Comparison of Different Mechanical Pretreatment Methods for the Anaerobic Digestion of Landscape Management Grass

Abstract

:1. Introduction

2. Materials and Methods

2.1. Description of the Harvest Area

2.2. Harvesting

2.3. Pretreatment Methods

2.3.1. Cross-Flow Grinder

2.3.2. Ball Mill

2.3.3. Amazone Grasshopper

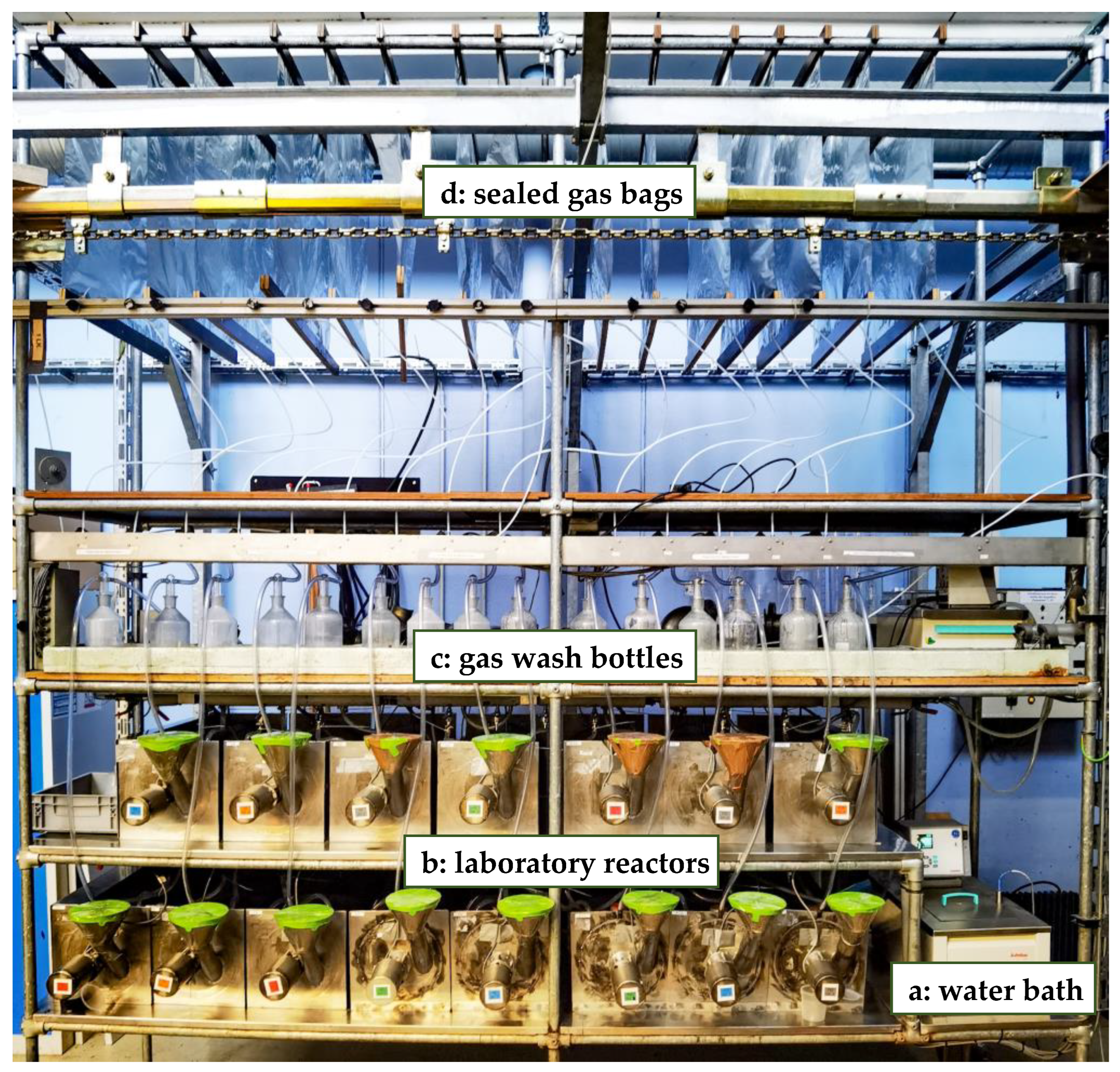

2.4. Batch Digestion Test

2.4.1. Digester

2.4.2. Inoculum

2.4.3. Experimental Setup

2.4.4. Gas Measurements

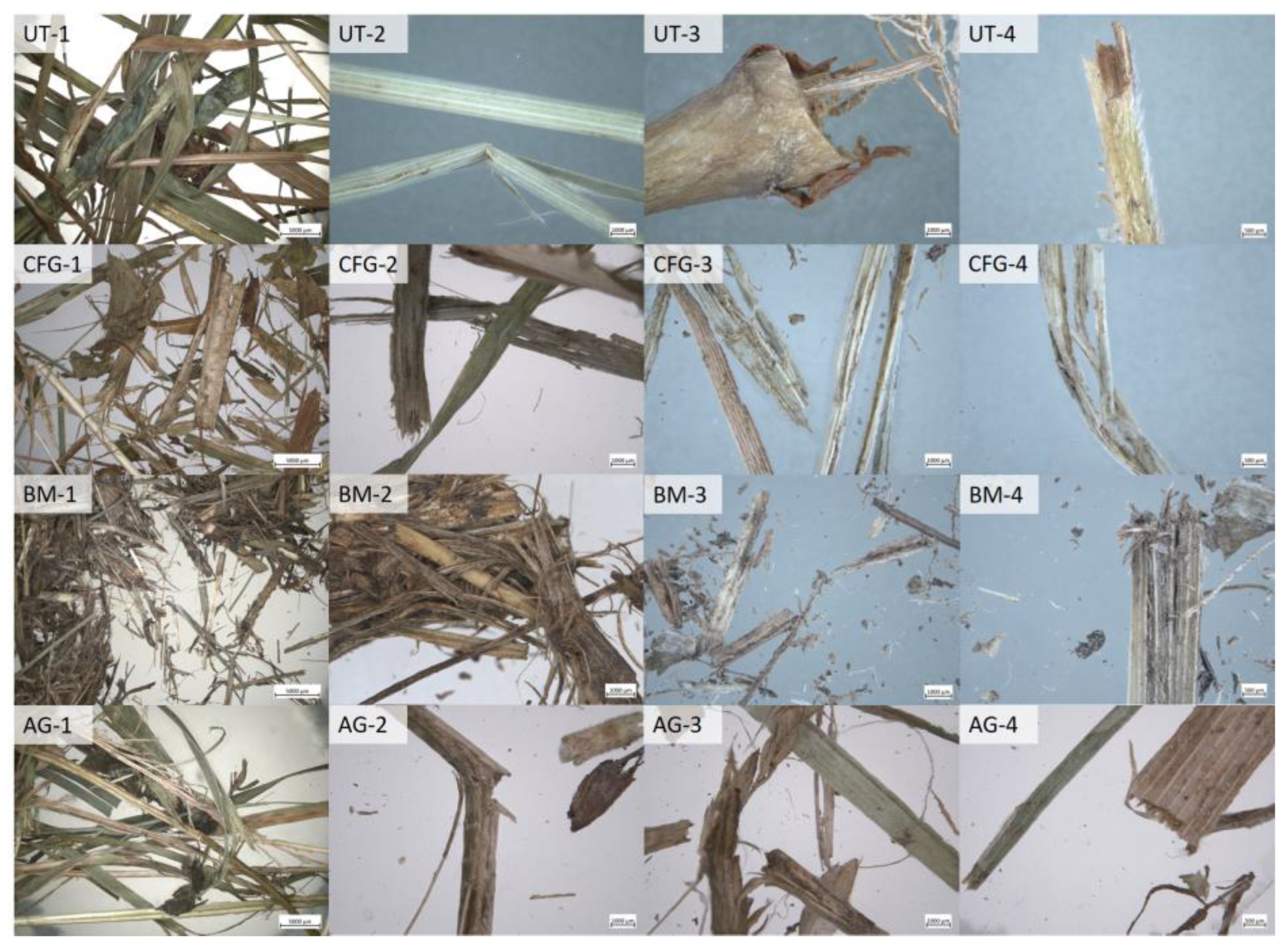

2.5. Microscopy

2.6. Chemical Composition Analysis

2.6.1. Total Solids and Volatile Solid

2.6.2. Ingredient Analysis

2.7. Calculations and Statistical Analysis

2.7.1. Modified Gompertz Model

2.7.2. Specific Energy Demand for Harvesting and Pretreatment

2.7.3. Energy Balance

2.7.4. Statistical Evaluation

3. Results and Discussion

3.1. Biomass Yields

3.2. Chemical Composition of Raw Materials

