A New Multi-Scale Method to Evaluate the Porosity and MICP Curve for Digital Rock of Complex Reservoir

Abstract

:1. Introduction

2. Methods

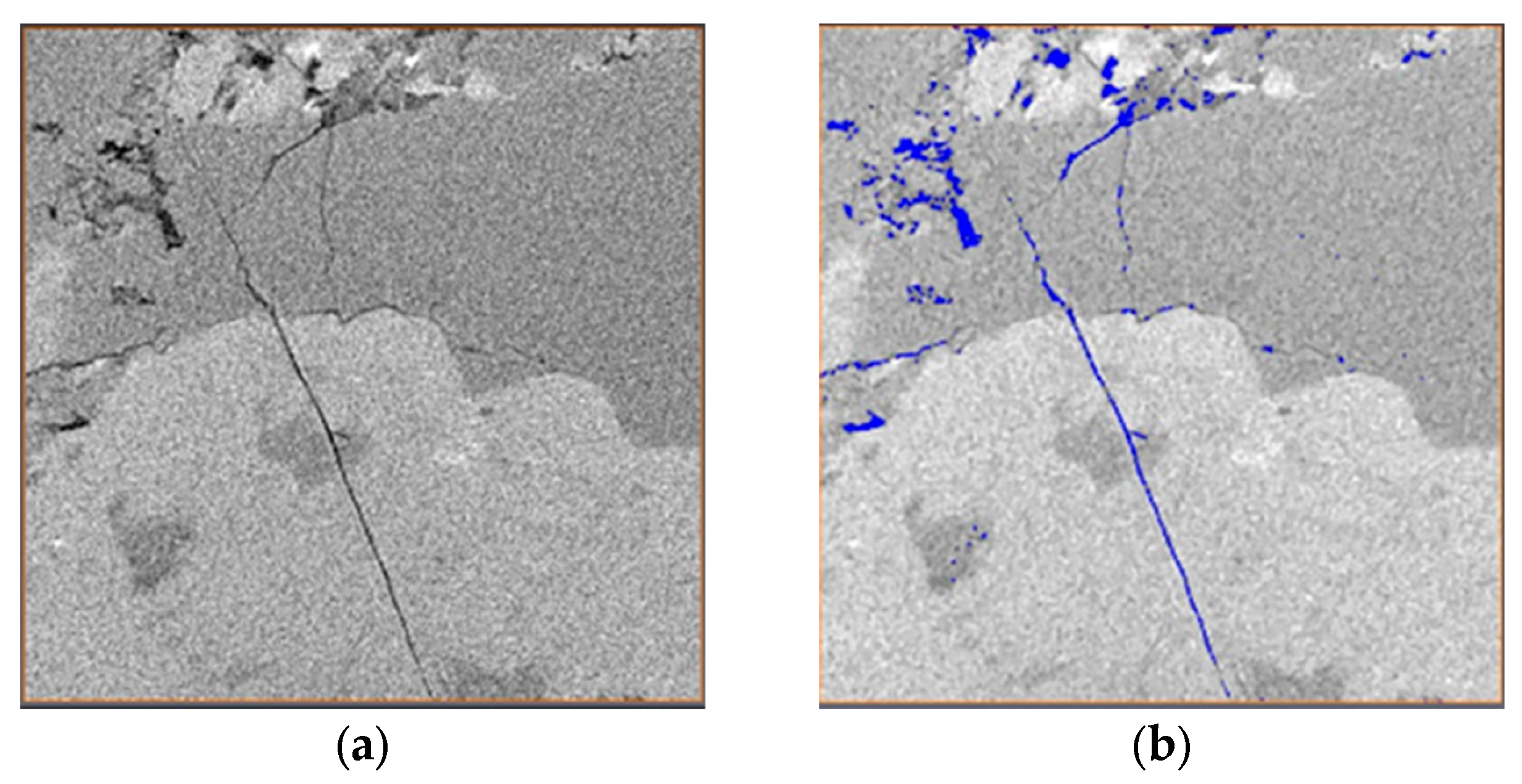

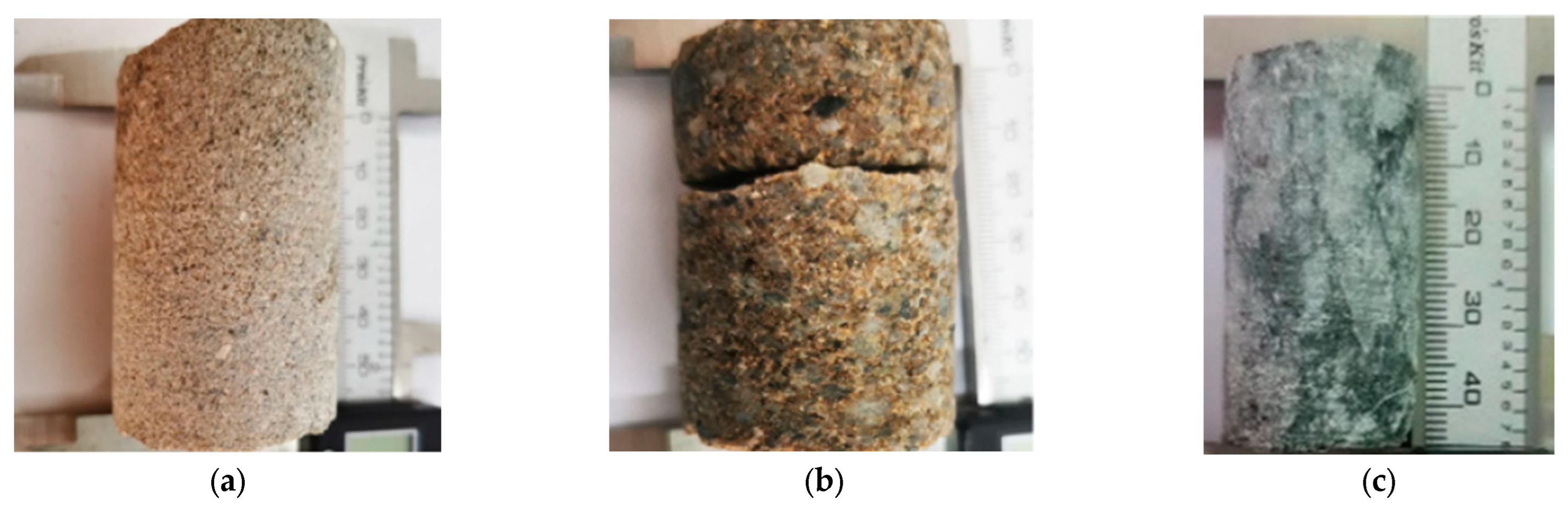

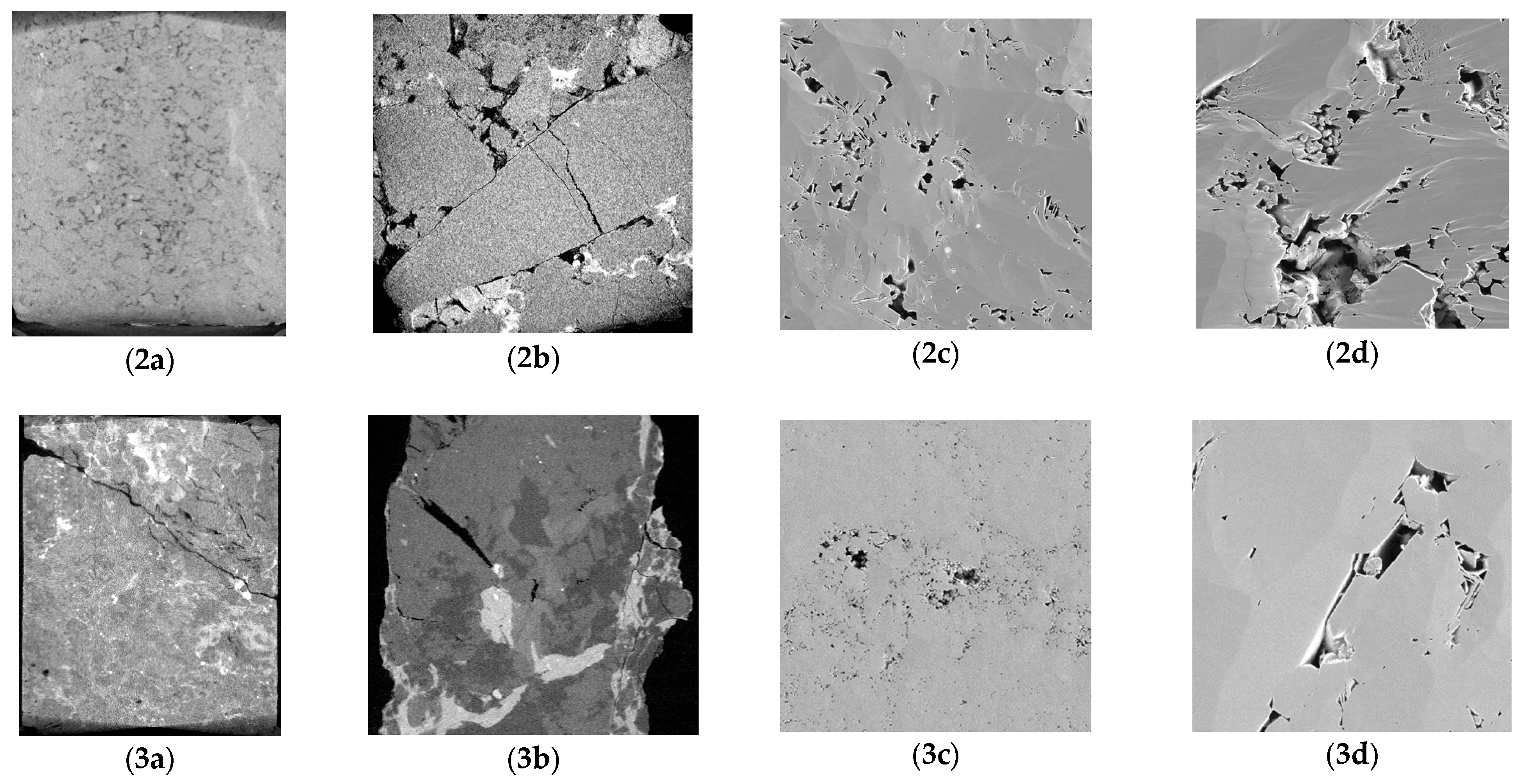

2.1. Image Acquisition Procedures

2.2. Image Segmentation Method

2.3. Calculation of the Porosity at Multi-Scale

2.4. Calculation of the Pore Structure and the Simulated MICP Curve

- 1.

- Pore size distribution: Based on the segmented pore spaces for micro-CT and SEM images, the frequencies or percentages of pores at different size ranges present in the rock sample can be combined together.

- 2.

- Pore radius assignment: Each identified pore is assigned a specific radius to provide the necessary input for Equation (4).

- 3.

- Young–Laplace equation: Equation (4) is then employed to relate the capillary pressure (ΔP) to the radius of curvature (R).

- 4.

- Capillary pressure calculation: Using the assigned pore radii and Equation (4), the capillary pressure for each pore is calculated to quantify the pressure difference for mercury injection.

- 5.

- Mercury saturation determination: The calculated capillary pressure values are then used to determine the corresponding mercury saturation to represent the ratio of the mercury-filled pore volume to the total pore volume.

2.5. Laboratory Measurement of the Porosity and MICP Curve

- 1.

- Core selection and preparation: Representative core plugs are chosen from extracted rock samples, ensuring removal of impurities and uneven sections.

- 2.

- Sample drying: Selected core plugs are placed in a temperature-controlled oven at 60 °C until a constant weight is achieved.

- 3.

- Core size measurement: Digital calipers are used to accurately measure the diameter and length of the plugs, with the results recorded.

- 4.

- Core saturation: Dry plugs are placed in a sealed container and saturated with deionized water to remove any residual air or gas.

- 5.

- Mass measurement in saturated state: The saturated plugs are removed and accurately weighed to determine their mass, with the results recorded.

- 6.

- Porosity calculation: The percentage of porosity is calculated based on the dry and saturated masses of the plugs.

