Abstract

Expanding green areas in cities results in growth in green waste generation. This study presents the findings of an investigation into green waste from selective collection in a large Central European city (Warsaw, Poland), which can be identified as a valuable biomass resource. The research objective was to identify the properties of garden waste from single-family housing to determine valorization opportunities, emphasizing the utilization of GW as a source of energy. The research yielded several findings, including a notable degree of variability in fuel properties, including moisture content (CV = 30%), lower heating value (CV = 14.3%), and ash content (CV = 62.7/56.2%). The moisture content suggests composting, while the fertilizing properties indicate suitability for anaerobic digestion. The instability of the fuel properties, coupled with the elevated levels of chlorine, sulfur, and moisture, constrains the use of garden waste in thermal processes and alternative fuel production. Pyrolysis could be a viable approach for green waste feedstock, offering value-added products depending on the processing conditions and pre-treatment. Nevertheless, implementing a selective collection system is a critical condition for the optimal utilization of bio-waste, facilitating the quality and property control of green and food waste. This is essential for their effective processing, including energy recovery, thereby contributing to the efficient valorization of biomass.

1. Introduction

Due to their sustainable development, the expansion of green areas in cities [1,2] also results in an increase in the generation of green waste (GW), which has become an environmental concern [3,4,5].

Green waste (GW) encompasses biodegradable garden waste and public park waste [6]. The term is defined in the Waste Framework Directive, along with food waste, as part of the bio-waste stream [7]. As indicated by Hanc et al. [8], the majority of the average yearly bio-waste collected from family houses during different seasons consists of grass, leaves, wood, and plants, representing over 75% of the total. Green waste is an indispensable component of the biodegradable municipal solid waste (MSW) fraction, representing 12–15% of the total MSW generated [9,10]. Green waste is generated primarily due to maintenance operations in private home gardens and public green areas, including parks [11,12].

In 2022, the amount of MSW generated per person in the EU was 513 kg; thus, the average generation rate of green waste per capita in the EU can be estimated as 61.5–77.0 kg/capita/year [13]. A 10% increase in MSW generated was observed between 1995 and 2022, as evidenced by data from Eurostat. This trend also applies to green waste [14]. In Poland, in 2022, 2157 thousand Mg of green waste was generated, which constituted approximately 15.5% of all MSW. Based on current projections, this figure is expected to reach 2363.4 thousand Mg of green waste by 2040, corresponding to 15.4% of all MSW [15].

Among the main current challenges related to GW, the following should be pointed out: seasonal variability, which creates logistical and operational problems, including insufficient processing capacity during high-output periods, storage irregularities, storage and transport costs and difficulties (due to bulk density and humidity), lack of proper collection systems, limited market for compost, cost and economic viability, and contamination [4,16].

The composition and characteristics of green waste are highly variable and dependent upon a number of factors, including the source of the waste, the season, local climate conditions, and the waste management strategies employed [17,18]. The quality and composition of green waste vary significantly depending on the season. This was demonstrated in the study by Boldrin and Christensen [12], which revealed that garden waste from the summer consisted of over 90% grass clippings, flowers, and hedge cuttings, while the winter was characterized by a prevalence of woody materials. However, on average, over the course of a year, material in the form of branches and wood constituted up to 25% of green waste. The fluctuations in composition and physical shape that occur seasonally present significant challenges in terms of transportation, storage, and processing [19]. Seasonal fluctuations also impact the carbohydrate, lipid, and protein composition of green waste. Given that cell walls are primarily comprised of lignocellulose, the total carbohydrate content increases with plant maturation while the proportion of proteins and lipids declines [20].

The properties of GW are strongly influenced by their morphological composition, which can include a variety of organic materials, including grass, leaves, branches, flowers, bark, and twigs [2,21]. Coarse fractions, comprising elements such as branches and bark, are characterized by a high lignocellulose content and demonstrate reduced decomposition rates due to biological processes. Fine fractions, also termed herbaceous green waste, are primarily composed of leaves and grass clippings [5,19]. These fractions undergo biodegradation processes at a faster rate [22]. Green waste is frequently described as lignocellulosic waste [18]. The proportion of cellulose, hemicellulose, and lignin in green waste is dependent on the source material and the method of analysis. According to [4,19,21,23], the average percentage of these components in green waste is within the range of 25.3–57%, 11–55%, and 3–22%, respectively. The values provided in the study of Zhang and Sun [10] fall within the ranges of 25.3–57%, 11–55%, and 3–22%, respectively.

In the context of GW management (collection and processing), the physical and chemical characteristics of the waste are of great importance [16,24,25,26]. The bulk density of GW is typically within the range of 200 to 400 kg·m−3 [4,12]. The chemical properties of GW are primarily defined by the following parameters: total solids (TS%), volatile solids (VS%), moisture content (MC%), elemental composition (percentages of C, N, and P in TS), and the C/N ratio [12]. The values of these parameters fall within the following range: The TS content was found to be 60.1%, while the VS ranged from 51.7% to 76.5%. The carbon (C) content was observed to be between 43.9% and 47%, while the nitrogen (N) content was noted to be between 0.56% and 1.02%. The phosphorus (P) content ranged from 0.1% to 0.21%. The C/N ratio was found to be within the range of 57 to 85. MC was found to be 28.7–46% [4,5,12,27]. It is also important to consider the fuel properties of GW. The literature includes research on the higher heating value (HHV), lower heating value (LHV), and ash content (AC) in GW. The HHV, LHV, and AC values were found to be in the ranges of 13.08–21.87 MJ·kg−1, 7.8–18.4 MJ·kg−1, and 5.1–43.4%, respectively [12,28,29,30,31]. In the context of processing and valorizing green waste, the content of proteins, fats, and sugars is also of great importance.

Currently, the dominant methods of valuable processing of GW are composting, co-composting [24], and different technological variants of use for energy production [19]. Technologies for the energetic use of GW include methane fermentation [21], dark fermentation [32], alcoholic fermentation [21], combustion [33,34], and pyrolysis [28]. Thermochemical processes represent a promising approach for utilizing GW, which frequently demonstrates enhanced physical and chemical characteristics in comparison to the conventional feedstocks employed as alternative fuels. As indicated by Hasan et al. [28], the pyrolysis of GW at varying time intervals (slow, fast, and flash pyrolysis) allows for the production of 52.8% bio-oil, 23.7% synthesis gas, and 21.5% biochar. Furthermore, there is a growing interest in utilizing carbonization for GW [35] and ethanol production [2,36]. As demonstrated in the aforementioned papers, the maximum yield for GW was observed in terms of dry matter (DM), reaching 267.1 mL·g−1 DM for biogas and 84 l·Mg−1 DM for ethanol. In a separate study [32], dark fermentation was identified as a noteworthy technique for GW processing. The biohydrogen yield from GW ranges from 36 mL3·g−1 DM (without pre-treatment) to 97 mL H2·g−1 DM (with pre-treatment in the form of combined hydrolysis), with an average yield of 66 mL H2·g−1 DM of GW. The predominant method for producing carbonized herbaceous biomass is hydrothermal carbonization (HTC) [19,22]. This process utilizes water as a reaction medium, rendering it an optimal choice for treating wet biomass without pre-drying, which is a requisite step in pyrolysis and gasification [22,37]. The principal products of HTC are hydrochar, process water, and gas.

In Poland, as in other countries of the region, over 90% of green waste is currently processed using composting technology [15]. In parallel with the growth of the circular economy [38] and the pursuit of enhanced GW valorization, novel technologies for extracting value from green waste are emerging [19]. Nevertheless, a review of the literature on GW reveals that its potential still needs to be explored [16]. The quantity and quality of collected GW and the costs associated with implementing technical-scale processes frequently present obstacles to implementing more complex solutions [36]. Therefore, each decision regarding the feasibility of implementing a specific technological strategy must be based on an in-depth analysis of local conditions, including assessing the quantity and quality of potential recovered GW valorization technologies. Consequently, certain systems propose the combination of GW with other substrates, including food waste [16,27,39] and sewage sludge [10,35,40,41]. Furthermore, the pre-treatment technique strategy is also significant [19].

This study presents the findings of a quantitative and qualitative investigation into GW from the selective collection in Warsaw. The technological properties of GW from single-family housing developments were examined. The objective of the research was to determine the technological characteristics of GW as a feedstock for valorization processes, with a particular focus on its potential as an energy source. In particular, this paper seeks to address significant data gaps and examine the status of GW in urbanized areas with a developing system of source separation of bio-waste (as part of the MSW management system). Such research is of great importance in the ongoing expansion of green areas in urbanized regions, both globally and in Poland. This has increased to GW, which, along with the excessive and rising levels of MSW recycling targets in all European Union (EU) countries, represents a significant challenge for individual municipalities and cities. This study is concerned with analyzing quantitative and qualitative data on green waste, with the objective of identifying opportunities for developing sustainable energy sources, enhancing biomass valorization, and implementing circular economy principles within municipal systems. The novelty of this study lies in filling data gaps on the technological properties of GW, with particular emphasis on fuel characteristics, as well as in the detailed examination of their variability and implications for energy recovery processes.

