3.1. Model Validation—Torque Measurements

The torque measurement test was conducted for the model validation/tuning purposes. The speed of the examined machine during the test was held constant at a value of

rpm (corresponding to the 3300 rpm of the load drive). The current was varied so that its amplitude was constant, and the angle of the current space vector was varied between 0 and 180 degrees in 10° increments. Such a test was conducted for many different values of the current amplitude. For each measurement point the

d- and

q-axis current components were calculated as:

where

and

are

d- and

q-axis current components, respectively [A],

is the current amplitude [A], and

is the current space vector angle [°].

Contrary to the induced voltage test described in

Section 2.2, the machine parts do heat up during the torque measurements due to the high current amplitude values. It is a well-known fact that automotive drives are designed for an excessive overload operation, i.e., continuous operation is provided to cover the working points of the most common road driving conditions, and the drive is working under the thermal overload conditions for short periods during the especially dynamic drive conditions (this topic is explained in detail in [

9]). At this point, it should be emphasized that in the used test setup, the original cooling system of Toyota was replaced with a much simpler and less performant cooling jacket, which also does not directly cool the machine’s rotor. It allows the conducting of laboratory tests, but it should be expected that the thermal overload conditions at the test bench will be more severe than during the normal operation of the transaxle.

Hence, care needs to be taken during the torque measurements because the machine can heat up substantially during the test. This is one of the reasons why the authors have equipped the machine under tests with temperature sensors. Each measurement is conducted so that the current flow duration is possibly short. It was found that the duration of 3 s is sufficient for the torque sensor output and speed to settle (there is some transient due to the sensor’s elasticity and limited dynamics of the load drive). Afterward, the measured value is averaged for the last 1 s of the pulse, which results in the overall current pulse duration of 4 s. The temperature is monitored during the tests, and there is a pause after each current pulse to cool the machine down. The pause duration was chosen manually by the test engineer conducting the measurements in such a way that a temperature of the hottest winding’s part remains in the range of ca. 40–47 °C.

In the beginning, it was found that the simulated torque values were much higher than the measured ones. The reason for that is the fact that the remanent flux density of the magnet decreases with rising temperature. Unfortunately, the temperature of the magnets cannot be directly measured as they are attached to the rotating part of the machine. Still, it is safe to assume that it reached temperatures higher than the 20 °C. It was found that the best matching between the experimental and simulation results is achieved for the remanent flux density value of

T. As the N40 magnet has the reversible temperature coefficient of

%/°C, it corresponds to the magnet temperature of the 40 °C [

18], which seems to be a reasonable value. Hence, all the following analyses assume the machine temperature is equal to 40 °C.

The comparison of the experimental results and the model output is depicted in

Figure 9. The left column (

Figure 9a,c) depicts the simulation results when machine losses are neglected. In that case, the model inaccuracy reaches 2.7% of the official maximal torque value of 163 Nm. The right column (

Figure 9b,d) depicts the results after including the losses in the simulation model. In that case, the matching is better since the remanent flux density value of the magnet was tuned based on these results. In that case, the model accuracy is always better than 2%. Based on these results, an excellent match of the model can be stated.

It is worth mentioning that the highest torque value obtained during the measurements equals 169.7 Nm, which is 4% higher than the value published by Toyota [

14]. It should be emphasized that the torque sensor was sent to the calibration right before the measurements, and the presented test results were obtained directly after the calibration. Hence, the measured value can be considered reliable. Toyota probably considered additional mechanical losses inside the transaxle or very high magnet temperature.

3.2. Flux-Linkage Maps

As the simulation model is established and validated, it can now be utilized to obtain data needed by drive control engineers. It is a common practice to describe the machine dynamics using the space-vector-based equations in the

rotor reference frame. The flux-linkage-based model can be described as [

1,

2]:

where

and

are

d- and

q-axis voltages, respectively [V],

and

are

d- and

q-axis flux linkages, respectively [Wb],

is the phase resistance [

],

is electrical angular speed [rad/s],

p is the number of pole pairs [-], and

is the electromagnetic torque [Nm].

