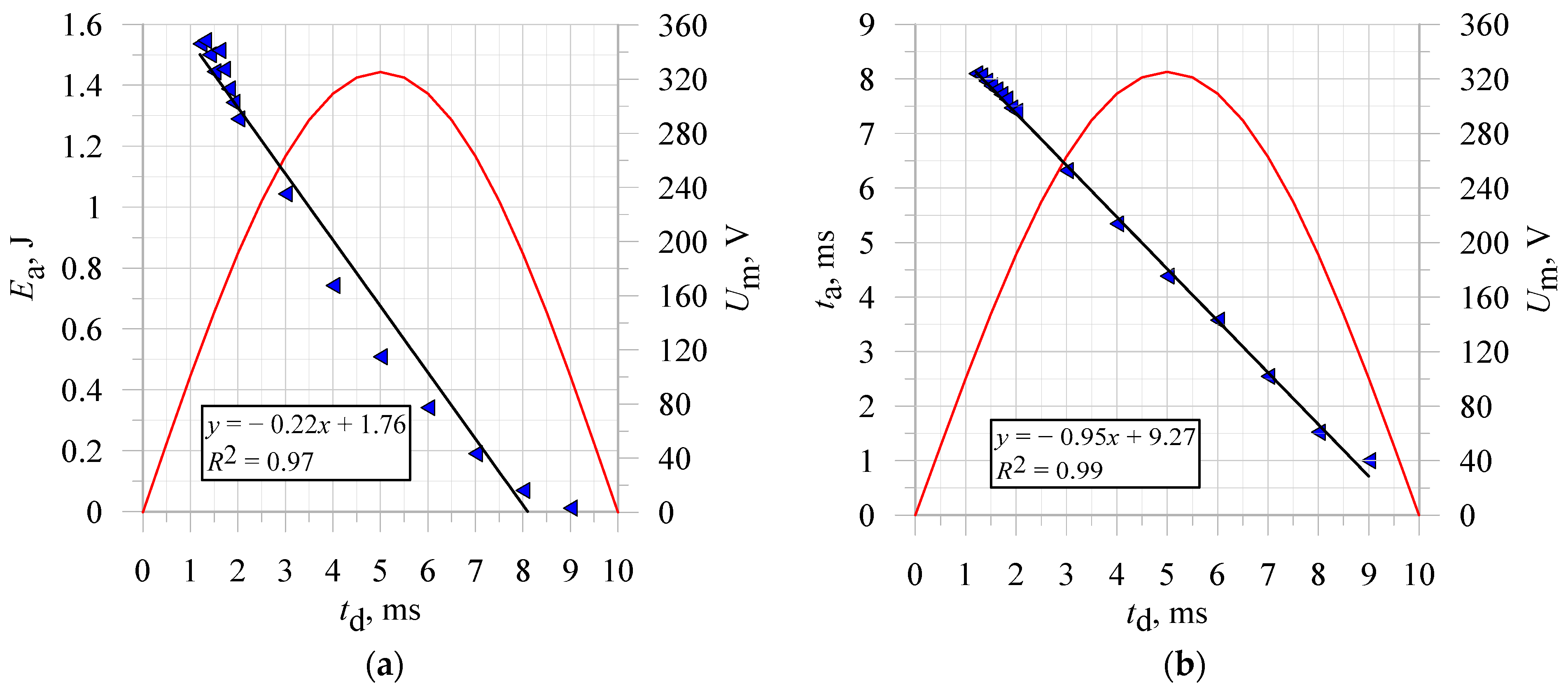

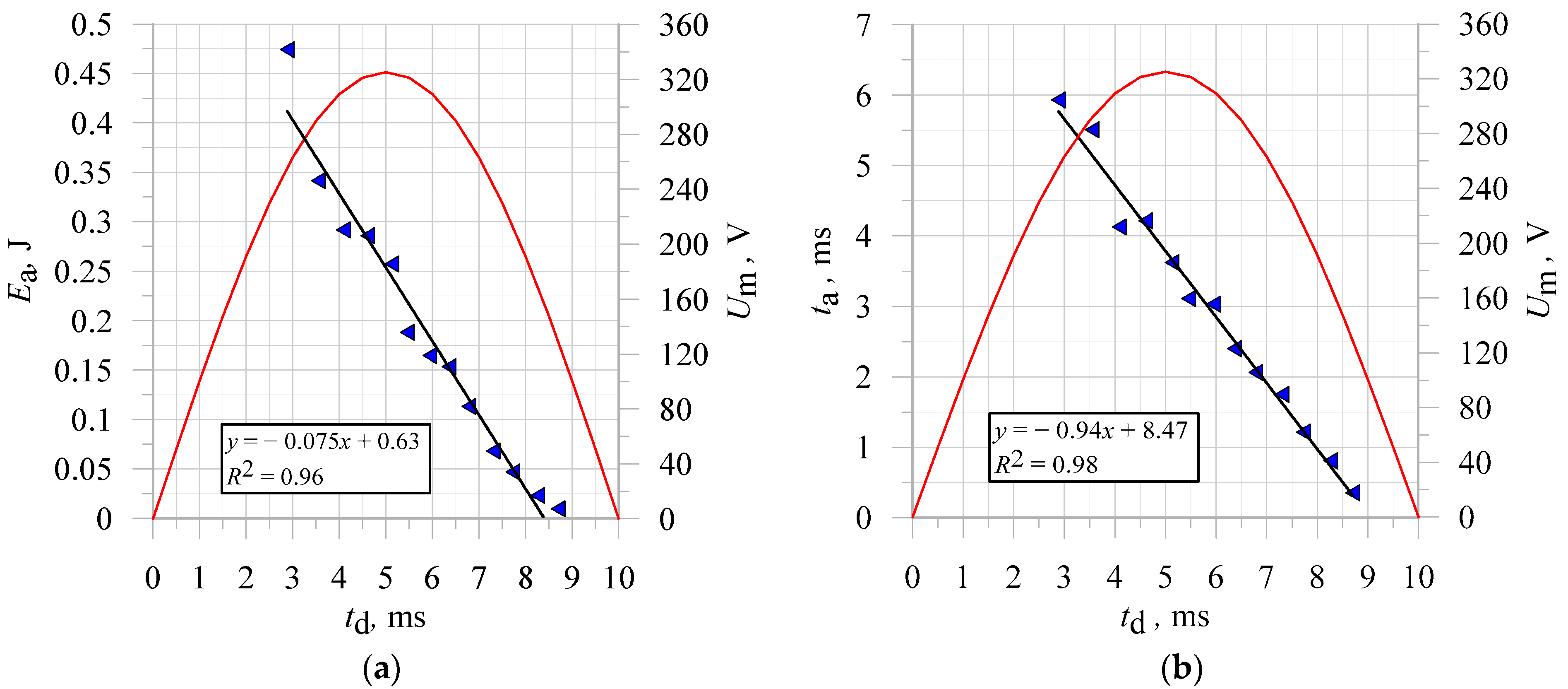

4. The Effect of the Delay in the Ignition Time of a Vacuum Electric Arc on Its Parameters

5. Conclusions

- the maximum arc energy for atmospheric pressure (p1 = 1.00 × 105 Pa) was about 1.55 J, and its burning time was about 8 ms;

- the maximum arc energy for the high vacuum environment (p2 = 4.00 × 10−3 Pa) was about 0.50 J, and its burning time was about 6 ms;

- for atmospheric pressure, the arc ignites after a delay time of about 1.2 ms from the passage of the current sine wave through zero, and as it increases, the arc energy and burning time decrease;

- for a high vacuum environment, arc ignition occurs after a time equal to about 3 ms, and as it increases, the arc energy and burning time also decrease.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Maksymiuk, J. Aparaty Elektryczne; Wydawnictwa Naukowo-Techniczne: Warszawa, Poland, 1992. [Google Scholar]