2. Materials and Methods

2.1. Tested Waste and Organization of Research

The research is comprised of two distinct components: basic and supplementary research.

The basic research was conducted on GW from the gardens of single-family houses in Warsaw. The samples were typical GW, representing a heterogeneous mixture comprising mainly grasses of various species composition and smaller quantities of leaves, small branches, twigs, flowers, soil particle residues, wood, and bark. The samples were obtained from locations exhibiting disparate levels of sunlight.

Sampling was conducted between April and November 2023. This aligns with the typical vegetation period in Poland, as documented in [42,43]. The research was conducted in 16 measurement series, with two samples taken per month. Under regulation on maintaining cleanliness and order in the capital city of Warsaw, which constitutes an act of local law, GW was collected separately from other municipal bio-waste [44]. The frequency of collection of GW from the property is as follows: every two weeks from March to November and every four weeks from December to February. The entire research cycle was comprised of four research periods, designated RP1–RP4 (RP1: April/May, RP2: June/July, RP3: August/September, RP4: October/November). A single company was engaged to collect the GW, which originated from the same designated collection routes. The waste was collected twice a week from single-family buildings following the MSW collection schedule in Warsaw. The GW was collected from 740 households in the Bielany and Żoliborz districts of Warsaw (57 collection routes), inhabited by 2586 people [45].

The initial stage of the study involved collecting a daily sample, with a mass of approximately 100 kg, at the base of the collection company. The waste was mixed and subjected to a process of averaging. A 10 kg sample was subsequently subjected to further analysis through the quartering method. GW was subjected to a series of tests to ascertain their fertilizing and fuel properties and chemical composition. The methodologies employed are outlined in Section 2.2.

A supplementary research campaign was conducted whereby individual fractions of GW were collected selectively from home gardens and divided into four fractions: leaves, grass, branches, and cones. The properties from which GW was collected were not equipped with home composters. The precise botanical identity of the plants was not known. GW was collected selectively as part of a controlled measurement campaign from 80 households from August to November 2023. The GW was collected over a two-week period in a manner analogous to that employed in the series of basic research campaigns. A total of eight samples of GW were collected.

The photographs of the tested GW fractions are presented in Figure 1.

Figure 1.

Photos of the tested GW fractions: (a) leaves, (b) grass, (c) cones, (d) branches.

Subsequently, samples of GW and individual fractions of GW were transported to the laboratory and subjected to drying in a dryer at 105 °C until a constant mass was achieved, determining the moisture content (MC). Subsequently, each sample was blended in a laboratory setting until the particle size was reduced to less than 1 mm. The powdered form of GW was then employed for further studies. This methodology has previously been employed by the authors of this research in bio-waste studies [45,46].

The following parameters were determined for the GW samples: moisture content (MC), organic matter content (volatile solids, VS), dry matter basis (DM and total solids, TS), total organic carbon (TOC), nutrients (N, P), combustible parts (CP), ash content (AC) as non-combustible parts, volatile matter in combustible parts (VM in CP), higher heating value (HHV), and elemental analysis (C, H, S, N, Cl, O as % CP). The C/N, C/P, and lower heating values (LHVDM, LHVAR) were calculated following the methodology described in Section 2.2.

2.2. The Analytical Methods

The research methods employed are under the generally accepted standards for laboratory tests of MSW. The following research standards were employed: EN 15002 [47] and VDI 4630 [48], which set out the procedures for sampling. The samples were prepared for analysis following the subsequent EN standards: 14346 [49] (determination of the dry residue and the water content), 13137 [50] (determination of total organic carbon (TOC) in waste, sludge, and sediment), 15169 [51] (determination of loss on ignition of waste, sludge and sediments) and PN-Z-15011 [52] (content of organic substances, organic carbon, nitrogen, phosphorus in biowaste). The concentration of lipids, proteins, and carbohydrates was analyzed in accordance with the methodology proposed by Alibardi and Cossu [53] using the official methods outlined by the AOAC [54]. The volatile matter in the combustible parts was analyzed following the procedures outlined in [55,56,57]. This entailed subjecting the prepared GW sample to a seven-minute heating period in a measuring crucible at 800 °C, after which the mass loss was determined under these conditions.

The higher heating value (HHV) represents the total enthalpy change when a compound is burned by the stoichiometric ratio at a reference temperature, with no water present in the liquid state. The standard unit for HHV is MJ·kg−1 DM. The HHV can be determined by calculation based on elemental analysis or by direct measurement in a bomb calorimeter [56]. In this study, the HHV was determined using a bomb calorimeter under the UNE-EN ISO 9831:2004 [58] standard method, as detailed in the procedure described by Arenas et al. [59]. In contrast to the HHV, the lower heating value (LHV) does not account for the latent heat of water contained in fuels, as the water remains in the gas phase in the flue gases [56]. As noted by Basu [60], the heating value (HHV or LHV) may be expressed on any of the following bases: the as-received basis (AR) and the dry matter basis (DM), also known as the moisture-free basis. The following nomenclature was adopted in this work: HHV, LHVDM, and LHVAR. LHVDM can be calculated from the known value of HHV, according to Equation (1) [56,57].

where:

LHV = HHV − 24.42∙(MC + 8.94H),

- 24.42—water evaporation at 25 °C, 1% content = 24.42 (J·g−1);

- MC—moisture content (MC%);

- hydrogen content (H% DM).

2.3. Quantitative Data

The proportion of GW in MSW was estimated using the only available official data on MSW composition in Poland, as outlined in the National Waste Management Plan until 2028 [15]. In 2021, the mean mass share of GW in MSW in Poland was 15.53%, with a proportion observed in large cities (15.27%). As indicated by KPGO 2028, the proportion of bio-waste from green areas, including biodegradable waste from urban and housing estate green areas, parks, and gardens, is projected to account for 15.45%, 15.31%, 15.34%, and 15.38% of the anticipated average material composition of MSW in Poland in 2025, 2030, 2035, and 2040, respectively. On the basis of the aforementioned assumptions regarding the proportion of biodegradable waste and the quantity of MSW projected to be generated, it is possible to estimate the potential GW in 2025.

2.4. Statistical Analysis

All tests were conducted in triplicate, in consecutive order. Basic descriptive statistics were calculated for all parameters measured, including minimum and maximum values, mean values, standard deviations (SD), and coefficient of variation (CV in%). The latter is defined as the ratio of the standard deviation to the mean [45].

The statistical analysis was conducted using the Kruskal–Wallis test, followed by Dunn’s post hoc test for multiple comparisons. The Kruskal–Wallis test is a non-parametric test that may be employed as an alternative to the analysis of variance test when the assumptions of parametric tests are not met [61,62]. The significance level α = 0.05 was adopted for all the statistical tests used.

The correlation analysis was conducted using the Pearson correlation coefficient. The correlation coefficient is a statistical measure used to show an association between variables. The significance level α = 0.05 was adopted for the correlation analysis [63].

3. Results

3.1. Fertilizing Properties of GW Studied

Table 1 presents the mean values of the fertilizing properties of GW, along with the SD and CV, for the specified research periods (RP1–RP4).

Table 1.

Mean values of the tested GW fertilizing parameters for research periods RP1–RP4.

The mean values of the tested GW fertilizing parameters for the entire research cycle are presented and discussed in Section 4 (Discussion).

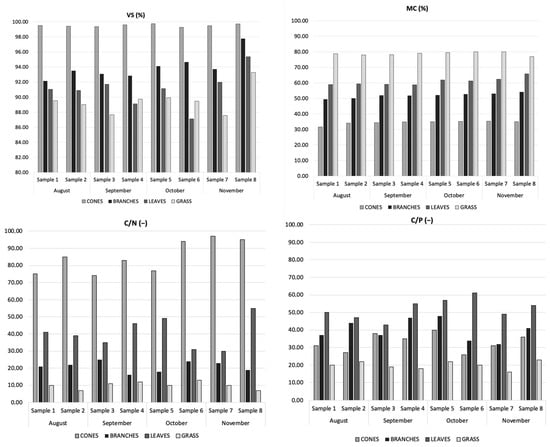

Figure 2 presents the mean values of the fertilizing properties tested of four GW fractions collected selectively from home gardens of single-family buildings: leaves (L), cones (C), grass (G), and branches (B).

Figure 2.

Mean values of the VS (%), MC (%), C/N, and C/P of four GW fractions collected selectively.

3.2. Fuel Properties of Tested GW

Table 2 presents the mean values of the combustion properties of GW, along with the standard deviation (SD) and coefficient of variation (CV) for the specified research periods RP1–RP4.

Table 2.

