Abstract

A conceptual design of coffee stem biomass gasification was developed using the Aspen Plus process simulator, which was analyzed based on energy criteria such as the lower heating value of the produced synthesis gas and cold gas efficiency. The results yielded a lower heating value of 5.07 kJ/MJ, with a cold gas efficiency of 77.45% and a yield of 2.75 kg gas/kg biomass, all operating under optimal conditions with studied parameters including an air-to-biomass ratio between 1.8 and 2.5, gasifying agent temperature of 260 °C, and biomass moisture content below 10%. A sensitivity analysis was conducted on the formation of the most important compounds for synthesis gas quality (H2, CO, CO2, H2O, CH4). This involved understanding the reactions occurring throughout the gasification reactor and evaluating process parameters such as feed moisture content, gasification section temperature, and the ratio between feed and gasifying agent flows to optimize the process with the aim of improving product quality and reducing residue formation. The simulation scheme was validated against experimental data, yielding results consistent with reality. This contributed valuable information towards process optimization for projects targeting the Colombian coffee sector, paving the way for future gasifier designs tailored to the quantity of raw material to be processed.

1. Introduction

Gasification is a thermochemical process in which a carbon-rich material, in this case, coffee stem biomass, is transformed through thermochemical reactions into a combustible gas with considerable calorific value. This gaseous fuel is commonly referred to as synthesis gas or more commonly (syngas) [1]. This syngas is the product of gasification, meaning it is a mixture of gases consisting of hydrogen and carbon monoxide. This composition will also include carbon dioxide, nitrogen, and methane, which will depend on various parameters such as the gasifying agent used, the design of the gasifier, and the process control variables (moisture content, gasification temperature, gasifying agent velocity, and gasifying agent/biomass ratio) [2]. The primary purpose of syngas is energy production through generators, turbines, or previously adapted internal combustion engines. This gas can be used in electricity production through its use in adapted turbines or internal combustion engines [3]. The study of the gasification process has gained relevance in recent years as a tool to reduce greenhouse gas emissions. During this time, various studies have been conducted to increase the energy efficiency of the gas and reduce harmful emissions from the design stage [4]. Additionally, different gasifying agents or mixtures of these agents have been evaluated for the same purpose [5]. Other uses of this syngas include its employment for the production of fuels and basic chemicals such as methane, hydrocarbons through the Fischer–Tropsch process, methanol, ethanol, and dimethyl ether [6], reaffirming the use of biomass conversion processes as an interesting alternative for cogeneration processes in other industries. Due to the variations in the gasification process with respect to the biomass used, the investigative focus has also centered on creating mathematical models that can predict the process behavior based on initial conditions, especially in processes that use wood residues. The importance of these theoretical models lies in their validation with experimental data [7], leading to significant improvements in defining mathematical models within simulation models. In addition to experimental models, theoretical and simulation models have been developed, where these reaction mechanisms are incorporated into mathematical models and mass and energy balances, allowing for the estimation of various parameters such as the ER (equivalence ratio), which determines the amount of stoichiometric air needed to carry out the gasification process, among other parameters for using these gases in regenerative electric turbines [8]. The development and research of the gasification process in Colombia have seen significant growth due to its great economic potential [9], especially in the coffee sector, since Colombia is the third-largest producer and exporter of coffee in the world. There is significant potential for energy production through the gasification process using coffee stems from coffee plantations [10]. An example of its figures was the production closure in 2019 of 14.8 million 60 kg coffee sacks [11]. It is worth noting that 90.5% of the total weight of the coffee fruit consists of waste that can be utilized as biomass for the production of synthesis gas. Its use would reduce environmental impact and avoid transportation costs for its disposal and storage. It can also be used as fuel in the following equipment: turbines, internal combustion engines, and boilers. This is why there is a need to carry out a conceptual design study of a technological scheme for a coffee stem gasification process. These coffee stems come from pruning practices. The Coffee Growers Federation reports that this practice is carried out in 5-year cycles, and coffee farms maintain an average density of 5000 trees/ha, resulting in 16 tons/ha of coffee stems. This amount can be calculated as 0.6 kg of dry stems per kg of coffee cherries [10]. Typically, this waste is used locally as fuel for cooking; other than this, the waste takes a long time to degrade. However, it requires space for storage or disposal, which has associated costs and can even cause environmental damage. This project enables the correlation between other simulation models and experimental processes. Additionally, it analyzes various operating parameters and energy criteria that allow for the optimization of syngas quality. This project promotes the involvement of biomass energy within the national territory, aiming to utilize residues, diversify the electrical grid, and support cogeneration projects that can employ these technologies. This scheme provides a foundation for analyzing the implementation of projects aimed at biomass utilization in the coffee industry and explains, through simulation, each stage of the process and the crucial parameters that occur in them, facilitating a general understanding of the process. Similarly, it provides an analysis of the most relevant parameters to control and measure, which are proportional to the quality of the syngas as an energy product and, therefore, should be prioritized in the development of small- and medium-scale [12,13] gasification projects.

2. Materials and Methods

For modeling the gasification process, it is necessary to establish the appropriate variables and design parameters based on the focus of the project, the criteria specific to the material being worked on, and the following information.

2.1. Conceptual Framework

There are several by-products in the coffee industry that can be utilized and leveraged as value-added products, such as syngas. Other by-products, like the mucilage from the coffee fruit, can be used in the production of biofuels through fermentation or in processes for extracting alcohols and caffeine [10]. Additionally, there are various scenarios for energy production through gasification or pyrolysis processes to obtain combustible syngas, which can also serve as a basis for hydrogen production and purification processes [7,14]. Coffee stems have high availability, with an estimated 1 kg of processed coffee generating approximately 0.6 kg of coffee stems [10]. Its low moisture content and elemental composition [14,15,16] make this material an ideal by-product for gasification processes. The above is shown in Table 1.

Table 1.

Physicochemical characterization of coffee stems.

Regarding previous analyses, coffee stems exhibit characteristics in their material such as low ash and fixed carbon content, which translates to low residue formation during the process. Additionally, there is a high volatile matter content, facilitating biomass transformation into gas. On the other hand, and importantly, the calorific value of this material is sufficient to carry out energy processes.

2.2. Study Parameters

There are many factors involved in the gasification process that are directly linked to product quality and residue formation [17]. In the previous section, we already described one of these factors: the biomass to be gasified. It was explained that, due to its characteristics of low moisture, high volatile matter content, and calorific capacity, the coffee stem is suitable for this process. Now, the gasifying agent used in the process is addressed. Since the scope of this project consists of providing a conceptual framework for the development of gasification projects, air is the most suitable gasifying agent for this purpose due to its easy handling and, unlike other gasifying agents such as steam or oxygen, it has an economic advantage, as it does not involve acquisition costs like the others. Although the calorific value of syngas using air as the gasifying agent may be lower due to the high nitrogen content of the air, as observed in [18], combustion with air allows for heat to be provided for material drying, along with increasing the temperature to facilitate the endothermic reactions that produce water and carbon dioxide, which will be reactants in the reduction section of the gasifier, favoring the formation of carbon monoxide and hydrogen [19].

The following sections explain the parameters of equivalence ratio, operating temperature, and moisture content, comparing and analyzing their variations concerning the quality and composition of the syngas produced.

