1. Introduction

In the power industry, with growing concerns over land resource scarcity and environmental pollution, the application of GIS using SF

6 as an insulating medium has been on the rise due to its compact and flexible design [

1,

2,

3,

4,

5]. However, during various stages, from manufacturing to operation, the introduction of various contaminants is inevitable [

6]. These contaminants include metal particles generated from the friction of internal metal components and foreign substances like metal debris and rubber particles introduced due to less stringent on-site installation procedures. The insulation level and operational reliability of GIS are significantly constrained by these defects, leading to frequent insulation failures. Moreover, extensive field test data indicate that nearly 28% of faults occur within seconds to minutes after switching operations [

7]. Laboratory studies have shown that the impact vibrations produced by circuit breaker operations can effectively trigger the mobilization of multiple latent microparticles within the GIS. These particles, which were previously stationary on the inner walls of the enclosure, may start to oscillate within the GIS chamber, potentially leading to insulation breakdown. Additionally, they may adhere to the surface of insulators, causing surface flashovers, thereby compromising the safe operation of the power grid [

8,

9,

10].

Academic research on the motion behavior of submillimeter particles began in the 1970s, initially focusing on the impact of dust on the breakdown voltage of air gaps. Japanese scholar Hiroshi Kuwahara was the first to explore particle motion behavior, conducting a study in 1978 on copper particles located at various positions within a GIS. His results indicated that under three types of voltage—AC voltage, impulse voltage, and AC voltage superimposed with impulse voltage—copper particles with a diameter of approximately 30 µm tended to either adhere to insulator surfaces or disperse within the gaseous medium [

11]. Building on Kuwahara’s work, Liu Shaojun and colleagues in 1988 reported similar findings using aluminum particles under DC voltage conditions [

12]. Entering the 21st century, the body of related research expanded significantly. Teams led by Liu Weidong and Li Qingmin conducted comprehensive studies on the motion behavior and discharge characteristics of submillimeter metal particles in GIS under various operating conditions. Their research covered areas such as visualization detection, high-sensitivity partial discharge measurement, motion-induced discharge mechanisms, and contamination prevention [

13,

14,

15]. However, these studies predominantly focused on homogeneous single particles, with limited research addressing nonmetal particles like fibers. Moreover, these studies did not explore the interaction between metal and nonmetal contaminants. However, in actual power equipment, contaminants originate from a wide variety of sources, involving complex formation mechanisms and exhibiting diverse physical characteristics. Consequently, there is a significant gap in research on mixed contaminants, particularly those primarily composed of submillimeter metal particles.

In recent years, scholars from North China Electric Power University, Xi’an Jiaotong University, and Tsinghua University have begun to focus on the effects of vibrations induced by switching operations on the motion of metal particles within GIS. Zhang Qiaogen’s team conducted simulations and experiments to investigate the jump patterns of metal particles under vibration excitation and analyzed the process of particle motion leading to gap breakdown [

9]. Ji Hongxin performed simulation analyses on the influence of casing vibrations on the motion behavior of linear particles on the casing surface and validated the simulation results through experiments [

16,

17]. Li Xing and colleagues developed an experimental platform that superimposes electric fields and impact vibrations to study the process by which metal particle motion induces surface flashover under the action of impact vibrations [

14,

18]. They also analyzed the partial discharge characteristics during this process, providing valuable insights for further research into the effects of impact vibration excitation.

This study constructed an experimental platform that superimposes AC voltage with impact vibrations to simulate the actual operating conditions during switching operations in GIS. The vertical impact vibrations were applied by striking the underside of a defect model with an impact hammer. The experimental subjects included submillimeter aluminum powder, millimeter-sized aluminum spheres, and rubber particles of varying sizes. Using this platform, we conducted a statistical analysis of characteristic voltages such as the initial jump voltage, stable jumping voltage, and extinction voltage of particles within GIS under the influence of impact vibrations. The influencing factors were examined from the perspective of charge accumulation and release. The findings of this study provide valuable insights into the understanding of insulation failures induced by complex particle defects associated with switching operations.