Mean values of the tested GW combustion parameters for research periods RP1–RP4.

The mean values of the GW fuel properties tested throughout the research cycle are presented and discussed in Section 4 (Discussion).

Table 3 shows the GW elemental analysis’s mean values, standard deviation (SD), and coefficient of variation (CV) for specific research periods RP1–RP4.

Table 3.

Mean values of the tested GW elemental analysis for research periods RP1–RP4.

The averaged values of the tested GW elemental analysis for the entire research cycle are presented and discussed in Section 4 (Discussion).

3.3. Protein, Fat, and Carbohydrate Content

Table 4 presents the averaged values of proteins, fats, and carbohydrates in GW tested along with the SD and CV for research periods RP1–RP4.

Table 4.

Mean values of proteins, lipids, and carbohydrates in the tested GW for research periods RP1–RP4.

The averaged values of proteins, fats, and carbohydrates in the tested GW for the entire research cycle are presented and discussed in Section 4 (Discussion).

3.4. Amount of GW Generated in Warsaw

As Szkatulnik [64] indicated, the aggregate mass of collected MSW in Warsaw in 2022 reached 832,793,882 Mg. This figure includes 43,678,000 Mg. This represents 5.2% of the total MSW. The available data on the proportion of GW waste in MSW (Section 2.3) indicates that the potential for its collection in Poland is significantly higher. Furthermore, as estimated by Rolewicz et al. [65], the efficiency of selective collection can be assumed to be 78.5%. By 2025, the amount of collected GW in Warsaw should reach 101,003,324 Mg.

4. Discussion

4.1. Fertilizing Properties of GW and Their Variability

The extant literature indicates that the most significant challenge associated with the processing and effective utilization of GW is its heterogeneity, mainly when GW is collected from numerous sources [15]. One of the principal factors influencing the characteristics of GW and their variability, as evidenced in the literature, is the season. Regarding the aforementioned considerations, the research cycle was conducted in four two-month periods throughout the growing season. The statistical analysis, conducted with the Kruskal–Wallis H test, indicated a significant difference in fertilizing properties (VS, TOC, C/N, and C/P) between the different sampling periods. The results of the test yielded the following values: for the VS (H = 9.85, p = 0.0199, η2 = 0.18), for the TOC (H = 14.13, p = 0.0027, η2 = 0.93), for the C/N (H = 8.66, p = 0.0342, η2 = 0.47), and the C/P (H = 11.87, p = 0.0078, η2 = 0.74).

GW demonstrated the lowest fertilizing properties from RP3 (August/September), corresponding to the transition between summer and autumn. The VS value was approximately 18% lower in this period than the mean value derived from the three other research periods. This observation contributes to the broader understanding of seasonal variations in green waste composition, as it differs from that of the research conducted in Aarhus, Denmark [12], in which the lowest VS values were observed at the turn of May and June (equivalent to RP1 and RP2), which were approximately 40% lower than the values observed in the other months. The lowest TOC, C/N, and C/P values were also observed in RP3. Such findings underscore the interconnection between seasonal changes and the chemical properties of green waste, likely attributable in this case to the increased presence of grass and flowering plants in GW, which have been demonstrated to contain higher nitrogen levels [66]. Additional tests on separately collected GW fractions revealed that the grasses fraction exhibited the lowest C/N values (Figure 2). The variability of VS and TOC parameters was found to be relatively limited across the individual research periods, with a range of 0.5% to 2.4%. This serves to confirm the appropriateness of the selected research periods and underscores the need to understand seasonal changes in green waste as a feedstock for creating value-added products. A deeper investigation into how specific plant species in green waste contribute to these changes could further refine the understanding of its fertilizing properties across different seasons.

In this study, more significant variability was observed for the C/N and C/P parameters across the individual research periods, with values ranging from 8.1% to 20.0%. However, throughout the entire research cycle, the variability of individual GW parameters was considerably higher, which emphasizes the complex interplay between seasonal factors and waste composition, ranging from 9.4% (for VS) to 29.9% (for C/P). A comparison of the variability in the research periods for VS and C/N with the results of the study conducted in Prague [8] reveals a similar seasonal variability for these parameters, with a CV of 11% for VS and 23% for C/N. This finding underscores the broader relevance of the study’s results beyond the regional context. Consequently, an analysis of the SD values for VS, TOC, and C/N for the entire research cycle suggests that the seasonal variability of GW is comparable to that observed in the study conducted by Boldrin and Christensen [12]. The averaged values of the tested GW fertilizing parameters for the entire research cycle are presented in Table 5.

Table 5.

The tested GW fertilizing parameters—mean values for the entire research cycle.

The supplementary tests conducted as part of this study provided novel insights, yielding data that enabled the differentiation of the selected properties of GW fractions that were collected separately. The highest MC is indicative of grass and leaves, respectively, exhibiting a 30% and 12% increase in moisture content relative to the average GW MC. The lowest moisture content was observed for cones, which exhibited a value 14.5% lower than the average moisture content of the tested GW. The high variability in MC in GW observed in this study is dependent on the proportion of individual fractions, mainly grass and leaves. As indicated by Hanc et al. [8], the MC of grass and leaves is approximately 13%, while the combined moisture content of plants is approximately 41.8%.

Conversely, Zeller et al. [67] posit that the proportion of grass and leaves in green waste is 35%. Conversely, the tested cones exhibited the highest VS and C/N content, while grass demonstrated the lowest C/N ratio (Figure 2). In the paper by Almedros et al. [68], the authors indicated that the VS for cones was 74.85%, and the C/N ratio was 173. In contrast, the study by Herman et al. [69] indicated that the C/N value for grasses ranged from 18 to 35.1. These variations in the chemical composition of green waste components underscore the importance of understanding their distinct properties, which are crucial for optimizing sustainable GW management practices. Some authors [4] recommend separate collection and recycling of the green and brown parts. Further, GW research should be conducted with division into at least two such factions.

Table 6 compares the mean values for the entire research cycle for the properties of the GW tested with the values recommended for organic recycling processes. The comparison also includes the fertilizing properties of food waste (FW) from single-family housing from the identical waste collection route in Warsaw from the previous research of the authors [45,46].

Table 6.

Comparison of the fertilizing properties of the GW with the literature data recommended for organic recycling processes and with the properties of the FW from Warsaw.

The tested GW, the subject of this study, exhibited a moisture level indicating processing in aerobic conditions (composting). However, the C/N and C/P parameters suggest they are more suitable for anaerobic digestion. The remaining parameters tested are deemed appropriate for both organic recycling processes. In order to enhance the characteristics of organic waste, including GW, for utilization in biological processes, it is possible to modify the parameters by combining different substrates with complementary properties. As evidenced in the literature review, GW is frequently employed with FW or sewage sludge. It can be observed that the incorporation of GW into FW produced in single-family households in Warsaw will enhance its characteristics in relation to aerobic processing during the composting process. In the aforementioned work [73], various pre-treatment methods utilizing physicochemical techniques were employed to prepare GW for the composting process in conjunction with FW. The objective was to accelerate the humification process of GW. This is also a factor that can be taken into account in the optimization of the technological process aiming for biomass valorization. There has been a growing interest in community composting [74,75], representing a valuable solution for managing green waste (also from the Warsaw area). This trend aligns with global efforts to develop a sustainable circular economy in waste management strategies.

The use of methane fermentation processes has seen increasing interest in recent years due to their potential to significantly advance environmental sustainability, with the role of pre-treatment becoming increasingly significant [15]. Due to its cellulose content, green waste is less recommended for anaerobic digestion than food waste. Nevertheless, integrating green waste as a co-substrate in anaerobic digestion processes presents an opportunity to explore the interconnections between different waste streams and optimize resource recovery. It can be employed as a co-substrate for such processes [64]. The enhancement of biogas generation from food and garden waste co-digestion compared to solely FW AD suggests the potential for process optimization, considering energy recovery from methane when utilizing GW. This aligns with the objectives of advancing waste management strategies that bridge multiple environmental spheres. Replacing 20% of FW with the lignocellulosic substrate resulted in delayed system acidification [76].

4.2. GW Fuel Properties and Their Variability

The averaged values of the tested GW combustion parameters and the elemental analysis for the entire test cycle are presented in Table 7 and Table 8. In this case, CP and AC are indicated in (% DM) and (%) due to the differing conversions of these parameters in the literature data.

Table 7.

The tested GW combustion properties—mean values for the entire test cycle.

Table 8.

The tested GW elemental analysis—mean values for the entire test cycle.