3. Results and Discussion

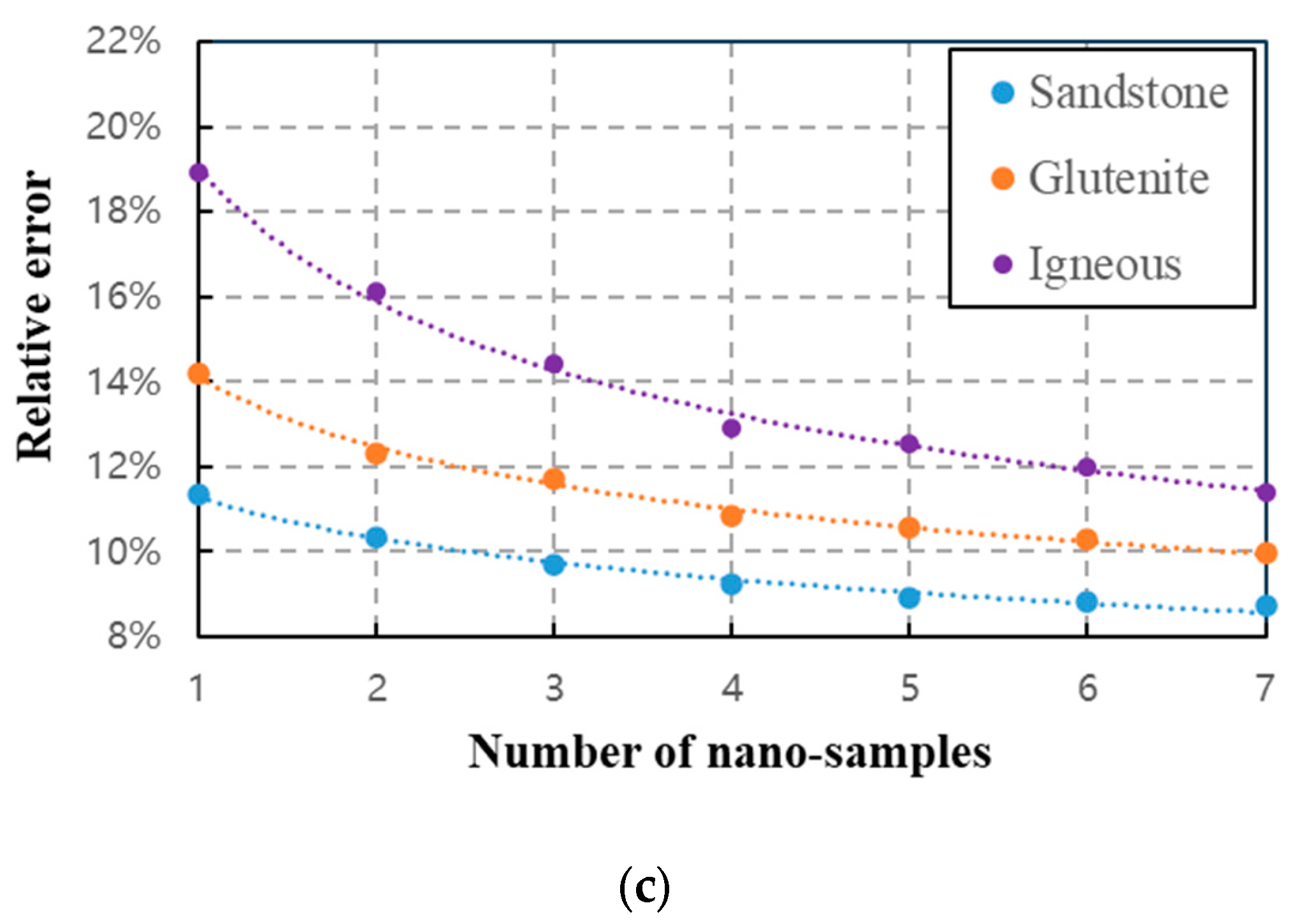

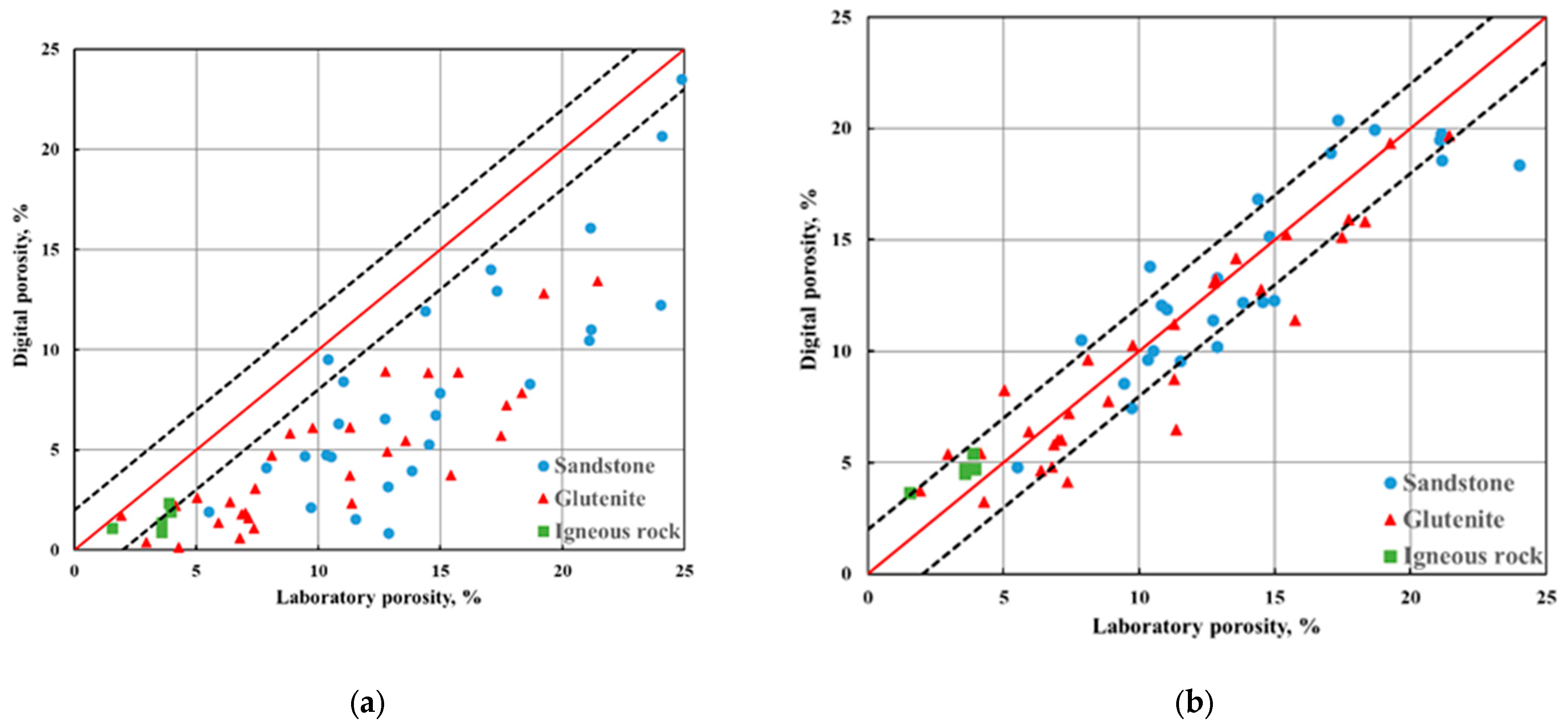

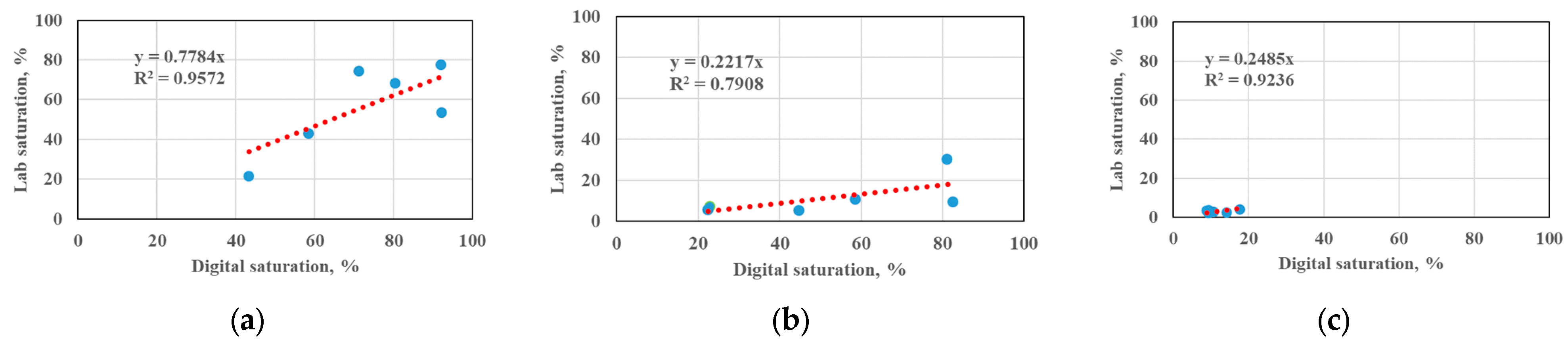

3.1. Evaluation of the Porosity at Multi-Scale

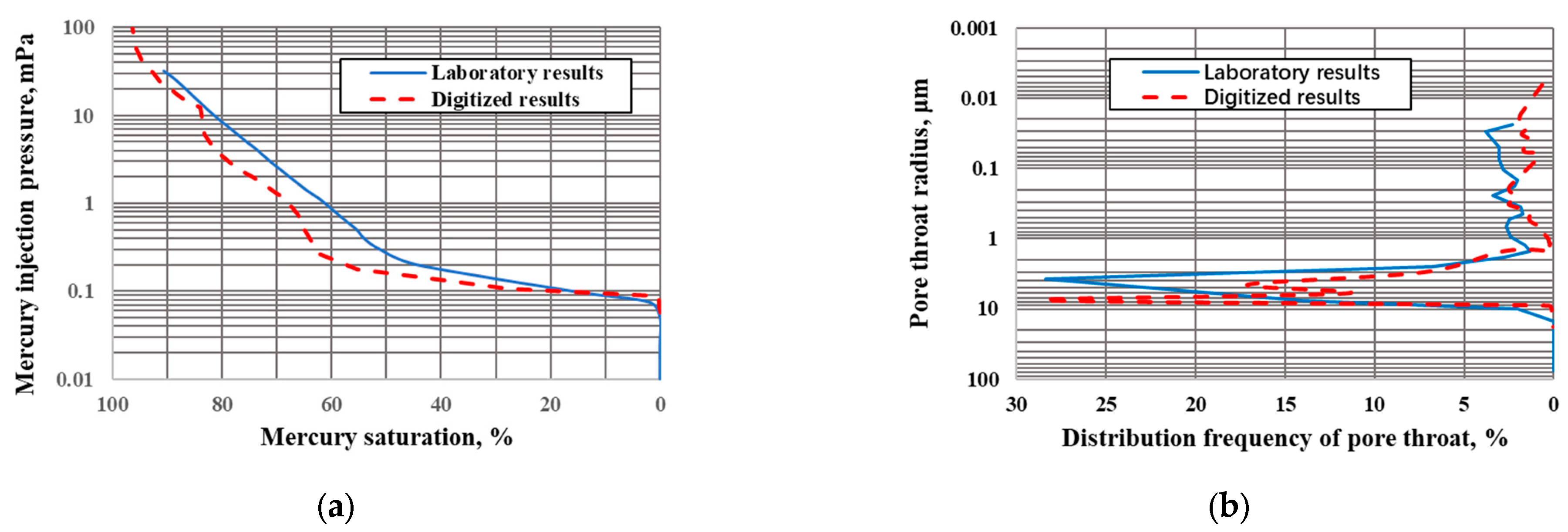

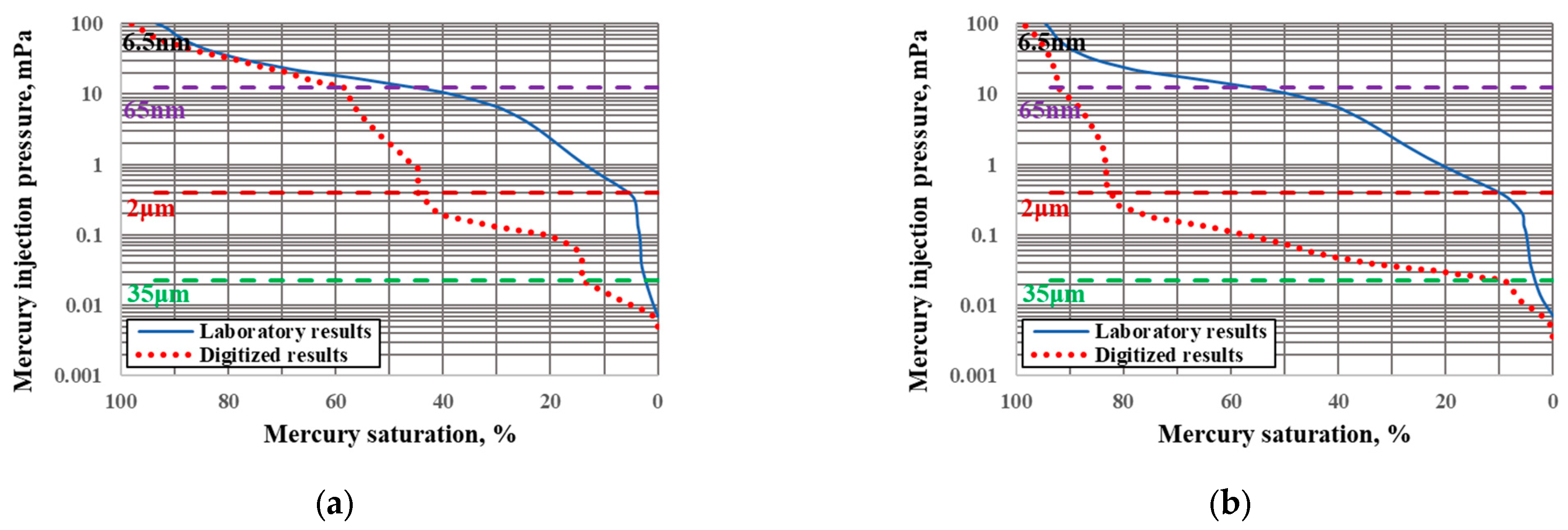

3.2. Evaluation of the Simulated MICP Curve at Multi-Scale

3.3. A Corrected DR Model for the Simulated MICP Curve

4. Conclusions

- (1)

- The traditional DR method by the single-resolution micro-CT scanning (usually 1~3 μm) cannot capture all the pore information, including the nano-pores less than 1 μm and macro-pores greater than 1 mm. Thus, the traditional single-scale DR often leads to lower porosity for both homogeneous and heterogeneous rock. The upscale DR model combining four scales represents the porosity and the pore throat distribution better by comparing to the laboratory experiments.

