Abstract

Hydrogen mobility embodies a promising solution to address the challenges posed by traditional fossil fuel-based vehicles. The use of hydrogen in small heavy-duty road vehicles based on internal combustion engines (ICEs) may be appealing for two fundamental reasons: Direct electrification seems less promising in heavy-duty transport systems, and fuel cell-based hydrogen vehicle implementation may not proceed at the expected pace due to higher investment costs compared to ICEs. On the other hand, hydrogen combustion is gaining attractiveness and relies on robust and cheap technologies, but it is not the only renewable solution. In this framework, this work presents a methodology to assess the Well-to-Wheel primary energy consumption and CO2 emissions of small heavy-duty vehicles. The methodology is applied in a real case study, namely a passenger coach traveling on a 100 km mission in non-optimized conditions. Therefore, the suitability of hydrogen is compared with standard diesel and other alternative diesel-type fuels (biodiesel and synthetic diesel types). Hydrogen shows competitivity with standard diesel from the point of view of CO2 emission reduction (−29%) while it hides a higher primary energy consumption (+40%) based on the current power-to-hydrogen efficiency declared by electrolyzer manufacturers. Nonetheless, HVO brings the highest benefits both from the point of view of primary energy consumption and emission reduction, namely −35% and 464–634 kgCO2/100km avoided compared to hydrogen. Moreover, the availability of HVO—like other biofuels—does not depend on carbon from CO2 capture and sequestration systems.

1. Introduction

The modernization of public transportation has become an imperative pursuit due to increasing environmental concerns and the need for carbon emissions reduction. In this context, the integration of hydrogen as a clean and renewable energy carrier to fuel transport media emerges as a promising avenue to address these challenges [1,2].

Current advancements focus on the use of hydrogen in fuel cell-based hybrid power trains [3], holding the promise of high efficiency and eco-friendliness. However, the straightforward substitution of the current bus fleet (or, at least, the extensive retrofit) seems to pose a big hurdle to transport companies [4]. Traditional internal combustion engines, known for their robustness, have a long-standing presence supported by extensive service networks. Fuel cell electric vehicles (FCEVs) and hydrogen internal combustion engines (ICEs) are not in direct competition; instead, their development mutually drives the establishment of a common hydrogen infrastructure [5], including production, transportation, and distribution [6]. Both technologies share vehicle storage tanks, reinforcing their collaborative advancement. For this reason, the utilization of hydrogen in well-established power trains based on ICEs attracts applied research interest [7]. The exploration of hydrogen’s role in ICE-based public road transport (i.e., buses, coaches) is not merely an exercise in technological curiosity; rather, it is a strategic move toward aligning transportation systems with the broader goals of sustainability. It is reasonable to assume that hydrogen-based ICEs can have an economic advantage against FCEV, whilst both solutions share the burden of the costs associated with on-board hydrogen tanks (more expensive compared to liquid diesel-type fuels).

1.1. Regulatory Framework

Hydrogen-powered vehicles strongly comply with stringent EU decarbonization goals, highlighting their potential for meeting environmental regulations [2]. At the EU level, the revised Renewable Directive (RED) sets ambitious targets for the transport sector, namely a 14% decrease in CO2 emissions related to all sub-sectors. Moreover, the new RED III binding targets are amended to 45% on final energy consumption by 2030 and 14.5% for transport [8]. Nowadays, the carbon intensity of energy usage in the transport sector is around 70 gCO2/MJ [9]. International regulation supports technological neutrality. Hence, novel solutions must meet the sustainability criteria set by the EU directive. Compared to the use of standard transport fuels (derived from fossil resources), GHG savings are expected to account for −70% by 2026 in the case of renewable fuels of non-biologic origin (RFNBOs) like H2 and −65% in the case of biofuels [8].

1.2. State of the Art: Power Train Concept Comparison

The use of hydrogen to improve the sustainability of low-haul and heavy-duty transport finds application in different types of power trains (Table 1): ICE vehicles fueled with fossil fuel products, biofuels, hydrogen, or a blend of hydrogen and other fuels, hydrogen FCEVs and battery electric vehicles (BEVs) [5]. In the first instance, hybrid configurations involving at least two basic technologies are neglected. Research has shown that adding hydrogen to gasoline fueling in spark ignition engines can lead to improved combustion, including a reduction in combustion duration, an increase in indicated thermal efficiency, and a decrease in specific energy consumption [10]. Additionally, hydrogen combustion can significantly reduce polluting emissions and greenhouse gases [11]. Furthermore, hydrogen direct injection in ICEs has been found to result in lower NOx emissions, which are one to three orders of magnitude less than those of conventional diesel operation at low load [12]. However, the high auto-ignition temperature of hydrogen limits the applicability of this combustion mode. Moreover, hydrogen-fueled ICEs have been studied extensively, with research focusing on various aspects such as combustion characteristics, injection methods, and performance optimization [13]. The results indicate that hydrogen can improve the combustion process due to its wide flammability, low ignition temperature, and high burning speed, leading to better engine performance compared to traditional gasoline-fueled engines. However, it is important to note that abnormal combustion may occur in H2-fueled engines under anomalous combustion conditions [14].

Table 1.

Qualitative comparison of long-haul transport power train options [5] (signs “+”stand for the qualitative evaluation intensity, where “+” is low, “++” is moderate, “+++” is good and “++++” is very good).

