Modelling the Reliability of Logistics Flows in a Complex Production System

Abstract

:1. Introduction

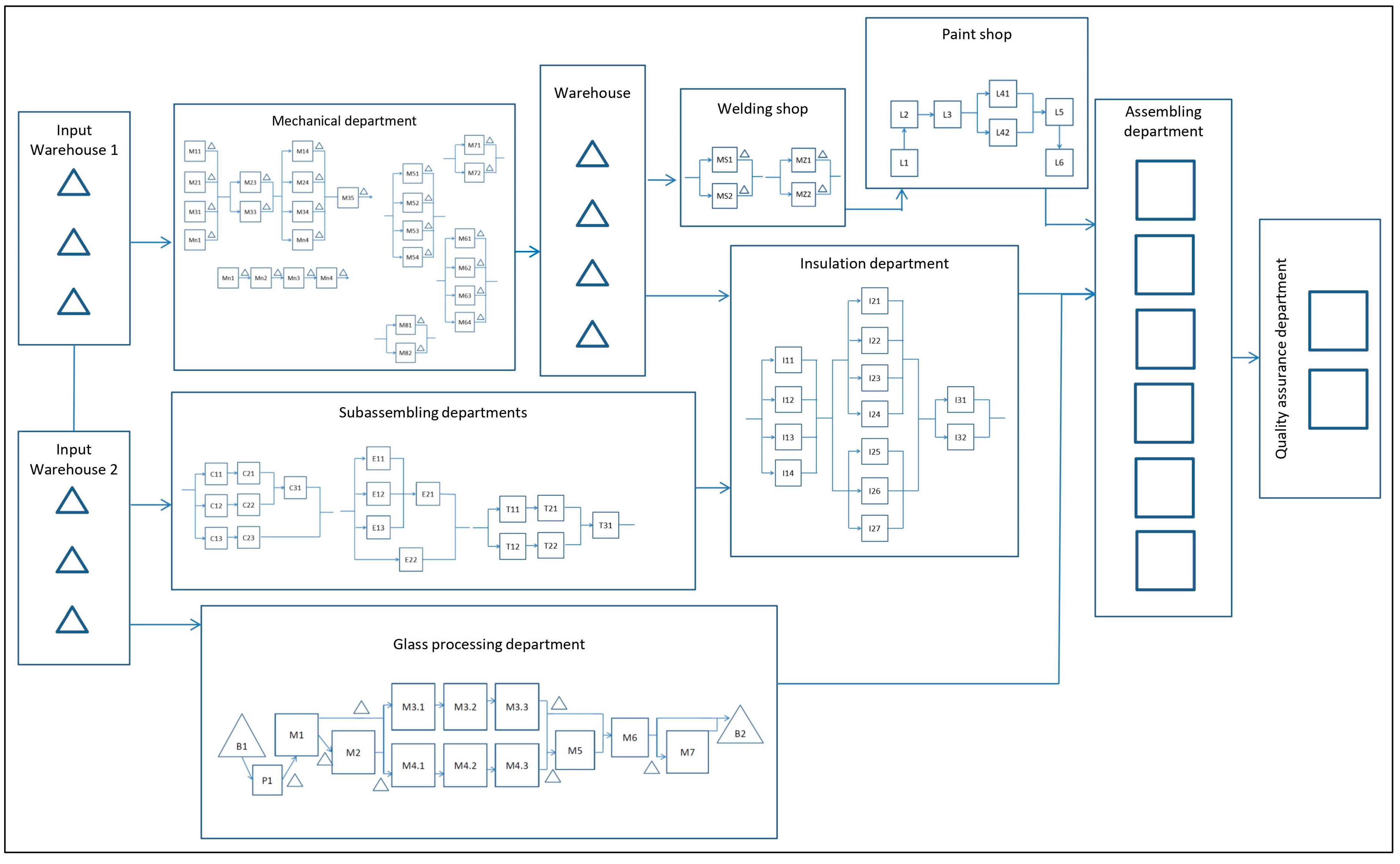

2. Materials and Methods

- Formalization of quasi-coherence at the first decomposition level—the level of separated departments: , where .

- Formalization of quasi-coherence at the second level of decomposition—the level of separated machines: , where can be equal:

- -

- Multi-stream case: for a given machine numbered where , there is quasi-coherence for with determined and ;

- -

- Stream case: for a given machine numbered , where , where is the beginning machine of the chain , there is quasi-coherence for a particular .