2.2.1. Equivalence Ratio (ER)

This is one of the most relevant parameters for a gasifier and essentially defined as the ratio of the amount of oxygen supplied to the system to the stoichiometric amount required for complete combustion. In other words, it defines the extent to which combustion will take place during gasification, which will have various implications both on the final gas composition and on tar formation. A high equivalence ratio implies an increase in the carbon dioxide composition, resulting in a lower heating value of the synthesis gas [17,20]. The calculation of the equivalence ratio is given by the following equation.

The equivalence ratio is also related to the ratio of the gasifying agent flow to the feedstock biomass. Therefore, when the material has a high moisture content or steam is used as the gasifying agent, increasing this ratio corresponds to seeking an increase in hydrogen in the final gas composition due to the water–gas shift reaction. This also aims to reduce tar formation by promoting its cracking [21].

The author [22] proposed an expression regarding the equivalence ratio to reduce the number of parameters on which the gasifier performance depends, taking into account the flow of the gasifying agent, which in this case, like in this project, is air. It also relates the biomass flow to the residence time, obtaining the following expression for an ideal system with a fugacity of ϕ = 1.

It is estimated that the ideal or theoretical operating range falls within the ER (equivalence ratio) value range of 0.2 to 0.4, allowing for effective dosing.

The effectiveness of gasification corresponds to the composition of the synthesis gas, which, depending on its concentration of carbon monoxide, hydrogen, and methane, determines its heating value.

The change in its composition as a function of ER was experimentally measured by [22]. They evaluated the composition profile also with respect to the ratio between the gasifying agent flow and the biomass. These relationships allow for an adequate visualization of each component, facilitating decision making based on the amount of gasifying agent flow to use to improve the quality of the syngas and reduce residue formation.

These relationships allow for estimating the necessary flow of gasifying agent for the operation of the gasifier under conditions that maximize the energy potential of the syngas and the thermal efficiency of the process. The analysis of this parameter does not vary with respect to the gasifying agent used; in the case of the aforementioned author, he used steam in his study. The differences presented by the various gasifying agents are in the composition and thus the heating value of the syngas.

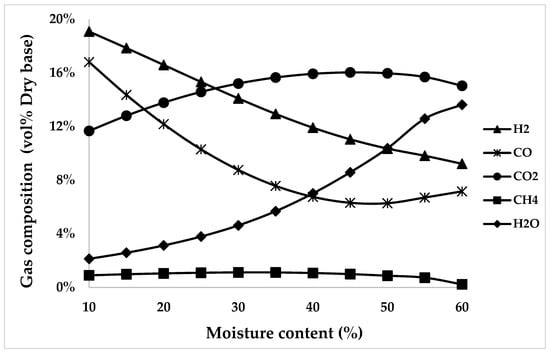

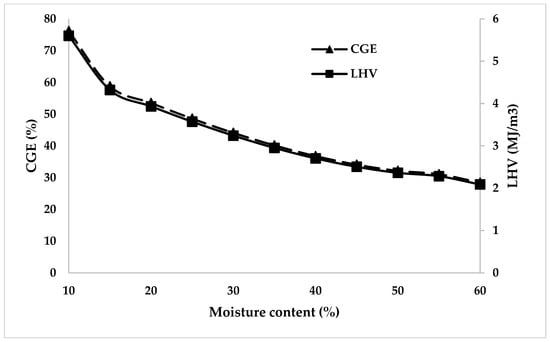

2.2.2. Moisture Content

The moisture content varies depending on the raw material to be gasified and is a determining factor as it involves energy consumption for drying the material [23]. Energy consumption is proportional to the material’s moisture and can also lead to changes in the syngas composition [24]. Moisture content implies a decrease in the quality of synthesis gas for the formation of compounds that contribute to the calorific value of the gas mixture, such as methane, hydrogen, and carbon monoxide. This is because water favors the formation of carbon dioxide, which does not contribute to the calorific value of the product. Additionally, for moisture values above 35%, hydrogen is reduced due to water formation in total combustion reactions. Since hydrogen is the main compound contributing to the calorific value of the process, it is not advisable to allow its reduction. The author [25] finds that low moisture values benefit the gasification process primarily due to the minimization of residue formation. They also analyze this parameter through the energy criteria of the produced syngas, observing that the calorific value varies minimally as moisture increases. The important factors are the tar fraction and the cold gas efficiency (CGE), which are minimum and maximum, respectively, at low moisture levels. The thermal efficiency of the process will be proportional to the moisture content of the biomass due to the increased energy demand for drying and a decrease in the quality of the syngas.

2.2.3. Gasification Temperature

In gasification schemes, in the designs of downdraft gasifiers commonly used in the industry, the temperature inside the gasifier is crucial in relation to energy expenditure based on the degradation of biomass into gases that undergo various thermochemical conversions. These schemes are divided into four stages: drying, pyrolysis, oxidation, and reduction. Each section operates at different temperature ranges and increases as it progresses from one stage to the next [26].

The reactions occurring in the gasifier are represented below:

From these reactions that transform the carbon in the biomass, the products hydrogen, carbon monoxide, and carbon dioxide continue to react as follows:

All these reactions are in chemical equilibrium; therefore, they will proceed in either direction depending on the system conditions (temperature, pressure, and concentration of the reacting species). These conditions will define the quality of the synthesis gas, where a higher concentration of hydrogen and carbon monoxide species is desired to increase the calorific value of the syngas [27].

On the other hand, throughout the process, there are various reactions, starting with the devolatilization and pyrolysis of the biomass that lead to heterogeneous reactions, and ending with the oxidation and reduction section of the gasifier where homogeneous reactions occur. The equilibrium of these reactions will also depend on the gasifying agent used. Various mixtures and analyses of gasifying agents can be employed, primarily air/steam mixtures or air with added enriched oxygen, to improve the performance and quality of the final gas [5].

The exit temperatures of the devolatilization or pyrolysis section favor the kinetics of oxidation reactions, which gradually release energy as most are exothermic. This promotes equilibrium and reaction rates in the reduction stage. Reactions occur according to the residence time of the gasifier; thus, temperature plays a crucial role in the composition and quality of the synthesis gas [28].

2.3. Simulation

A simulation process was developed in the ASPEN PLUS v10 program to analyze and evaluate the gasification process parameters mentioned earlier, comparing them with the experimental data from [14,29] to validate that the information provided by the simulator corresponds to reality.

2.3.1. Assumptions

The simulation development of the gasification process and its purification, in addition to its energy production stage, is carried out taking into account the following assumptions and conditions:

- Thermodynamic equilibrium is based on the minimization of Gibbs free energy in order to predict the composition of the synthesis gas and the yields of each compound [30,31].

- The system operates in a steady state, and the reactants reach chemical equilibrium [25,30].

- The operating pressure of the system is 1 bar.

- Pyrolysis or devolatilization stage occurs instantaneously in its elemental compounds (carbon, hydrogen, nitrogen, oxygen, and sulfur) according to their elemental analysis. Furthermore, pyrolysis and cracking reactions of its products are not considered due to the large number of possible products and intermediate products that may intervene in the system [32,33].

- The formed residues consist of ashes and unreacted gasification carbon [30]; they may also include sulfur if present in the elemental analyses of the raw material.