The state-of-the-art control algorithm for IPMSMs is the FOC, which facilitates current controllers [

19]. Hence, the model expressed in (2) needs to be converted into the current one. For the highly saturated machine, the flux linkages should be considered as functions of current:

Considering the exact integral of (

3) in (2) leads to the following current-based machine dynamics model:

with differential inductances defined as:

where

is a

d-axis differential self-inductance [H],

is a

q-axis differential self-inductance [H], and

and

are cross-saturation inductances [H].

It should be emphasized that this model considers only the DC conduction losses, and all the other machine losses are neglected. Hence, the machine parameters needed for this model are generated using the simulation with losses neglected.

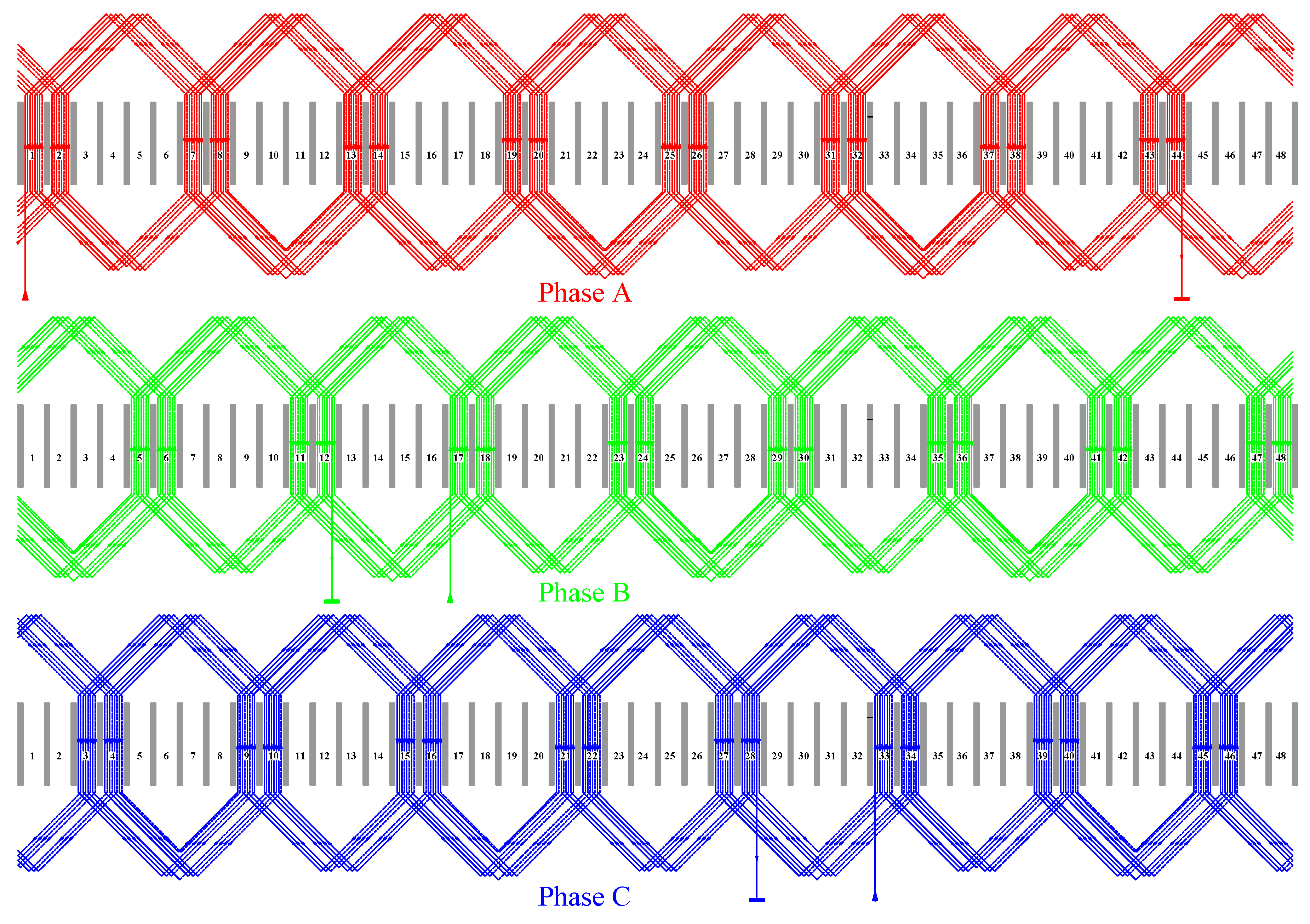

The extreme magnetic circuit saturation mentioned in the previous section is visible in the flux-linkage surfaces (see

Figure 10a,b). It is evident looking at the differential self-inductances in

Figure 10c,d as for the linear magnetic circuit, they would be constant in the whole depicted region. The cross-saturation is also visible, as the

d-axis flux linkage depends on the

q-axis current, and

q-axis flux linkage depends on the

d-axis current. This is also indicated by non-zero values of the cross-saturation inductances (see

Figure 10e). It should also be mentioned that the cross-saturation inductances

and

are equal. This results from the reciprocity condition [

20,

21,

22]. This condition is derived from the energy conservation rule when the iron losses are neglected. Hence, the results obtained with the lossless FEM model should also fulfill the reciprocity condition, i.e.,

. For a more detailed explanation of the physical meaning of the surfaces’ shapes depicted in

Figure 10, please refer to [

21,

22].

3.3. Maximal Torque per Current and Field Weakening

The following important task for the drive control is calculating the optimal current reference points for the controllers. This calculation can be performed based on the model (2) and machine parameters obtained with the lossless model (see

Figure 10).

The operational points in the base speed region were chosen using the state-of-the-art solution, i.e., the Maximal Torque per Current (MTPC) strategy [

1,

2,

19,

23,

24,