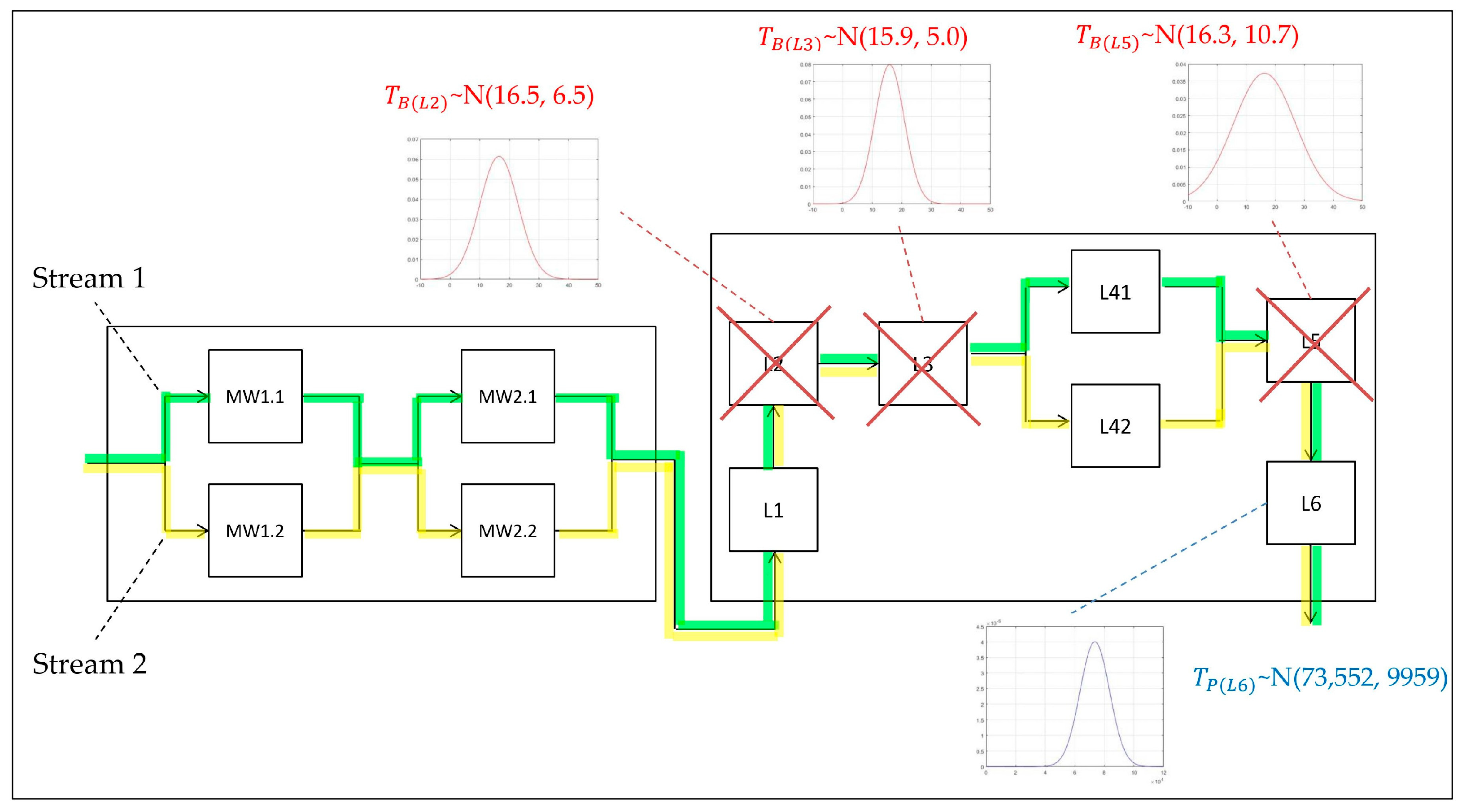

3. Methodology for the Class of Production Systems Chosen for Consideration

3.1. Exemplification of the Method When Using Gaussian Distribution for the Random Variables of Duration of Proper Operation and Duration of Breakdown

- -

- For MTTR, a set of durations of breakdowns or any type of downtime of a line or individual machine;

- -

- For MTTF, a set of durations of correct operation between elementary stops;

- -

- For MTBF, a set of durations between events of individual downtimes.

3.2. Exemplification of the Method When Using the Family of Gamma Distributions for the Random Variables of Duration of Proper Operation and Duration of Breakdown

