Prospects of Hydrogen Application as a Fuel for Large-Scale Compressed-Air Energy Storages

Abstract

1. Introduction

- Mechanical energy storage:

- Pumped hydropower storage;

- Compressed-air energy storage;

- Flywheels.

- Electrical energy storage:

- Batteries;

- Hydrogen.

- Thermal energy storage:

- Sensible heat storage;

- Latent heat storage;

- Thermochemical energy storage.

- Capacity: it indicates how much energy can be stored and it is directly linked to the size of the storage system and thermophysical properties of the storage medium.

- Power: it represents the rate at which energy can be charged to or discharged from the storage.

- Efficiency: it is defined as the ratio of discharged energy to charged energy and it quantifies how much energy is lost during storage or charging–discharging operating conditions.

- Storage period: it represents how long energy can be stored without losing usefulness.

- Charge and discharge time: the time needed to charge or discharge the energy storage. It can last from a few hours to many months for daily or seasonal storage, respectively.

- Cost: it is the sum of the capital and operating costs of the energy storage system. Operating costs strongly depend on the maintenance and lifetime of storage, i.e., they depend on how many operating cycles the storage and the medium can support. Costs for energy storage systems can be expressed in EUR/kWh or EUR/kW if the focus is on the capacity or power of the storage, respectively.

- Environmental impact: energy storage systems are suitable to be coupled with renewables to increase their penetration into the electricity market and reduce environmental impact.

- Primary energy consumption. A storage system must necessarily have a very low environmental impact to not lose its main purpose when it is coupled with renewables.

