1. Introduction

Presently, a mounting concern surrounds air pollution, propelled by the ongoing trend of economic growth and the increase in private car ownership. The emission of greenhouse gases from combustion engine vehicles has compounded these environmental concerns. In this context, battery electric vehicles (BEVs) are assuming a more significant role, driven by advancements in battery technology and the pressing demand for sustainable transportation solutions. Significantly, the allure of electric trains resides in their quiet operation and absence of emissions, both of which are advantageous for the environment [

1,

2,

3,

4,

5].

Among growing concerns about environmental pollution and the energy crisis, electric vehicles have become a focus for research and development in countries across the globe [

6]. However, most battery electric vehicles operate using electrochemical batteries as their primary energy storage system. Electrochemical batteries come with several disadvantages including short lifespan, restricted driving range, low power density, and high cost, which reduce the effectiveness of regenerative braking [

7].

To resolve various limitations, a hybrid energy storage paradigm for a regenerative braking system (HESP-RBS) employing a combination of batteries and supercapacitors (SCs) was adopted, aiming to enhance vehicle acceleration and extend battery lifespan. Moreover, other HESP alternatives have been introduced for BEVs. Specifically, the proposed HESP focuses on the advantages of the high energy density of SCs and batteries. However, the high-power electronic interface of a bidirectional DC/DC chopper contributes to cost inefficiency and, in addition, there is fast battery degradation [

8,

9].

