Abstract

Different preservation temperatures for sample storage in space stations and corresponding refrigerator devices have been designed. In the below-freezing environment, frost will occur on the inner wall surface and the sealing place of the refrigerator device, which may have an impact on the operating performance and sealing performance of the refrigerator device. This paper analyzes the impact of frost on refrigerator storage devices, and designs and verifies a scheme of air cooling with a hollow seal method to reduce the impact of frost. The designed refrigerator was tested for air cooling, sealing, and long-term performance. The tests show that the air-cooling structure designed in this paper can effectively reduce the frost on the sample surface. A cumulative helium mass spectrometry leak detection method is applied to verify that the hollow seal structure designed has a better sealing property, which can prevent the diffusion of water vapor and frosting at the sealing position. The design with air cooling and hollow sealing has less frost and more stable performance for long-term operation. The results demonstrate this refrigerator would have the capability of operating on-orbit. The frost-preventing method for space station refrigerator designed in this paper has significance for the design of similar cryogenic equipment in microgravity environments.

1. Introduction

There are several types of on-orbit refrigerators used on the International Space Station (ISS) and China’s space station (CSS) [1,2,3], which can be categorized into the experimental rack (ER) type and the experimental unit (EU) type [4].

The ER types of space station refrigerator include the Minus-Eighty-Degree Laboratory Freezer for ISS (MELFI) [5,6] and ISS Crew Refrigerator Freezer Rack (RFR) [7]. There are a number of separate units with Dewar structures in MFLFI, which covers the cooling temperature zones of −80 °C, −35 °C, AND 2 °C. The MELFI is divided into four large storage zones, each of which is subdivided into four smaller drawers.

The EU type of refrigeration devices include the Microgravity Experiment Research Locker Incubator (MERLIN, ISS) [8], General Laboratory Active Cryogenic ISS Experiment Refrigerator (GLACIER, ISS) [9], Refrigerator Storage Equipment (RSE, CSS) [10], etc., which are shown in Figure 1.

Figure 1.

Different refrigerators on space station.

The cooling parameters of these refrigerators are shown in Table 1. It can be seen that these refrigerators are at risk of frosting.

Table 1.

Parameters of refrigerators in space station.

In order to provide a suitable living environment for astronauts on the space station, a certain amount of air circulation is necessary. The temperature in the space station generally ranges from 19.5 °C to 26.5 °C, and the airflow generally ranges from 0.08 m/s to 0.5 m/s, while the humidity conditions are typically maintained between 30% and 70%. Various samples are stored for extended periods of time in the space station refrigerator. These samples include plants, cell culture boxes, protein storage boxes, and ice bricks, all of which are kept in a low-temperature environment. Experiments on the space station are continuous, so samples are constantly being taken and placed inside the station refrigerator. When the refrigerator door is opened, the water vapor from the cabin would diffuse into the refrigerator. When the door is closed, the diffused water vapor would frost on the walls of the refrigerator and the surface of the samples.

Furthermore, the absence of gravity on the space station makes it difficult for astronauts to perform some large torque and complex operations. Therefore, the sealing locking torque of the space station refrigerator is smaller than that of the ground refrigerator, which is easier for astronauts to operate in orbit. However, this reduced sealing force may result in poorer sealing performance compared to ground refrigerators, leading to slowly vapor diffusion into the refrigerator. Consequently, continuous frost occurs on the inside surface, the seal location, and other locations.

All space station refrigerators have some potential for frosting. There is no natural convective heat transfer between the surface and the air in a microgravity environment, which mainly relies on the thermal conductivity of the surface. After frosting, the frost layer will form on the surface of the refrigerator device, consisting of ice and air bubbles, which is forming a structure similar to an adiabatic material. The frost layer has low thermal conductivity and result in adverse effects on sample storage, refrigeration system operation, etc.

Refrigerator frost is a very common occurrence. On ground refrigerators, frost is generated in the coldest position of the refrigerator [14,15]. Frosting occurs when water vapor in the air comes into contact with a surface whose temperature is below the dew point temperature. In the early stages of frost generation, the independent frost crystals resemble ribs or fins. With time changes, the cold surface is gradually covered by ice crystals, forming a continuous frost layer. The refrigerator, in long-term use, will unavoidably see the occurrence of frost, which can be divided into the door-open frost and door-closed frost.