2. Relevance of the Research

3. Materials and Methods

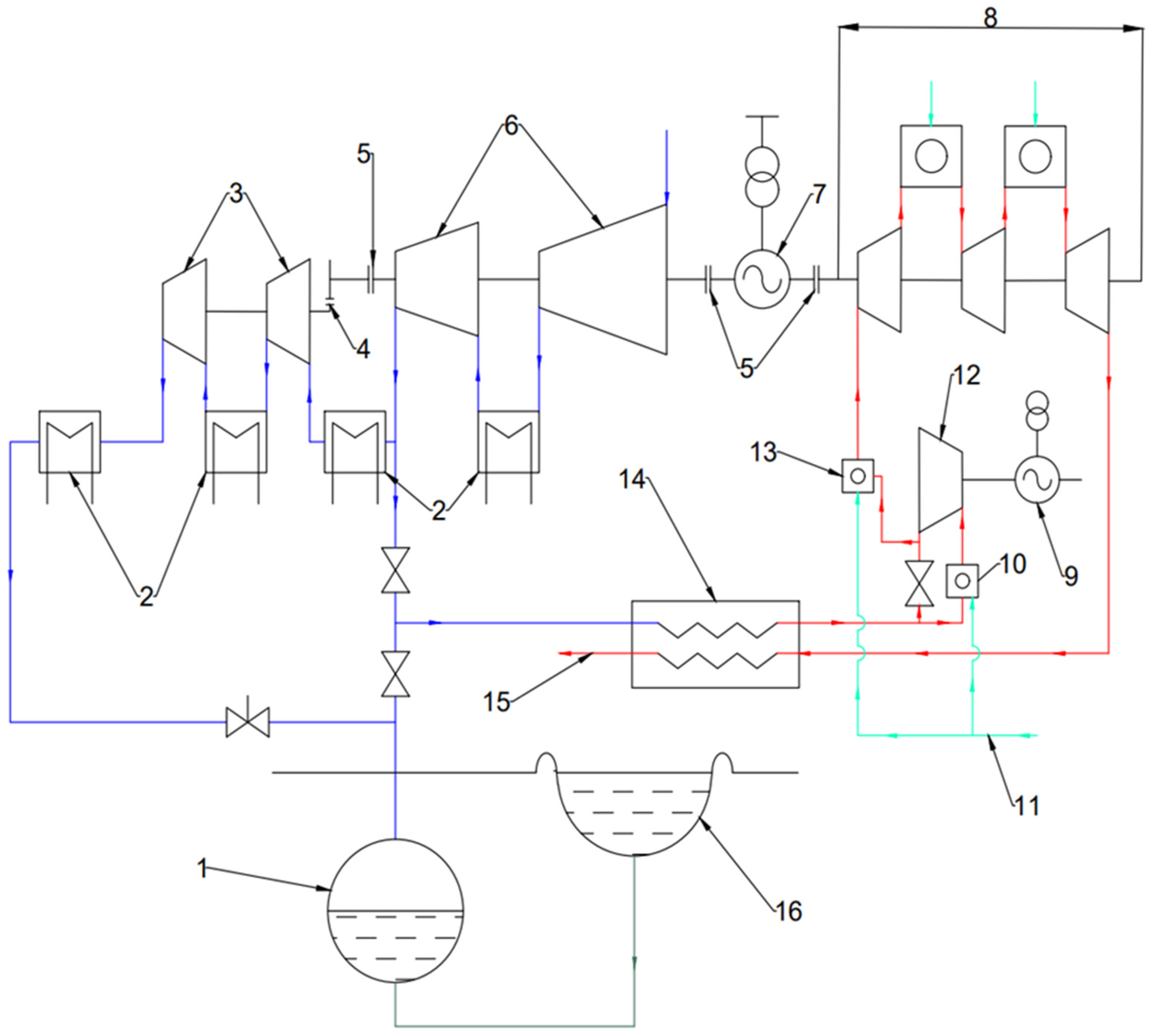