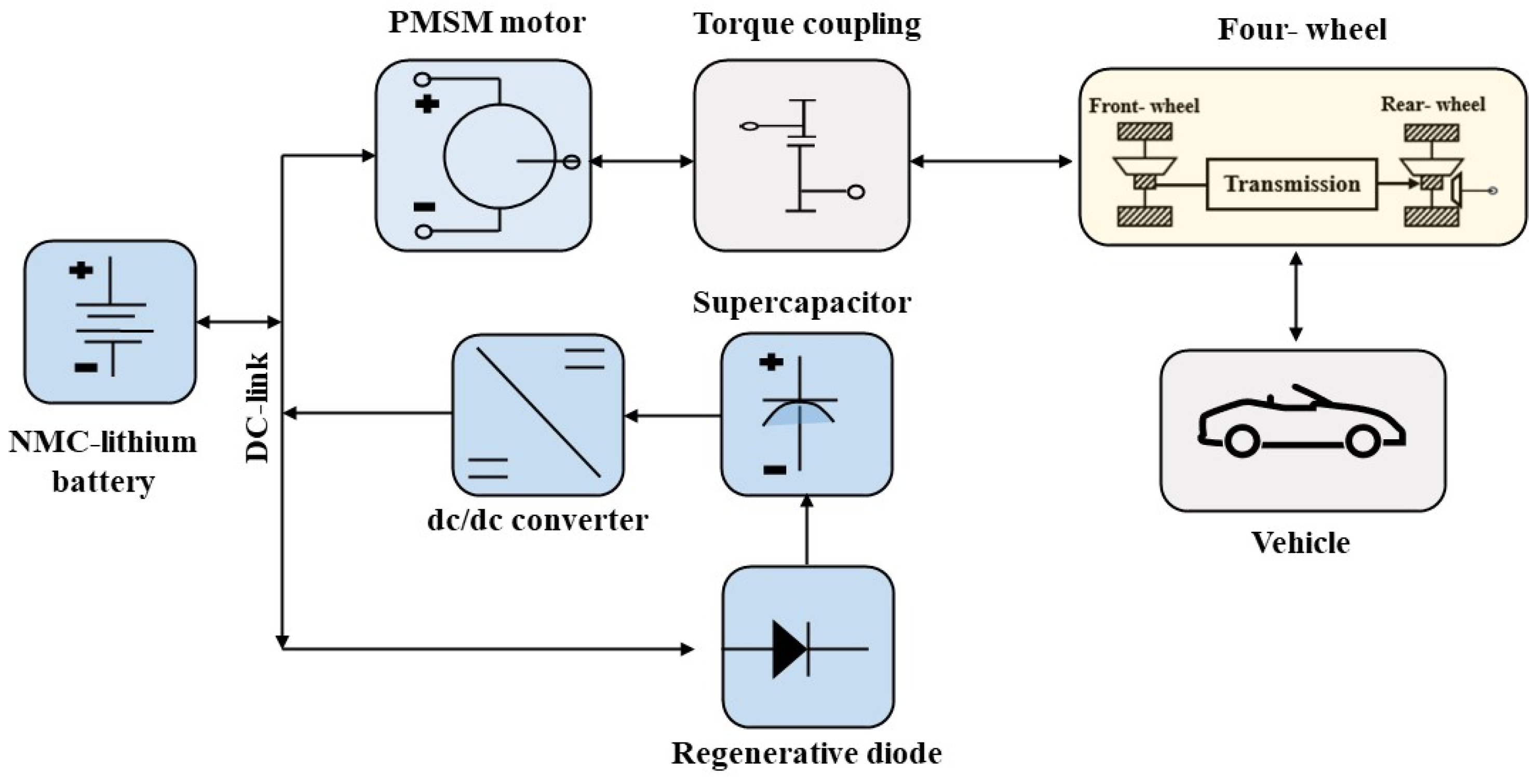

With enhanced SC innovation, the SC integrates the high potential energy density characteristics of an electrochemical double-layer capacitor (EDLC) with its pseudocapacitor with high energy density characteristics. A comparison of SC and NMC-lithium battery properties is shown in

Table 1. The HESP model combining SC and NMC-lithium batteries has the potential to achieve both the outstanding exceptional power density of the SC and the critical energy density of the battery. Therefore, in this paper, the recommended HESP setup consists of a multiple-cell battery unit, SC module, and high-power unidirectional DC/DC chopper. This scaleup transitioned from laboratory testing to industrial-scale implementation, employing high-grade batteries and permanent magnet synchronous motors (PMSMs) for real road electric vehicles. PMSMs are well-suited for regenerative braking systems, allowing them to efficiently convert kinetic energy into electrical energy during braking or deceleration. Furthermore, opting for unidirectional charging over bidirectional charging is anticipated to yield cost savings and promote battery longevity [

10]. Further, this research proposes the use of a single motor with a mechanical coupling system for all four wheels to achieve four-wheel drive capability while maintaining efficiency and reliability. The single motor’s torque is distributed to all four wheels through differentials and a driveshaft system.