3.3. Effects of Pretreatment on Surface Morphology

3.4. Harvest and Pretreatment Process Data

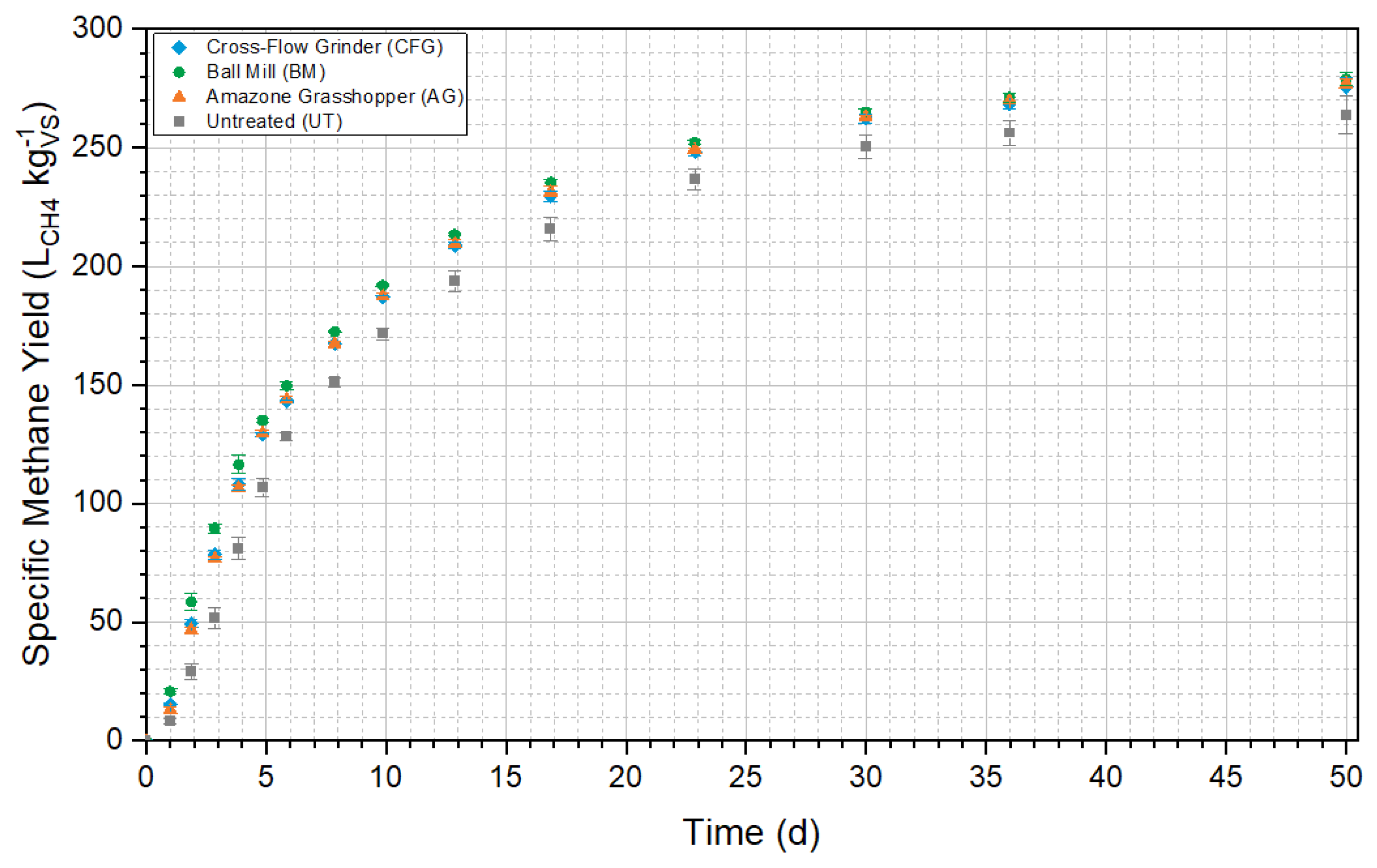

3.5. Effects of Pretreatment on Specific Methane Yield and Degradation Kinetics

3.6. Energy Balance of the Pretreatment and Consideration of Profitability

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khan, I.U.; Othman, M.H.D.; Hashim, H.; Matsuura, T.; Ismail, A.F.; Rezaei-DashtArzhandi, M.; Azelee, I.W. Biogas as a renewable energy fuel—A review of biogas upgrading, utilisation and storage. Energy Convers. Manag. 2017, 150, 277–294. [Google Scholar] [CrossRef]

- Fachverband Biogas e.V. Biogas Market Data in Germany 2022/2023 (Branchenzahlen 2022 und Prognose der Branchenenwicklung 2023), Freising. 2023. Available online: https://www.biogas.org/edcom/webfvb.nsf/id/DE_Branchenzahlen/$file/23-09-25_Biogasindustryfigures_2022-2023_english.pdf (accessed on 19 November 2023).