- Biomass particles are considered to have a constant size throughout the gasification process after passing through a grinding unit.

- Biomass and ashes are considered as inert components that do not participate in chemical reactions [31].

- The residence time in the gasification reactor is sufficiently prolonged to reach chemical equilibrium.

2.3.2. Properties Method

The properties for all conventional components are estimated using the Peng–Robinson equations because their use corresponds to non-polar or slightly polar mixtures, such as hydrocarbons, carbon oxides, and simple gases [34]. On the other hand, for the estimation of non-conventional components defined by biomass and ash, structured in the simulation as “biomass” and “ash”, respectively, their enthalpy and density are estimated using the HCOALGEN and DCOALGEN models (models focused on materials with various carbon contents that define these properties based on proximal and elemental analysis). These methods have also been employed in other studies [35].

2.4. Development of the Simulation Model

The development of the gasification process using the Aspen Plus V10 simulation environment is divided into the following sections: drying, devolatilization or pyrolysis, gasification, synthesis gas purification, and energy production.

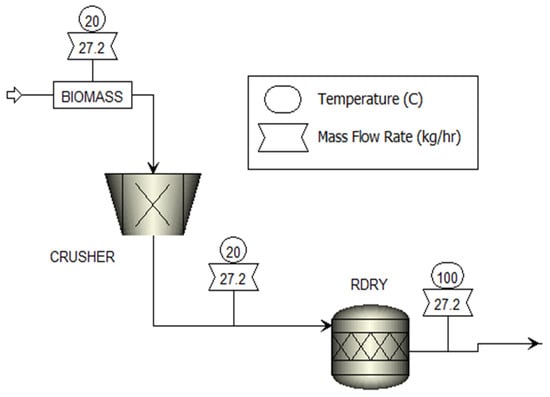

2.4.1. Drying Section

The biomass passes through a crusher (CRUSHER) resulting in a uniform biomass particle size of 2 cm, then enters the drying section involving a stoichiometric reactor (RDRY) where it decomposes the biomass at the moisture percentage, which, in the case of this project, is 8.7%. Subsequently, the water is separated using the SEP equipment, in which all the water content is separated, and the dried biomass (BIODRY) enters the pyrolysis or decomposition reactor; during this section the operational temperature range is between 200 and 400 °C. This process is illustrated in Figure 1.

Figure 1.

Drying section in the simulation model.

The drying section consists of a stoichiometric reactor and includes a crusher to fix the particle size at 2 cm.

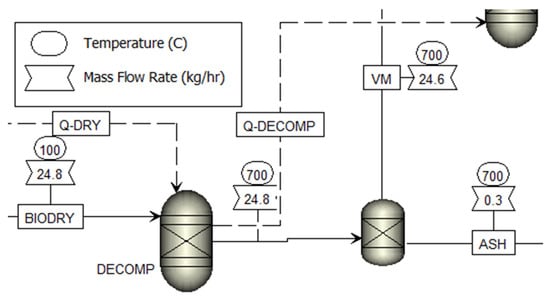

2.4.2. Pyrolysis or Devolatilization Section

The pyrolysis in the simulation model will consist of the decomposition of the raw material into its elemental components (H, C, N, O, S) in a yield reactor (DECOMP) [30]. The yields of these components are based on the proximate and elemental analysis of the biomass. This decomposition also includes the ashes (ASH), which will be separated in a continuous separation equipment SEP after the reactor, separating the volatile material from the ashes. During this section, the operational temperature range is between 400 and 700 °C.

As shown in Figure 2, the use of a yield reactor is essential in the simulation model as it allows transforming the biomass component that is inserted into the simulator as a non-conventional component, which, in other words, is a hypothetical component, into the volatile components and the residues that, as previously mentioned, consist of ash and solid carbon that cannot be converted. Thus, the composition of the pyrolysis products directed to the gasification zone is the transformation of biomass into real components based on elemental analysis. The pyrolysis section consists of a yield reactor and a separator.

Figure 2.

Devolatilization section in the simulation model.

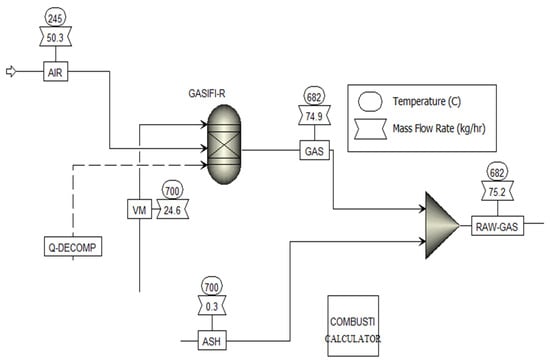

2.4.3. Gasification Section

The gasification section is developed using a Gibbs reactor that determines the products by minimizing Gibbs free energy (GASIFI-R) [36]. As shown in Figure 3, the main products from the volatile material from pyrolysis and air are H2, CO, CO2, CH4, and H2O gases, and the temperature will depend on the heat provided by the pyrolysis zone. The ashes are mixed back with the produced gas to outline the purification process in the following section.

Figure 3.

Gasification section in the simulation model.

The gasification section consists of a Gibbs reactor where the gasifying agent, which is air, enters, and then it goes into a mixer for a stream with residues according to reality. During this section, the operational temperature range is between 800 and 1000 °C.

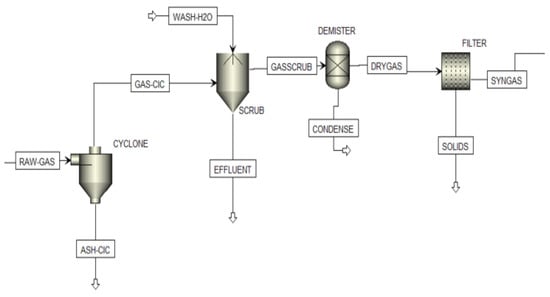

2.4.4. Purification Section

The purification section is carried out based on the main parameters from [31], using cyclone equipment, a gas scrubber, and a bag filter to remove solid tar residues and ashes, resulting in a synthesis gas free of impurities and residues. It is worth noting that the particle size, as explained in the assumptions, remains constant throughout the equipment, and, therefore, the separation of residues is based on the separation efficiencies of the equipment.

As shown in Figure 4 the purification section consists of a cyclone, a gas scrubber, and a filter.

Figure 4.

Purification section in the simulation model.

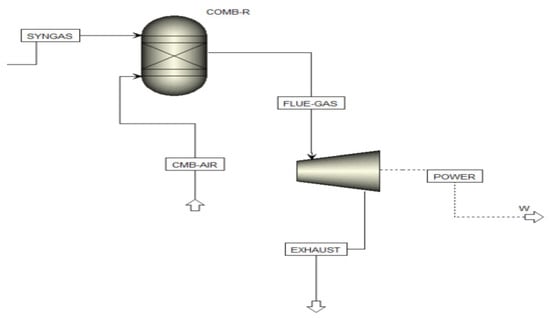

2.4.5. Energy Production Section

In the Figure 5 the synthesis gas enters a Gibbs reactor (COMB-R), where it undergoes a combustion process, resulting in high-temperature gas that can be used for boilers or internal combustion engines. Additionally, the resulting gas can be utilized in energy production cycles such as the Otto cycle in internal combustion engines.