- Klajn, A. Właściwości Dyfuzyjnego Wyładowania Łukowego w Próżni w Warunkach Wymuszonego Wyłączania Prądu; Oficyna Wydawnicza Politechniki Wrocławskiej: Wrocław, Poland, 2006. [Google Scholar]

- Kordus, A. Plazma: Właściwości i Zastosowania w Technice; Wydawnictwa Naukowo-Techniczne: Warszawa, Poland, 1985. [Google Scholar]

- Slade, P.G. The vacuum Interrupter: Theory, Design, and Application; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar]

- Gembarzhevskii, G.V. An Approach to Plasma Wake Studying. JMP 2015, 6, 46–57. [Google Scholar] [CrossRef]

- Lech, M.; Węgierek, P. Breakdown Initiation and Electrical Strength of a Vacuum Insulating System in the Environment of Selected Noble Gases at AC Voltage. Energies 2022, 15, 1154. [Google Scholar] [CrossRef]

- Gentsch, D.; Gorlt, K. High speed Observation of vacuum arcs between different contact diameter at TMF contact pair. In Proceedings of the 29th International Symposium on Discharges and Electrical Insulation in Vacuum (ISDEIV), Padova, Italy, 26–30 September 2021; pp. 177–180. [Google Scholar] [CrossRef]

- Jing, H.; Yang, J.; Pang, X.; Xiu, S. Simulation of vacuum arc cathode spot movement between transverse magnetic field contacts. AIP Adv. 2021, 11, 015324. [Google Scholar] [CrossRef]

- Guan, C.; Yao, X.; Zheng, J.; Zuo, X.; Li, X.; Liu, Z.; Wang, J.; Geng, Y. A Relationship Between Vacuum Arc Characteristics and Short-Circuit Current Interrupting Capability at Minimum Arcing Times. IEEE Trans. Plasma Sci. 2022, 50, 2670–2680. [Google Scholar] [CrossRef]

- Liu, S.; Ma, H.; Hu, F.; Liu, F.; Geng, Y.; Liu, Z.; Wang, J. Vacuum Arc Evolution Characteristics in Low-Voltage DC Current Interruption Under Composite Transverse Magnetic Fields. IEEE Trans. Plasma Sci. 2021, 49, 3927–3934. [Google Scholar] [CrossRef]

- Yan, W.; Wang, Z.; Cao, Z.; Li, H.; Sun, L.; Wang, J. Particle Generation, Their Behavior and Effect on Post-Arc Breakdowns After Capacitive-Current Vacuum Arc Interruption. IEEE Trans. Power Deliv. 2022, 37, 4303–4314. [Google Scholar] [CrossRef]

- Cao, Z.; Li, R.; Cao, B.; Yan, W.; Sun, L.; Wang, J.; Geng, Y.; Wang, Z. Hybrid plasma modeling of the interaction between the vacuum arc jet and the hot metallic particle near the current zero. Phys. Plasmas 2022, 29, 113512. [Google Scholar] [CrossRef]

- Ejiri, H.; Kumada, A.; Hidaka, K.; Taguchi, Y.; Inada, Y.; Yamano, Y.; Iwabuchi, H.; Kaneko, E. Late Breakdowns Caused by Microparticles After Vacuum Arc Interruption. IEEE Trans. Plasma Sci. 2019, 47, 3392–3399. [Google Scholar] [CrossRef]

- Gentsch, D.; Gorlt, K. Vacuum Interrupters Equipped with TMF Contacts and Contact Material Different from Each Other; a Study under Short Circuit Current Conditions and High-Speed Arc Observation During Current Interruption. In Proceedings of the 28th International Symposium on Discharges and Electrical Insulation in Vacuum (ISDEIV), Greifswald, Germany, 23–28 September 2018; pp. 595–598. [Google Scholar] [CrossRef]

- Hotta, K.; Inaguchi, T. Contact Welding Mechanism With Bounce Arc on Ag and Cu Contacts in Low-Voltage Switches. IEEE Trans. Compon. Packag. Manufact. Technol. 2017, 7, 363–370. [Google Scholar] [CrossRef]