The statistical analysis conducted with the Kruskal–Wallis H test indicated that there is a significant difference in fuel properties between the different sampling periods. The test resulted in the following values: for the MC (H = 12.99, p = 0.0046, η2 = 0.83), for CP (H = 10.68, p = 0.0136, η2 = 0.64), for AC (H = 13.27, p = 0.0041, η2 = 0.86), VM in CP (H = 9.42, p = 0.0242, η2 = 0.53), and HHV (H = 9.42, p = 0.0171, η2 = 0.6). The moisture content of the tested GW remained at a similar level in RP1–RP3, reaching a significantly lower value in RP4, which was more than twice the average value from the three previous research periods. Consequently, during the fourth research period (RP4), the GW exhibited the highest level of LHVAR (11.8 MJ·kg−1), which was more than twice the average value observed in the preceding three research periods (RP1–RP3). In turn, in RP3, the CP was recorded at a level 20% lower than the average value from the other three research periods while simultaneously exhibiting the highest AC content. Consequently, the lowest HHV and LHVDM values were observed in this research period (RP3). In general, the variability in moisture content (MC) and carbon content (CP) was observed to be relatively low, with coefficients of variation (CV) of 3.8% and 1.8%, respectively. However, the CVs for higher heating value (HHV), lower heating value (LHVDM), and ash content (AC) were slightly higher, at 8.9%, 9.4%, and 15.0%, respectively. In contrast, the variability of fuel properties of GW throughout the entire research cycle was considerably higher, particularly in the case of MC (CV = 30%) and AC (CV = 55.2%/62.7%), depending on the units used. These findings contribute to the broader understanding of how GW’s fluctuating properties can affect its viability as a renewable energy source. The instability of fuel parameters in waste represents a significant challenge to their utilization for energy purposes. This research highlights the need for tailored waste management strategies that address these challenges, particularly in urban settings. The significance of AC in the context of waste incineration cannot be overstated, as it has a profound impact on the quantity of ash and slag produced and the potential for autothermal combustion. The GW, which is the subject of the present study, exhibited low AC values (7%/14% DM), which is beneficial from the standpoint of fuel properties. In contrast, Vitetto et al. [2] observed that AC ranged between 2% and 25% DM, depending on the GW fraction. The highest content was recorded in grass (20%), followed by leaves (16%) and branches (7%).

The addition of specific quantities of organic soil during the sampling of this waste may result in elevated AC, particularly in the case of grass [12]. The tested GW was analyzed in order to meet the conditions of autothermal combustion, as determined based on the Tanner triangle diagram [77,78]. It aims to advance the fundamental understanding of waste properties necessary for optimizing combustion processes. However, the moisture content of the tested GW is at a borderline level. This underscores the need for precise control and adaptation of combustion conditions to ensure effective waste-to-energy conversion.

A review of the literature reveals a lack of available data concerning the content of VM in CP. A study of this nature was conducted on GW from Warsaw. Investigating this parameter is crucial for ensuring complete and efficient combustion, which impacts both the efficiency and environmental footprint of waste-to-energy processes. This knowledge enables the optimization of air distribution and assures an appropriate ratio between primary and secondary air. Given an average VM content in CP of 68.4%, as observed in the case of tested GW, the secondary air supplied to the afterburning chamber should represent approximately 70% of the total air volume utilized in the thermal conversion process. This finding contributes to a broader understanding of the technical requirements for effective waste-to-energy systems and aligns with interdisciplinary research on waste management and environmental impact, supporting the goals of the circular economy.

Furthermore, the necessity for alterations in the primary and secondary air flow rates is underscored by the findings of Li et al. [79] and Abdulyekeen et al. [80], which highlight the significance of the volatile fraction content in renewable biofuel derived from MSW. Nevertheless, the determination of VM in the CP of waste still needs to be fully standardized. Such an analysis should be conducted under conditions that allow the results to be replicated and compared. The elemental composition of the waste is supplementary to the data on the fuel properties of the waste. Specific attention is devoted to the analysis of the chlorine and sulfur content of the waste. This is due to the potential negative impact on the environment and combustion equipment, which may restrict the utilization of fuel derived from waste with elevated chlorine and sulfur content [81]. The environmental implications of these elements are significant, as they contribute to harmful emissions and can accelerate the degradation of combustion equipment. In the case of the GW investigated, the highest variability was observed in the content of sulfur and nitrogen in CP throughout the entire research cycle. The variability of the chlorine content was also high, at a level of approximately CV = 17%. In this case, the unstable fuel parameters of GW may also present an obstacle to its energy use. The content of elemental constituents in waste fuel affects the so-called aggressive constituents and emission levels. These insights contribute to the development of biomass valorization methods and strategies for bioresource recovery. Table 9 compares the elemental analysis of the tested GW with literature data. They were converted from % CP to % DM for comparative purposes.

Table 9.

Comparison of the results of elemental analysis of the tested GW with literature data.

The elemental composition of the tested GW is consistent with the literature data in most of the analyzed cases, underscoring the broader applicability and relevance of this study’s findings to other urban environments. In the context of waste incineration and the production of fuels from waste, particular attention is paid to sulfur and chlorine content. The work of [25] indicated the contents of sulfur and chlorine in MSW, primarily composed of plastic and food waste. The sulfur content ranged from 0.03% to 0.96%, while the chlorine content ranged from 0.22% to 1.09% [4]. These values are critical benchmarks for evaluating the environmental impact of incineration and the sustainability of waste management strategies. According to [31], the Cl content in GW ranges from 0.33% to 0.48% DM. Values in this range are also observed in the tested GW. This alignment validates the possibility of a broader application of the results obtained in this work. In accordance with European legal regulations on the thermal treatment of waste [82], the post-combustion process for waste with a chlorine content in organochlorine compounds below 1% should be carried out at a minimum temperature of 850 °C. For higher chlorine content, the minimum temperature must be 1100 °C. Therefore, knowledge of this parameter is of significant importance. Determining the element Cl in the elemental composition of waste is essential to managing harmful emissions, protecting the environment, reducing equipment corrosion, complying with regulations, and ensuring efficient operation. In turn, the criteria for alternative fuels include a minimum energy value of 14 MJ·kg−1, a maximum chlorine content of 0.2%, and a maximum sulfur content of 2.5%. These stringent criteria highlight the need for precise fuel characterization (also coming from GW) to meet regulatory standards and minimize environmental impact.

Furthermore, the combustion of fuels must be uniform, which implies a high and constant calorific value and a low and constant MC [83,84]. The GW, which is the subject of this study, is characterized by an excessively high chlorine content and a correspondingly low LHVAR, with an average value of 6.8 MJ·kg−1 across the entire research cycle, a consequence of the high MC. Notwithstanding the elevated mean value, considerable variability was observed, with a coefficient of variation (CV) of 14.3% for LHVDM and a CV value of 30% for MC. These values exceed the limits set by the cement industry. These fluctuations highlight the challenges in maintaining consistent fuel quality, which is critical for industrial applications and environmental impact. This study contributes to a broader, interdisciplinary discussion on the viability of green waste as an energy resource, which advances the understanding of environmental interactions and supports the circular economy. As posited by Ipiales et al. [29], GW, one of the most prevalent energy resources on Earth, cannot be regarded as an optimal fuel at the industrial level due to its fibrous composition, low bulk density, and calorific value in additional to its high MC, VM in CP, and AC. The properties of the tested GW indicate that it is necessary to stabilize at least the calorific value and moisture content for integrating GW into industrial energy systems while mitigating environmental concerns.

A Pearson correlation coefficient matrix was calculated to assess the linear relationship between GW fertilizing and combustion parameters (Table 10). The results demonstrate a statistically significant relationship between VS and most parameters. The correlation is positive for TOC (0.505), C/N (0.7217), C/P (0.5175), VM in CP (0.9716), and HHV (0.813), and a strong negative correlation is evident for AC (−0.9873). The C/N ratio shows a positive correlation with CP (0.6796), VM in CP (0.5994), and HHV (0.519), and a negative correlation for AC (−0.6796). CP has a positive correlation with all fuel parameters and most fertilizing parameters. In the case of MC, no statistically significant correlation was observed for any of the tested parameters.

Table 10.

A Pearson correlation coefficient matrix between GW fertilizing and combustion parameters.

4.3. Directions for Using GW

The analyzed literature data identify which GW properties are of particular importance with regard to specific processing methods. The analysis allowed for differentiating between biological (biochemical) and thermochemical methods. The literature data were compared with the properties of the GW generated in Warsaw, obtained based on original research (Table 11 and Table 12). This comparison has identified the most promising applications for the GW, contributing to the optimization of waste management strategies. The identification of potential applications of the tested GW has determined the optimal process and, ultimately, the cascade use of this type of feedstock, using biochemical, thermochemical, and thermal applications, also taking into account the possibility of combining the stream with the food biowaste fraction, enhancing.

Table 11.

Technological properties of GW with an indication of their thermochemical processing methods.

Table 12.

Technological properties of GW with indication of their biological processing methods.

