Abstract

In recent years, large power batteries have been widely used not only in automobiles and other vehicles but also in maritime vessels. The thermal uniformity of large marine battery packs significantly affects the performance, safety, and longevity of the electric ship. As a result, the thermal management of large power batteries has become a crucial technical challenge with traditional battery management system (BMS) that cannot effectively solve the battery heating problem caused by electrochemical reactions and joule heating during operation. To address this gap, a battery thermal management system (BTMS) has been newly designed. This article presents the design of a large marine battery pack, which features a liquid cooling system integrated into both the bottom and side plates of each pack. The flow plate is constructed from five independent units, each connected by manifold structures at both ends. These connections ensure the formation of a stable and cohesive flow plate assembly. Although research on the BTMS is relatively advanced, there is a notable lack of studies examining the effects of liquid temperature, flow rate, and battery discharge rate on the temperature consistency and uniformity of large marine battery packs. This work seeks to design the cooling system for the battery pack and analyzes the impact of the temperature, flow rate, and battery discharge rate of the liquid fluid on the consistency and uniformity of the battery pack temperature on the overall structure of the battery pack. It was found that, in low discharge conditions, there was good temperature consistency between the battery packs and between the different batteries within the battery pack, and the temperature difference did not exceed 1 °C. However, under high discharge rates, a C-rate of 4C, there might have been a decrease in temperature consistency; the temperature rise rate even exceeded 50% compared to when the discharge rate was low. The flow rate in the liquid flow characteristics had little effect on the temperature consistency between the batteries and the temperature uniformity on the battery surface, and the temperature fluctuation was maintained within 1 °C. Conversely, the liquid flow temperature had little effect on the temperature distribution between the batteries, but it caused discrepancies in the surface temperature of the batteries. In addition, the liquid flow temperature could cause the overall temperature of the battery to increase or decrease, which also occurs under different discharge rates.

1. Introduction

In the marine industry, the transition from conventional oil-based fuel to alternative fuels is more important than ever, as environmental concerns are growing larger, and thus the International Maritime Organization (IMO) as well as local governments have been enforcing stricter regulations. Responding to the new regulations, ship operators are required to apply new technologies and alternative fuels to reduce emissions [1]. Electrical propulsion powered by battery systems have been recognized as one of the most credible options to address this issue and achieve decarbonization in the marine industry [2]. As the shipbuilding industry advances, the proportion of electric ships in the shipbuilding market is constantly increasing. Electrified ships are becoming increasingly popular as the technology for large-scale battery storage and electric propulsion systems continue to improve. These ships are commonly used for short-distance transportation, such as ferries and small cargo vessels, but advancements in battery technologies have also been enabling the development of larger electric ships for longer journeys. Notably, the Yara Birkeland, depicted in Figure 1, stands as the world’s first zero-emission, fully electric, and autonomous container ship, highlighting the growing importance of effective thermal management for its core power battery systems.

Figure 1.

Yara Birkeland, the first fully electric and autonomous container ship [3].

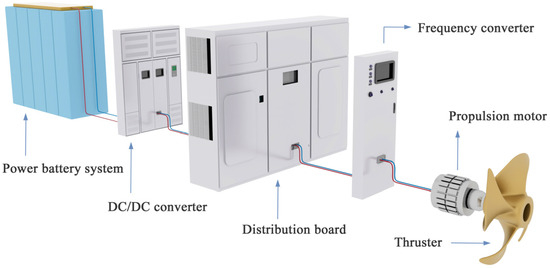

The ship’s electric propulsion system relies on batteries as the energy source, eliminating the traditional diesel engine propulsion system. This system comprises several key components, including a power battery system, a battery management system, a direct current (DC)–DC converter, a distribution board, an inverter, a propulsion motor, and a thruster, among others, as illustrated in Figure 2.

Figure 2.

Schematic diagram of electric propulsion system.

In the shipbuilding industry, the thermal management of batteries has mainly focused on lithium-ion batteries. However, the heat generated in the charging and discharging process of lithium-ion batteries will affect the working performance of the battery, which can lead to reduced battery life and compromised safety performance [4]. A battery pack is a complex system consisting of a number of battery modules (which contain cells that are connected in series and parallel), a battery management system, and cooling/heating circuits [5]. Effective thermal management of power batteries has become a crucial area of research.

For large battery packs for EVs and ships, the application of a BMS has traditionally been required. In general, the BMS refers to a management scheme that monitors, controls, and optimizes an individual’s performance or multiple battery modules in an energy storage system. A BMS can control the disconnection of the module(s) from the system in the event of abnormal conditions [6]. The existing BMS is insufficient in addressing the battery heating issue caused by electrochemical reactions and joule heating. To tackle this challenge, a battery thermal management system (BTMS) has been developed. The current simulation research on the BTMS primarily focuses on integrated thermal management simulation research of multiple thermal systems [7,8], the electrochemical model, and the equivalent circuit model (ECM) [9], and thermal management simulation research of power battery packs [10,11].

Firstly, in the research on the integrated thermal management simulation of multiple thermal systems, the primary methods currently used are one-dimensional simulation and three-dimensional simulation approaches, each with its own limitations. It is difficult for one-dimensional simulation methods to simulate changes in heat flow field characteristics, while the three-dimensional simulation method cannot achieve the correlation simulation between multiple thermal systems [12]. To address these shortcomings, V. Kumar et al. [13] and V. Kumar et al. [14] proposed a weak combination approach that integrates one-dimensional and three-dimensional simulation. Secondly, for radiator simulation research, the focus has mainly been on analyzing the flow and heat transfer characteristics of computational models [15,16], with relatively little emphasis on the overall heat transfer characteristics. Finally, in the simulation research on the thermal management of power battery packs, the current studies mainly concentrate on various cooling methods including air cooling, liquid flow cooling, heat pipe cooling, and phase change cooling [17,18]. G. Zhao et al. [19] and M. Bernagozzi et al. [20] provide research references for research on the battery thermal management system of electric vehicles. The main goal of these studies was to address the temperature inconsistency between batteries and enhance the overall performance of battery packs.