- Huang, X.; Sun, T.; Wu, Y.; Yang, S.; Zhao, L.; Ning, W.; Wang, L. Study of vacuum arc plasma transport characteristics during the DC interrupting process. J. Phys. D Appl. Phys. 2022, 55, 165501. [Google Scholar] [CrossRef]

- Jia, S.; Shi, Z.; Wang, L. Vacuum arc under axial magnetic fields: Experimental and simulation research. J. Phys. D Appl. Phys. 2014, 47, 403001. [Google Scholar] [CrossRef]

- Jiang, F.; Wu, Y.; Wu, Y.; Cui, Y.; Rong, M.; Sun, H.; Long, C. Experimental investigation on the erosion behavior in high-current vacuum arcs and resulting microparticles dynamics. J. Phys. D Appl. Phys. 2021, 54, 395201. [Google Scholar] [CrossRef]

- Kim, B.-C.; Kim, S.T.; Ahn, K.Y.; Kim, Y.G. A study on electrical lifespan of VI by means of calculation of arc energy during arcing time in synthetic tests. In Proceedings of the 3rd International Conference on Electric Power Equipment—Switching Technology (ICEPE-ST), Busan, Republic of Korea, 25–28 October 2015; pp. 81–84. [Google Scholar] [CrossRef]

- Li, S.; Yamano, Y.; Geng, Y.; Liu, Z.; Wang, J.; Zhang, C. A Method to Analyze Particle Induced Vacuum Breakdown with Obvious Field Emission Current. In Proceedings of the 29th International Symposium on Discharges and Electrical Insulation in Vacuum (ISDEIV), Padova, Italy, 26–30 September 2021; pp. 42–45. [Google Scholar] [CrossRef]

- Liao, M.; Ge, G.; Duan, X.; Huang, Z. A novel post-arc current measuring equipment based on vacuum arc commutation and arc blow. Meas. Sci. Technol. 2017, 28, 075901. [Google Scholar] [CrossRef]

- Logachev, A.A.; Poluyanova, I.N.; Zabello, K.K.; Barinov, Y.A.; Shkol’nik, S.M. Cathode Surface State and Cathode Temperature Distribution After Current Zero of Different AMF-Contacts. IEEE Trans. Plasma Sci. 2019, 47, 3516–3524. [Google Scholar] [CrossRef]

- Shi, W.; Wang, L.; Lin, R.; Deng, J.; Jia, S. Experimental investigation of triggered vacuum arc behavior under different TMF-AMF composite contacts. In Proceedings of the 4th International Conference on Electric Power Equipment—Switching Technology (ICEPE-ST), Xi’an, China, 22–25 October 2017; pp. 125–128. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Z.; Liu, J.; Zhou, Z.; Wang, J.; Geng, Y.; Liu, Z. Optical absorption spectroscopy of metallic (Cr) vapor in a vacuum arc. J. Phys. D Appl. Phys. 2018, 51, 035203. [Google Scholar] [CrossRef]

- Wang, L.; Shi, W.; Lin, R.; Wang, Y.; Ma, J.; Jia, S. Experimental Investigation of Vacuum Arc Behavior under Different Contacts in Vacuum Interrupters. In Proceedings of the 28th International Symposium on Discharges and Electrical Insulation in Vacuum (ISDEIV), Greifswald, Germany, 23–28 September 2018; pp. 223–226. [Google Scholar] [CrossRef]

- Wang, Z.; Yan, W.; Jiang, Y.; Li, Y.; Liu, J.; Wang, W.; Geng, Y.; Wang, J.; Liu, Z.; Sun, L. The effect and dynamic behavior of particles in high-current vacuum arc interruptions. J. Phys. D Appl. Phys. 2019, 52, 075205. [Google Scholar] [CrossRef]

- Slade, P.G. Criteria for the Application of Vacuum Interrupters in HVDC Circuit Breakers. In Proceedings of the 67th Holm Conference on Electrical Contacts (HLM), Tampa, FL, USA, 23–26 October 2022; pp. 1–7. [Google Scholar] [CrossRef]