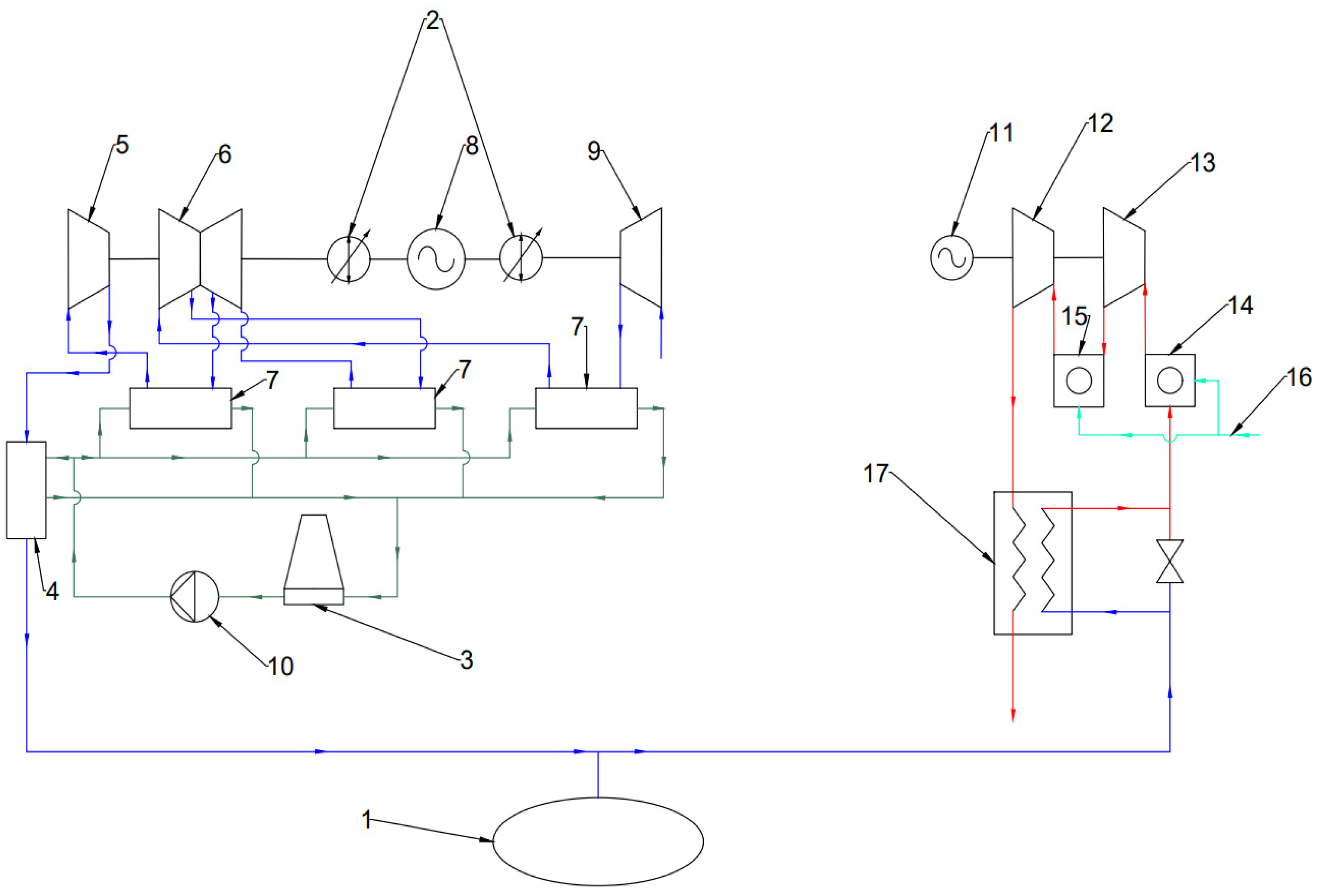

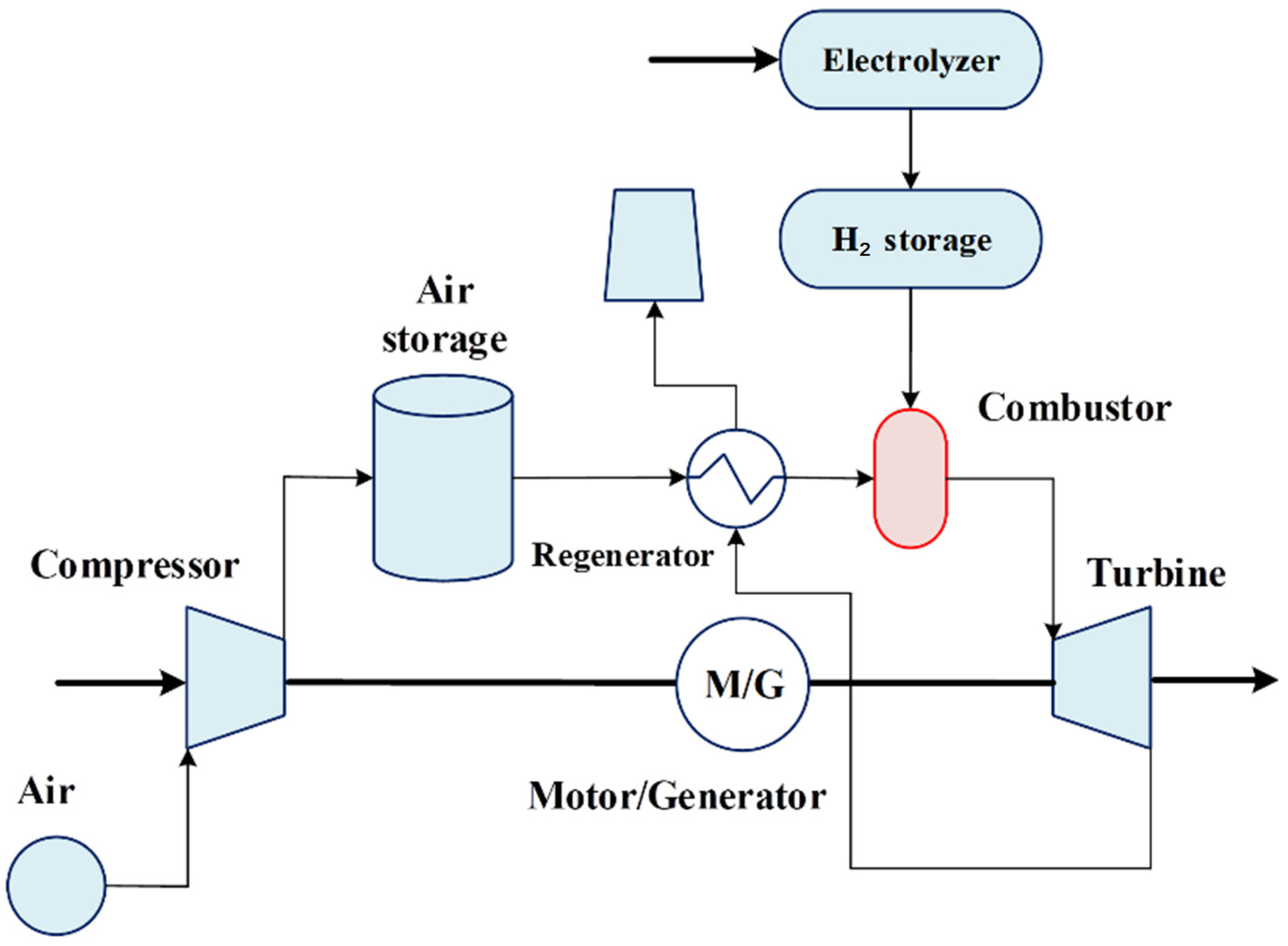

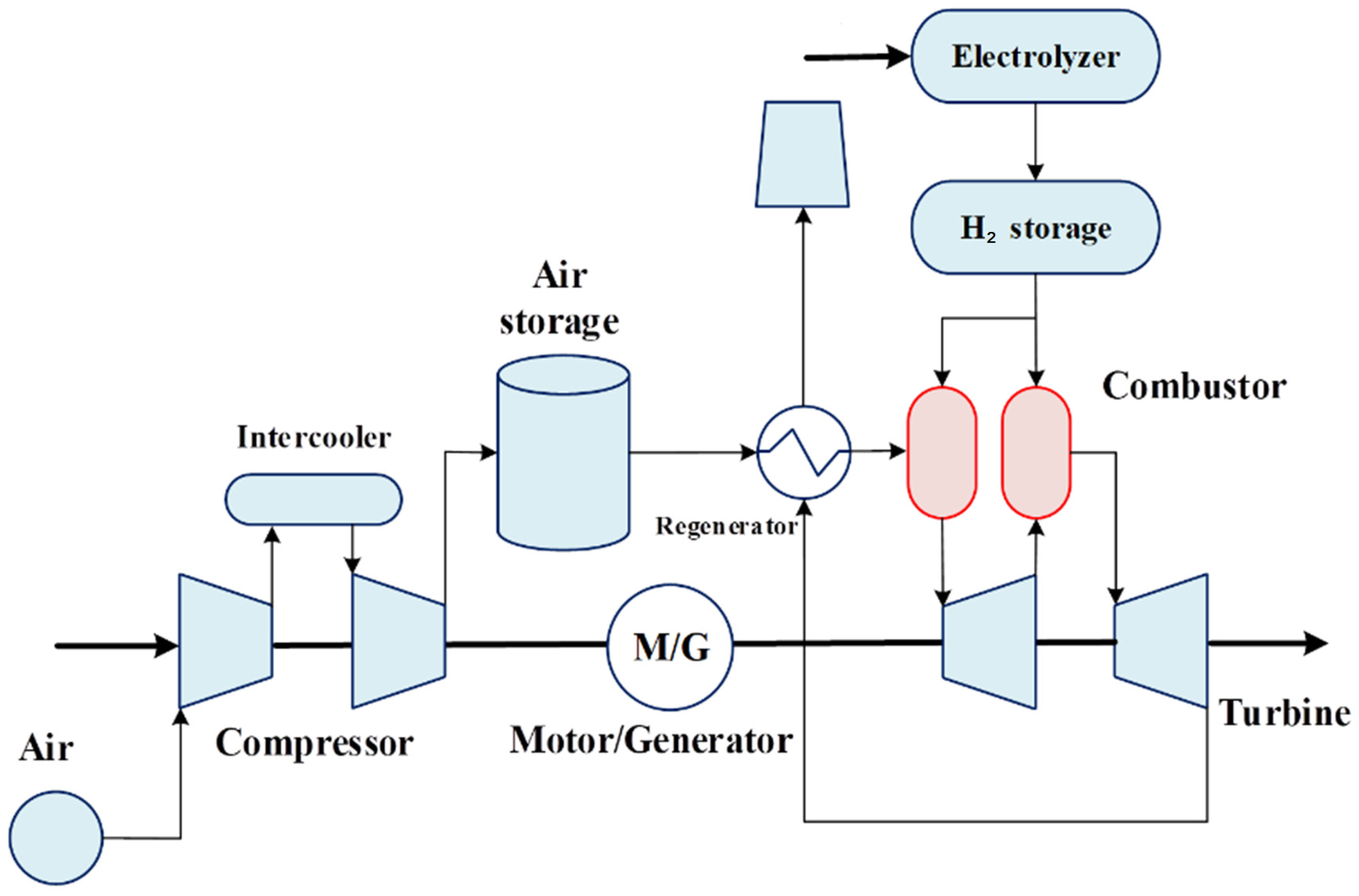