In the simulation research of thermal management of power battery packs, the current focus is primarily on technical methods such as air cooling, liquid flow cooling, heat pipe cooling, and phase change cooling. The efficient thermal management schemes are highly desirable to reduce the temperature rise [21]. The common objective of these studies is to address the issue of temperature inconsistency between batteries and improve the overall performance of battery packs. Air cooling, the earliest developed and simplest thermal management method, remains the most mature [22]; however, for large marine batteries, the cooling effect cannot be achieved. Especially in the liquid flow cooling technology, as an efficient thermal management method, its position in the simulation research on the thermal management of power battery packs is increasingly prominent [23,24]. The main advantages of using liquid as a heat transfer medium are high heat transfer capacity and fast cooling and heating. However, it also has drawbacks, such as the need for a liquid medium process space, external heat dissipation circulation system, high sealing requirements, large weight, and relatively complex structure [25,26]. A PCM-based BTMS, requiring no additional energy, boasts a simple structure and excellent temperature uniformity. However, there is a limit to the heat dissipation capacity of the PCM. With technological advancements, a liquid-cooled PCM-coupled BTMS may eventually replace liquid cooling for extensive applications.

A robust and efficient BTMS is essential for the battery packages of EVs and HEVs to deliver optimal performance and maintain a long service life. In recent years, electric locomotives and multiple units based on AC–DC–AC transmission technology have been widely used in railways [27]. Energy efficiency is critical for the sustainable development of AC-electrified railways [28]. The energy storage system (ESS) converts electric energy into a storable form, allowing it to be reused at a later time [29]. The ESS of railway trains also uses battery thermal management systems. Ships and other means of transportation have more complex working conditions. Therefore, more factors need to be considered when designing a BTMS [30]. Marine power battery thermal management systems are designed to endure harsh, variable marine environments and often involve robust, redundant designs. In contrast, the automotive systems focus on efficiency, integration with vehicle systems, and cost-effectiveness, with an emphasis on managing more moderate environmental conditions. Both systems aim to optimize battery performance and longevity but do so with different priorities based on their operational contexts. In this article, based on the characteristics of the ship’s large-scale battery panels, the frame of the battery thermal management system was designed by using high-strength aluminum plates, and the bottom steps and sides of the battery pack were cooled by liquid flow cooling.

This study presents the design of the fundamental liquid flow heat transfer structure for a large maritime battery pack. Based on the analysis of heat transfer in the bottom liquid flow plate, optimization is achieved through the implementation of a side placement scheme for the liquid flow plate and enhancement to thermal conductivity. Additionally, the study investigates how the temperature, flow rate, and battery discharge rate of the liquid fluid affect the consistency and uniformity of the battery pack’s temperature, considering the overall structure of the battery pack. The key contributions of this research are as follows:

Despite the limited number of studies on large-scale marine batteries compared to automotive batteries, the advancement and adoption of electric ship technology are expected to broaden the research and application prospects for large-scale marine batteries. Marine battery systems are generally larger than their automotive counterparts, necessitating larger battery components and more intricate thermal management systems. This article aims to simulate the design and analysis of large-scale marine batteries, providing valuable insights and references for their application in marine environments. This article not only designs the fundamental liquid heat transfer structure but also introduces a horizontal liquid flow plate placement scheme and a thermal conductivity enhancement plan, based on an analysis of the heat transfer characteristics of the bottom liquid flow plate. The study includes research on optimizing the heat transfer structure of the battery pack. Additionally, the article provides a comprehensive analysis of how factors such as liquid fluid temperature, flow rate, and battery discharge rate affect the temperature consistency and uniformity of the battery pack. This thorough analysis enhances the understanding of the battery pack’s operating characteristics and offers a more precise foundation for the optimal design of the battery pack structure and simulation model.

2. Battery Pack Simulation Model

To comprehensively analyze the effects of temperature, flow rate, and battery discharge rate on the temperature consistency and uniformity of the liquid flow heat transfer structure of battery packs, the COMSOL Multi-physics 6.2 software was employed to create a one-dimensional and three-dimensional joint simulation model [31]. This approach integrates one-dimensional and three-dimensional models into a collaborative framework. The one-dimensional model was used to rapidly capture the overall thermal behavior of the battery pack, offering macroscopic temperature trends, while the three-dimensional model provided a detailed simulation of the complex heat transfer and fluid flow within the battery, yielding more precise microscopic information. To ensure the accuracy and reliability of the simulation, a three-dimensional model was established using computational fluid dynamics (CFD) software of COMSOL Multi-physics 6.2, which accurately predicts the heat transfer and fluid dynamics within the battery pack. Specifically, a representative CFD simulation model was created for a battery pack featuring a liquid flow heat transfer structure, using one particular pack as an example. In constructing this simulation model, key factors such as computational domain, grid partitioning method, computational model, and sampling points were meticulously considered to guarantee the accuracy and effectiveness of the simulation results. This comprehensive approach facilitates a deeper understanding of the impact of various operating parameters on the thermal performance of battery packs, providing robust support for their optimization and thermal management.

2.1. Battery Pack Model

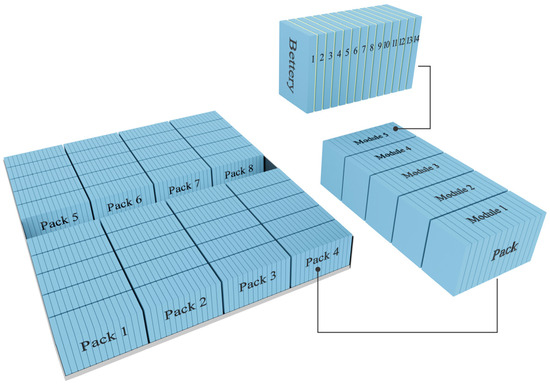

The battery module and pack specifications utilized in this study are as follows: each single-cell battery has a voltage of 3.2 V and a capacity of 10 Ah, with dimensions of 126 mm × 66 mm × 17 mm. The battery pack is composed of a total of 560 individual batteries, arranged into 8 battery packs, each containing 5 battery modules. These arrangements are illustrated in Figure 3.

