An Aero-Structural Model for Ram-Air Kite Simulations

Abstract

1. Introduction

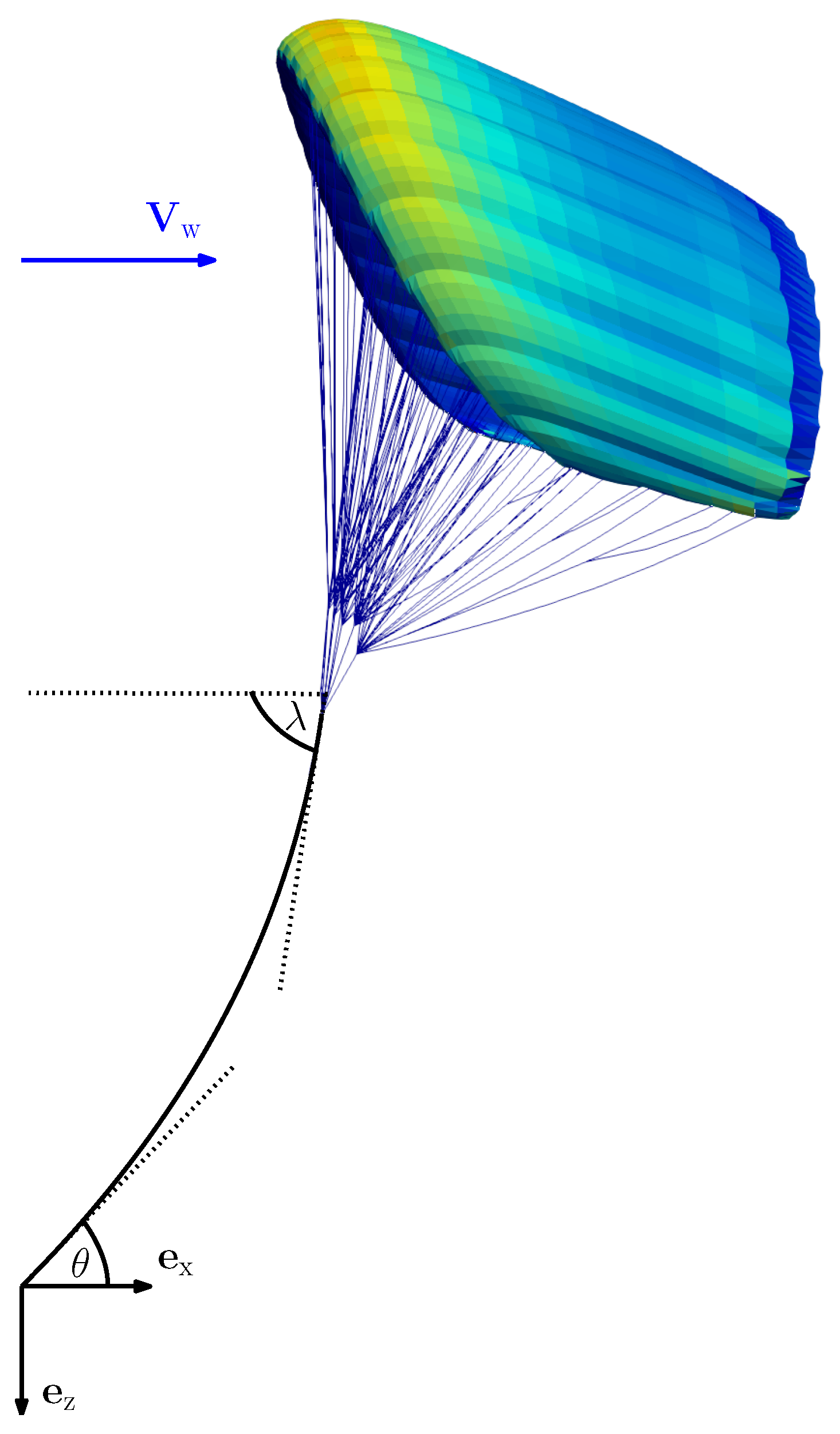

2. Methodology

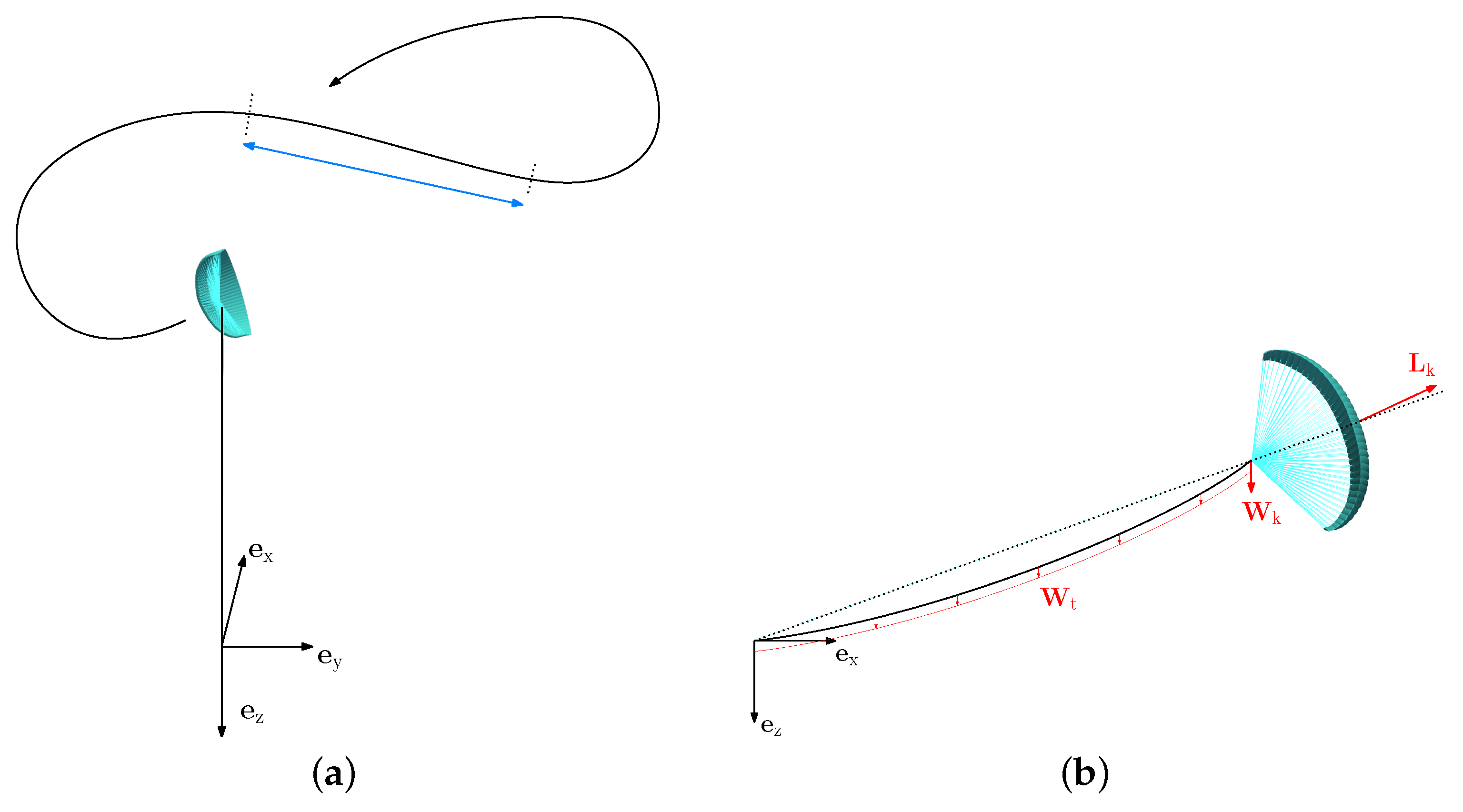

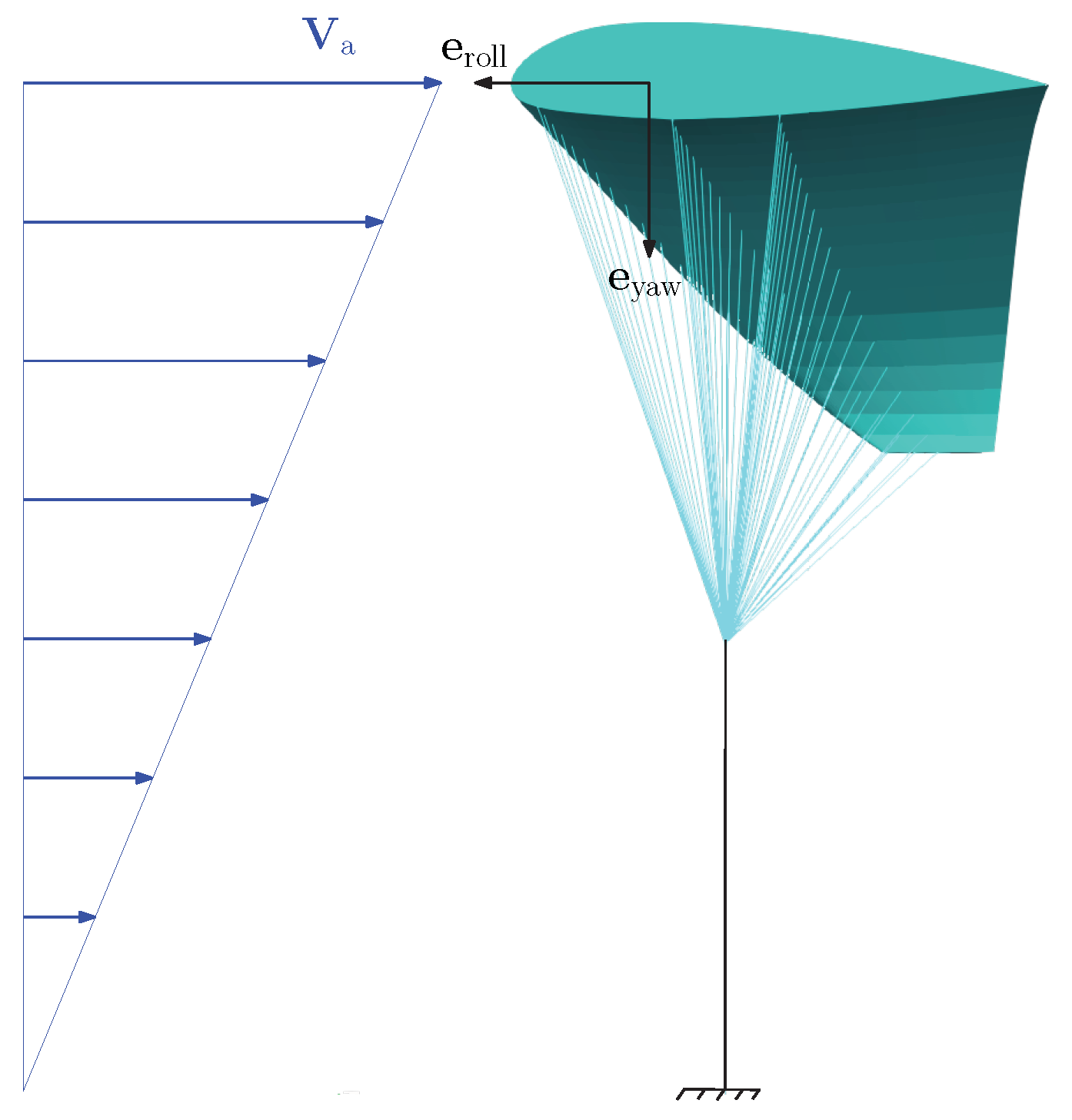

2.1. Simulation Setup–Virtual Wind Tunnel and Model Assumptions