Furthermore, the use of hydrogen in ICEs has been recognized as a promising approach from a whole life cycle perspective, indicating a good development prospect for hydrogen-fueled internal combustion engines. Compared to hydrogen FCEV, ICE frequently demonstrates compatibility with lower-grade hydrogen [15,16]. For instance, in scenarios where on-site hydrogen production involves methods like either steam methane (fossil or biogenic) reforming with carbon capture and storage or gasification, the produced hydrogen can be directly utilized in hydrogen engines without requiring severe purification. This resilience to impurities is particularly advantageous in the transportation sector, where the shift to high-quality green hydrogen is a gradual process. Electrolytic hydrogen produced with renewable power reaches a high purity level since in the worst case, the electrolyzer outflow is hydrogen with mild contamination of oxygen and water due to gas crossover [17]. This is an issue for PEM fuel cell-based automotive systems, which require a hydrogen purity of up to 99.99% [18] and hence, require extra hydrogen pre-processing [19]. Yet, little fractions of oxygen and water are not detrimental to combustion-based processes. In addition to that, while considering other green hydrogen production pathways, like the ones based on biogas/biosyngas, the problem of undesired compounds having a negative impact on the end-user is more severe (HCl, H2S, tars) [20,21,22]. Gas clean-up is mandatory to reach vehicle standards [21], being ICEs less sensitive to trace contaminants.

Beyond academic research, there are positive signals from the market regarding hydrogen ICEs. In December 2021, Toyota showcased an experimental hydrogen ICE vehicle, and in June 2022, two manufacturers (Sinotruck and Weichai) followed up [23].

1.3. Scope of the Paper

This paper delves into the evolving landscape of advanced fuels, focusing on hydrogen utilization in the context of ICE buses for passenger transportation. After presenting the assessment methodology used, this paper explores the potential performance that can be attained with hydrogen in a real-case scenario against the traditional use of diesel and renewable diesel-fueled ICE buses. The novelty of this paper stands in a simple model that can be replicated in many case studies to assess the suitability of advanced fuels in small heavy-duty road transport, where direct electrification seems not appealing, and fuel cells are not considered. This case study models a 100 km travel mission with the need for frequent stop-and-starts, where fuel consumption is not optimized. Moreover, it compares the envisaged solutions from the point of view of primary energy consumption and fuel life cycle GHG emissions (Well-to-Wheel). The economic comparison is expressly omitted from this study since energy and environmental criteria are identified as priorities to limit the number of reasonable applications for a future and accurate cost analysis.

2. Model and Assessment Methodology

The overarching methodology used for the assessment implements (i) the analysis of typical service routes with drive features, leading to the linear speed profile (Section 2.1), (ii) the calculation of the drive features—see instantaneous engine angular speed (Section 2.2), (iii) the simplified dynamic modeling of the coach leading to torque–shaft angular speed profiles (Section 2.3), (iv) the calculation of the fuel consumption profiles and eventually, the equivalent consumption in the case of alternative fuels (Section 2.4), (v) the carbon footprint estimation based on the energy requirements (Section 2.5). A sketch of the workflow is reported in Figure 1, while details are explained in the following.

Figure 1.

Schematic of assessment methodology.

2.1. Mission Load Profile: Route Analysis

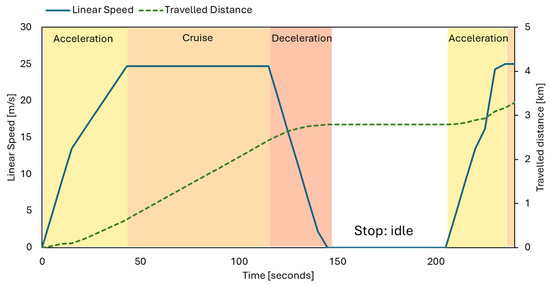

The route was analyzed considering the overall length and the distance between stops. A trapezoidal profile was chosen to undertake transients and describe the speed variation between two consecutive simulation steps, as depicted in Figure 2. The front part of the profile consists of a linear rise in the speed (acceleration) up to a determined value. The steady-state condition lasts for a duration compliant with the travel mission (distance between two consecutive stops of the coach). Then, the trail front represents the deceleration, where the speed linearly decreases to zero when the vehicle needs to stop.

Figure 2.

Simplified transient profile: route analysis method.

A literature analysis about coaches suggests reasonable values for the acceleration in the corresponding velocity range [24]—summarized in Table 2. The acceleration is assumed 0.9 m/s2 from 0 to 16.6 m/s (approximately 60 km/h). Above this threshold, the acceleration decreases up to 0.4 m/s2 until the maximum speed of 27.8 m/s is reached corresponding to 100 km/h. In the deceleration operations, the torque on the driving wheel is assumed to be null and the acceleration equal to −0.9 m/s2. This means that the deceleration is solely due to the brakes, thus neglecting the engine’s pumping operations.

Table 2.

Drive features: acceleration vs. speed range and maximum speed for each gear [24].

2.2. Mission Load Profile: Drive Features

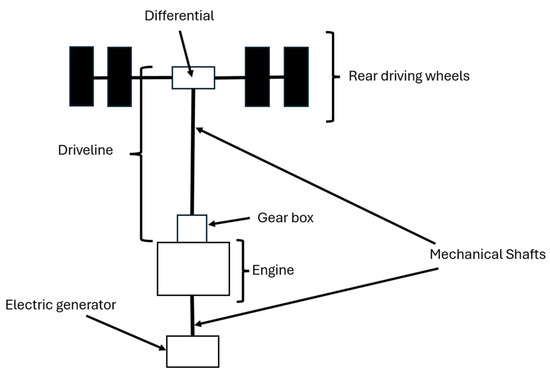

The coach power train and driveline are modeled according to the scheme in Figure 3, where the engine drives the rear wheels through the mechanical shaft. Moreover, the coach uses an electric generator for the ancillary services. For the sake of this work, the electric generator is assumed to be directly connected to the engine, adjoining an additional load to it. The model and the powertrain assumed for this study also require considering the speed range for each gear (Table 2).