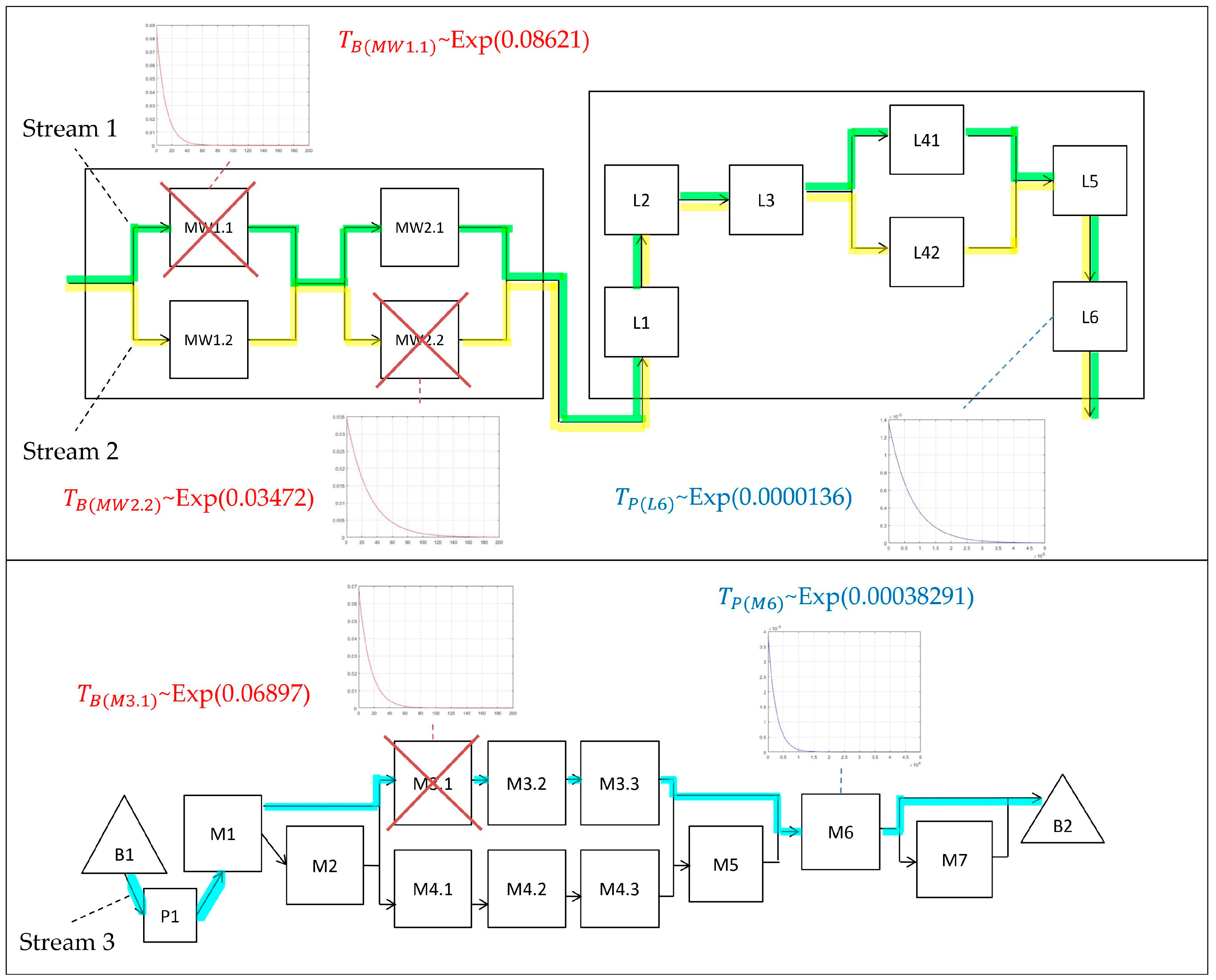

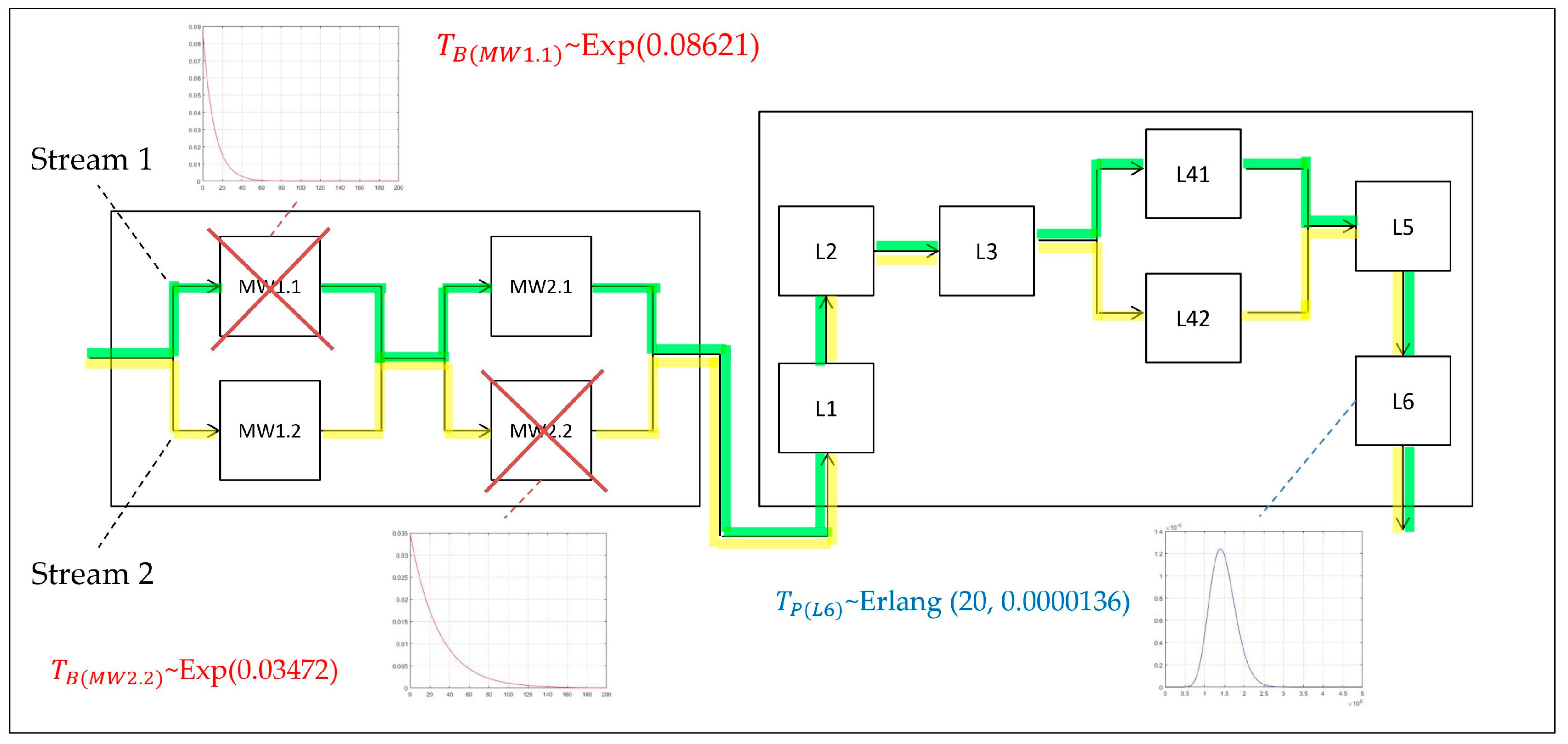

- Exponential distribution for and ;