Figure 3.

Schematic diagram of battery pack structure.

As illustrated in Figure 3, the battery pack configuration comprises 112 series connections and 5 parallel connections, resulting in a total capacity of 50 Ah and a voltage of 360 V. The coolant pipes between each battery pack are arranged in parallel, ensuring that the heat transfer effect is approximately uniform across all battery packs. The material properties of a single battery cell are detailed in Table 1.

Table 1.

The material properties of the single battery cell.

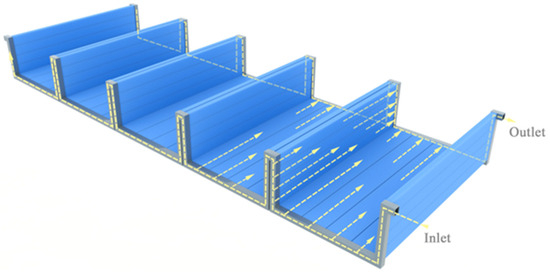

As depicted in Figure 4, in order to meet the dual requirements of lightweight and support strength of the flow plate, the flow plate is carefully composed of five independent units. These units are equipped with a manifold structure at both ends, which is designed to tightly connect them, forming a stable and complete flow plate structure. The interior of each splitter plate is carefully designed with a multi-channel structure, which not only ensures that the splitter plate has sufficient strength but also promotes uniform fluid flow to a certain extent, thereby significantly improving heat transfer consistency with the upper battery pack. For material selection, 3003 aluminum alloy was chosen due to its superior thermal conductivity, mechanical strength, and relatively low weight. The specific physical parameters of the alloy are as follows: density is 2720 kg/m3, specific heat capacity is 893 J/(kg·K), and thermal conductivity is 163 W/(m·K). These properties ensure efficient heat transfer in the liquid flow plate while maintaining structural stability and reliability.

Figure 4.

Schematic diagram of the flow plate of a battery pack.

For the structure between the internal batteries of the battery pack, we considered the tight and compact requirements between the batteries. A 0.5 mm thermal conductive silicone gasket was used between the batteries to ensure that the physical properties of the thermally conductive silicone gasket were as follows: density 1700 kg/m3, specific heat 1271 J/(kg·K), and thermal conductivity 3 W/(m·K). Additionally, the battery pack was enclosed in an aluminum box with separate upper and lower compartments for structural protection.

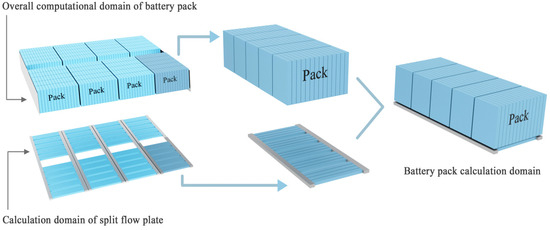

2.2. Computational Domain

In this study, a modular approach to defining the computational domain and a structured grid partitioning strategy is employed to enhance the computational quality and reduce the computational load. The core computational domain is defined for an individual battery pack. Once defined, these 8 core domains are combined to form the computational domain for the entire battery pack. This approach involves modularly defining the computational domains and partitioning grids. The entire battery pack is decomposed into multiple distinct computational domains for grid partitioning, which are then reassembled to form the complete computational domain for the battery pack. Figure 5 illustrates the domain decomposition scheme for the battery pack calculation. The calculation domain division for the battery pack in this study utilizes an interface method, not accounting for the effects on the interface grid. For grid partitioning, the approach involves initially dividing the air domain surrounding the battery cell and its upper section into grids. These grids are then processed and integrated into the overall battery pack grid structure.

Figure 5.

Decomposition diagram of battery pack calculation domain.

2.3. Simulation Model and Sampling Point

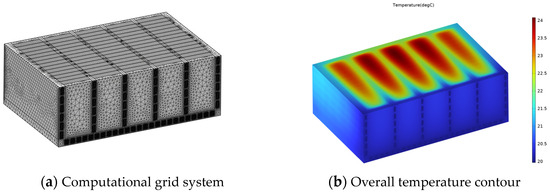

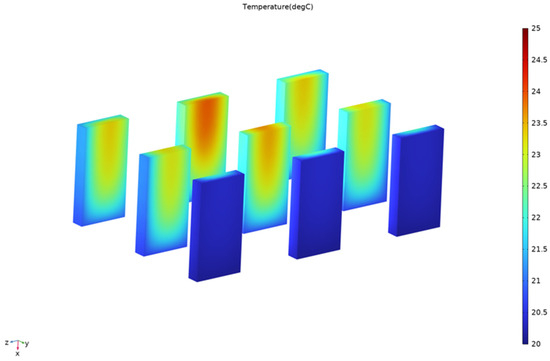

Figure 6a shows the computational grid systems. The pack has been meshed in all parts, each section is meshed differently. When designing the global grid size, the maximum grid size is 4.01 mm, and the minimum grid size is 0.722 mm. When designing the runner grid of the water-cooling plate, the maximum surface grid size of the inlet surface mesh is 1 mm, and the minimum surface mesh size is 0.5 mm. The battery is designed with a hexahedral structured grid with a maximum size of 4.02 mm and a minimum size of 0.0802 mm. A thermally conductive silicone gasket is designed with a hexahedral structured grid, with a maximum and minimum size of 0.2 mm. For the air and aluminum sheets, they are built to global dimensions. Figure 6b shows the overall temperature contour at discharge rate of 1C, a liquid fluid temperature of 20 °C, and a flow rate of 30 L/min.

Figure 6.

Computational grid system and overall temperature contour.

The heat rejection in the battery module was obtained from a three-dimensional thermal conduction equation as shown in Equation (1).

where is the density (kg/m3), is the specific heat (J/kg·K), is the thermal conductivity coefficient (W/m·K), and represents the volumetric heating source (W/m3) of the cell, respectively. The heating value in the cell was modeled as using the internal resistance value and current according to the temperature through the experiment.

