A Multi-Type Dynamic Response Control Strategy for Energy Consumption

Abstract

1. Introduction

1.1. Motivation and Related Works

1.2. Research Gap and Contributions

1.3. Article Organization

2. Industrial DR Cluster Demand Response Analysis

2.1. Analysis on Characteristics of Industrial Load DR Cluster

2.2. Electrolytic Aluminum Plant Response Model

3. Civil DR Cluster Response Analysis

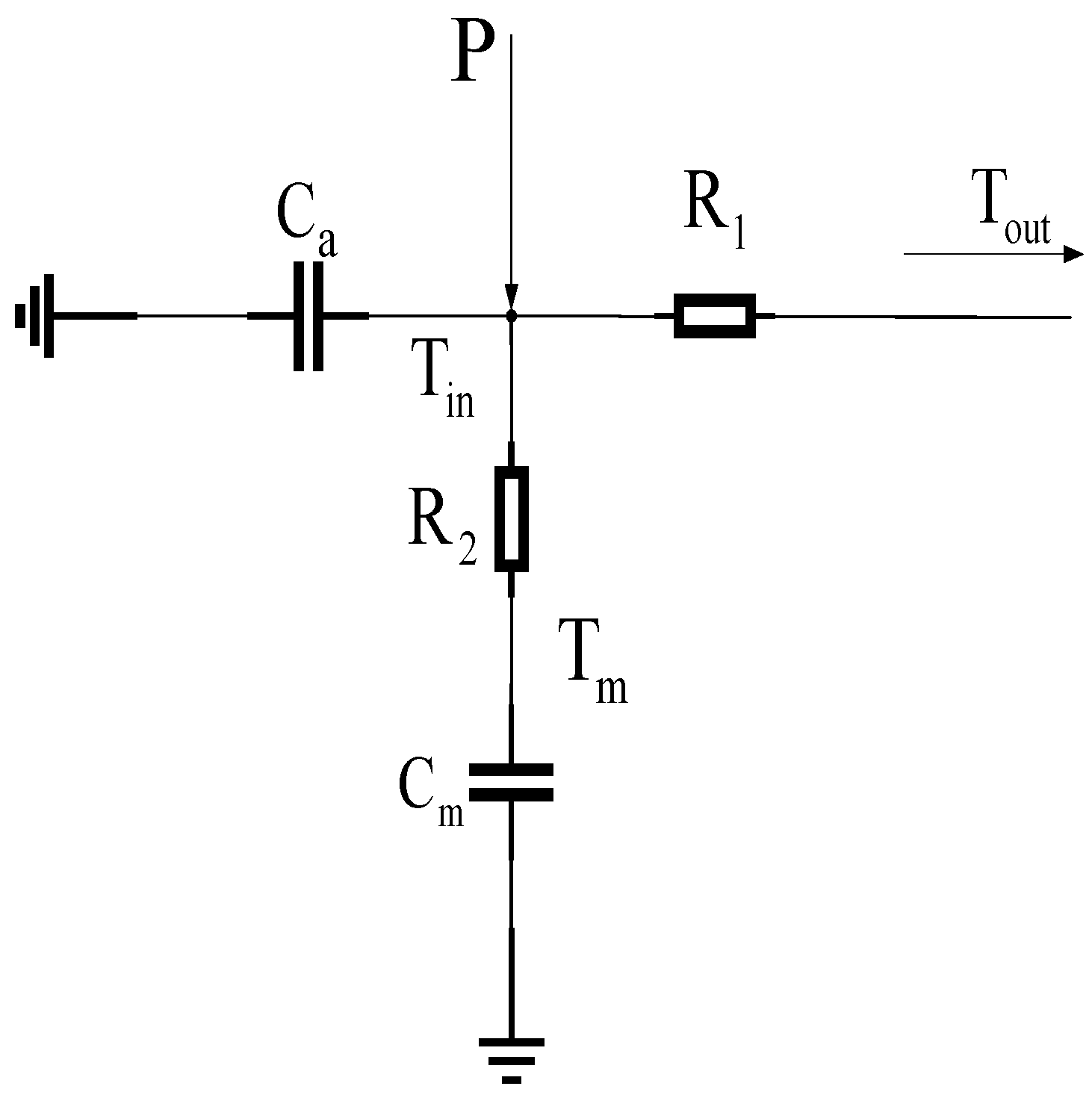

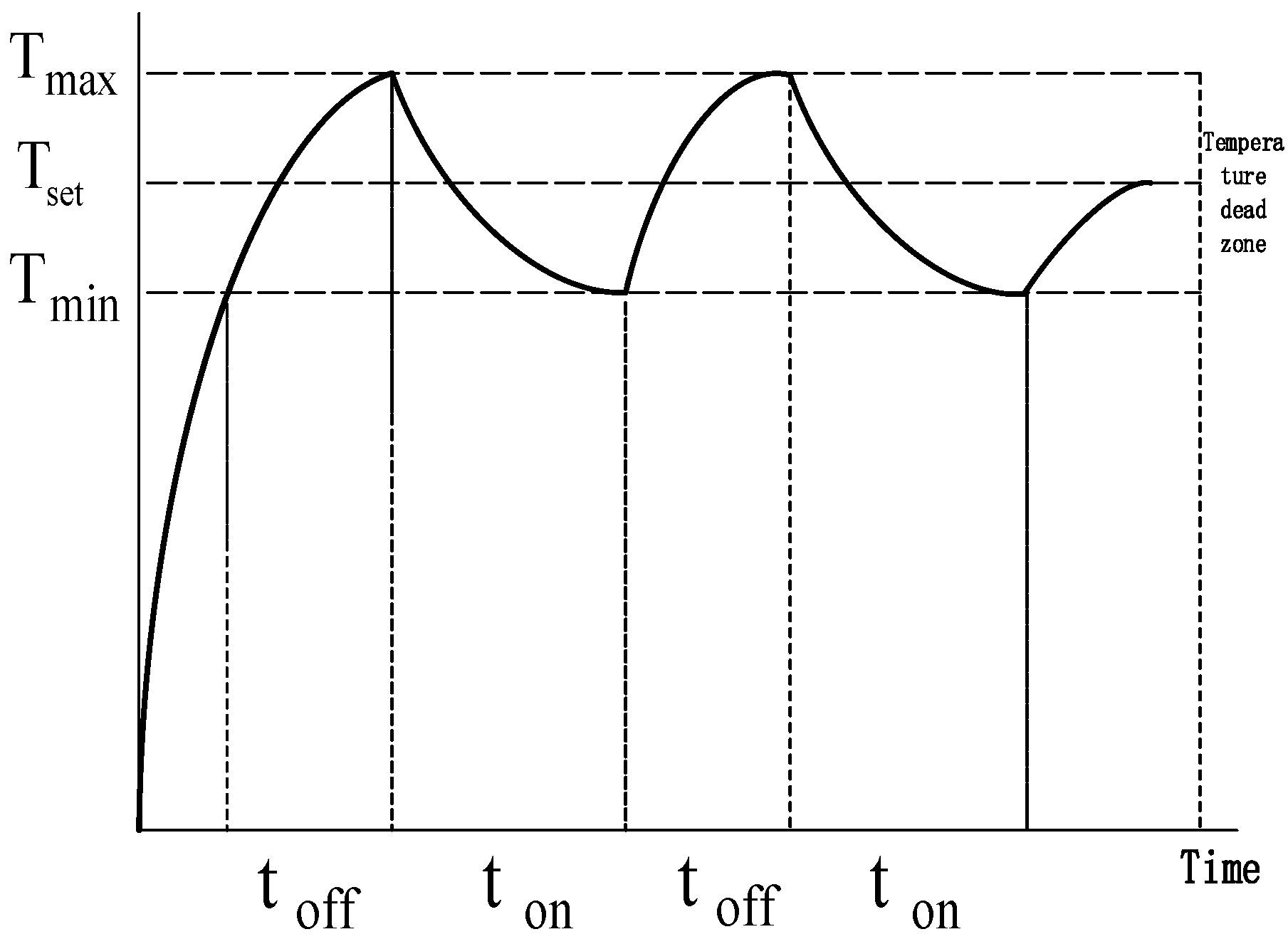

3.1. Response Analysis of Air Conditioning Model

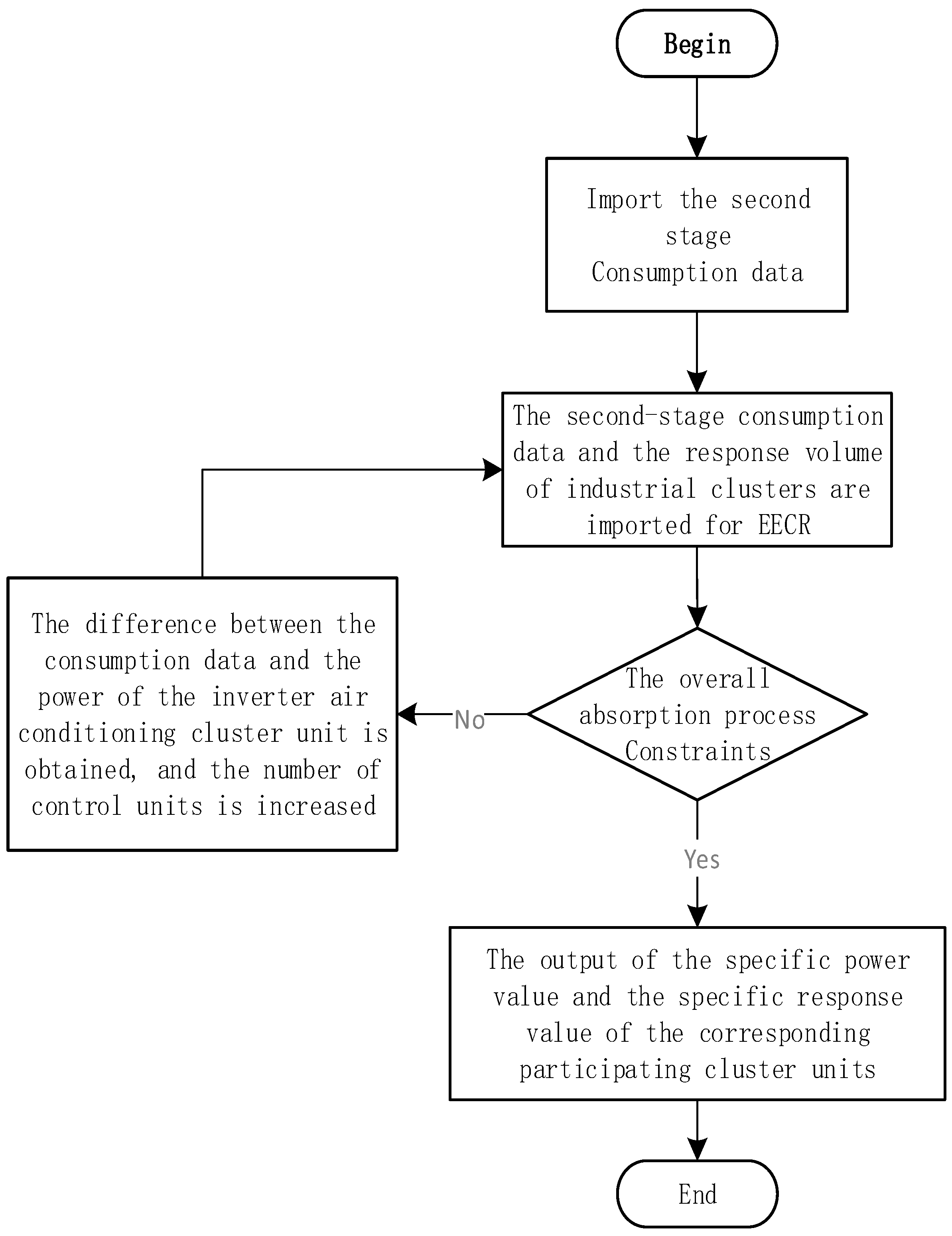

3.2. Response Strategy of Air Conditioning Cluster Unit Based on Equal Energy Consumption Ranking (EECR)

- a.

- The initial premise assumes that cluster units operate at rated power and specifically respond to turn-on runtime, using Equations (3) and (7).

- b.

- Equation (9) is used to solve the response participation power in the regulation interval of each cluster unit and to sort them according to the numerical value. At the same time, the response power of an air conditioning cluster unit can be obtained through logical processing and isothermal processing as follows:

4. Two-Stage Optimization Model

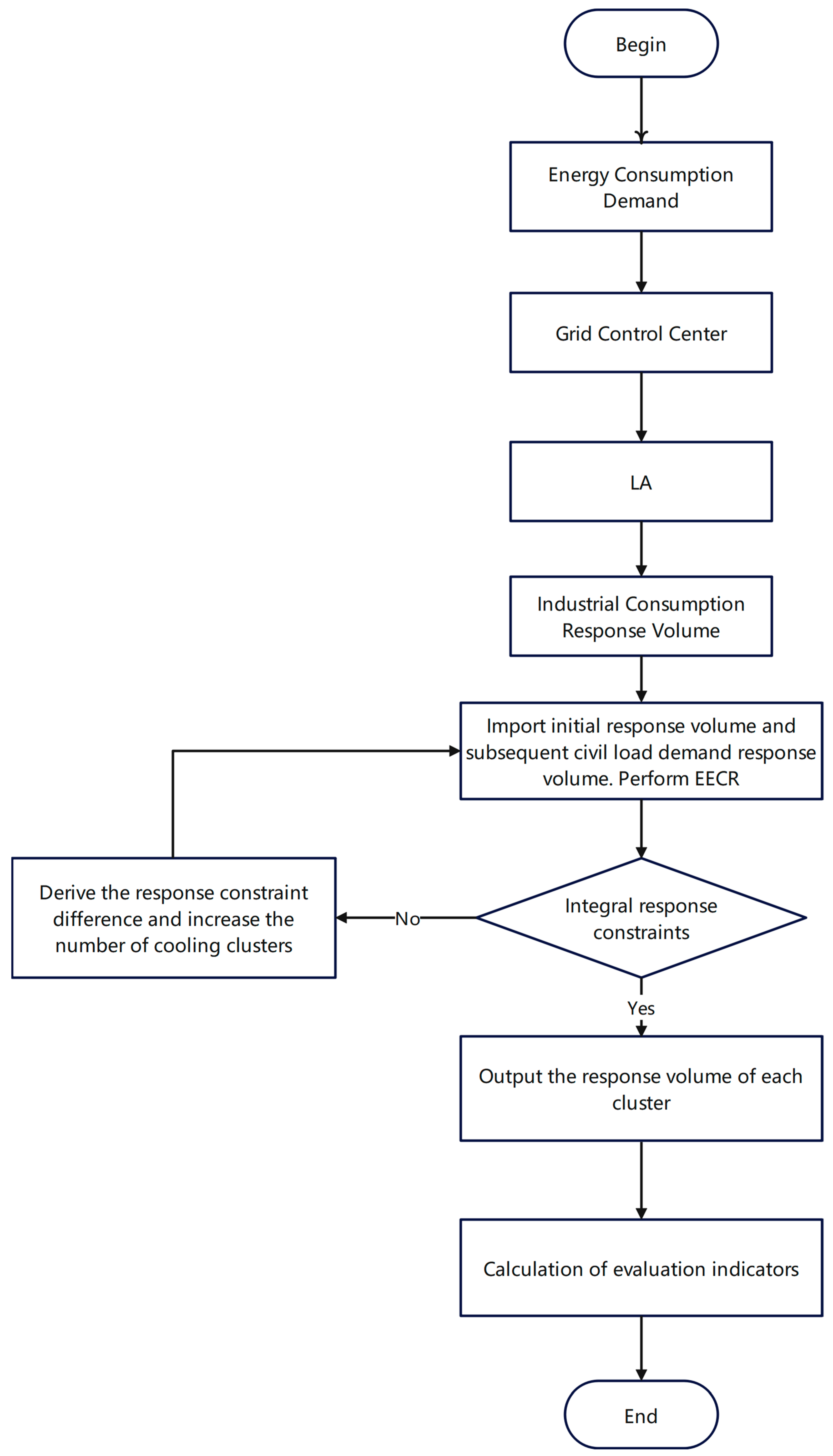

4.1. Aggregator Regulation Process

4.2. Two-Stage Optimization Model Construction

4.3. Overall Objective Function and Evaluation Index Construction

4.3.1. Integral Objective Function Construction

4.3.2. Construction of Consumption Evaluation Index

4.4. Consider the Load Regulation and Constraint Model under the Energy Consumption

4.4.1. One-Stage Constraints

- (1)

- Aggregation power constraints

- (2)

- Electrolytic aluminum plant power constraints:

- (3)

- Air conditioning regulation power constraints:

- (4)