2. Materials and Methods

2.1. Experimental System

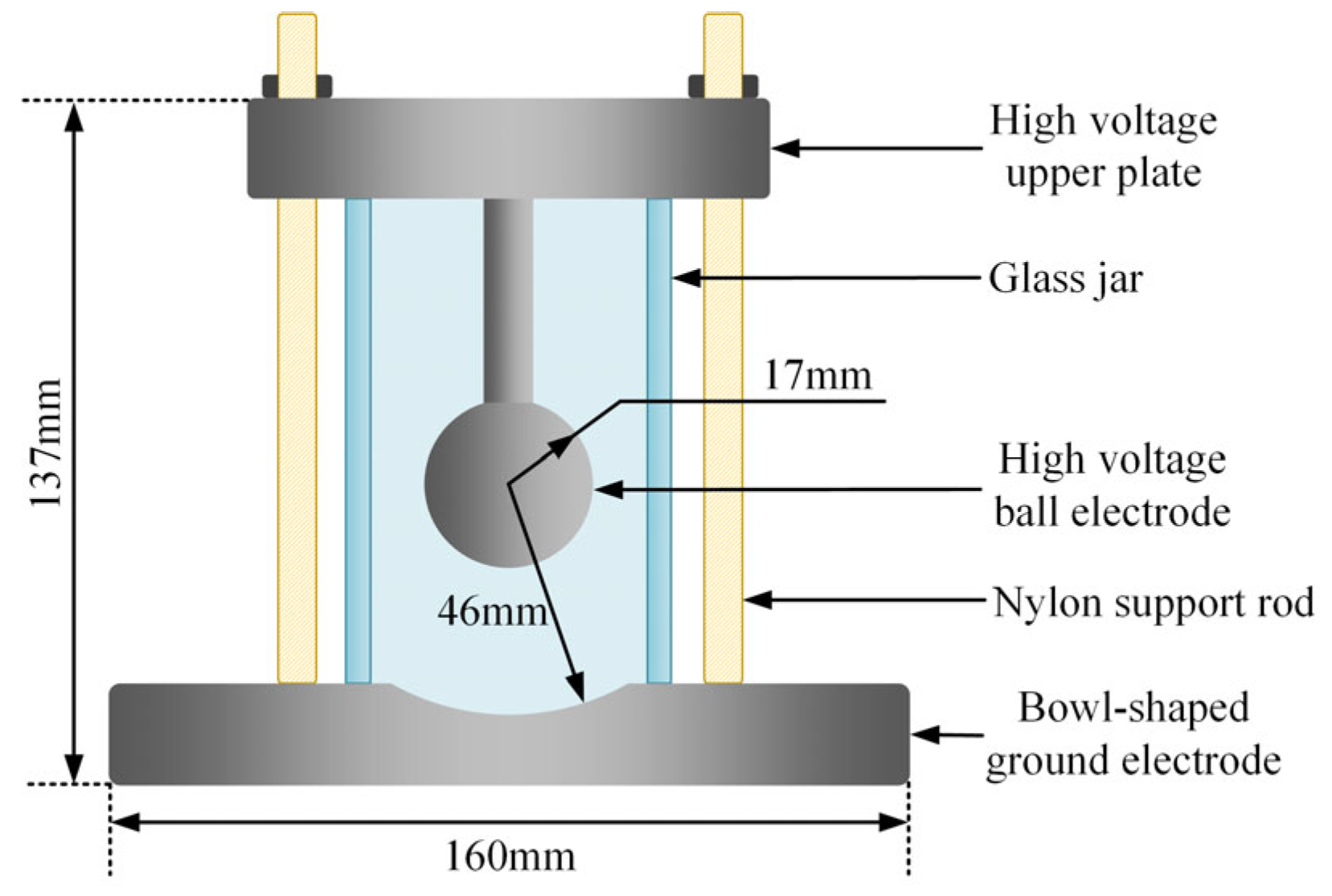

To replicate the electromechanical conditions during circuit breaker operations in GIS, a test platform capable of simultaneously generating AC voltage and impact vibration was constructed. This platform primarily consists of four components: a power frequency voltage application system, an impact vibration application system, a defect model, and a particle motion detection system, as shown in

Figure 1.

In the power frequency voltage application system, T1 functions as a voltage regulator, while the power frequency test transformer T2 (100 kV/10 kVA) (Sansion Power Electric, Wuhan, China) introduces the AC voltage to the upper electrode of the defect model. Resistors R1 and R2 serve as short-circuit protection resistors, safeguarding the transformer equipment from potential damage due to large short-circuit currents resulting from dielectric breakdown. The impact vibration application system utilizes an impact hammer to apply vertical vibrations to the defect model. The hammer is connected to an oscilloscope to record real-time vibration signals. The defect model is mounted on an insulating stand, with the upper electrode connected to the AC high voltage and the lower electrode grounded. In the particle motion detection system, a high-speed camera (SSZN SH3-108) (Shenzhen Sincevision Technology Co., Ltd., Shenzhen, China) equipped with a supplementary light source is employed to capture and document the movement characteristics of submillimeter metal particles. The camera is linked to a computer to enable real-time monitoring of particle motion behavior.

2.2. Electrode Modeling and Defects

The defect model consists of an equivalent structure comprising a spherical high-voltage electrode, a bowl-shaped ground electrode, a plexiglass tank, and nylon support columns to simulate an electric field environment resembling a coaxial cylindrical structure, as shown in

Figure 2. The overall height of the model is 137 mm, with the ground electrode having a diameter of 160 mm, the high-voltage spherical electrode having a diameter of 34 mm, and a spacing of 46 mm between the center of the sphere and the bowl-shaped ground electrode. During the experiment, a high-voltage wire is connected to the upper electrode to introduce AC voltage, while the bowl-shaped ground electrode is grounded. The plexiglass tank is sealed using nylon support columns and matching bolts and is filled with pure, dry SF

6 gas at a pressure of 0.45 MPa (absolute pressure).

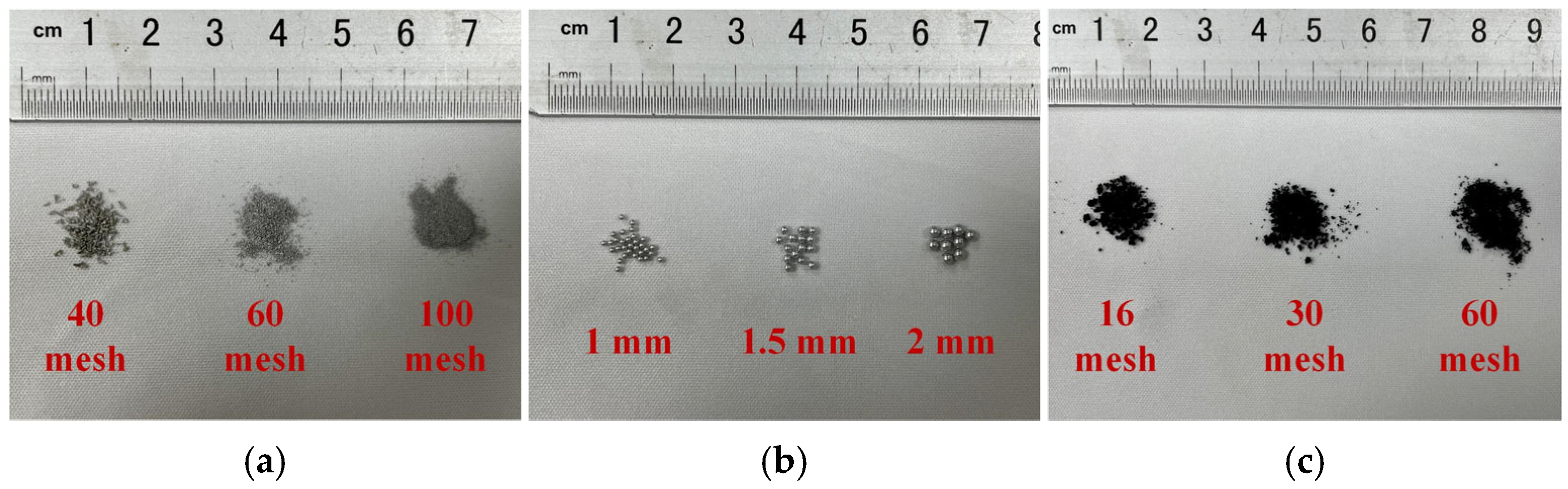

To simulate foreign objects generated in GIS due to factors such as the wear of disconnect switch contacts and inadequate cleaning of the gas chamber, irregular industrial aluminum powder, spherical aluminum particles, and rubber debris were selected as the test materials, as illustrated in