Figure 3.

Schematization of the powertrain and driveline of the coach.

2.3. Dynamic Coach Model: Torque–Velocity Correlation

The simplified dynamic modeling of the coach consists of the analysis of all forces acting on it during the whole mission. Despite its simplicity, this approach is suitable for predicting fuel consumption by determining the resultant force on the coach as a function of the route slope (). Moreover, the advantage of this method stands in a small number of input parameters. Then, the model allows us to simulate the flexibility of operation in routes featured by frequent starts and stops and considerable slopes, whose effect is to increase the total resistance and then the fuel consumption.

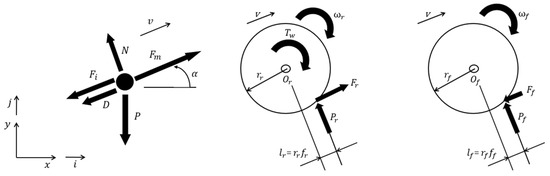

Equation (1) reports the vectorial Equation of the particle model of the coach. In detail, the forces are the inertial load due to the acceleration of the coach , the aerodynamic friction , the gravity load , the normal reaction force , and the traction between wheels and the ground , causing the rolling friction, and the forces parallel to the direction of the motion imposed by the vector . Details about the calculation method are displayed in Appendix A—see Equations (A1)–(A3). The force diagram is shown in the left-side picture of Figure 4. is distributed between the front and rear axles; thereby, it is expressed by the vectorial sum of two components and Equation (2). Then, on the one hand, Equation (3) shows the force equilibrium along the direction of the motion. On the other hand, along the normal direction, the force is balanced by the normal component of the force —Equation (4). Considering the extensive volume and mass of the coach, these forces are applied in different points of action. Namely, the traction acts on a small area on the tires, thus being considered as a concentrated force in the corresponding point of contact between the ground and the tire. The inertial and gravitational loads act on the whole volume of the coach, while the aerodynamic friction is distributed on its surface. Accordingly, Figure 4 reports the force and torque equilibrium diagram with regard to the rear (Figure 4, center) and front axles (Figure 4, right).

Figure 4.

Force diagrams: material point model (left), free body of driving wheels (center), and driven wheels (right) along a sloped path.

Nevertheless, this study stands on a simplified model that neglects the exact point of the application of every force in a 3-D model of the coach with detailed geometry. Therefore, for the calculation of the driving power (), the weight distribution is considered symmetric between the axles because of the collocation assumed for the engine, the transmission system, the steering system, and the tank (Figure 3). This assumption allows imposing the equilibrium of the moments of all forces and torque that acted on the driving and the driven wheels about their corresponding rotation centers (Or and Of, for the rear driving wheel and front driven wheels, respectively—Figure 4, center and right).

In Figure 4 center and right, each free-body diagram represents the wheels placed on each axle. The forces due to the hinge in the rotation center are not reported because their moments at these points are null. The normal component of the force is decomposed in two equi-modulus forces acting on the rear and front wheels, namely and —Equations (A4) and (A5) in the Appendix A section. The inertia of the wheels is neglected because it is assumed to be smaller compared to the whole mass of the coach. The driving torque () contributes to the moment equilibrium of the driving wheels on the rear axle. Then, the equilibrium of the moments on the wheels determines the moduli of and as in Equations (5) and (6), respectively (complementary notation at Equations (A5) and (A6) from Appendix A). Therefore, the combination of Equations (5) and (6) with Equation (3) allows the expressing of the torque required at the driving rear wheels as a function of the dynamic resistances (under the rough assumption that front and rear wheels have the same radius = and the same rolling friction coefficient —see also Equation (A7)).

Moreover, the assumption that front and rear wheels have the same radius implies that their angular velocity is the same (). As a result, the multiplication of the left- and right-hand sides of Equation (7) by the angular velocity allows for expressing the power provided to the rear wheels , as required for the motion of the coach with a linear speed equal to —Equation (8) and Equation (A8) from Appendix A. In addition to , the ancillary functions add a further load, equal to a net power requirement named . Therefore, Equation (9) shows the resulting power required at the engine given by the sum of the gross share of and , where represents the driveline efficiency (including the gearbox, the shaft, and the differential), and represents the ancillaries’ power conversion efficiency. Finally, the total engine torque (hereinafter referred to as “torque”) is given by Equation (10), where the engine angular velocity is found as the product of the angular velocity of the wheels and the gear ratio of the whole driveline .

The set of Equations presented here allows the simulation of the power, torque and rotating speed profiles by using the mission data as inputs, including the slope of the path, as well as the gear ratio variation resulting from the drive features application. The mission profiles result in diagrams where power, torque and rotating speed are depicted on the vertical axis, while the horizontal axis reports either the traveled distance or the traveled time (related by a cinematic constraint). The simulation of the engine profiles is performed by applying the abovementioned Equation to discrete time intervals

2.4. Primary Energy Consumption: Calculation and Comparison Metrics

The specific energy consumption of the engine is extracted from the literature T- curves, available in the literature for the types of engines under consideration [25].

This gives the organic engine efficiency as a function of engine rotating speed and torque. As a result, once the lower heating value of the fuel is specified, the fuel consumption rate is determined with Equation (11). Like the power, torque and rotating speed profiles, it is possible to draw the history of fuel consumption by implementing Equation (11) in the time-discrete simulation. As a result, since the simulation is performed on discrete time intervals, the whole fuel consumption during the mission is found as the summation of the total mission duration—Equation (12).