- (2)

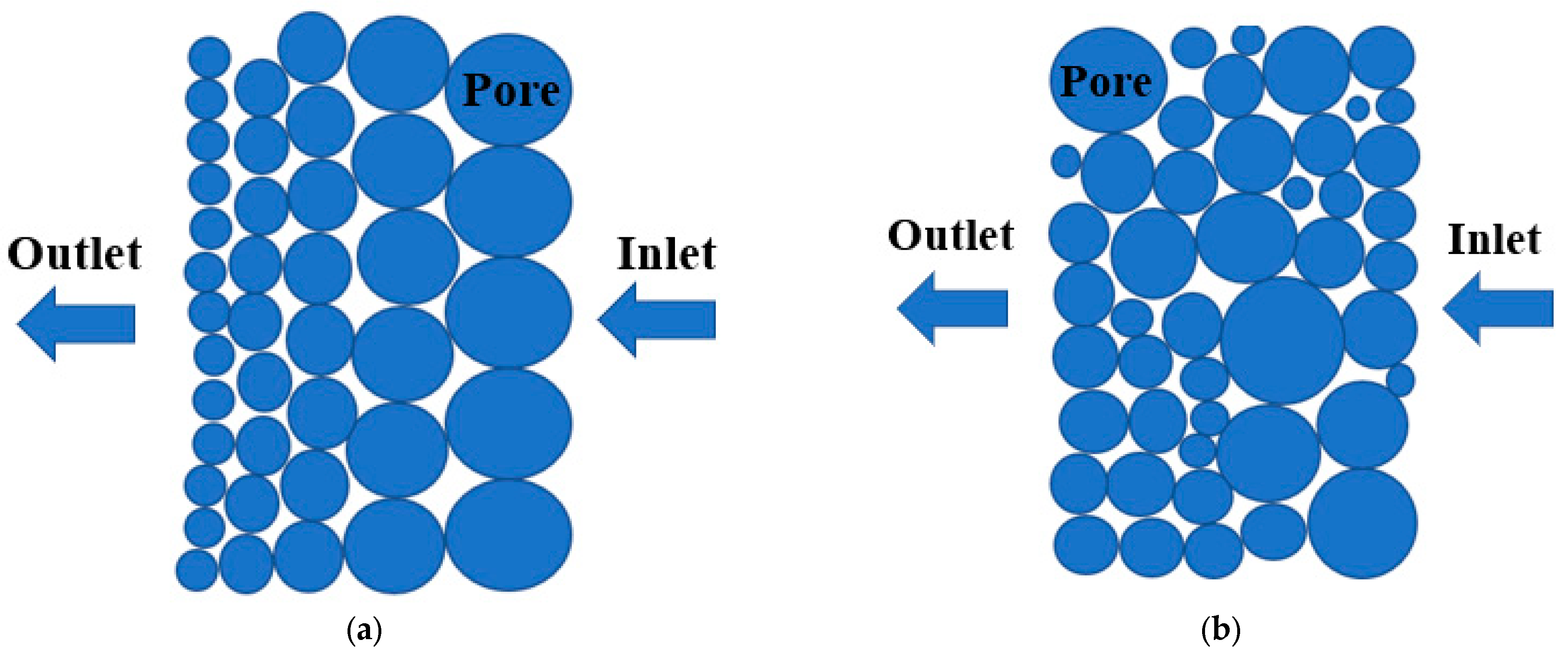

- The pore distribution and the simulated MICP curve from the multi-scale DR agree well with the experiments for sandstones with good homogeneity, but a large discrepancy has been observed for heterogenous rock such as glutenite. A further analysis is performed to investigate the discrepancy, where DR obtains the pore throat distribution from images first, and then calculates the simulated MICP curve from the pore throat distribution through Equation (4), while the laboratory experiment measures the MICP curve first, and then calculates the pore throat distribution. Also, the multi-scale DR accounts for all the pore information at four scales, while the mercury injection experiment only accounts for the connected pores. Thus, the pore throat distribution by multi-scale DR is more accurate, while the MICP curve by the laboratory experiments is more representative. The simulated MICP curve by the multi-scale DR model assumes the mercury enters the pore throats from large to small, while in the experiment mercury enters large and small pores at the same time, as shown in Figure 8.

- (3)

- The multi-scale DR method involves the integration of high-resolution digital imaging and advanced modeling techniques to assess the porous structure of rocks at multiple scales. In comparison to previous upscaling methods, the new method demonstrates a higher level of accuracy in depicting the full range of pore structures across different length scales. This work also allows for more comprehensive comparison with experimental data, which addresses the limitations of previous methods and improves the confidence for the DR application. The implications for petroleum exploration and development are crucial, as rock pore structure greatly affects the flow of fluids, such as oil and gas, through rock formations. Consequently, a better understanding of pore structures via DR techniques can significantly enhance the accuracy of reservoir characterization, forecasting production rates, and optimizing petroleum recovery strategies. The multi-scale DR method offers a potentially valuable tool for these purposes.

- (4)

- The present study utilized the DR model at four different scales to upscale porosity values from the nano-scale to core scale. However, it is worth noting that the characterization of pore connectivity is essential to gain a comprehensive understanding of the pore structure within rock samples. Unfortunately, the pore connectivity can only be determined using the single-scale DR at the 2 µm resolution, which restricts the accuracy in the evaluation of pore connectivity. Thus, the total pore connectivity cannot be accurately captured by the multi-scale DR method and can lead to discrepancies for some rocks. Further research is recommended to investigate this limitation and explore methods that can accurately capture pore connectivity down to the nano-scale.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Antonio, R.C.; Azita, A.S.; Abdelaziz, O. Analysis of the length scale characterized by the yield stress fluids porosimetry method for consolidated media: Comparison with pore network models and mercury intrusion porosimetry. Hydrogeol. J. 2019, 29, 2853–2866. [Google Scholar]

- Blunt, M.J.; Bijeljic, B.; Dong, H.; Gharbi, O.; Iglauer, S.; Mostaghimi, P.; Paluszny, A.; Pentland, C. Pore-scale imaging and modelling. Adv. Water Resour. 2013, 51, 197–216. [Google Scholar] [CrossRef]

- Raza, S.S.; Ge, L.; Rufford, T.E.; Chen, Z.; Rudolph, V. Anisotropic coal permeability estimation by determining cleat compressibility using mercury intrusion porosimetry and stress–strain measurements. Int. J. Coal Geol. 2019, 205, 75–86. [Google Scholar] [CrossRef]

- Radwan, A.E.; Husinec, A.; Benjumea, B.; Kassem, A.A.; Abd El Aal, A.K.; Hakimi, M.H.; Shehata, A.A. Diagenetic overprint on porosity and permeability of a combined conventional-unconventional reservoir: Insights from the Eocene pelagic limestones, Gulf of Suez, Egypt. Mar. Pet. Geol. 2022, 146, 105967. [Google Scholar] [CrossRef]