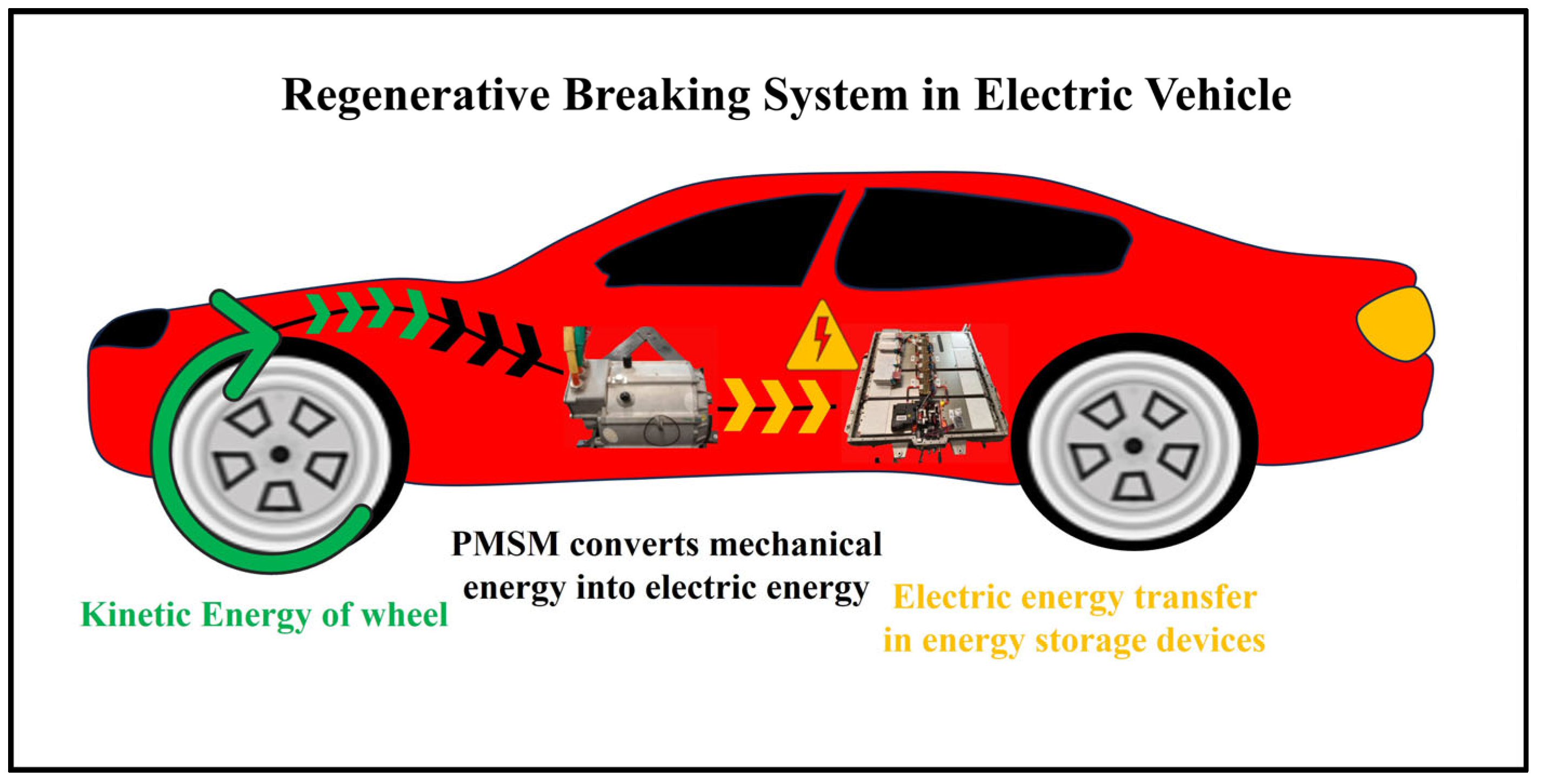

This study conducts experiments on the HESP framework of a recommended SC/NMC-lithium battery of a four-wheel BEV powered by a three-phase PMSM. The investigation spans four distinct operational scenarios: the normal scenario, the acceleration scenario, and the SC and battery activated regenerative braking scenario as shows how of the working system in

Figure 1. To increase vehicle performance, an ANN-equipped control mechanism for the RBS has been implemented, a mechanism that aims to increase vehicle acceleration and extend life. The study structure is as follows:

Section 1 is an introduction;

Section 2 offers an in-depth exploration of the HESP, focusing on its various functional scenarios and configurations;

Section 3 elaborates on the innovative control mechanism equipped with the ANN that drives the proposed RBS;

Section 4 presents the outcomes derived from simulations and real-world experiments conducted on the suggested regenerative braking scenario; and

Section 5 provides the conclusion.