The propulsion solutions investigated in this paper are compared through the “Primary energy consumption” metrics defined in the following. First, the fuel consumption is expressed in normalized terms, as distance-specific fuel consumption, on a mission distance of 100 km—Equation (13). Then, the equivalent direct primary energy requirement is calculated by Equation (14) in order to compare the energy footprint of several alternative fuels used as substitutes for conventional diesel oil. Furthermore, the solutions investigated are compared through the total primary energy consumption of the mission () adding the primary energy consumption required for the provision of the fuel to , as in Equation (15). The coefficient stands for the energy consumed in the fuel production and provision phase to deliver one unit of energy for the final use. These values are retrieved from the JRC report, as explained later in Section 3.3.

2.5. Carbon Footprint: Calculation and Comparison Metrics

The propulsion solutions investigated in this paper are also compared through the carbon footprint metrics defined in this subsection. In order to address the environmental impact, the equivalent CO2 emissions ascribed to a 100 km travel mission are accounted for, considering both Well-to-Tank emissions () arising in the fuel production and provision phases—Equation (16)—and Tank-to-Wheel emissions () allocated on the fuel direct use—Equation (17). The terms and represent the generic fuel’s equivalent CO2 emission factors specific to the energy used (i.e., gCO2/MJfuel). The overall CO2 emissions are referred to as the Well-to-Wheel cycle (W-t-W), therefore according to Equation (18).

3. Case Study

This section presents the particular data used to run the simulations, namely referred to the suburban public transport routes (Section 3.1), coach engine assets and fuel options (Section 3.2), and the simulation plan (Section 3.3).

3.1. Route

The coach run was simulated on a real mission profile, with an overall length of 100 km and an average slope of 1.2–1.4%. The detailed slope variation was obtained from the Google Earth [26] database and implemented in the calculation model presented in Section 2 (the slope represented the tangent of the route profile as the vertical increase to a horizontal distance of 100 m). During the mission, 35 stops lasting 110 s were scheduled. The choice related to the simulation scenario appeared suitable to represent a typical road public transport mission with speed variation and several start and stop intervals.

3.2. Coach Engines and Fuel Properties

The methodology described in Section 2 was employed to simulate the engine profiles and calculate related primary energy and carbon footprints during the mission of a commercial-type coach suitable for the chosen path (Section 3.1). Thus, technical parameters for such vehicle types were estimated from technical literature and commercial catalogs and are summarized in Table 3. The calculation of the fuel consumption was performed considering that the coach weight (vehicles + passengers) is constant. This simplification is precautionary since it neglects the emptying of the tank and considers the same number of passengers throughout the entire mission. Moreover, the drag coefficient was assumed equal to an average value suitable for the velocity range exhibited in the mission [27].

Table 3.

Representative values for the coach analyzed in this study.

The engine options under investigation are reported in Table 4, with reference to technical datasheets regarding DI compression ignition and DI spark ignition engines. The baseline fuel option is conventional diesel fuel, referred to fossil resources-based standard fuel production process. As alternatives to RFNBOs, synthetic diesel fuels (synthetic diesel produced with electrolysis-assisted Fischer Tropsch or wood gasification + CCS Fischer Tropsch) and biogenic substitutes for fossil diesel are considered. Concerning the latter, Fatty Acid Methyl Ester (FAME) [28] and Hydrotreated Vegetable Oil (HVO) [29] are included in this assessment. Normally, paraffinic fuels like HVO tend to lower gravimetric fuel consumption. Conversely, FAME-type fuels increase fuel consumption, even by 15%. All fuel properties are recapped in Table 5, including the equivalence factor, which represented the gravimetric equivalent fuel consumption compared to standard fossil diesel.

Table 4.

Engines technical parameters.

3.3. Design of Simulation Cases

The simulation was run under 6 cases, namely DI compression ignition engine fueled with standard diesel B0 (case 0, assumed as baseline for the validation of the proposed methodology), DI compression ignition engine fueled with synthetic diesel produced via the Fisher Tropsch process (case 1 synthetic diesel from electrolytic hydrogen and CO2 from combustion flue gases and case 2 synthetic diesel derived from wood gasification coupled with CSS) and biodiesel (case 3 FAME and case 4 HVO), and finally spark ignition engine fueled with hydrogen (case 5). Related GHG emissions are disaggregated into W-t-T and T-t-W. Regarding hydrogen, the T-t-W phase is carbon neutral, yet hydrogen production causes negligible GHG emissions, depending on the process [31]. Considering hydrogen from an electrolytic pathway, GHG emissions are influenced by electricity carbon intensity [32]. Therefore, the W-t-T emission factor for hydrogen refers to the electrolysis processes and EU mix for grid CO2 emissions as reported from energy bulletins related to 2022 [33]. The option of fully renewable hydrogen produced only from solar and wind power sources was not considered since it is hard to be widely implemented due to the current deployment of GW-scale RES generators completely devoted to chemical plants—like large-scale electrolysis facilities. In addition to that, the latter would need noteworthy electric storage to avoid complete grid electricity withdrawal.

Table 5.

Fuel properties and CO2 emissions coefficients (Reference: Vehicle category Type4 forecast 2025+, from JRC report [33]). Abbreviations: see the Nomenclature section.

Table 5.