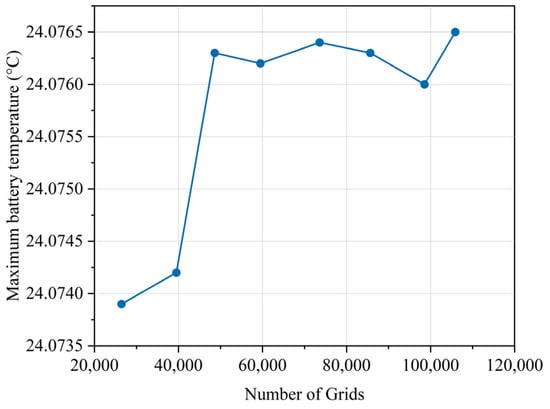

To verify the influence of meshing on the simulation results, a grid dependency test was carried out for different number of grids. A structured hexahedral mesh was used for the battery domains and a free prismatic mesh was used for cooling plate as shown in Figure 6a. When the number of grids exceeds 50,000, the maximum temperature value of the tested battery tends to be stable as shown in Figure 7. In this work, the number of grids is about 59,500.

Figure 7.

Grid dependency test.

As shown in Figure 3, the simulation model of the battery pack comprises eight individual packs. These packs are connected in parallel using a liquid flow channel, with each pack equipped with effective insulation pads. It can be considered that the outer surface of the battery pack model is insulated. Therefore, the simulation model can only simulate and analyze one battery pack. For turbulence calculations, the standard k-epsilon model was adopted. To simulate the different discharge rates of the batteries, an internal heat source was specified into the simulation model. The volumetric heat sources for varying discharge rates were derived from the experimental data obtained from tests conducted on the same battery pack under insulated conditions. The data are presented in Table 2.

Table 2.

Volumetric heat rejection for cell discharge rate.

In the work, the velocity inlet and pressure outlet were specified as inlet and outlet on the cooling plate. The boundary conditions on the inlet side needed to consider their turbulence intensity and hydraulic diameter. The turbulence intensity and Reynolds number can be calculated using Equations (2) and (3), respectively.

where is the turbulence intensity at the inlet of the liquid fluid, is the Reynolds number of liquid fluid, is the density of liquid fluid(kg/m3), is the flow velocity of liquid fluid (m/s), is the hydraulic diameter of liquid fluid(m), and is the kinematic viscosity of the liquid fluid (m2/s).

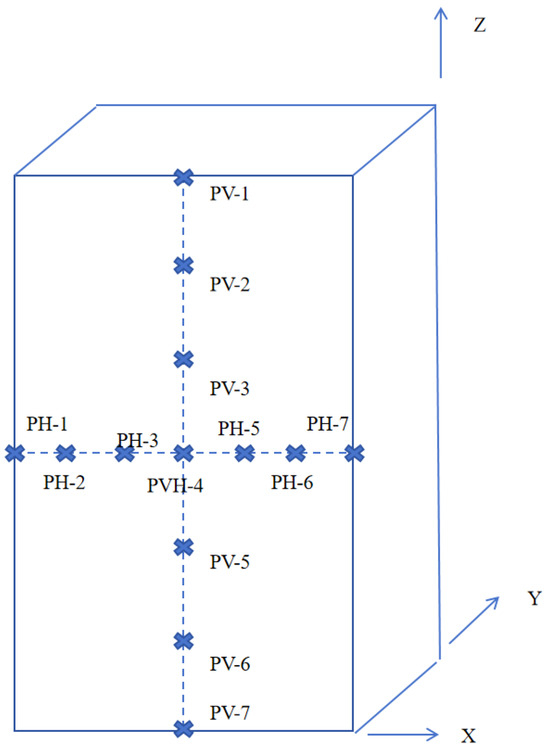

The basic operating conditions used in this article include the discharge rate of 1C, the liquid fluid temperature of 20 °C, and a flow rate of 30 L/min. In addition, the appropriate sampling points and batteries positioned at different locations were selected for testing. The configurations for the sampling points and battery numbers are illustrated in Figure 8 and Figure 9.

Figure 8.

Distribution of sampling points on the battery cell surface.

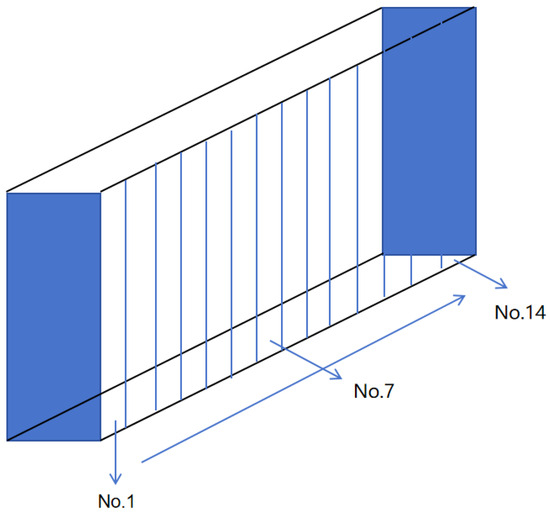

Figure 9.

Battery cell number index for module.

3. Simulation Results

As previously outlined, the basic operating conditions used in this work include the discharge rate of 1C, a liquid fluid temperature of 20 °C, and a flow rate of 30 L/min. Under these conditions, the center temperature and surface temperature of the battery modules and individual batteries are analyzed to identify fundamental distribution patterns and establish methods for differentiation.