- Overall wind rejection rate constraint

4.4.2. Two-Stage Constraints

4.5. Model Solution Method

5. The Example Analysis

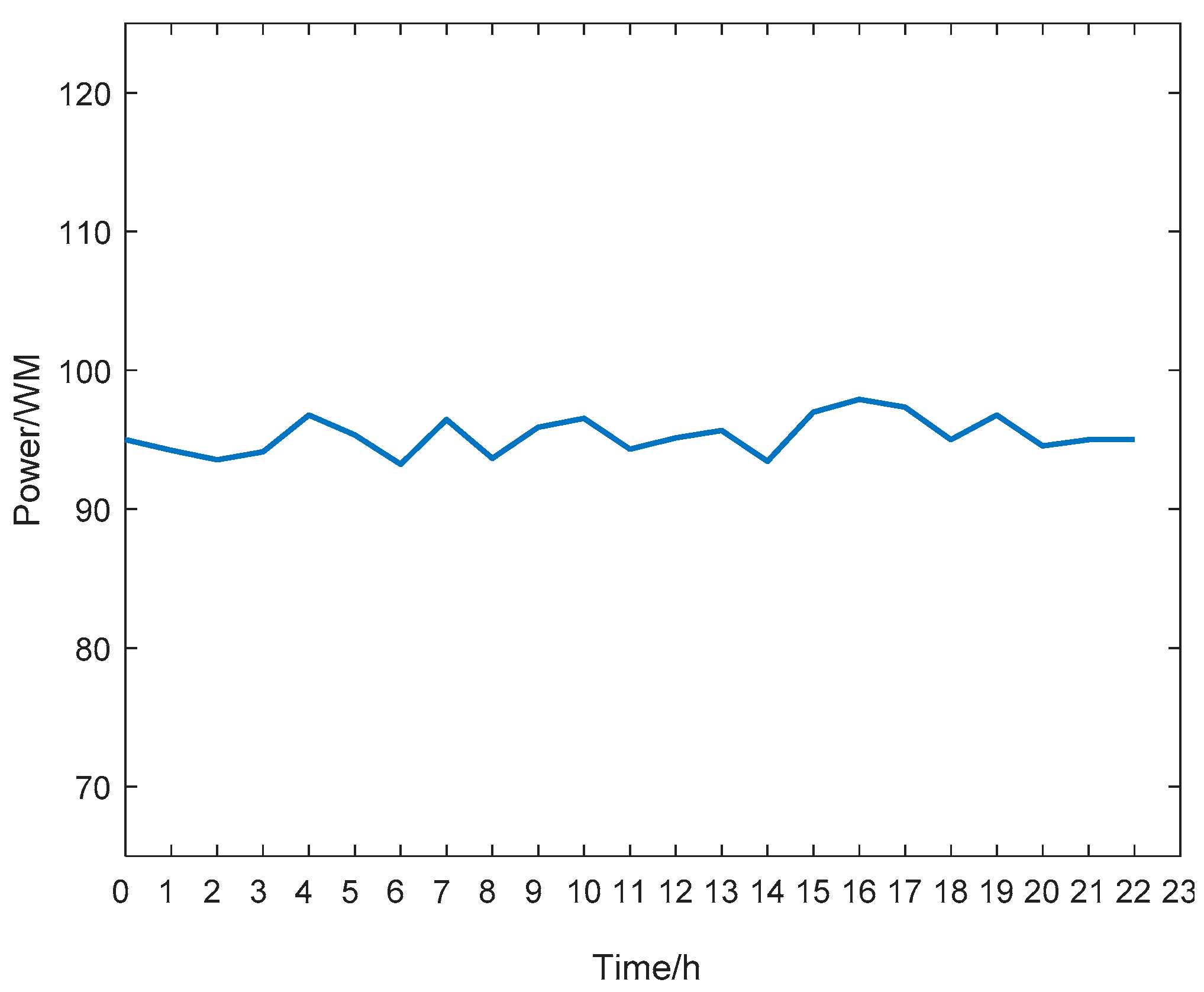

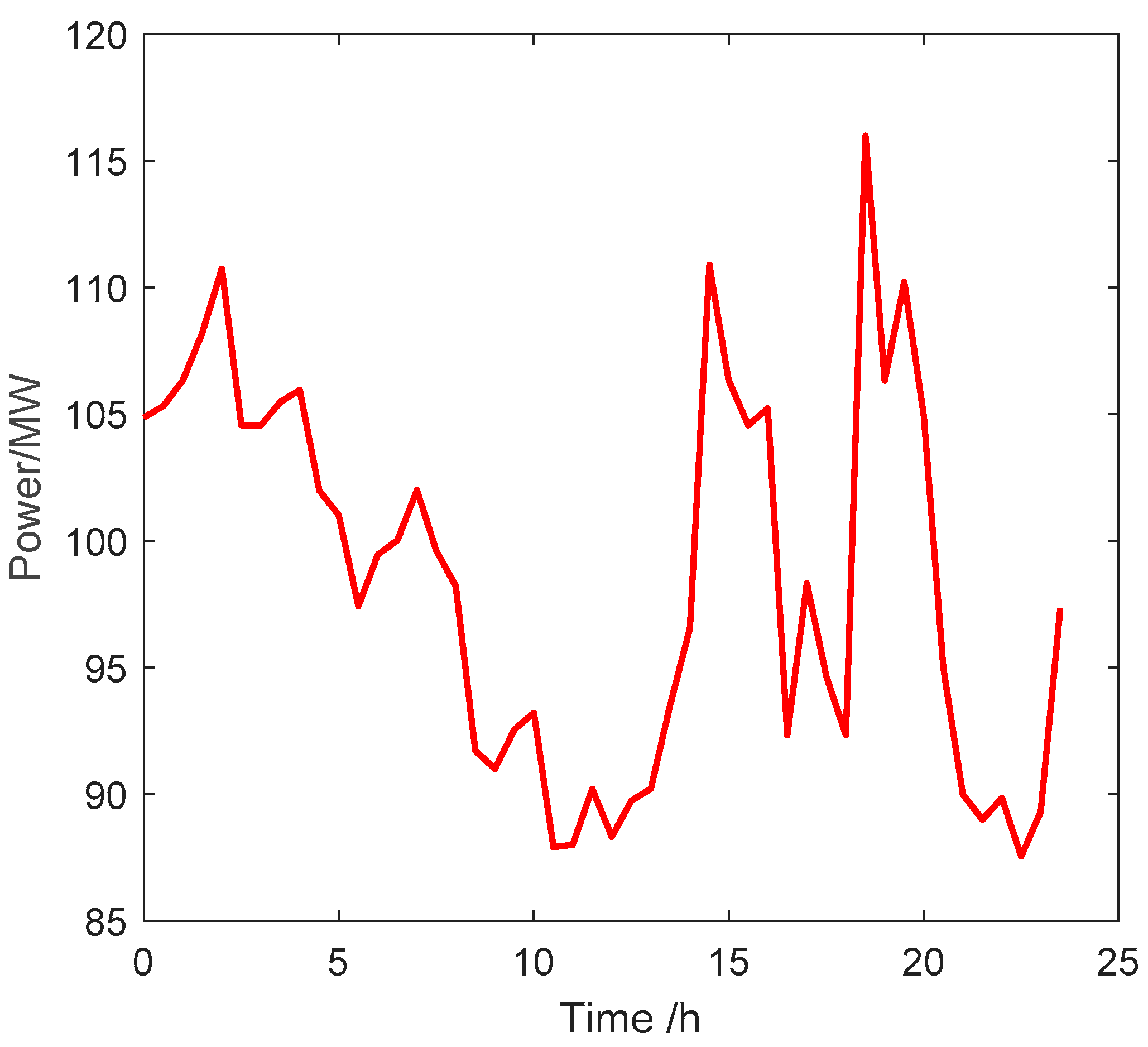

5.1. Calculation Data Description

- (1)

- The data in the figure are initially grouped into 48 clusters. To streamline the data research and cleaning procedures, the starting time of the initial target consumption cluster is provisionally set at 0 time. Following the response patterns of the industrial DR cluster, a data selection interval of 2 h is employed, resulting in the formation of 12 data groups comprising the first target consumption cluster. The second target consumption demand consists of 48 groups of predicted wind power consumption data. Based on the optimization allocation model described above, specific parameters for industrial and civil load price contracts within a designated area are chosen as follows:

- (2)