Oveido-Ocana et al. [16] observed that comprehensive and detailed qualitative characteristics of processed bio-waste, including GW, are seldom provided in the existing literature. Addressing this gap is essential for advancing fundamental understanding and developing more effective and sustainable waste management strategies. It is thus imperative to address this gap in the existing literature and analyze the data regarding their technological properties and potential for valorization. This study contributes novel insights by evaluating these properties through an interdisciplinary approach, bridging biological and thermochemical processing methods. In studies examining the processing of various forms of GW, the most frequently indicated quality parameters include VS, particularly in the case of biological methods, MC and AC, especially in the case of thermochemical methods. The VS values of GW subjected to the aforementioned processing methods (Table 11 and Table 12) fall within the 72.68–95.60% range. Furthermore, the VS content of GW, which is the subject of this study, also falls within this range.

In contrast, Liczbinski and Borowski [86] reported the composition of grass and leaves to be 82–88% VS. However, the MC of GW is observed to vary considerably, with a range of 0.79% to 46.12% in the context of the analyzed data. The tested GW displays a slight excess above the upper limit of the range above. It should be noted, however, that some of the values presented in Table 11 and Table 12 pertain to GW that has undergone natural drying or drying during the preparation process for valorization, particularly in the case of thermochemical methods. This is not always explicitly indicated in the literature on the subject.

Furthermore, the AC values exhibit a considerable range, spanning from 4.0% to 34.21%. This variability underscores the complex nature of GW and its potential impact on energy recovery processes, emphasizing the importance of detailed characterization for optimizing energy recovery from waste. The energy value of GW is most often assessed based on the HHV or the LHVDM, with the latter sometimes also including the lower heating value at standard conditions LHVAR. A literature review (Table 11 and Table 12) reveals a range of HHV and LHVDM values between 13.08 and 21.87 MJ·kg−1 DM and 15.95 and 19.93 MJ·kg−1, respectively, which includes GW, which is the subject of this study. In the case of the GW tested, a markedly lower LHVAR value was observed, which can be attributed to the higher water content in this waste compared to the data set under comparison. The LHVAR value depends on several factors, including the moisture content of the waste material. The HHV and LHVDM values are more reliable for comparison purposes. In this context, the consistency of the tested GW data with existing literature affirms the validity of the methodologies employed and supports the broader applicability of the results.

In addition to conventional organic recycling and thermochemical methods, the potential exists for GW to be used materially [2]. The principal products are proteins, organic acids, lipids, and phenolic compounds. The typical protein content of herbaceous material ranges from 1.5% to 4.5% for grasslands and 5% to 12.3% for different grasses. The lipid concentration is approximately 2.5% of the dry matter for yard waste, including grasses and leaves [19]. The data highlight the versatility of GW as a resource for producing valuable biochemicals, which could lead to its use in more sustainable and integrated waste management strategies. Table 13 compares the protein, carbohydrate, and lipid content of the tested GW with literature data on GW, for example, FW and vegetable waste.

Table 13.

Comparison of the content of carbohydrates, lipids, and proteins in the tested GW with literature data.

According to literature data [20], the content of proteins, lipids, and carbohydrates is seasonally variable. The results of the tested GW research confirm, in particular, the literature data on the content of proteins, the share of which usually decreases with the plant’s maturation. In the tested GW, the lowest protein content was recorded in RP4 (October/November), although variability throughout the research cycle (CV) was 16%. Additionally, the share of proteins is consistent with the literature data regarding their content in other GW and vegetable waste. However, the share of proteins, lipids, and carbohydrates is related to the content of lignocellulose, which was not tested in this research. Future studies should incorporate lignocellulose analysis to further elucidate its impact on subsequent processing methods. According to Alibardi and Cossu [53], municipal organic waste is an excellent feedstock for biochemical conversion processes in biorefineries, primarily due to the content of three main groups of organic matter: carbohydrates, proteins, and lipids. Alibardi and Cossu [53] evaluated the effects of carbohydrate, protein, and lipid content of organic waste on hydrogen yields, volatile fatty acid production, and carbon fate. Acetic and butyric acids were the primary products of dark fermentation, with their ratio showing a link with the carbohydrate and protein content. Also, the study [15] shows that many valuable chemicals and materials can be produced from green waste, including those based on protein extraction. However, economic and ecological evaluations of such alternative methods still need to be improved. Papers [88,89] also highlight green waste as a viable alternative to meet human and animal protein and nutrient requirements. This potential underscores the importance of further research to optimize the use of GW as a feedstock in sustainable bioconversion technologies.

Table 14 presents the potential for valorization of the GW tested from Warsaw, based on the quantities planned to be collected in 2025 (in accordance with the results presented in Section 3.4) and taking into account their properties, as determined through original research (fertilizer and fuel properties) and literature data in terms of: biogas production potential from GW and mass loss in the process at the level of 267.1 m3·Mg−1 DM and 13.5%, respectively, according to Sofokleus et al. [21], the average yield of biohydrogen and bioethanol from green waste at the level of 66 m3 H2·Mg−1 DM and 4.4 kg·Mg−1 DM, respectively [21,32], the average yield of hydrochar is reported to be 63.5% [19], the shares of individual pyrolysis products (moderate pyrolysis) estimated to be 52.8% (bio-oil), 21.5% (biochar), 27.3% (syngas) based on the findings of [90], the yield of biochar from green waste at the level of 48% in the pyrolysis process (carbonization) at 300 °C (with a heating rate of 5 °C min−1 for 30 min) according to [91], and a gas yield of 50–65% of GW in a gasification process at temperatures between 700 and 900 °C reported by Tezer et al. [85]. The co-fermentation products of FW with GW were estimated based on the share of FW in the forecasted average material composition of MSW in Poland in 2025, which was calculated to be 13.09% [60], with a selective collection efficiency of 55% (in line with the EU requirements for preparing MSW for reuse and recycling in 2025), and a 20% share of GW in relation to the waste from FW to the methane fermentation process, following the recommendations of [75], must be considered.

Table 14.

Possibilities of valorization of GW produced and collected in Warsaw.

Considering the current state of GW treatment in Poland, including Warsaw and the experience of other EU member states, aerobic methods (composting) are and will continue to be widely applied, provided that the produced fertilizer can be used. Moreover, dedicated biogas installation expansions are planned aimed at co-fermentation of GW with FW (it is visible that co-fermentation of FW with GW in the right proportion gives greater potential for biogas yield). Despite the possibility of obtaining energy, direct combustion should be treated as secondary to methods enabling recycling. Various pyrolysis methods make it possible to obtain various value-added products depending on the process conditions and the use of appropriate pre-treatment. From the point of view of energy acquisition possibilities, three methods seem to be equivalent: methane fermentation (with the combustion of biogas), HTC (with the combustion of half of the produced hydrochar), and gasification (with the combustion of syngas). However, these methods involve high energy consumption. Conversion in the form of alcohol fermentation (with the combustion of ethanol) and dark fermentation (with the combustion of the produced biohydrogen and ethanol) is characterized by approximately 4-fold and 8-fold lower energy yield, respectively. The least energetically advantageous is GW incineration, although, in the case of the tested GW, autothermal combustion is possible. It was assumed that neither the biochar from the carbonization process nor the compost from the composting process would be used for energy. However, according to [4], the composting process emits several greenhouse gases (GHGs), notably carbon dioxide and methane. In contrast, methods such as anaerobic digestion, waste-to-energy (incineration), pyrolysis, and gasification can generate environmental credits, provided the produced bioenergy substitutes fossil fuels. The broad application of technologically advanced, sustainable valorization methods will be possible after analyzing the operating experience of full-scale implementations. Field studies and practical implementations will be essential to understanding these processes and their environmental benefits. The results of this work not only quantify the potential valorization pathways for the tested GW but also underscore the necessity of a multifaceted approach to green waste management in general.

5. Conclusions

GW from Warsaw is gathered during vegetation growth, which spans from March to November in the conditions of Poland and Central Europe. This variability concerns quantity since GW is produced in different amounts in Poland for, at most, nine months of the year. A notable degree of seasonal variability is evident in the properties of GW. The most significant variability in fuel properties is observed in the following parameters: MC–CV = 30%, LHV–CV = 14.3%, and AC–CV = 62.7/56.2%. The seasonal instability of GW affects their variable technological properties in different months, thereby posing a challenge in terms of selecting effective methods for their utilization, including energy recovery. This is corroborated by the literature on the characteristics of GW. The variability in GW properties also results from their different fraction composition. The research and literature review conducted thus far indicate that a higher content of coarse fractions (branches, cones) affects a higher content of hemicellulose in GW and their lower moisture.

At the present stage of development, most GW from Warsaw and other Central European cities is treated via aerobic biological processes. Given its cellulose content, using homogeneous stream GW waste in AD processes is generally less recommended than in the case of FW. However, the findings of this study support the hypothesis that the tested GW exhibits pronounced fertilizing properties, thereby rendering it suitable for diverse forms of organic recycling, including anaerobic conditions with biogas generation. The collection system for bio-waste in Warsaw offers the additional benefit of separating GW from FW. This increases the potential for valorization of both bio-waste fractions as biomass resources through the possibility of controlled feedstock modification to optimize their properties. It seems likely that in the near future, there will be developments in the field of anaerobic technologies, including FW co-fermentation with GW. From the perspective of fuel properties, it is notable that the GW exhibited a relatively high moisture content, indicating the necessity for drying prior to thermal processing.