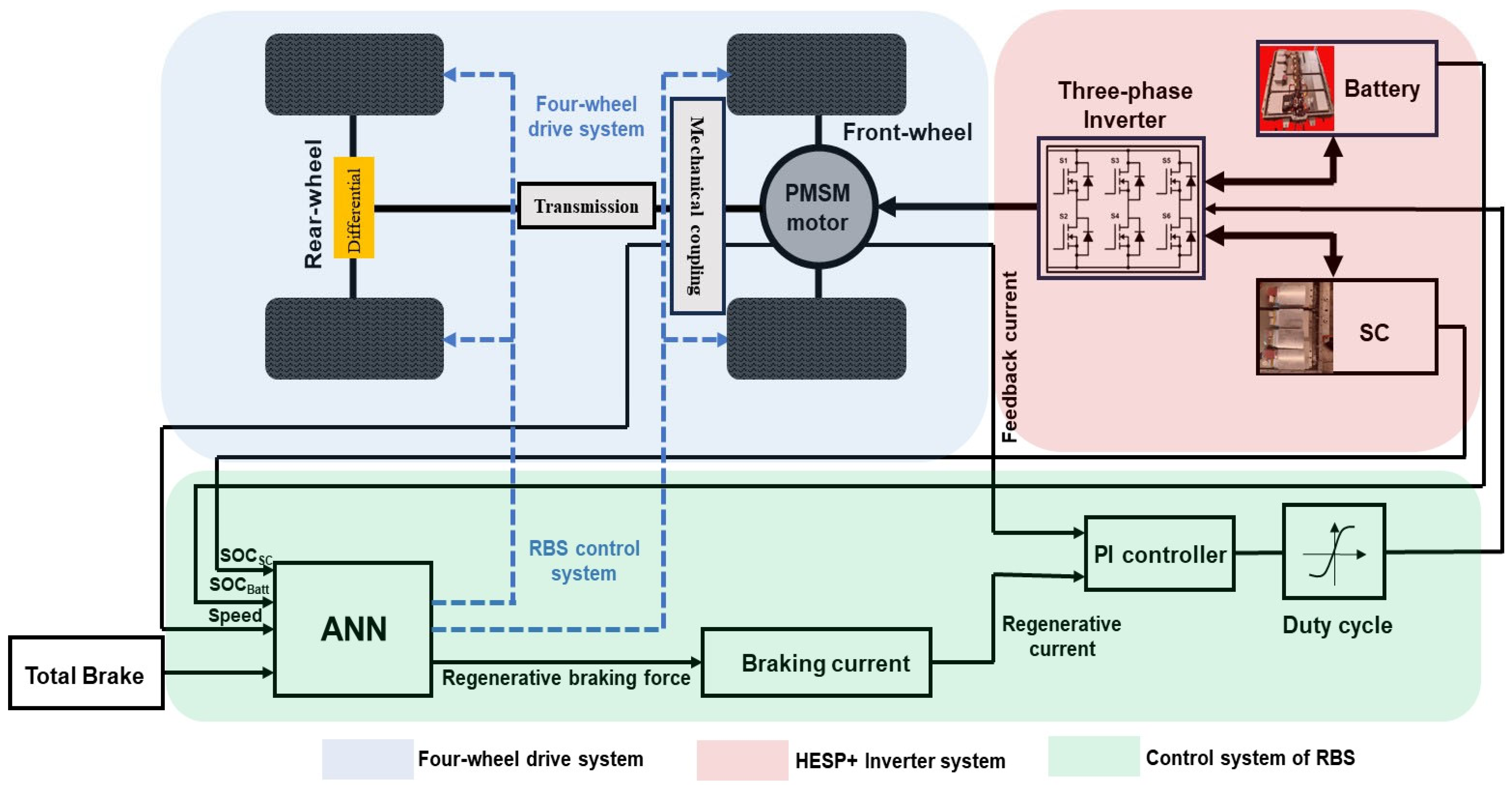

2. The HESP and Functional Scenario

Figure 2 shows the experimental hybrid energy storage paradigm (HESP), which comprises three main components: the SC unit with multiple cells, the battery unit featuring multiple cells, and a unidirectional DC/DC chopper. Direct DC link connection to the battery ensures stability and linking the battery to the SC unit involves the use of a unidirectional DC/DC chopper. This arrangement guarantees that the voltage of the SC unit remains higher than that of the battery. Additionally, a regenerative diode (

D3) is used to connect the SC unit in parallel with the battery. The voltage generated by the HESP is then supplied to the three-phase inverter, which, in turn, powers a three-phase PMSM. The HESP operates in four distinct scenarios: the normal scenario, the acceleration scenario, and the SC and NMC-lithium battery activated regenerative braking scenario [

10].

In the normal scenario, the battery’s power output adequately fulfills the vehicle power requirements, resulting in the SC voltage being higher compared to the battery voltage. Consequently, the reverse conducting power diode of

D3 comes into play. In this scenario, the battery functions as the exclusive voltage source for the three-phase PMSM.

Figure 3 shows a diagram of the HESP system during a normal functional scenario [

10].

In the acceleration scenario, the power of the motor

Pmotor will be greater battery power rating

PBatt,rated. The battery enters deep discharge cycles, which impairs the vehicle’s drivability. Therefore, the SC will maintain a level to boost the battery until the SC voltage is greater than the battery voltage. In this condition,

D2 will always be in a reverse conducting state, and energy from both SC and the battery will be used to power the PMSM. The SC of the HESP system can rapidly discharge to supplement battery power. This is especially true in such situations due to the high energy demand.

Figure 4 provides an illustrative representation of the energy flow during acceleration conditions [

10].

During deceleration, the regenerative braking system activates, converts kinetic energy into electrical energy, and stores it in the SC or battery. The performance of HESP-RBS during deceleration directly affects its ability to recover and store energy efficiently.