3.1. Comparison of the D-CAES Technological Scheme

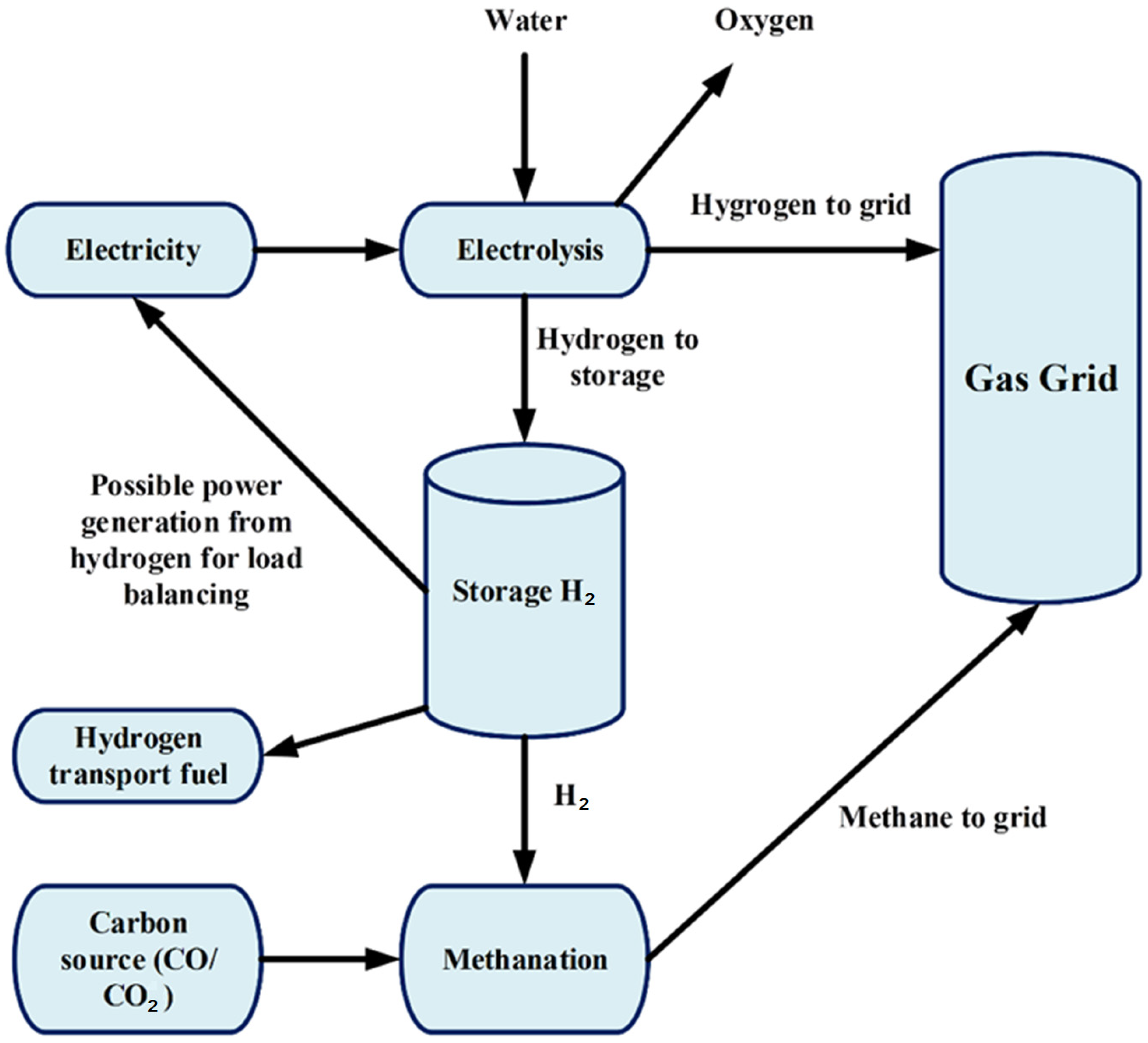

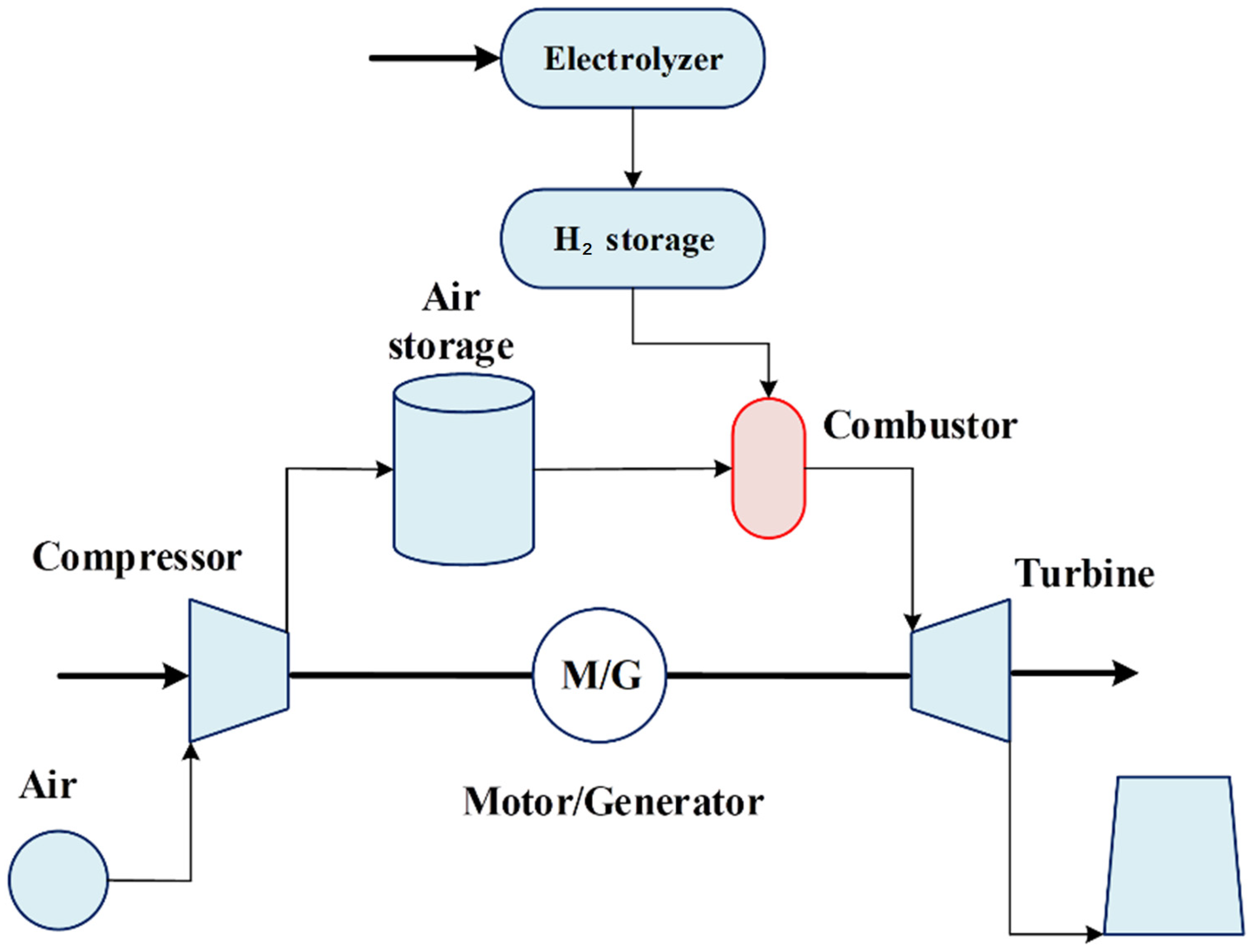

3.2. Fundamentals of Power-to-Gas Technology and Hydrogen Integration into CAES

- Alkaline electrolysis;