Moreover, the most tremendous variability of the tested GW was observed concerning fuel properties, mainly the ash and the combustible fraction content. However, preceded by appropriate pre-treatment, thermochemical methods will become more widely used. Research studies indicate that GW is also an excellent feedstock in advanced biorefinery processes thanks to the content of carbohydrates, proteins, and lipids. Further studies on GW should consider its morphological composition, including the proportion of impurities and the cellulose, hemicellulose, and lignin contents.

The findings of this study indicate that it is advisable to consider the joint use of green waste and food waste values. However, it is crucial to note that a separate collection of these fractions allows for controlling bio-waste quality and properties, which is essential for valuable processing.

In light of these findings, it is essential to develop targeted strategies for managing GW that consider its variable characteristics throughout the year. Embracing innovations in thermochemical and anaerobic technologies, along with refining collection systems, will play a vital role in maximizing the benefits of GW in sustainable bio-waste management.

Author Contributions

Conceptualization, K.L.-S. and P.M.; methodology, K.L.-S.; validation, A.R.-K. and P.M.; formal analysis, A.R.-K.; investigation, K.L.-S. and P.M.; resources, A.R.-K.; data curation, K.L.-S. and P.M.; writing—original draft preparation, K.L.-S.; writing—review and editing, A.R.-K. and P.M.; visualization, A.R.-K.; supervision, P.M.; funding acquisition, K.L.-S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by financial support provided by the Warsaw University of Technology under a grant for financing scientific research in the discipline of Environmental Engineering, Mining, and Energy, title: “Valorization of green waste - research on technological properties” (Agreement no. 9/2023). Warsaw, 2023.

Data Availability Statement

Data will be made available on request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bille, R.A.; Jensen, K.E.; Buitenwerf, R. Global patterns in urban green space are strongly linked to human development and population density. Urban For. Urban Green. 2023, 86, 127980. [Google Scholar] [CrossRef]

- Viretto, A.; Gontard, N.; Angellier-Coussy, H. Urban parks and gardens green waste: A valuable resource for the production of fillers for biocomposites applications. Waste Manag. 2021, 120, 538–548. [Google Scholar] [CrossRef] [PubMed]

- Gong, X.; Li, S.; Sun, X.; Wang, L.; Cai, L.; Zhang, J.; Wei, L. Green waste compost and vermicompost as peat sub-stitutes in growing media for geranium (Pelargonium zonale L.) and calendula (Calendula officinalis L.). Sci. Hortic. 2018, 236, 186–191. [Google Scholar] [CrossRef]

- Liu, X.; Xie, Y.; Sheng, H. Green waste characteristics and sustainable recycling options. Resour. Environ. Sustain. 2023, 11, 100098. [Google Scholar] [CrossRef]

- Reyes-Torres, M.; Oviedo-Ocaña, E.R.; Dominguez, I.; Komilis, D.; Sánchez, A. A systematic review on the composting of green waste: Feedstock quality and optimization strategies. Waste Manag. 2018, 77, 486–499. [Google Scholar] [CrossRef]

- Eades, P.; Kusch-Brandt, S.; Heaven, S.; Banks, C.J. Estimating the generation of garden waste in England and the differences between rural and urban areas. Resources 2020, 9, 8. [Google Scholar] [CrossRef]

- Directive (EU) 2008/98 of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives (Text with EEA Relevance, Consolidated Version 18 February 2024). Available online: http://data.europa.eu/eli/dir/2008/98/oj (accessed on 27 July 2024).

- Hanc, A.; Novak, P.; Dvorak, M.; Habart, J.; Svehla, P. Composition and parameters of household bio-waste in four seasons. Waste Manag. 2011, 31, 1450–1460. [Google Scholar] [CrossRef]

- Manu, M.K.; Kumar, R.; Garg, A. Physical and chemical characterization of yard waste. Int. J. Appl. Eng. Res. 2013, 8, 1891–1895. [Google Scholar]

- Zhang, L.; Sun, X. Influence of bulking agents on physical, chemical, and microbiological properties during the two-stage composting of green waste. Waste Manag. 2016, 48, 115–126. [Google Scholar] [CrossRef]

- Bengoechea, C.; Batista, A.P.; Álvarez-Castillo, E.; Guerrero, A.; Gontard, N.; Angellier-Coussy, H. Biocomposites from porcine plasma protein and urban parks and gardens green waste. Ind. Crops Prod. 2023, 198, 116714. [Google Scholar] [CrossRef]

- Boldrin, A.; Christensen, T.H. Seasonal generation and composition of garden waste in Aarhus (Denmark). Waste Manag. 2010, 30, 551–557. [Google Scholar] [CrossRef] [PubMed]

- Eurostat. Municipal Waste by Waste Management Operations 2022. Available online: https://ec.europa.eu/eurostat/databrowser/view/env_wasmun__custom_9634214/default/table?lang=en (accessed on 27 September 2024).

- Brusselaers, J.; Van Der Linden, A. Bio-Waste in Europe—Urning Challenges into Opportunities; EEA Report No 04/2020; European Environment Agency: Copenhagen, Denmark, 2020; ISSN 1977-8449. [Google Scholar] [CrossRef]

- Resolution No. 96 of the Council of Ministers of 12 June 2023 on the National Waste Management Plan 2028 (M.P. 2023 poz. 702). Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WMP20230000702 (accessed on 15 June 2024). (In Polish)

- Oviedo-Ocaña, E.R.; Abendroth, C.; Domínguez, I.C.; Sánchez, A.; Dornack, C. Life cycle assessment of biowaste and green waste composting systems: A review of applications and implementation challenges. Waste Manag. 2023, 171, 350–364. [Google Scholar] [CrossRef] [PubMed]

- Mishra, S.K.; Yadav, K.D. Disposal of garden waste using food waste inoculant in rotary drums and their ranking using analytical hierarchy process. Bioresour. Technol. Rep. 2021, 15, 100710. [Google Scholar] [CrossRef]

- Parab, C.; Yadav, K.D.; Prajapati, V. Genomics and microbial dynamics in green waste composting: A mini review. Ecol. Genet. Genom. 2023, 29, 100206. [Google Scholar] [CrossRef]

- Langsdorf, A.; Volkmar, M.; Holtmann, D.; Ulber, R. Material utilization of green waste: A review on potential valorization methods. Bioresour. Bioprocess. 2021, 8, 19. [Google Scholar] [CrossRef] [PubMed]

- Hanifzadeh, M.; Garcia, E.C.; Viamajala, S. Production of lipid and carbohydrate from microalgae without compromising biomass productivities: Role of Ca and Mg. Renew. Energy 2018, 127, 989–997. [Google Scholar] [CrossRef]

- Sofokleous, M.; Christofi, A.; Malamis, D.; Mai, S.; Barampouti, E.M. Bioethanol and biogas production: An alternative valorisation pathway for green waste. Chemosphere 2022, 296, 133970. [Google Scholar] [CrossRef]

- Medick, J.; Teichmann, I.; Kemfert, C. Hydrothermal Carbonization (HTC) of Green Waste: An Environmental and Economic Assessment of HTC Coal in the Metropolitan Region of Berlin. Germany. 2017. Available online: http://www.diw.de/discussionpapers (accessed on 12 June 2024).

