The Design of Water Loop Facility for Supporting the WCLL Breeding Blanket Technology and Safety

Abstract

:1. Introduction

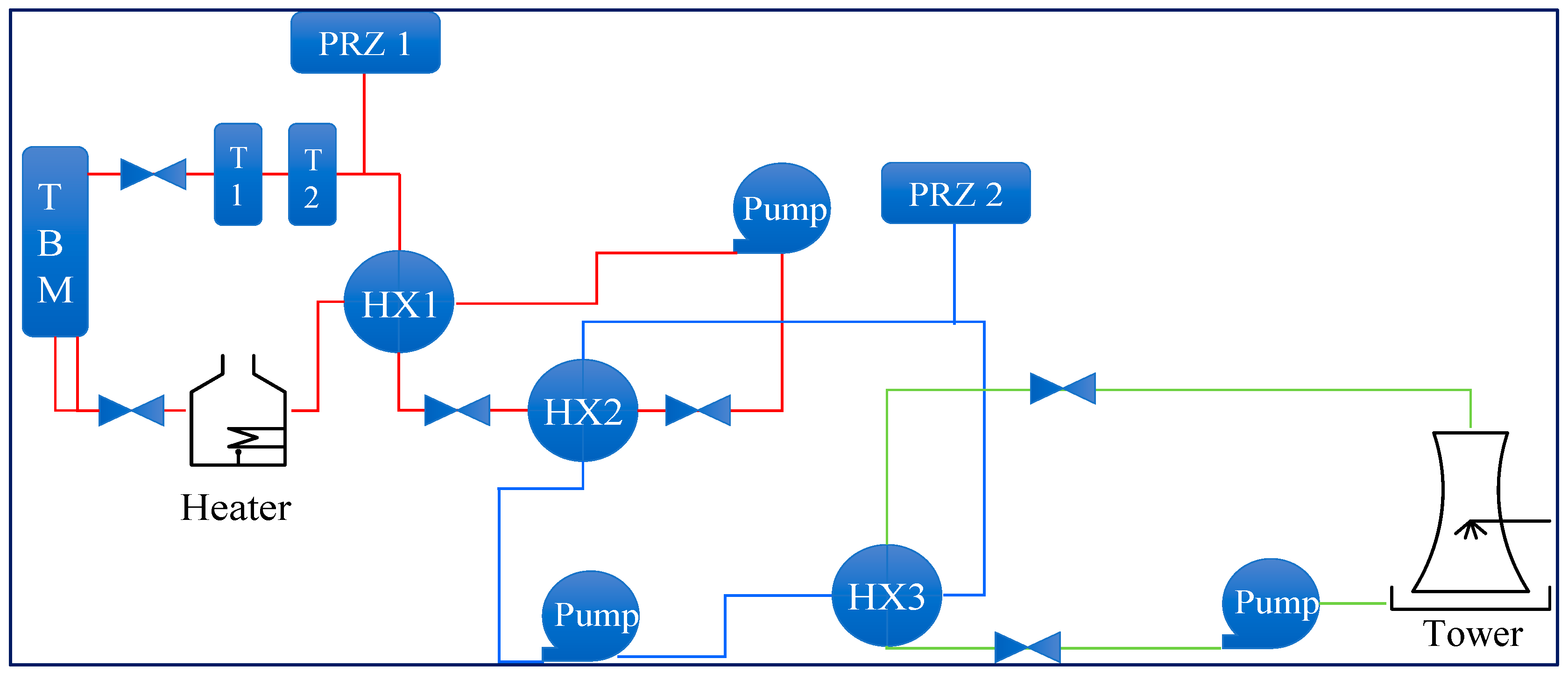

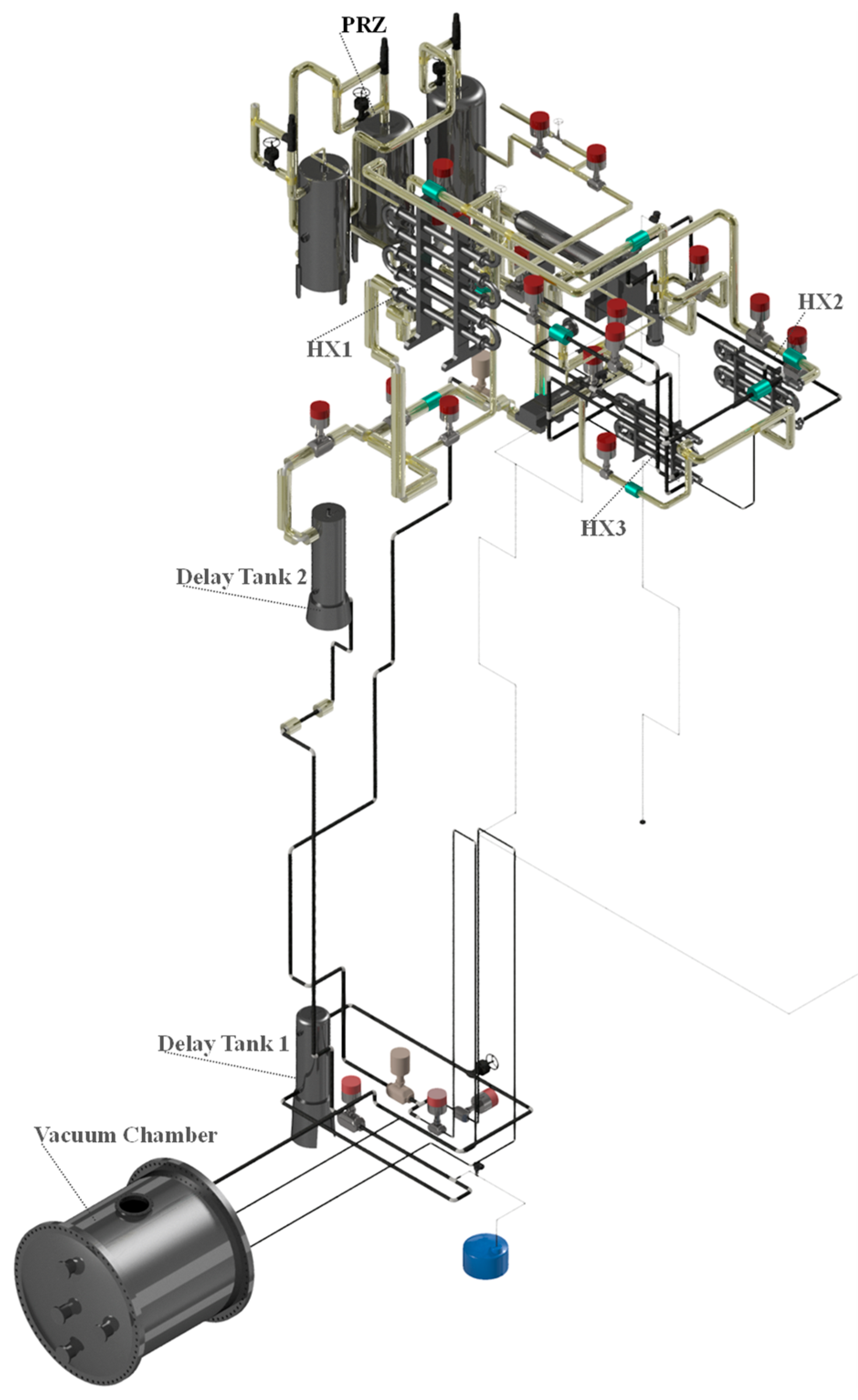

2. Water Loop Facility Objectives and Description

2.1. WL Primary System

2.2. WL Secondary System

2.3. WL Tertiary System

3. Numerical Analyses in Support of the Design

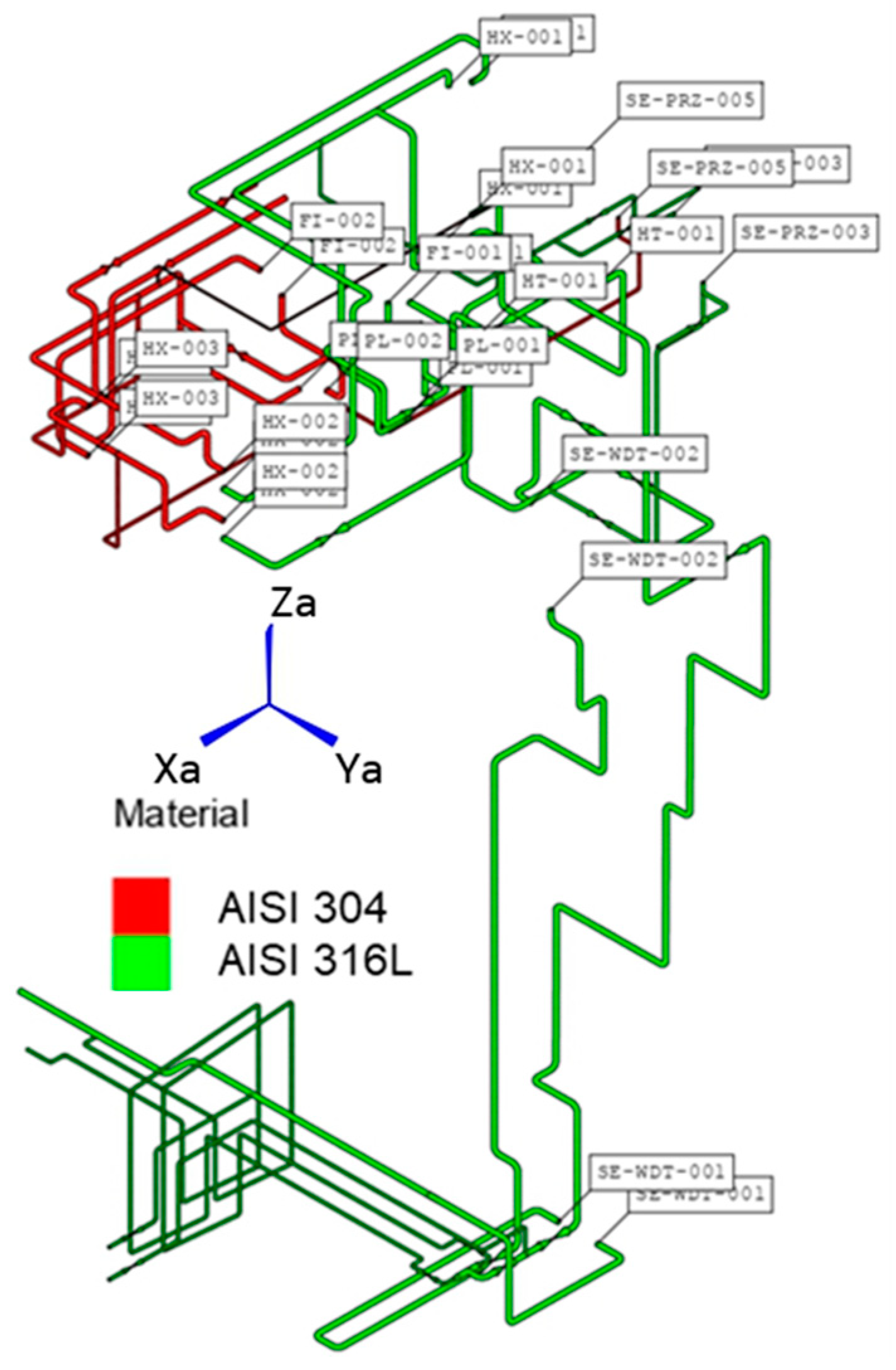

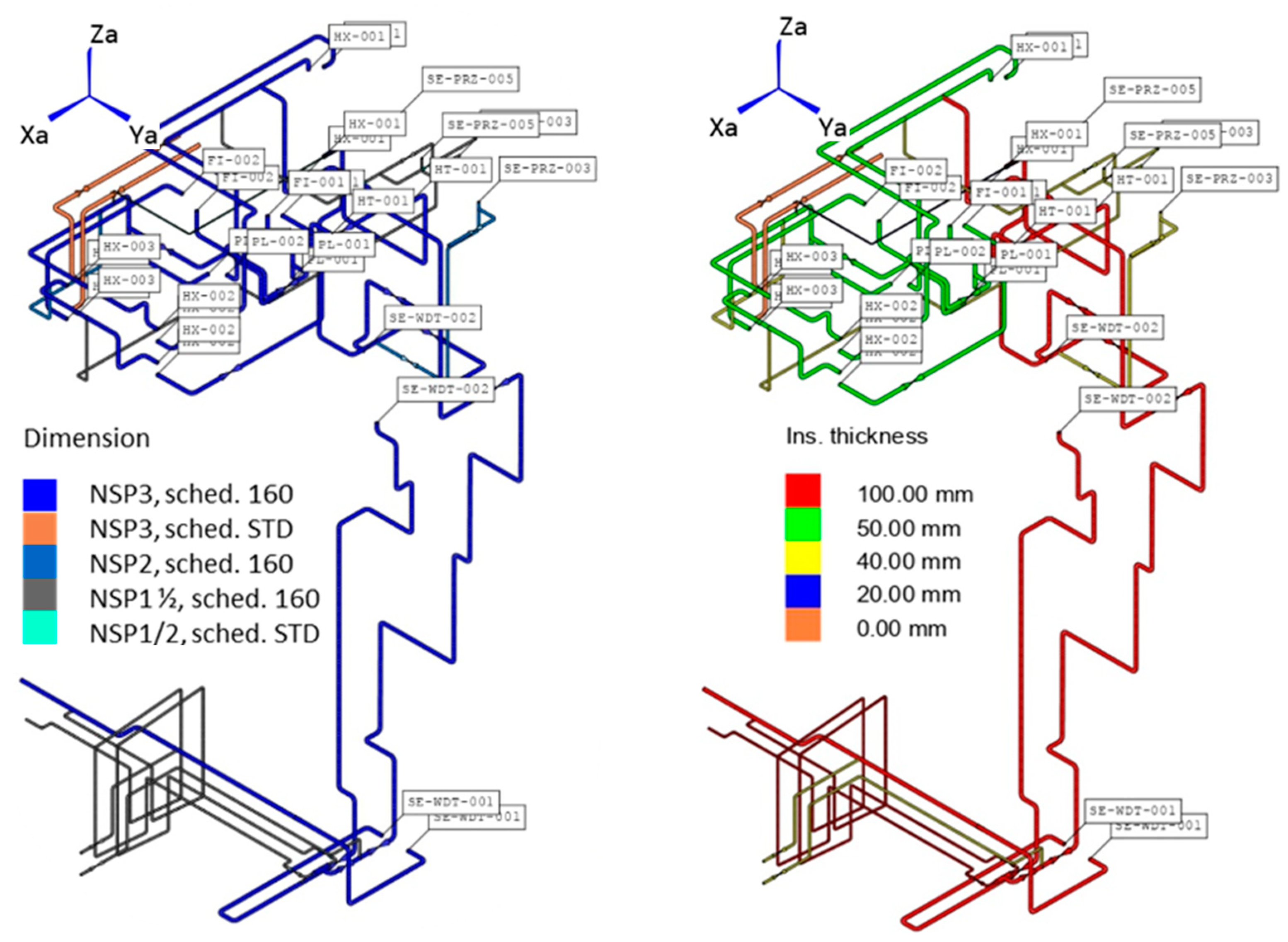

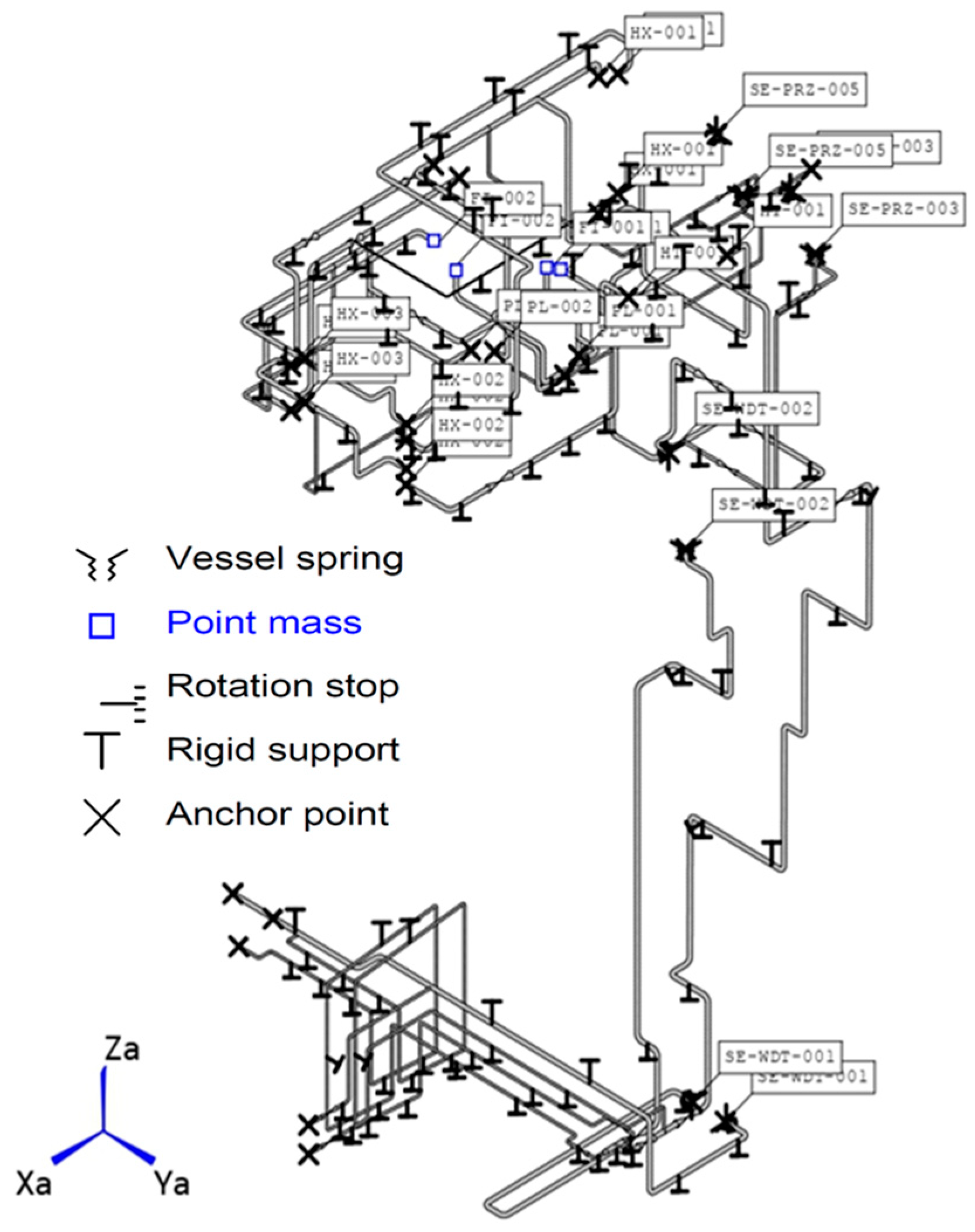

3.1. Pipe Stress Analysis in Support of the Design

3.1.1. Numerical Model, Loads, and Boundary Conditions

- -

- Primary loads or sustained loads (SSL), which include the primary loads related to the load case “Dead Load” (i.e., gravity and internal pressure);

- -

- Secondary loads or thermal range (SE), which include only the effect of the axial thermal expansion, calculated as a combination of the two load cases “Dead Load” and “POS/NOS Cat. I”;

- -

- Primary plus secondary loads (STE), which consider all the loads acting during the normal operation loading scenario.

