Abstract

A proper remedy for the overexploitation of biomass and biobased materials in the bioeconomy is the valorization of biorefineries’ side streams into meaningful products. Hence, in pursuit of a cascade utilization of renewables, a unique biorefinery byproduct was investigated for its biogas potential, specifically methane, in continuously operated anaerobic filters. For this purpose, 5-Hydroxymethylfurfural process-wastewater, after supplementation of necessary nutrients, was diluted down to 10, 20, 30, 40, and 50 gCOD/L concentrations and thereafter tested individually at 43 °C and 55 °C. Maximum methane conversion efficiency at either temperature was observed for test substrates with 10 gCOD/L and 20 gCOD/L concentrations. At 43 °C, the anaerobic filters exhibited their highest biogas yields when supplied with the 30 gCOD/L feedstock. Further exposure of the mesophilic and thermophilic consortia to the ensuing 5-Hydroxymethylfurfural process-wastewater dilutions compromised the stability of the anaerobic process due to the soaring concentrations of short-chained volatile fatty acids. The supplementation of necessary nutrients to unlock the methane potential of the given recalcitrant substrate appears insufficient. Techniques like micro aeration, photolysis, or the use of activated carbon in the fixed bed might have the ability to enhance the biochemical methane conversion of such feedstock; otherwise, the introduction of trace elements alone may be adequate if aiming for platforms (volatile fatty acids) via anaerobic technologies.

1. Introduction

The excessive use and exploitation of fossil fuels in a linear economy have resulted in significant environmental degradation, climate change, and resource depletion [1,2]. A viable alternative to such an economy guided by the “take-make-dispose” approach can be the circular bioeconomy’s “reduce-reuse-recycle” model implemented in biorefineries [3], where carbon-based renewables are transformed into biobased fuels, bio- and platform chemicals, and other biomaterials through the application of distinctive conversion techniques [4] such as thermochemical, biochemical, mechanical, and chemical processes [5].

Platform biorefineries, according to the IEA’s Task 42 report, play a pivotal role in the bioeconomy by manufacturing key intermediates and therefore linking the different biorefinery concepts and production chains [6]. Some prominent biobased platforms, among others, as per the US Department of Energy are diacids (e.g., succinic, fumaric, and malic acids), furans (e.g., furfural, 5-hydroxymethylfurfural, and furandicarboxylic acid), and sugar alcohols (e.g., glycerol, xylitol, and sorbitol) [7]. Within furans, 5-Hydroxymethylfurfural (5-HMF) has garnered notable attention in recent years, mainly for being a precursor to about 175 downstream biochemicals and over 20 performance polymers [8]. Exhibiting such a strong potential as a platform compound makes 5-HMF a fundamental building block for biorefineries [9].

Synthesis of 5-HMF from lignocellulosic feedstocks in a biorefinery has been described earlier [10,11,12]. A significant drawback associated with processing such a platform in biorefineries is the substantial volume of process-wastewater or the aqueous material produced, often containing high concentrations of pollutants [13]. Moreover, being inherently renewable, the availability of biomass is constrained by its dependence on land use. At present, integrated biorefineries (coupling platform and waste biorefineries) to produce biochemicals and biogas simultaneously is the sole alternative to alleviate such limiting factors through the cascade utilization of biomass, which promotes sustainability and resource efficiency, thereby closing the loop (circular) [14]. Biogas (methane: 50–75%, carbon dioxide: 25–50%) is the product of the biochemical conversion of organic-rich substances orchestrated by the microbial consortia in an oxygen-free environment, the methane content of which can be harnessed for energy production [15].

Studies evaluating the biogas potential of process-wastewaters or aqueous materials generated through techniques similar to those executed in biorefineries have been reported by a handful of researchers [16,17,18,19,20]. The low methane yields in the mentioned investigations were commonly attributed to the intricate characteristics of the wastewater, primarily due to the presence of furans, phenols, and weak acids resulting from the applied conversion process parameters (severity factor) to the biobased materials [21,22]. These components, with their elevated concentrations in the process-wastewater, are known to hinder the anaerobic process [13]. Since research on the anaerobic conversion of such refuse is still in its infancy, comprehensive mechanisms of their toxicity are not yet well understood. Nevertheless, the modes of inhibition concerning the individual constituents of the aqueous materials have been thoroughly highlighted by Almeida et al. [23] and Ibraheem et al. [24].

The objective of this study is to investigate the biogas potential, particularly methane, of the process-wastewater generated during the industrial-scale synthesis and refinement of 5-HMF under different digestion conditions in continuously operated anaerobic filters (AFs), as such bioreactors are considered appropriate for handling and treating the wastewaters of biorefinery and industrial processes [25]. 5-HMF process-wastewater is an established recalcitrant substrate [13], therefore, as suggested by the authors in their previous works, trace elements (TEs) will be supplemented to the substrate in question to accommodate the microbial consortia. Furthermore, due to its toxic nature, the dosage of the process-wastewater to the AFs will initiate with its reduced concentration [gCOD/L], which will be increased stepwise until the process is halted or restricted. Such a study will attempt to align with the cascading biorefinery concept for 5-HMF and biogas production, also proposed by Świątek et al. [11].