Figure 5.

Energy production section in the simulation model.

These high-temperature gases can be used in heat transfer processes, such as heating air in coffee bean drying processes, for generating steam in a boiler, or for energy utilization in other processes within a biorefinery scheme.

3. Results

3.1. Energy Criteria

To evaluate the gasification process regarding the quality of the produced synthesis gas and the energy efficiency in producing it, parameters such as the lower heating value (LHV) and the cold gas efficiency (CGE) are taken into account, respectively.

3.1.1. Lower Heating Value

This parameter refers to the energy released from a material during combustion, assuming that the water vapor generated during the process does not condense [37]. It is calculated using the following expression [36].

3.1.2. Cold Gas Efficiency

Cold gas efficiency (CGE) is one of the most important parameters for evaluating the biomass gasification process. It is explained that CGE is an indicative parameter of the system’s ability to harness the energy content of biomass, transforming it into available energy in the synthesis gas. This parameter is defined as the percentage of the energy content of biomass in relation to the energy content of the syngas [38]. Energy deficiency implies shortcomings in the gasifier [39]. A related situation would be biomass with high moisture content, as it causes a decrease in the gasifier temperature and requires additional energy consumption for drying to meet the necessary requirements to proceed to the pyrolysis section. The additional moisture contributes to a decrease in syngas quality and promotes tar formation.

According to [31], this parameter defines the potential energy production relative to the energy input through biomass. This parameter is calculated by:

3.2. Model Validation with Experimental Data

The simulated model is evaluated with respect to the experimental values from the authors [14,29]. Additionally, it is compared with author [31], who developed a simulation model based on previous experimental articles. Thus, the approximation of the simulation model in this work is analyzed alongside the previous one concerning experimental values to determine factors influencing deviations. Four comparisons were made in total, divided into two groups corresponding to the experimental information, with Group 1 being validation with respect to [14] and Group 2 for [29].

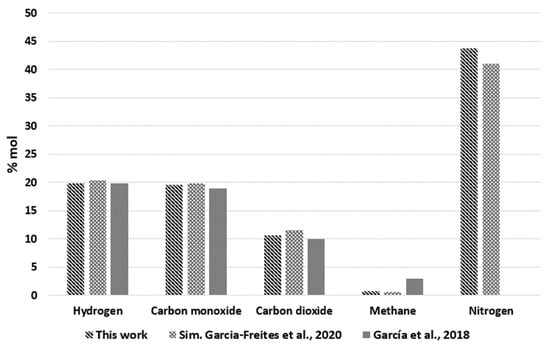

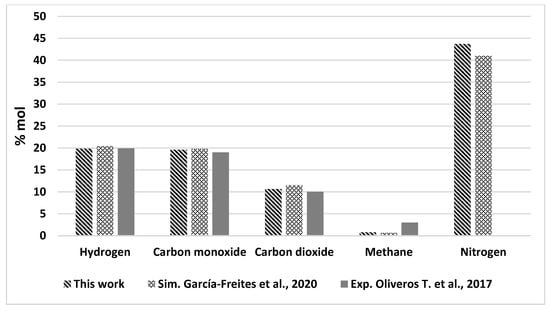

The information of the values obtained by each author is grouped in Table 2 and Table 3, and these values are also illustrated in Figure 6 and Figure 7.

Table 2.

Validation of Group 1 of the Aspen Plus simulation with respect to experimental values.

Table 3.

Validation of Group 2 of the Aspen Plus simulation with respect to experimental values.

Figure 6.

Graphic of validation of Group 1 of the Aspen Plus simulation with respect to experimental values [14,31].

Figure 7.

Graphic of validation of Group 2 of the Aspen Plus simulation with respect to experimental values [29,31].

The compositions of hydrogen and carbon monoxide, which are the most relevant compounds regarding the quality of the synthesis gas, are the ones that most closely approximate reality compared with the other simulation. The difference is due to the thermodynamic method used for this study, which is the Peng–Robinson method. Additionally, the author includes a model for preheating the air using the unpurified synthesis gas from the gasifier, which varies the temperature of the air at the system inlet, resulting in compositions higher than expected. Since this study does not consider the air preheating model during simulation, the obtained values have a difference of less than 0.7 percentage units with respect to the compounds of interest.

Regarding the composition of methane and nitrogen in both comparison groups, the concentration of these, mainly methane, tends to be much lower than indicated by experimental values. This is because the simulation model is based on chemical equilibrium, and the methane formation given by the methanation reaction decreases for temperatures above 800 °C [40].

Another phenomenon to consider regarding the difference in methane concentrations compared with experimental values is that the simulation model only involves air as a gas consisting exclusively of nitrogen and oxygen. However, air contains a variety of other compounds in smaller amounts, such as argon, various noble gases, water vapor, ozone, and methane [41]. Even though its concentration in the air is low, it significantly influences the composition of the synthesis gas and its heating value.

The gas yield is influenced by the aforementioned reasons. However, it is worth noting that the gas yield of this work is lower than the compared simulation and experimental values [31] because it does not involve energy integration that allows preheating the air, favoring the Gibbs free energy in the formation of gaseous compounds from the solid carbon from the pyrolysis section. On the other hand, the experimental data involve a sufficient residence time to crack all solid products from pyrolysis. Although the model assumes a sufficient residence time to reach chemical equilibrium, this model is not as thermodynamically favored by the air inlet temperature as the simulation with energy integration is.

The simulation results show good agreement with the set of experimental data for the molar fractions of the gas species H2, CO, CO2, and N2, and with the gas production yield and the lower heating value (LHV) of the gas.

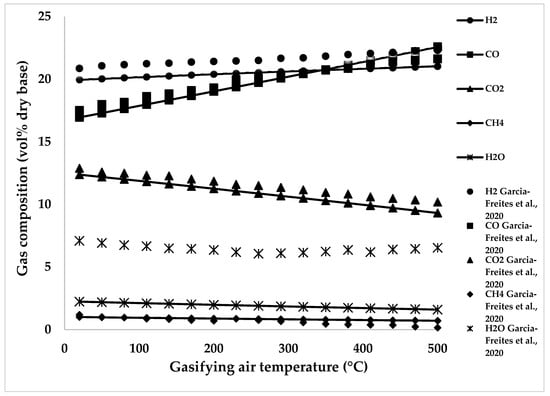

Finally, in Figure 8, the composition profiles of the synthesis gas are compared [31] by varying the air temperature to determine the consistency in the obtained data. The following data are obtained.

Figure 8.

Validation of the Aspen Plus simulation model with respect to the composition profile varying the air temperature [31].

The concentrations of the compounds are analyzed without considering nitrogen because, in gasification processes where air is used as the gasifying agent, nitrogen tends to occupy the majority of the gas, making it difficult to accurately visualize the concentrations of other compounds. Both studies highlight how an increase in temperature favors the formation of carbon monoxide and hydrogen, as the equilibrium of reduction reactions favors these desired products while decreasing the concentration of by-products such as water and carbon dioxide. High temperatures increase the calorific value and cold gas efficiency; however, they also lead to an increase in residue formation.