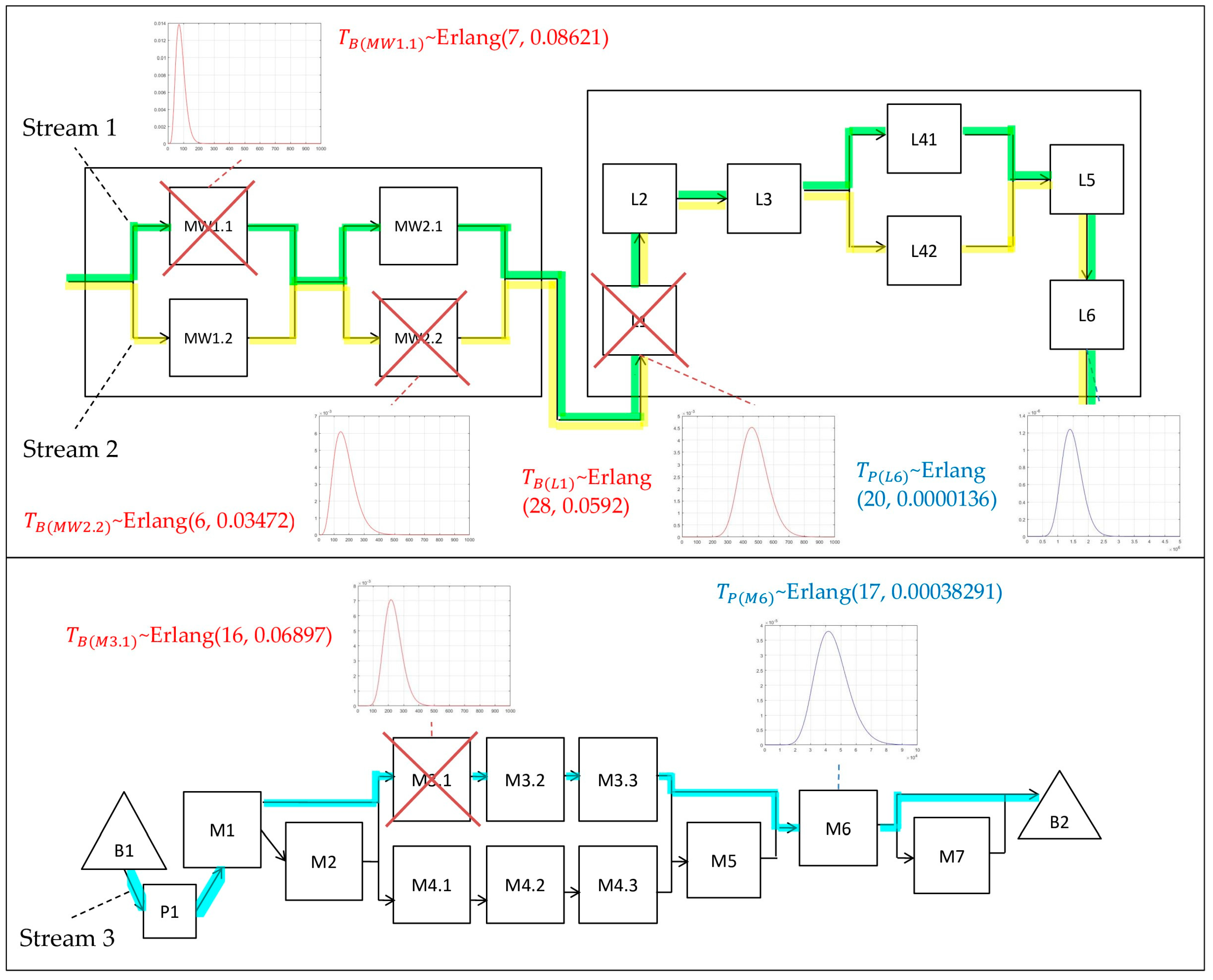

- Erlang distribution for and ;