2. Materials and Methods

2.1. Anaerobic Filters

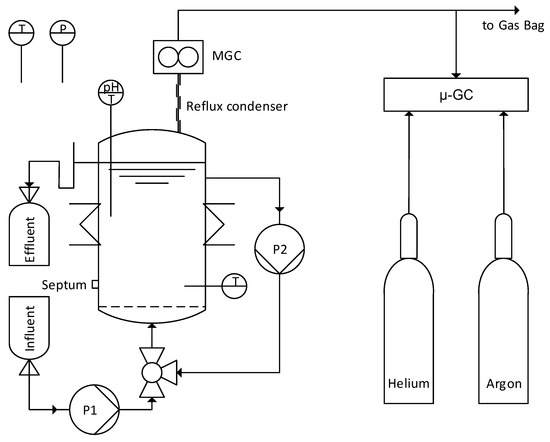

The experiment was conducted using six lab-scale up-flow anaerobic filters (AFs) of identical construction. Each reactor contained carrier materials (HX09 by Christian Stöhr, Marktrodach, Germany) of 9 mm diameter, 7 mm length, and 861 m2/m3 surface area. The working volume and headspace for the individual reactor after incorporation of the carrier materials were evaluated to be 2.6 and 0.7 L, respectively. A water bath (Type E by Julabo, Seelbach, Germany) with integrated pumps and thermostats provided the necessary heat to the AFs. To ensure sustained temperatures, the reactors were enfolded with 32 mm flexible elastomeric foam mats (Armaflex by Armacell, Münster, Germany). A combined electrode (CPS16D by Endress + Hauser, Weil am Rhein, Germany) mounted at the top of each AF provided the process parameter measurements, including pH, redox, and temperature, while an additional sensor (TMR31 by Endress + Hauser, Weil am Rhein, Germany) at the lower half of the AF measured the temperature only. Two peristaltic pumps (Series 114 by Watson-Marlow, Falmouth, UK), i.e., P1 and P2 as depicted in Figure 1, carried out the substrate feeding and circulation in the reactor, respectively. The substrate to the AF was fed from a plastic bag coupled to P1, whereas the discharged effluent was collected into a second bag of similar make.

Figure 1.

Schematic diagram of a fixed bed anaerobic filter, based on [25].

The produced biogas from the AF was directed into a pre-calibrated volumetric gas-counter (MGC-1 by Ritter Apparatebau, Bochum, Germany) via a reflux condenser. With the help of temperature (TMR31 by Endress + Hauser, Weil am Rhein, Germany) and pressure (Cerabar T by Endress + Hauser, Weil am Rhein, Germany) sensors at the gas counter, the measured biogas volumes were recalculated to standard temperature and pressure (STP) conditions (0 °C, 1 atm). A gas chromatograph (3000 µ-GC Inficon, Bad Ragaz, Switzerland) conducted the qualitative analyses of the biogas from each AF every hour. All process data were recorded in a relational database for further analysis.

2.2. Analytical Methods

The Inficon 3000 µ-GC, equipped with two channels (channel A and channel B), performed the qualitative analysis of the produced biogas. Channel A with a Molsieve column (14 m × 320 µm × 30 µm) and Argon as the carrier gas analyzed the H2, O2, N2, and CH4 content of the biogas, whereas channel B with a PLOTQ column (8 m × 320 µm × 20 µm) and Helium as the carrier gas analyzed the CO2 and H2S. The sample inlet and injector temperatures for both channels were set to 80 °C, while the column temperature was 100 °C and 60 °C with an operating pressure of 2 and 1.7 bars for channel A and channel B, respectively. The sample pump operated for 15 s for the two channels [26].

The COD (chemical oxygen demand) measurements of the influent and the effluent were performed via the Hach Lange COD cuvette test technique by utilizing the high-performance heating block (HT 200 S by Hach Lange, Berlin, Germany) for sample digestion at 170 °C for 15 min; subsequently, a VIS spectrophotometer (DR 3900 by Hach Lange, Berlin, Germany) was used for evaluating Cr3+ green coloration in the sample cuvettes owing to K2Cr2O7 consumption by oxidizable components in the sample [25].

As given by Lemmer and Krümpel [27], the VFAs (volatile fatty acids) content of the influent and the effluent was determined by Shimadzu GC-2010 Plus gas chromatography with Helium as a carrier gas. The apparatus contains an SGE 25 m × 0.32 mm column with a BP21 polyethylene glycol-bonded 0.25 µm film together with a flame ionization detector (FID). The program initiates at 60 °C for two minutes followed by raising the temperature to 150 °C at a rate of 30 °C/min and eventually to 240 °C at a rate of 8 °C/min.

Carbon and nitrogen contents of the substrate, determined as total carbon (TC), inorganic carbon (IC), and total nitrogen (TN), were measured using Analytik Jena multi N/C 2100 S (ChD) BU [27]. Deducting IC from TC yielded the total organic carbon (TOC) of the test sample. Dissolved carbon (DC), dissolved inorganic carbon (DIC), and dissolved nitrogen (DN) contents were acquired by letting the prepared test samples pass through a 0.45 µm filter. Dissolved organic carbon (DOC) was calculated in a similar manner as TOC.

Determination of macro and micronutrients was conducted by ionizing the samples in a NexION 2000 ICP-MS. The samples were initially digested with 6 mL Suprapur HNO3 at 220 °C and max 25 bar and later diluted with bi-distilled water. Via the generated high-temperature plasma in the instrument, the prepared samples were vaporized, atomized, and/or ionized and subsequently separated and identified based on their mass-to-charge ratio using the mass spectrometer.

Compositional analysis of the process-wastewater was performed by utilizing the Merck Hitachi Primaide HPLC system with BioRad Aminex HPX-87H column (300 mm × 7.8 mm). First, 4 mM of H2SO4 was diluted together with bi-distilled and degassed water and used as an eluent. At an operating temperature of 70 °C and a flow rate of 0.65 mL/min, the major components of the process-wastewater were identified [16,28].

2.3. Substrate Preparation

The chemical composition of the 5-HMF process-wastewater has been reported earlier [25]. The process-wastewater profoundly lacked major nutrients (N, P, and S) along with the necessary trace elements (Fe, Mn, Zn, Cu, Ni, Mo, Co, and Se) required for the growth and activities of the anaerobic consortia. Hence, nitrogen, phosphorus, and sulfur were added to the process-wastewater as CO(NH2)2, NaH2PO4, and MgSO4.7H2O, respectively, to attain a CNPS ratio of 600:20:5:1. Similarly, 170, 15.5, 12, 3, 0.5, 0.35, 0.18, and 0.07 mg/L of iron, manganese, zinc, copper, nickel, molybdenum, cobalt, and selenium were supplemented into the process-wastewater in the form of FeCl2.4H2O, MnCl2.4H2O, ZnCl2, CuCl2.2H2O, NiCl2.6H2O, Na2MoO4.2H2O, CoCl2.6H2O, and Na2SeO3, respectively, to elevate the concentration of the respective TEs. Following the addition of the macro and micronutrients, the CNPS ratio of the process-wastewater was evaluated to be 525.18:21.80:4.15:1.00 with a pH of 5.10. The process-wastewater parameters and its elemental composition after the inclusion of the aforementioned compounds are provided in Table 1.