2.2. Force Coefficients and Glide Ratio

2.3. Coupling Algorithm

| Algorithm 1 FSI coupling procedure. |

|

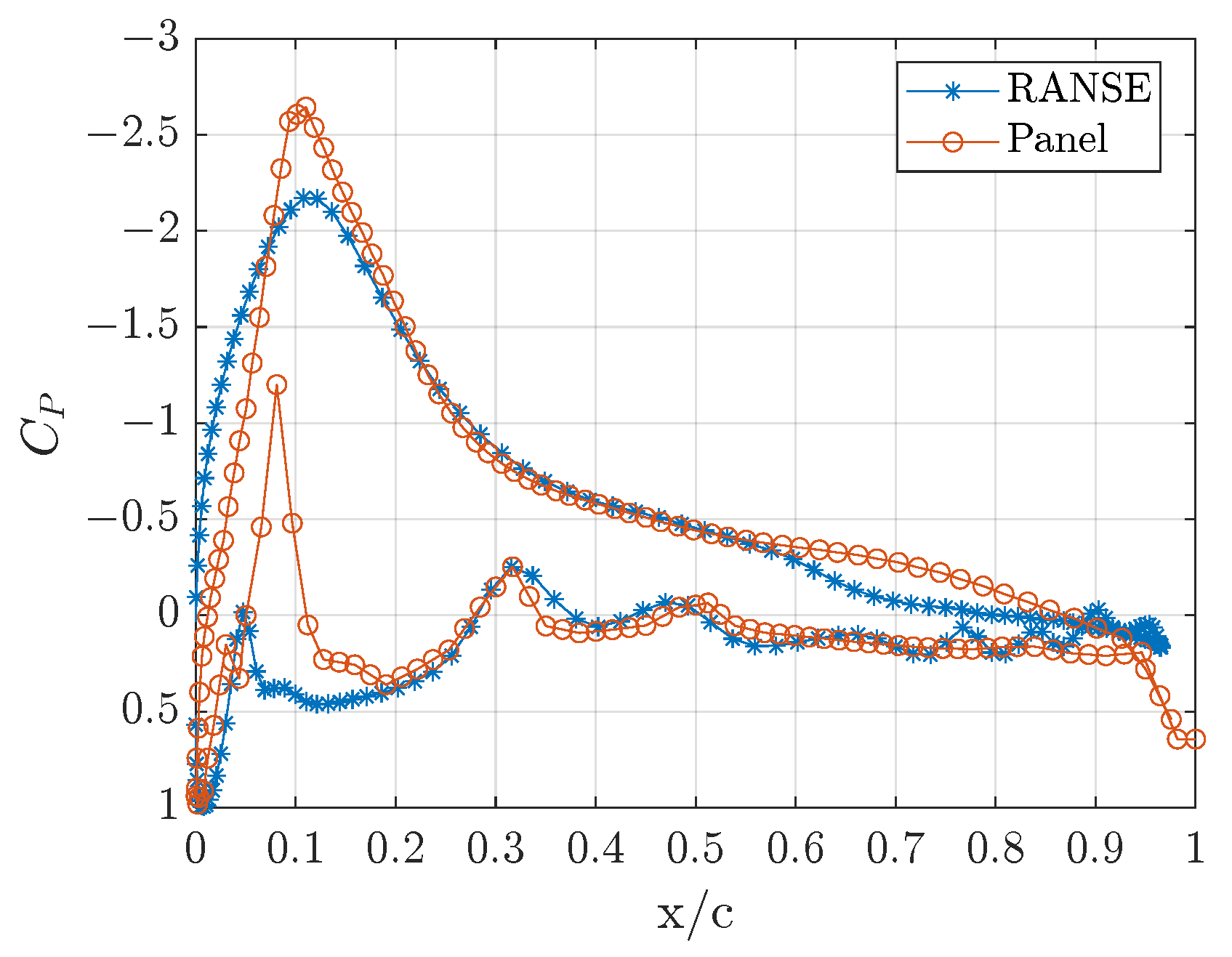

2.4. Solver Verification

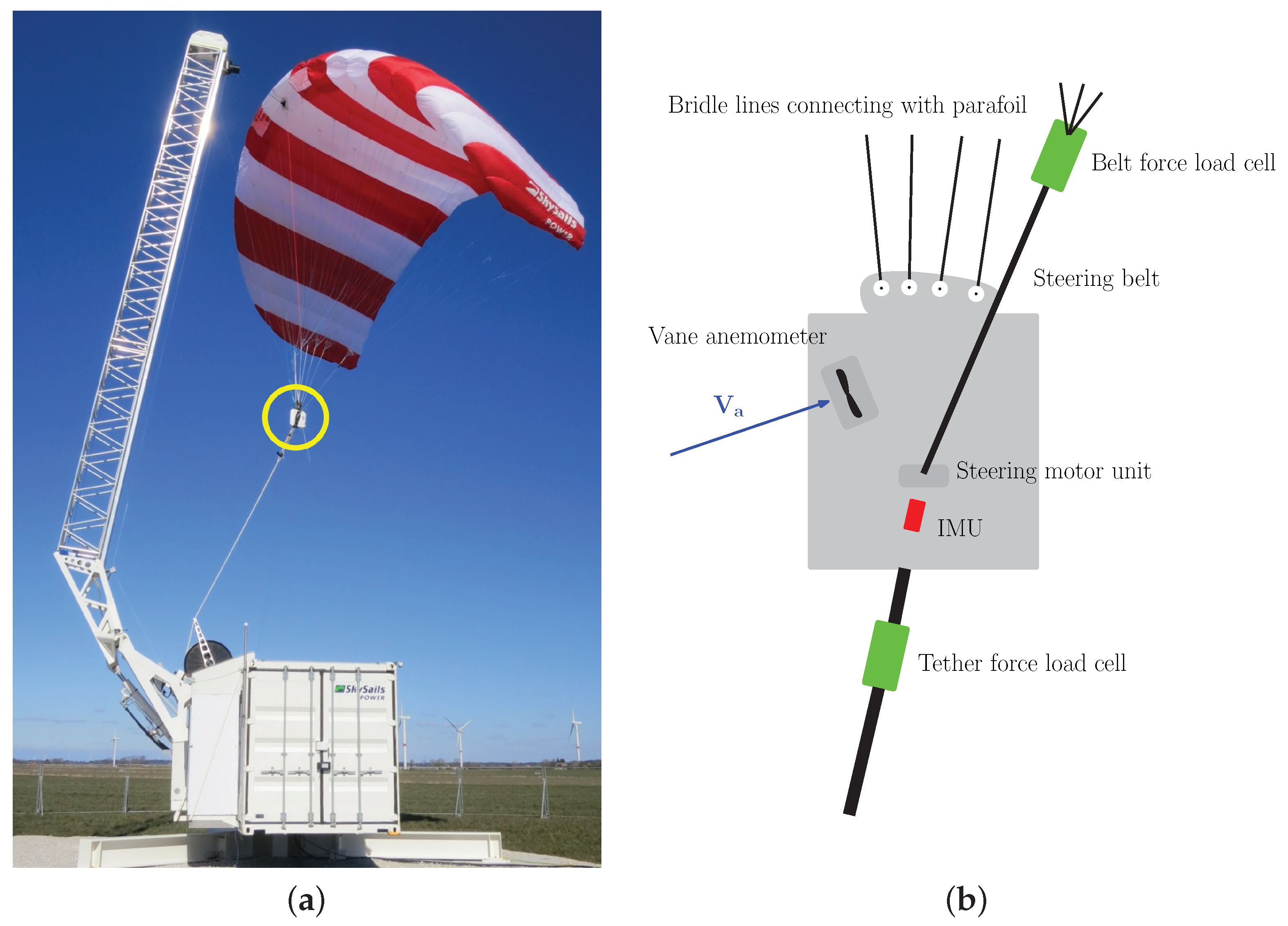

2.5. Measurement Setup, Data Acquisition, and Postprocessing

- The data were smoothed with a 3 s moving average to level out short-term fluctuations using the Matlab function movmean. It was found that this procedure provided a good smoothing behavior without influencing the measurement over a power cycle.

- The symmetry assumption of the parafoil was enforced by selecting only data points during the straight flight when the steering belt position was not further than 5 cm from the neutral position in both directions.

- To enforce the quasi-steady flight assumption, the magnitude of the measured acceleration during the flight was used to select data points which satisfied a g offset.