- Tsapekos, P.; Kougias, P.G.; Angelidaki, I. Anaerobic Mono- and Co-digestion of Mechanically Pretreated Meadow Grass for Biogas Production. Energy Fuels 2015, 29, 4005–4010. [Google Scholar] [CrossRef]

- Boob, M.; Elsaesser, M.; Thumm, U.; Hartung, J.; Lewandowski, I. Harvest Time Determines Quality and Usability of Biomass from Lowland Hay Meadows. Agriculture 2019, 9, 198. [Google Scholar] [CrossRef]

- Menzel, N.; Thoss, C. From Landscape Management Material to Biogas-A Consulting Folder (Vom Landschaftspflegematerial zum Biogas–ein Beratungsordner); Landschaft als Lebensraum No. 22, Ansbach, 2014. Available online: https://www.dvl.org/uploads/tx_ttproducts/datasheet/DVL-Publikation-Schriftenreihe-22_Vom_Landschaftspflegematerial_zum_Biogas-ein_Beratungsordner.pdf (accessed on 10 October 2023).

- Letalik, C.; Hofmann, D.; Ebertseder, F.; Niedermeier-Stürzer, H.; Menzel, N.; Thoss, C.; Koch-Steindl, H.; Grantner, T. Energetic Use of Landscape Management Material in Biogas Plants No. 26, Freising, 2021. Available online: https://www.biogas-forum-bayern.de/media/files/0005/energetische-nutzung-von-landschaftspflegematerial-in-biogasanlagen.pdf (accessed on 25 September 2023).

- Prochnow, A.; Heiermann, M.; Plöchl, M.; Linke, B.; Idler, C.; Amon, T.; Hobbs, P.J. Bioenergy from permanent grassland—A review: 1. Biogas. Bioresour. Technol. 2009, 100, 4931–4944. [Google Scholar] [CrossRef] [PubMed]

- Yu, L.; Bule, M.; Ma, J.; Zhao, Q.; Frear, C.; Chen, S. Enhancing volatile fatty acid (VFA) and bio-methane production from lawn grass with pretreatment. Bioresour. Technol. 2014, 162, 243–249. [Google Scholar] [CrossRef] [PubMed]

- Federal Nature Conservation Act: Act on Nature Conservation and Landscape Management (Bundesnaturschutzgesetz: Gesetz über Naturschutz und Landschaftspflege): BNatSchG, 2009. Available online: https://www.gesetze-im-internet.de/bnatschg_2009/BJNR254210009.html (accessed on 30 September 2023).

- Krenz, L.M.M.; Pleissner, D. Valorization of landscape management grass. Biomass Conv. Bioref. 2022, 1–17. [Google Scholar] [CrossRef]

- Meyer, A.; Ehimen, E.A.; Holm-Nielsen, J.B. Future European biogas: Animal manure, straw and grass potentials for a sustainable European biogas production. Biomass Bioenergy 2018, 111, 154–164. [Google Scholar] [CrossRef]

- Ginni, G.; Kavitha, S.; Kannah, Y.; Bhatia, S.K.; Kumar, A.; Rajkumar, M.; Chi, N.T.L. Valorization of agricultural residues: Different biorefinery routes. J. Environ. Chem. Eng. 2021, 9, 105435. [Google Scholar] [CrossRef]

- Gyimóthy, A.; Schumacher, J. Climate and Nature Protection: Hand in Hand (Klima- und Naturschutz: Hand in Hand): A Handbook for Municipalities, Regions, Climate Protection Officers, Energy-, Urban-and Landscape Planning Offices (Ein Handbuch für Kommunen, Regionen, Klimaschutzbeauftrage, Energie-, Stadt- und Landschaftsplanungsbüros), Berlin 2019; Federal Agency for Nature Conservation (Bundesamt für Naturschutz): Leipzig, Germany, 2019; ISBN 9783982102993. [Google Scholar]

- Deutsches Biomasse Forschungs Zentrum gGmbH DBFZ. Focus Magazine-Landscape Conservation; Energetic Use of Biomass No. 1, Leipzig, 2011. Available online: https://www.energetische-biomassenutzung.de/fileadmin/user_upload/Downloads/Ver%C3%B6ffentlichungen/Fokusheft_Landschaftspflege.pdf (accessed on 28 August 2023).

- Mattioli, A.; Boscaro, D.; Dalla Venezia, F.; Correale Santacroce, F.; Pezzuolo, A.; Sartori, L.; Bolzonella, D. Biogas from Residual Grass: A Territorial Approach for Sustainable Bioenergy Production. Waste Biomass Valor. 2017, 8, 2747–2756. [Google Scholar] [CrossRef]

- Meyer, A.; Raju, C.S.; Kucheryavskiy, S.; Holm-Nielsen, J.B. The energy balance of utilising meadow grass in Danish biogas production. Resour. Conserv. Recycl. 2015, 104, 265–275. [Google Scholar] [CrossRef]

- Boob, M.; Truckses, B.; Seither, M.; Elsäßer, M.; Thumm, U.; Lewandowski, I. Management effects on botanical composition of species-rich meadows within the Natura 2000 network. Biodivers Conserv. 2019, 28, 729–750. [Google Scholar] [CrossRef]

- Herrmann, C.; Prochnow, A.; Heiermann, M.; Idler, C. Biomass from landscape management of grassland used for biogas production: Effects of harvest date and silage additives on feedstock quality and methane yield. Grass Forage Sci. 2014, 69, 549–566. [Google Scholar] [CrossRef]

- De Keulenaere, B.; Laub, K.; Michels, E.; Van Poucke, R.; Boeve, W.; Depuydt, T.; Trapp, M.; Bolzonella, D.; Ryckaert, B.; Bamelis, L.; et al. Recommendations for Biogas Plant Owners and Operators: Good Practice Guide for Grass Valorisation, Ghent, 2016. Available online: https://www.izes.de/sites/default/files/publikationen/GR3_manual_grass_biogas%20owners_operators.pdf (accessed on 10 November 2023).