In the SC regenerative braking scenario, the pressure of the DC link needs to be in a boost state, so

D2 is forward conducting, and braking energy can be transferred and stored to the SC (

Figure 5). Traditionally, an additional buck–boost DC chopper transfers the braking energy to the SC. However, this approach is burdened with heightened implementation expenses and reduced energy transfer efficiency resulting from power dissipation. To overcome this, the integration of inductors into a three-phase PMSM can be considered, alongside the optimal switching scheme generated by an ANN through the bidirectional three-phase inverter [

10].

In the NMC-lithium battery regenerative braking scenario, if the SC voltage is less than or equal to the SC maximum standard voltage (

VSC ≥ VSC,max), braking energy cannot be transferred to the SC anymore. For this reason, regeneration during braking is switched to the battery [

10]. The principle of operation in this scenario resembles the previous scenario, the DC link voltage can be increased, and then energy from braking is transferred to the battery via

D2, as shown in

Figure 6.

3. Presentation of Regenerative Braking System

Equivalent circuits of the proposed inverter, PMSM, and HESP are shown in

Figure 7, where EMF

a, EMF

b, and EMF

c are the back-EMF shields of the a, b, and c phases, respectively. During the regenerative braking scenario, the DC link voltage undergoes amplification, leading to the accumulation of braking energy in the SC through

D3, followed by transfer to the battery through

D2 [

11].

During the braking scenario, six insulated gate bipolar transistors (IGBTs) are activated according to the rotor position sequence. This is determined through a Hall effect sensor. High-side half-bridge IGBT regenerative braking will not work, while the low-side switch is modulated through a proportional–integral (PI) controller.

Figure 8 shows the back-EMF waveforms, armature current, and switching patterns in the regenerative braking scenario.

This study involved an examination of the dynamic adhesive energy requirements for the battery electric vehicle powertrain with a foundation in vehicle kinematics including rolling resistance force, aerodynamic drag force, grading force, and wheel force.

Rolling resistance occurs while the tire is rolling. The rolling resistance force

FR is expressed as

where

Kr is the rolling resistance (vehicle), typical values are 0.007–0.015,

m is the mass of the vehicle (kg), and

g is the gravitational constant which is 9.807 (m/s

2) [

12].

Aerodynamic drag force inevitably comes into contact with aerodynamic drag (i.e., external flow and internal flow) during driving, and aerodynamic drag force (

FA) is expressed as [

12]

where

is the density of air (kg/m

3) depending on humidity, temperature, pressure, and altitude at sea level, the temperature is 25 °C, and the standard atmospheric pressure is 1013.25 pascals, where

is 1225 (kg/m

3),

Ca is the aerodynamic drag coefficient, the normal value is 0.25–0.35, A

e is the cross-sectional area of the vehicle (m

2),

vvehicle is the vehicle speed (m/s),

vwind is the wind speed (m/s) [

13].

The gradient force (

FG) acts parallel to the road due to the road inclination and is shown as

where

α is the angle between the road level and the horizontal plane of the vehicle (radians).

dv and

dh are the vertical distances and horizontal distances, respectively.

Wheel force

FW is the force exerted by the vehicle against the wheels to maintain speed and is expressed as

If

FW (

t) is positive, it will accelerate the car and, if it is negative, it destroys the regenerated force or frictional braking. The maximum traction (

Fmax) on the wheel is controlled by the normal force on the wheel (

FN) or by the coefficient of friction (

Cf) between the tire and the road, which is defined as

The wheel power (

Pw) can be determined by the product of traction force acting on the wheels (

Fw) and vehicle speed (

vvehicle).

The total energy available to the wheels can be determined by

The relationship between velocity and acceleration time is defined as follows:

Acceleration work

W =

FD, acceleration force

F =

ma, where the distance (

D) is in meters [

13]

In

Figure 9, the control arrangement for the RBS comprises both an ANN and a PI controller. Normally, during braking operations, the kinematic energy is progressively channeled to the SC and subsequently to the battery (i.e., HESP). However, the HESP rarely reaches its full capacity, making it impossible to add extra charges in exceptional cases. To counterbalance the surplus braking energy, the involvement of the rear-wheel mechanical brakes plays a vital role in distributing the braking force effectively [

12,

13,

14,

15]. In

Table 2 the characteristics of the battery electric vehicle and the driving simulation are presented.