Figure 3. The industrial aluminum powder has particle sizes of 40 mesh, 60 mesh, and 100 mesh (380 μm, 250 μm, and 150 μm, respectively). The spherical aluminum particles are chosen with diameters of 1 mm, 1.5 mm, and 2 mm. Black synthetic rubber powder with particle sizes of 16, 30, and 60 mesh is used to simulate the debris generated from the wear of sealing materials and other insulating components in GIS.

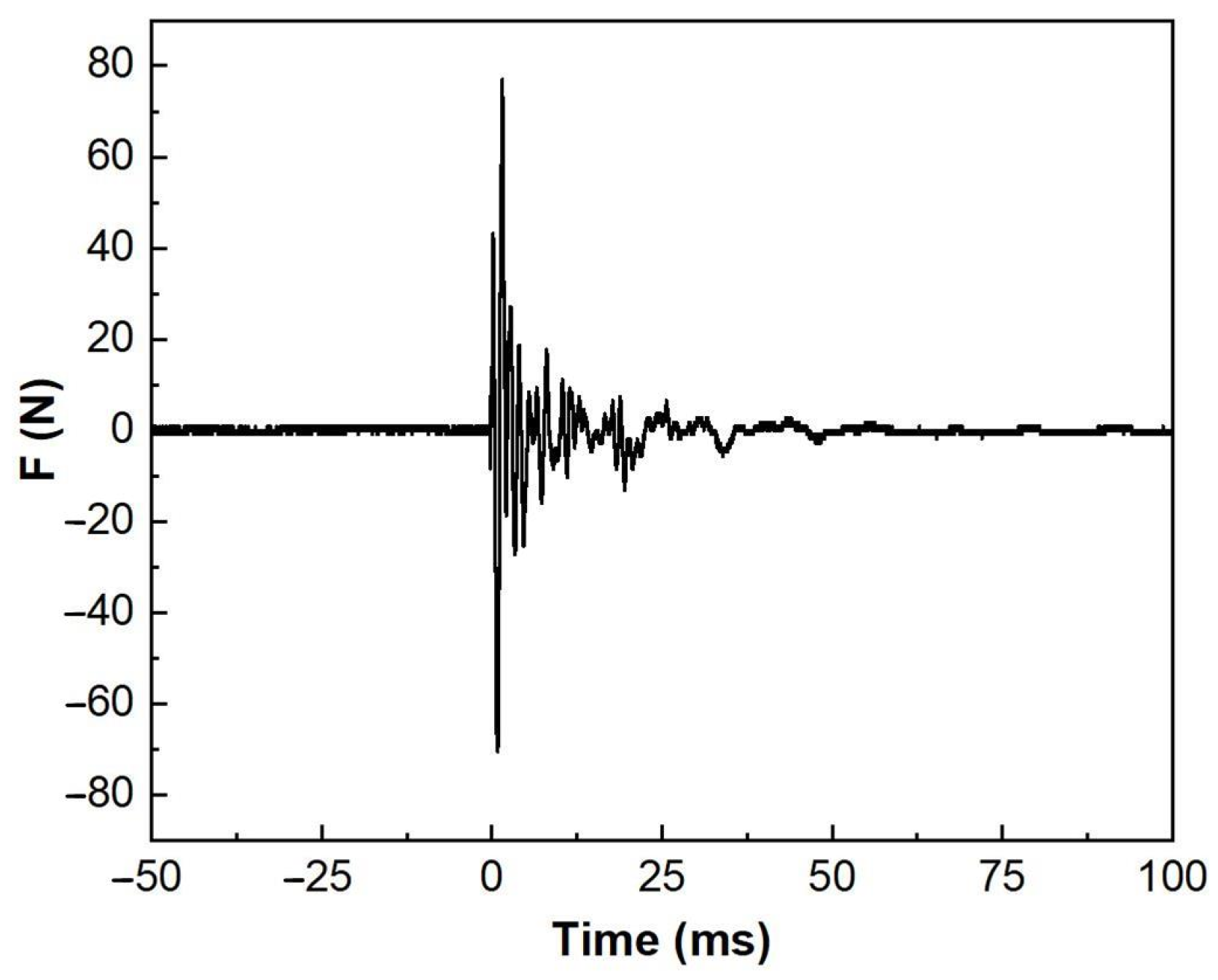

2.3. Impact Vibration Simulation

A modal impact hammer (SALC05KE) (Shiao Technology Co., Ltd., Wuxi, China) is utilized to generate impact vibrations perpendicular to the defect model. The hammer has a sensitivity of 1 mV/N, a measurement range of 5 kN, and a resonance frequency of ≥40 kHz [

8]. It is equipped with buffer heads made of four different materials: nylon, rubber, aluminum, and stainless steel. It can be observed that the waveform generated using the aluminum buffer head, in combination with a counterweight, closely replicates the vibration signal measured during the actual operation of a circuit breaker [

8]. Therefore, the aluminum buffer head is employed in this study, as shown in

Figure 4. Since the vibration amplitude can be monitored in real time using an oscilloscope, the magnitude of the impact vibration can be observed throughout the experiment. This real-time observation allows for minimizing absolute errors resulting from improper strikes of the impact hammer.

2.4. Experimental Methods

Under the combined influence of the electric field and impact vibration, the movement of submillimeter metal particles becomes intense. These particles may not only leap vertically towards the high-voltage electrode but also exhibit significant horizontal motion, scattering throughout the model cavity during multiple charge and discharge cycles. To prevent ablation marks and debris on the aluminum alloy electrode surfaces from affecting particle movement behavior, the experimental cavity is thoroughly wiped with silk cloth soaked in anhydrous ethanol prior to the experiment. Once the ethanol completely evaporates, the particles are placed in the center of the bottom electrode, and the cavity is evacuated before being filled with SF6 gas at 0.45 MPa. During the filling process, the airflow is carefully controlled to be smooth and steady to avoid affecting the distribution of the particles.