- Kavitha, S.; Kannah, R.Y.; Kasthuri, S.; Gunasekaran, M.; Pugazhendi, A.; Rene, E.R.; Pant, D.; Kumar, G.; Banu, J.R. Profitable biomethane production from delignified rice straw biomass: The effect of lignin, energy and economic analysis. Green Chem. 2020, 22, 8024–8035. [Google Scholar] [CrossRef]

- Kissel, R.; Henkelmann, G.; Dollhofer, V.; Lebuhn, M.; Seidel, J.; Koch, K. Substrate treatment-To improve the degradation of fibre-rich biomass (Substrataufbereitung-Zur Verbesserung des Abbaus faserreicher Biomasse): To improve the degradation of fibre-rich biomass. 2019. [Google Scholar] [CrossRef]

- Blokhina, Y.N.; Prochnow, A.; Plöchl, M.; Luckhaus, C.; Heiermann, M. Concepts and profitability of biogas production from landscape management grass. Bioresour. Technol. 2011, 102, 2086–2092. [Google Scholar] [CrossRef] [PubMed]

- Stürmer, B. Feedstock change at biogas plants–Impact on production costs. Biomass Bioenergy 2017, 98, 228–235. [Google Scholar] [CrossRef]

- Leible, L.; Kälber, S.; Kappler, G.; Oechsner, H.; Mönch-Tegeder, M. Biogas from Landscape Management Grass: Possibilities and Limitations. (Biogas aus Landschaftspflegegras: Möglichkeiten und Grenzen); KIT Scientific Reports; KIT Scientific Publishing: Karlsruhe, Germany, 2015; Volume 7691, ISBN 978-3-7315-0353-8. [Google Scholar]

- Fernandez, H.C.; Franco, R.T.; Bayard, R.; Buffiere, P. Mechanical Pre-treatments Evaluation of Cattle Manure Before Anaerobic Digestion. Waste Biomass Valor. 2020, 11, 5175–5184. [Google Scholar] [CrossRef]

- Patinvoh, R.J.; Osadolor, O.A.; Chandolias, K.; Sárvári Horváth, I.; Taherzadeh, M.J. Innovative pretreatment strategies for biogas production. Bioresour. Technol. 2017, 224, 13–24. [Google Scholar] [CrossRef]

- Veluchamy, C.; Kalamdhad, A.S.; Gilroyed, B.H. Advanced Pretreatment Strategies for Bioenergy Production from Biomass and Biowaste. In Handbook of Environmental Materials Management; Hussain, C.M., Ed.; Springer International Publishing: Cham, Germany, 2019; pp. 1507–1524. ISBN 978-3-319-73644-0. [Google Scholar]

- Mankar, A.R.; Pandey, A.; Modak, A.; Pant, K.K. Pretreatment of lignocellulosic biomass: A review on recent advances. Bioresour. Technol. 2021, 334, 125235. [Google Scholar] [CrossRef]

- Zhao, L.; Sun, Z.-F.; Zhang, C.-C.; Nan, J.; Ren, N.-Q.; Lee, D.-J.; Chen, C. Advances in pretreatment of lignocellulosic biomass for bioenergy production: Challenges and perspectives. Bioresour. Technol. 2022, 343, 126123. [Google Scholar] [CrossRef]

- Eswari, A.P.; Ravi, Y.K.; Kavitha, S.; Banu, J.R. Recent insight into anaerobic digestion of lignocellulosic biomass for cost effective bioenergy generation. E-Prime-Adv. Electr. Eng. Electron. Energy 2023, 3, 100119. [Google Scholar] [CrossRef]

- Kratky, L.; Jirout, T. Biomass Size Reduction Machines for Enhancing Biogas Production. Chem. Eng. Technol. 2011, 34, 391–399. [Google Scholar] [CrossRef]

- Heller, R.; Roth, P.; Hülsemann, B.; Böttinger, S.; Lemmer, A.; Oechsner, H. Effects of Pretreatment with a Ball Mill on Methane Yield of Horse Manure. Waste Biomass Valorization 2023, 1–15. [Google Scholar] [CrossRef]

- Arce, C.; Kratky, L. Mechanical pretreatment of lignocellulosic biomass toward enzymatic/fermentative valorization. iScience 2022, 25, 104610. [Google Scholar] [CrossRef] [PubMed]

- Hernández-Beltrán, J.U.; Hernández-De Lira, I.O.; Cruz-Santos, M.M.; Saucedo-Luevanos, A.; Hernández-Terán, F.; Balagurusamy, N. Insight into Pretreatment Methods of Lignocellulosic Biomass to Increase Biogas Yield: Current State, Challenges, and Opportunities. Appl. Sci. 2019, 9, 3721. [Google Scholar] [CrossRef]

- Tsapekos, P.; Kougias, P.G.; Angelidaki, I. Mechanical pretreatment for increased biogas production from lignocellulosic biomass; predicting the methane yield from structural plant components. Waste Manag. 2018, 78, 903–910. [Google Scholar] [CrossRef] [PubMed]

- Mönch-Tegeder, M.; Lemmer, A.; Jungbluth, T.; Oechsner, H. Effects of full-scale substrate pretreatment with a cross-flow grinder on biogas production. Agric. Eng. Int. CIGR J. 2014, 16, 138–147. [Google Scholar]

- Fernandez, H.C.; Buffiere, P.; Bayard, R. Understanding the role of mechanical pretreatment before anaerobic digestion: Lab-scale investigations. Renew. Energy 2022, 187, 193–203. [Google Scholar] [CrossRef]

- European Commission DG Environment. Interpretation Manual of European Union Habitats Version EUR28, Brussels, 2013. Available online: https://circabc.europa.eu/ui/group/3f466d71-92a7-49eb-9c63-6cb0fadf29dc/library/37d9e6d9-b7de-42ce-b789-622e9741b68f/details (accessed on 15 September 2023).