- Komilis, D.P.; Ham, R.K. The effect of lignin and sugars to the aerobic decomposition of solid wastes. Waste Manag. 2003, 23, 419–423. [Google Scholar] [CrossRef]

- Bieniek, J.; Gaze, B.; Knutel, B.; Rać, K.; Góraj, S. Analysis of the Effectiveness of Green Waste Composting under Hyperbaric Conditions. Sustainability 2022, 14, 5108. [Google Scholar] [CrossRef]

- Li, Y.; Xue, Z.; Li, S.; Sun, X.; Hao, D. Prediction of composting maturity and identification of critical parameters for green waste compost using machine learning. Bioresour. Technol. 2023, 385, 129444. [Google Scholar] [CrossRef]

- Saer, A.; Lansing, S.; Davitt, N.H.; Graves, R.E. Life cycle assessment of a food waste composting system: Environmental impact hotspots. J. Clean. Prod. 2013, 52, 234–244. [Google Scholar] [CrossRef]

- Soto-Paz, J.; Oviedo-Ocaña, E.R.; Angarita-Rangel, M.A.; Rodríguez-Flórez, L.V.; Castellanos-Suarez, L.J.; Nabarlatz, D.; Sanchez-Torres, V. Optimization of lignocellulolytic bacterial inoculum and substrate mix for lignocellulose degradation and product quality on co-composting of green waste with food waste. Bioresour. Technol. 2022, 359, 127452. [Google Scholar] [CrossRef] [PubMed]

- Hasan, M.M.; Rasul, M.G.; Jahirul, M.I.; Mofijur, M. Fuelling the future: Unleashing energy and exergy efficiency from municipal green waste pyrolysis. Fuel 2024, 357, 129815. [Google Scholar] [CrossRef]

- Ipiales, R.P.; Mohedano, A.F.; Diaz, E.; De la Rubia, M.A. Energy recovery from garden and park waste by hydrothermal carbonisation and anaerobic digestion. Waste Manag. 2022, 140, 100–109. [Google Scholar] [CrossRef] [PubMed]

- Trombley, J.B.; Wang, C.; Thennadil, S.N. Model-free measurements of calorific content and ash content of mixed garden wastes using a bomb calorimeter. Fuel 2023, 352, 129105. [Google Scholar] [CrossRef]

- Hla, S.; Roberts, D. Characterisation of chemical composition and energy content of green waste and municipal solid waste from Greater Brisbane, Australia. Waste Manag. 2015, 41, 12–19. [Google Scholar] [CrossRef]

- Ramprakash, B.; Incharoensakdi, A. Dark fermentative hydrogen production from pretreated garden wastes by Escherichia coli. Fuel 2022, 310, 122217. [Google Scholar] [CrossRef]

- Noblet, C.; Besombes, J.L.; Lemire, M.; Pin, M.; Jaffrezo, J.L.; Favez, O.; Albinet, A. Emission factors and chemical characterization of particulate emissions from garden green waste burning. Sci. Total Env. 2021, 798, 149367. [Google Scholar] [CrossRef]

- Pradhan, P.; Arora, A.; Mahajani, S.M. Pilot scale evaluation of fuel pellets production from garden waste biomass. Energy Sustain. Dev. 2018, 43, 1–14. [Google Scholar] [CrossRef]

- Guo, Y.; Rene, E.R.; Wang, J.; Ma, W. Biodegradation of polyaromatic hydrocarbons and the influence of environmental factors during the co-composting of sewage sludge and green forest waste. Bioresour. Technol. 2020, 297, 122434. [Google Scholar] [CrossRef]

- Mohapatra, S.; Mishra, C.; Behera, S.S.; Thatoi, H. Application of pretreatment, fermentation and molecular techniques for enhancing bioethanol production from grass biomass—A review. Renew. Sustain. Energy Rev. 2017, 78, 1007–1032. [Google Scholar] [CrossRef]

- Zhang, Z.; Duan, C.; Liu, Y.; Li, A.; Hu, X.; Chen, J.; Cui, X. Green waste and sewage sludge feeding ratio alters co-composting performance: Emphasis on the role of bacterial community during humification. Bioresour. Technol. 2023, 380, 129014. [Google Scholar] [CrossRef] [PubMed]

- Maina, S.; Kachrimanidou, V.; Koutinas, A. A roadmap towards a circular and sustainable bioeconomy through waste valorization. Curr. Opin. Green Sustain. Chem. 2017, 8, 18–23. [Google Scholar] [CrossRef]

- Hernández-Gómez, A.; Calderón, A.; Medina, C.; Sanchez-Torres, V.; Oviedo-Ocaña, E.R. Implementation of strategies to optimize the co-composting of green waste and food waste in developing countries. A case study. Environ. Sci. Pollut. Res. 2021, 28, 24321–24327. [Google Scholar] [CrossRef]

- Grgas, D.; Štefanac, T.; Barešić, M.; Toromanović, M.; Ibrahimpašić, J.; Pavičić, T.V.; Habuda-Stanić, M.; Herceg, Z.; Dragičević, T.L. Co-composting of Sewage Sludge, Green Waste, and Food Waste. J. Sustain. Dev. Energy Water Environ. Syst. 2023, 11, 1100415. [Google Scholar] [CrossRef]

- Ellersdorfer, M. Hydrothermal co-liquefaction of chlorella vulgaris with food processing residues, green waste and sewage sludge. Biomass Bioenergy 2020, 142, 105796. [Google Scholar] [CrossRef]

- Szyga-Pluta, K.; Tomczyk, A.M.; Piniewski, M.; Eini, M.R. Past and future changes in the start, end, and duration of the growing season in Poland. Acta Geophys. 2023, 71, 3041–3055. [Google Scholar] [CrossRef]

- Tomczyk, A.M.; Szyga-Pluta, K. Variability of thermal and precipitation conditions in the growing season in Poland in the years 1966–2015. Theor. Appl. Climatol. 2019, 135, 1517–1530. [Google Scholar] [CrossRef]

- Resolution No. XCI/3002/2023 of the Capital City Council of Warsaw of 7 December 2023 on the Regulations for Maintaining Cleanliness and Order within the Capital City of Warsaw, Item 14577, Warsaw. 15 December 2023. Available online: https://edziennik.mazowieckie.pl/WDU_W/2023/14577/akt.pdf (accessed on 9 June 2024). (In Polish).

- Manczarski, P.; Rolewicz-Kalińska, A.; Lelicińska-Serafin, K. Quantitative Analysis of Household Food Waste Collection in Warsaw: Assessing Efficiency and Waste Minimization. Sustainability 2023, 15, 16827. [Google Scholar] [CrossRef]

- Lelicińska-Serafin, K.; Manczarski, P.; Rolewicz-Kalińska, A. An Insight into Post-Consumer Food Waste Characteristics as the Key to an Organic Recycling Method Selection in a Circular Economy. Energies 2023, 16, 1735. [Google Scholar] [CrossRef]

- EN 15002; Characterization of Waste—Preparation of Test Portions from the Laboratory Sample. CEN: Brussels, Belgium, 2015.

- VDI 4630; Fermentation of Organic Materials—Characterisation of the Substrate, Sampling, Collection of Material Data, Fermentation Tests. Verlag des Vereins Deutscher Ingenieure: Düsseldorf, Germany, 2016.

- EN 14346; Characterization of Waste—Calculation of dry matter by determination of dry residue or water content. CEN: Brussels, Belgium, 2006.

- EN 13137; Characterization of Waste—Determination of Total Organic Carbon (TOC) in Waste, Sludges and Sediments. CEN: Brussels, Belgium, 2001.

- EN 15169; Characterization of Waste—Determination of Loss on Ignition in Waste, Sludge, and Sediments. CEN: Brussels, Belgium, 2007.

- PN-Z-15011-3:2001—Polish Version; Compost from Municipal Waste—Determination: pH, Organic Matter Content, Organic Carbon, Nitrogen, Phosphorus and Potassium. The Polish Committee for Standardization: Warsaw, Poland, 2001.

- Alibardi, L.; Cossu, R. Effects of carbohydrate, protein and lipid content of organic waste on hydrogen production and fermentation products. Waste Manag. 2016, 47, 69–77. [Google Scholar] [CrossRef] [PubMed]

- AOAC. Official Methods of Analysis of the Association of Official’s Analytical Chemists, 17th ed.; Association of Official Analytical Chemists (AOAC): Arlington, VA, USA, 2003. [Google Scholar]

- Jabłońska, B.; Kiełbasa, P.; Korenko, M.; Dróżdż, T. Physical and Chemical Properties of Waste from PET Bottles Washing as A Component of Solid Fuels. Energies 2019, 12, 2197. [Google Scholar] [CrossRef]

- Kalivodová, M.; Baláš, M.; Milčák, P.; Lisá, H.; Lisý, M.; Lachman, J.; Vejražka, K. The determination of higher heating value by calculation based on elemental analysis. Paliva 2022, 14, 8–20. [Google Scholar] [CrossRef]

- Skalmowski, K.; Wolska, K.; Pieniak, U.; Roszczyńska, I. Badania Właściwości Technologicznych Odpadów Komunalnych:Ćwiczenia Laboratoryjne; Oficyna Wydawnicza—Politech: Warsaw, Poland, 2004; pp. 94–97. (In Polish) [Google Scholar]

- UNE-EN ISO 9831:2004; Animal Feeding Stuffs, Animal Products, and Faeces or Urine—Determination of Gross Calorific Value—Bomb Calorimeter Method (ISO 9831:1998). AENOR: Madrid, Spain, 2004.