- Polymer electrolyte membrane electrolysis;

- Solid oxide electrolyzer cell.

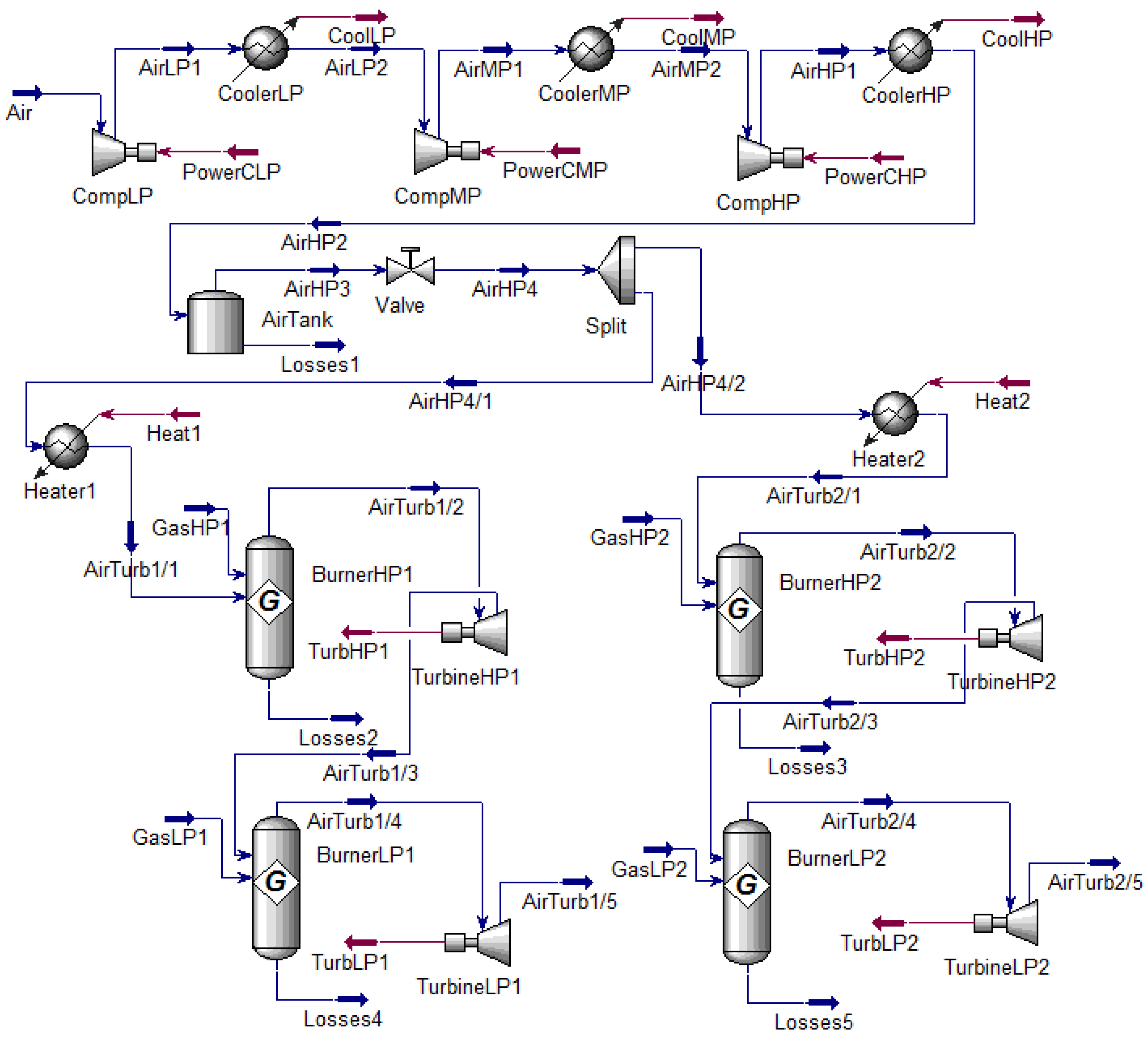

3.3. Modeling of the CAES SENECA-1A

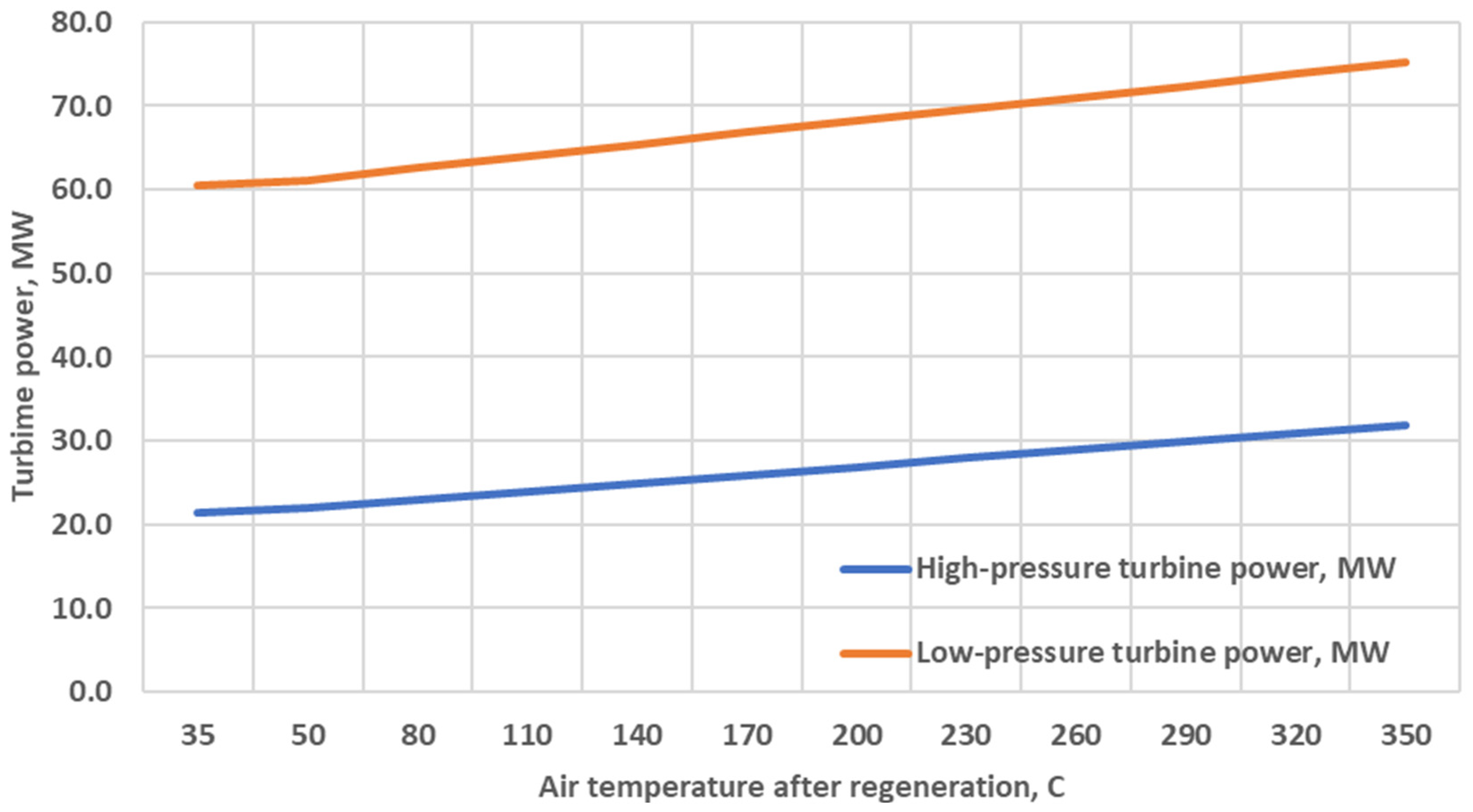

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Stadler, I. Power grid balancing of energy systems with high renewable energy penetration by demand Response. Util. Policy 2008, 16, 90–98. [Google Scholar] [CrossRef]

- Bloess, A.; Schill, W.; Zerrahn, A. Power-to-heat for renewable energy integration: A review of technologies, modeling approaches, and flexibility potentials. Appl. Energy 2018, 212, 1611–1626. [Google Scholar] [CrossRef]

- Rogalev, N.; Rogalev, A.; Kindra, V.; Naumov, V.; Maksimov, I. Comparative Analysis of Energy Storage Methods for Energy Systems and Complexes. Energies 2022, 15, 9541. [Google Scholar] [CrossRef]

- Hasan, K.N.; Preece, R.; Milanovic, J.V. Existing approaches and trends in uncertainty modelling and probabilistic stability analysis of power systems with renewable generation. Renew. Sustain. Energy Rev. 2019, 101, 168–180. [Google Scholar] [CrossRef]

- Steffen, B.; Weber, C. Efficient storage capacity in power systems with thermal and renewable generation. Energy Econ. 2013, 36, 556–567. [Google Scholar] [CrossRef]

- Beccali, M.; Cellura, M.; Mistretta, M. Environmental effects of energy policy in Sicily: The role of renewable energy. Renew. Sustain. Energy Rev. 2007, 11, 282–298. [Google Scholar] [CrossRef]

- Hsieh, E.; Anderson, R. Grid flexibility: The quiet revolution. Electr. J. 2017, 30, 1–8. [Google Scholar] [CrossRef]

- Huber, M.; Dimkova, D.; Hamacher, T. Integration of wind and solar power in Europe: Assessment of flexibility requirements. Energy 2014, 69, 236–246. [Google Scholar] [CrossRef]

- Denholm, P.; Margolis, R.M. Evaluating the limits of solar photovoltaics (PV) in traditional electric power systems. Energy Policy 2007, 35, 2852–2861. [Google Scholar] [CrossRef]

- De Cesaro, J.; Porter, K.; Milligan, M. Wind Energy and Power System Operations: A Review of Wind Integration Studies to Date. Electr. J. 2009, 22, 34–43. [Google Scholar] [CrossRef]

- Lund, P.D.; Lindgren, J.; Mikkola, J.; Salpakari, J. Review of energy system flexibility measures to enable high levels of variable renewable electricity. Renew. Sustain. Energy Rev. 2015, 45, 785–807. [Google Scholar] [CrossRef]

- Salpakari, J.; Mikkola, J.; Lund, P.D. Improved flexibility with large-scale variable renewable power in cities through optimal demand side management and power-to-heat conversion. Energy Convers. Manag. 2016, 126, 649–661. [Google Scholar] [CrossRef]

- Ubertini, S.; Facci, A.L.; Andreassi, L. Hybrid Hydrogen and Mechanical Distributed Energy Storage. Energies 2017, 10, 2035. [Google Scholar] [CrossRef]

- Han, Z.; Guo, S. Investigation of operation strategy of combined cooling, heating and power (CCHP) system based on advanced adiabatic compressed air energy storage. Energy 2018, 160, 290–308. [Google Scholar] [CrossRef]