When the refrigerator door was opened, the water vapor would be brought in and would cause a significant amount of frost [16]. If the refrigerator temperature is low, the frost layer will be directly generated on the walls and samples. Therefore, opening the door should be avoided for a long time to reduce the entry of water vapor.

In the closed state, the main exchange of water vapor comes from the leakage around the door seal [17]. A frost layer may form on the seal or on the wall surface near the sealing strip. After a long time of operation, the frost layer would form from the outside to inside, respectively, on the wall surface.

The current methods to prevent frost are mainly to reduce cold leakage, enhance the seal, and enhance the magnetic attraction of the door [18,19]. For the space station refrigerator, the operation should be reasonably optimized. Frosting can be reduced by optimizing sample storage to reduce the number of times doors are opened, and by reducing operation time through astronaut ground training and ergonomic design. The design of enhanced sealing and frost reduction on sample surfaces should be considered in space station refrigerators.

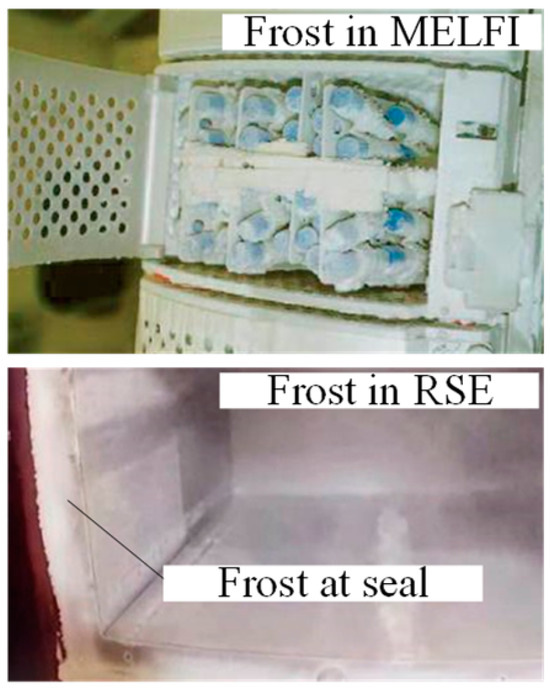

The multiple picking and storage of samples in the refrigerator device require multiple instances of opening and closing the door, which can cause the thickening of the frost layer, increasing the adverse effect of frosting as the operating time increases in the space station. The frost on the samples and seals is shown as Figure 2.

Figure 2.

Frosting on the samples and seals in MELFI and RSE.

In addition, the frosting at the sealing area of the refrigerator can cause possible microleakage. Water vapor outside of the refrigerator could diffuse into the refrigerator, generating additional frost at the sealing area and the surface. When the frost layer reaches a certain thickness, it may cause the sealing failure of the refrigerator device.

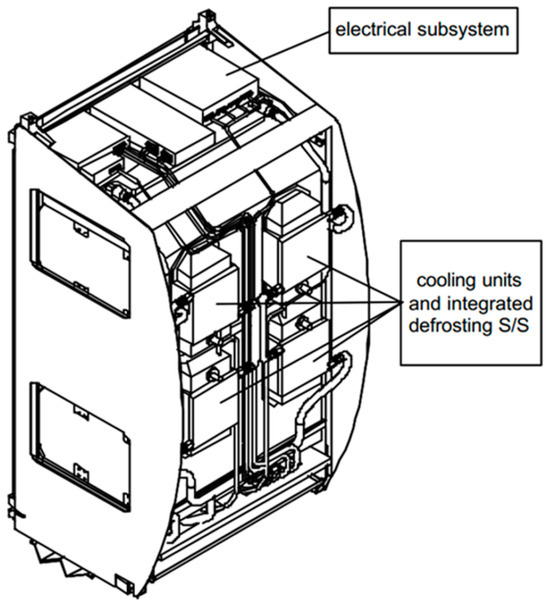

Therefore, a refrigerator in orbit should be defrosted periodically. There are two types of defrosting methods, active defrosting and passive defrosting. Passive defrosting has a stopping operation and slow melting of the frost layer, and active defrosting uses the heating method to defrost. After defrosting, the water is manually wiped off by the astronauts. RFR and MERLIN use their own TEC reverse heating capability to achieve active defrost, the RFR defrosting system is shown as Figure 3. MELFI defrosts with a slow temperature rise, then hold to 2 °C. MSE uses an additional electric heater for defrosting. After defrosting, the water droplets generated in refrigerators are wiped away by an astronaut. The above products consider the preparation of frost after it has been generated. However, there is no special design on the current space station refrigerator to prevent frost formation.