The main difference between both models is the water concentration, which is mainly due to the moisture content in the biomass in each model. For the author, it is 10%, while in this work, it is 8.7%. Furthermore, it may also be because the author developed their model with respect to another thermodynamic property package, either an ideal model or unlike this work, which uses the Peng–Robinson equations. The author could have used these equations along with a gas phase equation of state that better describes interactions in the gas phase. This also influences the behavior of the hydrogen and carbon monoxide concentrations. While both cases show a similar increasing trend, it is observed that the compared model initially has higher compositions. However, the rate of increase in these compositions decreases as the temperature increases. This is unlike this work, where the growth has a linear trend with respect to the air temperature. This is explained by the fact that the author’s simulation model involves an air preheating unit, allowing thermodynamic favoring by the air temperature. This justifies why the author’s compositions are higher and their rate of increase subsequently decreases, because the temperature differential in the preheating unit will be lower, so the thermodynamic favoring will not be as significant.

3.3. Sensitivity Analysis

The sensitivity analyses that were conducted, taking into account the main parameters affecting the energy criteria and synthesis gas composition, yielded the following results. These will allow determining the appropriate operating conditions regarding the quality of the produced gas, energy efficiency, and reduction of residue formation.

3.3.1. Gasifying Air Temperature

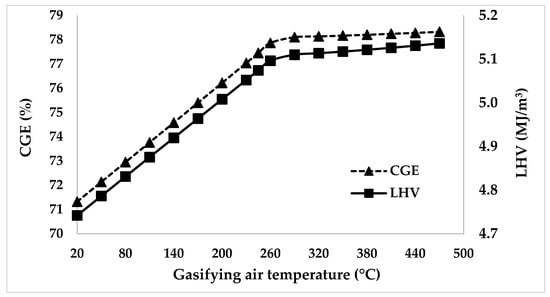

According to the results, the composition profile, cold gas efficiency, and resulting synthesis gas heating value are presented. Additionally, the relationship between gasification temperature and inlet air temperature is included. The latter is important due to its direct relationship with the chemical and thermodynamic equilibrium of the process.

Temperature is crucial for the formation of the compounds of interest, which are in turn favored by the chemical equilibrium as the temperature increases. Therefore, by reducing the temperature differential between the gasifying agent and the reactor, heat transfer to the surroundings and variations in thermal equilibrium are minimized, allowing for a gradual increase in temperature. This also favors the cracking of tar from pyrolysis, forming gaseous products and reducing residue formation.

On the other hand, as shown in Figure 9, a decrease in the constant growth of energy criteria is observed at 240 °C due to the increase in exothermic reactions from complete combustion. From this point on, the increase shifts from being linear to logarithmic, and, even if we raise the gasification temperature as an option to enhance the thermal efficiency of the process, this increase will not be significant.

Figure 9.

Heating value and cold gas efficiency as a function of gasifying air temperature.

The increase in the formation of hydrogen and carbon monoxide primarily contribute to the heating value, and the cold gas efficiency. However, it is essential to consider the energy consumption involved in introducing air at the studied temperatures.

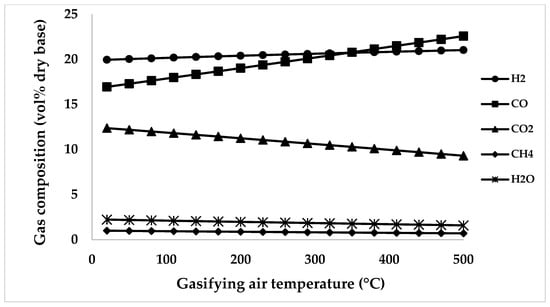

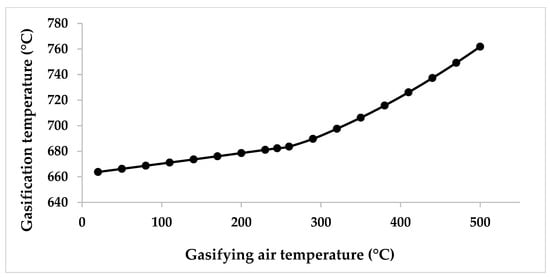

As shown in Figure 10, compounds such as methane and carbon dioxide decrease their concentration, respectively, with increasing temperature, so a higher temperature is desired in the gasification section. In another hand in Figure 11 gasification temperature increases linearly against the gasifying air temperature.

Figure 10.

Variation of the synthesis gas composition as a function for gasifying air temperature.

Figure 11.

Effect of the gasification section temperature relative to the gasifying air temperature.

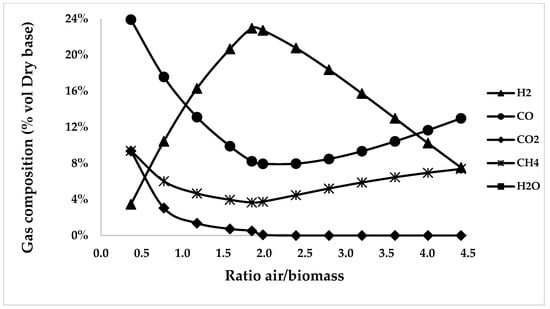

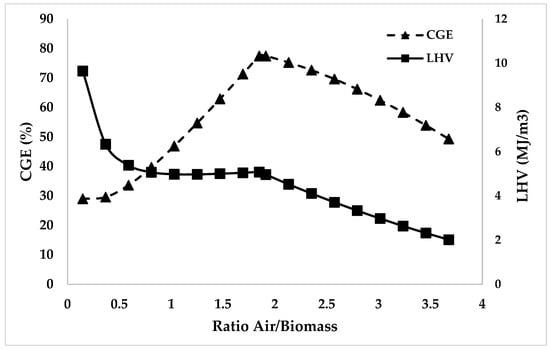

3.3.2. Ratio Air/Biomass

Regarding the relationship between air and biomass, the concentration of hydrogen observed in Figure 12 decreases with increasing an air-to-biomass ratio, while carbon monoxide reaches its maximum concentration at values of 2 to 2.5. Conversely, carbon dioxide is at its minimum point, implying that the combustion of carbon monoxide occurs from that maximum point. By promoting complete combustion reactions, the increase in water vapor and carbon dioxide significantly decreases the synthesis gas quality. Therefore, it is recommended for coffee stem gasification to operate with an air-to-biomass ratio of less than 2.5.

Figure 12.

Effect of ratio air/biomass on gas composition.

This operational parameter is also supported by Figure 13, as the cold gas efficiency is maximized at this point, where the concentrations of carbon monoxide and hydrogen are at their highest and these components have not yet been oxidized. Additionally, the calorific value decreases significantly from this point.

Figure 13.

Heating value and cold gas efficiency as a function of the air/biomass ratio.

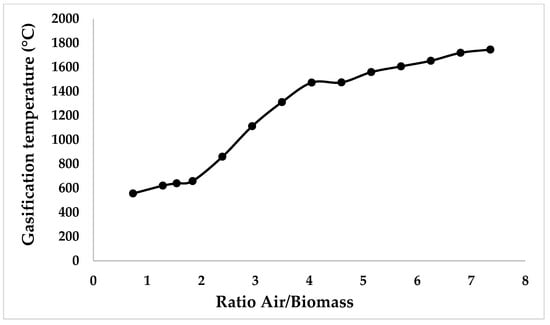

As shown in Figure 14, the amount of oxygen present in the air promotes exothermic oxidation reactions, so high values are not suitable due to the excessive increase in the gasifier temperature, promoting the total oxidation of biomass.