- The compensation strategy of industrial load price

5.2. Optimization Results

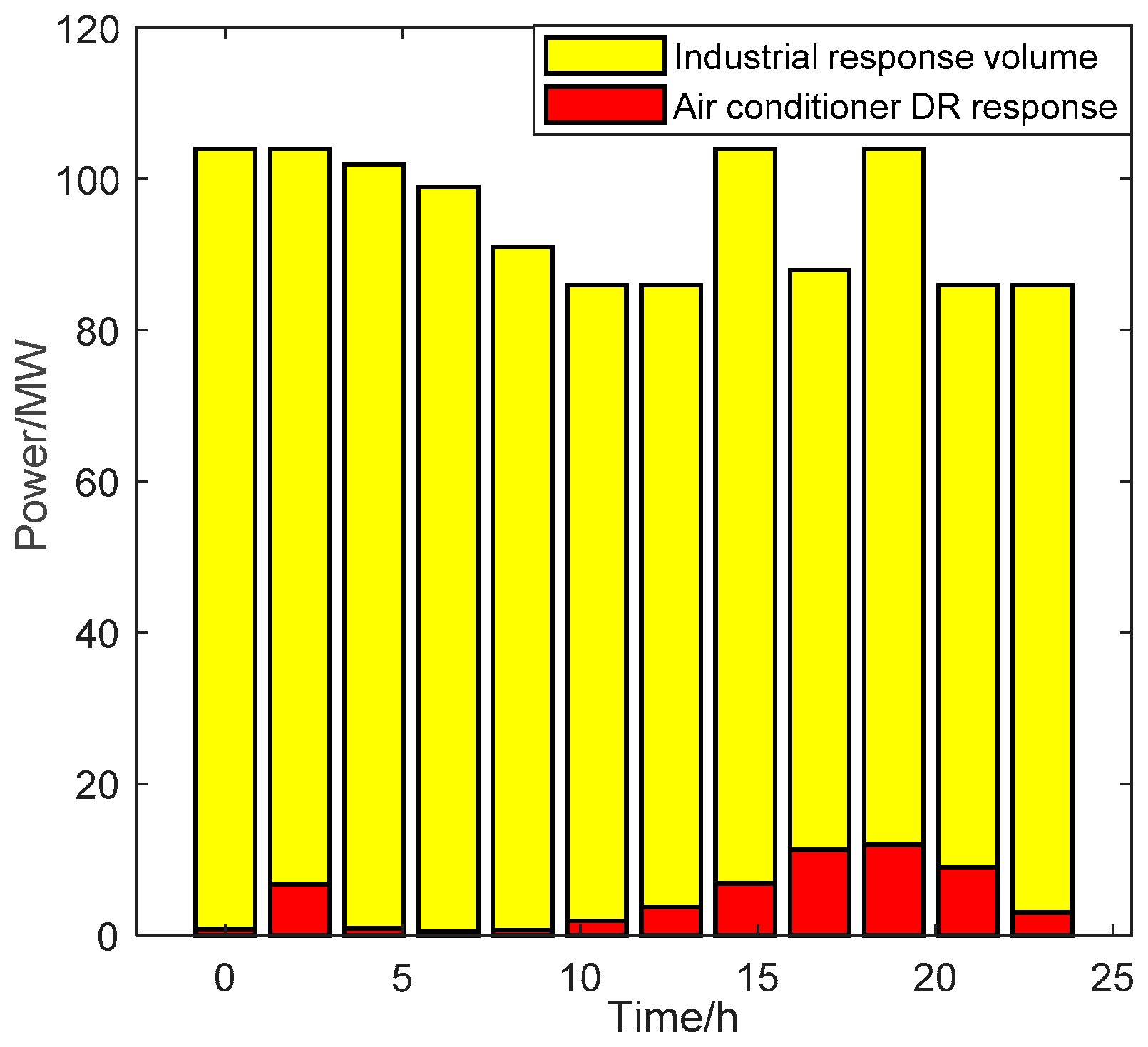

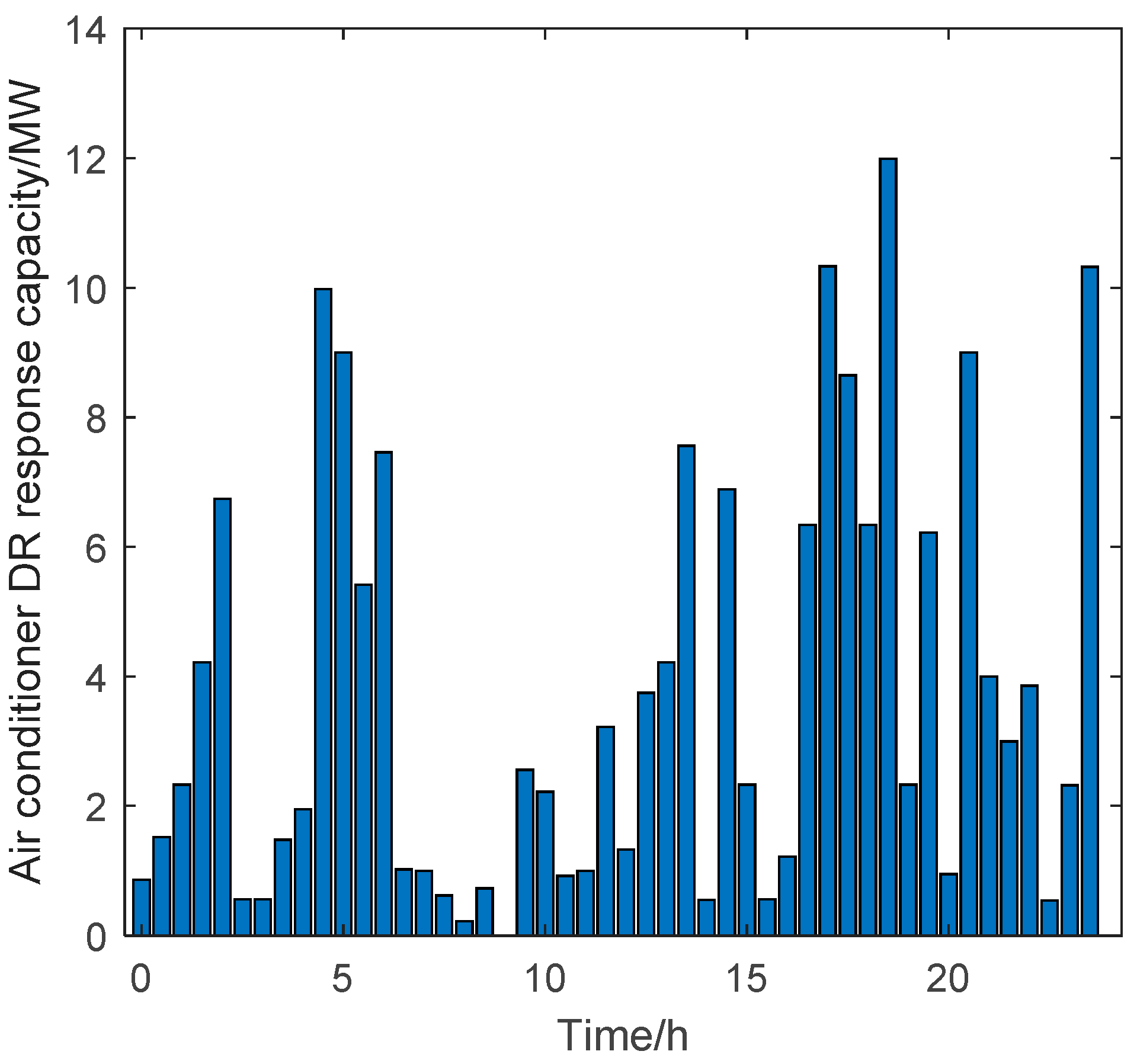

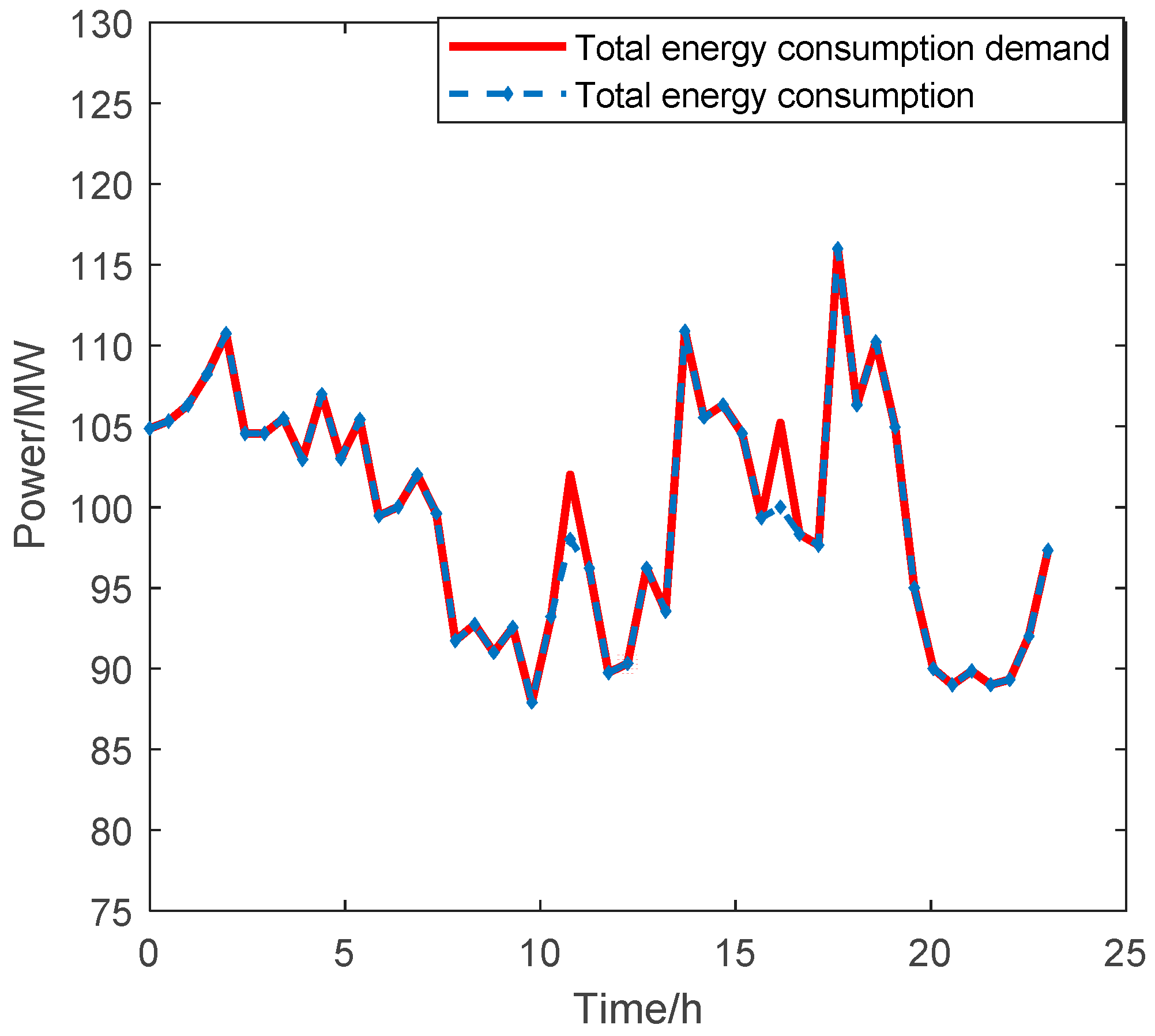

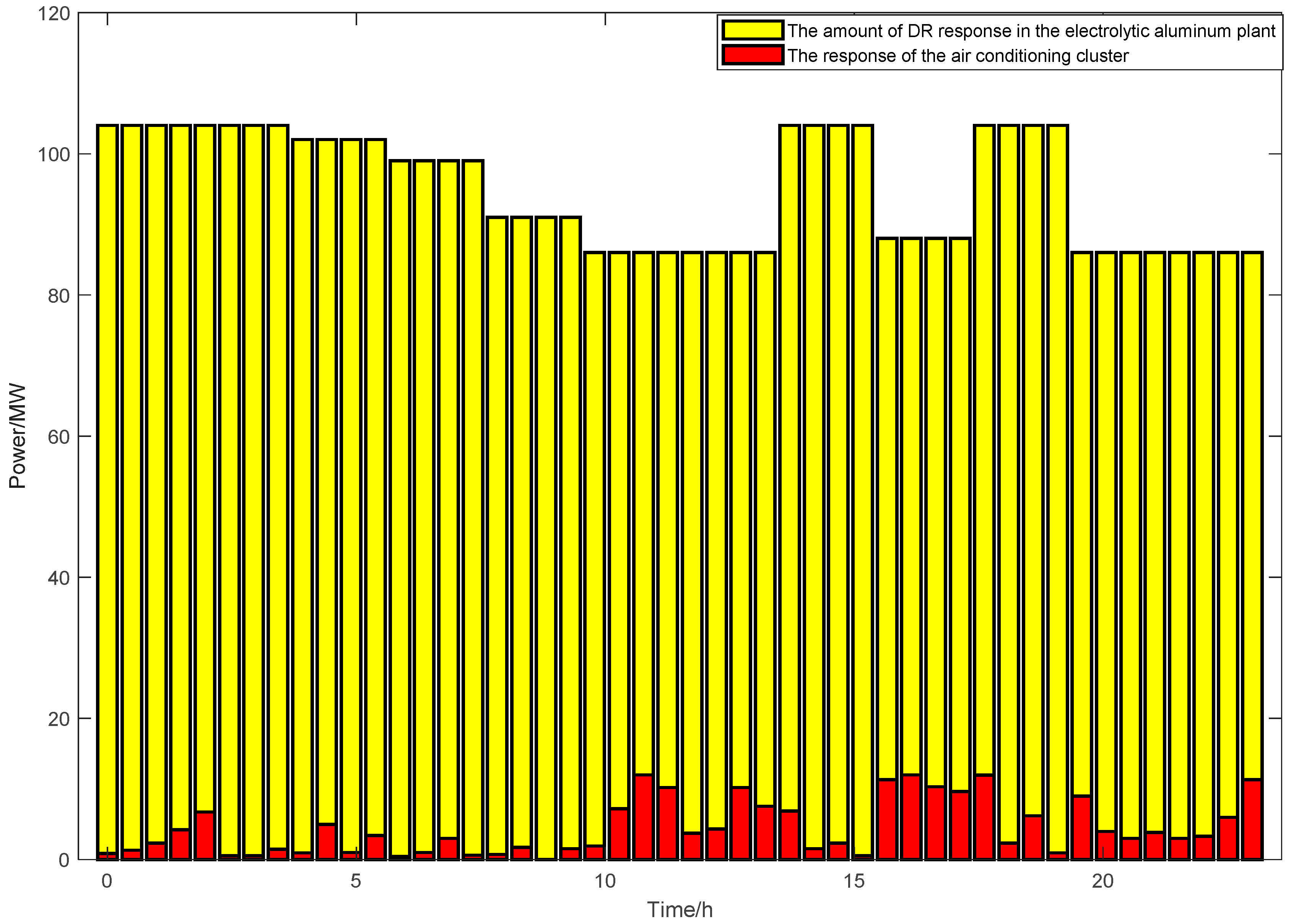

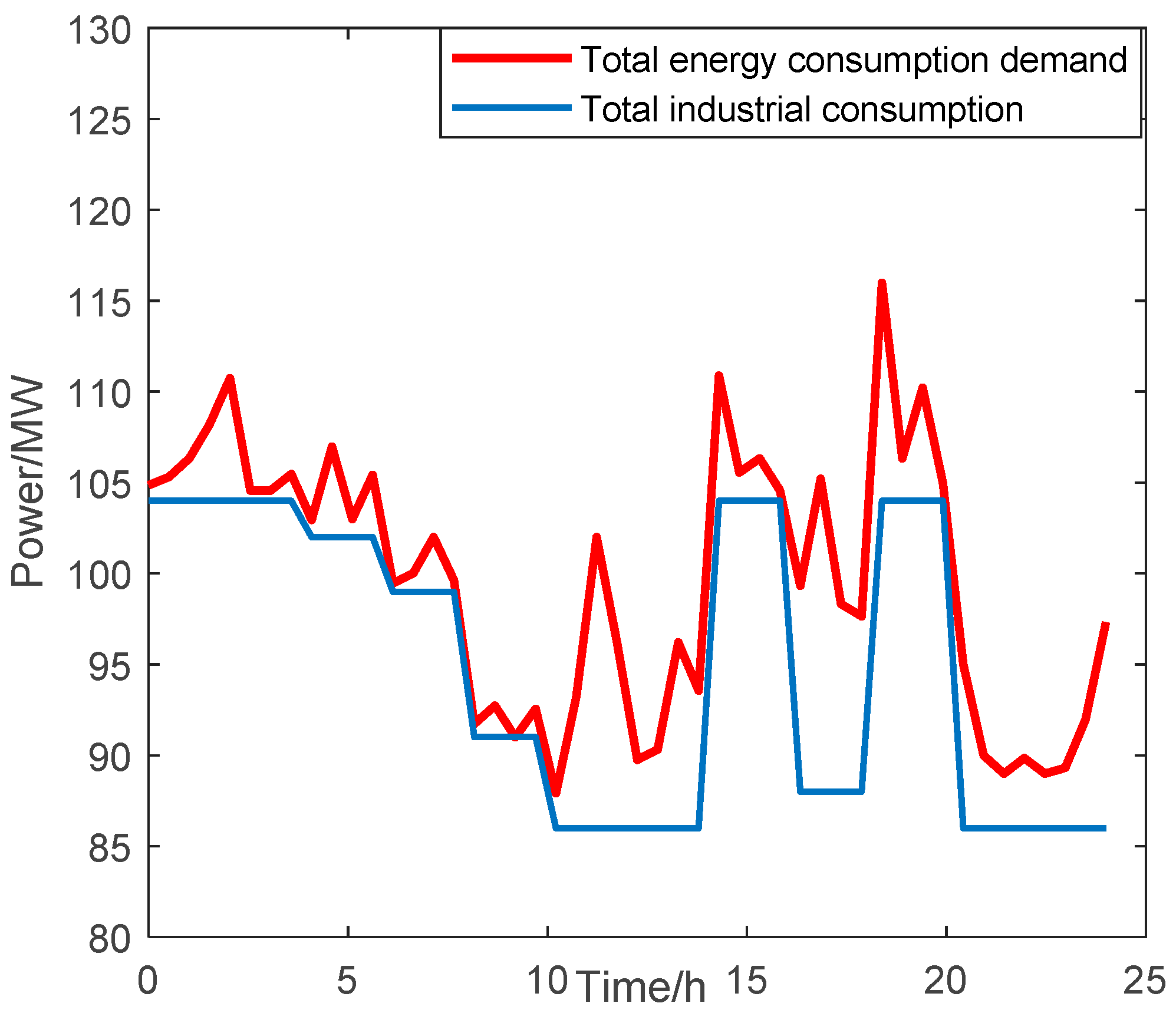

5.2.1. One-Stage Optimization Calculation Results

5.2.2. Two-Stage Optimization Results

5.3. Compare Optimization Schemes

6. Conclusions

- In scenarios involving large-scale wind power consumption, individual civil load clusters exhibit limited energy consumption, posing challenges in maintaining high energy consumption rates and meeting system stability requirements.

- The energy consumption of single industrial loads is significant due to adjustment intervals, leading to prolonged duration issues. Managing the strong fluctuations in energy consumption demand during the control operation stage becomes challenging, resulting in difficulties in matching fluctuations, leading to problems of over-consumption and under-consumption. This situation hampers the power grid’s frequency and phase adjustments.

- The proposed MLCDR response strategy leverages the characteristics of civil air conditioning clusters and electrolytic aluminum loads. This strategy effectively combines the small-load and high-consumption features of industrial loads, reducing response aggregation costs. By utilizing civil loads as auxiliary components to industrial loads, the strategy ensures that industrial loads can positively and flexibly respond to energy consumption demands within control intervals. This approach enhances the flexibility and auxiliary response capabilities of industrial loads, thereby improving industrial load auxiliary service flexibility. The simulation model incorporates energy economic indicators, demonstrating the effectiveness of the proposed strategy in addressing large-scale wind power consumption fluctuations. The simulation data reveal a wind energy consumption rate that exceeds 99%, ensuring optimal control strategy benefits amounting to CNY 971,732.09 for LA.