- Landesanstalt für Umwelt Baden-Württemberg. Data and Map Service of the LUBW (Daten- und Kartendienst der LUBW). Erfassungseinheit Nr.: 6510800046035802; Flurstücksnummer: 4794; Gemarkung Eningen unter Achalm (Landkreis Reutlingen, Germany). Available online: https://udo.lubw.baden-wuerttemberg.de/public/api/processingChain?conditionValuesSetHash=8A6D6EE&selector=ROOT.Natur%20und%20Landschaft.Natura%202000%20-%20FFH-M%C3%A4hwiesen.nais_map%3Anais_map_z_mw_udo_permalink.sel&processings=nais_map%3Anais_map_mw_erhebungsbogen%2Fnais_map_mw_erhebungsbogen_udo.rpt&sourceOrderAsc=false&columns=94bdfa8e-48c9-4654-abaa-9bb9a33b5ed2&offset=0&limit=2147483647&executionConfirmed=false (accessed on 13 November 2023).

- Seither, M.; Engel, S.; King, K.; Elsäßer, M. FFH-Mowing Meadows (FFH–Mähwiesen): Basics-Management-Restoration (Grundlagen-Bewirtschaftung-Wiederherstellung) MLR 11-2014-23/62, Aulendorf, 2018. Available online: https://fortbildung-lazbw.lgl-bw.de/lazbw/webbasys/download/Shop/2018_GL_lazbw_FFH_Maehwiesen_Grundlagen.pdf (accessed on 20 August 2023).

- Steidle, J.L.M.; Kimmich, T.; Csader, M.; Betz, O. Negative impact of roadside mowing on arthropod fauna and its reduction with ‘arthropod-friendly’ mowing technique. J. Appl. Entomol. 2022, 146, 465–472. [Google Scholar] [CrossRef]

- Krogmann, L.; Betz, O.; Geldmann, J.; Goulson, D.; Menzel, R.; Riecken, U.; Ruther, J.; Sorg, M.; Steidle, J.; Tscharntke, T.; et al. Nine-point plan against insect mortality-The perspective of science (Neun-Punkte-Plan gegen das Insektensterben–Die Perspektive der Wissenschaft). Entomologische Zeitschrift; Wissenschaftlicher Verlag Peks: Schwanfeld, Germany, 2018; pp. 247–249. [Google Scholar]

- Wabnig, H. Patent Document-Decomposing Device. 04011761.6, 18 May 2004. [Google Scholar]

- Haag, N.L.; Nägele, H.-J.; Reiss, K.; Biertümpfel, A.; Oechsner, H. Methane formation potential of cup plant (Silphium perfoliatum). Biomass Bioenergy 2015, 75, 126–133. [Google Scholar] [CrossRef]

- Mittweg, G.; Oechsner, H.; Hahn, V.; Lemmer, A.; Reinhardt-Hanisch, A. Repeatability of a laboratory batch method to determine the specific biogas and methane yields. Eng. Life Sci. 2012, 12, 270–278. [Google Scholar] [CrossRef]

- Hülsemann, B.; Zhou, L.; Merkle, W.; Hassa, J.; Müller, J.; Oechsner, H. Biomethane Potential Test: Influence of Inoculum and the Digestion System. Appl. Sci. 2020, 10, 2589. [Google Scholar] [CrossRef]

- VDI Department of Energy Technology. Fermentation of Organic Materials (VDI 4630): Characterization of the Substrate, Sampling, Collection of Material Data, Fermentation Tests; VDI-Society Energy and Environment: Düsseldorf, Germany, 2016.

- Li, B.; Dinkler, K.; Zhao, N.; Ran, X.; Sobhi, M.; Dong, R.; Müller, J.; Xiong, W.; Huang, G.; Guo, J.; et al. Response of phosphorus speciation to organic loading rates and temperatures during anaerobic co-digestion of animal manures and wheat straw. Sci. Total Environ. 2022, 838, 155921. [Google Scholar] [CrossRef] [PubMed]

- DIN EN 12880:2000; Characterization of Sludges-Determination of Dry Residue and Water Content. Beuth Verlag GmbH: Berlin, Germany, 2001.

- DIN EN 12879:2000; Characterization of Sludges-Determination of the Loss on Ignition of Dry Mass. Beuth Verlag GmbH: Berlin, Germany, 2001.

- VDLUFA. Method Book III-The Chemical Analysis for Feedstuffs: Incl. 1st–3rd Supplement Delivery, 3rd ed.; VDLUFA-Verlag: Darmstadt, Germany, 1976. [Google Scholar]

- Budiyono; Widiasa, I.N.; Johari, S.; Sunarso, J. The Kinetic of Biogas Production Rate from Cattle Manure in Batch Mode. Int. J. Chem. Biol. Eng. 2010, 3, 39–45. [Google Scholar]

- Etuwe, C.N.; Momoh, Y.O.L.; Iyagba, E.T. Development of Mathematical Models and Application of the Modified Gompertz Model for Designing Batch Biogas Reactors. Waste Biomass Valor. 2016, 7, 543–550. [Google Scholar] [CrossRef]

- Yusuf, M.; Debora, A.; Ogheneruona, D.E. Ambient temperature kinetic assessment of biogas production from co-digestion of horse and cow dung. Res. Agr. Eng. 2011, 57, 97–104. [Google Scholar] [CrossRef]

- Feng, L. Kinetik modelling of gas generated from anearobic fermentation of kitchen waste with microaerobic pretreatment. Appl. Ecol. Environ. Res. 2019, 17, 10671–10683. [Google Scholar] [CrossRef]

- Schnute, J. A Versatile Growth Model with Statistically Stable Parameters. Can. J. Fish. Aquat. Sci. 1981, 38, 1128–1140. [Google Scholar] [CrossRef]

- Zwietering, M.H.; Jongenburger, I.; Rombouts, F.M.; van’t Riet, K. Modeling of the bacterial growth curve. Appl. Environ. Microbiol. 1990, 56, 1875–1881. [Google Scholar] [CrossRef]

- Mönch-Tegeder, M.; Lemmer, A.; Oechsner, H.; Jungbluth, T. Investigation of the methane potential of horse manure. Agric. Eng. Int. CIGR J. 2013, 15, 161–172. [Google Scholar]

- Maxima. 2023. Available online: https://maxima.sourceforge.io/ (accessed on 10 August 2023).