Figure 14.

Effect of temperature in the gasification section relative to the air-to-biomass ratio.

3.3.3. Influence of Moisture Content

The decrease in hydrogen and carbon monoxide is undesirable since these are the desired products in the quality of the synthesis gas. Additionally, it affects other parameters such as the gasification temperature and the energy consumption of the drying section. The moisture content in the system determines a negative effect on the synthesis gas production. Therefore, the lower the moisture content, the more acceptable the energy generation potential. If not, alternatives should be sought to reduce moisture without incurring high energy costs. This can be evidenced in Figure 15 and Figure 16.

Figure 15.

Synthesis gas composition as a function of biomass moisture content.

Figure 16.

Heating value and cold gas efficiency as a function of biomass moisture content.

4. Discussion

The development of the simulation provides information on the behavior of the coffee stem gasification process that aligns with reality regarding the synthesis gas composition and the energy potential of the product. Additionally, it allows for specifying various system conditions such as moisture content, air composition, and even temperature. On the other hand, it considers biomass characteristics, as the composition of coffee stems may vary depending on the species used in cultivation and the growth conditions. Furthermore, it observes how the composition of the synthesis gas varies in various sensitivity analyses and its quality, suggesting the need for a purification system.

Moreover, the energy analyses enable the calculation of the product’s heating value and analysis of potential energy integration processes using the combustion gases from the dirty synthesis gas to cool and proceed to the purification processes.

This project enables the determination of optimal operating conditions, which are summarized in Table 4.

Table 4.

Optimal operating conditions。

The various stages and technological aspects of the gasification process were identified, taking into account the context of a biorefinery. This involved preprocessing coffee stems to reduce their moisture to below 10%. The gasification process comprised four stages: drying, pyrolysis, oxidation, and reduction. Subsequent treatment involves separating ash and tar residues using a cyclone, a gas washer, and a bag filter.

Relevant and critical parameters for the proposed gasification scheme were selected, such as conducting the process in a downdraft fixed-bed gasifier, an air/biomass flow ratio ranging from 1.5 to 2, and a gasifying air temperature between 230 to 260 °C, with moisture content entering the gasification system below 10%. The importance of gasification temperature, biomass composition, residence time, and gasifying agent flow rate as parameters to control for optimal gasification was understood.

The gasification process was developed through simulation using Aspen Plus V10, implementing energy criteria such as lower heating value (LHV) with a value of 5.06 MJ/kg from optimal conditions and a cold gas efficiency of 76.14%. Various sensitivity studies led to hydrogen and carbon monoxide concentrations of 18.5% and 22.9%, respectively.

The sensitivity analysis conducted provided information about the key parameters of the process (CGE, LHV, and gasification temperature). These varied according to the defined control parameters, which were the air/biomass ratio and the temperature of the gasifying agent. The results obtained are shown below.

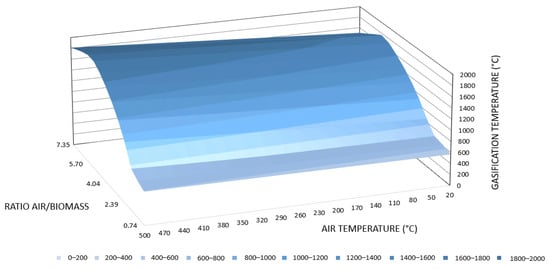

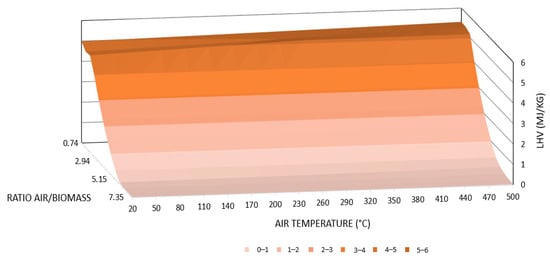

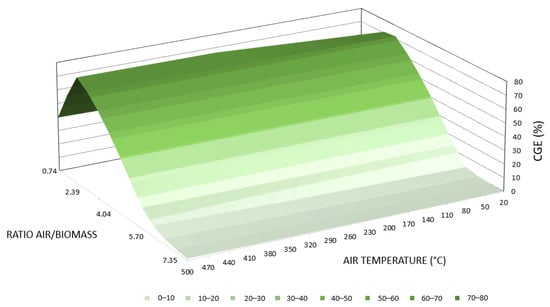

The relevance of the relationship between the gasifying agent and the feedstock (coffee stems) was observed in the Figure 17, Figure 18 and Figure 19, particularly concerning the energy criteria of the process. At low values, maximization occurred; however, the CGE was found to have a maximum at an air/biomass ratio of 1.84. This corresponded to the stoichiometric amount of oxygen needed to carry out a partial oxidation of the raw material, maximizing CO formation by limiting the gasifying agent in the process. On the other hand, opposite behavior was analyzed concerning the gasification temperature; in this case, the behavior of both parameters was proportional. However, the desired gasification temperature range was between 900 and 1100 °C to favor the thermodynamic equilibrium of homogeneous reactions that produce hydrogen, carbon monoxide, and methane. Therefore, values between 1.8 and 2.5 were estimated to maintain the described temperature range, though it was necessary to balance these values to avoid reducing the energy parameters.

Figure 17.

Ratio air/biomass and air temperature as a function of gasification temperature.

Figure 18.

Ratio air/biomass and air temperature as a function of lower heating value (LHV).

Figure 19.

Ratio air/biomass and air temperature as a function of cold gas efficiency (CGE).

Finally, a higher inlet temperature of the gasifying agent increased all the key evaluated parameters, though not significantly. Therefore, it is recommended to integrate these gasification processes with thermal cogeneration or preheating processes to treat the flow of the used gasifying agent, thus increasing the efficiency of the process and maintaining syngas quality. At high temperature values, the production of residues represented by the tar fraction was favored, which is a parameter sought to be minimized since it implies energy consumption in the subsequent purification section to clean and remove impurities from the synthesis gas. Therefore, the determining factor that implies the operation of high temperatures in the gasifier is cold gas efficiency, which essentially involves the energy utilization of biomass regarding the transformation into a gas with available energy. This is because the increase in reactions in the oxidation section releases enough energy to facilitate the temperature requirement within the range of 800 to 1200 °C, where reduction reactions favor the production of hydrogen and carbon monoxide.

5. Conclusions

A conceptual scheme was determined for the development of a coffee stem gasification process, which was divided into subsections: a drying section for biomass treatment, a pyrolysis section that causes the feedstock to volatilize into its elemental and relevant components, leaving ash and a fraction of tar as residues, and finally, the gases from pyrolysis pass through the gasification section, where partial oxidation and reduction reactions occur with a gasifying agent (air is used in this study), resulting in a gas with considerable calorific value. All this was carried out within the framework of a biorefinery that processes various wastes from the coffee industry through bioconversion processes. In this context, the stems of coffee shrubs were processed using gasification as a conversion process to produce syngas, which can be used for energy production in the sector or in cogeneration processes within the coffee industry.