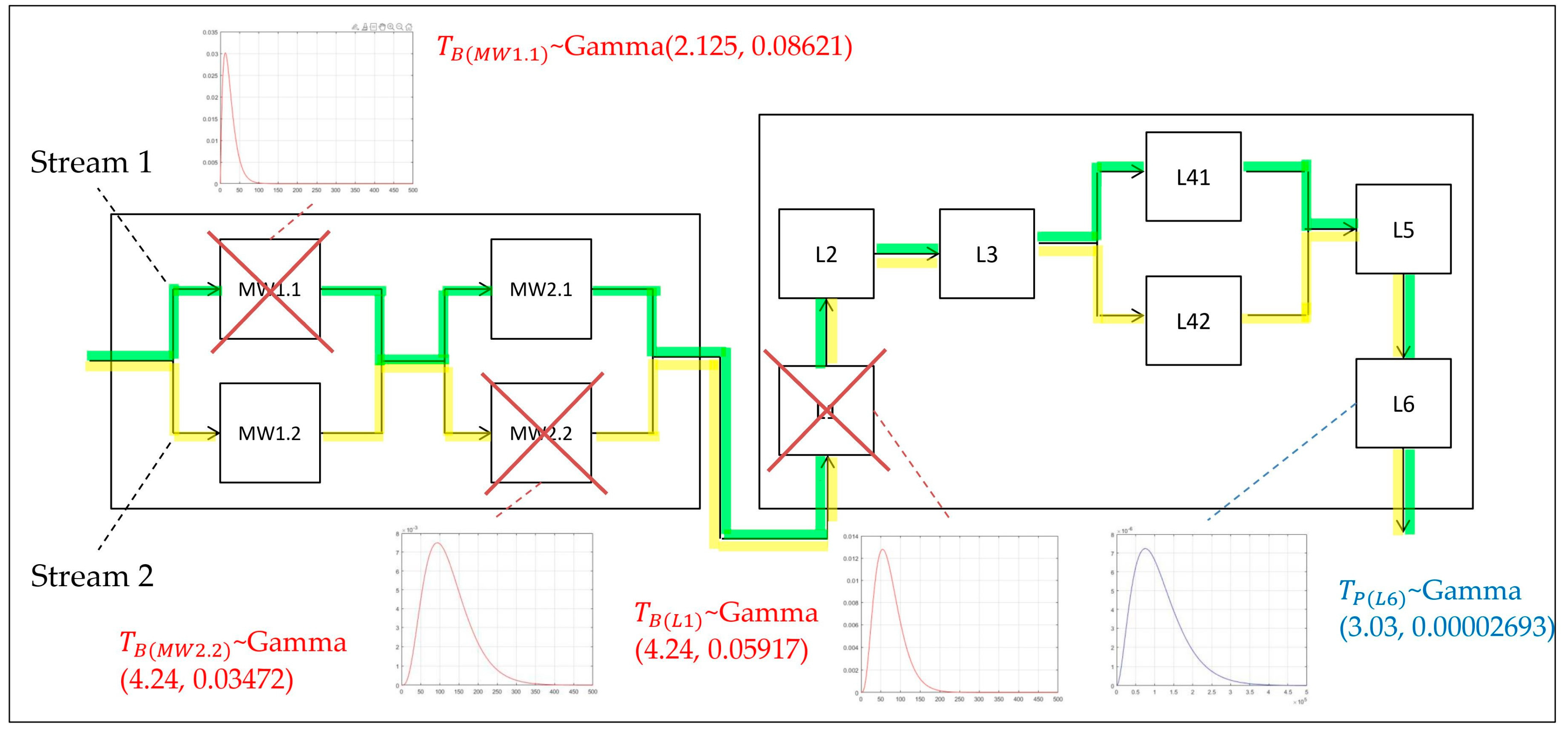

- Gamma distribution for and .

3.2.1. The Case of Using an Exponential Distribution for the Random Variables of Duration of Proper Operation and Duration of Breakdown

3.2.2. The Case of Using an Erlang Distribution for the Random Variables of Duration of Proper Operation and Duration of Breakdown

- The supply subsystem of the automatic paint shop line:

- -

- The highest energy demand in the line is for the furnace; hence, the reference to the correct operation duration of this module is ;

- -

- One type of failure occurring on three different machines belonging to three different relation chains was assumed, where for each object at a given the following was calculated: ; ; .

- The subsystem of the glass tempering line:

- -

- The mean time of the correct operation of the glass tempering furnace is ;

- -

- The mean time of one type of failure of a machine belonging to the chain of relations supplying the furnace is .

- -

- —;

- -

- —;

- -

- —

3.2.3. Gamma Distribution Use Case for and

4. Results and Discussion of Future Studies

5. Conclusions

- -

- and , and then the random variable of difference ;

- -

- and ;

- -

- and ;

- -

- and ;

- -

- and .

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sumant, K.B.; Sushil. Environmental uncertainty, leadership and organisation culture as predictors of strategic knowledge management and flexibility. Int. J. Knowl. Manag. 2020, 11, 393–407. [Google Scholar] [CrossRef]

- Maarof, M.; Nawanir, G.; Fakhrul, M. The Concepts and Determinants of Manufacturing Flexibility. In Enabling Industry 4.0 through Advances in Manufacturing and Materials; Lecture Notes in Mechanical Engineering; Springer: Singapore, 2022; pp. 189–197. [Google Scholar] [CrossRef]

- Vanichchinchai, A. The effects of the Toyota Way on agile manufacturing: An empirical analysis. J. Manuf. Technol. Manag. 2022, 33, 1450–1472. [Google Scholar] [CrossRef]

- Miroshnychenko, I.; Strobl, S.; Matzler, K.; De Massis, A. Absorptive capacity, strategic flexibility, and business model innovation: Empirical evidence from Italian SMEs. J. Bus. Res. 2021, 130, 670–682. [Google Scholar] [CrossRef]

- Enrique, D.V.; Marcon, É.; Charrua-Santos, F.; Frank, A.G. Industry 4.0 enabling manufacturing flexibility: Technology contributions to individual resource and shop floor flexibility. J. Manuf. Technol. Manag. 2022, 33, 853–875. [Google Scholar] [CrossRef]

- Pinheiro, J.; Lages, L.F.; Silva, G.M.; Dias, A.L.; Preto, M.T. Effects of absorptive capacity and innovation spillover on manufacturing flexibility. Int. J. Product. Perform. Manag. 2022, 71, 1786–1809. [Google Scholar] [CrossRef]

- Wallner, B.; Trautner, T.; Pauker, F.; Kittl, B. Evaluation of process control architectures for agile manufacturing systems. Procedia CIRP 2021, 99, 680–685. [Google Scholar] [CrossRef]

- Höse, K.; Amaral, A.; Götze, U.; Peças, P. Manufacturing Flexibility through Industry 4.0 Technological Concepts—Impact and Assessment. Glob. J. Flex. Syst. Manag. 2023, 24, 271–289. [Google Scholar] [CrossRef]

- Ding, B.; Hernández, X.F.; Jané, N.A. Combining lean and agile manufacturing competitive advantages through Industry 4.0 technologies: An integrative approach. Prod. Plan. Control 2023, 34, 442–458. [Google Scholar] [CrossRef]

- Romana, F.A.; Gestoso, C.G. Economic performance and the implementation of lean management model. Econ. Financ. 2023, 11, 13–23. Available online: https://economics-and-finance.com/files/archive/EF_2023_1(13-23).pdf (accessed on 15 September 2023). [CrossRef]

- Yadav, G.; Luthra, S.; Huisingh, D.; Mangla, S.K.; Narkhede, B.E.; Liu, Y. Development of a lean manufacturing framework to enhance its adoption within manufacturing companies in developing economies. J. Clean. Prod. 2020, 245, 118726. [Google Scholar] [CrossRef]

- Enrique, D.V.; Druczkoski, J.C.M.; Lima, T.M.; Charrua-Santos, F. Advantages and difficulties of implementing Industry 4.0 technologies for labor flexibility. Procedia Comput. Sci. 2021, 181, 347–352. [Google Scholar] [CrossRef]