Figure 3.

Defrosting system for RFR.

Frosting can cause performance reduction and possible sample storage failure issues. It also causes additional operations such as additional sample transfers and defrosting. Therefore, refrigerators need to be designed to minimize frosting.

2. Design for Frost Prevention

In order to minimize frost and defrosting times on the space station, two design measures were implemented. Firstly, sealing is an effective way to prevent water vapor from leaking into the low-temperature storage. This will help maintain the samples without the need for frequent defrosting at a high temperature. Secondly, an air-cooling design has been designed to control the evenness of frost formation, especially in the coldest location. By preventing excessive frost in the refrigerator, the refrigerator could have an optimal performance on orbit.

2.1. Sealing Design

The main consideration for the sealing design is the door seal. On the ground refrigerator, two to three seal strips are usually used for multi-layer sealing, as shown in the diagram below.

However, in a spacecraft, the available installation size is limited, making it difficult to use multi-layer sealing. Therefore, a single-layer sealing method was applied to increase volume efficiency.

To achieve this, hollow rubber sealing strips were applied for sealing. Due to the hollow structure, it has better compressibility and achieves a better sealing effect. In addition, the hollow structure is filled with air, which itself has certain insulation properties, allowing for a greater temperature difference between the inside and outside of the sealing strip, leading to frost formation on the outer side of the sealing ring.

Space station devices are affected by a high-level mechanical vibration during launch and transportation, which may result in friction between the door and the seal, causing damage to the seal. Solid sealing strips with high structural strength can withstand the mechanical vibration environment, and have applications in space station refrigerators (for example, RSE) and vacuum containers.

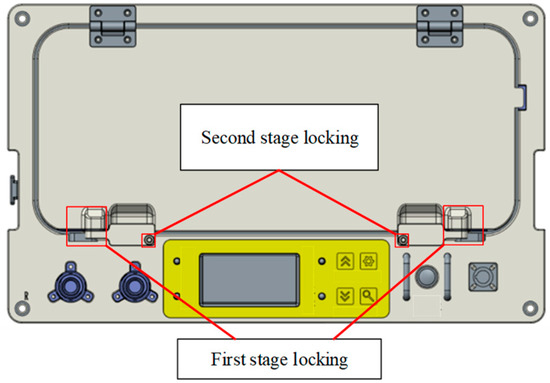

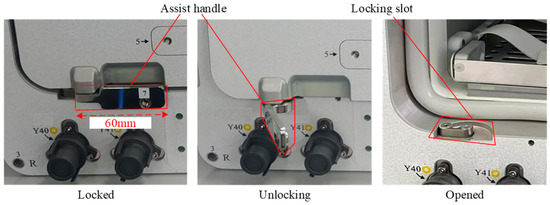

To solve the problem of the poor structural strength of hollow sealing strips, a two-stage locking structure is applied in this paper, which can prevent the destruction of the sealing strips under space station mechanical vibration conditions. The first-stage locking is a lever structure, which could reduce the operation force and is used in all periods. The second-stage locking is a screw locking, which can effectively control the relative position of the door and the seal, and is used in the transportation and launching periods. This locking structure is shown as Figure 4 and Figure 5.

Figure 4.

Two-stage locking structure.

Figure 5.

Locking design of the space station refrigerators.

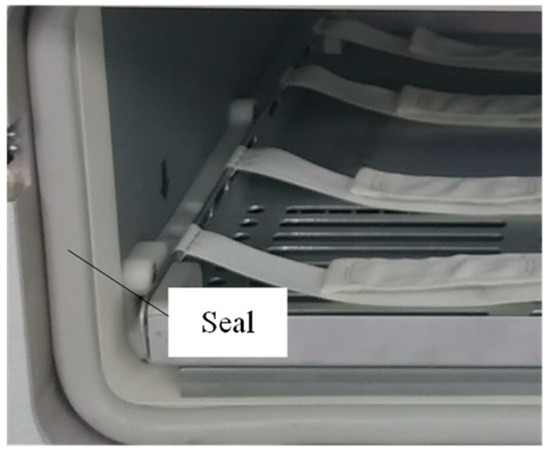

Silicone rubber is used more in low-temperature seals, but has fewer applications in a spacecraft. In order to test the performance of the silicone rubber sealing, two methods were considered: the leakage testing method and the thermal insulation performance testing method. The sealing strip is shown in Figure 6.