- Miao, Z.; Jindong, W.; Xuehai, F.; Haifeng, L.; Zhiyong, D.; Lirong, L.; Hao, W. Multifractal Characteristics and Genetic Mechanisms of Pore Throat Structures in Coal Measure Tight Sandstone. Nat. Resour. Res. 2022, 31, 2885–2900. [Google Scholar] [CrossRef]

- Zhao, X.; Yang, Z.; Zhou, S.; Luo, Y.; Liu, X.; Zhang, Y.; Lin, W.; Xiao, Q.; Niu, Z. Research on Characterization and Heterogeneity of Microscopic Pore Throat Structures in Tight Oil Reservoirs. ACS Omega 2021, 6, 24672–24682. [Google Scholar] [CrossRef]

- Wang, R.; Shi, W.; Xie, X.; Zhang, W.; Qin, S.; Liu, K.; Busbey, A.B. Clay mineral content, type, and their effects on pore throat structure and reservoir properties: Insight from the Permian tight sandstones in the Hangjinqi area, north Ordos Basin, China. Mar. Pet. Geol. 2020, 115, 104281. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, Y.; Fang, Z. Pore throat structure and classification of Paleogene tight reservoirs in Jiyang depression, Bohai Bay Basin, China. Pet. Explor. Dev. 2021, 48, 308–322. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, X.; Zhao, Y.; Zhou, Y.; Shan, B. Effect of pore throat structure on micro-scale seepage characteristics of tight gas reservoirs. Nat. Gas Ind. B 2020, 7, 160–167. [Google Scholar] [CrossRef]

- Lai, J.; Wang, G.; Wang, Z.; Chen, J.; Pang, X.; Wang, S.; Zhou, Z.; He, Z.; Qin, Z.; Fan, X. A review on pore structure characterization in tight sandstones. Earth-Sci. Rev. 2018, 177, 436–457. [Google Scholar] [CrossRef]

- Liu, G.; Bai, Y.; Gu, D.; Lu, Y.; Yang, D. Determination of static and dynamic characteristics of microscopic pore throat structure in a tight oil-bearing sandstone formation. AAPG Bull. 2018, 102, 1867–1892. [Google Scholar] [CrossRef]

- Wang, L.; He, Y.; Peng, X.; Deng, H.; Liu, Y.; Xu, W. Pore structure characteristics of an ultradeep carbonate gas reservoir and their effects on gas storage and percolation capacities in the Deng IV member, Gaoshiti-Moxi Area, Sichuan Basin, SW China. Mar. Pet. Geol. 2020, 111, 44–65. [Google Scholar] [CrossRef]

- Jia, L.; Ross, C.M.; Kovscek, A.R. A Pore-Network-Modeling Approach to Predict Petrophysical Properties of Diatomaceous Reservoir Rock. SPE Res. Eval. Eng. 2007, 10, 597–608. [Google Scholar] [CrossRef]

- Karpyn, Z.T.; Piri, M.; Singh, G. Experimental investigation of trapped oil clusters in a water-wet bead pack using X-ray microtomography. Water Resour. Res. 2010, 46, W04510. [Google Scholar] [CrossRef]

- Singh, K.; Niven, R.K.; Senden, T.J.; Turner, M.L.; Sheppard, A.P.; Middleton, J.P.; Knackstedt, M.A. Remobilization of residual non-aqueous phase liquid in porous media by freeze-thaw cycles. Environ. Sci. Technol. 2011, 45, 3473–3478. [Google Scholar] [CrossRef]

- Landry, J.C.; Karpyn, Z.T.; Ayala, O. Relative permeability of homogenous-wet and mixed-wet porous media as determined by pore-scale lattice Boltzmann modeling. Water Resour. Res. 2014, 50, 3672–3689. [Google Scholar] [CrossRef]

- AlRatrout, A.; Raeini, A.Q.; Bijeljic, B.; Blunt, M.J. Automatic measurement of contact angle in pore-space images. Adv. Water Resour. 2017, 109, 158–169. [Google Scholar] [CrossRef]

- Tawfik, M.; Adishesha, A.; Hsi, Y.; Purswani, P.; Johns, R.; Shokouhi, P.; Huang, X.; Karpyn, Z. Comparative Study of Traditional and Deep-Learning Denoising Approaches for Image-Based Petrophysical Characterization of Porous Media. Front. Water 2022, 3, 800369. [Google Scholar] [CrossRef]

- Giudici, L.; Raeini, A.; Akai, T.; Blunt, M.; Bijeljic, B. Pore-scale modeling of two-phase flow: A comparison of the generalized network model to direct numerical simulation. Phys. Rev. E 2023, 107, 035107. [Google Scholar] [CrossRef]

- Bultreys, T.; De Boever, W.; Cnudde, V. Imaging and image-based fluid transport modeling at the pore scale in geological materials: A practical introduction to the current state-of-the-art. Earth-Sci. Rev. 2016, 155, 93–128. [Google Scholar] [CrossRef]

- Cnudde, V.; Boone, M.N. High-resolution X-ray computed tomography in geosciences: A review of the current technology and applications. Earth-Sci. Rev. 2013, 123, 1–17. [Google Scholar] [CrossRef]

- Wildenschild, D.; Sheppard, A.P. X-ray imaging and analysis techniques for quantifying pore-scale structure and processes in subsurface porous medium systems. Adv. Water Resour. 2013, 51, 217–246. [Google Scholar] [CrossRef]

- Qajar, J.; Arns, C.H. A comparative study of micro-CT and mercury intrusion techniques for predicting permeability and surface area evolution during chemical dissolution. Adv. Water Resour. 2022, 168, 104301. [Google Scholar] [CrossRef]

- Chhatre, S.S.; Sahoo, H.; Leonardi, S.; Vidal, K.; Rainey, J.; Braun, E.M.; Patel, P. A Blind Study of Four Digital Rock Physics Vendor Laboratories on Porosity, Absolute Permeability, and Primary Drainage Capillary Pressure Data on Tight Outcrops. Petrophysics 2018, 59, 15–24. [Google Scholar] [CrossRef]

- Jin, X.; Yu, C.; Wang, X.; Liu, X.; Li, J.; Jiao, H.; Su, L. Multi-Scale Digital Rock Quantitative Evaluation Technology on Complex Reservoirs. Presented at the SPE Asia Pacific Oil and Gas Conference and Exhibition, Brisbane, Australia, 23–25 October 2018. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, C.; Yao, J.; Gao, Y. A new voxel upscaling method based on digital rock. Int. J. Multiscale Comput. Eng. 2015, 13, 339–346. [Google Scholar] [CrossRef]

- Hertel, S.A.; Rydzy, M.; Anger, B.; Berg, S.; Appel, M.; de Jong, H. Upscaling of Digital Rock Porosities by Correlation with Whole-Core CT-Scan Histograms. Petrophysics 2018, 59, 694–702. [Google Scholar] [CrossRef]