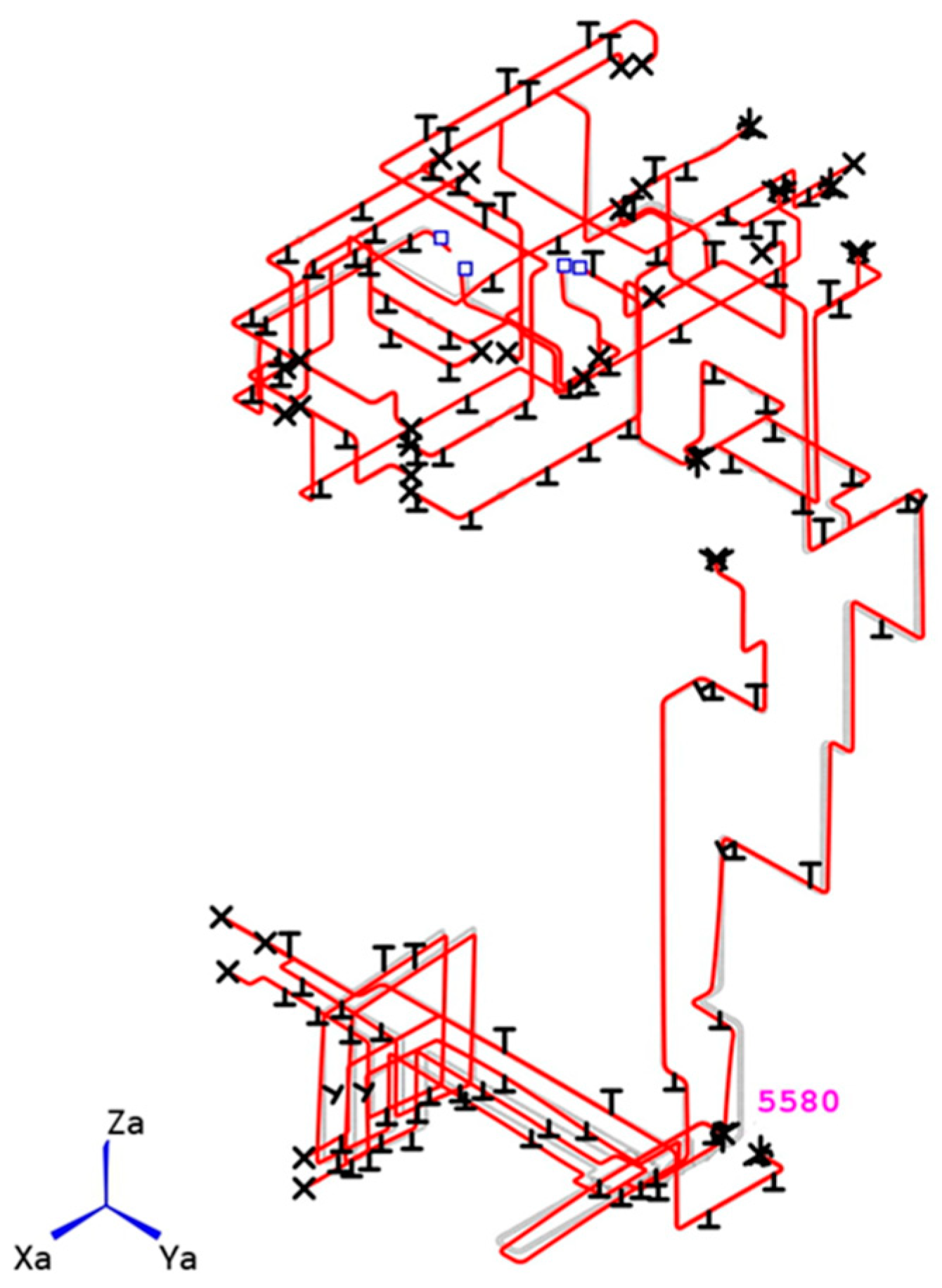

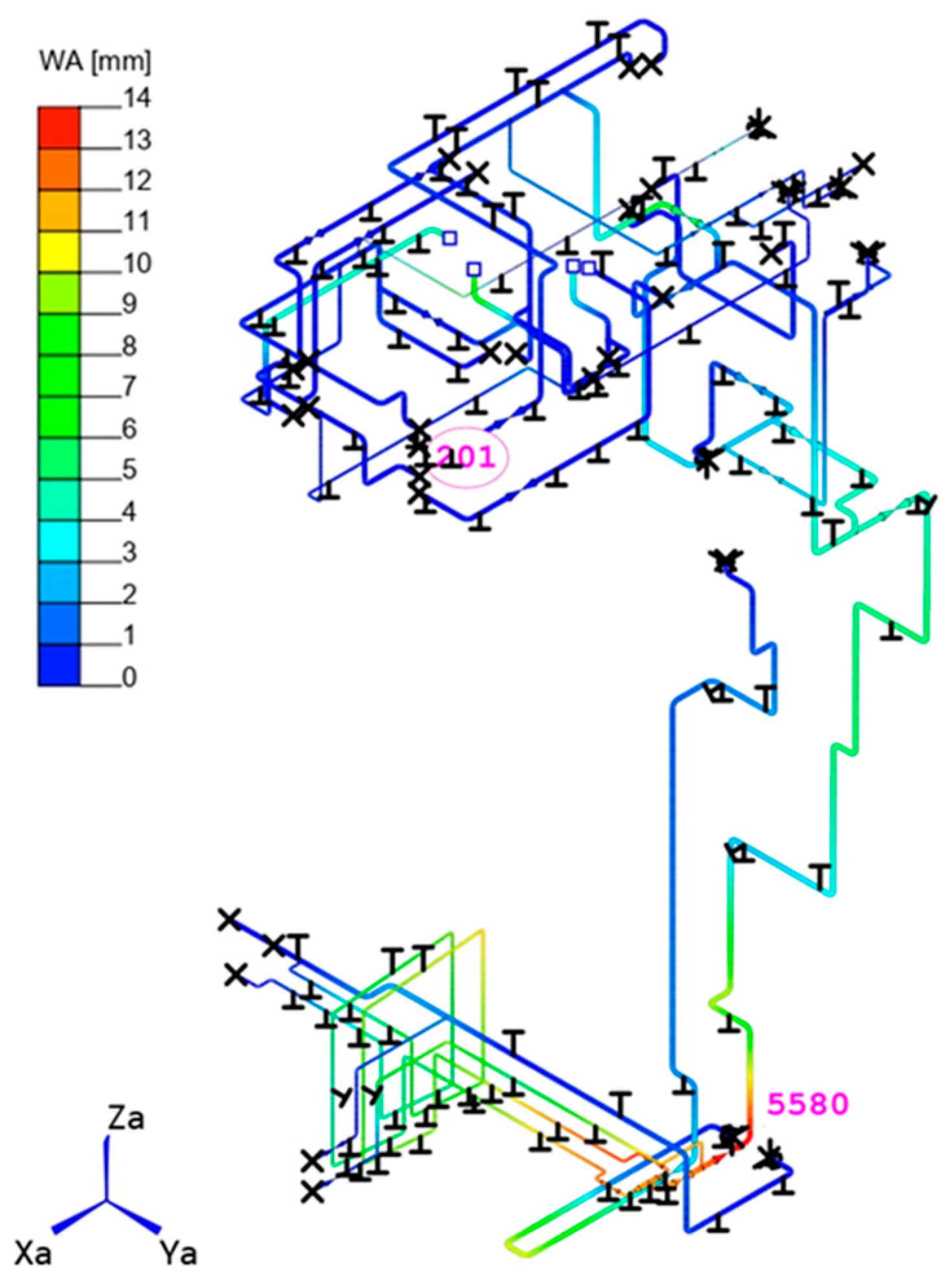

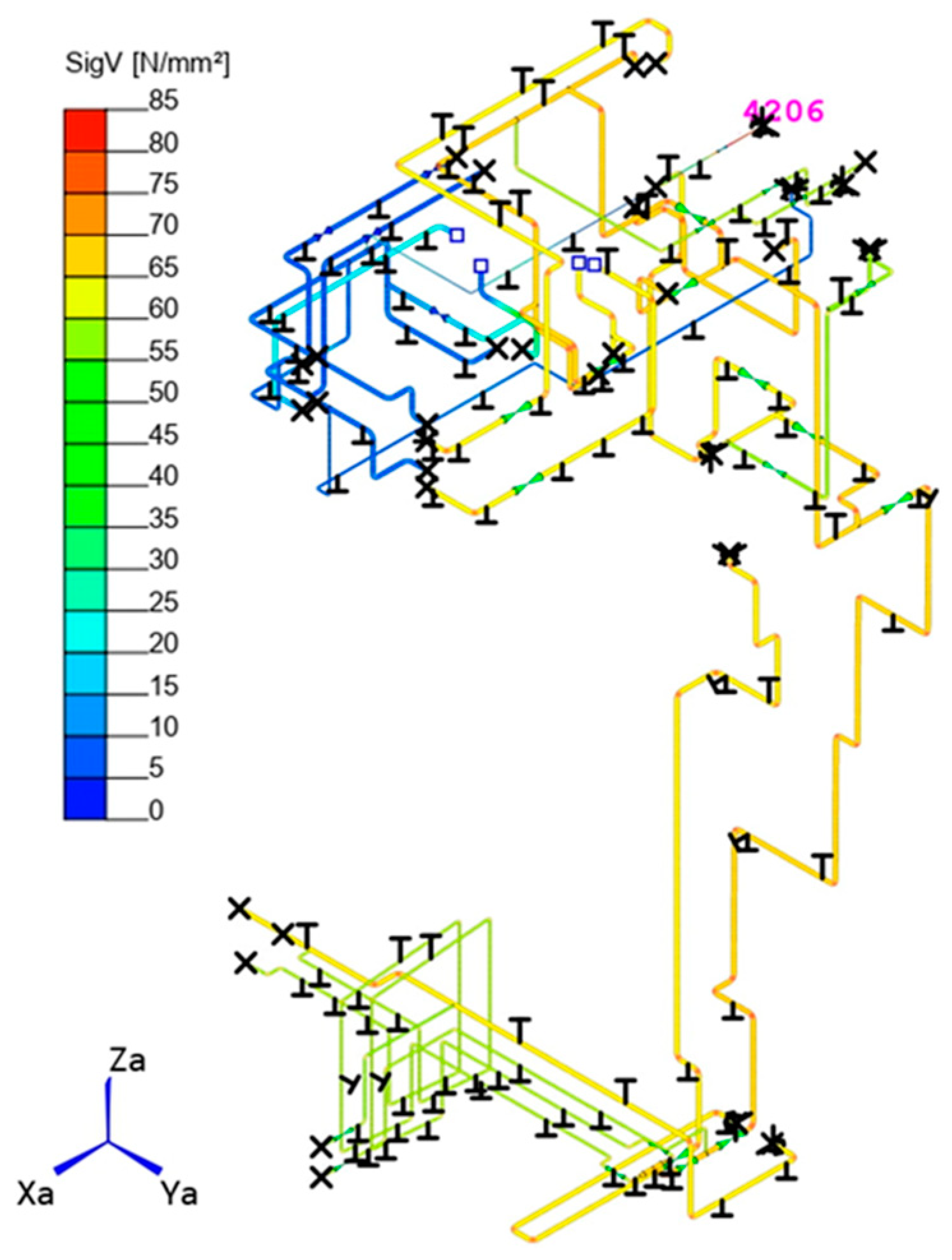

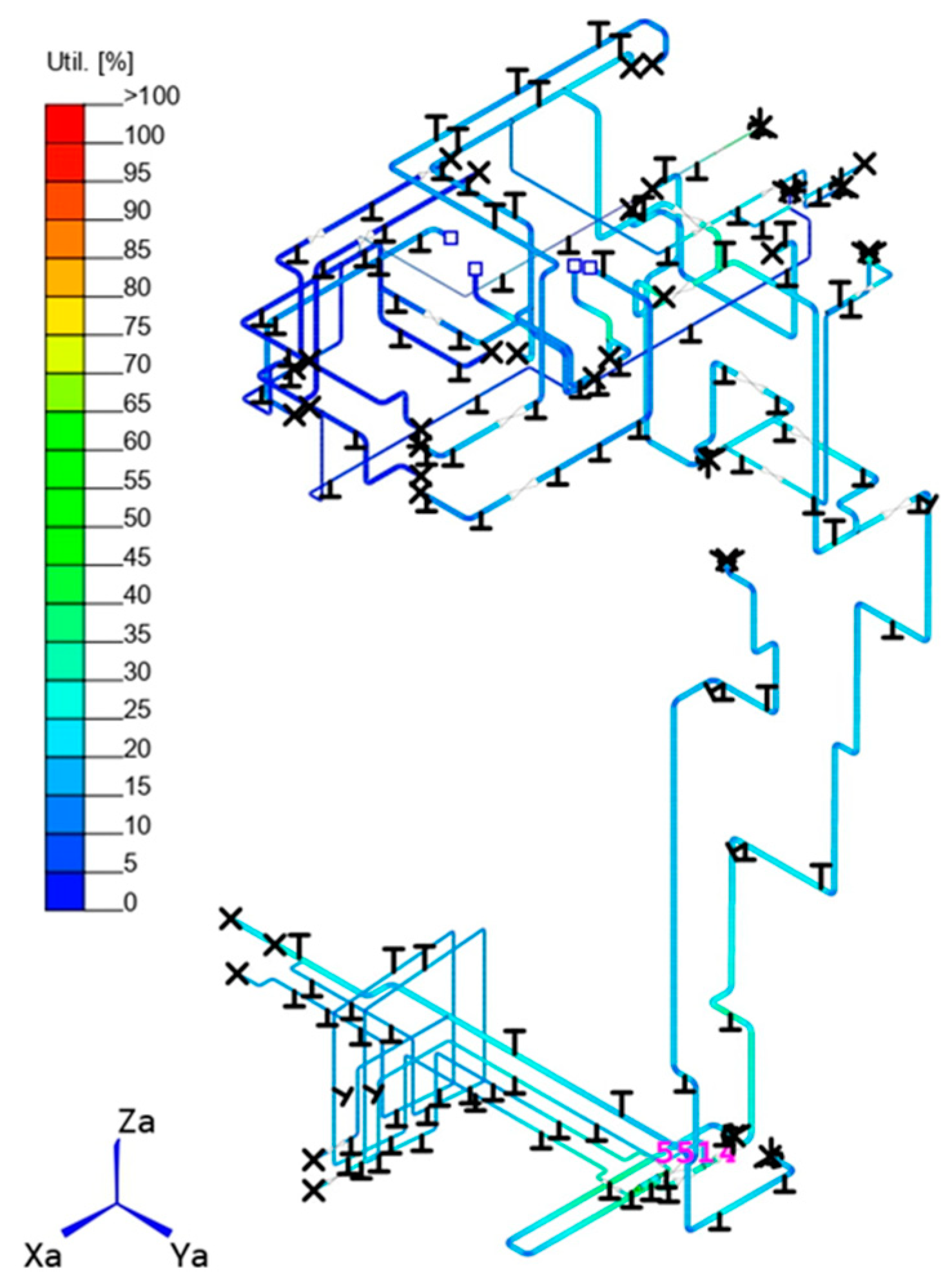

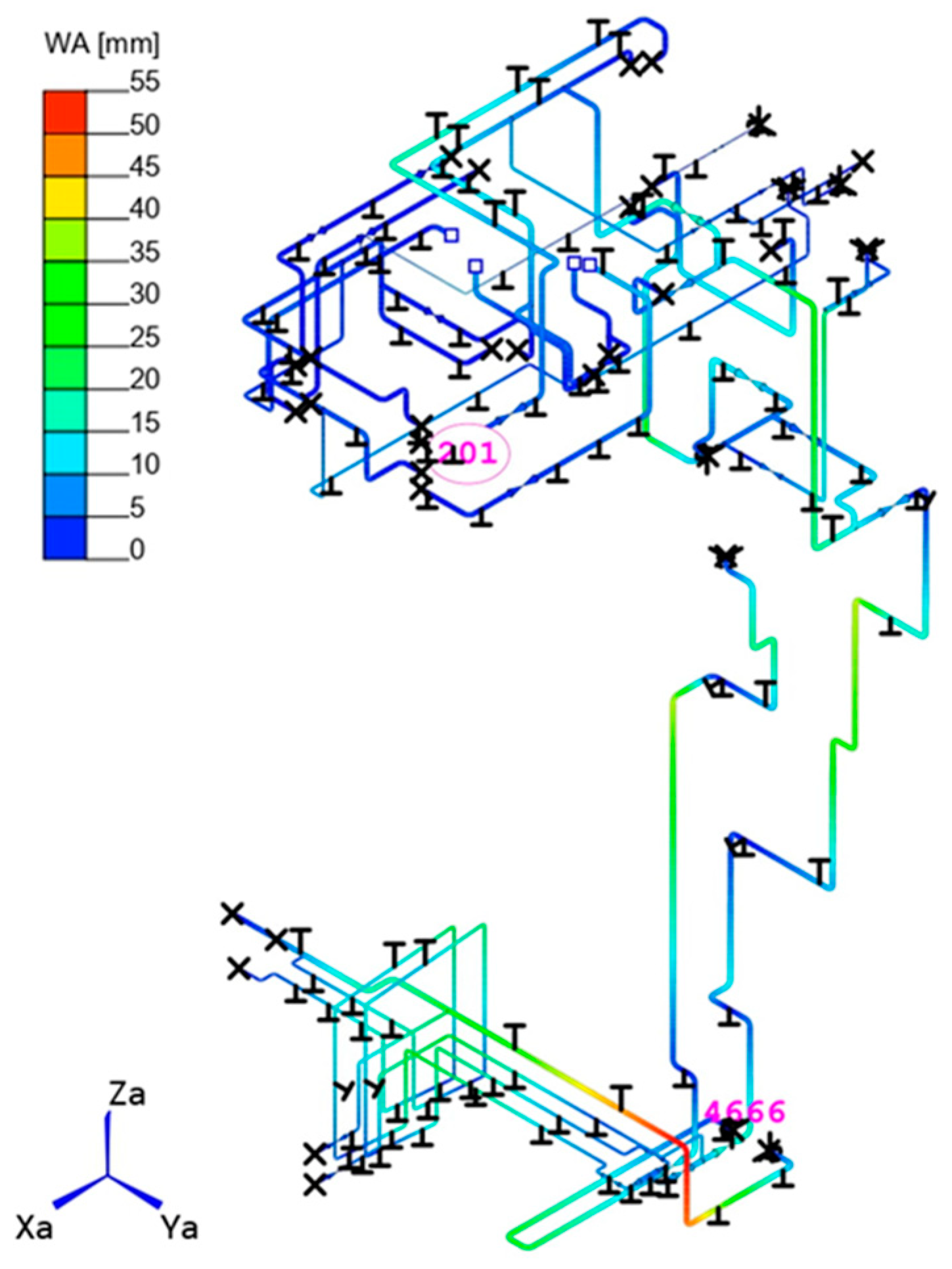

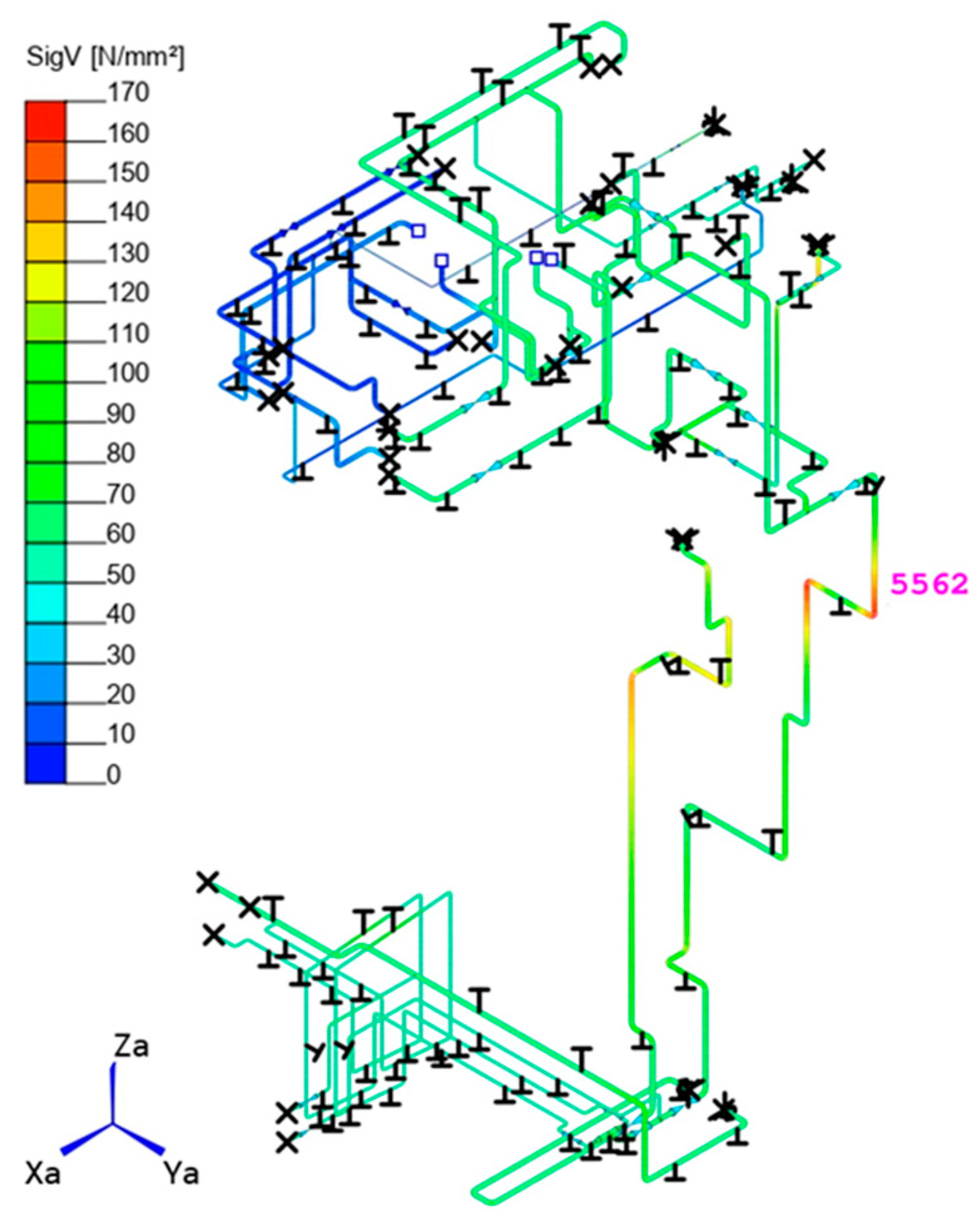

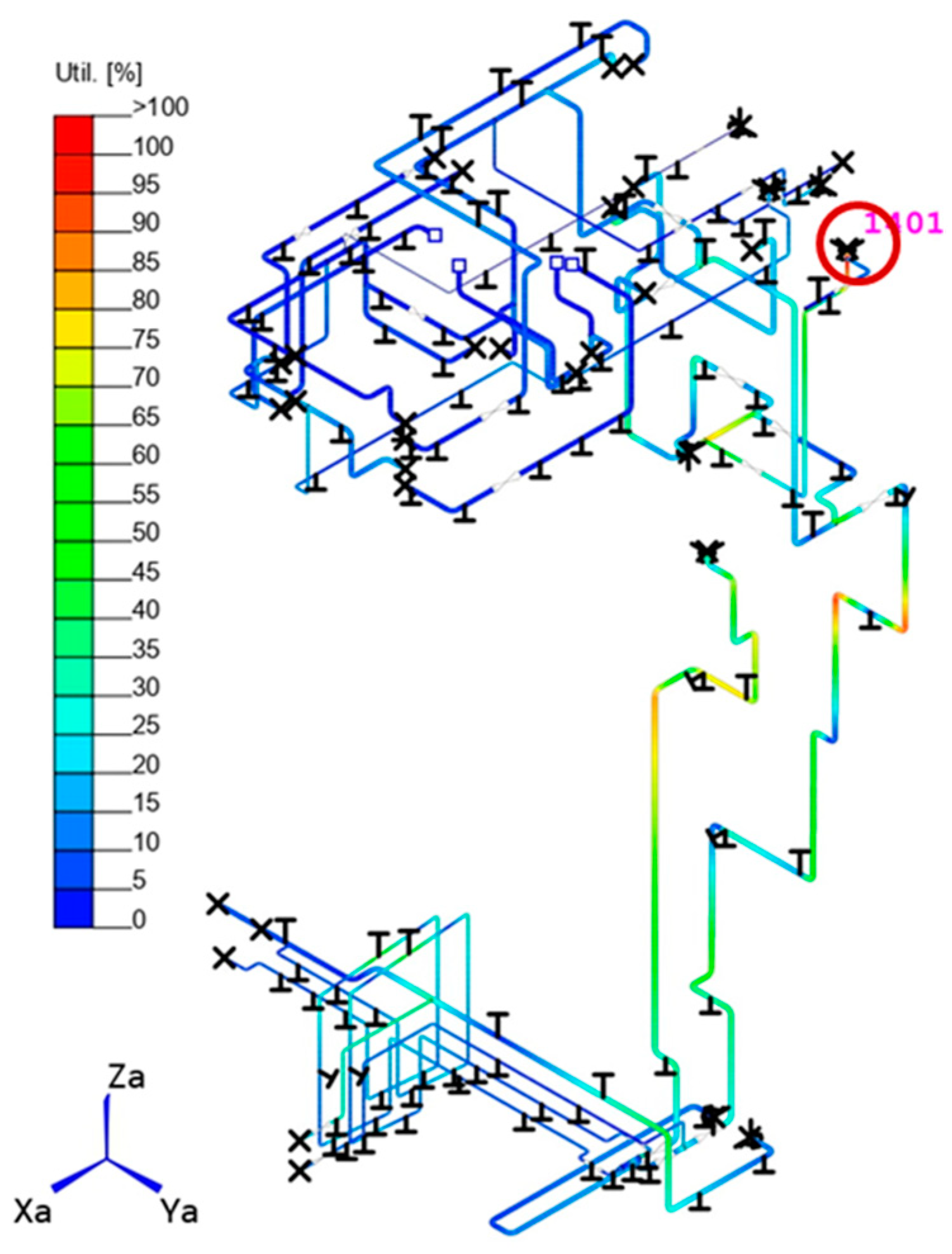

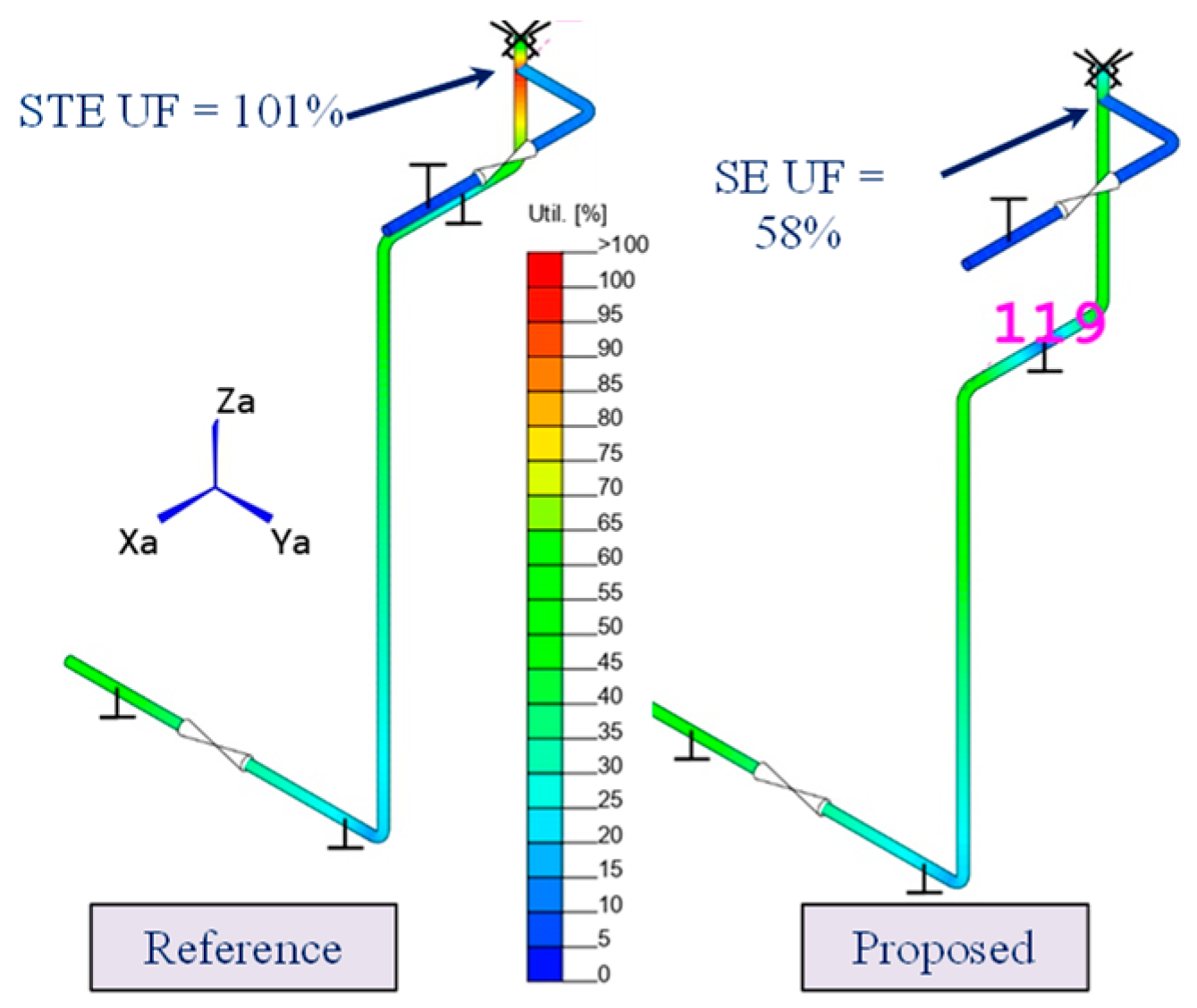