Figure 6.

Sealing in the refrigerator.

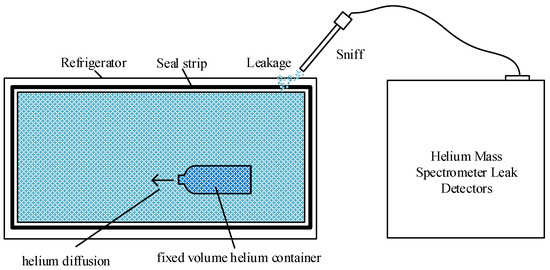

The seal strip with solid silicone rubber and hollow silicone rubber are tested after locking using helium mass spectrometry leak detection (HMSLT). The principle of HMSLT is to put in a certain amount of helium gas and use a helium mass spectrometer to detect helium leaks [20]. Since the space station refrigerator does not have a gas vent for HMSLT testing, a cumulative helium leakage detection method (CHMSLT) was developed for the refrigerator leakage testing in this paper.

2.2. Air-Cooling Design

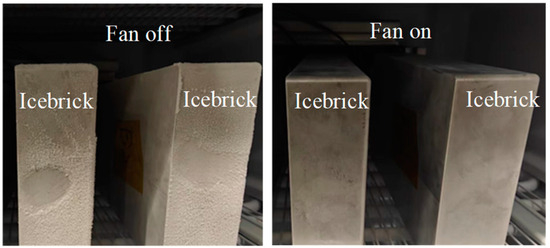

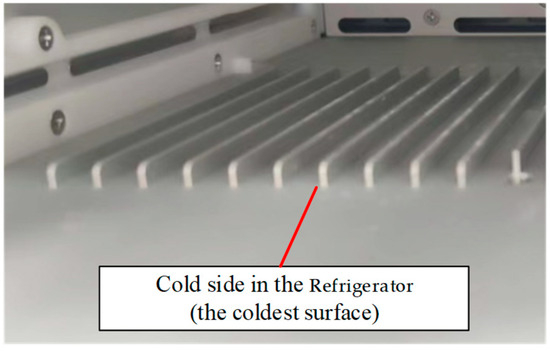

Air cooling is a great method with which to prevent frost formation on the ground. Two groups of ice bricks were compared in a refrigerator in fan-on and fan-off modes. As the hollow sealing strip has superior thermal insulation and sealing performance, there is no frosting at the sealing position, while, in the sample position (ice brick), there is a clear difference in the thickness of the frost. The results show that there is much less frost on the ice brick in the fan-on mode than in the fan-off mode, which could be seen in Figure 7. It indicated that air cooling is an effective method with which to reduce frost in the sample position. It could be concluded that the internal airflow was driven by a fan to frost at the coldest surface, thus avoiding frost at the sample location and seal location.

Figure 7.

Impact of fans on frosting.

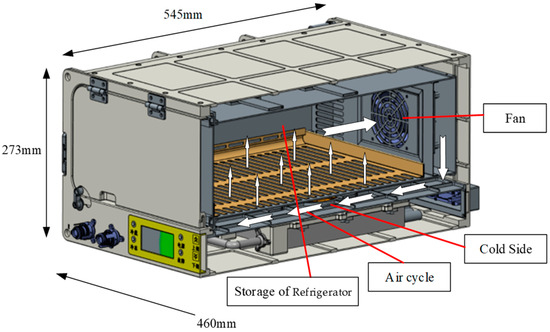

The size of all devices is greatly constrained in space station, making it difficult to use the commonly used cross-flow fans. Therefore, a micro fan and micro flow channel structure were designed in our refrigerator, as shown in Figure 8. This design ensures airflow inside the refrigerator even in a microgravity environment, allowing for a more even temperature distribution on the surfaces. Due to the circulation of air, the location of the frost is more evenly distributed, reducing the thickness of the frost layer in the coldest areas. Additionally, the presence of airflow enhances the internal heat conduction of the refrigerator, minimizing the impact of frost on the performance of the refrigerator.

Figure 8.

Refrigerator with micro fan structure.

3. Results

Three methods were designed to verify the validity of the refrigerator using silicone rubber sealing and air cooling: leakage testing, thermal insulation performance testing, and long-term testing.

3.1. Leakage Testing

The helium mass spectrometry leak detection method is a nondestructive testing method that can be used to test the hermeticity of a product without damaging the structure. The common helium mass spectrometry leak detection methods are the sniffer direct method and the vacuum box method. These methods require a special filling port to fill the helium gas, then detect outside with a leak detector.