Table 1.

Characteristics of the 5-HMF process-wastewater after the addition of macro and micronutrients.

2.4. Experimental Design and Procedure

For the current trial, the prepared process-wastewater was diluted down (with tap water) from 68.4 gCOD/L to the target concentrations of 10, 20, 30, 40, and 50 gCOD/L, consequently yielding five distinctive test substrates that were individually investigated for their biogas (especially methane) production potential at thermophilic (~55 °C) and mesophilic (~43 °C) temperatures. For the six AFs, each combination of temperature and the individual test substrate was inspected in triplicate. In order to achieve a uniform feeding rate and hydraulic retention time (HRT) throughout the trial, the test substrates with the achieved gCOD/L concentrations (hereafter referred to as wastewater-1, wastewater-2, wastewater-3, wastewater-4, and wastewater-5, respectively) were fed to the AFs at an organic loading rate (OLR) of 2, 4, 6, 8, and 10 gCOD/L.d, respectively, resulting in a total of five trial phases.

To neutralize the test substrates, NaHCO3 was added to all of the prepared feedstock except for wastewater-1. The quantities supplemented are provided in Supplementary Material Table S1.

Prior to the test substrate dosages, the AFs were fed with synthetic substrates (COD range: 37.5–39 g/L) for 3 months with stepwise increments, and decrements in the OLRs (4, 8, 12, 4, 2, and 1 gCOD/L.d) with the COD degradation (% ± sd) at the end reaching 96.5 ± 1.8 and 93.0 ± 1.1 for mesophilic- and thermophilic-conditioned AFs, respectively. Brief characteristics of the synthetic substrate are given elsewhere [25].

2.5. Analysis of Recorded Data

Values from the reactors’ sensors and the attached instruments were recorded in a database via LabVIEW (version 14.0.1 by National Instruments, Austin, TX, USA) and subsequently compiled to daily resolutions for each AF for further assessments in the current study.

Statistical analyses for the measured mean specific methane yields (SMYs) of the fed test substrates at the given temperatures were carried out with the post-hoc Tukey test at a significance level of α = 0.05.

Data processing, analysis, and visualization were carried out with Rstudio version 4.1.2, OriginPro 9.7, and Microsoft Excel 2016.

The current feeding regime resulted in an HRT of ~5 days; therefore, data mostly corresponding to Time [d] 5, 10, and 15 were considered for assessment in the current study, with special emphasis given on the last day of each substrate-feeding phase.

3. Results and Discussion

3.1. Biogas Quality and Quantity

Figure 2 depicts the quantity and the quality of the biogas produced during each trial phase, where five different test substrates (with regards to COD concentrations) originating from the 5-HMF process-wastewater were fed to the mesophilic and thermophilic AFs at OLRs of 2, 4, 6, 8, and 10 gCOD/L.d respectively. The parametric and compositional analyses (TE only) for such test substrates are given in Supplementary Material Tables S1 and S2, respectively.

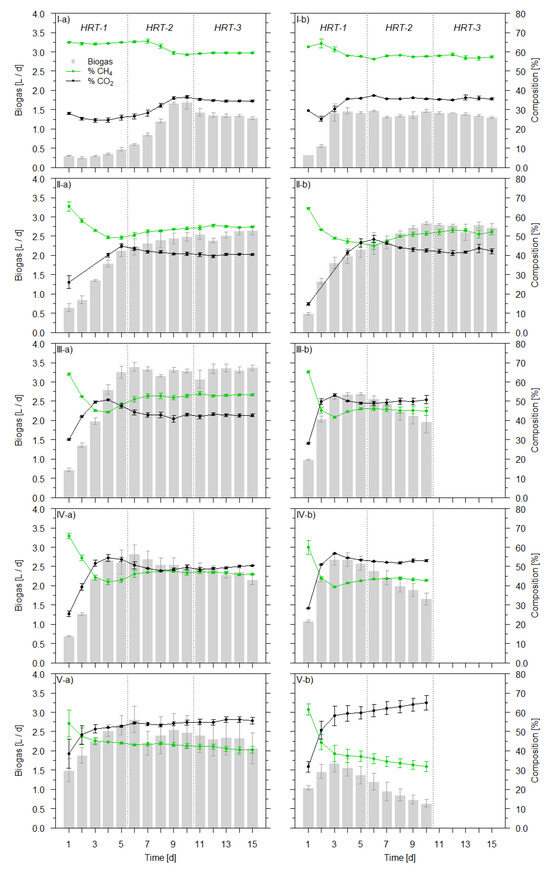

Figure 2.

Daily mean biogas yield and its composition at (a) mesophilic and (b) thermophilic temperatures for test substrates with (I) 10, (II) 20, (III) 30, (IV) 40, and (V) 50 gCOD/L concentrations fed at an organic loading rate (OLR) of 2, 4, 6, 8, and 10 gCOD/L.d, respectively. [Error bars: standard error; HRT-1, -2, and -3: hydraulic retention time of 5 days each].

Initially, swift and robust biodegradation of the test substrate in thermophilic AFs, in contrast to mesophilic AFs, was observed during phase 1, where the former reached the peak per day biogas yields during the first retention time (day 3, HRT-1), while the latter achieved the plateau at day 9 (HRT-2). Despite such distinctive beginnings in the feedstock conversion, the mean biogas yields on day 15 (HRT-3) at 43 °C and 55 °C were alike, viz. 1.28 and 1.29 L/d, with mean methane contents of 59.5% and 57.3% and corresponding mean carbon dioxide contents of 34.5% and 35.5%, respectively.

Originally, the anaerobic consortia in the bioreactors were unaccustomed to the refractory substrate; hence, the dissimilar degradation patterns of the feedstock might be indicative of the acclimatization or adaptation of the microbial communities at varying paces to the newly introduced recalcitrant substrate at the respective temperatures.