- Slade, P.G. The Application of Vacuum Interrupters in HVDC Circuit Breakers. IEEE Trans. Plasma Sci. 2022, 50, 4675–4682. [Google Scholar] [CrossRef]

- Baeva, M.; Benilov, M.S.; Zhu, T.; Testrich, H.; Kewitz, T.; Foest, R. Modelling and experimental evidence of the cathode erosion in a plasma spray torch. J. Phys. D Appl. Phys. 2022, 55, 365202. [Google Scholar] [CrossRef]

- Santos, D.F.N.; Lisnyak, M.; Almeida, N.A.; Benilova, L.G.; Benilov, M.S. Numerical investigation of AC arc ignition on cold electrodes in atmospheric-pressure argon. J. Phys. D Appl. Phys. 2021, 54, 195202. [Google Scholar] [CrossRef]

- Ferreira, N.G.C.; Almeida, P.G.; Benilov, M.S.; Panarin, V.A.; Skakun, V.S.; Tarasenko, V.F.; Naidis, G.V. Computational and Experimental Study of Time-Averaged Characteristics of Positive and Negative DC Corona Discharges in Point-Plane Gaps in Atmospheric Air. IEEE Trans. Plasma Sci. 2020, 48, 4080–4088. [Google Scholar] [CrossRef]

- Ferreira, N.G.C.; Naidis, G.V.; Benilov, M.S. Simulation of pre-breakdown discharges in high-pressure air: II. Effect of surface protrusions. J. Phys. D Appl. Phys. 2021, 54, 255203. [Google Scholar] [CrossRef]

- Cunha, M.D.; Kaufmann, H.T.C.; Santos, D.F.N.; Benilov, M.S. Simulating changes in shape of thermionic cathodes during operation of high-pressure arc discharges. J. Phys. D Appl. Phys. 2019, 52, 504004. [Google Scholar] [CrossRef]

- Cunha, M.D.; Wenzel, N.; Almeida, P.G.C.; Hartmann, W.; Benilov, M.S.A. Simple Model of Distribution of Current Over Cathodes of Vacuum Circuit Breakers. IEEE Trans. Plasma Sci. 2019, 47, 3462–3469. [Google Scholar] [CrossRef]

- Benilov, M.S.; Kaufmann, H.T.C.; Hartmann, W.; Benilova, L.G. Revisiting Theoretical Description of the Retrograde Motion of Cathode Spots of Vacuum Arcs. IEEE Trans. Plasma Sci. 2019, 47, 3434–3441. [Google Scholar] [CrossRef]

- Cunha, M.D.; Hartmann, W.; Wenzel, N.; Benilov, M.S.; Almeida, P.G.C. Simulating Propagation of Spots over Cathodes of High-Power Vacuum Circuit Breakers. In Proceedings of the 28th International Symposium on Discharges and Electrical Insulation in Vacuum (ISDEIV), Greifswald, Germany, 23–28 September 2018; pp. 385–388. [Google Scholar] [CrossRef]

- Kaufmann, H.T.C.; Profatilova, I.; Popov, I.; Wuensch, W.; Benilov, M.S. Investigation of Vacuum Breakdown in Pulsed DC Systems. In Proceedings of the 29th International Symposium on Discharges and Electrical Insulation in Vacuum (ISDEIV), Padova, Italy, 26–30 September 2021; pp. 19–22. [Google Scholar] [CrossRef]

- Baeva, M. Reversal of the electric field and the anode fall in DC arcs in air during contact opening. J. Phys. D Appl. Phys. 2024, 57, 39LT01. [Google Scholar] [CrossRef]

- Baeva, M.; Boretskij, V.F.; Gonzalez, D.; Methling, R.; Murmantsev, O.; Uhrlandt, D.; Veklich, A. Unified modelling of low-current short-length arcs between copper electrodes. J. Phys. D Appl. Phys. 2021, 54, 025203. [Google Scholar] [CrossRef]