3. Results

3.1. Tether and Steering Belt Forces

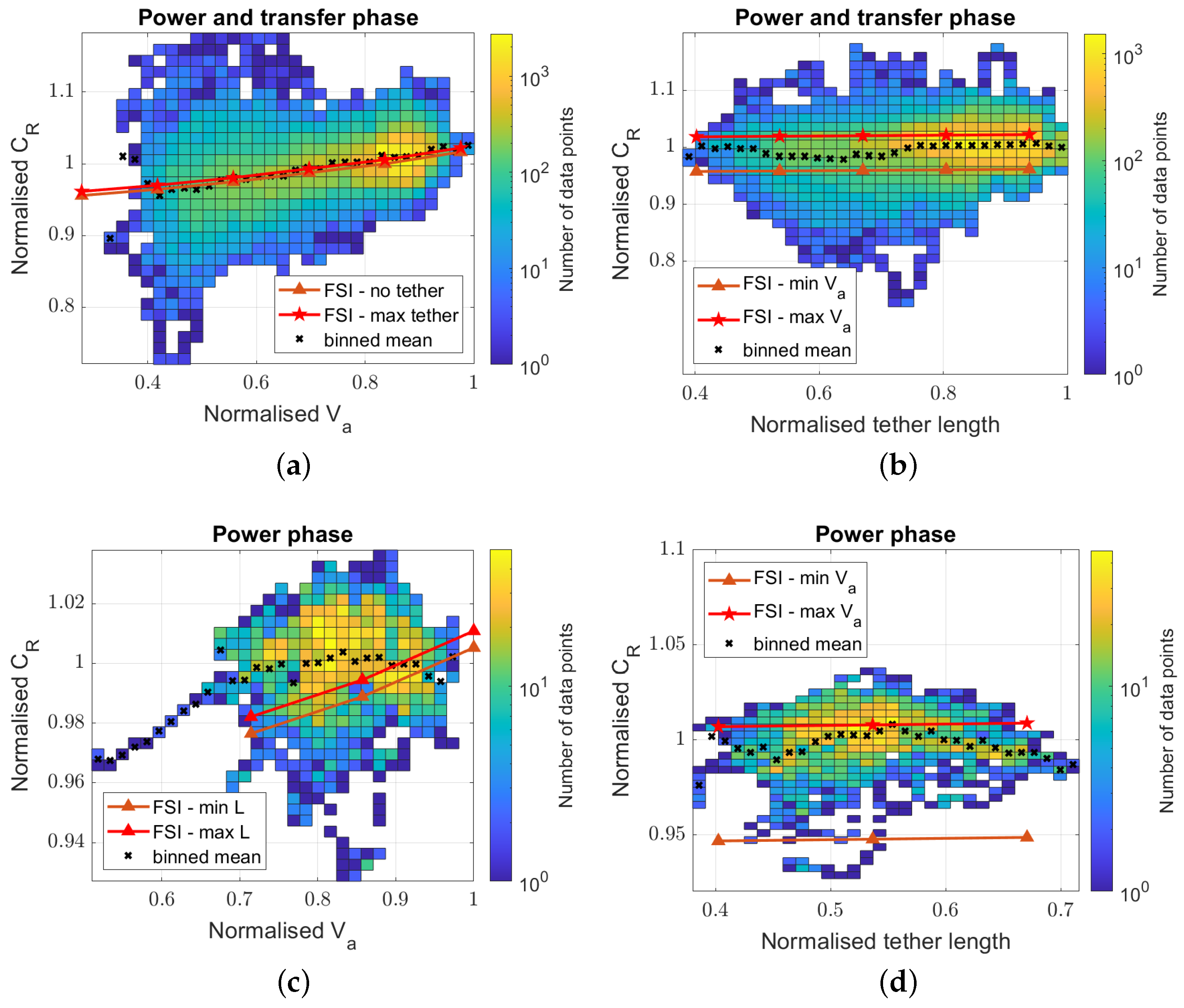

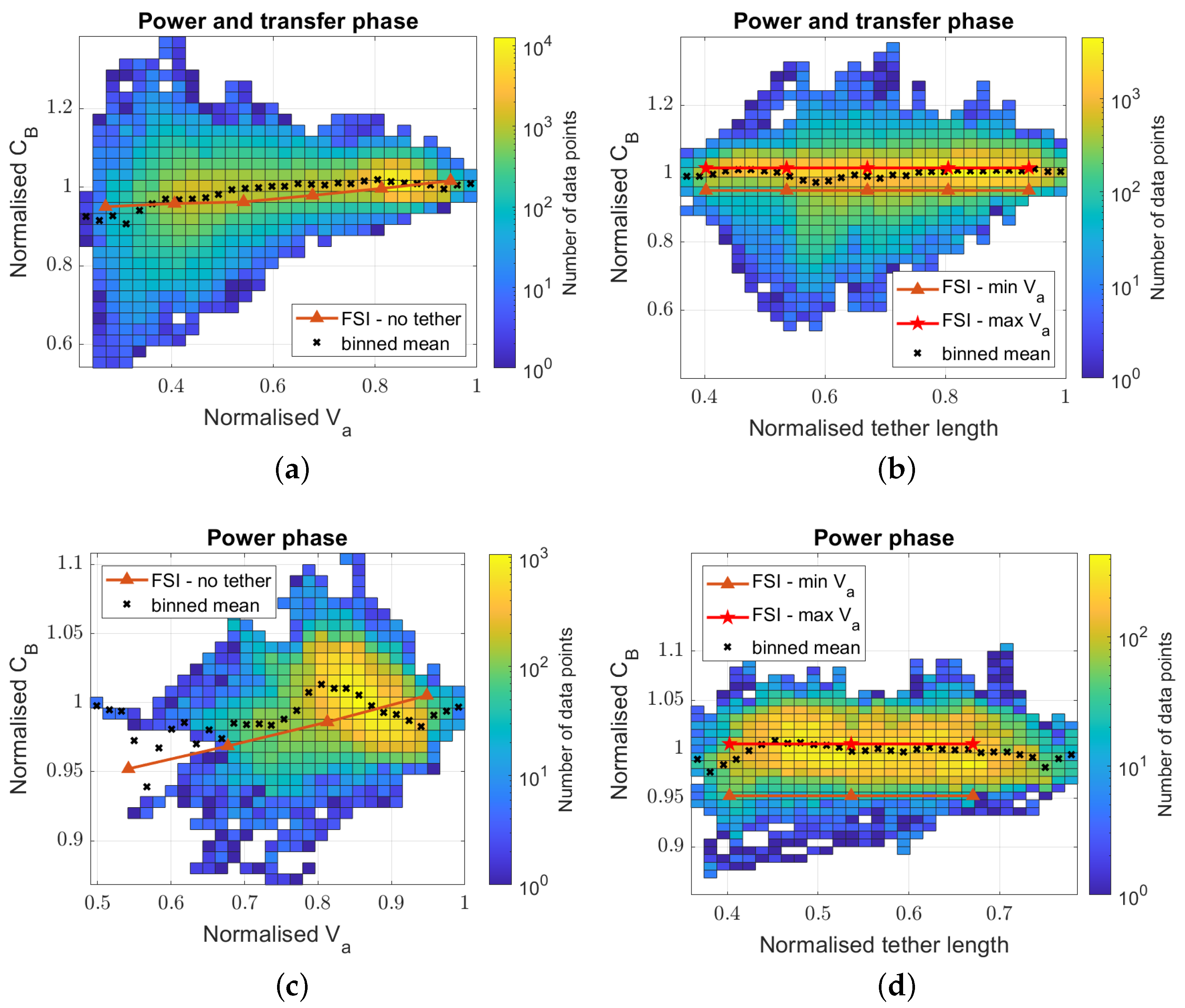

3.2. Tether and Belt Force Coefficients

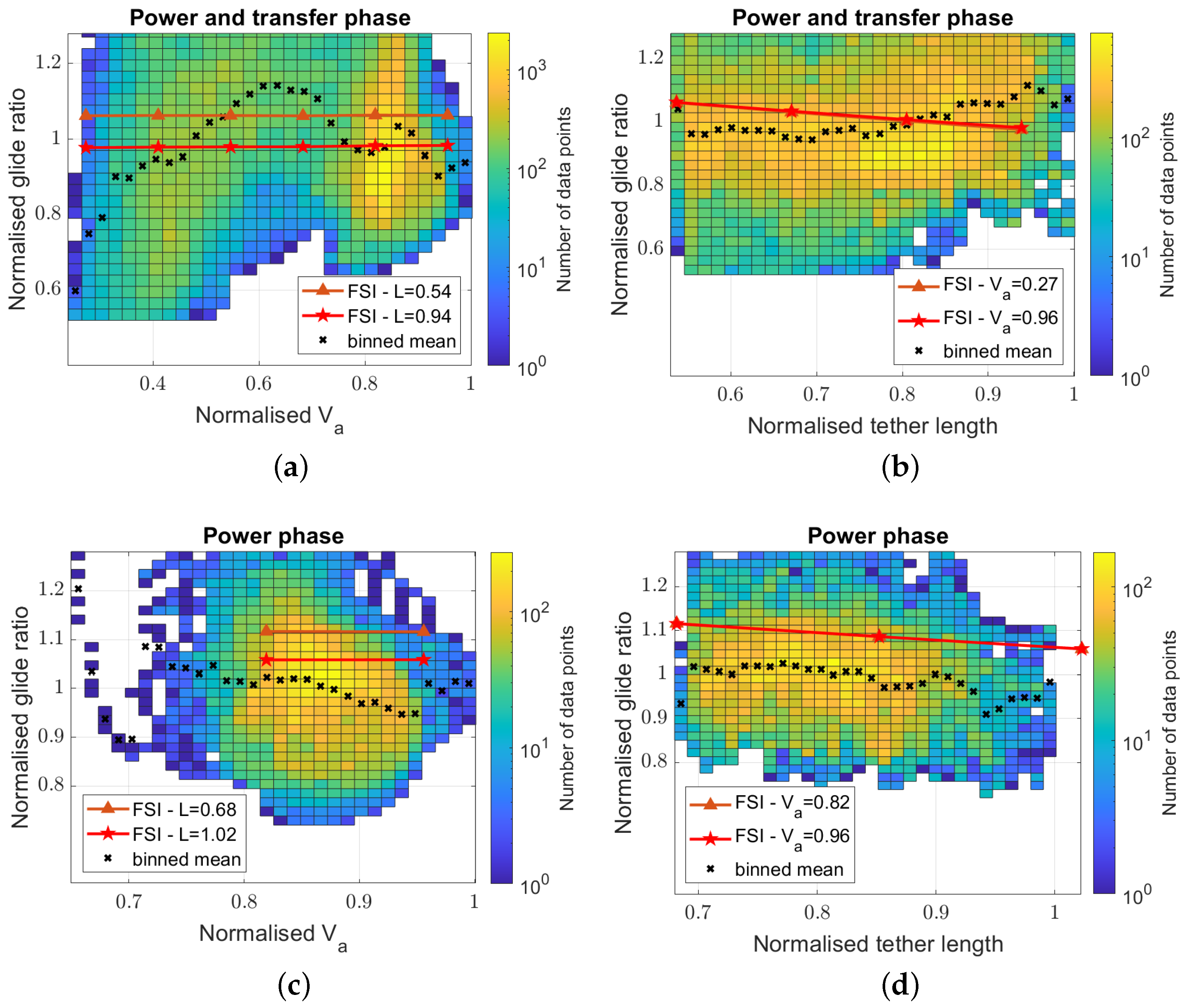

3.3. Glide Ratio

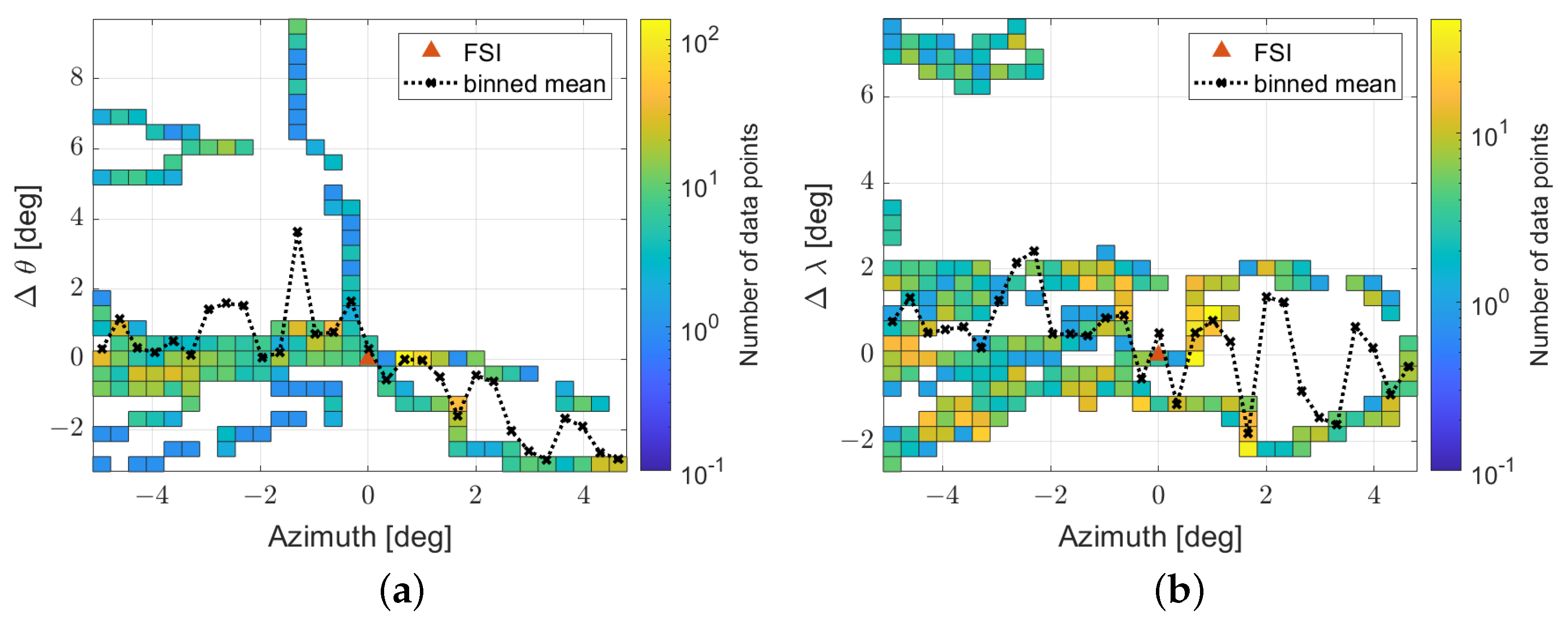

3.4. Neutral Flight

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- International Renewable Energy Agency (IRENA). Renewable Power Remains Cost-Competitive amid Fossil Fuel Crisis. Available online: https://www.irena.org/News/pressreleases/2022/Jul/Renewable-Power-Remains-Cost-Competitive-amid-Fossil-Fuel-Crisis (accessed on 13 January 2023).

- Weber, J.; Marquis, M.; Cooperman, A.; Draxl, C.; Hammond, R.; Jonkman, J.; Lemke, A.; Lopez, A.; Mudafort, R.; Optis, M.; et al. Airborne Wind Energy. Technical Report NREL/TP-5000-79992, National Renewable Energy Laboratory (NREL). 2021. Available online: https://www.nrel.gov/docs/fy21osti/79992.pdf (accessed on 1 February 2022).

- Argatov, I.; Rautakorpi, P.; Silvennoinen, R. Estimation of the mechanical energy output of the kite wind generator. Renew. Energy 2009, 34, 1525–1532. [Google Scholar] [CrossRef]