Phase 2 concerned feeding 20 gCOD/L substrate at an OLR of 4 gCOD/L.d to the AFs. Unlike wastewater-1, the degradation of wastewater-2 into biogas, at the earlier stage, was defined by nonexponential (logarithmic) trends at either temperature. Characteristics of such biogas formation curves are briefly described in VDI 4630 [29]. In comparison to wastewater-1, increasing the concentration by twofold returned higher biogas yields for each retention time, implying successful acclimatization of the consortia to the toxic feedstock at the operating temperatures. Ultimately, the mean biogas yields (aggregate) for HRT-1, -2, and -3 at 43 °C were evaluated to be 6.7, 11.8, and 12.7 L, while at 53 °C, they were calculated to be 7.7, 12.8, and 13.7 L, respectively. However, the increased biogas volumes produced were at the expense of the rise in their carbon dioxide contents. For example, the mean carbon dioxide contents during the third retention time of phase 2 were evaluated to be 40.3% and 42.1%, whereas, for phase 1, they were estimated to be 34.7% and 35.6%, at mesophilic and thermophilic conditions, respectively.

Transitioning from wastewater-2 to -3 as a substrate resulted in the hampering of the anaerobic process at 55 °C. Hence, a 10-day feeding regime for the thermophilic AFs was implemented to avoid complete inhibition. In contrast, consistent degradation of the wastewater-3 in mesophilic AFs in the course of the second and third HRTs was observed, where the aggregate biogas produced during the aforesaid HRTs was computed to be 16.4 L, separately. As for the mean methane content at days 5, 10, and 15 of the current phase, it was determined to be 48%, 52.8%, and 53.2%, respectively. Conversely, the mean carbon dioxide concentration in the produced biogas at 55 °C surpassed the mean methane content from day 2 onwards until the termination of substrate feeding (day 10), where the composition of the biogas was documented to be 44.8% and 50.8% for methane and carbon dioxide, respectively.

As seen in Figure 2(IV-a–V-b), the bioconversion of wastewater-4 and -5 at 43 °C and 55 °C was characterized by reduced biogas yields, with carbon dioxide being the major gas component. Under the mesophilic condition, the mean accumulated biogas for the third retention time of wastewater-4 and -5 in the AFs were accounted to be 11.7 L (CO2: 5.8 L, CH4: 5.5 L) and 11.4 L (CO2: 6.3 L, CH4: 4.8 L), respectively. Regarding the thermophilic condition, the impediment to the biodegradation of the aforementioned test substrates was replicated, as was the case for wastewater-3. Furthermore, the anaerobic process for wastewater-5 more or less entered full inhibition, generating only 2.8 L carbon dioxide and 1.4 L methane for the last retention time.

It is noteworthy that a five-day recovery period (no feeding) between the phases, i.e., switching from one test substrate to another, was implemented in order to minimize or eliminate the influence of the previous feedstock on the newly fed one.

Presently, two possible scenarios are postulated for the increased concentration of carbon dioxide in the biogas produced from the anaerobically treated test substrates, i.e., wastewater-4 and -5 at 43 °C and wastewater-3, -4 and -5 at 55 °C. As declared earlier, NaHCO3 was incorporated into the test substrates to prevent the possible acidification of the reactors [30]. A corresponding increase in the amount of buffering agent was implemented as the concentration of the wastewater was elevated. Hence, the dissociation of the NaHCO3 and the subsequent formation of H2CO3 might have induced immoderate carbon dioxide production from the above-mentioned wastewaters as the said acid is unstable in aqueous material and readily converts into water and carbon dioxide.

The second and most probable assumption is the arrest of the anaerobic process at its terminal phase by hindering the acetoclastic and hydrogenotrophic pathways, resulting in the accumulation of VFAs and increased carbon dioxide levels in the produced biogas, respectively. The bicarbonates (HCO3−) generated through the breakdown of the VFAs to acetate by hydrogen-producing acetogenic bacteria (oxidation reaction) can interact with the produced protons (H+), prompting carbon dioxide release [31,32] and, as assumed, accumulate acetate, stalling the methanogens in the current setup.

3.2. Bioconversion Efficiencies

The daily SMYs and the COD degradation percents (at the end of each retention time) of the particular test substrate for the given organic loading rate (OLR) at mesophilic and thermophilic conditions are depicted in Figure 3(A-i,B-i,A-ii,B-ii).

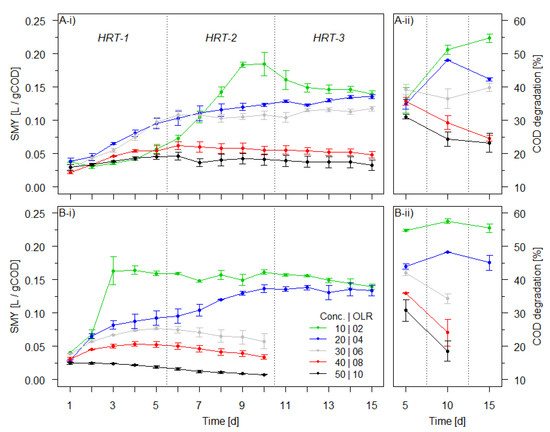

Figure 3.

(A-i,B-i) Daily mean specific methane yields and (A-ii,B-ii) the mean percent COD degradation (at the end of each HRT) at (A) mesophilic and (B) thermophilic temperatures for the given concentrations (gCOD/L) of the test substrates fed at the corresponding OLRs (gCOD/L.d) [Error bars: standard error; HRT-1, -2, and -3: hydraulic retention time of 5 days each].

It is evident that a stepwise increase in the concentration of the substrate, along with the OLR, returned diminishing SMYs at both operating temperatures. The mean SMY at the conclusion of the initial phase was similar at 43 °C and 55 °C, amounting to 0.14 L/gCOD added. However, at day 5, a difference of 0.1 L/gCOD among the mesophilic and thermophilic operated AFs was computed, indicating a lag phase in the former and active biomass in the latter.