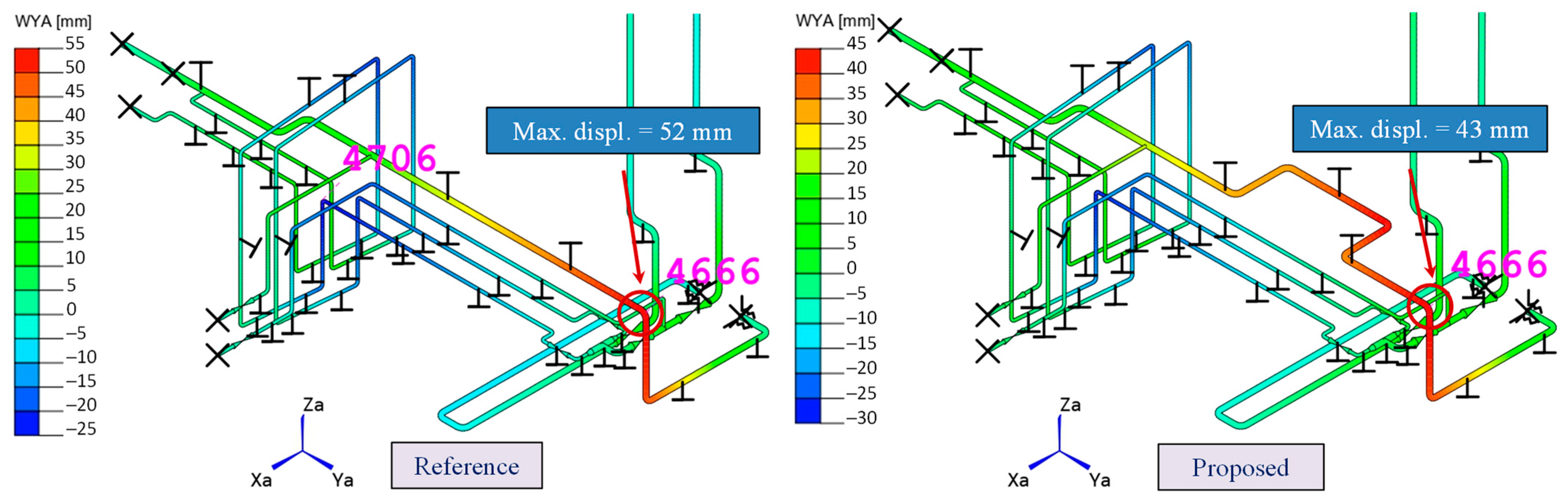

3.1.2. ROHR2 Results

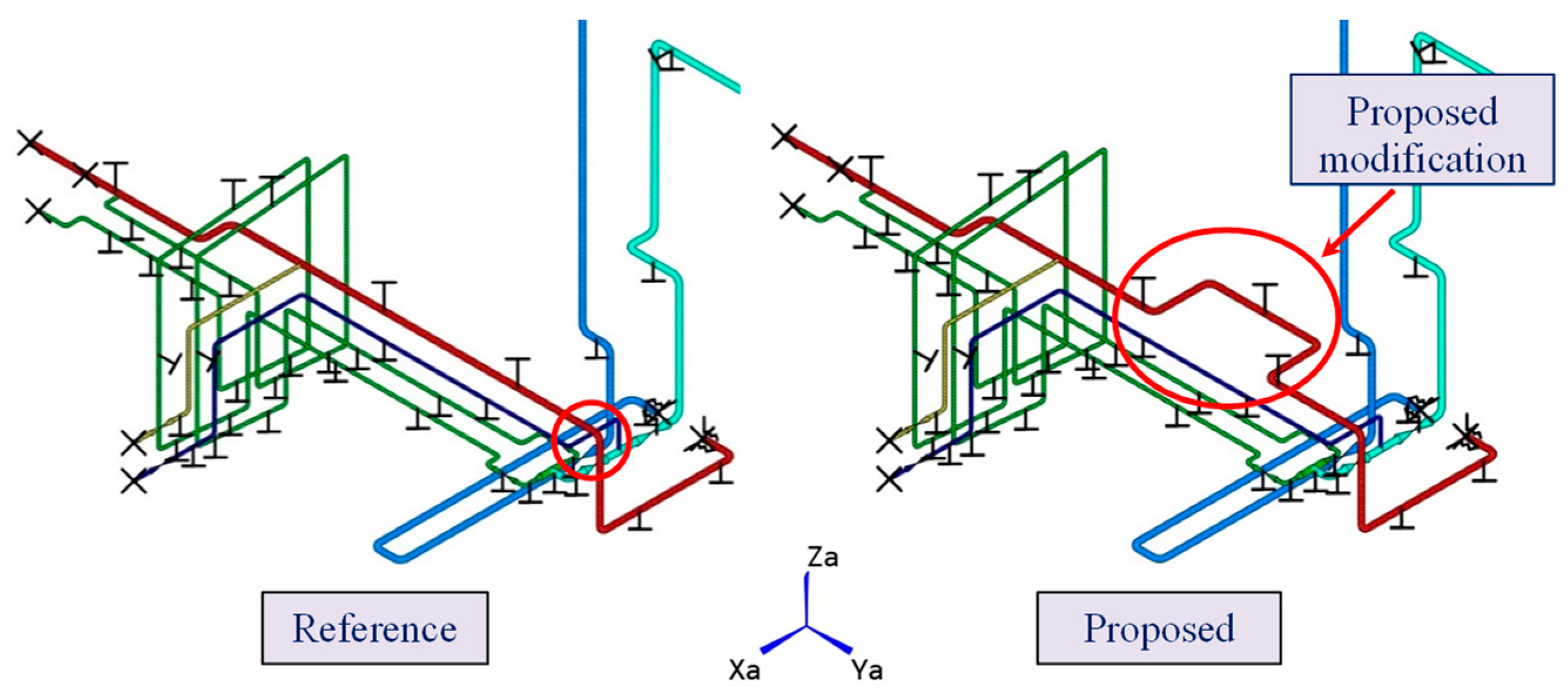

3.1.3. Investigated Layout Optimization Solutions

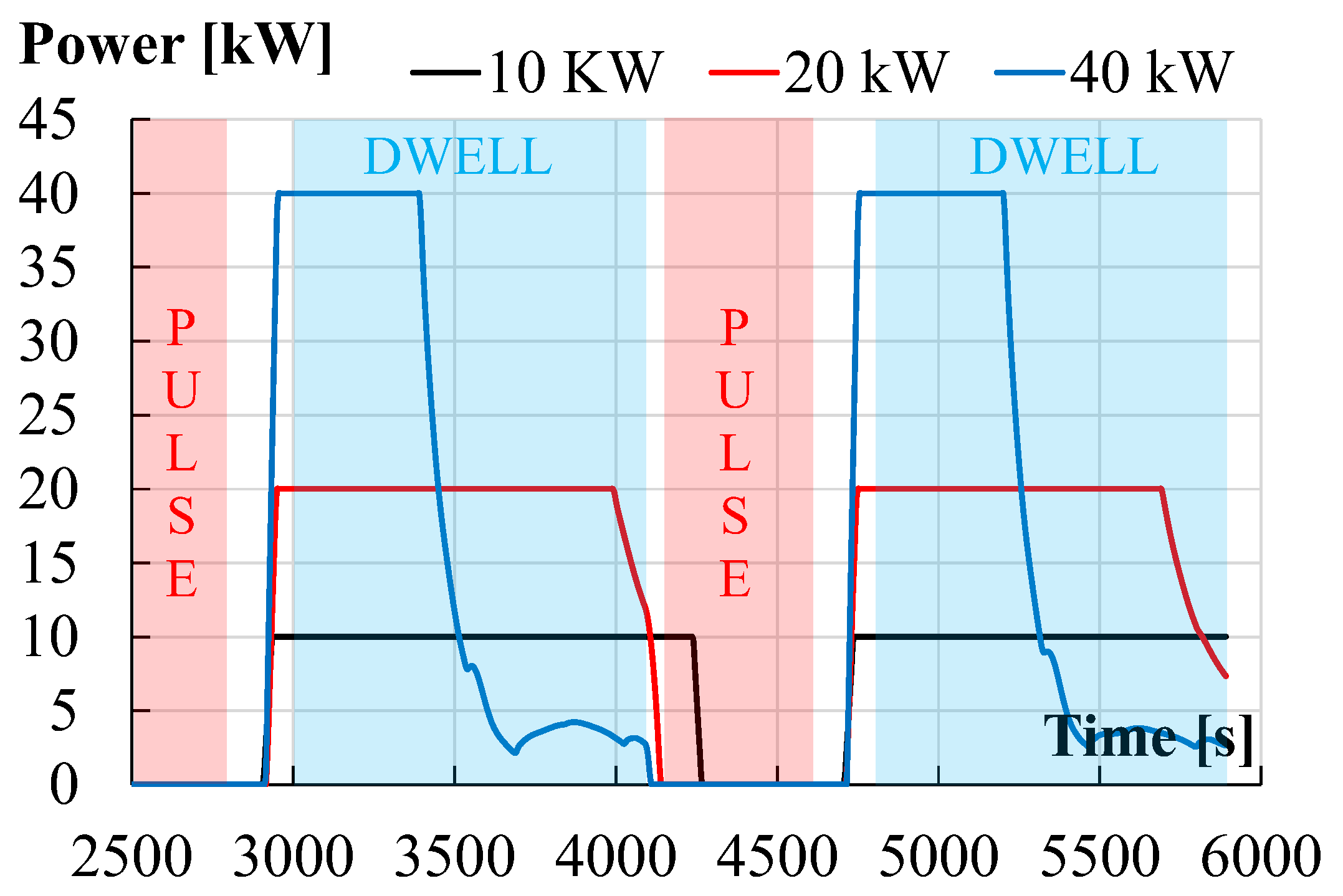

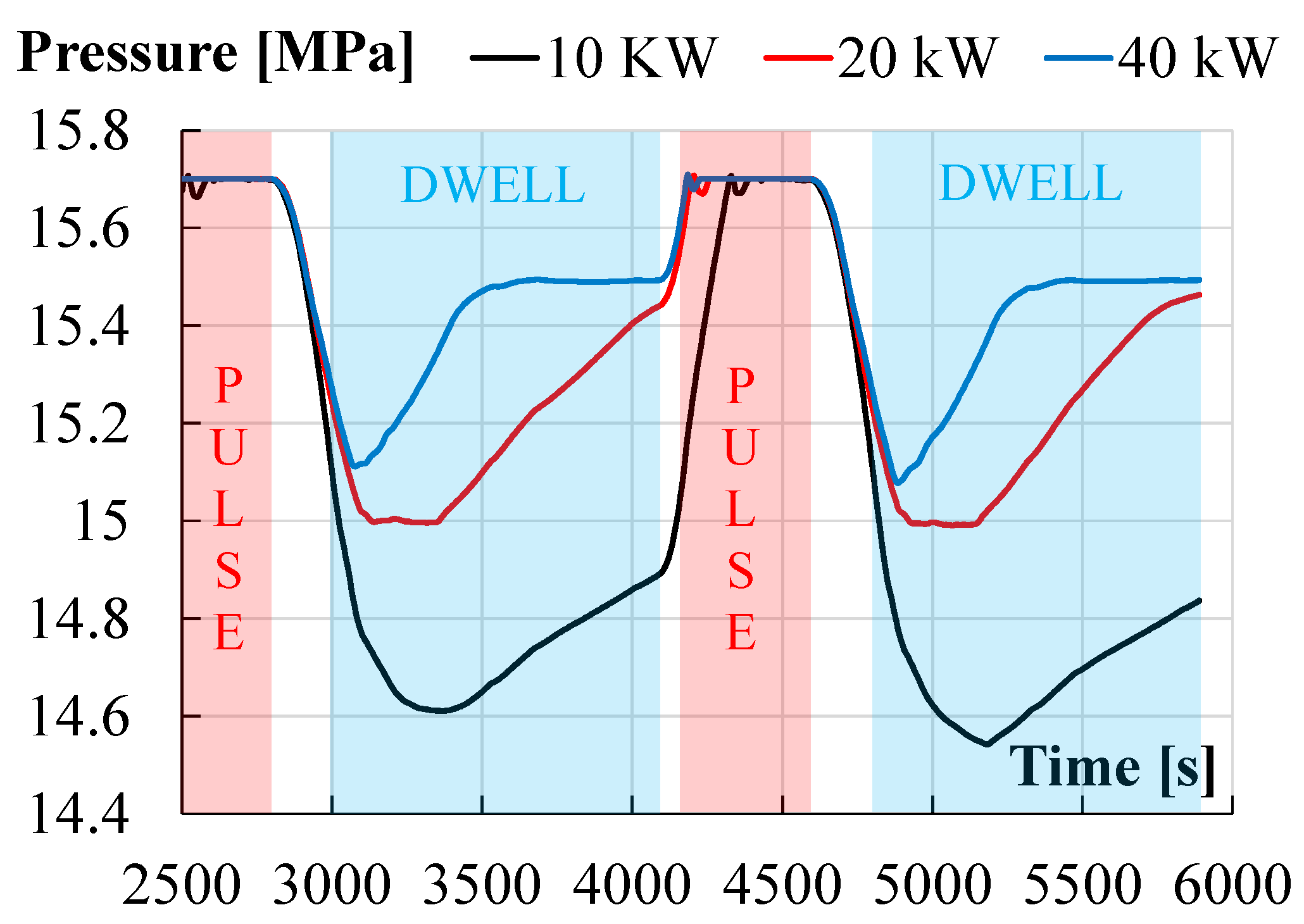

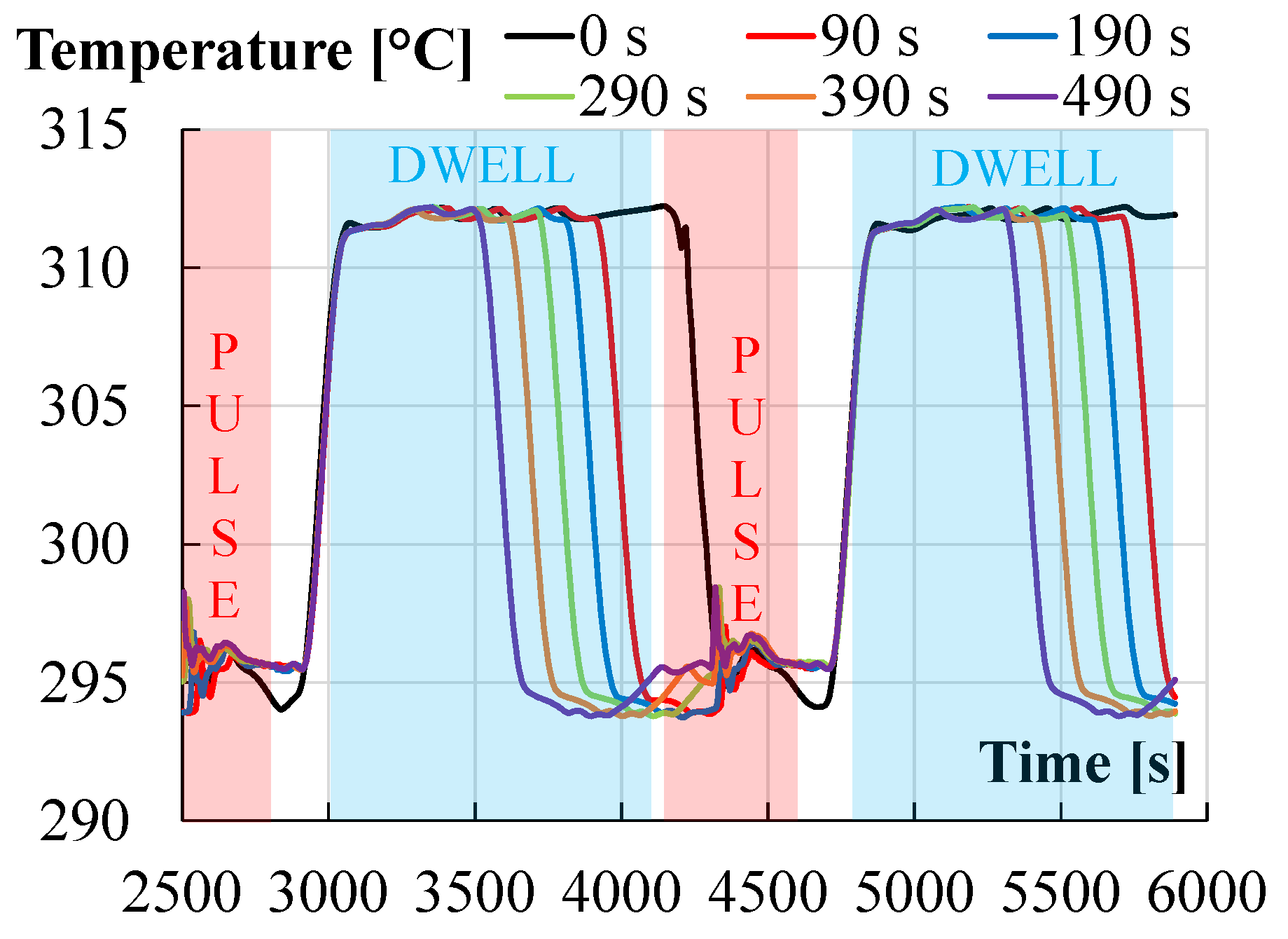

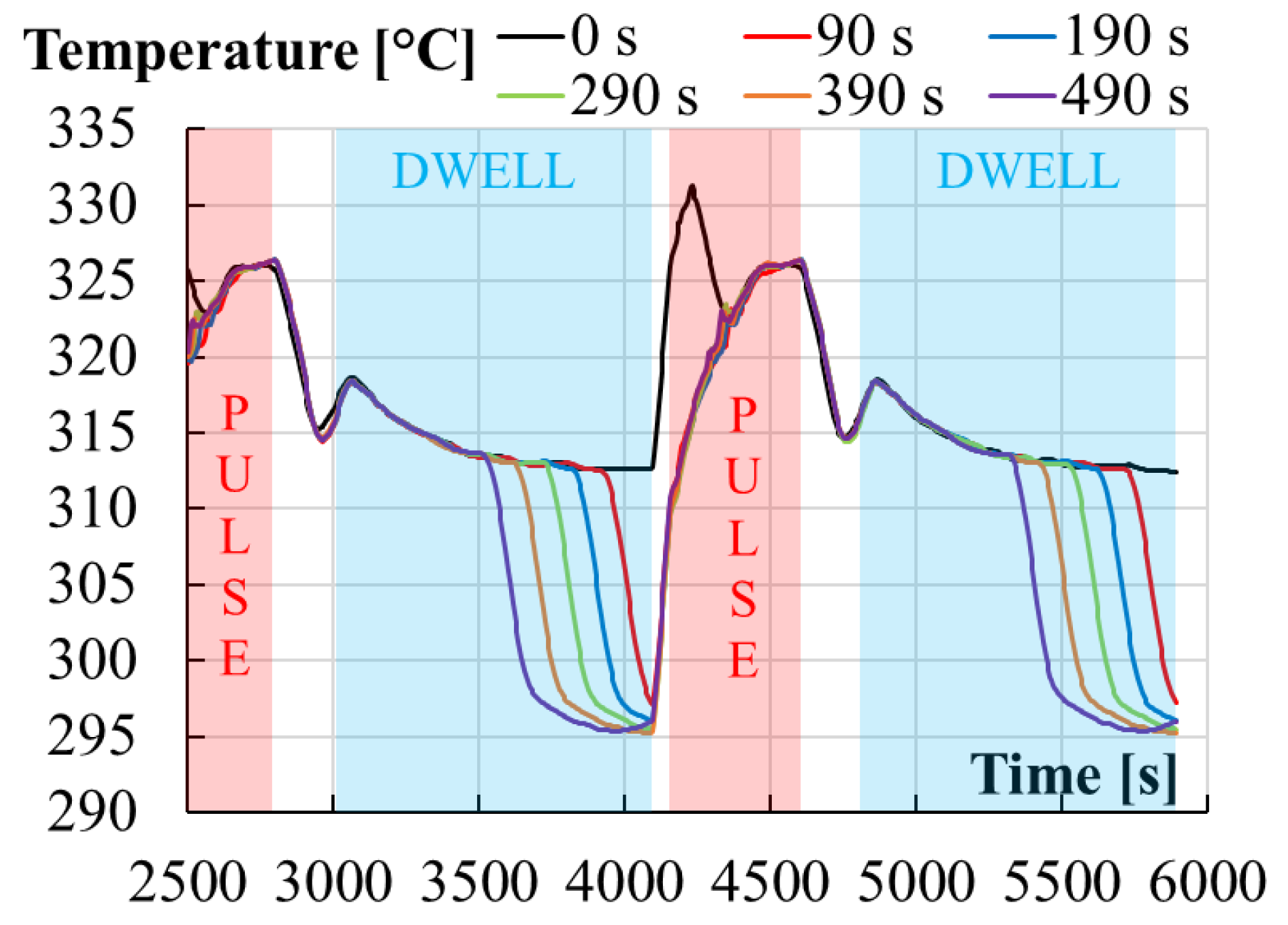

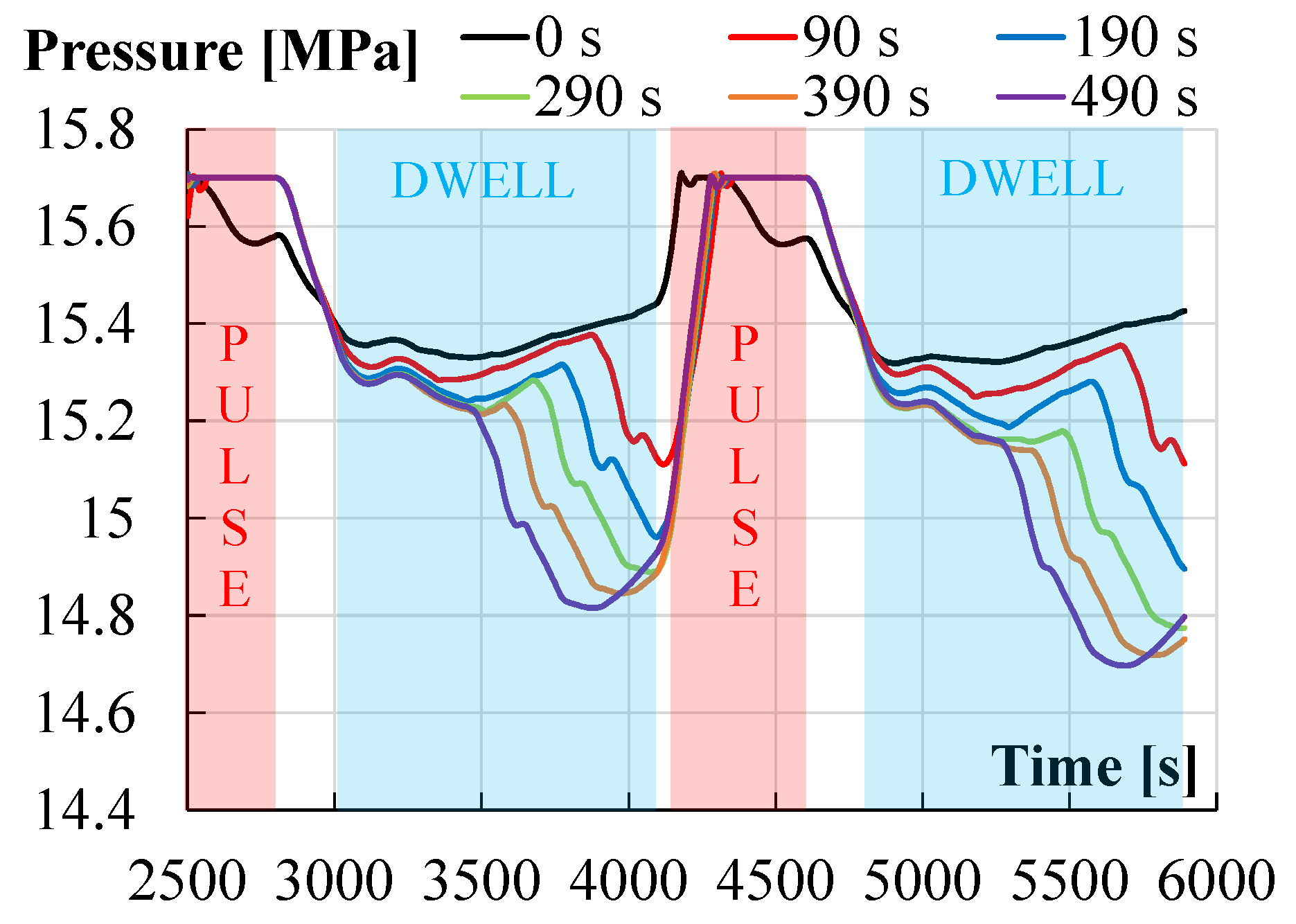