25]. This strategy assumes the minimization of the current for the given reference torque, as discussed in [

24,

25]. The constant torque isolines are depicted in

Figure 11a as orange lines. For each reference torque isoline, the point of the minimal current space vector’s length was chosen as the reference operational point. The resulting MTPC locus is depicted with green color in

Figure 11a. The maximal torque obtained with the given parameters equals 173.4 Nm.

According to (2), the voltage needed to reach some current space vector rises with speed. Above some speed (different for each torque value), the voltage available for the current controllers is not enough for following the MTPC strategy any longer. Assuming Space Vector Modulation (SVM) is applied, the maximal phase voltage on the inverters’ output is limited to the value of:

where

is the maximal phase voltage amplitude [V],

is the DC-link voltage of the inverter [V]. The presented calculation results were obtained with the maximal DC-link voltage of the Toyota Prius, i.e.,

V. The operational points that can be reached using the MTPC strategy under the assumed conditions are marked with green color in

Figure 11b.

The maximal voltage isolines drawn in the current

-plane (see purple lines in

Figure 11a) have ellipsoidal shapes and converge with the rising speed to a particular point, i.e., the motor characteristic current. This current is defined as the

d-axis current amplitude sufficient to weaken the

d-axis flux to zero, i.e.,

where

is the motor characteristic current [A]. This is a very important quantity, which defines the field weakening performance of the drive [

24]. This value equals

A for the examined machine.

The characteristic current of the machine is an important factor impacting the field-weakening performance of the drive. According to the theory derived in [

24], it can describe a level of the inverter’s volt–ampere rating utilization. For this purpose, a so-called drive characteristic factor should be calculated first as:

where

is the drive characteristic factor [-]. It is well known that the value of

divides the PMSM drives into two sub-classes [

24,

25]. For

, the drive has finite maximal speed and poor field-weakening performance. For

, the drive has infinite maximal speed and good field-weakening performance, but it is achieved at the cost of a low power factor and poor inverter volt–ampere rating utilization [

24].