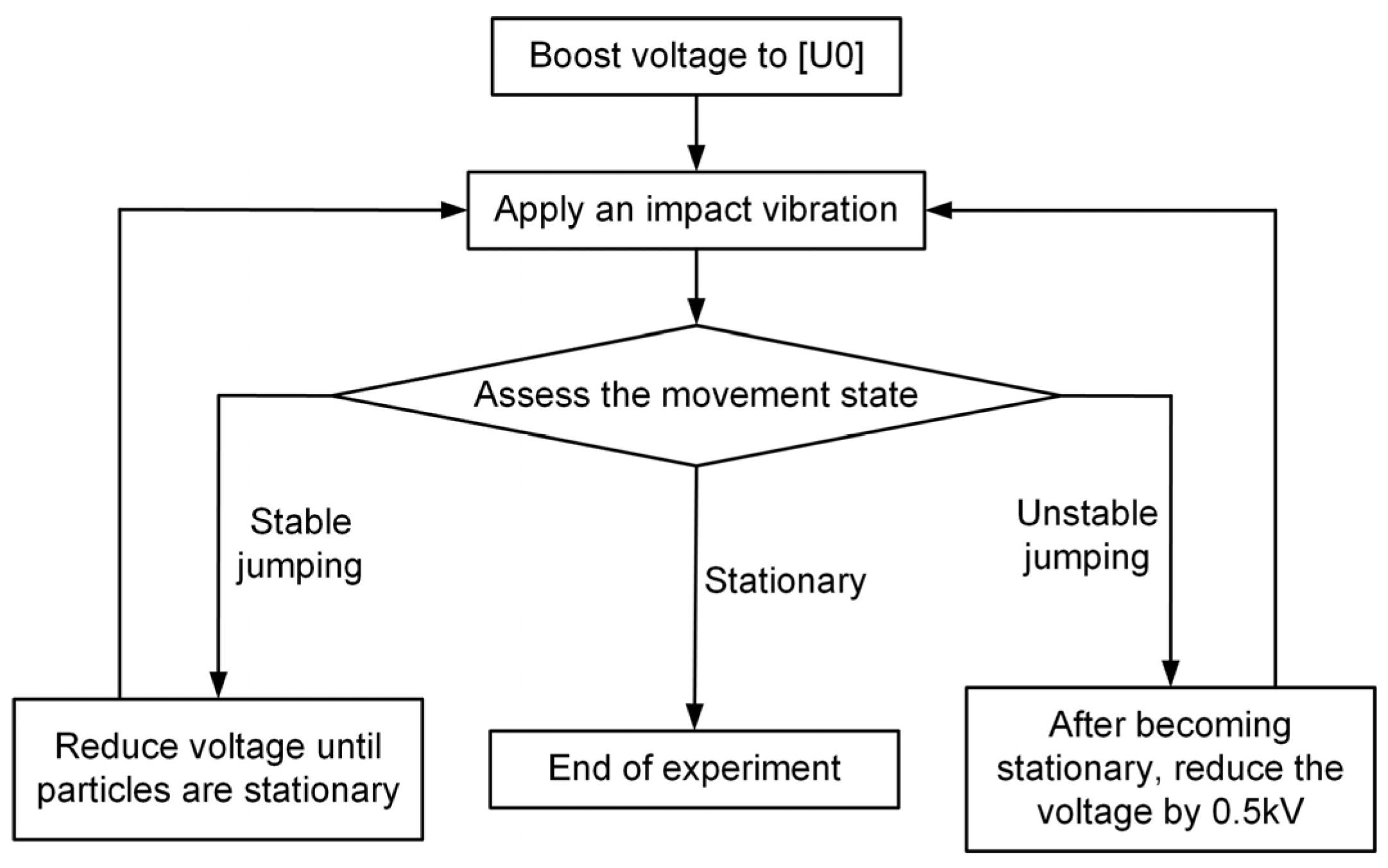

To simulate the initial movement characteristics of submillimeter particles under the impact vibrations generated during the operation of GIS circuit breakers, an experimental method based on three characteristic voltages—initial jumping voltage (Ui), stable jumping voltage (Us), and extinguishing voltage (Ue)—was designed. The initial jumping voltage is defined as the voltage at which the particles first leave their stationary state. The initial jumping voltage refers to the specific voltage at which particles, previously in a stationary state, begin to overcome the forces keeping them at rest and initiate movement. This voltage threshold marks the point where the electrostatic forces acting on the particles are strong enough to cause them to detach or dislodge from their initial position. The stable jumping voltage, on the other hand, is the voltage level at which particles transition from either a stationary or erratic, unstable motion to a continuous and consistent movement pattern. At this stage, the particles exhibit a stable and sustained motion, typically maintained for a period of at least one minute, indicating that a dynamic equilibrium has been reached between the forces acting on them. Finally, the extinguishing voltage is defined as the voltage at which particles that are in motion gradually slow down and eventually return to a stationary state. This transition from motion back to rest is sustained, with the particles remaining stationary for at least one minute. The extinguishing voltage represents the threshold below which the electrostatic forces are no longer sufficient to sustain particle motion, allowing them to settle once again.

The flowchart of the experiment is shown in

Figure 5. Prior to superimposing the impact vibration, a preliminary test is conducted to determine the stable jumping voltage U0 under normal conditions. During the experiment, the voltage is first increased to [U0], where the particles remain stationary. Then, a single vertical impact vibration is applied to the bottom electrode of the defect model. If the particles enter a stable jumping state, the voltage is reduced until the particles become stationary. If the particles enter an unstable jumping state, the voltage is reduced by 0.5 kV after the particles become stationary. This process is repeated until the particles remain stationary after the impact vibration is applied. The voltage at which stable jumping last occurs after applying the impact vibration is recorded as the stable jumping voltage under superimposed impact vibration. The voltage at which unstable jumping last occurs is recorded as the initial jumping voltage under superimposed impact vibration.