3.2. RELAP5 Analyses for the Optimization of the Facility Operation during Pulsed–Dwell–Pulsed Operation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Muratov, V.P.; Saksagansky, G.L.; Filatov, O.G. ITER—International Thermonuclear Experimental Reactor. In Fundamentals of Magnetic Thermonuclear Reactor Design; Woodhead Publishing Series in Energy; Woodhead Publishing: Sawston, UK, 2018; pp. 39–67. [Google Scholar] [CrossRef]

- Boccaccini, L.V.; Arbeiter, F.; Arena, P.; Aubert, J.; Buhler, L.; Cristescu, I.; Del Nevo, A.; Emboli, M.; Forest, L.; Harrington, C.; et al. Status of maturation of critical technologies and systems design: Breeding blanket. Fusion Eng. Des. 2022, 179, 113116. [Google Scholar] [CrossRef]

- Ibarra, A.; Kurtz, R. ITER-TBM and Blanket Programs toward DEMO. In Proceedings of the 3rd IAEA DEMO Programme Workshop, Hefei, China, 11–14 May 2015; Available online: https://nucleus.iaea.org/sites/fusionportal/Technical%20Meeting%20Proceedings/3rd%20DEMO/website/talks/May%2013%20Sessions/Ibarra_A%20Intro.pdf (accessed on 8 July 2022).