3.1. Analysis of Surface Center Temperature of Batteries

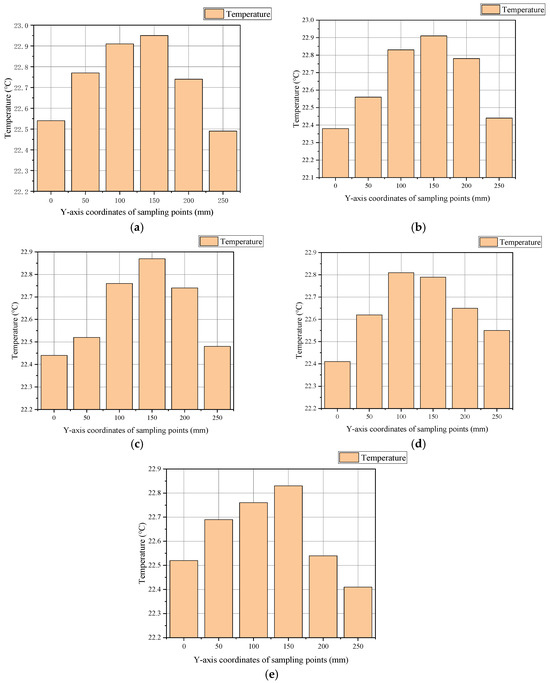

The overall temperature characteristics of the battery pack are evaluated by measuring the temperature at the center point of the battery surface within the pack. The battery pack comprises five modules, and each module contains 14 battery cells. As depicted in Figure 9, the temperatures are recorded at the center points of the two measuring surfaces of batteries No. 1, No. 7, and No. 14. Additionally, the temperatures at the center points on both sides of each battery are analyzed to assess the consistency of the temperature across the battery group, as illustrated in Figure 10.

Figure 10.

Bar chart of surface center temperature for different groups of batteries. (a) Bar chart of surface center temperature for Group 1 (°C); (b) Bar chart of surface center temperature for Group 2 (°C); (c) Bar chart of surface center temperature for Group 3 (°C); (d) Bar chart of surface center temperature for Group 4 (°C); (e) Bar chart of surface center temperature for Group 5 (°C).

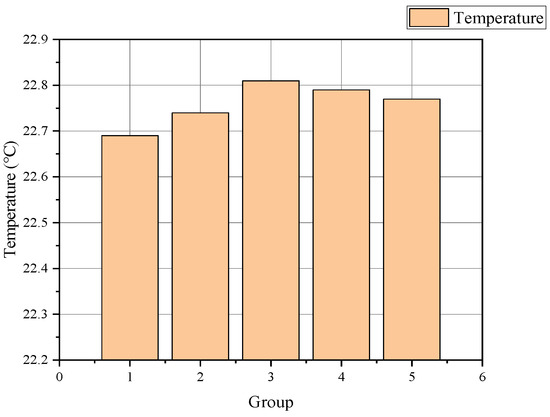

According to the surface center temperature data of each battery group, as shown in Figure 10, it can be observed that the temperature inside each battery group exhibits excellent uniformity. Specifically, battery group 1 has a temperature range of between 22.49 °C and 22.95 °C, resulting in a temperature difference of only 0.46 °C. Similarly, the temperature fluctuation within battery group 2 is between 22.38 °C and 22.91 °C, with a temperature difference of 0.53 °C. Battery groups 3 and 4 also demonstrate consistent temperature distributions, with battery group 3 showing a temperature range from 22.44 °C to 22.87 °C, and battery group 4 ranging from 22.41 °C to 22.81 °C, both having a temperature difference of 0.4 °C. Finally, battery group 5 exhibits a temperature range from 22.41 °C to 22.83 °C, with a temperature difference of 0.42 °C. These data indicate that the temperature deviation within each battery group is minimal, leading to the conclusion that the surface center temperature within each battery group is highly consistent. The temperature at the center point of each battery group is utilized to evaluate the consistency of battery surface temperatures across different battery groups. As illustrated in Figure 11, the temperature differences at the center points of batteries among various groups are relatively minor. Thus, it can be concluded that employing parallel-flow liquid cooling plates effectively maintains consistent battery temperatures across the pack.

Figure 11.

Battery cell center temperature of different battery groups.

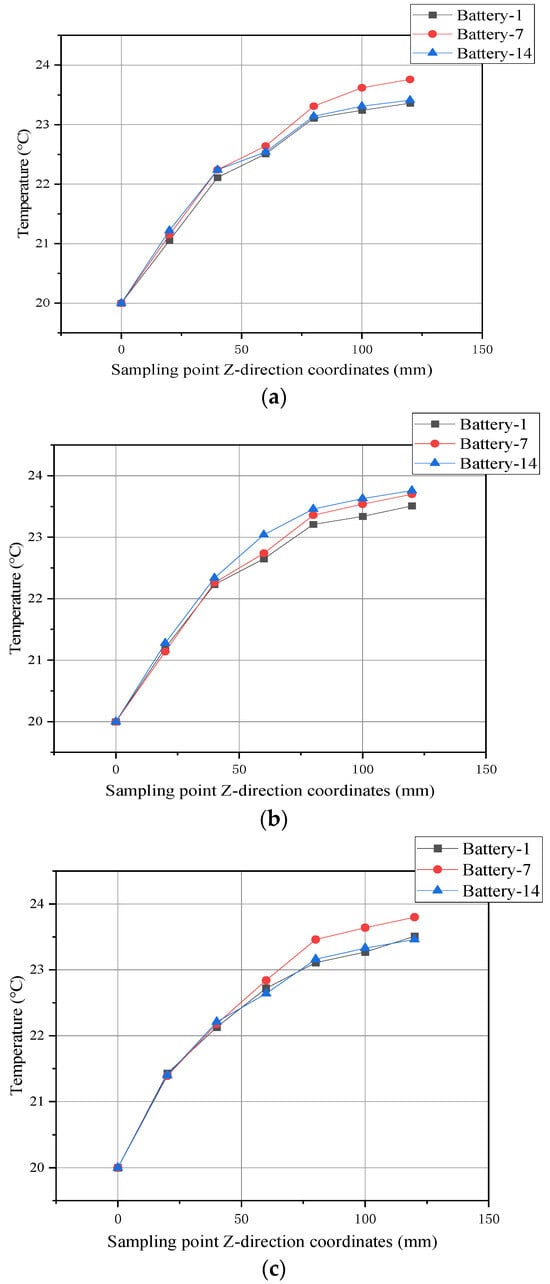

As shown in Figure 12, the temperature distribution along the vertical direction of the battery surface of batteries 1, 7, and 14 from battery groups 1, 3, and 5 are taken from the simulation test results.

Figure 12.

The temperature distributions of the 3 groups.