- Zhang, T. MPS-Driven Digital Rock Modeling and Upscaling. Math. Geosci. 2015, 47, 937–954. [Google Scholar] [CrossRef]

- Liu, X.; Yan, J.; Zhang, X.; Zhang, L.; Ni, H.; Zhou, W.; Wei, B.; Li, C.; Fu, L. Numerical upscaling of multi-mineral digital rocks: Electrical conductivities of tight sandstones. J. Pet. Sci. Eng. 2021, 201, 108530. [Google Scholar] [CrossRef]

- Liu, Y.; Teng, Q.; He, X.; Yang, X. Improved throat finding algorithm of 3D core images. J. Sichuan Univ. Eng. Sci. Ed. 2012, 44 (Suppl. S1), 171–176. [Google Scholar]

- Carrillo, F.J.; Bourg, I.C.; Soulaine, C. Multiphase flow modeling in multiscale porous media: An open-source micro-continuum approach. J. Comput. Phys. X 2020, 8, 100073. [Google Scholar] [CrossRef]

- Okabe, H.; Blunt, M.J. Pore space reconstruction of vuggy carbonates using microtomography and multiple-point statistics. Water Resour. Res. 2007, 43, W12S02. [Google Scholar] [CrossRef]

- Mohebi, A.; Fieguth, P.; Ioannidis, M.A. Statistical fusion of two-scale images of porous media. Adv. Water Resour. 2009, 32, 1567–1579. [Google Scholar] [CrossRef]

- Tahmasebi, P.; Javadpour, F.; Sahimi, M. Multiscale and multiresolution modeling of shales and their flow and morphological properties. Sci. Rep. 2015, 5, 16373. [Google Scholar] [CrossRef]

- Wang, Y.; Armstrong, R.T.; Mostaghimi, P. Enhancing Resolution of Digital Rock Images with Super Resolution Convolutional Neural Networks. J. Pet. Sci. Eng. 2019, 182, 106261. [Google Scholar] [CrossRef]

- Armstrong, R.T.; Sun, C.; Mostaghimi, P.; Berg, S.; Rücker, M.; Luckham, P.; Georgiadis, A.; McClure, J.E. Multiscale Characterization of Wettability in Porous Media. Transp. Porous Med. 2021, 140, 215–240. [Google Scholar] [CrossRef]

- Walczak, M.; Binkowski, M.; Sulikowska-Drozd, A.; Wrobel, Z. Maximum sphere method for shell patency measurements in viviparous land snails based on X-ray microcomputed tomography imaging. Comput. Biol. Med. 2015, 64, 187–196. [Google Scholar] [CrossRef]

- Hosseinzadeh, S.; Kadkhodaie, A.; Mosaddegh, H.; Kadkhodaie-IIkhchi, R. Pore throat size characterization of carbonate reservoirs by integrating core data, well logs and seismic attributes. Geopersia 2019, 9, 395–410. [Google Scholar]

- Ruspini, L.C.; Øren, P.E.; Berg, S.; Masalmeh, S.; Bultreys, T.; Taberner, C.; Sorop, T.; Marcelis, F.; Appel, M.; Freeman, J.; et al. Multiscale Digital Rock Analysis for Complex Rocks. Transp. Porous Media 2021, 139, 301–325. [Google Scholar] [CrossRef]

- Knoll, G.F. Radiation Detection and Measurement, 3rd ed.; Wiley: New York, NY, USA, 2000. [Google Scholar]

- Attix, F.H. Introduction to Radiological Physics and Radiation Dosimetry; WILEY-VCH Verlag GmbH & Co., Ltd., KGaA: Weinheim, Germany, 2004. [Google Scholar]

- Arganda-Carreras, I.; Kaynig, V.; Rueden, C.; Eliceiri, K.W.; Schindelin, J.; Cardona, A.; Seung, H.S. Trainable Weka Segmentation: A machine learning tool for microscopy pixel classification. Bioinformatics 2017, 33, 2424–2426. [Google Scholar] [CrossRef]

- Sun, H.; Vega, S.; Tao, G. Analysis of heterogeneity and permeability anisotropy in carbonate rock samples using digital rock physics. J. Pet. Sci. Eng. 2017, 156, 419–429. [Google Scholar] [CrossRef]

- Al-Kharusi, A.S.; Martin, J. Network extraction from sandstone and carbonate pore space images. J. Pet. Sci. Eng. 2007, 56, 219–231. [Google Scholar] [CrossRef]

- Hilpert, M.; Miller, C. T Pore-morphology based simulation of drainage in totally wetting porous media. Adv. Water Resour. 2001, 24, 243–255. [Google Scholar] [CrossRef]

- Xiao, L.; Mao, Z.Q.; Zou, C.C.; Jin, Y.; Zhu, J.C. A new methodology of constructing pseudo capillary pressure (Pc) curves from nuclear magnetic resonance (NMR) logs. J. Pet. Sci. Eng. 2016, 147, 154–167. [Google Scholar] [CrossRef]

- Zankoor, A.; Khishvand, M.; Mohamed, A.; Wang, R.; Piri, M. In-situ capillary pressure and wettability in natural porous media: Multi-scale experimentation and automated characterization using X-ray images. J. Colloid Interface Sci. 2011, 603, 356–369. [Google Scholar] [CrossRef] [PubMed]