- This paper demonstrates how the research content of wider application scenarios can be applied to the new energy station power supply model, effectively improving the robustness of the power grid. However, in some periods, if the elimination of the overall need for the industrial load demand is significantly lower than the baseload power demand, the scheduling response strategy needs to be further optimized and adjusted.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tong, Y.; Fan, W.; Liu, Z. Influence of Wind Power Generation System Accessing to Traction Power Supply System on Power Quality; Lecture Notes in Electrical Engineering; Jia, L., Qin, Y., Liang, J., Liu, Z., Diao, L., An, M., Eds.; Springer: Singapore, 2022; Volume 864. [Google Scholar]

- Tsai, W.-C.; Hong, C.-M.; Tu, C.-S.; Lin, W.-M.; Chen, C.-H. A Review of Modern Wind Power Generation Forecasting Technologies. Sustainability 2023, 15, 10757. [Google Scholar] [CrossRef]

- Bagdadee, A.H.; Zhang, L. Electrical Power Crisis Solution by the Developing Renewable Energy Based Power Generation Expansion. Energy Rep. 2020, 6, 480–490. [Google Scholar] [CrossRef]

- Moradi-Sepahvand, M.; Amraee, T. Integrated expansion planning of electric energy generation, transmission, and storage for handling high shares of wind and solar power generation. Appl. Energy 2021, 298, 117–137. [Google Scholar] [CrossRef]

- Impram, S.; Nese, S.V.; Oral, B. Challenges of Renewable Energy Penetration on Power System Flexibility: A Survey. Energies 2020, 13, 100539. [Google Scholar] [CrossRef]

- Guerra, K.; Haro, P.; Gutiérrez, R.E.; Gómez-Barea, A. Facing the High Share of Variable Renewable Energy in the Power System: Flexibility and Stability Requirements. Appl. Energy 2022, 310, 118561. [Google Scholar] [CrossRef]

- Silvestri, L.; De Santis, M. Renewable-Based Load Shifting System for Demand Response to Enhance Energy-Economic-Environmental Performance of Industrial Enterprises. Appl. Energy 2024, 358, 122562. [Google Scholar] [CrossRef]

- Woltmann, S.; Kittel, J. Development and Implementation of Multi-Agent Systems for Demand Response Aggregators in an Industrial Context. Appl. Energy 2022, 314, 118841. [Google Scholar] [CrossRef]

- Li, Y.; Yang, Z.; Li, G.; Zhao, D.; Tian, W. Optimal scheduling of an isolated microgrid with battery storage considering load and renewable generation uncertainties. IEEE Trans. Ind. Electron. 2019, 66, 1565–1575. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Q.; Sun, W. Quantifying flexibility provisions of the ladle furnace refining process as cuttable loads in the iron and steel industry. Appl. Energy 2023, 342, 121178. [Google Scholar] [CrossRef]

- Liu, Y.; Mauter, M.S. Assessing the demand response capacity of U.S. drinking water treatment plants. Appl. Energy 2020, 267, 114899. [Google Scholar] [CrossRef]

- Khan, M.W.; Wang, J. Multi-agents based optimal energy scheduling technique for electric vehicles aggregator in microgrids. Int. J. Electr. Power Energy Syst. 2022, 134, 107346. [Google Scholar] [CrossRef]

- Hong, J.; Hui, H.; Zhang, H.; Dai, N.; Song, Y. Event-Triggered Consensus Control of Large-Scale Inverter Air Conditioners for Demand Response. IEEE Trans. Power Syst. 2022, 37, 4954–4957. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, C.; Wang, B. Adaptive model predictive control of a heat pump-assisted solar water heating system. Energy Build. 2023, 300, 113682. [Google Scholar] [CrossRef]

- Srithapon, C.; Månsson, D. Predictive control and coordination for energy community flexibility with electric vehicles, heat pumps and thermal energy storage. Appl. Energy 2023, 347, 121500. [Google Scholar] [CrossRef]

- Yang, Y.; Zhou, Z.; Xiao, X.; Pang, Y.; Shi, L. Intelligent day-ahead optimization scheduling for multi-energy systems. Front. Energy Res. 2024, 11, 1349194. [Google Scholar]

- Tostado-Véliz, M.; Hasanien, H.M.; Jordehi, A.R.; Turky, R.A.; Jurado, F. Risk-averse optimal participation of a DR-intensive microgrid in competitive clusters considering response fatigue. Appl. Energy 2023, 339, 120960. [Google Scholar] [CrossRef]

- Oskouei, M.Z.; Zeinal-Kheiri, S.; Mohammadi-Ivatloo, B.; Abapour, M.; Mehrjerdi, H. Optimal Scheduling of Demand Response Aggregators in Industrial Parks Based on Load Disaggregation Algorithm. IEEE Syst. J. 2022, 16, 945–953. [Google Scholar] [CrossRef]

- Hu, X.; Xu, G.; Shang, C.; Wang, L.; Wen, M.; Cheng, H. Joint Planning of Battery Energy Storage and Demand Response for Industrial Parks Participating in Peak Shaving. Autom. Electr. Power Syst. 2019, 43, 116–123. [Google Scholar]

- Dehghan-Dehnavi, S.; Fotuhi-Firuzabad, M.; Moeini-Aghtaie, M.; Dehghanian, P.; Wang, F. Decision-Making Tree Analysis for Industrial Load Classification in Demand Response Programs. IEEE Trans. Ind. Appl. 2021, 57, 26–35. [Google Scholar] [CrossRef]

| Industrial DR Type | Regulation Ratio | Control Times | Regulation Duration | Adjustment Method |

|---|---|---|---|---|

| Electrolytic Aluminum | −10~10% | Repeatedly | 2 h | Upward Downward |

| Civilian Type | Regulation Ratio | Control Times | Regulation Duration |

|---|---|---|---|

| Air conditioning | Aggregated power | Multiple regulation | 0.5 h |

| Peak Hour Electricity Price (CNY/mWh) | Off-Peak Electricity Price (CNY/mWh) | Valley Hour Price (CNY/mWh) |

|---|---|---|

| 260 | 145 | 96 |

| Parameters | Numerical |

|---|---|

| Equivalent thermal resistance/ω | 2 |

| Average power/kw | 2 |

| Setpoint/°C | 24 |

| Temperature dead zone/°C | 5 |

| Average heat capacity ca/f | 2 |

| Energy efficiency ratio | 2.5 |

| Number of air conditioners i | 10,000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jing, L.; Wei, E.; Wang, L.; Li, J.; Zhang, Q. A Multi-Type Dynamic Response Control Strategy for Energy Consumption. Energies 2024, 17, 3092. https://doi.org/10.3390/en17133092

Jing L, Wei E, Wang L, Li J, Zhang Q. A Multi-Type Dynamic Response Control Strategy for Energy Consumption. Energies. 2024; 17(13):3092. https://doi.org/10.3390/en17133092

Chicago/Turabian StyleJing, Lantao, Enyu Wei, Liang Wang, Jinkuo Li, and Qiang Zhang. 2024. "A Multi-Type Dynamic Response Control Strategy for Energy Consumption" Energies 17, no. 13: 3092. https://doi.org/10.3390/en17133092

APA StyleJing, L., Wei, E., Wang, L., Li, J., & Zhang, Q. (2024). A Multi-Type Dynamic Response Control Strategy for Energy Consumption. Energies, 17(13), 3092. https://doi.org/10.3390/en17133092