- Buer, S.-V.; Semini, M.; Strandhagen, J.O.; Sgarbossa, F. The complementary effect of lean manufacturing and digitalisation on operational performance. Int. J. Prod. Res. 2021, 59, 1976–1992. [Google Scholar] [CrossRef]

- Cañas, H.; Mula, J.; Díaz-Madroñero, M.; Campuzano-Bolarín, F. Implementing Industry 4.0 principles. Comput. Ind. Eng. 2021, 158, 107379. [Google Scholar] [CrossRef]

- Margherita, E.G.; Braccini, A.M. Industry 4.0 Technologies in Flexible Manufacturing for Sustainable Organizational Value: Reflections from a Multiple Case Study of Italian Manufacturers. Inf. Syst. Front. 2023, 25, 995–1016. [Google Scholar] [CrossRef]

- Pozzi, R.; Rossi, T.; Secchi, R. Industry 4.0 technologies: Critical success factors for implementation and improvements in manufacturing companies. Prod. Plan. Control 2023, 34, 139–158. [Google Scholar] [CrossRef]

- Valamede, L.S.; Akkari, A.C.S. Lean 4.0: A New Holistic Approach for the Integration of LeanManufacturing Tools and Digital Technologies. Int. J. Math. Eng. Manag. Sci. 2020, 5, 851–868. [Google Scholar] [CrossRef]

- Ejsmont, K.; Gladysz, B.; Corti, D.; Castaño, F.; Mohammed, W.M.; Martinez Lastra, J.L. Towards ‘Lean Industry 4.0’—Current trends and future perspectives. Cogent Bus. Manag. 2020, 7, 1781995. [Google Scholar] [CrossRef]

- Wiercioch, J. Development of a hybrid predictive maintenance model. J. KONBiN 2023, 53, 141–157. [Google Scholar] [CrossRef]

- Yürekli, S.; Schulz, C. Compatibility, opportunities and challenges in the combination of Industry 4.0 and Lean Production. Logist. Res. 2022, 15, 14. Available online: https://www.bvl.de/files/1951/1988/1852/2913/10.23773_2022_9.pdf (accessed on 5 October 2023).

- Khin, S.; Kee, D.M.H. Factors influencing Industry 4.0 adoption. J. Manuf. Technol. Manag. 2022, 33, 448–467. [Google Scholar] [CrossRef]

- Kumar, S.; Suhaib, M.; Asjad, M. Industry 4.0: Complex, disruptive, but inevitable. Manag. Prod. Eng. Rev. 2020, 11, 43–51. [Google Scholar] [CrossRef]

- Masood, T.; Sonntag, P. Industry 4.0: Adoption challenges and benefits for SMEs. Comput. Ind. 2020, 121, 103261. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, K.; Jain, S.K. Agility enhancement through agile manufacturing implementation: A case study. TQM J. 2022, 34, 1527–1546. [Google Scholar] [CrossRef]

- Büchi, G.; Cugno, M.; Castagnoli, R. Smart factory performance and Industry 4.0. Technol. Forecast. Soc. Change 2020, 150, 119790. [Google Scholar] [CrossRef]

- Qamar, A.; Hall, M.A.; Chicksand, D.; Collinson, S. Quality and flexibility performance trade-offs between lean and agile manufacturing firms in the automotive industry. Prod. Plan. Control 2020, 31, 723–738. [Google Scholar] [CrossRef]

- Frąś, J.; Frąś, M. Methods and tools of machines maintenance management in a modern production system. Probl. Nauk Stosow. 2018, 8, 69–80. [Google Scholar]

- Zwolińska, B.; Tubis, A.A.; Chamier-Gliszczyński, N.; Kostrzewski, M. Personalization of the MES System to the Needs of Highly Variable Production. Sensors 2020, 20, 6484. [Google Scholar] [CrossRef] [PubMed]

- Sangwa, N.R.; Sangwan, K.S. Continuous Kaizen implementation to improve leanness: A case study of Indian automotive assembly line. In Enhancing Future Skills and Entrepreneurship, 3rd Indo-German Conference on Sustainability in Engineering; Chapter 6; Sangwan, K.S., Herrmann, C., Eds.; Springer: Cham, Switzerland, 2020; pp. 51–70. [Google Scholar] [CrossRef]

- Palange, A.; Dhatrak, P. Lean manufacturing a vital tool to enhance productivity in manufacturing. Mater. Today Proc. 2021, 46, 729–736. [Google Scholar] [CrossRef]

- Romana, F.A. Impact Assessment on the Economic and Financial Indicators of the Implementation of Lean Management Model. J. Intercult. Manag. 2020, 2, 49–69. [Google Scholar] [CrossRef]

- Jamwal, A.; Agrawal, R.; Sharma, M.; Giallanza, A. Industry 4.0 Technologies for Manufacturing Sustainability: A Systematic Review and Future Research Directions. Appl. Sci. 2021, 11, 5725. [Google Scholar] [CrossRef]

- Shi, Z.; Xie, Y.; Xue, W.; Chen, Y.; Fu, L.; Xu, X. Smart factory in Industry 4.0. Syst. Res. Behav. Sci. 2020, 37, 607–617. [Google Scholar] [CrossRef]

- Attiany, M.; Al-kharabsheh, S.; Al-Makhariz, l.; Abed-Qader, M.; Al-Hawary, S.; Mohammad, A.; Rahamneh, A. Barriers to adopt industry 4.0 in supply chains using interpretive structural modeling. Uncertain Supply Chain Manag. 2023, 11, 299–306. [Google Scholar] [CrossRef]

- Banáš, D.; Hrablik Chovanová, H. Agile Manufacturing vs. Lean Manufacturing. Res. Pap. Fac. Mater. Sci. Technol. Trnava 2023, 31, 58–67. [Google Scholar] [CrossRef]