- Borri, E.; Tafone, A.; Comodi, G.; Romagnoli, A.; Cabeza, L.F. Compressed Air Energy Storage—An Overview of Research Trends and Gaps through a Bibliometric Analysis. Energies 2022, 15, 7692. [Google Scholar] [CrossRef]

- Briola, S.; Gabbrielli, R.; Delgado, A. Energy and economic performance assessment of the novel integration of an advanced configuration of liquid air energy storage plant with an existing large-scale natural gas combined cycle. Energy Convers. Manag. 2020, 205, 112434. [Google Scholar] [CrossRef]

- Budt, M.; Wolf, D.; Span, R.; Yan, J. A review on compressed air energy storage: Basic principles, past milestones and recent developments. Appl. Energy 2016, 170, 250–268. [Google Scholar] [CrossRef]

- King, M.; Jain, A.; Bhakar, R.; Mathur, J.; Wang, J. Overview of current compressed air energy storage projects and analysis of the potential underground storage capacity in India and the UK. Renew. Sustain. Energy Rev. 2021, 139, 110705. [Google Scholar] [CrossRef]

- Li, P.; Hu, Q.; Han, Z.; Wang, C.; Wang, R.; Han, X.; Wang, Y. Thermodynamic analysis and multi-objective optimization of a trigenerative system based on compressed air energy storage under different working media and heating storage media. Energy 2022, 239, 122252. [Google Scholar] [CrossRef]

- Soltani, M.; Kashkooli, F.M.; Jafarizadeh, H.; Hatefi, M.; Fekri, H.; Gharali, K.; Nathwani, J. Diabatic Compressed Air Energy Storage (CAES) Systems: State of the Art. In Encyclopedia of Energy Storage; Elsevier: Amsterdam, The Netherlands, 2022; pp. 173–187. [Google Scholar] [CrossRef]

- Mucci, S.; Bischi, A.; Briola, S.; Baccioli, A. Small-scale adiabatic compressed air energy storage: Control strategy analysis via dynamic modelling. Energy Convers. Manag. 2021, 243, 114358. [Google Scholar] [CrossRef]

- Salvini, C.; Giovannelli, A. Techno-Economic Comparison of Utility-Scale Compressed Air and Electro-Chemical Storage Systems. Energies 2022, 15, 6644. [Google Scholar] [CrossRef]

- Zhou, Q.; Du, D.; Lu, C.; He, Q.; Liu, W. A review of thermal energy storage in compressed air energy storage system. Energy 2019, 188, 115993. [Google Scholar] [CrossRef]

- Mousavi, S.B.; Adib, M.; Soltania, M.; Razmi, A.R.; Nathwani, J. Transient thermodynamic modeling and economic analysis of an adiabatic compressed air energy storage (A-CAES) based on cascade packed bed thermal energy storage with encapsulated phase change materials. Energy Convers. Manag. 2021, 243, 114379. [Google Scholar] [CrossRef]

- Li, J.; Lu, W.; Luo, Z.; Zeng, Y. Synthesis and thermal properties of novel sodium nitrate microcapsules for high-temperature thermal energy storage. Sol. Energy Mater. Sol. Cells 2017, 159, 440–446. [Google Scholar] [CrossRef]

- Chen, L.; Wang, Y.; Xie, M.; Ye, K.; Mohtaram, S. Energy and exergy analysis of two modified adiabatic compressed air energy storage (A-CAES) system for cogeneration of power and cooling on the base of volatile fluid. J. Energy Storage 2021, 42, 103009. [Google Scholar] [CrossRef]

- Zhao, P.; Lai, Y.; Xu, W.; Zhang, S.; Wang, P.; Wang, J. Performance investigation of a novel near-isothermal compressed air energy storage system with stable power output. Energy Res. 2020, 44, 11135–11151. [Google Scholar] [CrossRef]

- Sarmast, S.; Fraser, R.A.; Dusseault, M.B. Performance and cyclic heat behavior of a partially adiabatic Cased-Wellbore Compressed Air Energy Storage system. J. Energy Storage 2021, 44, 103279. [Google Scholar] [CrossRef]

- Olkhovsky, G.G.; Kazaryan, V.A.; Stolyarevsky, A.Y. Compressed-Air and Gas Turbine Power Plants (CAGTPP); Institute of Computer Research: Izhevsk, Russia, 2011; p. 360. (In Russian) [Google Scholar]

- NYSEG. Seneca Compressed Air Energy Storage (CAES) Demonstration Project; Final Phase 1 Technical Report; UNT: Denton, TX, USA, 2012; p. 66. Available online: https://digital.library.unt.edu/ark:/67531/metadc841509/m1/1 (accessed on 1 August 2023).

- Buttler, A.; Spliethoff, H. Current status of water electrolysis for energy storage, grid balancing and sector coupling via power-to-gas and power-to-liquids: A review. Renew. Sustain. Energy Rev. 2018, 82, 2440–2454. [Google Scholar] [CrossRef]

- Sanchez, M.; Amores, E.; Abad, D.; Rodriguez, L.; Clemente-Jul, C. Aspen Plus model of an alkaline electrolysis system for hydrogen production. Int. J. Hydrog. Energy 2020, 45, 3916–3929. [Google Scholar] [CrossRef]

- Rivera-Tinoco, R.; Farran, M.; Bouallou, C.; Aupretre, F.; Valentin, S.; Millet, P.; Ngameni, J.R. Investigation of power-to-methanol processes coupling electrolytic hydrogen production and catalytic CO2 reduction. Int. J. Hydrog. Energy 2016, 41, 4546–4559. [Google Scholar] [CrossRef]

- Er-Rbib, H.; Bouallou, C. Modeling and simulation of methanation catalytic reactor for renewable electricity storage. Chem. Eng. Trans. 2013, 35, 541–546. [Google Scholar] [CrossRef]

- Sharifian, S.; Harasek, M. Simulation of COx methanation reactor for the production of natural gas. Chem. Eng. Trans. 2015, 45, 1003–1008. [Google Scholar] [CrossRef]

- Sharifian, S.; Miltner, M.; Harasek, M. Thermodynamic and Kinetic Based Simulation Approach to CO2 and CO Methane Hydrogenation. Chem. Eng. Trans. 2016, 52, 565–570. [Google Scholar] [CrossRef]