The use of an ANN to enhance the performance of an RBS is an innovative approach to novel architecture. An ANN resembles the structure and functioning of the human brain, and it can learn complex patterns and relationships from data. Using an ANN to increase the efficiency of regenerative braking is a form of optimizing the energy recovery process during braking in vehicles.

Figure 10 shows that the RSB control mechanism incorporates an ANN-equipped three-layer multilayer perceptron (MLP) algorithmic scheme [

16]. This control mechanism adjusts the braking force between the front and rear wheels. The inputs encompass the vehicle speed, the states of charge (SOCs) for both the SC and the battery, and the number of braking times per driving cycle. The consequences of the ANN algorithmic scheme comprise the mechanical braking forces exerted on the front and rear wheels, along with the regenerative braking force applied to the front wheel. MATLAB was used to simulate braking force (i.e., rear–front, regenerative braking force) on all 522 input combinations. However, selecting a three-layer MLP of the artificial neural network will enable it to receive more data capacity. Support for a total of 522 inputs means the model can withstand a wide range of operating conditions and environmental factors that can affect the performance of an RBS, which can be adapted to various real-world situations effectively.

Figure 11 shows the simulated drivetrain configuration in MATLAB/SIMULINK R2016a. Meanwhile, the layer contained in the algorithmic framework contains 5 neurons with sigmoid activation functions as shown below.

The evaluation of the MLP algorithmic scheme equipped with the ANN involved the utilization of the NRMSE [

17,

18,

19,

20,

21,

22].

Table 3 delineates the drive cycle, a crucial factor ensuring the accuracy of simulation outcomes, particularly in braking scenarios.

where

S and

O are the estimated and target results, respectively, and

i is the data unit number. In this study, the NRMSE values were determined to be 0.015, 0.019, and 0.022 for the mechanical braking forces of the rear and front wheels, as well as regenerative braking force applied to the front wheel.

An ANN is a structure that generates braking force including rear, front, and force of regenerative braking, which causes the braking force on the front wheel to be converted into regenerated braking current (

I) as follows [

23,

24,

25,

26]:

The PI controller modulates the regenerative braking current through the utilization of the PWM duty cycle algorithm scheme, allowing the regenerated braking force to enable safe driving (

Figure 8).

To evaluate the overall performance of the RBS, the following equation was used:

In Equation (14),

n is the number of cars slowing or braking, ∆

ESupercapacitor is variation in the energy stored (SC module) before and after braking.

where ∆

EBattery is the accumulated energy (battery) under braking (J),

C is the module of supercapacitor capacity (Farad),

V1 and

V2 are the voltage of the SC module before and after braking, respectively.

where

R is battery charge resistance,

Vbattery is battery voltage,

ibattery is battery current,

t1 and

t2 are the starting and ending points of braking, and ∆

Ekinematic is the kinematic energy (J) with variation of the vehicle, shown as

where

m is vehicle mass,

v1 is speed of the vehicle before braking, and

v2 is speed of the vehicle after braking [

12].

4. Simulation and Experimental Results

In this study, simulations were conducted using MATLAB/SIMULINK for the proposed RBS program in the BMW X model. The simulations were performed for the EU legislative cycles (extra-urban drive cycle, EUDC) with a drive cycle distance of 6955.19 m and a total travel time of 408.25 s. The average speed per drive cycle was recorded as 62.6 km/h.

Table 4 shows the experiment’s statistical test before and after implementing an HESP-RBS in an EV. From the table data, it is found that the average driving distances and drive cycles of a traditional BEV are 245.46 km (~35 cycles), for an RBS-only battery they are 282.56 km (~40 cycles), and for the HESP-RBS they are 338.78 km (~48 cycles).

Table 5 presents the collated data for the simulated and experimental HESP consisting of an SC, NMC-lithium battery, three-phase PMSM, and on-board charger. In addition, to validate the model used in MATLAB/SIMULINK, a pilot program was made based on the performance of the speed test and speed reference with real vehicles (

Figure 12).

Table 6 shows the technical parameters of a three-phase permanent magnet synchronous motor, and

Table 7 represents the technical parameters of the controller in the HESP.