Fuel properties and CO2 emissions coefficients (Reference: Vehicle category Type4 forecast 2025+, from JRC report [33]). Abbreviations: see the Nomenclature section.

| Case | Fuels | LHV MJ/kg | gCO2eq/MJfuel | gCO2eq/MJfuel | MJWtT/MJTtW |

|---|---|---|---|---|---|

| 0 | Fossil Diesel B0 | 42.7 | 69.3 | 76.7 | 0.28 |

| 1 | Syn. Diesel (e-fuel) | 44.0 | −42.4 | 74.1 | 1.57 |

| 2 | Syn. Diesel (FT Wood gas+CCS) | 44.0 | −133.3 | 74.1 | 1.33 |

| 3 | FAME (Rapeseed) | 37.1 | −24.6 | 79.6 | 1.13 |

| 4 | HVO (Waste cooking oil) | 44.4 | −355.6 | 74.1 | 0.17 |

| 5 | Hydrogen (electrolysis, EU electricity mix) | 120.0 | 35.7 | 0 | 0.35 |

FT synthetic diesel fuels show different W-t-T emission factors according to sub-process implemented for hydrogen production. The option reported in case 1 from Table 5 is featured by a mildly negative value because of the combined impact of hydrogen production from electrolysis (see case 6 = 35.7 gCO2eq/MJfuel for hydrogen) and carbon utilization. However, the implementation of wood gasification with subsequent CCS has a totally negative carbon emissions balance in the W-t-T phase.

4. Results and Discussion

The proposed calculation model was required to be validated to assess its reliability in providing accurate results. This reason suggested determining the fuel consumption when the coach performed the mission by employing a commercial DI compression ignition engine fueled with standard diesel oil (B0), as reported in case 0. After that, the validated simulation profiles were used to assess the impact of alternative diesel-type fuels, as well as apply the model to the case of the hydrogen spark ignition engine.

4.1. Travel Mission Simulation in the Base Case: Results and Validation

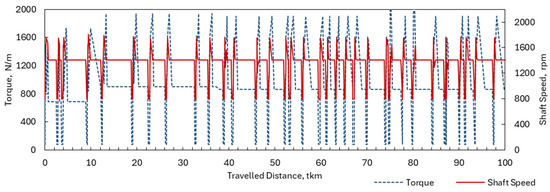

Figure 5 reports the simulation profiles for the torque and shaft speed required to accomplish the defined travel mission. The results revealed that the fuel consumption requested by the mission profile was 2.08 km/L for a speed of 41.5 km/h and appeared acceptable in comparison with the references that estimated a fuel consumption between 1.4 and 3.4 km/L. Furthermore, the validation indicated that the maximum power, torque, and rotating speed provided by the engine fell within the limit proposed for this engine since they were about 310 kW, 1950 Nm, and 1800 rpm, respectively. Therefore, these travel profiles obtained and validated for the DI compression ignition engine were taken as reference profiles to evaluate the energy and emission parameters for all alternative fuels.

Figure 5.

Mission profile for the passenger coach: torque and shaft speed vs. traveled distance.

4.2. Direct Fuel Consumption

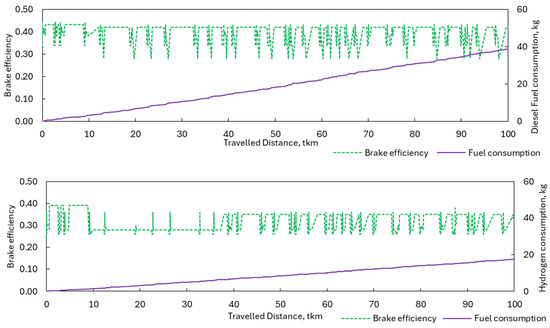

Figure 6 reports the brake efficiency profiles, as well as the integral of the fuel consumption. In the top graph of Figure 6, the brake efficiency and fuel consumption are depicted for the reference DI compression ignition engine. In this case, the 100 km travel mission requires 38.6 kg of standard diesel oil, equivalent to 37.5 kg of synthetic diesel (cases 1 and 2), 44.4 kg of FAME biodiesel (case 3), and 37.1 kg of HVO biodiesel (case 4). Regarding the hydrogen spark ignition engine, the brake efficiency profiles and integral of the fuel consumption are shown in the bottom graph of Figure 6. For this application, the total fuel consumption requires 18.1 kg. The profile for the brake efficiency and subsequent instantaneous fuel consumption are referred to the engine map available at [25,26,27,28,29,30], as previously noted in Table 4. The integral of the fuel consumption obtained in the two simulations is set as the basis for the Well-to-Wheel energy and emissions assessment discussed in the next subsection.

Figure 6.

Brake efficiency profile and fuel consumption integral: DI compression ignition diesel-type ICE (top), DI spark ignition hydrogen ICE (bottom).

4.3. Well-to-Wheel Assessments

The methodology shown in Section 2.5 was applied to the cases from Table 5 based on the direct fuel consumption obtained from the 100 km travel mission simulation.