3. Results

3.1. Effect of Particle Size

During the operational processes of circuit breakers, submillimeter-sized metal particles of varying dimensions may be present within the cavities, posing a significant threat to the insulation of the power equipment. The specific surface area of these particles, which varies with size, can substantially influence the surface effects of irregular particles. Consequently, it is of paramount importance to investigate the initial phase characteristics of submillimeter metal particles of different sizes under impact vibration.

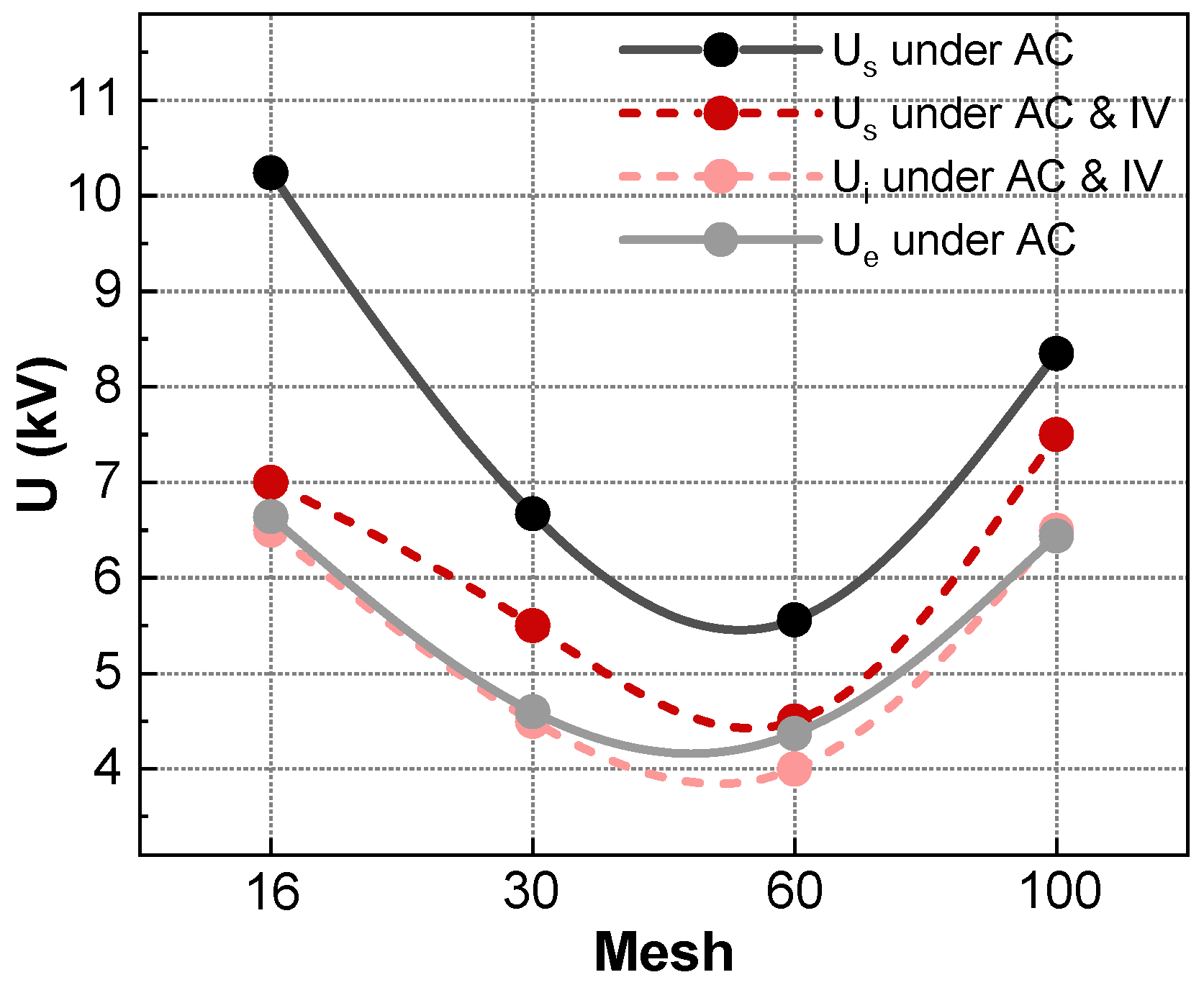

In this section, irregular aluminum particles with mesh sizes of 16, 30, 60, and 100 were selected as the research subjects, with a particle mass set at 0.01 g. Preliminary tests were first conducted to determine the stable jumping voltage

Us and extinguishing voltage

Ue of the particles under the influence of voltage alone. Subsequently, the experiments were performed according to the procedure illustrated in

Figure 5, recording the initial lift-off voltage

Ui and stable jumping voltage

Us of each particle type under the combined influence of AC voltage and impact vibration. The experimental results are presented in

Figure 6.

The experimental results reveal that as the particle size decreases, the initial lift-off voltage Ui, stable jumping voltage Us, and extinguishing voltage Ue all exhibit a trend of first decreasing and then increasing, reaching their maximum values at 16-mesh and 100-mesh particles and their minimum value at 60-mesh particles. This phenomenon, observed in both the initial lift-off and stable jumping voltages, can be attributed to the differing forces acting on particles of varying sizes. On the one hand, larger particles are more subject to Coulomb force, gravity, buoyancy, electric field gradient force, viscous drag, and supporting force, with the lift-off field strength generally satisfying the relation “”. Consequently, the lift-off voltage decreases with the reduction in particle size initially. On the other hand, when the interparticle distance is relatively small, van der Waals forces become predominant. As a result, the tendency for particle deposition and adsorption increases with further reduction in particle size, making the particles more prone to adhering to the aluminum bottom electrode. Additionally, the enhanced van der Waals forces among the particles within the powder heap may lead to the formation of a tightly bound “large particle”, further increasing the lift-off voltage.