The sealing area to be tested in this paper was the internal storage of the refrigerator. In order to prevent heat leakage from the refrigerator, there was no special helium-filled port between the inside and outside of the refrigerator. If helium was blown directly into the internal storage, a large amount of helium would leak into the external environment, then affect the detection.

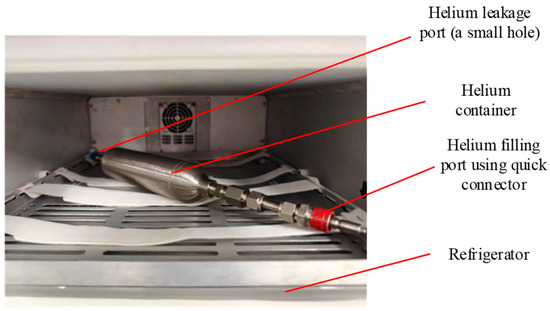

Therefore, a cumulative helium mass spectrometry leak detection method is used in this paper. A fixed volume container was filled with helium gas which would slowly diffuse in the internal storage. Then, the leakage of this refrigerator was detected using a leak detector outside. The schematic diagram is shown as Figure 9 and Figure 10.

Figure 9.

Leakage detection.

Figure 10.

Helium container in the refrigerator.

The testing steps are: (1) put a fixed volume helium container with a small hole into the storage device and quickly close the door seal; (2) leave it for about 4 h and wait for the helium to slowly leak into the inside of the refrigerator device; (3) use the helium mass spectrometry leak detector to detect the external environment and the standard leakage holes, respectively; (4) use the helium mass spectrometry leak detector to detect the sealing position; and (5) carry out the calculation of the leakage rate.

The formula for calculating the leakage rate is shown below:

where I is the leak detector indication at the leak location, I0 is the leak detector indication at the ambient, Ic is the leak detector indication at the standard leakage hole, Qc is the leakage rate at the standard leakage hole, V is the storage volume of the refrigerator, and VHe is the volume of helium container. The maximum leakage rate is shown in Table 2.

Table 2.

Comparison of leakage with solid silicone rubber and hollow silicone rubber.

Obviously, in the sealing of the door, hollow silicone rubber sealing has a greater advantage, which can allow us to avoid the leakage of gases, especially water vapor, into the internal part of the refrigerator to cause serious frosting.

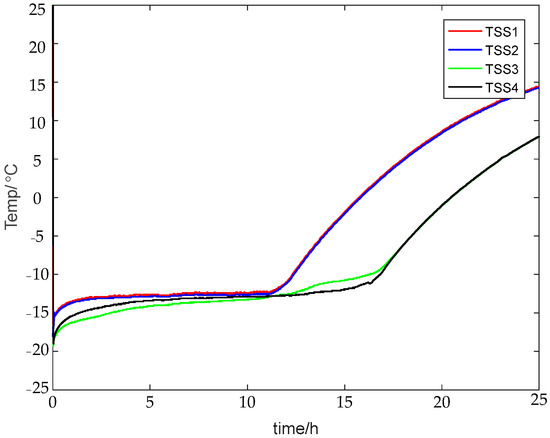

3.2. Thermal Insulation Performance Testing

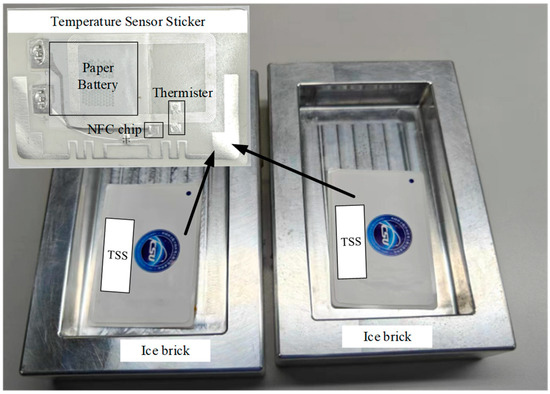

To further investigate the impact of sealing on heat leakage in the refrigerator, an ice brick was used for a cooling capacity maintenance test. The sealed ice brick has a melting point of around −15 °C to −13 °C. During the test, the power of the refrigerator was switched off. TSS1 and TSS2 are located on the ice brick in a refrigerator using solid silicone rubber sealing, while TSS3 and TSS4 are located on the ice brick in a refrigerator using hollow silicone rubber sealing.