In addition to analyzing battery consistency through center point temperatures, it is also crucial to evaluate the uniformity of the battery surface temperature by examining temperatures at vertical and horizontal sampling points on the battery surface. For this analysis, the temperatures at the vertical and horizontal sampling points on the surfaces of batteries 1, 7, and 14 from battery groups 1, 3, and 5 were recorded, as shown in Figure 13. As illustrated in Figure 13, the temperature distribution along the vertical direction of the battery surface shows lower temperatures at the bottom and higher temperatures at the top. The lower temperature at the bottom is due to its contact with the cooling flow plate, which efficiently dissipates heat generated by the battery through the circulating fluid. In contrast, the higher temperature at the top results from the heat generated there needing to be transferred to the flow plate at the bottom. This transfer occurs through the battery material and the external silicone gasket, with some heat also being lost to the external air at the top. The need to overcome the thermal resistance of both the battery material and the silicone gasket contributes to the observed temperature difference, with the top of the battery being warmer and the bottom cooler.

Figure 13.

The temperatures distributions along the vertical direction on the battery surface (a) group 1; (b) group 3; (c) group 5.

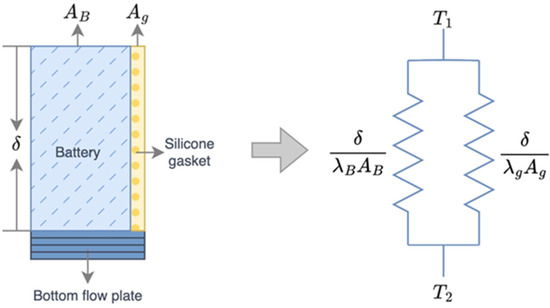

A one-dimensional heat transfer equation is employed to model the thermal conductivity process between the external air, battery, silicone gasket, and bottom flow plate. It is assumed that both the battery and silicone gasket are uniform conductors and that convective and radiative heat transfers with the external environment are negligible. As shown in Figure 14, due to the presence of the flow plate at the bottom, the temperature at the top of the battery is higher than at the bottom during heat generation. Therefore, in the thermal conductivity model, the top temperature of the battery and silicone gasket is considered higher than the bottom temperature. The thermal conductivity of the battery is denoted as , with the contact area with the flow plate defined as . The thermal conductivity of the silicone gasket is denoted as , with the contact area with the flow plate defined as . Assuming that the length of the battery and silicone gasket in the direction perpendicular to the flow plate is equal, the thermal conductivity length of both the battery and silicone gasket is denoted as .

Figure 14.

Schematic diagram of thermal conductivity process.

The thermal conductivity of the battery and the silicone gasket belongs to the parallel thermal conductivity form as shown in Figure 14. Therefore, the total thermal resistance of the two is equal to the reciprocal of the sum of the battery thermal resistance and the silicone gasket thermal resistance . Thus, the expression for the total thermal conductivity and resistance is as follows:

where total thermal conductivity is related to the thermal conductivity , contact area A, and thermal conductivity length of the material itself. In terms of utilizing contact area A and thermal conductivity length , it can be considered to use the contact between the side end of the battery and the flow plate to increase the contact area and reduce the heat transfer length, thereby achieving a reduction in thermal conductivity resistance.

3.2. Effect on the Cell Temperature of Cooling Conditions

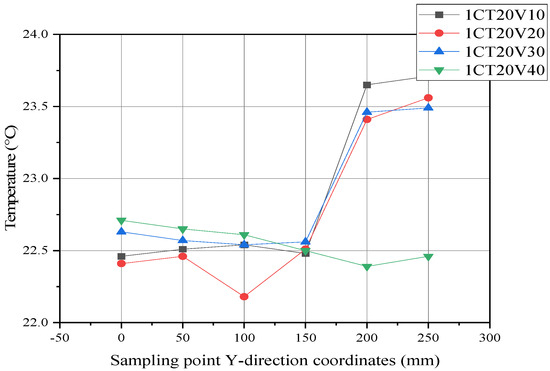

The focus is on how liquid flow rate and temperature affect the heat transfer efficiency of the battery pack, with a special emphasis on maintaining temperature consistency and uniformity across battery groups. Under the basic operating conditions, the liquid flow rate varied at 10 L/min, 20 L/min, 30 L/min, and 40 L/min, while the liquid temperature was assessed at 15 °C, 20 °C, 25 °C, 30°C, 35 °C, and 40 °C. The temperature data from the center points on both sides of the battery surface in battery group 3 were analyzed, as shown in Figure 15. In Figure 15, “1CT20V10” denotes the conditions of a 1C discharge rate, 20 °C temperature, and 10 L/min flow rate. The results indicate that the temperature at the center point of the battery surface exhibits strong consistency, with fluctuations remaining within 1 °C. Variations in the liquid flow rate have a relatively minor effect on the temperature consistency between batteries, with no significant fluctuations observed as flow rate changes. Consequently, changes in the flow rate have a minimal impact on battery temperature.

Figure 15.

Central temperature curve of battery group for varying flow rate.

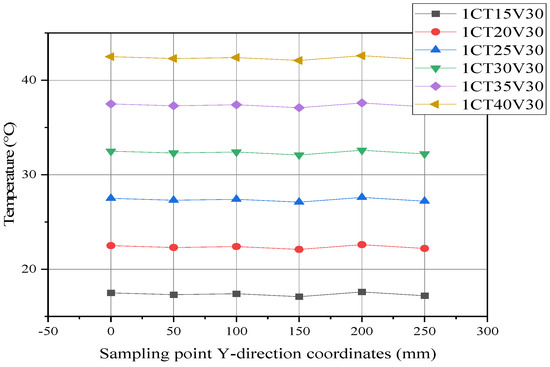

In evaluating the impact of liquid flow temperature, it is important to note that the temperature consistency between the battery groups remains robust under identical operating conditions. For this analysis, the temperature data from the surface center points on both sides of battery group 3 were used, as shown in Figure 16. The figure demonstrates that as the liquid flow temperature increases, the center temperature of the battery surface also rises, highlighting a significant effect of liquid flow temperature on the stable temperature of the battery. However, the increase in liquid flow temperature does not lead to substantial differences in the center temperature across various battery surfaces within the same group, with deviations remaining very small. Specifically, the temperature variations at different points under the same conditions are kept within 1 °C. Thus, changes in the liquid flow temperature have minimal impact on the temperature consistency between the different batteries.