Furthermore, under the provided digestion conditions for phase 2, a nearly identical conversion of wastewater-2 to methane (in terms of SMYs per day) was observed. For instance, such yields at the termination of the first and third retention times, at either temperature, were estimated to be 0.09 and 0.13 L/gCOD, respectively. Although, on day 10, they were assessed to be 0.12 L/gCOD and 0.13 L/gCOD at 43 °C and 55 °C, respectively.

Increasing the substrate’s concentration to 30 gCOD/L brought about a 12.2% and 13.2% decrease in the daily mean SMYs at 43 °C on days 10 and 15, respectively. For the thermophilic condition, the substrate replacement (from wastewater-2 to -3) impaired the process, generating only 0.16 gCOD worth of methane on day 10. Moreover, elevating the test substrate concentration further to 40 and 50 gCOD/L prompted severe hampering of methane production in the mesophilic and thermophilic processes, with complete inhibition occurring for the latter by dosing with 50 gCOD/L substrate. Eventually, the mean SMYs at 43 °C and 55 °C for wastewater-4 and -5, at the end point of their respective degradation phases (4 and 5), were evaluated to be 0.048, 0.034, 0.033, and 0.008 L/gCOD. The conversion efficiencies for the discussed SMYs are given in Supplementary Material Table S4.

COD is the most commonly used parameter for denoting the “strength” of the wastewater; therefore, such an analysis was performed for the effluents of the test substrates discharged from the system at the end of each HRT to evaluate the degradation efficiency of the applied treatment processes. As seen, the test substrates’ COD degradation degree, measured at the end of the individual trial phase, reflected the outcomes of their respective SMYs. In other words, the increased COD concentration of the wastewater was inversely proportional to its biological decomposition, delineating the underperformance of the consortia with increasing substrate loading rates. With 54.7% and 55.5% mean COD degradation measured at day 15, the anaerobic digestion of wastewater-1 was considered effective enough at 43 °C and 55 °C, respectively. Similarly, the effluents for wastewater-2 were estimated to be at 11.6 and 11.0 g O2/L for the given digestion conditions. For succeeding test substrates (wastewater-3, -4, and -5), 12.0, 9.7, and 11.2 gCOD/L of their original concentrations, respectively, were degraded by the end of HRT -3. In parallel, at 55 °C, the undegraded percent of CODs concerning the forenamed wastewaters were evaluated to be 65.6%, 75.6%, and 81.4% at the closure of their respective feeding regimes. The methane conversion efficiency and COD degradation degree of the substrate are not to be considered interchangeable.

The wastewater under consideration constituted a mixture of compounds that included 5-HMF and furfural (namely furans), levulinic, formic, acetic, lactic, and glycolic acids (referred to as weak acids), with 5-HMF being the major shareholder (30.1% of the wastewater’s DOC). Notably, furans are distinguished for the inactivations of the essential fermentative enzymes [33] such as aldehyde dehydrogenase (ALDH), responsible for converting aldehydes to carboxylic acids, and alcohol dehydrogenase (ADH), linked with coenzyme-specific (NADH and NADPH) reduction of furans [34,35]. Additionally, the combined presence of furans (5-HMF + furfural) and/or furans with weak acids inflicts a synergistic inhibitory effect on the degradation process [24,36]. Furthermore, the bioconversion of 5-HMF initiates after the full decomposition of furfural when the latter’s concentration comparatively to 5-HMF is low [37]. Thus, the degradation of the test substrates, under the present conditions, can be deduced to have commenced with the minor concentration compounds followed by the major shareholder [13]. Consequently, these constraints, among others, solely or collectively might have contributed to the test substrates’ lower gas yields and reduced degradation degrees, and as their (the test substrates’) intensities grew in the systems, they impeded and suppressed the anaerobic process toward the trial’s end for both temperatures.

The biodegradability of the full-scale 5-HMF process-wastewater in a continuous system has been previously documented [25]. By administering 0.5 gCOD of the said substrate into the reactor containing synthetic hydrolysate, the author observed a mean methane conversion (for the introduced substrate) of 54.6% within 48 h. However, discrepancies within the replicates were also detected, such as impediment of the anaerobic process, implying the refractory characteristics of the given wastewater, even with such a minute dosage.

Likewise, biochemical methane potential tests of the selfsame substrate via the batch processes were investigated by Khan et al. [13]. The reported conclusions of the study aligned with the current trial’s outcomes, i.e., declining SMYs and methane production rates [mL/gCOD.d] with increasing feedstock concentration in the assays at mesophilic and thermophilic conditions. Furthermore, the heightened wastewater concentration [gCOD/L] in their research was associated with extended lag phases, which according to Park et al. [38] has the potential to steer the anaerobic process toward significant deterioration.

3.3. Effluents’ Composition

Figure 4 showcases the concentrations of short-chained VFAs accumulated after each trial phase in the bioreactors operated at 43 °C and 55 °C.

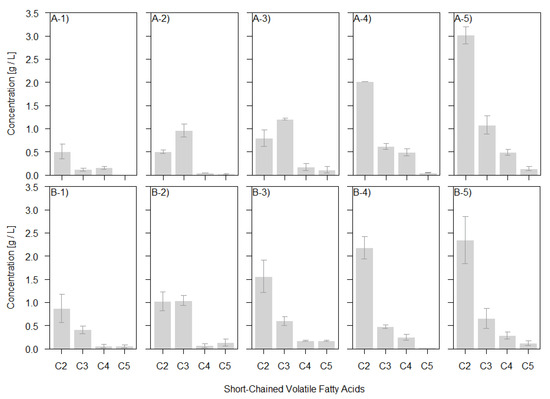

Figure 4.

Mean concentrations of short-chained VFAs (at the end of each trial phase) in (A) mesophilic and (B) thermophilic reactors with (1) 10, (2) 20, (3) 30, (4) 40, and (5) 50 gCOD/L concentrations of the test substrates fed. C2, C3, C4, and C5 represent acetic, propionic, butyric, and valeric acids, respectively. [Error bars: standard deviations].