- Semin, D.V.; Fedyukhin, A.V.; Dronov, S.A.; Panarin, V.E.; Savostikov, A.E. Aspen Plus model of a Power-to-Gas technology for methane-hydrogen mixture production. In Proceedings of the 4th International Youth Conference on Radio Electronics, Electrical and Power Engineering, REEPE, Moscow, Russia, 17–19 March 2022. [Google Scholar] [CrossRef]

- Genbach, A.A.; Bondartsev, D.Y.; Iliev, I.K. Modelling of capillary coatings and heat exchange surfaces of elements of thermal power plants. Bulg. Chem. Commun. 2018, 50, 133–139. [Google Scholar]

- Genbach, A.A.; Bondartsev, D.Y.; Iliev, I.K.; Georgiev, A.G. Scientific method of creation of ecologically clean capillary-porous systems of cooling of power equipment elements of power plants on the example of gas turbines. Energy 2020, 199, 117458. [Google Scholar] [CrossRef]

| Parameter/CAES | Huntorf | McIntosh | UT | Matagorda | Seneca |

|---|---|---|---|---|---|

| Status | In operation | In operation | Project | Project | Project |

| Charging time, hours | 8 | 8 | - | 8 | 8 |

| Discharge time, hours | 2 | 8 | 20 | 16 | 10 |

| Total turbine power | 290 | 110 | 250 | 135 | 214 |

| Total compressor power | 60 | 50 | 203 | - * | 184 |

| Outlet pressure of low-pressure compressor, bar | 6 | - * | 16 | - * | 46.9 |

| Outlet pressure of high-pressure compressor, bar | 60 | 60 | 67.5 | 64 | 103.4 |

| Airflow through compressors, kg/s | 108 | 91 | - * | - * | 270 |

| Inlet pressure of high-pressure turbine, bar | 43 | 42 | 66 | 49 | 73 |

| The inlet temperature of high-pressure turbine, °C | 550 | 540 | 540 | - * | 620 |

| Flow through one high-pressure turbine, kg/s | 417 | 155 | - * | 185 | 136 |

| Inlet pressure of low-pressure turbine, bar | 11 | 15 | 11 | - * | 18 |

| The inlet temperature of the low-pressure turbine, °C | 825 | 870 | 1095 | - * | 850 |

| Exhaust gas temperature, °C | 390 | 370 | - * | - * | 447 |

| Heat regeneration | no | yes | yes | yes | yes |

| Parameter | Units | Value |

|---|---|---|

| Total compressor power | MW | 184 |

| Airflow through compressors | kg/s | 270 |

| Estimated storage capacity | m3 | 450,000 |

| Estimated storage temperature | °C | 35 |

| Maximum storage pressure | bar | 103 |

| Total turbine power | MW | 214 |

| Flow rate through one high-pressure turbine for natural gas/hydrogen | kg/s | 136/135.4 |

| Flow through one low-pressure turbine for natural gas/hydrogen | kg/s | 137.5/136.0 |

| Inlet pressure of high-pressure turbine | bar | 75 |

| Inlet pressure of low-pressure turbine | bar | 20 |

| Full charge/discharge period | h | 12 |

| Total consumption of natural gas/hydrogen | kg/s | 5.0/2.0 |

| Carbon dioxide emissions for natural gas/hydrogen | kg/s | 8.8/0.0 |

| Water vapor emission for natural gas/hydrogen | kg/s | 17.6/27.4 |

| Exhaust gas temperature | °C | 447 |

| Efficiency | % | 62.1 |

| Parameter | Units | D-CAES | A-CAES |

|---|---|---|---|

| Total consumption of natural gas/hydrogen | kg/s | 5.0/2.0 | 0.0 |

| Carbon dioxide emissions for natural gas/hydrogen | kg/s | 8.8/0.0 | 0.0 |

| Water vapor emission for natural gas/hydrogen | kg/s | 17.6/27.4 | 0.0 |

| Total compressor power | MW | 184 | 184 |

| Airflow through compressors | kg/s | 270 | 270 |

| Total turbine power | MW | 214 | 131.6 |

| Flow rate through one high-pressure turbine for natural gas/hydrogen | kg/s | 136/135.4 | 135.0 |

| Flow through one low-pressure turbine for natural gas/hydrogen | kg/s | 137.5/136.0 | 135.0 |

| Carbon dioxide emissions for natural gas/hydrogen | kg/s | 8.8/0.0 | 0.0 |

| Water vapor emission for natural gas/hydrogen | kg/s | 17.6/27.4 | 0.0 |

| Efficiency | % | 62.1 | 71.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iliev, I.K.; Fedyukhin, A.V.; Semin, D.V.; Valeeva, Y.S.; Dronov, S.A.; Beloev, I.H. Prospects of Hydrogen Application as a Fuel for Large-Scale Compressed-Air Energy Storages. Energies 2024, 17, 518. https://doi.org/10.3390/en17020518

Iliev IK, Fedyukhin AV, Semin DV, Valeeva YS, Dronov SA, Beloev IH. Prospects of Hydrogen Application as a Fuel for Large-Scale Compressed-Air Energy Storages. Energies. 2024; 17(2):518. https://doi.org/10.3390/en17020518

Chicago/Turabian StyleIliev, Iliya K., Alexander V. Fedyukhin, Daniil V. Semin, Yulia S. Valeeva, Stanislav A. Dronov, and Ivan H. Beloev. 2024. "Prospects of Hydrogen Application as a Fuel for Large-Scale Compressed-Air Energy Storages" Energies 17, no. 2: 518. https://doi.org/10.3390/en17020518

APA StyleIliev, I. K., Fedyukhin, A. V., Semin, D. V., Valeeva, Y. S., Dronov, S. A., & Beloev, I. H. (2024). Prospects of Hydrogen Application as a Fuel for Large-Scale Compressed-Air Energy Storages. Energies, 17(2), 518. https://doi.org/10.3390/en17020518