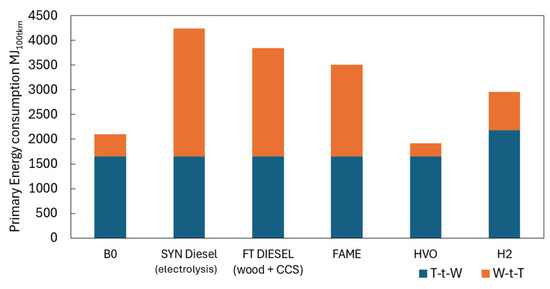

4.3.1. Primary Energy

Figure 7 compares the fuels from the point of view of the overall Well-to-Wheel primary energy consumption. In particular, the bar plot reports the primary energy consumption disaggregated into the direct consumption ascribed to the travel mission (in other words, the energy related to the fuel consumption of the DI compression ignition ICE for the diesel-type fuels and DI spark ignition hydrogen ICE), and the primary energy consumption necessary upstream is the fuel utilization in the coach engine. In Figure 7, the data series is identified as Tank-to-Wheel, like the nomenclature used for the emissions computation. This data series reflects the integral of fuel consumption, as already shown in Figure 6. For that, all diesel-type fuels have the same indicator, while the hydrogen direct energy consumption is higher because of the average brake efficiency exhibited in the profile in Figure 6 (bottom). To complete the Well-to-Wheel energy assessment, the Well-to-Tank (W-t-T) primary energy consumption is calculated (orange data series from Figure 7) and summed to the previous data series to obtain —see Equation (15). The results show that the primary energy consumption in case 5 (hydrogen) exceeds 40% in case 0 (B0). This gap is expected to decrease together with the development of commercial electrolyzers, pointing to a higher power-to-hydrogen efficiency. Nowadays, power-to-hydrogen efficiency ranges from 50–60% for low-temperature electrolyzers (Polymer Electrolyte Membranes and Alkaline electrolyzers) to 80–85% for high-temperature electrolyzers, which exhibit a lower technologic and market readiness level compared to PEM and Alkaline systems [34]. In addition to the higher primary energy consumption calculated in the direct utilization, electrolytic hydrogen shows a higher κf ratio compared to standard diesel (0.35 vs. 0.28). The least primary energy consumption is obtained in case 4 (HVO), where the W-t-T primary emission consumption is lower by −9% compared to the reference case 0. All other diesel-type alternative fuels (case 1, case 2, and case 3) exhibit higher W-t-T primary energy consumption, especially synthetic e-fuels, which carry the efficiency burden of intermediate hydrogen production (case 1, +101% regarding reference).

Figure 7.

Well-to-Wheel primary energy consumption comparison: W-t-T and T-t-W breakdown.

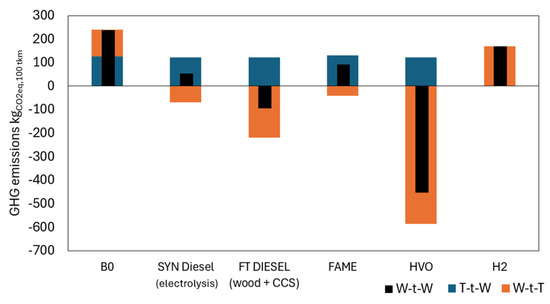

4.3.2. GHG Emissions Assessment

Figure 8 compares the fuels from the point of view of the overall Well-to-Wheel equivalent GHG emissions. The black bar plot reports the total CO2 emissions specific to the 100 km travel mission, disaggregated into W-t-T and T-t-W emissions (namely the orange and the blue data series).

Figure 8.

Well-to-Wheel equivalent GHG emissions comparison: W-t-T and T-t-W breakdown.

As expected, the reference case 0 shows a higher impact in terms of W-t-W emissions, being both the W-t-T and the T-t-W components positive. Conversely, the alternative diesel-type fuels exhibit negative emissions in the W-t-T phase. This happens because the alternative fuels of biological origin (case 2, case 3, and case 4) involve the transformation of biomass, hence a zero or negative balance of carbon, while pure RFNBOs (case 1) require CCS to provide CO2 for synthetic hydrocarbon production [35]. In particular, the combination of a biological feedstock (wood) with CCS in an FT synthesis process brings excellent results in terms of CO2 emission reduction—see case 2. However, the best result for what concerns W-t-W GHG emissions is obtained with HVO, where the final net emission is −464 kgCO2/100km (vs. case 0, 240 kgCO2/100km), thereby resulting in a net carbon sink with a carbon sequestration capacity of (−704.58 kgCO2/100km versus standard diesel). The performances obtained with hydrogen in case 5 are encouraging looking at the direct comparison with case 0 since there are no direct T-t-W CO2 emissions and moderate W-t-T emissions due to the electric grid residual carbon footprint and electrolysis efficiency (169.97 kgCO2/100km, −29% compared to case 0). The W-t-T emissions in case 5 can be reduced moderately considering different pathways for hydrogen production (i.e., renewable hydrogen production from biogas exhibits a lower compared to electrolytic hydrogen in the EU mix scenario [33]) or to the uttermost whether hydrogen production is achieved with fully renewable electricity coming from a dedicated power plant. However, the latter scenario calls for large-scale electric storage and does not appear realistic in the short–medium term. While considering the EU grid electricity mix as a reference, it is reasonable to assume a gradual increase of RES penetration in the upcoming year, therefore a moderate yet continuous reduction of the carbon footprint. Under these circumstances, hydrogen would gain convenience against FAME. Nevertheless, the gap between case 4 and case 5 (HVO vs. hydrogen) is too wide for a positive W-t-W outlook regarding hydrogen.

5. Conclusions

This work presented a methodology for the simulation of power, efficiency, and fuel consumption profiles for road vehicles, followed by a Well-to-Wheel evaluation of primary energy consumption and equivalent GHG emissions (CO2). The methodology was applied to the case study of a passenger coach, achieving travel missions with frequent starts and stops and considerable road slopes. The results obtained were normalized against a travel distance of 100 km. In the same case study, two different power trains were evaluated, namely a DI compression ignition ICE for diesel-type fuels, and a DI spark ignition ICE for hydrogen. It is recalled that the travel mission chosen for this study models non-optimized operating conditions, hence reflecting realistic driving needs. The W-t-W energy and emission assessment revealed that hydrogen can compete with standard diesel from the point of view of CO2 emission reduction (−29% in the actual case of electrolysis run with electricity from the EU grid), while it hides a higher primary energy consumption (+40%). For the same mission, among the analyzed alternative fuels, the best results were achieved with HVO, bringing benefits both from the point of view of primary energy consumption (−30%) and net carbon sequestration performance (−193%) compared to standard diesel fuel.