- Mohsni, C.; Baeva, M.; Franke, S.; Gortschakow, S.; Araoud, Z.; Charrada, K. Effect of a bidirectional coupling of an LTE arc column to a refractory cathode in atmospheric pressure argon. Phys. Plasmas 2020, 27, 073514. [Google Scholar] [CrossRef]

- Baeva, M.; Loffhagen, D.; Uhrlandt, D. Unified Non-equilibrium Modelling of Tungsten-Inert Gas Microarcs in Atmospheric Pressure Argon. Plasma Chem. Plasma Process. 2019, 6, 1359–1378. [Google Scholar] [CrossRef]

- Saifutdinov, A.I. Numerical study of various scenarios for the formation of atmospheric pressure DC discharge characteristics in argon: From glow to arc discharge. Plasma Sources Sci. Technol. 2022, 31, 094008. [Google Scholar] [CrossRef]

- Saifutdinov, A.I. Unified simulation of different modes in atmospheric pressure DC discharges in nitrogen. J. Appl. Phys. 2021, 129, 093302. [Google Scholar] [CrossRef]

- Lech, M.; Węgierek, P. Effect of selected parameters on the electrical strength of a high-voltage vacuum insulation system. Arch. Electr. Eng. 2023, 72, 597–611. [Google Scholar] [CrossRef]

- Lech, M. Disassemblable Vacuum Chamber as An Innovative Test Stand Designed for Research on Improving the Operational Parameters of Power Switching Apparatus. Inform. Autom. Pomiary Gospod. Ochr. Sr. 2020, 10, 66–69. [Google Scholar] [CrossRef]

- Florkowski, M.; Furgał, J.; Kuniewski, M.; Pająk, P. Overvoltage Impact on Internal Insulation Systems of Transformers in Electrical Networks with Vacuum Circuit Breakers. Energies 2020, 13, 6380. [Google Scholar] [CrossRef]

| Electrodes Material | Limit Voltage | Limit Current |

|---|---|---|

| V | A | |

| Cu | 12–13 | 0.40 |

| Ag | 12 | 0.40 |

| Au | 15 | 0.30–0.40 |

| W | 15–16 | 0.80–1.20 |

| Ni | 14 | 0.40–0.50 |

| Fe | 13–15 | 0.30–0.50 |

| C | 20 | 0.01–0.02 |

| Pt | 17 | 0.70–1.10 |

| Pd | 15–16 | 0.80–0.90 |

| Circuit Component | Value |

|---|---|

| R1 | 50 kΩ |

| R2 | 10 kΩ |

| R3 | 10 kΩ |

| C1 | 15 pF |

| C2 | 10 µF |

| C3 | 10 µF |

| C4 | 100 nF |

| C5 | 100 nF |

| p | Ea(max), J | ta(max), ms |

|---|---|---|

| p1 = 1.00 × 105 Pa | 1.55 | 8.00 |

| p2 = 4.00 × 10−3 Pa | 0.50 | 6.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lech, M.; Węgierek, P.; Kozak, C.; Pachulski, P. Methodology for Testing Selected Parameters of Low-Current Vacuum Electric Arc. Energies 2024, 17, 5101. https://doi.org/10.3390/en17205101

Lech M, Węgierek P, Kozak C, Pachulski P. Methodology for Testing Selected Parameters of Low-Current Vacuum Electric Arc. Energies. 2024; 17(20):5101. https://doi.org/10.3390/en17205101

Chicago/Turabian StyleLech, Michał, Paweł Węgierek, Czesław Kozak, and Przemysław Pachulski. 2024. "Methodology for Testing Selected Parameters of Low-Current Vacuum Electric Arc" Energies 17, no. 20: 5101. https://doi.org/10.3390/en17205101

APA StyleLech, M., Węgierek, P., Kozak, C., & Pachulski, P. (2024). Methodology for Testing Selected Parameters of Low-Current Vacuum Electric Arc. Energies, 17(20), 5101. https://doi.org/10.3390/en17205101