A simulation process for the gasification of coffee stems was developed and validated with experimental data. Additionally, various sensitivity analyses were carried out on the most influential parameters of the process, such as the moisture content of the biomass, its elemental composition, the ratio between the gasifying agent flow and the feedstock, and the temperature in the gasification section. This information allowed for the determination of optimal values for these parameters, resulting in higher quality syngas. For the process evaluated in this study, with an air/biomass ratio between 1.8 and 2.5, a moisture content of less than 10%, and a gasifying agent temperature of 245 °C, the syngas produced had a hydrogen concentration of 18.5% and carbon monoxide concentration of 22.9%, with a yield of 2.75 kg of gas per kg of biomass, a lower heating value (LHV) of 5.07 MJ/kg, and a gas conversion efficiency (CGE) greater than 75%.

This scheme provides a foundation for analyzing the implementation of projects aimed at biomass utilization. In this case, a specific study was conducted on the gasification process of coffee stems to be employed in the coffee industry. This allows for an understanding of the behavior of the gasification system with this type of biomass and the ideal conditions to optimize the process. Additionally, for future research, it is suggested to analyze this process through exergy flows to determine exergetic efficiencies and to carry out econometric analyses based on this variable.

Author Contributions

Conceptualization, C.A.G.-M., L.A.P.-M., J.E.A.-C. and S.C.-G.; data curation, L.A.P.-M., S.C.-G., W.A.G., O.H.A.J. and J.C.A.; formal analysis, L.E.G.-M. and E.F.L.; funding acquisition, L.E.G.-M., W.A.G., J.C.A. and E.F.L.; investigation, J.E.A.-C., L.A.P.-M., L.E.G.-M. and J.C.A.; methodology, C.A.G.-M., L.A.P.-M., J.E.A.-C., W.A.G. and E.F.L.; project administration, C.A.G.-M., L.A.P.-M., J.E.A.-C., S.C.-G., L.E.G.-M., W.A.G., O.H.A.J., J.C.A. and E.F.L.; resources, L.A.P.-M. and O.H.A.J.; software, C.A.G.-M. and J.C.A.; supervision, J.E.A.-C., S.C.-G., O.H.A.J. and E.F.L.; validation, C.A.G.-M. and S.C.-G.; visualization, L.A.P.-M., S.C.-G., J.C.A. and E.F.L.; writing—original draft, J.E.A.-C. and L.A.P.-M.; writing—review and editing, J.E.A.-C., L.A.P.-M., S.C.-G., O.H.A.J. and E.F.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Universidad de America (Grant No. IIQ-004, 2022) and was supported for publication by PROPESP/UFPA (PAPQ). The UNIVERSIDADE FEDERAL DO PARÁ (UFPA, Brazil) and the UNIVERSIDAD DE AMÉRICA (FUA, Colombia)—PROCESO 23073.053603/2022-70.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding authors.

Acknowledgments

The authors acknowledge the international cooperation agreement between the UNIVERSIDADE FEDERAL DO PARÁ (UFPA, Brazil) and the UNIVERSIDAD DE AMÉRICA (FUA, Colombia)—PROCESO 23073.053603/2022-70.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Instituto para la Diversificación y Ahorro de la Energía y Besel. Biomasa; IDEA: Madrid, Spain, 2007. [Google Scholar]

- Higman, C. Chapter 11—Gasification. In Combustion Engineering Issues for Solid Fuel Systems; Miller, B.G., Tillman, D.A., Eds.; Academic Press: Burlington, MA, USA, 2008; pp. 423–468. [Google Scholar] [CrossRef]

- Basu, P. Chapter 5—Gasification Theory and Modeling of Gasifiers. In Biomass Gasification and Pyrolysis; Basu, P., Ed.; Academic Press: Boston, MA, USA, 2010; pp. 117–165. [Google Scholar] [CrossRef]

- Kukharets, S.; Jasinskas, A.; Golub, G.; Sukmaniuk, O.; Hutsol, T.; Mudryk, K.; Čėsna, J.; Glowacki, S.; Horetska, I. The Experimental Study of the Efficiency of the Gasification Process of the Fast-Growing Willow Biomass in a Downdraft Gasifier. Energies 2023, 16, 578. [Google Scholar] [CrossRef]

- Gomes, H.G.M.F.; Matos, M.A.A.; Tarelho, L.A.C. Influence of Oxygen/Steam Addition on the Quality of Producer Gas during Direct (Air) Gasification of Residual Forest Biomass. Energies 2023, 16, 2427. [Google Scholar] [CrossRef]

- Schulzke, T. Biomass gasification: Conversion of forest residues into heat, electricity and base chemicals. Chem. Pap. 2019, 73, 1833–1852. [Google Scholar] [CrossRef]

- Kukharets, S.; Golub, G.; Wrobel, M.; Sukmaniuk, O.; Mudryk, K.; Hutsol, T.; Jasinskas, A.; Jewiarz, M.; Cesna, J.; Horetska, I. A Theoretical Model of the Gasification Rate of Biomass and Its Experimental Confirmation. Energies 2022, 15, 7721. [Google Scholar] [CrossRef]

- Abdalla, M.E.; Abdalla, S.A.; Taqvi, S.A.A.; Naqvi, S.R.; Chen, W.-H. Investigation of Biomass Integrated Air Gasification Regenerative Gas Turbine Power Plants. Energies 2022, 15, 741. [Google Scholar] [CrossRef]

- Aristizábal-Marulanda, V.; Chacón-Perez, Y.; Alzate, C.A.C. Chapter 3—The biorefinery concept for the industrial valorization of coffee processing by-products. In Handbook of Coffee Processing By-Products; Galanakis, C.M., Ed.; Academic Press: Cambridge, MA, USA, 2017; pp. 63–92. [Google Scholar] [CrossRef]

- Rodriguez, N.; Zambrano, D.A. Los Subproductos del Café: Fuente de Energía Renovable; Cenicafé: Chinchiná, Caldas, 2010. [Google Scholar]

- Producción de Café de Colombia Cerró el 2019 en 14,8 Millones de Sacos, Federación Nacional de Cafeteros. [En Línea]. Available online: https://federaciondecafeteros.org/wp/listado-noticias/produccion-de-cafe-de-colombia-cerro-el-2019-en-148-millones-de-sacos/ (accessed on 16 November 2021).