- Dos Santos, L.M.A.L.; da Costa, M.B.; Kothe, J.V.; Benitez, G.B.; Schaefer, J.L.; Baierle, I.C.; Nara, E.O.B. Industry 4.0 collaborative networks for industrial performance. J. Manuf. Technol. Manag. 2020, 32, 245–265. [Google Scholar] [CrossRef]

- Hughes, L.; Dwivedi, Y.K.; Rana, N.P.; Williams, M.D.; Raghavan, V. Perspectives on the future of manufacturing within the Industry 4.0 era. Prod. Plan. Control 2022, 33, 138–158. [Google Scholar] [CrossRef]

- Alshurideh, M.; Al-Hadrami, A.; Alquqa, E.; Alzoubi, H.; Hamadneh, S.; Kurdi, B. The effect of lean and agile operations strategy on improving order-winners: Empirical evidence from the UAE food service industry. Uncertain Supply Chain Manag. 2023, 11, 87–94. [Google Scholar] [CrossRef]

- Jadoon, G.; Ud Din, I.; Almogren, A.; Almajed, H. Smart and Agile Manufacturing Framework, A Case Study for Automotive Industry. Energies 2020, 13, 5766. [Google Scholar] [CrossRef]

- Pinheiro, J.; Silva, G.M.; Dias, Á.L.; Lages, L.F.; Preto, M.T. Fostering knowledge creation to improve performance: The mediation role of manufacturing flexibility. Bus. Process Manag. J. 2020, 26, 1871–1892. [Google Scholar] [CrossRef]

- Bueno, A.; Godinho-Filho, M.; Frank, A.G. Smart production planning and control in the Industry 4.0 context: A systematic literature review. Comput. Ind. Eng. 2020, 149, 106774. [Google Scholar] [CrossRef]

- Ammar, M.; Haleem, A.; Javaid, M.; Walia, R.; Bahl, S. Improving material quality management and manufacturing organizations system through Industry 4.0 technologies. Mater. Today Proc. 2021, 45, 5089–5096. [Google Scholar] [CrossRef]

- Coimbra, H.; Cormican, K.; McDermott, O.; Antony, J. Leading the transformation: Agile success factors in an Irish manufacturing company. Total Qual. Manag. Bus. Excell. 2023, 34. [Google Scholar] [CrossRef]

- Agarwal, V.; Hameed, A.Z.; Malhotra, S.; Mathiyazhagan, K.; Alathur, S.; Appolloni, A. Role of Industry 4.0 in agile manufacturing to achieve sustainable development. Bus. Strategy Environ. 2023, 32, 3671–3688. [Google Scholar] [CrossRef]

- Vandana; Singh, S. R.; Sarkar, M.; Sarkar, B. Effect of Learning and Forgetting on Inventory Model under Carbon Emission and Agile Manufacturing. Mathematics 2023, 11, 368. [Google Scholar] [CrossRef]

- Impram, S.; Varbak-Nese, S.; Oral, B. Challenges of renewable energy penetration on power system flexibility: A survey. Energy Strategy Rev. 2020, 31, 100539. [Google Scholar] [CrossRef]

- Suleiman, Z.; Shaikholla, S.; Dikhanbayeva, D.; Shehab, E.; Turkyilmaz, A. Industry 4.0: Clustering of concepts and characteristics. Cogent Eng. 2022, 9, 2034264. [Google Scholar] [CrossRef]

- Ching, N.T.; Ghobakhloo, M.; Iranmanesh, M.; Maroufkhani, P.; Asadi, S. Industry 4.0 applications for sustainable manufacturing: A systematic literature review and a roadmap to sustainable development. J. Clean. Prod. 2022, 334, 130133. [Google Scholar] [CrossRef]

- Amjad, M.S.; Rafique, M.Z.; Khan, M.A. Modern divulge in production optimization: An implementation framework of LARG manufacturing with Industry 4.0. Int. J. Lean Six Sigmat 2021, 15, 992–1016. [Google Scholar] [CrossRef]

- Doh, J.P.; Tashman, P.; Benischke, M.H. Adapting to Grand Environmental Challenges Through Collective Entrepreneurship. Acad. Manag. Perspect. 2019, 33, 4. [Google Scholar] [CrossRef]

- Ghobakhloo, M. Industry 4.0, digitization, and opportunities for sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

- Mohamed, N.; Al-Jaroodi, J.; Lazarova-Molnar, S. Leveraging the Capabilities of Industry 4.0 for Improving Energy Efficiency in Smart Factories. Int. J. Product. Perform. Manag. 2019, 7, 18008–18020. [Google Scholar] [CrossRef]

- Szum, K.; Nazarko, J. Exploring the Determinants of Industry 4.0 Development Using an Extended SWOT Analysis: A Regional Study. Energies 2020, 13, 5972. [Google Scholar] [CrossRef]

- Akrami, A.; Doostizadeh, M. Aminifar, FPower system flexibility: An overview of emergence to evolution. J. Mod. Power Syst. Clean Energy 2019, 7, 987–1007. [Google Scholar] [CrossRef]

- Matsunaga, F.; Zytkowski, V.; Valle, P.; Deschamps, F. Optimization of Energy Efficiency in Smart Manufacturing Through the Application of Cyber–Physical Systems and Industry 4.0 Technologies. J. Energy Resour. Technol. 2022, 144, 102104. [Google Scholar] [CrossRef]

- Ojstersek, R.; Acko, B.; Buchmeister, B. Simulation study of a flexible manufacturing system regarding sustainability. Int. J. Simul. Model. 2020, 19, 65–76. [Google Scholar] [CrossRef]

- Boccella, A.R.; Centobelli, P.; Cerchione, R.; Murino, T.; Riedel, R. Evaluating Centralized and Heterarchical Control of Smart Manufacturing Systems in the Era of Industry 4.0. Appl. Sci. 2020, 10, 755. [Google Scholar] [CrossRef]