| Index | (%) | (%) | (%) | (%) | (mD) | Type |

|---|---|---|---|---|---|---|

| 1 | 2.17 | 12.81 | 19.34 | 19.25 | 25.29 | Glutenite |

| 2 | 0.90 | 7.84 | 15.83 | 18.34 | 12.91 | Glutenite |

| 3 | 0.65 | 13.44 | 19.68 | 21.44 | 38.09 | Glutenite |

| 4 | 2.24 | 5.71 | 15.12 | 17.47 | 54.44 | Glutenite |

| 5 | 2.29 | 5.47 | 14.18 | 13.56 | 2.35 | Glutenite |

| 6 | 2.46 | 7.23 | 15.93 | 17.72 | 13.29 | Glutenite |

| 7 | 3.69 | 3.75 | 15.25 | 15.43 | 1.24 | Glutenite |

| 8 | 2.88 | 4.93 | 13.24 | 12.83 | 0.62 | Glutenite |

| 9 | 1.90 | 8.88 | 11.41 | 15.74 | 54.13 | Glutenite |

| 10 | 3.08 | 8.85 | 12.78 | 14.51 | 206.19 | Glutenite |

| 11 | 2.74 | 6.10 | 10.28 | 9.76 | 15.64 | Glutenite |

| 12 | 2.28 | 8.92 | 13.07 | 12.75 | 3.62 | Glutenite |

| 13 | 2.52 | 3.08 | 7.22 | 7.41 | 0.33 | Glutenite |

| 14 | 1.09 | 5.82 | 7.77 | 8.85 | 0.24 | Glutenite |

| 15 | 2.13 | 2.35 | 6.49 | 11.36 | 2.04 | Glutenite |

| 16 | 2.32 | 4.74 | 9.62 | 8.10 | 0.49 | Glutenite |

| 17 | 1.19 | 1.73 | 3.73 | 1.92 | 0.00 | Glutenite |

| 18 | 2.46 | 1.79 | 5.80 | 6.86 | 0.10 | Glutenite |

| 19 | 1.59 | 2.41 | 4.65 | 6.39 | 0.05 | Glutenite |

| 20 | 1.20 | 0.62 | 4.81 | 6.78 | 0.15 | Glutenite |

| 21 | 0.84 | 1.10 | 4.12 | 7.36 | 0.21 | Glutenite |

| 22 | 1.60 | 1.62 | 6.01 | 7.13 | 0.09 | Glutenite |

| 23 | 2.14 | 2.22 | 5.42 | 4.16 | 0.02 | Glutenite |

| 24 | 2.05 | 0.14 | 3.25 | 4.27 | 0.11 | Glutenite |

| 25 | 2.05 | 1.88 | 6.03 | 7.01 | 0.11 | Glutenite |

| 26 | 1.83 | 0.40 | 5.37 | 2.96 | 0.02 | Glutenite |

| 27 | 1.42 | 2.61 | 8.25 | 5.03 | 0.03 | Glutenite |

| 28 | 1.64 | 1.37 | 6.39 | 5.92 | 0.01 | Glutenite |

| 29 | 2.95 | 3.72 | 8.74 | 11.30 | 4.92 | Glutenite |

| 30 | 3.72 | 1.56 | 9.57 | 11.51 | 1.95 | Sandstone |

| 31 | 4.96 | 3.16 | 10.20 | 12.86 | 5.93 | Sandstone |

| 32 | 5.50 | 10.47 | 19.50 | 21.09 | 1.21 | Sandstone |

| 33 | 2.25 | 6.74 | 15.14 | 14.80 | 0.29 | Sandstone |

| 34 | 9.20 | 0.86 | 13.29 | 12.87 | 0.08 | Sandstone |

| 35 | 4.51 | 20.48 | 26.15 | 25.46 | 280.09 | Sandstone |

| 36 | 5.28 | 6.34 | 12.08 | 10.81 | 0.16 | Sandstone |

| 37 | 3.07 | 16.08 | 19.77 | 21.14 | 25.72 | Sandstone |

| 38 | 3.35 | 8.31 | 19.95 | 18.67 | 216.63 | Sandstone |

| 39 | 8.27 | 15.08 | 25.08 | 28.96 | 666.30 | Sandstone |

| 40 | 6.60 | 16.79 | 27.05 | 31.05 | 1563.74 | Sandstone |

| 41 | 3.85 | 11.02 | 18.58 | 21.16 | 80.12 | Sandstone |

| 42 | 3.65 | 20.66 | 25.17 | 24.08 | 39.27 | Sandstone |

| 43 | 3.12 | 23.51 | 27.33 | 24.87 | 758.01 | Sandstone |

| 44 | 4.81 | 12.25 | 18.36 | 24.02 | 41.06 | Sandstone |

| 45 | 1.58 | 9.54 | 13.80 | 10.40 | 5.07 | Sandstone |

| 46 | 2.32 | 14.01 | 18.90 | 17.06 | 969.66 | Sandstone |

| 47 | 2.25 | 8.43 | 11.88 | 11.02 | 7.69 | Sandstone |

| 48 | 2.56 | 7.86 | 12.30 | 14.98 | 259.27 | Sandstone |

| 49 | 2.90 | 11.93 | 16.84 | 14.37 | 58.94 | Sandstone |

| 50 | 3.11 | 6.15 | 11.22 | 11.30 | 53.04 | Sandstone |

| 51 | 2.98 | 5.27 | 12.23 | 14.54 | 2.27 | Sandstone |

| 52 | 2.57 | 4.66 | 10.02 | 10.52 | 0.29 | Sandstone |

| 53 | 1.75 | 4.71 | 8.57 | 9.44 | 0.91 | Sandstone |

| 54 | 2.09 | 6.55 | 11.39 | 12.73 | 96.31 | Sandstone |

| 55 | 2.74 | 16.71 | 27.39 | 27.44 | 2994.98 | Sandstone |

| 56 | 2.81 | 19.40 | 27.04 | 28.60 | 5770.15 | Sandstone |

| 57 | 4.12 | 12.95 | 20.37 | 17.32 | 20.95 | Sandstone |

| 58 | 2.16 | 4.75 | 9.63 | 10.31 | 2.75 | Sandstone |

| 59 | 3.40 | 2.13 | 7.46 | 9.70 | 1.41 | Sandstone |

| 60 | 2.33 | 3.98 | 12.18 | 13.83 | 1.37 | Sandstone |

| 61 | 1.48 | 4.13 | 10.52 | 7.87 | 0.06 | Sandstone |

| 62 | 1.60 | 1.92 | 4.79 | 5.50 | 0.01 | Sandstone |

| 63 | 2.35 | 1.94 | 4.71 | 3.95 | 0.17 | Igneous |

| 64 | 2.35 | 2.34 | 5.41 | 3.88 | 0.05 | Igneous |

| 65 | 1.80 | 1.37 | 4.52 | 3.58 | 0.05 | Igneous |

| 66 | 1.74 | 1.11 | 3.64 | 1.54 | 0.03 | Igneous |

| 67 | 2.23 | 0.89 | 4.70 | 3.58 | 0.01 | Igneous |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, T.; Chen, M.; Jin, Y.; Zhang, W.; Shao, H.; Wang, G.; Long, E.; Long, W. A New Multi-Scale Method to Evaluate the Porosity and MICP Curve for Digital Rock of Complex Reservoir. Energies 2023, 16, 7613. https://doi.org/10.3390/en16227613

Xiong T, Chen M, Jin Y, Zhang W, Shao H, Wang G, Long E, Long W. A New Multi-Scale Method to Evaluate the Porosity and MICP Curve for Digital Rock of Complex Reservoir. Energies. 2023; 16(22):7613. https://doi.org/10.3390/en16227613

Chicago/Turabian StyleXiong, Ting, Ming Chen, Yuan Jin, Wei Zhang, Haipeng Shao, Guanqun Wang, Ethan Long, and Wei Long. 2023. "A New Multi-Scale Method to Evaluate the Porosity and MICP Curve for Digital Rock of Complex Reservoir" Energies 16, no. 22: 7613. https://doi.org/10.3390/en16227613

APA StyleXiong, T., Chen, M., Jin, Y., Zhang, W., Shao, H., Wang, G., Long, E., & Long, W. (2023). A New Multi-Scale Method to Evaluate the Porosity and MICP Curve for Digital Rock of Complex Reservoir. Energies, 16(22), 7613. https://doi.org/10.3390/en16227613