- Giancarli, L.M.; Bravo, X.; Cho, S.; Ferrari, M.; Hayashi, T.; Kim, B.-Y.; Leal-Pereira, A.; Martins, J.-P.; Merola, M.; Pascal, R.; et al. Overview of recent ITER TBM Program activities. Fusion Eng. Des. 2020, 158, 111674. [Google Scholar] [CrossRef]

- Federici, G. An overview of the EU Breeding Blanket design strategy as an integral part of the DEMO design effort. Fusion Eng. Des. 2019, 141, 30–42. [Google Scholar] [CrossRef]

- Ricapito, I.; Cismondi, F.; Federici, G.; Poitevin, Y.; Zmitko, M. European TBM programme: First elements of RoX and technical performance assessment for DEMO breeding blankets. Fusion Eng. Des. 2020, 156, 111584. [Google Scholar] [CrossRef]

- Arena, P.; Del Nevo, A.; Moro, F.; Noce, S.; Mozzillo, R.; Imbriani, V.; Giannetti, F.; Edemetti, F.; Froio, A.; Savoldi, L.; et al. The demo water-cooled lead–lithium breeding blanket: Design status at the end of the pre-conceptual design phase. Appl. Sci. 2023, 11, 11592. [Google Scholar] [CrossRef]

- Donné, A.J.H. European roadmap to fusion energy. In Proceedings of the 2018 Symposium on Fusion Technology (SOFT), Giardini Naxos, Italy, 16–21 September 2018. [Google Scholar]

- Tincani, A.; Arena, P.; Bruzzone, M.; Catanzaro, I.; Ciurluini, C.; Del Nevo, A.; Di Maio, P.A.; Forte, R.; Giannetti, F.; Lorenzi, S.; et al. Conceptual design of the main Ancillary Systems of the ITER Water Cooled Lithium Lead Test Blanket System. Fusion Eng. Des. 2021, 167, 112345. [Google Scholar] [CrossRef]

- EUROfusion. Available online: https://www.euro-fusion.org/ (accessed on 30 September 2023).

- Vannoni, A.; Lorusso, P.; Eboli, M.; Giannetti, F.; Ciurluini, C.; Tincani, A.; Marinari, R.; Tarallo, A.; Del Nevo, A. Development of a Steam Generator Mock-Up for EU DEMO Fusion Reactor: Conceptual Design and Code Assessment. Energies 2023, 16, 3729. [Google Scholar] [CrossRef]

- Ciattaglia, S.; Federici, G.; Barucca, L.; Stieglitz, R.; Taylor, N. EU DEMO safety and balance of plant design and operating requirements: Issues and possible solutions. Fusion Eng. Des. 2019, 146 Pt B, 2184–2188. [Google Scholar] [CrossRef]

- Ciurluini, C.; Vannoni, A.; Del Moro, T.; Lorusso, P.; Tincani, A.; Del Nevo, A.; Barucca, L.; Giannetti, F. Thermal-hydraulic assessment of Once-Through Steam Generators for EU-DEMO WCLL Breeding Blanket primary cooling system application. Fusion Eng. Des. 2023, 193, 113688. [Google Scholar] [CrossRef]

- Tincani, A.; Ciurluini, C.; Nevo, A.D.; Giannetti, F.; Tarallo, A.; Tripodo, C.; Cammi, A.; Vannoni, A.; Eboli, M.; Del Moro, T.; et al. Conceptual Design of the Steam Generators for the EU DEMO WCLL Reactor. Energies 2023, 16, 2601. [Google Scholar] [CrossRef]

- Eboli, M. The LIFUS5 separate effect test facility experimental programme. Nucl. Eng. Des. 2023, 411, 112425. [Google Scholar] [CrossRef]

- ROHR2, Version 33; SIGMA Ingenieurgesellschaft mbH: Unna, Germany, 2021. Available online: www.rohr2.de (accessed on 30 June 2022).

- BPVC.III.1.NC-2015; Boiler and Pressure Vessel Code—Section III: Rules for Construction of Nuclear Power Plant Components, Division 1, Subsection NC: Class 2 Components. The American Society of Mechanical Engineers (ASME): New York, NY, USA, 2015.

- Ciurluini, C.; Giannetti, F.; Tincani, A.; Del Nevo, A.; Caruso, G.; Ricapito, I.; Cismondi, F. Thermal-hydraulic modeling and analysis of the Water Cooling System for the ITER Test Blanket Module. Fusion Eng. Des. 2020, 158, 111709. [Google Scholar] [CrossRef]

- Ciurluini, C.; Narcisi, V.; Tincani, A.; Ferrer, C.O.; Giannetti, F. Conceptual design overview of the ITER WCLL Water Cooling System and supporting thermal-hydraulic analysis. Fusion Eng. Des. 2021, 171, 112598. [Google Scholar] [CrossRef]

- ISL Inc. RELAP5/Mod3.3 Code Manual Volume I: Code Structure, System Models, and Solution Methods; ISL Inc. (Nuclear Safety Analysis Division): San Diego, CA, USA, 2003. [Google Scholar]

- Gonfiotti, B.; Ciurluini, C.; Giannetti, F.; Arena, P.; Del Nevo, A. Assessment of the relevancy of ENEA Water Loop facility with respect to ITER WCLL TBS Water Cooling System by considering their thermal-hydraulic performances during selected transient conditions. In Proceedings of the ISFNT-15 Conference, Las Palmas de Gran Canaria, Spain, 10–15 September 2023. [Google Scholar]

| Primary System | |||

| 1 | Max. electrical heating power | kW | 1000 |

| 2 | Max. EB gun power | kW | 800 |

| 3 | Max. Pressurizer (PRZ) heaters power | kW | 12 |

| 4 | Design pressure | MPa | 18.5 |

| 5 | Design coolant temperature | °C | 350 |

| 6 | Max. pumping head | m | 169 |

| 7 | Nominal mass flow rate | kg/s | 3.74 |

| 8 | Structural Material | -- | AISI316L |

| Secondary System | |||

| 9 | Max. PRZ heaters power | kW | 2 |

| 10 | Design pressure | MPa | 2.5 |

| 11 | Design coolant temperature | °C | 220 |

| 12 | Max. pumping head | m | 36 |

| 13 | Nominal mass flow rate | kg/s | 4.3 |

| 14 | Structural Material | -- | AISI316L |

| Tertiary System | |||

| 15 | Design pressure | MPa | 0.6 |

| 16 | Design coolant temperature | °C | 80 |

| 17 | Max. pumping head | m | 31 |

| 18 | Nominal mass flow rate | kg/s | 17.3 |

| 19 | Structural Material | -- | AISI304 |

| Dead Load | POS/NOS Cat. I | |

|---|---|---|

| Thermal expansion | X | |

| Acceleration due to gravity | X | X |

| Forces due to internal pressure | X | X |

| Output | Node ID | Unit | Value |

|---|---|---|---|

| Maximum displacement | 5580 | (mm) | X: 9.81/Y: −8.45/Z: −2.53 |

| Maximum equivalent stress | 4206 | (Mpa) | 80.9 |

| Maximum utilization factor for SSL as per ASME III Class 2 | 5514 | (%) | 53.7 |

| Output | Node ID | Unit | Value |

|---|---|---|---|

| Maximum displacement | 4666 | (mm) | X: 5.56/Y: 51.40/Z: 5.19 |

| Maximum equivalent stress | 5562 | (Mpa) | 163.6 |

| Maximum utilization factor for SE as per ASME III Class 2 | 1401 | (%) | 133.7 |

| Primary System | |

|---|---|

| Initial steady state | From 0 s to 1000 s |

| Ramp down | From 1000 s to 1200 s |

| Dwell phase | From 1200 s to 2290 s |

| Ramp up | From 2290 s to 2350 s |

| Pulse phase | From 2350 s to 2800 s |

| Ramp down | From 2800 s to 3000 s |

| Dwell phase | From 3000 s to 4090 s |

| Ramp up | From 4090 s to 4150 s |

| Pulse phase | From 4150 s to 4600 s |

| Ramp down | From 4600 s to 4800 s |

| Dwell phase | From 4800 s to 5890 s |

| Ramp up | From 5890 s to 5950 s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vannoni, A.; Arena, P.; Gonfiotti, B.; Eboli, M.; Lorusso, P.; Tincani, A.; Badodi, N.; Cammi, A.; Giannetti, F.; Ciurluini, C.; et al. The Design of Water Loop Facility for Supporting the WCLL Breeding Blanket Technology and Safety. Energies 2023, 16, 7746. https://doi.org/10.3390/en16237746

Vannoni A, Arena P, Gonfiotti B, Eboli M, Lorusso P, Tincani A, Badodi N, Cammi A, Giannetti F, Ciurluini C, et al. The Design of Water Loop Facility for Supporting the WCLL Breeding Blanket Technology and Safety. Energies. 2023; 16(23):7746. https://doi.org/10.3390/en16237746

Chicago/Turabian StyleVannoni, Alessandra, Pietro Arena, Bruno Gonfiotti, Marica Eboli, Pierdomenico Lorusso, Amelia Tincani, Nicolò Badodi, Antonio Cammi, Fabio Giannetti, Cristiano Ciurluini, and et al. 2023. "The Design of Water Loop Facility for Supporting the WCLL Breeding Blanket Technology and Safety" Energies 16, no. 23: 7746. https://doi.org/10.3390/en16237746

APA StyleVannoni, A., Arena, P., Gonfiotti, B., Eboli, M., Lorusso, P., Tincani, A., Badodi, N., Cammi, A., Giannetti, F., Ciurluini, C., Forgione, N., Galleni, F., Catanzaro, I., Vallone, E., Di Maio, P. A., Agostini, P., & Del Nevo, A. (2023). The Design of Water Loop Facility for Supporting the WCLL Breeding Blanket Technology and Safety. Energies, 16(23), 7746. https://doi.org/10.3390/en16237746