As using wired temperature sensors would damage the seal, temperature sensor stickers (TSS) were used to record the internal temperature. The TSSs are powered by paper batteries and have built-in microcircuits for temperature collection and storage, which are shown in Figure 11. After the test, the TSSs are removed and the recorded data can be read using NFC.

Figure 11.

TSS and ice brick.

The data from the cooling capacity maintenance test are shown in Figure 12.

Figure 12.

Cold maintenance capacity with different seals.

The performance of solid silicone rubber sealing at low temperatures is lower than that of hollow silicone rubber sealing, and the cold retention performance is probably only about two-thirds that of hollow silicone rubber. Therefore, during the design of the space station refrigerator, the use of hollow silicone rubber for sealing can ensure the sealing of the container to prevent gas leakage leading to frost on the furniture.

From the results, it can be seen that the performance of solid silicone rubber sealing at low temperatures is lower, with a cooling performance of only about two-thirds of hollow silicone rubber. Therefore, it is recommended to use hollow silicone rubber for sealing to improve the cold maintenance capacity and prevent gas leakage that can lead to frosting.

3.3. Long-Term Testing of Frost Prevention Design

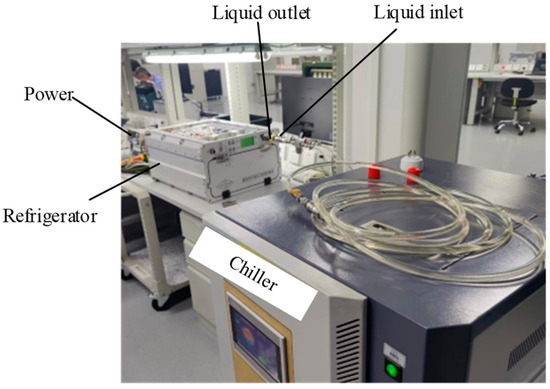

An extended long-term test for this refrigerator is applied to verify the validity of the design using hollow silicone rubber sealing and an air-cooling structure, which is shown as Figure 13.

Figure 13.

Diagram of equipment in long-term testing.

In the long-term testing, a 100 V DC power were supplied to provide power to this refrigerator. A model Lanhaishenjun-2500D water chiller was used as the cooling source. The chiller drove a water and ethylene glycol solution into the cold plate of the refrigerator for heat dissipation. The refrigerator product described in this article uses a thermoelectric cooler as the cooling components. The cold side of the thermoelectric cooler was closely attached to the inner wall surface of the refrigerator storage. A cold plate was installed on the hot side of the thermoelectric cooler to carry away the heat generated by the thermoelectric cooler through the water and ethylene glycol solution.

The refrigerator door was kept closed for most of the time during the long-term testing. It was necessary to bring in outside water vapor in order to accelerate frosting for observation. Therefore, during the testing period, one door-opening operation was performed to simulate the process of astronauts taking samples on orbit.

In addition, the refrigerator described in this paper requires the space station cooling fluids as a heat sink on orbit, which supply lots of devices at the same time. The number of devices connected into the cooling fluid system is constantly changing, which will cause the refrigerator’s cooling flow rate to have certain corresponding changes, resulting in certain impacts on the cooling effect. Therefore, the adjustment of the flow rate was simulated in the long-term testing. The flow rate was controlled to be between 0.8 kg/min to 1.2 kg/min.

The frost in the refrigerator is shown as Figure 14. After running for a long period of 30 days, a small amount of frost has appeared, which is very thin and difficult to measure. It has minimal impact on the overall performance. The sealing area has not experienced any frosting.

Figure 14.

Frost in the refrigerator.