To conclude, it is worth mentioning that the wider implementation of HVO rather than H2 simplifies the vehicles’ retrofit and the fuel on-board storage, with HVO being available in the liquid phase at environmental conditions and having a higher energy density compared to standard diesel. Nevertheless, hydrogen profitability may be better exploited in energy supply chains featuring an extremely high penetration of variable renewable energy sources and scarce/expensive access to bio-based energy products. Different case-specific results may be found under unlike travel missions and vehicle category assumptions.

Author Contributions

Conceptualization, A.B. and M.F.; methodology, A.B. and M.F.; validation, M.A.; investigation, A.B. and M.F.; writing—original draft preparation, A.B.; writing—review and editing, M.A.; visualization, A.B. and M.F.; supervision, M.A., funding acquisition M.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded in the framework of the National Recovery and Resilience Plan (NRRP), Mission 4, Component 2 Investment 1.3—Call for Tender No. 1561 of 11 October 2022 of Ministero dell’Università e della Ricerca (MUR), funded by the European Union—NextGenerationEU. Award Number: Project Code PE0000021, Concession Decree No. 1561 of 11 October 2022 adopted by Ministero dell’Università e della Ricerca (MUR), CUP—I53C22001450006, Project Title “Network 4 Energy Sustainable Transition—NEST”.

Data Availability Statement

Data derived from public domain resources.

Conflicts of Interest

The authors declare no conflicts of interest.

Nomenclature

| BEV | Battery electric vehicle |

| CCS | Carbon capture and storage |

| DI | Direct injection |

| EU | Europe |

| FAME | Fatty Acid Methyl Ester |

| FC | Fuel cell |

| FCEV | Fuel cell electric vehicle |

| FT | Fisher Tropsch |

| GHG | Green House Gas |

| HVO | Hydrotreated Vegetable Oil |

| ICE | Internal combustion engine |

| LHV | Low Heating Value |

| PEM | Polymer Electrolyte Membrane |

| RED | Renewable Energy Directive |

| RFNBO | Renewable Fuel of Non-Biologic Origin |

| TKM | traveled kilometer |

| T-t-W | Tank-to-Wheel |

| W-t-T | Well-to-Tank |

| W-t-W | Well-to-Wheel |

References

- Pyza, D.; Gołda, P.; Sendek-Matysiak, E. Use of hydrogen in public transport systems. J. Clean. Prod. 2022, 335. [Google Scholar] [CrossRef]

- Hren, R.; Vujanović, A.; Van Fan, Y.; Klemeš, J.J.; Krajnc, D.; Čuček, L. Hydrogen production, storage and transport for renewable energy and chemicals: An environmental footprint assessment. Renew. Sustain. Energy Rev. 2023, 173. [Google Scholar] [CrossRef]

- Andaloro, L.; Napoli, G.; Micari, S.; Dispenza, G.; Sergi, F.; Fragiacomo, P.; Antonucci, V. Experimental activities on a PEFC based powertrain for a hybrid electric minibus. Int. J. Hydrogen Energy 2020, 45, 34011–34023. [Google Scholar] [CrossRef]

- Rinscheid, A.; Rosenbloom, D.; Markard, J.; Turnheim, B. From terminating to transforming: The role of phase-out in sustainability transitions. Environ. Innov. Soc. Transitions 2021, 41, 27–31. [Google Scholar] [CrossRef]

- International Energy Agency. Global Hydrogen Review 2022; International Energy Agency: Paris, France, 2022. [Google Scholar]

- Genovese, M.; Cigolotti, V.; Jannelli, E.; Fragiacomo, P. Hydrogen Refueling Process: Theory, Modeling, and In-Force Applications. Energies 2023, 16, 2890. [Google Scholar] [CrossRef]

- Shinde, B.J.; Karunamurthy, K. Recent progress in hydrogen fuelled internal combustion engine (H2ICE)—A comprehensive outlook. Mater. Today Proc. 2022, 51, 1568–1579. [Google Scholar] [CrossRef]

- European Commission. Directive (EU) 2023/2413 of the European Parliament and of the Council; European Commission: Brussels, Belgium, 2023. [Google Scholar]

- International Energy Agency. Energy Statistics Data Browser; International Energy Agency: Paris, France, 2023. [Google Scholar]

- Georgescu, R.; Pana, C.; Negurescu, N.; Cernat, A.; Nutu, C.; Sandu, C. Theoretical and experimental research on the use of hydrogen in the automotive spark ignition engine. IOP Conf. Ser. Mater. Sci. Eng. 2023, 1290, 012010. [Google Scholar] [CrossRef]

- Ugurlu, A. An emission analysis study of hydrogen powered vehicles. Int. J. Hydrogen Energy 2020, 45, 26522–26535. [Google Scholar] [CrossRef]

- Yip, H.L.; Srna, A.; Yuen, A.C.Y.; Kook, S.; Taylor, R.A.; Yeoh, G.H.; Medwell, P.R.; Chan, Q.N. A Review of Hydrogen Direct Injection for Internal Combustion Engines: Towards Carbon-Free Combustion. Appl. Sci. 2019, 9, 4842. [Google Scholar] [CrossRef]