It is a common practice to design the drives precisely on the boundary of these two sub-classes, i.e., with

, as it provides a good compromise between the field-weakening performance and inverter utilization. An excellent example of such a practice is the traction machine from the BMWi3 described in [

11].

The examined drive from the Toyota Prius is a counter-example of this practice. The drive characteristic factor of

is an extreme example of the infinite maximal speed drive class. Let us put it in numbers. For the Toyota Prius inverter, the volt–ampere rating of the inverter can be calculated as follows:

where

S is the apparent power of the inverter [VA]. According to the approximations derived in [

24], the asymptotic power reached by the drive at high speed can be approximated by:

where

is the approximated power reached at high speeds [W]. Substituting

yields that one could design the motor, which could reach approx. 129.9 kW power at the shaft when supplied from the Toyota Prius inverter. At the same time, substituting the value from the Toyota Prius motor, i.e.,

, results in the shaft power of

kW, which is very near to the value of 53 kW obtained later in this section (it should be remembered that Equation (

9) is only an approximation). It means that only 40.8% of the potential power of the inverter is utilized.

Coming back to the working points calculation, the field-weakening strategy needs to be applied above the speeds where the MTPC points can be reached. The Maximal Torque per Voltage (MTPV) strategy limits the maximum torque for a given speed. This strategy’s current space vector locus lies at the points where the torque isolines are tangential to the voltage isolines at a given speed [

24]. The maximal drive torque obtained with the MTPV strategy is depicted with black color in

Figure 11b. The maximal power achieved equals 82.2 kW (see constant power hyperbole depicted in

Figure 11b). This value is much higher than the official value of 53 kW published by Toyota. Hence, the constant power hyperbole for the value of 53 kW was drawn too. It reveals that the torque curve of the drive converges to this official value. This means that the official value published by Toyota does not refer to the peak power but to the maximal power available in the wide speed range. The fact that the calculated torque curve matches so closely with the official value of the maximal power acts as an additional validation of the presented model.

For the partial load operation, i.e., for torque values lower than the MTPV curve, another field-weakening strategy must be applied. In that case, the space vectors on the intersection of the torque isolines (for the given torque) and maximal voltage isolines (for the given speed) should be chosen. These points are depicted in different colors for each torque value in

Figure 11. The colors for each torque value in

Figure 11a and in

Figure 11b match each other.

3.4. Comparison with the Linearized Model

As mentioned in

Section 2.4, the examined motor is an extreme example of a highly saturated machine. It can be seen not only in the flux density plot depicted in

Figure 7b, but the shape of the MTPC current locus also indicates it. For the linear motor model, the maximum reluctance torque lies at the angle 45° between the current vector and the

q-axis. Hence, the angle of the current vector corresponding to the peak torque lies in the range of 0–45° and converges asymptotically to the value of 45° when the motor saliency goes to infinity [

24]. The fact that this angle substantially exceeds the value of 45° for the examined motor indicates an extreme saturation of the machine. It can be directly compared with the value obtained for the BMWi3 motor [

11], which is very near the value 45°. This indicates that the Toyota Prius machine has an even more non-linear magnetic circuit than the BMWi3 machine (already considered highly saturated).

This difference can be further investigated by comparing it with the linearized model. Additionally, despite being known that the non-linear models should be used for the highly-saturated machines, it is still interesting to quantify the calculation errors resulting from the model linearization for some real-world examples.

For this purpose, the flux linkages should be described using the linear functions as follows:

where

and

are the linearized

d- and

q-axis flux linkages [Wb], respectively,

and

are the constant

d- and

q-axis inductances [H], respectively, and

is the constant permanent magnet flux linkage [Wb].