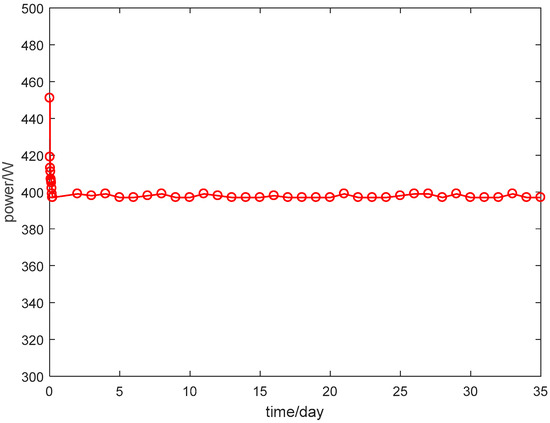

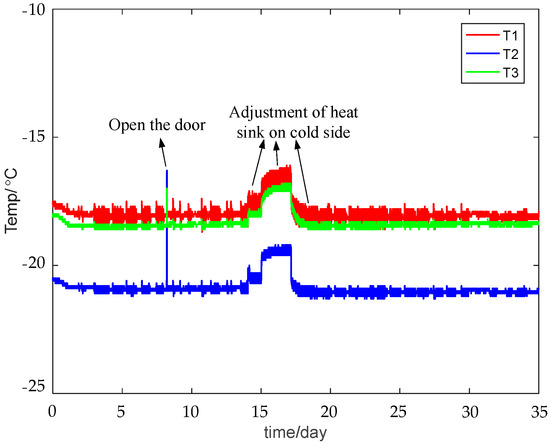

The power consumption of the refrigeration system and the internal temperature of the product after one month of continuous operation are shown in Figure 15. During this period, the flow rate adjustment and door opening operation were carried out, and it can be seen that, after the sealing design and the anti-frost design of the self-contained fan, after a long time of operation, the temperature of the storage area remained stable and was not affected by the frosting of the door opening.

Figure 15.

Power of the refrigerator in a long-term test.

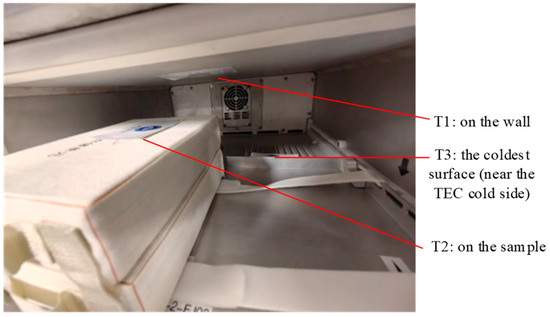

The internal temperature of the refrigerator is shown in Figure 16 and Figure 17. Flow adjustment and door opening operations were performed during this period. T1 and T2 in the figure represent the air temperature, and T3 represents the temperature of the coldest surface.

Figure 16.

TSSs in the refrigerator.

Figure 17.

Temperature in a long-term test.

It can be seen that, after the long-term operation, the temperature of the storage remains stable and is not affected by the frost caused by opening the door. The hollow silicone rubber and air-cooled design of the refrigerator in this article are effective in preventing frost.

4. Conclusions

According to the difficulty of maintaining the refrigerator of the space station after frosting, this paper proposes two measures to prevent frosting: hollow silicone rubber sealing and air cooling. The effectiveness of the design has been verified through a long-term test. Hollow silicone rubber sealing has a greater advantage than solid silicone rubber, and air cooling is useful in reducing the frost in the refrigerator.

- (1)

- The refrigerator designed in this paper can operate for a long time, reduce the impact of frosting on the system, and maintain a stable operating performance. The design concept can be applied to similar low-temperature sealing devices in spacecrafts.

- (2)

- This paper presents a fixed-volume helium mass spectrometry leak detection method and a cooling capacity maintenance test method for a sealed refrigerator. These methods can effectively verify the sealing design of refrigerator devices and assess the impact of sealing.

- (3)

- The micro-fan structure in this paper has been applied to the spacecraft refrigerator, which is currently the first air-cooling refrigerator on the China’s space station. With the air-cooling design, frosting could be controlled at the coldest position. A long-term test has shown that the frost on the sample surface is avoided, which could effectively protect the samples and facilitate the astronauts’ operation. Through the design of a hollow strip, better sealing could be accomplished under smaller operating torque. Through the long-term test on the ground, the frost layer of the device is basically very thin, and the power consumption and temperature of the refrigerator system remained stable. Simultaneously, other refrigerators of the same design would be able to operate well on orbit.

Currently, the refrigerator can operate stably at a maximum condition of −27 °C. For lower-temperature conditions, the existing fans are unable to meet the requirements. Further research is needed to design low-temperature fans and components, as well as develop a more efficient internal circulation system for achieving lower temperatures.

Author Contributions

Conceptualization, D.G.; methodology, D.G.; software, H.Z.; validation, T.D., H.Z., Y.Z. and Q.S.; data curation, D.G.; writing—original draft preparation, D.G.; writing—review and editing, D.G. and Q.S.; project administration, D.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Science and Technology Major Project of China (No. T3142711PN).