- Luo, Y.; Zhao, C. An Overview of Pre-ignition of Hydrogen Engine. J. Sci. Res. Rep. 2020, 26, 1–7. [Google Scholar] [CrossRef]

- Guo, H.; Zhou, S.; Zou, J.; Shreka, M. A Numerical Investigation on De-NOx Technology and Abnormal Combustion Control for a Hydrogen Engine with EGR System. Processes 2020, 8, 1178. [Google Scholar] [CrossRef]

- Wróbel, K.; Wróbel, J.; Tokarz, W.; Lach, J.; Podsadni, K.; Czerwiński, A. Hydrogen Internal Combustion Engine Vehicles: A Review. Energies 2022, 15, 8937. [Google Scholar] [CrossRef]

- Moriconi, N.; Laranci, P.; D’Amico, M.; Bartocci, P.; D’Alessandro, B.; Cinti, G.; Baldinelli, A.; Discepoli, G.; Bidini, G.; Desideri, U.; et al. Design and preliminary operation of a gasification plant for micro-CHP with internal combustion engine and SOFC. Energy Procedia 2015, 81, 298–308. [Google Scholar] [CrossRef]

- Haug, P.; Koj, M.; Turek, T. Influence of process conditions on gas purity in alkaline water electrolysis. Int. J. Hydrogen Energy 2017, 42, 9406–9418. [Google Scholar] [CrossRef]

- Taner, T. The novel and innovative design with using H2 fuel of PEM fuel cell: Efficiency of thermodynamic analyze. Fuel 2021, 302, 121109. [Google Scholar] [CrossRef]

- Du, Z.; Liu, C.; Zhai, J.; Guo, X.; Xiong, Y.; Su, W.; He, G. A Review of Hydrogen Purification Technologies for Fuel Cell Vehicles. Catalysts 2021, 11, 393. [Google Scholar] [CrossRef]

- Shayan, E.; Zare, V.; Mirzaee, I. Hydrogen production from biomass gasification; a theoretical comparison of using different gasification agents. Energy Convers. Manag. 2018, 159, 30–41. [Google Scholar] [CrossRef]

- Han, J.; Kim, H. The reduction and control technology of tar during biomass gasification/pyrolysis: An overview. Renew. Sustain. Energy Rev. 2006, 12, 397–416. [Google Scholar] [CrossRef]

- Persson, M.; Jonsson, O.; Wellinger, A. Biogas Upgrading To Vehicle Fuel Standards and Grid. IEA Bioenergy 2007, 37, 1–32. [Google Scholar]

- Chinatrucks.com. China’s First Hydrogen Internal Combustion Engine Powered Heavy Truck; Chinatrucks: Beijing, China, 2022. [Google Scholar]

- Vuchic, V.R. Urban Transit Systems and Technology; Wiley: Hoboken, NJ, USA, 2007. [Google Scholar] [CrossRef]

- Korn, T. The new highly efficient hydrogen internal combustion engine as ideal powertrain for the heavy-duty sector. In Internationaler Motorenkongress 2019; Springer: Berlin/Heidelberg, Germany, 2019; pp. 385–400. [Google Scholar] [CrossRef]

- Google Earth. Available online: https://www.google.it/intl/it/earth/index.html (accessed on 1 May 2024).

- Bayındırlı, C.; Çelik, M. The Experimentally and Numerically Determination Of The Drag Coefficient Of A Bus Model. Int. J. Automot. Eng. Technol. 2018, 7, 117–123. [Google Scholar] [CrossRef][Green Version]

- ETIP Bioenergy. Fatty Acid Methyl Esters (FAME) Fact Sheet; ETIP Bioenergy: Brussels, Belgium, 2023. [Google Scholar]

- ETIP Bioenergy. Hydrogenated Vegetable Oil (HVO); ETIP Bioenergy: Brussels, Belgium, 2020. [Google Scholar]

- Kulikov, I.; Kozlov, A.; Terenchenko, A.; Karpukhin, K. Comparative Study of Powertrain Hybridization for Heavy-Duty Vehicles Equipped with Diesel and Gas Engines. Energies 2020, 13, 2072. [Google Scholar] [CrossRef]

- Wojcieszyk, M.; Kroyan, Y.; Kaario, O.; Larmi, M. Prediction of heavy-duty engine performance for renewable fuels based on fuel property characteristics. Energy 2023, 285, 129494. [Google Scholar] [CrossRef]

- Gustafsson, M.; Svensson, N.; Eklund, M.; Öberg, J.D.; Vehabovic, A. Well-to-wheel greenhouse gas emissions of heavy-duty transports: Influence of electricity carbon intensity. Transp. Res. Part D Transp. Environ. 2021, 93, 102757. [Google Scholar] [CrossRef]

- Prussi, M.; Yugo, M.; De Prada, L.; Padella, M.; Edwards, R.; Lonza, L. “JEC Well-To-Wheels Report v5” EUR 30284 EN; Publications Office of the European Union: Luxembourg, 2020; ISBN 978-92-76-20109-0. [Google Scholar] [CrossRef]

- Staffolani, A.; Baldinelli, A.; Bidini, G.; Nobili, F.; Barelli, L. Operando Analysis of Losses in Commercial-Sized Solid Oxide Cells: Methodology Development and Validation. Energies 2022, 15, 4978. [Google Scholar] [CrossRef]

- Cinti, G.; Baldinelli, A.; Di Michele, A.; Desideri, U. Integration of Solid Oxide Electrolyzer and Fischer-Tropsch: A sustainable pathway for synthetic fuel. Appl. Energy 2016, 162, 308–320. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).