The linearized model parameters

,

, and

can be obtained using the linearization of the non-linear flux linkage surfaces (see

Figure 10) at some particular operational point. In this study, a point corresponding to the peak torque of the machine is utilized, i.e.,

A and

A. Hence, the linearized model’s parameters can be calculated as:

The flux linkages calculated with the linear model (

10) are depicted as black planes in

Figure 12a,b. For the comparison, the flux linkages obtained with the non-linear FEM model are depicted as blue surfaces. The electromagnetic torque (

2c) calculated using both models is shown in

Figure 12c.

Since the operating points of the drive during the motor operation lie solely in the second quadrant of the current

-plane, this quadrant was depicted as a separate plot in

Figure 12d for improved readability. The points corresponding to the maximal current limitation are drawn with thick solid lines, and the MTPC loci calculated for both models are depicted as white filled dots. For the low

d-axis current values, the reluctance torque is low, and the majority of the torque is the permanent magnet torque, i.e., torque depends mainly on the

d-axis flux linkage. It can be seen in

Figure 12a that this flux linkage component of the non-linear model substantially drops in that region due to the cross-saturation. Hence, a relatively big difference in calculated torques can be observed in the low

d-axis current region. On the other hand, this region corresponds to the MTPC locus of the linear model (current vector angles to

q-axis lower than 45°) and results in a high difference between the MTPC loci calculated with both models.

The MTPC loci are also depicted at the current

-plane in

Figure 13a for better readability, and the resulting torque vs. current magnitude plots are shown in

Figure 13b. As the results obtained with the non-linear model can be considered as the reference for the comparison, the linearized model’s calculation error can be expressed as the difference between the values calculated with both models expressed in percents of the nominal torque 163 Nm (see gray curve in

Figure 13b). The torque calculation error for the linearized model varies in the range of −12.1% to +15.5%, which is almost twice as big as the error obtained in the similar analysis for the BMWi3 [

11]. This is another indicator that the saturation of the Toyota Prius machine’s magnetic circuit is higher.

To complement the analysis, the torque vs. speed curves for different current limitation values were calculated with both models, and the results are depicted in

Figure 14.

It can be seen that the current vector loci at low speeds (see

Figure 14a) are very different for both models as they result from the MTPC calculation presented before. As a result, the torque vs. speed curves calculated with both models differ substantially in the base speed operational region (see

Figure 14b).

On the other hand, the torque vs. speed curves calculated at high speeds, i.e., during the field-weakening operation, are very similar for both models (see

Figure 14b). This is caused by the fact that the MTPV loci of both models lie in the region where the difference between the torque surfaces calculated with different models do not differ much from each other (compare MTPV loci in

Figure 14a with torque surfaces in

Figure 12d). A similar phenomenon was observed when analyzing the results for the BMWi3 machine [

11].

3.5. Efficiency and Losses

The previous analysis was carried out using the lossless model. Hence, it should be complemented by the results obtained with the model where losses are included. For this purpose, the dedicated sub-module of the Motor-CAD software (version 2023.2.2) was utilized [

26].

After considering the losses, the maximal torque of the drive equals 171.8 Nm, and the peak power drops to 80 kW compared to the results obtained with the lossless model. The torque curve at high speed again converges to the officially published value of 53 kW.

The peak machine efficiency is very high and equals 98%, and the high-efficiency operational region is vast. Compared to the previous generation of Toyota Prius, the efficiency at high speeds rose by approximately 2% [

6].

The total losses in the machine (see

Figure 15b) reach a peak value of 5.5 kW. Most of the total machine losses consist of copper losses (see

Figure 15c). In comparison, the iron losses (see

Figure 15d,f) are much lower, and the magnet losses are almost negligible (see

Figure 15e).

Since the primary source of the losses is the joule losses in the conductors, the machine’s total losses map is similar to the copper losses map. The losses in the base speed region are mostly torque-dependent (since higher torque means higher current). On the other hand, the iron losses are mostly speed-dependent. It can also be observed that there is a slight increase in the copper losses with rising speed. This is caused by the AC component of the copper losses, which is frequency-dependent.

In deep field-weakening regions, all the losses seem rather power-dependent.