- de Priall, O.; Gogulancea, V.; Brandoni, C.; Hewitt, N.; Johnston, C.; Onofrei, G.; Huang, Y. Modelling and experimental investigation of small-scale gasification CHP units for enhancing the use of local biowaste. Waste Manag. 2021, 136, 174–183. [Google Scholar] [CrossRef]

- Durán-Sarmiento, M.A.; Del Portillo-Valdés, L.A.; Rueda-Ordonez, Y.J.; Florez-Rivera, J.S.; Rincón-Quintero, A.D. Study on the gasification process of the biomass obtained from agricultural waste with the purpose of estimating the energy potential in the Santander region and its surroundings. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1253, 012001. [Google Scholar] [CrossRef]

- García, C.A.; Peña, Á.; Betancourt, R.; Cardona, C.A. Energetic and environmental assessment of thermochemical and biochemical ways for producing energy from agricultural solid residues: Coffee Cut-Stems case. J. Environ. Manag. 2018, 216, 160–168. [Google Scholar] [CrossRef]

- Ortega, N.R.; Toro, A.F.; Pardo, L.M.; Velasco, A.C. Evaluación de las propiedades fisicoquímicas y térmicas de tallos de café y su análisis económico para la producción de pellets como biocombustible sólido. Ing. De Recur. Nat. Y Del Ambiente 2011, 10, 79–91. [Google Scholar]

- Quintero, J.A.; Moncada, J.; Cardona, C.A. Techno-economic analysis of bioethanol production from lignocellulosic residues in Colombia: A process simulation approach. Bioresour. Technol. 2013, 139, 300–307. [Google Scholar] [CrossRef]

- Susastriawan, A.A.P.; Saptoadi, H. Comparison of the gasification performance in the downdraft fixed-bed gasifier fed by different feedstocks: Rice husk, sawdust, and their mixture. Sustain. Energy Technol. Assess. 2019, 34, 27–34. [Google Scholar] [CrossRef]

- Giltrap, D.; McKibbin, R.; Barnes, G. A steady state model of gas-char reactions in a downdraft biomass gasifier. Sol. Energy 2003, 74, 85–91. [Google Scholar] [CrossRef]

- Basu, P. Combustion and Gasification in Fluidized Beds; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar] [CrossRef]

- Sheth, P.N.; Babu, B. Experimental studies on producer gas generation from wood waste in a downdraft biomass gasifier. Bioresour. Technol. 2009, 100, 3127–3133. [Google Scholar] [CrossRef] [PubMed]

- Sansaniwal, S.; Pal, K.; Rosen, M.; Tyagi, S. Recent advances in the development of biomass gasification technology: A comprehensive review. Renew. Sustain. Energy Rev. 2017, 72, 363–384. [Google Scholar] [CrossRef]

- Zainal, Z.; Rifau, A.; Quadir, G.; Seetharamu, K. Experimental investigation of a downdraft biomass gasifier. Biomass Bioenergy 2002, 23, 283–289. [Google Scholar] [CrossRef]

- Gao, N.; Li, A. Modeling and simulation of combined pyrolysis and reduction zone for a downdraft biomass gasifier. Energy Convers. Manag. 2008, 49, 3483–3490. [Google Scholar] [CrossRef]

- Beohar, H.; Gupta, B.; Sethi, D.V.; Pandey, D.M.; Parmar, H. Effect of Air Velocity, Fuel Rate and Moisture Content on the Performance of Updraft Biomass Gasifier Using Fluent Tool. [En Línea]. Available online: https://www.semanticscholar.org/paper/Effect-of-Air-Velocity-%2C-Fuel-Rate-and-Moisture-on-Beohar-Gupta/db1ea8f9428730e0c6c193a27ac21f07c6c19909 (accessed on 9 November 2023).

- Doherty, W.; Reynolds, A.; Kennedy, D. Aspen Plus Simulation of Biomass Gasification in a Steam Blown Dual Fluidised Bed. En. Materials and Processes for Energy: Communicating Current Research and Technological Developments, Formatex Research Centre, 2013. [En línea]. Available online: https://arrow.tudublin.ie/engmecbk/2 (accessed on 12 January 2024).

- Hameed, S.; Ramzan, N.; Rahman, Z.-U.; Zafar, M.; Riaz, S. Kinetic modeling of reduction zone in biomass gasification. Energy Convers. Manag. 2014, 78, 367–373. [Google Scholar] [CrossRef]

- McKendry, P. Energy production from biomass (part 3): Gasification technologies. Bioresour. Technol. 2002, 83, 55–63. [Google Scholar] [CrossRef]

- Haryanto, A.; Fernando, S.D.; Pordesimo, L.O.; Adhikari, S. Upgrading of syngas derived from biomass gasification: A thermodynamic analysis. Biomass Bioenergy 2009, 33, 882–889. [Google Scholar] [CrossRef]

- Oliveros, C.E.; Sanz, J.R.; Rodriguez, N. Evaluación de un Gasificador de Flujo Descendente Utilizando Astillas de Madera de café. Evaluation of a Downstream Gasifier Using Coffee Wood Chips, 2017. [En Línea]. Available online: https://biblioteca.cenicafe.org/handle/10778/1084 (accessed on 4 November 2023).

- Nikoo, M.B.; Mahinpey, N. Simulation of biomass gasification in fluidized bed reactor using ASPEN PLUS. Biomass Bioenergy 2008, 32, 1245–1254. [Google Scholar] [CrossRef]

- Garcia-Freites, S.; Welfle, A.; Lea-Langton, A.; Gilbert, P.; Thornley, P. The potential of coffee stems gasification to provide bioenergy for coffee farms: A case study in the Colombian coffee sector. Biomass Convers. Biorefinery 2020, 10, 1137–1152. [Google Scholar] [CrossRef]

- Rubiano, J.E.; Oliveros, C.; Posso, F.R.; Acevedo, J.C. Simulation of tar reduction alternatives in the coffee stems gasification process. J. Phys. Conf. Ser. 2018, 1126, 012011. [Google Scholar] [CrossRef]

- Puig-Arnavat, M.; Bruno, J.C.; Coronas, A. Coronas, Review and analysis of biomass gasification models. Renew. Sustain. Energy Rev. 2010, 14, 2841–2851. [Google Scholar] [CrossRef]

- Aspen Technology, Inc. Aspen Plus. User Guide, 2nd ed.; Aspen Technology, Inc.: Cambrigdge, MA, USA, 2010; Volume 10. [Google Scholar]

- Ramzan, N.; Ashraf, A.; Naveed, S.; Malik, A. Simulation of hybrid biomass gasification using Aspen plus: A comparative performance analysis for food, municipal solid and poultry waste. Biomass Bioenergy 2011, 35, 3962–3969. [Google Scholar] [CrossRef]

- Zhang, Q.; Wu, Y.; Dor, L.; Yang, W.; Blasiak, W. A thermodynamic analysis of solid waste gasification in the Plasma Gasification Melting process. Appl. Energy 2013, 112, 405–413. [Google Scholar] [CrossRef]

- Poder Calorífico. [En Línea]. Available online: https://ingemecanica.com/tutoriales/poder_calorifico.html (accessed on 16 November 2021).

- Evaluación de la Incidencia de Pellets y Astillas de Madera en el Desempeño de un Gasificador Tipo “Downdraft”|Revista Forestal Mesoamericana Kurú. Sep. 2018, [En Línea]. Available online: https://revistas.tec.ac.cr/index.php/kuru/article/view/3847 (accessed on 9 November 2023).

- Prins, M.J. Thermodynamic Analysis of Biomass Gasification and Torrefaction. Ph.D. Thesis 1 (Research TU/e/Graduation TU/e), Technische Universiteit Eindhoven, Eindhoven, The Netherlands, 2005. [Google Scholar] [CrossRef]

- Sittisun, P.; Tippayawong, N.; Pang, S. Biomass gasification in a fixed bed downdraft reactor with oxygen enriched air: A modified equilibrium modeling study. Energy Procedia 2019, 160, 317–323. [Google Scholar] [CrossRef]

- Ambientum, Composición de la Atmósfera—Enciclopedia Medioambiental. Ambientum Portal del Medioambiente. [En Línea]. Available online: https://www.ambientum.com/ (accessed on 16 November 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).