- Fachagentur Nachwachsende Rohstoffe e.V. Key Data Bioenergy-Germany 2022 (Basisdaten Bioenergie-Deutschland 2022): Graphics, Tables, Key Values (Grafiken, Tabellen, Kennwerte), Gülzow-Prüzen, 2022. Available online: https://www.fnr.de/fileadmin/Projekte/2022/Mediathek/broschuere_basisdaten_bioenergie_2022_06_web.pdf (accessed on 1 October 2023).

- Remmele, E. Reference Values for Biogas (Faustzahlen Biogas): Association for Technology and Structures in Agriculture KTBL (Kuratorium für Technik und Bauwesen in der Landwirtschaft e.V), 3rd ed.; KTBL: Darmstadt, Germany, 2013; pp. 1219–1230. ISBN 978-3-941583-85-6. [Google Scholar]

- Society of Nutrition Physiology. Recommendations for the Energy and Nutrient Supply of Dairy Cows and Heifers in Germany (Empfehlungen zur Energie- und Nährstoffversorgung der Milchkühe und Aufzuchtrinder); DLG-Verl.: Frankfurt, Germany, 2001; ISBN 3-7690-0591-0. [Google Scholar]

- Zaiontz, C. Real Statistics Resource Pack Software, 2023. Available online: https://real-statistics.com/free-download/real-statistics-resource-pack/ (accessed on 1 September 2023).

- Karlik, P.; Poschlod, P. History or abiotic filter: Which is more important in determining the species composition of calcareous grasslands? Preslia 2009, 81, 321–340. [Google Scholar]

- Grüebler, M.U.; Schaller, S.; Keil, H.; Naef-Daenzer, B. The occurrence of cavities in fruit trees: Effects of tree age and management on biodiversity in traditional European orchards. Biodivers Conserv. 2013, 22, 3233–3246. [Google Scholar] [CrossRef]

- Stolz, J.; Megerle, H.E. Geotrails as a Medium for Education and Geotourism: Recommendations for Quality Improvement Based on the Results of a Research Project in the Swabian Alb UNESCO Global Geopark. Land 2022, 11, 1422. [Google Scholar] [CrossRef]

- Prochnow, A.; Heiermann, M.; Drenchhan, A.; Schelle, H. Seasonal Pattern of Biomethanisation of Grass from Landscape Management. Agric. Eng. Int. CIGR Ejournal. 2005, 7. [Google Scholar]

- Prochnow, A.; Streßmann, U.; Kleinke, M. Decomposition of grassland growth after mulching (Zersetzung von Grünlandaufwuchs nach dem Mulchen). Landtechnik 2000, 55, 216–217. [Google Scholar] [CrossRef]

- Prochnow, A. Technological Fundamentals for Large-Area Landscape Management in the Nuthe-Nieplitz Region (Verfahrenstechnische Grundlagen für die großflächige Landschaftspflege am Beispiel der Nuthe-Nieplitz-Niederung). Ph.D. Thesis, Humboldt-Universität zu Berlin, Berlin, Germany, 1995. [Google Scholar]

- Roj-Rojewski, S.; Wysocka-Czubaszek, A.; Czubaszek, R.; Kamocki, A.; Banaszuk, P. Anaerobic digestion of wetland biomass from conservation management for biogas production. Biomass Bioenergy 2019, 122, 126–132. [Google Scholar] [CrossRef]

- Jilg, T. Feeding High-Performance Cows with FFH Grassland-Is It Possible? (Fütterung von Hochleistungskühen mit FFH-Grünland–geht das?), Aulendorf, 2011. Available online: https://www.km-bw.de/pb/site/pbs-bw-new/get/documents/MLR.LEL/PB5Documents/lazbw_rh/pdf/f/F%C3%BCtterung%20Hochleistungsk%C3%BChe%20FFH%20Gr%C3%BCnland%202011.pdf?attachment=true (accessed on 1 September 2023).

- Bassignana, M.; Clementel, F.; Kasal, A.; Peratoner, G. The forage quality of meadows under different management practices in the Italian Alps. 16th Symposium of the European Grassland Federation 2011. Grassland Farming and Land Management Systems in Mountainous Regions. In Proceedings of the 16th Symposium of the European Grassland Federation, Gumpenstein, Austria, 29–31 August 2011; pp. 220–222. [Google Scholar]

- Li, W.; Khalid, H.; Zhu, Z.; Zhang, R.; Liu, G.; Chen, C.; Thorin, E. Methane production through anaerobic digestion: Participation and digestion characteristics of cellulose, hemicellulose and lignin. Appl. Energy 2018, 226, 1219–1228. [Google Scholar] [CrossRef]

- Krauss, J.; Klein, A.-M.; Steffan-Dewenter, I.; Tscharntke, T. Effects of habitat area, isolation, and landscape diversity on plant species richness of calcareous grasslands. Biodivers Conserv. 2004, 13, 1427–1439. [Google Scholar] [CrossRef]

- Rahmann, G. Ecological Sheep and Goat Farming (Ökologische Schaf- und Ziegenhaltung): 100 Questions and Answers for the Practice (100 Fragen und Antworten für die Praxis), 4th ed.; Johann Heinrich von Thünen-Institut: Braunschweig, Germany, 2013; ISBN 978-3-86576-037-1. [Google Scholar]

- Bavarian State Institute for Agriculture. Gruber Table for Feeding Dairy Cows, Breeding Cattle, Sheep, Goats). (Gruber Tabelle zur Fütterung der Milchkühe, Zuchtrinder, Schafe, Ziegen), Freising-Weihenstephan, 2021. Available online: https://www.lfl.bayern.de/mam/cms07/publikationen/daten/informationen/gruber_tabelle_fuetterung_milchkuehe_zuchtrinder_schafe_ziegen_lfl-information.pdf (accessed on 27 September 2023).