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Evetts, S.N. Space life and biomedical sciences in support of the global exploration roadmap and societal development. Space Policy 2014, 30, 143–145. [Google Scholar] [CrossRef]

- Brinckmann, E. ESA hardware for plant research on the International Space Station. Adv. Space Res. 2005, 36, 1162–1166. [Google Scholar] [CrossRef]

- Barmin, I.; Bryukhanov, N.; Egorov, A.; Filatov, I.; Markov, A.; Senchenkov, A.; Tsvetkov, V. Using the progress transport spacecraft in structure of the international space station for realization of scientific experiments under microgravity conditions. Acta Astronaut. 2002, 51, 255–259. [Google Scholar] [CrossRef] [PubMed]

- Gu, Y. The China Space Station: A new opportunity for space science. Natl. Sci. Rev. 2022, 9, nwab219. [Google Scholar] [CrossRef] [PubMed]

- Cheganças, J. MELFI-The First Freezer for Science in Space Station; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2001. [Google Scholar]

- Thompson, S.W.; Lake, R.E. Conducting Research on the International Space Station Using the Express Rack Facilities. In Proceedings of the 29th American Society for Gravitational and Space Research, Pasadena, CA, USA, 3–8 November 2013. [Google Scholar]

- Winter, J.; Zell, M.; Hummelsberger, B.; Cassese, F.; Corsini, R.; Wynne, N.; Meyer, C.; Townsend, P.; Nelson, J.; Stifle, K. The Refrigerator/Freezer Rack for the International Space Station; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1999. [Google Scholar]

- Brendel, L.P.M.; Caskey, S.L.; Ewert, M.K.; Hengeveld, D.; Braun, J.E.; Groll, E.A. Review of vapor compression refrigeration in microgravity environments. Int. J. Refrig. 2021, 123, 169–179. [Google Scholar] [CrossRef]

- Uri, J.J.; Sotomayor, J.L. The International Space Station as a Research Laboratory: A View to 2010 and beyond. In Proceedings of the 58th International Astronautical Congress, Hyderabad, India, 24–28 September 2007. [Google Scholar]

- Zhang, Y.; Wang, B.; Luo, G.Q.; Ni, Z.Q.; Wu, W.W. Study on a gas-bearing Stirling cryocooler for space station low temperature storage device. Cryog. Supercond. 2022, 50, 73–78. [Google Scholar]

- Bhatia, R.S. Review of spacecraft cryogenic coolers. J. Spacecr. Rocket. 2002, 39, 329–346. [Google Scholar] [CrossRef]

- Petrivelli, A. The ESA laboratory support equipment for the ISS. ESA Bull. 2002, 109, 35–36. [Google Scholar] [PubMed]

- Resource Manual for Scientific Experiments on China’s Space Station. Available online: http://www.csu.cas.cn/gb/201905/P020190507639578655422.pdf (accessed on 11 October 2023).

- Xiao, J.; Wang, W.; Zhao, Y.H.; Zhang, F.R. An analysis of the feasibility and characteristics of photoelectric technique applied in defrost-control. Int. J. Refrig. 2009, 32, 1350–1357. [Google Scholar] [CrossRef]

- Xiao, J.; Wang, W.; Guo, Q.C.; Zhao, Y.H. An experimental study of the correlation for predicting the frost height in applying the photoelectric technology. Int. J. Refrig. 2010, 33, 1006–1014. [Google Scholar] [CrossRef]

- Saidur, R.; Sattar, M.A.; Hasanuzzaman, M.; Cheng, C.F.; Masjuki, H.H. Open and closed door moisture transport and corresponding energy consumption in household refrigerator. J. Energy Environ. 2007, 6, 18–27. [Google Scholar]

- Stein, M.A.; Inan, C.; Bullard, C.; Newell, T. Closed door moisture transport in refrigerator/freezers. Int. J. Energy Res. 2002, 26, 793–805. [Google Scholar] [CrossRef]

- Chen, G.F. Optimization and lmprovement Analysis of Condensation lnside Refrigerator. Electr. Appl. 2023, 9, 107–111. [Google Scholar]

- Cheng, L.; Wang, J.; Zhou, G.H.; Liu, P. Optimization research and application of frost reduction technology for horizontal direct-cooling freezer. J. Appl. Sci. Technol. 2021, zk, 238–241. [Google Scholar]

- Mordaunt, K.M. Helium mass spectrometer leak testing of commercial airliner production fuel tanks. Mater. Eval. 2002, 60, 553–557. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).