It was anticipated that increasing the test substrate concentration as well as the OLR would result in a profound accumulation of VFAs in the reactors and the subsequent analyses revealed as such. Therefore, as previously narrated, a 5-day recovery period in between the phases was introduced to alleviate VFA levels in the AFs.

For the effluents of wastewater-1 generated at 43 °C and 55 °C, acetic acid was identified to be the main component, with mean concentrations of 0.5 and 0.9 g/L, respectively. In comparison, the mesophilic effluent of wastewater-2 contained on average 0.9 g/L of propionic acid, whereas the thermophilic effluent exhibited an equal ratio of acetic and propionic acids, each averaging 1 g/L. For the consecutive phase, mesophilic effluent comprised 0.8 g/L of acetic acid and 1.2 g/L of propionic acid. Conversely, acetic acid emerged as the predominant component with a mean concentration of 1.5 g/L against 0.6 g/L for propionic acid in the thermophilic effluent. Likewise, the effluents from the succeeding phases (4 and 5) executed at mesophilic and thermophilic conditions displayed comparable attributes to the thermophilic effluent of phase 3, i.e., excessive acetic acid concentration outweighing the remaining short-chained VFAs, as seen in Figure 4(A-4,A-5,B-4,V-5). These (acetic acid) concentrations were quantified to be 2.0, 3.0, 2.1, and 2.3 g/L for the mesophilic and thermophilic phases 4 and 5, respectively.

Eventually, the mean VFA concentrations (acetic acid equivalent) accumulated in the mesophilic reactors at the end of each phase, in sequential order, were evaluated to be 0.7, 1.3, 2.0, 2.9, and 4.3 g/L. For the thermophilic rectors, they were calculated to be 1.3, 2.0, 2.3, 2.7, and 3.1 g/L.

The latter trial phases for the wastewater biodegradation (43 °C: phases 4 and 5; 55 °C: phases 3, 4, and 5), as described earlier, were considered ineffective due to process hindrance or inhibition. It is plausible to assume such failure due to over-the-top concentrations of acetic acid in the presence of furans; as stated previously, this combination could lead to unfavorable digestion conditions. In short, the accumulation of VFAs in the presence of furans in an anaerobic fermenter is a recipe for calamity.

A treatment system is considered to be in its optimal state when the concentrations of acetic acid, together with propionic, butyric, and valeric acids, are less than 1.0, 0.25, 0.05, and 0.05 g/L, respectively [39]. Furthermore, methanogenic archaea are described to be inhibited when the VFA concentrations (acetic acid equivalent) surpass 2 g/L [31]. These predefined thresholds, specifically for the acetic acid and the acetic acid equivalent concentrations, validated our classification of the phases in the present study.

The rationale for the inhibitory trait of the anaerobic process on account of weak acids, as highlighted by Palmqvist et al. [40], is through intracellular anions accumulation, concurrently with the increased level of protons (H+) in the microbial cytosol. Additionally, undissociated carboxylic acids are recognized to function interactively with other inhibitors in dampening the fermentation process [24,41].

The concentrations of TE in the effluents collected at the end of each trial phase under various digestion conditions are presented in Supplementary Material Table S3.

4. Conclusions

A typical biorefinery’s byproduct was investigated for its gas production potential, particularly methane, at different gCOD/L concentrations through the anaerobic process at 43 °C and 55 °C. The test substrate with the least concentration achieved the highest mean specific methane yield of 140 mL/gCOD on the 15th day at either operating temperature. Further increases in the concentrations of the fed toxic substrate led to an increment in the carbon dioxide and a decrement in the methane concentrations [%] of the produced biogas, which was apparent at 55 °C. Peak biogas yields were obtained from the test substrates possessing 20 gCOD/L and 30 gCOD/L concentrations and were evaluated to be 2.6 and 3.2 L/d from 0.5 L/d dosed fresh mass during HRT-3 at thermophilic and mesophilic conditions, respectively. Feeding consecutive test substrates severely hindered the anaerobic processes due to the extreme accumulation of the short-chained VFAs in the mesophilic and thermophilic bioreactors.

The methane conversion efficiencies of the examined test substrates were not exceptional under the given digestion conditions even after the supplementation of the necessary major and minor nutrients. Hence, the authors’ previous remark, “the provision of energy with such feedstock is questionable” remains valid. Nevertheless, the study may still hold valuable implications for the production of other valuable products, i.e., short-chained VFAs, also contemplated as platform chemicals, from biorefineries’ refractory side streams. Again, such a perspective can be of particular relevance when discussing a cascading biorefinery approach.

If the focus is primarily on producing methane, then micro aeration (to generate facultative microbial consortia in the anaerobic system), photodissociation (e.g., treating the recalcitrant substrates with ultraviolet light), and/or the use of activated carbon (as a carrier material for microbial biomass), among others, can presumably be some of the promising remedial measures to improve the bioconversion of biorefineries’ waste products.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/en16227576/s1.

Author Contributions

Conceptualization, M.T.K., J.K. and A.L.; methodology, M.T.K., J.K. and A.L.; validation: M.T.K., J.K. and A.L.; formal analysis, M.T.K., J.K. and D.W.; investigation, M.T.K., J.K. and D.W.; resources, D.W. and A.L.; data curation, M.T.K.; writing—original draft preparation, M.T.K.; writing—review and editing, M.T.K. and J.K.; visualization, M.T.K., J.K. and A.L.; supervision, J.K. and A.L.; project administration, J.K.; funding acquisition, A.L. All authors have read and agreed to the published version of the manuscript.