Regarding the extinguishing voltage, this behavior can be explained by the residual charges on the particles. After the stable jumping phase between the electrodes ends, particles accumulate charges due to collisions and friction within the electric field. As the particle size decreases, the influence of gravity diminishes, requiring a more substantial reduction in the electric field strength to suppress the jumping tendency of the particles. However, with further size reduction, the adsorption effect induced by van der Waals forces causes an increase in the diffusion radius of the particles. If particles are adsorbed in the weak electric field regions farther from the center of the bottom electrode, they are more likely to transition from stable jumping to a stationary state, thereby causing the extinguishing voltage to rise.

The figure further illustrates that the stable jumping voltage significantly decreases after the addition of impact vibration, with reductions of 31.6%, 17.5%, 19.1%, and 10.2% observed for the 16-mesh, 30-mesh, 60-mesh, and 100-mesh particles, respectively. This trend indicates that as the particle size decreases, the effect of impact vibration on reducing the stable jumping voltage diminishes. In other words, larger particles are more susceptible to the influence of impact vibration, resulting in a more pronounced decrease in stable jumping voltage. From a force perspective, the dominant van der Waals forces in smaller particles enhance the adhesion between particles and between particles and the bottom electrode, thereby counteracting part of the impact vibration’s effect and leading to a less noticeable decrease in the stable jumping voltage for smaller particles.

Additionally, the figure reveals that, for the four types of particles examined in the experiment, the extinguishing voltage under the sole influence of AC voltage is closely comparable to the initial lift-off voltage when impact vibration is applied, with the difference being less than 0.4 kV. This observation suggests that, in contrast to the stable jumping voltage, the influence of impact vibration on the initial lift-off voltage is relatively consistent, effectively adjusting the voltage conditions from those favoring extinction to those promoting jumping.

3.2. Effect of Mixed Particle Types

In practical GIS systems, the residual metal contaminants are diverse in both type and origin. While submillimeter metal particles predominate, there may still be a mixture of larger particles, including centimeter-scale ones.

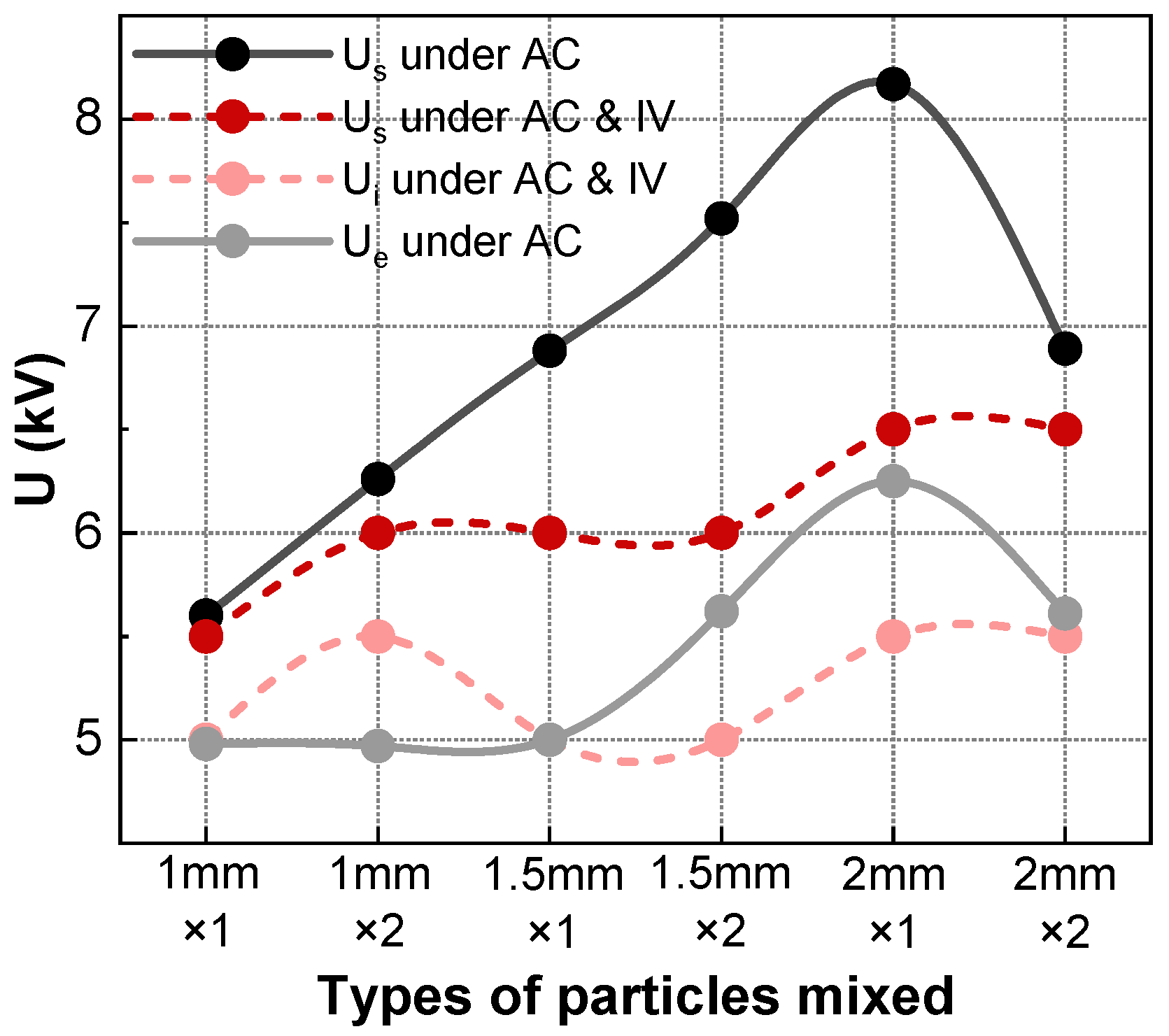

To investigate the initial motion characteristics of submillimeter metal particles when mixed with larger particles under impact and vibration, an experimental study was conducted. In this study, 1 or 2 spherical aluminum particles with diameters of 1 mm, 1.5 mm, and 2 mm were mixed into 0.01 g of 40-mesh industrial aluminum powder, following the method illustrated in

Figure 7.