- Arenas, J.P.; Cardona, L.F.; Zapata-Benabithe, Z.; Velásquez, J.A. Estimating the high heating value of a high-calorie food using a rigorous thermodynamical approach. Chem. Eng. Commun. 2024, 211, 763–780. [Google Scholar] [CrossRef]

- Basu, P. Biomass Gasification and Pyrolysis: Practical Design and Theory; Academic Press: Cambridge, MA, USA, 2010. [Google Scholar] [CrossRef]

- Longjan, G.G.; Dehouche, Z. Nutrient characterisation and bioenergy potential of common Nigerian food wastes. Waste Manag. Res. 2018, 36, 426–435. [Google Scholar] [CrossRef]

- Olmedillas del Moral, M.; Fröhlich, N.; Figarella, K.; Mojtahedi, N.; Garaschuk, O. Effect of caloric restriction on the in vivo functional properties of aging microglia. Front. Immunol. 2020, 11, 750. [Google Scholar] [CrossRef]

- Janse, R.J.; Hoekstra, T.; Jager, K.J.; Zoccali, C.; Tripepi, G.; Dekker, F.W.; van Diepen, M. Conducting correlation analysis: Important limitations and pitfalls. Clin. Kidney J. 2021, 14, 2332–2337. [Google Scholar] [CrossRef]

- Szkatulnik, P. Analysis of the Municipal Waste Management in Warsaw for 2022. Official Information from the City Office. Available online: https://bip.warszawa.pl/NR/rdonlyres/5DF29B69-22BE-403B-9CC3-9D639656A538/1873267/ANALIZAza2022r2022024_sig.pdf (accessed on 10 June 2024). (In Polish).

- Rolewicz-Kalińska, A.; Lelicińska-Serafin, K.; Manczarski, P. The Circular Economy and Organic Fraction of Municipal Solid Waste Recycling Strategies. Energies 2020, 13, 4366. [Google Scholar] [CrossRef]

- Gislum, R.; Griffith, S.M. Production and Development in Perennial Ryegrass in Relation to Nitrogen Use. J. Plant Nutr. 2005, 27, 2135–2148. [Google Scholar] [CrossRef]

- Zeller, V.; Lavigne, C.; D’Ans, P.; Towa, E.; Achten, W.M.J. Assessing the environmental performance for more local and more circular biowaste management options at city-region level. Sci. Total Environ. 2020, 745, 140690. [Google Scholar] [CrossRef]

- Almendros, A.I.; Martín-Lara, M.A.; Ronda, A.; Pérez, A.; Blázquez, G.; Calero, M. Physico-chemical characterization of pinecone shell and its use as biosorbent and fuel. Bioresour. Technol. 2015, 196, 406–412. [Google Scholar] [CrossRef] [PubMed]

- Herman, W.A.; McGill, W.B.; Dormaar, J.F. Effects of initial chemical composition on decomposition of roots of three grass species. Can. J. Soil Sci. 1977, 57, 205–215. [Google Scholar] [CrossRef]

- Chia, W.Y.; Chew, K.W.; Le, C.F.; Lam, S.S.; Chee, C.S.C.; Ooi, M.S.L.; Show, P.L. Sustainable utilization of biowaste compost for renewable energy and soil amendments. Environ. Pollut. 2020, 267, 115662. [Google Scholar] [CrossRef] [PubMed]

- Casallas-Ojeda, M.R.; Marmolejo-Rebellón, L.F.; Torres-Lozada, P. Identification of factors and variables that influence the anaerobic digestion of municipal biowaste and food waste. Waste Biomass Valori. 2021, 12, 2889–2904. [Google Scholar] [CrossRef]

- Pereira, F.; Silva, C. Energetic valorization of bio-waste from municipal solid waste in Porto Santo Island. Clean Technol. 2023, 5, 233–258. [Google Scholar] [CrossRef]

- Xu, Z.; Ma, Y.; Li, Y.; Li, G.; Nghiem, L.D.; Luo, W. Comparison between cold plasma, ultrasonication, and alkaline hydrogen peroxide pretreatments of garden waste to enhance humification in subsequent composting with kitchen waste: Performance and mechanisms. Bioresour. Technol. 2022, 354, 127228. [Google Scholar] [CrossRef] [PubMed]

- Marcello, B.; Di Gennaro, V.; Ferrini, S. Let the citizens speak: An empirical economic analysis of domestic organic waste for community composting in Tuscany. J. Clean. Prod. 2021, 306, 127263. [Google Scholar] [CrossRef]

- Sánchez, A. Decentralized composting of food waste: A perspective on scientific knowledge. Front. Chem. Eng. 2022, 4, 850308. [Google Scholar] [CrossRef]

- Perin, J.K.H.; Borth, P.L.B.; Torrecilhas, A.R.; da Cunha, L.S.; Kuroda, E.K.; Fernandes, F. Optimization of methane production parameters during anaerobic co-digestion of food waste and garden waste. J. Clean. Prod. 2020, 272, 123130. [Google Scholar] [CrossRef]

- Dolgen, D.; Sarptas, H.; Alpaslan, N.; Kucukgul, O. Energy Potential of Municipal Solid Wastes. Energy Sources 2005, 27, 1483–1492. [Google Scholar] [CrossRef]

- The World Bank. Municipal Solid Waste Incineration. World Bank Technical Guidance Report. 1999. Available online: https://web.mit.edu/urbanupgrading/urbanenvironment/resources/references/pdfs/MunicipalSWIncin.pdf (accessed on 1 June 2024).

- Li, S.; Zhang, M.; Hu, H.; Guo, G.; Gong, L.; Dong, L.; Yao, H. Fate of sulfur and chlorine during co-incineration of municipal solid waste and industrial organic solid waste. Sci. Total Env. 2024, 920, 171040. [Google Scholar] [CrossRef] [PubMed]

- Abdulyekeen, K.A.; Daud, W.M.A.W.; Patah, M.F.A. Torrefaction of wood and garden wastes from municipal solid waste to enhanced solid fuel using helical screw rotation-induced fluidised bed reactor: Effect of particle size, helical screw speed and temperature. Energy 2024, 293, 130759. [Google Scholar] [CrossRef]

- Paszkowski, J.; Domański, M.; Caban, J.; Zarajczyk, J.; Pristavka, M.; Findura, P. The use of refuse derived fuel (RDF) in the power industry. Agric. Eng. 2020, 24, 83–90. [Google Scholar] [CrossRef]

- BATC. Commission Implementing Decision (EU) 2019/2010 Establishing the Best Available Techniques (BAT) Conclusions, under Directive 2010/75/EU of the European Parliament and of the Council, for Waste Incineration. 2019. Available online: https://eur-lex.europa.eu/eli/dec_impl/2019/2010/oj (accessed on 20 June 2024).

- Rahman, A.; Rasul, M.G.; Khan, M.M.K.; Sharma, S. Recent development on the uses of alternative fuels in cement manufacturing process. Fuel 2015, 145, 84–99. [Google Scholar] [CrossRef]

- Strigáč, J. Effect of selected alternative fuels and raw materials on the cement clinker quality. Sel. Sci. Pap. -J. Civ. Eng. 2015, 10, 81–92. [Google Scholar] [CrossRef]

- Tezer, O.; Karabag, N.; Ozturk, M.U.; Ongen, A.; Ayol, A. Comparison of green waste gasification performance in updraft and downdraft fixed bed gasifiers. Int. J. Hydrog. Energy 2022, 47, 31864–31876. [Google Scholar] [CrossRef]

- Liczbiński, P.; Borowski, S. Effect of hyperthermophilic pretreatment on methane and hydrogen production from garden waste under mesophilic and thermophilic conditions. Bioresour. Technol. 2021, 335, 125264. [Google Scholar] [CrossRef]

- Song, Y.; Meng, S.; Chen, G. Co-digestion of garden waste, food waste, and tofu residue: Effects of mixing ratio on methane production and microbial community structure. J. Environ. Chem. Eng. 2021, 9, 106504. [Google Scholar] [CrossRef]

- Domokos-Szabolcsy, É.; Yavuz, S.R.; Picoli, E.; Fári, M.G.; Kovács, Z.; Tóth, C.; Kaszás, L.; Alshaal, T.; Elhawat, N. Green Biomass-Based Protein for Sustainable Feed and Food Supply: An Overview of Current and Future Prospective. Life 2023, 13, 307. [Google Scholar] [CrossRef]

- Volkmar, M.; Maus, A.L.; Weisbrodt, M.; Bohlender, J.; Langsdorf, A.; Holtmann, D.; Ulber, R. Municipal green waste as substrate for the microbial production of platform chemicals. Bioresour. Bioprocess. 2023, 10, 43. [Google Scholar] [CrossRef]

- Chintakanan, P.; Vitidsant, T.; Reubroycharoen, P.; Kuchonthara, P.; Kida, T.; Hinchiranan, N. Bio-jet fuel range in biofuels derived from hydroconversion of palm olein over Ni/zeolite catalysts and freezing point of biofuels/Jet A-1 blends. Fuel 2021, 293, 120472. [Google Scholar] [CrossRef]

- Ghiat, I.; Pradhan, S.; Govindan, R.; Mackey, H.R.; McKay, G.; Al-Ansari, T. Biochar: A sustainable approach of green waste management in agricultural practices under controlled microclimate. Chem. Eng. Trans. 2022, 92, 331–336. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).