Funding

The GRACE project received funding from the Bio-based Industries Joint Undertaking (JU) under the European Union’s Horizon 2020 research and innovation program under grant agreement No. 745012. The JU receives support from the European Union’s Horizon 2020 research and innovation program and the Bio-based Industries Consortium.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors would like to thank our project partners Stefan Krawielitzki and Gilbert Anderer from AVA Biochem BSL AG for providing the necessary resources for our current and subsequent research.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| AF | anaerobic filter |

| COD | chemical oxygen demand |

| DC | dissolved carbon |

| DIC | dissolved inorganic carbon |

| DOC | dissolved organic carbon |

| DN | dissolved nitrogen |

| 5-HMF | 5-Hydroxymethylfurfural |

| IC | inorganic carbon |

| HRT | hydraulic retention time |

| OLR | organic loading rate |

| SMY | specific methane yield |

| TC | total carbon |

| TE | trace element |

| TOC | total organic carbon |

| TN | total nitrogen |

| VFA | volatile fatty acid |

| VDI | Association of German Engineers |

References

- Takkellapati, S.; Li, T.; Gonzalez, M.A. An overview of biorefinery-derived platform chemicals from a cellulose and hemicellulose biorefinery. Clean Technol. Environ. Policy 2018, 20, 1615–1630. [Google Scholar] [CrossRef] [PubMed]

- Leong, H.Y.; Chang, C.-K.; Khoo, K.S.; Chew, K.W.; Chia, S.R.; Lim, J.W.; Chang, J.-S.; Show, P.L. Waste biorefinery towards a sustainable circular bioeconomy: A solution to global issues. Biotechnol. Biofuels 2021, 14, 87. [Google Scholar] [CrossRef] [PubMed]

- Ubando, A.T.; Felix, C.B.; Chen, W.-H. Biorefineries in circular bioeconomy: A comprehensive review. Bioresour. Technol. 2020, 299, 122585. [Google Scholar] [CrossRef] [PubMed]

- Kohli, K.; Prajapati, R.; Sharma, B. Bio-Based Chemicals from Renewable Biomass for Integrated Biorefineries. Energies 2019, 12, 233. [Google Scholar] [CrossRef]

- Cherubini, F. The biorefinery concept: Using biomass instead of oil for producing energy and chemicals. Energy Convers. Manag. 2010, 51, 1412–1421. [Google Scholar] [CrossRef]

- De Jong, E.; Higson, A.; Walsh, P.; Wellisch, M. Bio-based Chemicals Value Added Products from Biorefineries. IEA Bioenergy Task 42 2011, 34, 1–36. [Google Scholar]

- Werpy, T.; Petersen, G. Top Value Added Chemicals from Biomass: Volume I—Results of Screening for Potential Candidates from Sugars and Synthesis Gas; Technical Report; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2004.

- Krawielitzki, S.; Kläusli, T.M. Modified Hydrothermal Carbonization Process for Producing Biobased 5-HMF Platform Chemical. Ind. Biotechnol. 2015, 11, 6–8. [Google Scholar] [CrossRef]

- Bozell, J.J.; Petersen, G.R. Technology development for the production of biobased products from biorefinery carbohydrates—The US Department of Energy’s “Top 10” revisited. Green Chem. 2010, 12, 539–554. [Google Scholar] [CrossRef]

- Menegazzo, F.; Ghedini, E.; Signoretto, M. 5-Hydroxymethylfurfural (HMF) production from real biomasses. Molecules 2018, 23, 2201. [Google Scholar] [CrossRef]

- Świątek, K.; Olszewski, M.P.; Kruse, A. Continuous synthesis of 5-hydroxymethylfurfural from biomass in on-farm biorefinery. GCB Bioenergy 2022, 14, 681–693. [Google Scholar] [CrossRef]

- Götz, M.; Rudi, A.; Heck, R.; Schultmann, F.; Kruse, A. Processing Miscanthus to high-value chemicals: A techno-economic analysis based on process simulation. GCB Bioenergy 2022, 14, 447–462. [Google Scholar] [CrossRef]

- Khan, M.T.; Huelsemann, B.; Krümpel, J.; Wüst, D.; Oechsner, H.; Lemmer, A. Biochemical Methane Potential of a Biorefinery’s Process-Wastewater and its Components at Different Concentrations and Temperatures. Fermentation 2022, 8, 476. [Google Scholar] [CrossRef]

- Fehrenbach, H.; Köppen, S.; Kauertz, B.; Detzel, A.; Wellenreuther, F.; Breitmayer, E.; Essel, R.; Carus, M.; Bienge, K.; Geible, J. BIOMASS CASCADES: Increasing Resource Efficiency By Cascading Use of Biomass—From Theory to Practice; Umweltbundesamt: Dessau-Roßlau, Germany, 2017.

- Zheng, Y.; Zhao, J.; Xu, F.; Li, Y. Pretreatment of lignocellulosic biomass for enhanced biogas production. Prog. Energy Combust. Sci. 2014, 42, 35–53. [Google Scholar] [CrossRef]

- Cao, Z.; Hülsemann, B.; Wüst, D.; Illi, L.; Oechsner, H.; Kruse, A. Valorization of maize silage digestate from two-stage anaerobic digestion by hydrothermal carbonization. Energy Convers. Manag. 2020, 222, 113218. [Google Scholar] [CrossRef]

- Erdogan, E.; Atila, B.; Mumme, J.; Reza, M.T.; Toptas, A.; Elibol, M.; Yanik, J. Characterization of products from hydrothermal carbonization of orange pomace including anaerobic digestibility of process liquor. Bioresour. Technol. 2015, 196, 35–42. [Google Scholar] [CrossRef] [PubMed]

- Tommaso, G.; Chen, W.T.; Li, P.; Schideman, L.; Zhang, Y. Chemical characterization and anaerobic biodegradability of hydrothermal liquefaction aqueous products from mixed-culture wastewater algae. Bioresour. Technol. 2015, 178, 139–146. [Google Scholar] [CrossRef]

- Seyedi, S.; Venkiteshwaran, K.; Benn, N.; Zitomer, D. Inhibition during anaerobic co-digestion of aqueous pyrolysis liquid from wastewater solids and synthetic primary sludge. Sustainability 2020, 12, 8–11. [Google Scholar] [CrossRef]

- Van der Wijst, C.; Ghimire, N.; Bergland, W.H.; Toven, K.; Bakke, R.; Eriksen, Ø. Improving carbon product yields in biocarbon production by combining pyrolysis and anaerobic digestion. BioResources 2021, 16, 3964–3977. [Google Scholar] [CrossRef]