Figure 16.

Temperature curve at the center of the battery group.

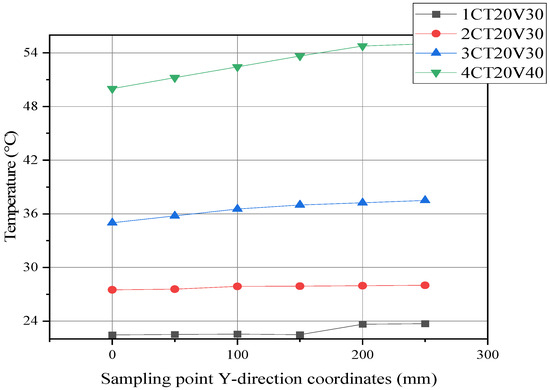

3.3. Analysis of Discharge Rate

The stable operating temperature of a battery typically falls within a relatively narrow range. When analyzing the effects of different discharge rates, it is observed that the heat generated by the battery increases with higher discharge rates, resulting in continuous changes in battery temperature. To assess the impact of discharge rate on temperature consistency, the center temperatures of different batteries in battery group 3 were analyzed, as shown in Figure 17. The analysis reveals that the central temperature of the battery rises with increasing discharge rate, with the overall battery pack temperature exceeding 50 °C at a 4C discharge rate. This suggests that the current liquid flow plate thermal control method is insufficient for maintaining temperature stability across battery groups under varying discharge rates. Specifically, temperature stability refers to maintaining the battery group’s operating temperature within a range, such as 40 °C ± 5 °C. At high discharge rates, even with higher liquid temperatures, it is challenging to keep the battery temperature within a stable range. Therefore, it is necessary to adjust the fluid temperature in the thermal control system according to the different discharge rates to ensure effective temperature management.

Figure 17.

Central temperature curve of battery group.

4. Conclusions

This article designs a large-scale battery panel and water-cooled plate thermal management system for ships, as well as compares and analyzes the differences between the applications of an automotive battery thermal management system and a marine battery thermal management system. There are few studies on the thermal simulation of large ship batteries. In this article, we hope to compare the research on battery thermal simulation for electric vehicles, design the thermal management system of large batteries for ships, and carry out thermal simulation based on temperature consistency. This article presents the design of the fundamental liquid flow heat transfer structure within a large power battery pack, employing a block battery configuration and a bottom flow plate heat exchange approach. Furthermore, a comprehensive analysis is conducted to investigate the influence of various parameters, such as liquid temperature, flow rate, and battery discharge rate, on the consistency and uniformity of battery temperature within the overall battery pack structure.

A steady-state analysis reveals that under consistent operating conditions, temperature consistency remains high among the various battery packs as well as among the individual batteries within each pack. However, at elevated discharge rates, a reduction in temperature consistency may occur. Notably, the flow rate within the liquid flow characteristics exhibits minimal influence on both the temperature consistency among batteries and the temperature uniformity across the battery surface. While the liquid flow temperature has a limited impact on the temperature consistency among batteries, it can introduce variations in their surface temperatures. Furthermore, the liquid flow temperature contributes to changes in the overall battery temperature, whether it be an increase or decrease, and this occurs regardless of the discharge rate.

Author Contributions

Conceptualization, F.J.; writing—original draft preparation, F.J.; writing—review and editing, F.J. and G.L.; supervision, G.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by Material Component Package Technology Development Project (No. 20011458) funded by the Ministry of Trade, Industry & Energy (MOTIE, Korea).

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kolodziejski, M.; Michalska-Pozoga, I. Battery energy storage systems in ships’ hybrid/electric propulsion systems. Energies 2023, 16, 1122. [Google Scholar] [CrossRef]

- Jeong, B.; Jeon, H.; Kim, S.; Kim, J.; Zhou, P. Evaluation of the Lifecycle Environmental Benefits of Full Battery Powered Ships: Comparative Analysis of Marine Diesel and Electricity. J. Mar. Sci. Eng. 2020, 8, 580. [Google Scholar] [CrossRef]

- Yara Birkeland, World’s 1st Fully-Electric Boxship, Prepares for Commercial Ops. Available online: https://www.offshore-energy.biz/yara-birkeland-worlds-1st-fully-electric-boxship-prepares-for-commercial-ops/ (accessed on 8 May 2024).

- Fan, Y.; Wang, Z.; Xiong, X.; Panchal, S.; Fraser, R.; Fowler, M. Multi-objective optimization design and experimental investigation for a prismatic lithium-ion battery integrated with a multi-stage Tesla valve-based cold plate. Processes 2023, 11, 1618. [Google Scholar] [CrossRef]

- Ramesh Babu, A.; Andric, J.; Minovski, B.; Sebben, S. System-level Modeling and Thermal Simulations of Large Battery Packs for Electric Trucks. Energies 2021, 14, 4796. [Google Scholar] [CrossRef]

- Gabbar, H.A.; Othman, A.M.; Abdussami, M.R. Review of battery management systems (BMS) development and industrial standards. Technologies 2021, 9, 28. [Google Scholar] [CrossRef]

- Pang, S.C.; Kalam, M.A.; Masjuki, H.H.; Hazrat, M.A. A Review on Air Flow and Coolant Flow Circuit in Vehicles Cooling System. Int. J. Heat Mass Transf. 2012, 55, 6295–6306. [Google Scholar] [CrossRef]

- Chanfreau, M.; Joseph, A.; Butler, D.; Swiatek, R. Advanced Engine Cooling Thermal Management System on a Dual Voltage 42V-14V Minivan; SAE International: Warrendale, PA, USA, 2001; Volume 111, pp. 107–114. [Google Scholar] [CrossRef]

- Hameed, M.M.; Mansor, M.B.; Azau, M.A.M.; Alshara, A.K. Computational design and analysis of LiFePO4 battery thermal management system (BTMS) using thermoelectric cooling/thermoelectric generator (TEC–TEG) in electric vehicles (EVs). J. Energy Storage 2023, 72, 108394. [Google Scholar] [CrossRef]