In

Figure 13, the simulated speed profiles of the HESP-RBS in battery electric vehicles are illustrated for a single drive cycle. Within this cycle, the vehicle underwent acceleration, reaching an initial constant speed of approximately 60 km/h for a duration of 145 s, after which it decelerated and came to an idle state. The second cycle commenced 50 s after the start, during which the vehicle reached and maintained a consistent speed of approximately 75 km/h for a duration of 190 s before transitioning into the deceleration phase. Following a 50 s interval, the third and fourth cycles were approximately 100 km/h (230 s) and 115 km/h (295 s), respectively. The final cycle was initiated, during which the vehicle was propelled to a steady speed of 140 km/h and maintained for a period of 350 s. In addition, motor torque profiles that correspond to the cycles were made. The highest motor torque recorded was approximately 390 N.m. across all three scenarios. The black-shaded regions indicate the regenerative braking energy that has been transferred and stored within the HESP. As the speed and the braking force of an EV increase, the kinetic energy of the vehicle will also increase. During braking the RBS captures the kinetic energy and converts it into electrical energy. Both increasing speed and braking force contribute to the improved performance of the RBS in an EV by providing more kinetic energy for regeneration. This observation underscores the efficacy of the suggested RBS control mechanism, as demonstrated in

Figure 8. The experimental results of the motor properties in

Figure 14 show the efficiency maps for all three motors in terms of torque–speed and planes with speed are highlighted in the torque velocity plane plot. In addition,

Figure 15 also shows the behavior of the torque velocity characteristics of the PMSM within its complete operating range.

The mechanism of braking force between the front and rear wheels using the RBS-equipped ANN was studied. From the comparison, the largest proportion of the total braking force is applied to the front wheels (i.e., regenerative and mechanical forces). During the acceleration of the vehicle, the SC module provides additional power to the battery.

Figure 16a,b illustrate the examination of the RBS control mechanism. The beginning state of charge (SOC) of the SC was set to be lower (89.8%) and higher (97.4%), with the highest safety at 97.6%, with corresponding battery SOCs of 82.7% and 83.4%, respectively. In

Figure 16a, the beginning SOC is below the highest safety standard. The regenerated energy of braking is transferred to the SC and, after reaching the 97.6% standard, is transferred to the battery. In

Figure 16b, the beginning SOC is above the highest safety standard, which allows regenerated braking energy to be transferred directly to storage in the battery. The energy transfer mechanism between the SC and battery in the HESP typically involves a control strategy aimed at optimizing the energy flow depending on factors such as energy demand, SOC of the components, and efficiency considerations. When the vehicle decelerates or brakes, kinetic energy is converted into electrical energy through regenerative braking. This energy is initially stored in the SC due to its high power density and ability to rapidly charge and discharge. Control algorithms monitor the SOC of both the SC and the battery. When the SC’s SOC is above a certain threshold or when power demand exceeds the supercapacitor’s capability, energy transfer occurs from the SC to the battery for long-term storage [

10].

Figure 17 shows the driving distance of the electric vehicle from the simulation using the EUDC driving pattern in a traditional BEV, RBS-only battery, and HESP-RBS.

Figure 18 illustrates the upcycling to a commercial-scale experimental arrangement of the RBS program, which includes the HESP, DC/DC chopper [

27,

28], and a three-phase PMSM. The specifications of these experimental components are provided in

Table 5.

The waveforms of the DC link voltage and current are shown in

Figure 19 under a regenerative braking condition in which the battery and SC are activated. When the brake is applied, the RBS mechanism is activated to control the DC link voltage. The regenerated current is transferred to the SC, and when the SC voltage exceeds the maximum safety standard (97.6%), the mechanism transfers the regenerated current to the battery.

As shown in

Figure 20a–c, the engagement of brakes led to a decrease in the back-EMFs, and the RBS control mechanism evenly allocated the braking force to the mechanical brakes of both the front and rear wheels.

In

Figure 21, the DC link voltage across different operating periods is 1.25, 2.50, and 3.75, resulting in the corresponding motor speeds of 2500, 3000, and 3500 rpm, respectively.

The experimental outcomes provide validation for the effectiveness of the proposed ANN-equipped RBS program in significantly improving regenerative braking energy. This is supported by the observed increase in travel distance, with electric vehicles with HESP-RBS achieving a longer distance of 338.78 km (48 cycles) which is an increase of 93.32 km (13 cycles) compared to the traditional BEV distance of 245.46 km (35 cycles). The HESP, which uses hybrid energy storage sources from the SC and battery based on the RBS, can significantly improve the driving efficiency of electric vehicles.

Table 8 compares the hybrid energy storage paradigm with the literature.