The results, as shown in

Figure 7, reveal a discernible trend: with the exception of cases involving two 2 mm particles, there is a notable increase in all three characteristic voltages as the number and size of the mixed large particles increase. The most pronounced effect is observed in the stable jumping voltage under AC voltage, which rises significantly from an initial 5.6 kV to 8.17 kV, indicating that the presence of larger particles can markedly inhibit the submillimeter particles from entering a stable motion phase. Conversely, the trends in the first jump voltage and extinction voltage are less pronounced, suggesting that larger particles exert a greater influence during the development stage.

Furthermore, it is evident from

Figure 7 that, compared with the application of AC voltage alone, the addition of impact vibration results in a reduction in the stable jumping voltage, with the extent of reduction correlating positively with the number and size of the mixed particles. For instance, when one 1 mm particle was mixed, the voltage decreased by 18% from 5.6 kV to 5.5 kV, whereas with one 2 mm particle, the reduction was 20.4%, from 8.17 kV to 6.5 kV. This suggests that an increased quantity of mixed particles makes them more susceptible to the effects of impact vibration. The observed decrease in characteristic voltage when two 2 mm particles were mixed may be attributed to adhesion caused by the erosion of the large particles on the surface of the bottom electrode, leading to electric field distortion near the submillimeter particles and thus facilitating their easier initiation of motion.

On the other hand, the presence of nonmetal components, such as sealing structures in GIS, may lead to the introduction of rubber particles into the cavity. The interaction between these rubber particles and submillimeter metal particles could potentially impact the internal insulation structure of power equipment. To investigate this effect, this section employs 16-mesh irregular industrial rubber particles. Five sets of test materials with varying rubber content were prepared, as illustrated in

Figure 8.

Set A consists of 0.02 g of 40-mesh submillimeter metal particles, Set E contains 0.02 g of 16-mesh rubber particles, and Sets B, C, and D comprise mixtures of metal and rubber particles with a total mass of 0.02 g, and mass ratios of 3:1, 1:1, and 1:3, respectively. The experimental results are presented in

Figure 9.

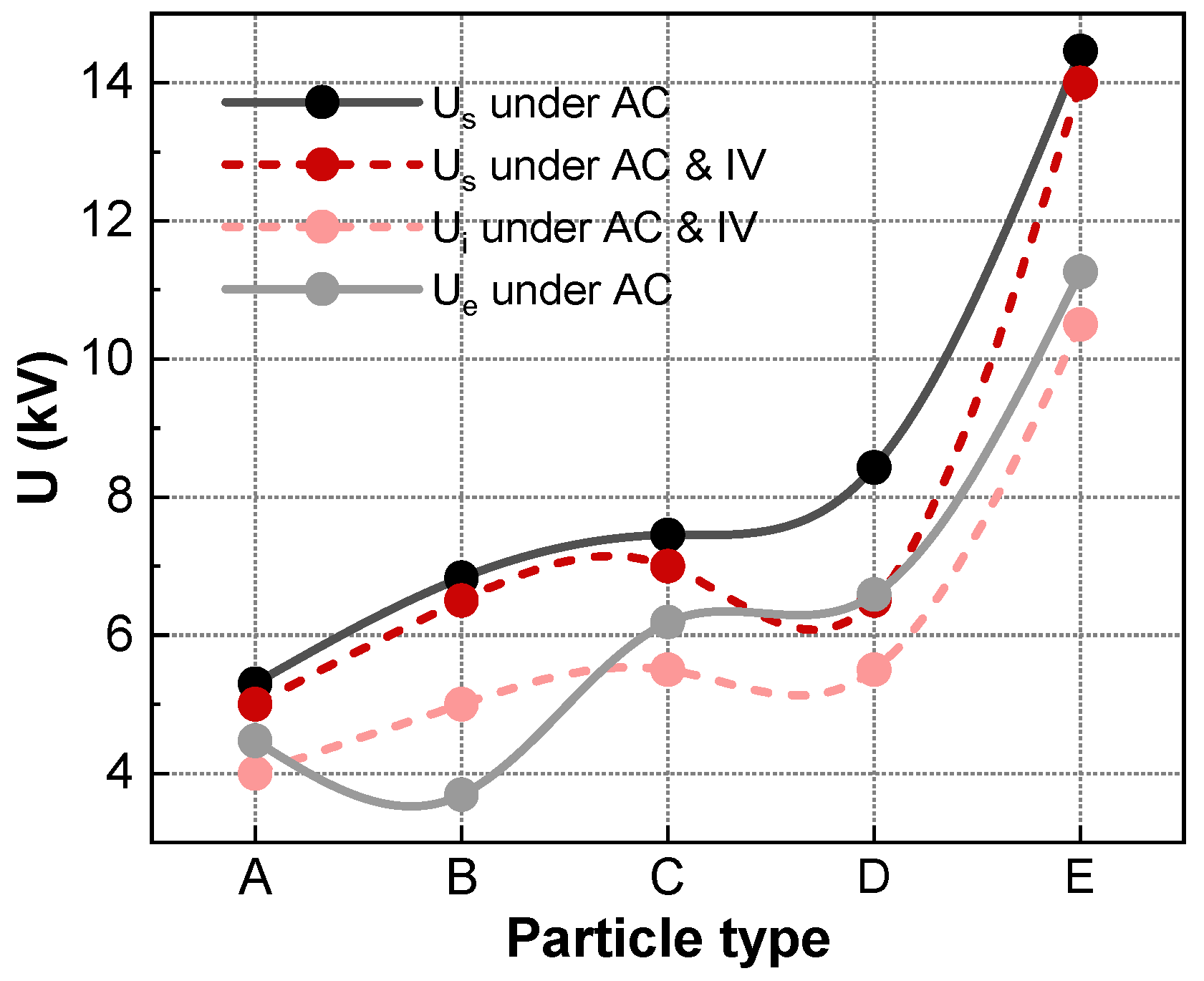

As observed in

Figure 9, with the increasing proportion of rubber particles in the test materials, all four characteristic voltages exhibit an upward trend, despite some fluctuations. Notably, the stable voltage under the application of AC voltage alone rises from 5.3 kV to 14.46 kV, and the extinction voltage increases from 4.47 kV to 11.26 kV. Although the stable jumping voltage decreases after the addition of impact vibration, the reduction is relatively minor. The experimental results for Set E indicate that rubber particles exhibit a jumping phenomenon similar to that of metal particles under the combined influence of an AC electric field and impact vibration. Additionally, the characteristic voltages of the rubber particles show significant dispersion during the experiments.