- Hasan, A.S.M.M.; Trianni, A. Boosting the adoption of industrial energy efficiency measures through Industry 4.0 technologies to improve operational performance. J. Clean. Prod. 2023, 425, 138597. [Google Scholar] [CrossRef]

- Michlowicz, E.; Wojciechowski, J. A method for evaluating and upgrading systems with parallel structures with forced redundancy. Eksploat. I Niezawodn.–Maint. Reliab. 2021, 23, 770–776. [Google Scholar] [CrossRef]

- Oprychal, L. Is mean time to failure (MTTF) equal to mean time of life for unrepairable systems? J. KONBiN 2021, 51, 255–264. [Google Scholar] [CrossRef]

- Filipe, D.; Pimentel, C. Production and Internal Logistics Flow Improvements through the Application of Total Flow Management. Logistics 2023, 7, 34. [Google Scholar] [CrossRef]

- Kong, Y.S.; Abdullah, S.; Singh, S.S.K. Distribution characterisation of spring durability for road excitations using maximum likelihood estimation. Eng. Fail. Anal. 2022, 134, 106041. [Google Scholar] [CrossRef]

- Zwolińska, B.; Wiercioch, J. Selection of Maintenance Strategies for Machines in a Series-Parallel System. Sustainability 2022, 14, 11953. [Google Scholar] [CrossRef]

- Mejía-Hernández, Y.; Hernández-González, S.; Guerrero-Campanur, A.; Jiménez-García, J.A. Effect of Variability on the Optimal Flow of Goods in Supply Chains Using the Factory Physics Approach. In Trends in Industrial Engineering Applications to Manufacturing Process; García-Alcaraz, J.L., Realyvásquez-Vargas, A., Z-Flores, E., Eds.; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Helmold, M.; Küçük Yılmaz, A.; Flouris, T.; Winner, T.; Cvetkoska, V.; Dathe, T. 5S Concept: Muda, Muri and Mura. In Lean Management, Kaizen, Kata and Keiretsu. Management for Professionals; Springer: Cham, Switzerland, 2022. [Google Scholar] [CrossRef]

- Kubica, Ł.; Zwolińska, B. Shaping of the risk of a series-parallel manufacturing structure maintenance according to quasi-coherence and the k-th survival value. J. Process Control, 2023; unpublished work-submitted. [Google Scholar] [CrossRef]

- Szkutnik-Rogoż, J.; Małachowski, J.; Ziołkowski, J. An innovative computational algorithm for modelling technical readiness coefficient: A case study in automotive industry. Comput. Ind. Eng. 2023, 179, 108942. [Google Scholar] [CrossRef]

- Jin, Y.; Geng, J.; Lv, C.; Chi, Y.; Zhao, T. A methodology for equipment condition simulation and maintenance threshold optimization oriented to the influence of multiple events. Reliab. Eng. Syst. Saf. 2023, 229, 108879. [Google Scholar] [CrossRef]

- Ben-Daya, M.; Duffuaa, S.O.; Raouf, A.; Knezevic, J.; Ait-Kadi, D. Handbook of Maintenance Management and Engineering; Springer: London, UK, 2009. [Google Scholar] [CrossRef]

- Jasiulewicz, H.; Kordecki, W. Convolutions of Erlang and Pascal distributions with applications to reliability. Demonstr. Math. 2003, 36, 231–238. [Google Scholar] [CrossRef]

- Meserović, M.D. Foundations for a general systems theory. In View of General Systems Theory; Wiley: New York, NY, USA, 1964. [Google Scholar]

- Klir, G.J. An Approach to General Systems Theory; Van Nostrang Reinhold: New York, NY, USA, 1969. [Google Scholar]

| Parameters of the Random Variable Breakdown Durations | Parameters of the Random Variable Proper Operation Durations | Value of the Indicator th Survival Value |

|---|---|---|

| Parameters of the Random Variable Breakdown Durations | Parameters of the Random Variable Proper Operation Durations | Value of the Indicator th Survival Value |

|---|---|---|

| Parameters of the Random Variable Breakdown Durations | Parameters of the Random Variable Proper Operation Durations | Value of the Indicator th Survival Value |

|---|---|---|

| Parameters of the Random Variable Breakdown Durations | Parameters of the Random Variable Proper Operation Durations | Value of the Indicator th Survival Value |

|---|---|---|

| Parameters of the Random Variable Breakdown Durations | Parameters of the Random Variable Proper Operation Durations | Value of the Indicator th Survival Value |

|---|---|---|

| Parameters of the Random Variable Breakdown Durations | Parameters of the Random Variable Proper Operation Durations | Value of the Indicator th Survival Value |

|---|---|---|

| Parameters of the Random Variable Breakdown Durations | Parameters of the Random Variable Proper Operation Durations | Value of the Indicator th Survival Value |

|---|---|---|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zwolińska, B.; Wiercioch, J. Modelling the Reliability of Logistics Flows in a Complex Production System. Energies 2023, 16, 8071. https://doi.org/10.3390/en16248071

Zwolińska B, Wiercioch J. Modelling the Reliability of Logistics Flows in a Complex Production System. Energies. 2023; 16(24):8071. https://doi.org/10.3390/en16248071

Chicago/Turabian StyleZwolińska, Bożena, and Jakub Wiercioch. 2023. "Modelling the Reliability of Logistics Flows in a Complex Production System" Energies 16, no. 24: 8071. https://doi.org/10.3390/en16248071

APA StyleZwolińska, B., & Wiercioch, J. (2023). Modelling the Reliability of Logistics Flows in a Complex Production System. Energies, 16(24), 8071. https://doi.org/10.3390/en16248071