- Al-Sulaimi, I.N.; Nayak, J.K.; Alhimali, H.; Sana, A.; Al-Mamun, A. Effect of Volatile Fatty Acids Accumulation on Biogas Production by Sludge-Feeding Thermophilic Anaerobic Digester and Predicting Process Parameters. Fermentation 2022, 8, 184. [Google Scholar] [CrossRef]

- Smyth, B.M.; Murphy, J.D.; O’Brien, C.M. What is the energy balance of grass biomethane in Ireland and other temperate northern European climates? Renew. Sustain. Energy Rev. 2009, 13, 2349–2360. [Google Scholar] [CrossRef]

- Dubgaard, A. Economic Analyses of Nature Management Methods in Protected Areas (Økonomiske Analyser af Naturplejemetoder i Beskyttede Områder); Fødevareøkonomisk Institut: Frederiksberg, Denmark, 2012; ISBN 978-87-92591-10-4. [Google Scholar]

- von Cossel, M.; Bauerle, A.; Boob, M.; Thumm, U.; Elsaesser, M.; Lewandowski, I. The Performance of Mesotrophic Arrhenatheretum Grassland under Different Cutting Frequency Regimes for Biomass Production in Southwest Germany. Agriculture 2019, 9, 199. [Google Scholar] [CrossRef]

- Lemmer, A.; Oechsner, H. Use of grass or field crops for biogas production. In Proceedings of the AgEng, Budapest, Hungary, 30 June–4 July 2002. [Google Scholar]

- Amon, T.; Bodiroza, V.; Kryvoruchko, V.; Machmüller, A.; Bauer, A. Energy Use of Common Reed from Extensive Conservation Grassland in the National Parc Neusiedler See and of Macrophytes in the Lake Neusiedler See (Energetische Nutzung von Schilfgras von Extensiven Naturschutzflächen des Nationalparks Neusiedler See und Makrophyten des Neusiedler Sees); University of Natural Resources and Life Sciences: Vienna, Austria, 2007. [Google Scholar]

- Amon, T.; Amon, B.; Kryvoruchko, V.; Machmüller, A.; Hopfner-Sixt, K.; Bodiroza, V.; Hrbek, R.; Friedel, J.; Pötsch, E.; Wagentristl, H.; et al. Methane production through anaerobic digestion of various energy crops grown in sustainable crop rotations. Bioresour. Technol. 2007, 98, 3204–3212. [Google Scholar] [CrossRef] [PubMed]

- McEniry, J.; O’Kiely, P. Anaerobic methane production from five common grassland species at sequential stages of maturity. Bioresour. Technol. 2013, 127, 143–150. [Google Scholar] [CrossRef]

- Tsapekos, P.; Kougias, P.G.; Egelund, H.; Larsen, U.; Pedersen, J.; Trénel, P.; Angelidaki, I. Improving the energy balance of grass-based anaerobic digestion through combined harvesting and pretreatment. Anaerobe 2017, 46, 131–137. [Google Scholar] [CrossRef] [PubMed]

- Tsapekos, P.; Kougias, P.G.; Egelund, H.; Larsen, U.; Pedersen, J.; Trénel, P.; Angelidaki, I. Mechanical pretreatment at harvesting increases the bioenergy output from marginal land grasses. Renew. Energy 2017, 111, 914–921. [Google Scholar] [CrossRef]

- Dahunsi, S.O. Mechanical pretreatment of lignocelluloses for enhanced biogas production: Methane yield prediction from biomass structural components. Bioresour. Technol. 2019, 280, 18–26. [Google Scholar] [CrossRef] [PubMed]

- Kaiser, F.; Gronauer, A. Methane Productivity of Renewable Raw Materials in Biogas Plants (Methanproduktivität Nachwachsender Rohstoffe in Biogasanlagen), Freising-Weihenstephan, 2007. Available online: https://www.lfl.bayern.de/mam/cms07/publikationen/daten/informationen/p_27455.pdf (accessed on 5 December 2023).

- Dalle Fratte, M.; Montagnoli, A.; Anelli, S.; Armiraglio, S.; Beatrice, P.; Ceriani, A.; Lipreri, E.; Miali, A.; Nastasio, P.; Cerabolini, B.E.L. Mulching in lowland hay meadows drives an adaptive convergence of above- and below-ground traits reducing plasticity and improving biomass: A possible tool for enhancing phytoremediation. Front. Plant Sci. 2022, 13, 1062911. [Google Scholar] [CrossRef] [PubMed]

- Theuerl, S.; Herrmann, C.; Heiermann, M.; Grundmann, P.; Landwehr, N.; Kreidenweis, U.; Prochnow, A. The Future Agricultural Biogas Plant in Germany: A Vision. Energies 2019, 12, 396. [Google Scholar] [CrossRef]

- Act on the Expansion of Renewable Energies-Renewable Energy Sources Act (Gesetz für den Ausbau erneuerbarer Energien-Erneuerbare-Energien-Gesetz): EEG 2023; 2023; Available online: https://www.gesetze-im-internet.de/eeg_2014/EEG_2023.pdf (accessed on 17 November 2023).

- Mönch-Tegeder, M.; Lemmer, A.; Oechsner, H. Enhancement of methane production with horse manure supplement and pretreatment in a full-scale biogas process. Energy 2014, 73, 523–530. [Google Scholar] [CrossRef]

- Rusanowska, P.; Zieliński, M.; Dudek, M.; Dębowski, M. Mechanical Pretreatment of Lignocellulosic Biomass for Methane Fermentation in Innovative Reactor with Cage Mixing System. J. Ecol. Eng. 2018, 19, 219–224. [Google Scholar] [CrossRef]

- Tsapekos, P.; Kougias, P.G.; Treu, L.; Campanaro, S.; Angelidaki, I. Process performance and comparative metagenomic analysis during co-digestion of manure and lignocellulosic biomass for biogas production. Appl. Energy 2017, 185, 126–135. [Google Scholar] [CrossRef]

- Lopes, M.; Baptista, P.; Duarte, E.; Moreira, A.L.N. Enhanced biogas production from anaerobic co-digestion of pig slurry and horse manure with mechanical pre-treatment. Environ. Technol. 2019, 40, 1289–1297. [Google Scholar] [CrossRef] [PubMed]

- Hofmann, J.; Müller, L.; Weinrich, S.; Debeer, L.; Schumacher, B.; Velghe, F.; Liebetrau, J. Assessing the Effects of Substrate Disintegration on Methane Yield. Chem. Eng. Technol. 2020, 43, 47–58. [Google Scholar] [CrossRef]

- Ministerium für Ernährung, Ländlichen Raum und Verbraucherschutz. Promotion of Nature Conservation, Landscape Management and Biodiversity (Förderung von Naturschutz, Landschaftspflege und Biodiversität). Available online: https://foerderung.landwirtschaft-bw.de/pb/,Lde/Startseite/Foerderwegweiser/Foerderung+von+Naturschutz_+Landschaftspflege+und+Biodiversitaet (accessed on 18 October 2023).