- Ipiales, R.P.; de la Rubia, M.A.; Diaz, E.; Mohedano, A.F.; Rodriguez, J.J. Integration of Hydrothermal Carbonization and Anaerobic Digestion for Energy Recovery of Biomass Waste: An Overview. Energy Fuels 2021, 35, 17032–17050. [Google Scholar] [CrossRef]

- Ghimire, N.; Bakke, R.; Bergland, W.H. Liquefaction of lignocellulosic biomass for methane production: A review. Bioresour. Technol. 2021, 332, 125068. [Google Scholar] [CrossRef] [PubMed]

- Almeida, J.R.; Modig, T.; Petersson, A.; Hähn-Hägerdal, B.; Lidén, G.; Gorwa-Grauslund, M.F. Increased tolerance and conversion of inhibitors in lignocellulosic hydrolysates by Saccharomyces cerevisiae. J. Chem. Technol. Biotechnol. 2007, 82, 340–349. [Google Scholar] [CrossRef]

- Ibraheem, O.; Ndimba, B.K. Molecular adaptation mechanisms employed by ethanologenic bacteria in response to lignocellulose-derived inhibitory compounds. Int. J. Biol. Sci. 2013, 9, 598–612. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.T.; Krümpel, J.; Wüst, D.; Lemmer, A. Anaerobic Degradation of Individual Components from 5-Hydroxymethylfurfural Process-Wastewater in Continuously Operated Fixed Bed Reactors. Processes 2021, 9, 677. [Google Scholar] [CrossRef]

- Krümpel, J.; Schäufele, F.; Schneider, J.; Jungbluth, T.; Zielonka, S.; Lemmer, A. Kinetics of biogas production in Anaerobic Filters. Bioresour. Technol. 2016, 200, 230–234. [Google Scholar] [CrossRef] [PubMed]

- Lemmer, A.; Krümpel, J. Demand-driven biogas production in anaerobic filters. Appl. Energy 2017, 185, 885–894. [Google Scholar] [CrossRef]

- Wüst, D.; Correa, C.R.; Jung, D.; Zimmermann, M.; Kruse, A.; Fiori, L. Understanding the influence of biomass particle size and reaction medium on the formation pathways of hydrochar. Biomass Convers. Biorefinery 2020, 10, 1357–1380. [Google Scholar] [CrossRef]

- VDI VDI 4630. Fermentation of organic materials: Characterisation of the substrate, sampling, collection of material data, fermentation tests. In VDI-Handbuch Energietechnik; Beuth Verlag GmbH: Berlin, Germany, 2006; pp. 44–59. [Google Scholar]

- Valença, R.B.; dos Santos, L.A.; Firmo, A.L.B.; da Silva, L.C.S.; de Lucena, T.V.; de Santos, A.F.M.S.; Jucá, J.F.T. Influence of sodium bicarbonate (NaHCO3) on the methane generation potential of organic food waste. J. Clean. Prod. 2021, 317, 128390. [Google Scholar] [CrossRef]

- Khanal, S.K. Anaerobic Biotechnology for Bioenergy Production: Principles and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2009; ISBN 0813823463. [Google Scholar]

- Krümpel, J.H.; Illi, L.; Lemmer, A. Intrinsic gas production kinetics of selected intermediates in anaerobic filters for demand-orientated energy supply. Environ. Technol. 2017, 39, 558–565. [Google Scholar] [CrossRef]

- Almeida, J.R.M.; Bertilsson, M.; Gorwa-Grauslund, M.F.; Gorsich, S.; Lidén, G. Metabolic effects of furaldehydes and impacts on biotechnological processes. Appl. Microbiol. Biotechnol. 2009, 82, 625–638. [Google Scholar] [CrossRef]

- Modig, T.; Lidén, G.; Taherzadeh, M.J. Inhibition effects of furfural on alcohol dehydrogenase, aldehyde dehydrogenase and pyruvate dehydrogenase. Biochem. J. 2002, 363, 769–776. [Google Scholar] [CrossRef] [PubMed]

- Almeida, J.R.M.; Röder, A.; Modig, T.; Laadan, B.; Lidén, G.; Gorwa-Grauslund, M.F. NADH- vs NADPH-coupled reduction of 5-hydroxymethyl furfural (HMF) and its implications on product distribution in Saccharomyces cerevisiae. Appl. Microbiol. Biotechnol. 2008, 78, 939–945. [Google Scholar] [CrossRef] [PubMed]

- Taherzadeh, M.J.; Gustafsson, L.; Niklasson, C.; Lidén, G. Conversion of furfural in aerobic and anaerobic batch fermentation of glucose by Saccharomyces cerevisiae. J. Biosci. Bioeng. 1999, 87, 169–174. [Google Scholar] [CrossRef] [PubMed]

- Ghasimi, D.S.M.; Aboudi, K.; de Kreuk, M.; Zandvoort, M.H.; van Lier, J.B. Impact of lignocellulosic-waste intermediates on hydrolysis and methanogenesis under thermophilic and mesophilic conditions. Chem. Eng. J. 2016, 295, 181–191. [Google Scholar] [CrossRef]

- Park, J.H.; Yoon, J.J.; Park, H.D.; Lim, D.J.; Kim, S.H. Anaerobic digestibility of algal bioethanol residue. Bioresour. Technol. 2012, 113, 78–82. [Google Scholar] [CrossRef] [PubMed]

- Drosg, B. Process Monitoring in Biogas Plants; IEA Bioenergy: Paris, France, 2013; ISBN 9781910154038. [Google Scholar]

- Palmqvist, E.; Hahn-Hägerdal, B. Fermentation of lignocellulosic hydrolysates. II: Inhibitors and mechanisms of inhibition. Bioresour. Technol. 2000, 74, 25–33. [Google Scholar] [CrossRef]

- Taherzadeh, M.J.; Eklund, R.; Gustafsson, L.; Niklasson, C.; Lidén, G. Characterization and Fermentation of Dilute-Acid Hydrolyzates from Wood. Ind. Eng. Chem. Res. 1997, 36, 4659–4665. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).