- Luchsinger, R.H. Pumping Cycle Kite Power. In Airborne Wind Energy; Ahrens, U., Diehl, M., Schmehl, R., Eds.; Green Energy and Technology; Springer: Berlin/Heidelberg, Germany, 2013; Chapter 3; pp. 47–64. [Google Scholar] [CrossRef]

- Erhard, M.; Strauch, H. A Simple Comprehensible Model of Tethered Kite Dynamics. In Airborne Wind Energy; Ahrens, U., Diehl, M., Schmehl, R., Eds.; Green Energy and Technology; Springer: Berlin/Heidelberg, Germany, 2013; Chapter 8; pp. 141–165. [Google Scholar] [CrossRef]

- van der Vlugt, R.; Bley, A.; Schmehl, R.; Noom, M. Quasi-Steady Model of a Pumping Kite Power System. Renew. Energy 2019, 131, 83–99. [Google Scholar] [CrossRef]

- Cherubini, A.; Papini, A.; Vertechy, R.; Fontana, M. Airborne Wind Energy Systems: A review of the technologies. Renew. Sustain. Energy Rev. 2015, 51, 1461–1476. [Google Scholar] [CrossRef]

- Vermillion, C.; Cobb, M.; Fagiano, L.; Leuthold, R.; Diehl, M.; Smith, R.S.; Wood, T.A.; Rapp, S.; Schmehl, R.; Olinger, D.; et al. Electricity in the air: Insights from two decades of advanced control research and experimental flight testing of airborne wind energy systems. Annu. Rev. Control 2021, 52, 330–357. [Google Scholar] [CrossRef]

- Paulig, X.; Bungart, M.; Specht, B. Conceptual Design of Textile Kites Considering Overall System Performance. In Airborne Wind Energy; Ahrens, U., Diehl, M., Schmehl, R., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 547–562. [Google Scholar] [CrossRef]

- Dunker, S. Ram-Air Wing Design Considerations for Airborne Wind Energy. In Airborne Wind Energy; Ahrens, U., Diehl, M., Schmehl, R., Eds.; Green Energy and Technology; Springer: Berlin/Heidelberg, Germany, 2013; pp. 517–546. [Google Scholar] [CrossRef]

- Desabrais, K.J.; Bergeron, K.; Nyren, D.; Johari, H. Aerodynamic investigations of a ram-air parachute canopy and an airdrop system. In Proceedings of the 23rd AIAA Aerodynamic Decelerator Systems Technology Conference, Daytona Beach, FL, USA, 30 March–2 April 2015; pp. 1–17. [Google Scholar] [CrossRef]