- Williford, R.E.; Viswanathan, V.V.; Zhang, J.G. Effects of Entropy Changes in Anodes and Cathodes on the Thermal Behavior of Lithium-ion Batteries. J. Power Sources 2009, 189, 101–107. [Google Scholar] [CrossRef]

- Chen, D.; Jiang, J.; Kim, G.-H.; Yang, C.; Pesaran, A. Comparison of Different Cooling Methods for Lithium Ion Battery Cells. Appl. Therm. Eng. 2016, 94, 846–854. [Google Scholar] [CrossRef]

- Yeh, T.J.; Chen, Y.J.; Hwang, W.Y.; Lin, J.L. Incorporating Fan Control into Air-conditioning Systems to Improve Energy Efficiency and Transient Response. Appl. Therm. Eng. 2009, 29, 1955–1964. [Google Scholar] [CrossRef]

- Kumar, V.; Kapoor, S.; Arora, G.; Saha, S.K.; Dutta, P.A. Combined CFD and Flow Network Modeling Approach for Vehicle Underhood Air Flow and Thermal Analysis; SAE International: Warrendale, PA, USA, 2009. [Google Scholar] [CrossRef]

- Kumar, V.; Shendge, S.A.; Baskar, S. Underhood Thermal Simulation of a Small Passenger Vehicle with Rear Engine Compartment to Evaluate and Enhance Radiator Performance; SAE International: Warrendale, PA, USA, 2010. [Google Scholar] [CrossRef]

- Hsieh, C.T.; Jang, J.Y. 3-D Thermal-hydraulic Analysis for Louver Fin Heat Exchangers with Variable Louver Angle. Appl. Therm. Eng. 2006, 26, 1629–1639. [Google Scholar] [CrossRef]

- Malapure, V.P.; Mitra, S.K.; Bhattacharya, A. Numerical Investigation of Fluid Flow and Heat Transfer over Louvered Fins in Compact Heat Exchanger. Int. J. Therm. Sci. 2007, 46, 199–211. [Google Scholar] [CrossRef]

- Rao, Z.H.; Zhang, G.Q. Thermal Properties of Paraffin Wax-based Composites Containing Graphite. Energy Sources Part A-Recovery Util. Environ. Eff. 2011, 33, 587–593. [Google Scholar] [CrossRef]

- Rao, Z.; Wang, S.; Wu, M.; Lin, Z.; Li, F. Experimental Investigation on Thermal Management of Electric Vehicle Battery with Heat Pipe. Energy Convers. Manag. 2013, 65, 92–97. [Google Scholar] [CrossRef]

- Zhao, G.; Wang, X.; Negnevitsky, M.; Zhang, H. A review of air-cooling battery thermal management systems for electric and hybrid electric vehicles. J. Power Sources 2021, 501, 230001. [Google Scholar] [CrossRef]

- Bernagozzi, M.; Georgoulas, A.; Miche, N.; Marengo, M. Heat pipes in battery thermal management systems for electric vehicles: A critical review. Appl. Therm. Eng. 2023, 219, 119495. [Google Scholar] [CrossRef]

- Li, H.; Yang, H.; Yan, J.; Cen, K.; Ostrikov, K.K.; Bo, Z. Energy and entropy generation analysis in a supercapacitor for different operating conditions. Energy 2022, 260, 124932. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, X.; Yang, B.; Cai, S. A review of battery thermal management systems using liquid cooling and PCM. J. Energy Storage 2024, 76, 109836. [Google Scholar] [CrossRef]

- Fang, M.; Qiao, L.; Wu, M.; Ye, Y.; Yang, M.; Liu, S.; Ma, X. Hydrogen-bond-rich Composite Membrane with Improved Conductivity and Selectivity for Flow Battery. J. Power Sources 2023, 563, 232815. [Google Scholar] [CrossRef]

- Lei, J.; Yao, Y.; Huang, Y.; Lu, Y.C. A Highly Reversible Low-Cost Aqueous Sulfur–Manganese Redox Flow Battery. ACS Energy Lett. 2023, 8, 429–435. [Google Scholar] [CrossRef]

- Rehman, W.; Kimball, J.W.; Bo, R. Multi-layered Energy Management Framework for Extreme Fast Charging Stations Considering Demand Charges, Battery Degradation, and Forecast Uncertainties. IEEE Trans. Transp. Electrif. 2023, 10, 760–776. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhang, C.; Li, X. Opportunities and Challenges of Organic Flow Battery for Electrochemical Energy Storage Technology. J. Energy Chem. 2022, 67, 621–639. [Google Scholar] [CrossRef]

- Zhou, F.; Tang, Z.; Tian, Z. Research on comprehensive utilization technology of regenerative braking energy for heavy haul railway. In Proceedings of the 2023 5th Asia Energy and Electrical Engineering Symposium, (AEEES), Chengdu, China, 23–26 March 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1574–1581. [Google Scholar] [CrossRef]

- Chen, J.; Hu, H.; Wang, M.; Ge, Y.; Wang, K.; Huang, Y.; Yang, K.; He, Z.; Xu, Z.; Li, Y.R. Power flow control-based regenerative braking energy utilization in ac electrified railways: Review and future trends. IEEE Trans. Intell. Transp. Syst. 2024, 25, 6345–6365. [Google Scholar] [CrossRef]

- Perin, I.; Walker, G.R.; Ledwich, G. Load sharing and wayside battery storage for improving ac railway network performance with generic model for capacity estimation—Part 2. IEEE Trans. Ind. Electron. 2018, 65, 9459–9467. [Google Scholar] [CrossRef]

- Wu, Y.; Yang, B.; Zhang, X.; Ying, S. Research progress in battery thermal management system under vessel working conditions. J. Energy Storage 2024, 96, 112761. [Google Scholar] [CrossRef]

- COMSOL. COMSOL Multiphysics 6.2 User’s Guide. 2023. Available online: www.comsol.com (accessed on 10 March 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).