4. Discussion

Experimental results indicate that both particle size and the properties of mixed particles significantly influence the initial behavior of submillimeter metal particles under impact-induced vibration. Initially, the forces acting on the particles and their motion within a two-dimensional coordinate system are analyzed. At the outset, particles at rest on the bottom of the enclosure are subjected to Coulomb forces from the enclosure, electric field gradient forces, support forces, gravitational forces, and viscous drag.

Assuming the dust particles are ideal spheres, the gravitational force on a dust particle can be expressed as follows:

Various forces exerted by the fluid on particles include drag, buoyancy, and rotational resistance. For fine particles, fluid drag is typically the dominant force, while Brownian motion becomes significant only at the nanoscale. Drag is the force exerted by the fluid on a solid with a relative velocity, acting in the direction opposite to the motion of the solid. In fluid mechanics, the Reynolds number (Re) is a dimensionless quantity used to characterize the flow regime of the fluid. By estimating Re, the type of gas drag can be determined, and Re is defined as follows:

where

v is the relative velocity between the dust particle and the gas, assumed here to be 1 m/s, yielding an Re value of 2. For 1 < Re < 5, the drag force should be calculated using the Oseen approximation, and the formula for drag is as follows:

Van der Waals forces, originally referring to intermolecular forces, are increasingly used in the context of fine particles to describe the macroscopic attractive forces between closely situated particles due to molecular interactions. As a short-range force, van der Waals interactions are pivotal in particle agglomeration, surface deposition, and postcontact behavior. The van der Waals force between contacting dust particles can be expressed as follows:

where

w represents the work of adhesion between dust particles,

h is the separation distance between spherical dust particles, and

z0 is the equilibrium distance for van der Waals forces. When the dust particles are not in contact, the van der Waals force can be expressed as follows:

Electrostatic forces, in addition to fluid dynamics and van der Waals forces, are the most pervasive, possessing long-range characteristics and often being the dominant force. Consequently, they frequently determine the attraction of particles from far-field to near-field regions. In GIS, the electrostatic forces on dust particles generally comprise the electric field force

Fe under an external field and the Coulomb attraction or repulsion

F between charged dust particles. The relevant equations are as follows:

where

r is the distance between the centers of spherical dust particles, and

Q1 and

Q2 represent the charges carried by the two dust particles, respectively.

Based on the above analysis, the forces acting on submillimeter metal particles resting at the center of the bottom electrode under impact-induced vibration are illustrated in the figure. At this point, the particles will initially move upward with the enclosure at an acceleration a, maintaining the same velocity.

The impact-induced vibration acceleration generated by switching operations can be approximated as follows:

where

A is the acceleration amplitude of the impact-induced vibration signal,

t is the damping coefficient of the impact-induced vibration acceleration,

f is the vibration frequency, which is significantly higher than the power frequency, and

a is the initial phase.

During the upward motion, the acceleration a diminishes progressively. The frequency of change in a is much higher than that of the applied power frequency, suggesting that the variation in Coulomb force Fq on the metal particles lags behind the variation in the support force FN from the GIS enclosure. As the metal particles ascend, they reach a critical lift-off condition when the support force FN from the enclosure becomes zero, at which point they depart from the enclosure with an initial velocity, continuing their upward trajectory. This marks the conclusion of the initial phase of particle motion.

From a forces and energy perspective, the lift-off behavior of submillimeter particles is primarily governed by the balance of external forces and energy. For smaller particles, surface effects dominate, with van der Waals and electrostatic forces being relatively large, necessitating more energy to overcome these adhesive forces, thereby hindering lift-off. With increasing particle size, gravity and inertia grow, and although adhesive forces diminish, the kinetic energy required for lift-off escalates, making larger particles similarly challenging to lift. Intermediate-sized particles strike a balance between adhesive and inertial forces, requiring comparatively less energy, which facilitates lift-off. In the presence of large metal particles, the system’s overall mass and contact area increase, amplifying van der Waals forces and adhesion energy. This requires additional energy to overcome these forces, further complicating lift-off. Rubber particles, owing to their elastic properties, absorb some of the impact energy, while their high viscosity increases interparticle adhesion, further elevating the difficulty of lift-off. Overall, the presence of both large and rubbery particles reduces the characteristic voltage of submillimeter metal particles, which inhibits particle motion. Impact-induced vibrations increase the energy input frequency, with the additional vibrational energy modifying the critical conditions needed to overcome adhesive and support forces, thereby reducing the required characteristic voltage and facilitating particle lift-off.

5. Conclusions

This study investigates the initial motion characteristics of submillimeter metal particles in GIS under impact and vibration excitation, leading to the following conclusions:

As the particle size of submillimeter metal particles decreases, Us, Ui, and Ue initially decrease and then increase, forming a “U”-shaped curve. Us decreases significantly when impact vibration is superimposed. However, as the particle size decreases, the effect of impact vibration on reducing Us diminishes gradually. Ue under the application of AC voltage alone is similar to Ui when impact vibration is added.

Upon mixing with centimeter-scale large particles, the characteristic voltages all show a tendency to increase, with the most pronounced rise observed in Us under AC voltage. Conversely, the increases in Ui and Ue are less significant. After the addition of impact vibration, Us decreases, with the reduction magnitude increasing alongside the number and size of the mixed particles. When rubber particles are mixed in, the characteristic voltages exhibit an increasing trend. While Us decreases after the addition of impact vibration, the extent of this decrease is relatively minor.

The movement behavior of submillimeter metal particles is significantly inhibited by mixing centimeter-sized large particles and rubber particles, so more attention should be paid to latent discharge triggers for the formation of mixing defects.