- Benedetti, D.M.; Veras, C.A.G. Wind-Tunnel Measurement of Differential Pressure on the Surface of a Dynamically Inflatable Wing Cell. Aerospace 2020, 8, 34. [Google Scholar] [CrossRef]

- Thedens, P.; Oliveira, G.; Schmehl, R. Ram-Air Kite Airfoil and Reinforcements Optimization for Airborne Wind Energy Applications. Wind Energy 2019, 22, 653–665. [Google Scholar] [CrossRef]

- Ortega, E.; Flores, R.; Pons-Prats, J. Ram-air parachute simulation with panel methods and staggered coupling. J. Aircr. 2017, 54, 807–814. [Google Scholar] [CrossRef]

- Fogell, N.A.T. Fluid-Structure Interaction Simulation of the Inflated Shape of Ram-Air Parachutes. Ph.D. Thesis, Imperial College London, London, UK, 2014. [Google Scholar] [CrossRef]

- Fogell, N.A.; Iannucci, L.; Bergeron, K. Fluid-structure interaction simulation study of a semi-rigid ram-air parachute model. In Proceedings of the 24th AIAA Aerodynamic Decelerator Systems Technology Conference, Denver, CO, USA, 5–9 June 2017; p. 3547. [Google Scholar] [CrossRef]

- Lolies, T.; Gourdain, N.; Charlotte, M.; Belloc, H.; Goldsmith, B. Numerical Methods for Efficient Fluid–Structure Interaction Simulations of Paragliders. Aerotec. Missili Spaz. 2019, 98, 221–229. [Google Scholar] [CrossRef]

- Folkersma, M.; Schmehl, R.; Viré, A. Steady-state aeroelasticity of a ram-air wing for airborne wind energy applications. J. Phys. Conf. Ser. 2020, 1618, 032018. [Google Scholar] [CrossRef]

- Thedens, P. mem4py Repository. Available online: https://github.com/pthedens/mem4py (accessed on 1 February 2023).

- Thedens, P. An Integrated Aero-Structural Model for Ram-Air Kite Simulations with Application to Airborne Wind Energy. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2022. [Google Scholar] [CrossRef]

- Fagiano, L.; Quack, M.; Bauer, F.; Carnel, L.; Oland, E. Autonomous Airborne Wind Energy Systems: Accomplishments and Challenges. Annu. Rev. Control Robot. Auton. Syst. 2022, 5, 603–631. [Google Scholar] [CrossRef]

- Schmehl, R.; Noom, M.; van der Vlugt, R. Traction Power Generation with Tethered Wings. In Airborne Wind Energy; Ahrens, U., Diehl, M., Schmehl, R., Eds.; Green Energy and Technology; Springer: Berlin/Heidelberg, Germany, 2013; Chapter 2; pp. 23–45. [Google Scholar] [CrossRef]

- Dunker, S. Tether and Bridle Line Drag in Airborne Wind Energy Applications. In Airborne Wind Energy; Schmehl, R., Ed.; Green Energy and Technology; Springer: Singapore, 2018; pp. 29–56. [Google Scholar] [CrossRef]

- Filković, D. Apame—Aircraft 3D Panel Method. Available online: https://www.3dpanelmethod.com (accessed on 1 June 2022).

- Barnes, M.R. Form-finding and analysis of prestressed nets and membranes. Comput. Struct. 1988, 30, 685–695. [Google Scholar] [CrossRef]

- Barnes, M.R. Form finding and analysis of tension structures by dynamic relaxation. Int. J. Space Struct. 1999, 14, 89–104. [Google Scholar] [CrossRef]

- Jarasjarungkiat, A.; Wüchner, R.; Bletzinger, K.U. A wrinkling model based on material modification for isotropic and orthotropic membranes. Comput. Methods Appl. Mech. Eng. 2008, 197, 773–788. [Google Scholar] [CrossRef]

- Bungartz, H.J.; Lindner, F.; Gatzhammer, B.; Mehl, M.; Scheufele, K.; Shukaev, A.; Uekermann, B. preCICE—A fully parallel library for multi-physics surface coupling. Comput. Fluids 2016, 141, 250–258. [Google Scholar] [CrossRef]

- Oehler, J.; Schmehl, R. Aerodynamic Characterization of a Soft Kite by in Situ Flow Measurement. Wind. Energy Sci. 2019, 4, 1–21. [Google Scholar] [CrossRef]

- Erhard, M.; Strauch, H. Automatic Control of Pumping Cycles for the SkySails Prototype in Airborne Wind Energy. In Airborne Wind Energy: Advances in Technology Development and Research; Schmehl, R., Ed.; Springer: Singapore, 2018; pp. 189–213. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thedens, P.; Schmehl, R. An Aero-Structural Model for Ram-Air Kite Simulations. Energies 2023, 16, 2603. https://doi.org/10.3390/en16062603

Thedens P, Schmehl R. An Aero-Structural Model for Ram-Air Kite Simulations. Energies. 2023; 16(6):2603. https://doi.org/10.3390/en16062603

Chicago/Turabian StyleThedens, Paul, and Roland Schmehl. 2023. "An Aero-Structural Model for Ram-Air Kite Simulations" Energies 16, no. 6: 2603. https://doi.org/10.3390/en16062603

APA StyleThedens, P., & Schmehl, R. (2023). An Aero-Structural Model for Ram-Air Kite Simulations. Energies, 16(6), 2603. https://doi.org/10.3390/en16062603