- Ministerium für Ernährung, Ländlichen Raum und Verbraucherschutz. Agri-Environmental Programme FAKT II-Traditional Orchard Measure C1 (Agrarumweltprogramm FAKT II-Streuobstmaßnahme C1). Available online: https://streuobst.landwirtschaft-bw.de/pb/,Lde/Startseite/Foerderung/FAKT (accessed on 18 October 2023).

- Hansjürgens, B. Flora-Fauna-Habitat lawsuit by the EU-Homework not done (Flora-Fauna-Habitat-Klage der EU-Hausaufgaben nicht gemacht). Wirtschaftsdienst 2021, 101, 156. [Google Scholar] [CrossRef]

- Hansjürgens, B.; Schröter-Schlaack, C.; Berghöfer, A.; Wittmer, H. Demonstrate and Integrate Values of Nature (Werte der Natur aufzeigen und in Entscheidungen integrieren): A synthesis (Eine Synthese); Helmholtz Zentrum für Umweltforschung-UFZ: Leipzig, Germany, 2018; ISBN 978-3-944280-40-0. [Google Scholar]

- Wiedermann, E.; Hübner, R.; Kilian, S.; Wiesmeier, M. Determination of Carbon in Orchard Meadows of the Alpine Foreland (Festlegung von Kohlenstoff in Streuobstwiesen des Alpenvorlands); LfL Schriftenreihe: Freising, Germany, 2022; ISSN 1611-4159. [Google Scholar]

- Albert, C.; von Haaren, C. Ecosystem Benefits in Rural Areas (Ökosystemleistungen in ländlichen Räumen): Basis for Human Well-Being and Sustainable Economic Development (Grundlage für Menschliches Wohlergehen und nachhaltige Wirtschaftliche Entwicklung), 2016th ed.; Naturkapital Deutschland-TEEB DE: Hannover/Leipzig, Germany, 2016; ISBN 978-3-944280-25-7. [Google Scholar]

- Naturschutzbund Deutschland (NABU) e.V. Deficiencies in Enforcement and Violations of the Deterioration Ban for FFH Habitat Types on Grassland Sites Sites in Germany (Vollzugsdefizite und Verstöße gegen das Verschlechterungsverbot bei FFH-Lebensraumtypen auf Grünlandstandorten in Deutschland): NABU Complaint to the European Commission for Non-Compliance with Community Law (Beschwerde des NABU an die Europäische Kommission wegen Nichtbeachtung des Gemeinschaftsrechts), Berlin, 2014. Available online: https://www.nabu.de/imperia/md/content/nabude/landwirtschaft/gruenland/140403-nabu-beschwerde_ffh-gr__nland.pdf (accessed on 2 September 2023).

| Determination Method | Unit | Treatment Variant | |||

|---|---|---|---|---|---|

| UT | CFG | BM | AG | ||

| Total solids (TS) | % FM | 26.9 | 25.9 | 25.8 | 25.2 |

| Volatile solids (VS) | % TS | 89.3 | 84.3 | 85.3 | 83.8 |

| Acetic acid (AA) | g kgFM−1 | 0.09 | 0.14 | 0.35 | 0.10 |

| Sugar (S) | g kgVS−1 | 75.5 | 42.5 | 27.0 | 30.5 |

| Crude protein (XP) | g kgVS−1 | 51.9 | 55.9 | 55.8 | 58.9 |

| Crude fat (XL) | g kgVS−1 | 21.2 | 22.3 | 20.2 | 22.4 |

| Crude fiber (XF) | g kgVS−1 | 370.4 | 360.9 | 380.5 | 376.4 |

| Neutral detergent fiber (aNDF) | g kgVS−1 | 659.7 | 567.9 | 622.7 | 645.9 |

| Acid detergent fiber (ADF) | g kgVS−1 | 423.6 | 402.9 | 434.3 | 440.6 |

| Acid detergent lignin (ADL) | g kgVS−1 | 81.2 | 91.0 | 96.1 | 98.3 |

| Nitrogen free extracts (NfE) | g kgVS−1 | 556.5 | 560.9 | 543.5 | 542.3 |

| Gross energy (GE) | MJ kgTS−1 | 17.7 | 16.8 | 16.8 | 17.2 |

| Metabolizable energy (ME) | MJ kgTS−1 | 7.5 | 7.2 | 6.6 | 6.9 |

| Net energy lactation (NEL) | MJ kgTS−1 | 4.2 | 4.1 | 3.7 | 3.9 |

| Activity and Determination Method | Unit | Treatment Variant | |||

|---|---|---|---|---|---|

| UT | CFG | BM | AG | ||

| Setup Time | s ha−1 | 951 | - | - | 190 |

| Mowing | s ha−1 | 4739 | - | - | 22,731 |

| Swathing | s ha−1 | 4396 | - | - | - |

| Loading | s ha−1 | 3086 | - | - | - |

| Total Harvesting Time | s ha−1 | 13,172 | 13,172 | 13,172 | 22,921 |

| Total Harvesting Time | s tVS−1 | 4244 | 4244 | 4244 | 7384 |

| Specific Energy Demand (Harvesting) | kWh tVS−1 | 95.2 | 95.2 | 95.2 | 163.9 |

| Specific Energy Demand (Treatment) | kWh tVS−1 | - | 32.4 | 36.2 | - |

| Total Energy Demand (Harvesting + Treatment) | kWh tVS−1 | 95.2 | 127.6 | 131.4 | 163.9 |

| Determination Method | Unit | Treatment Variant | |||

|---|---|---|---|---|---|

| UT | CFG | BM | AG | ||

| Specific methane yield | LCH4 kgVS−1 | 263.9 ± 7.9 a | 275.7 ± 4.0 ab | 279.1 ± 2.9 b | 277.2 ± 2.0 b |

| Additional methane yield | % | - | 4.5 ± 3.0 | 5.8 ± 2.9 | 5.1 ± 2.8 |

| Methane energy | MJ kgVS−1 | 9.5 | 9.9 | 10.0 | 10.0 |

| Energy recovery | % | 58.3 | 68.1 | 68.4 | 65.0 |

| Determination Method | Unit | Treatment Variant | |||

|---|---|---|---|---|---|

| UT | CFG | BM | AG | ||

| Rm | LCH4 kgVS−1 d−1 | 24.4 ± 0.9 a | 25.2 ± 0.6 ab | 25.8 ± 0.5 ab | 26.2 ± 0.4 b |

| λ | d | 1.02 ± 0.2 a | 0.56 ± 0.5 ab | 0.01 ± 0.0 b | 0.43 ± 0.0 ab |

| ½M(x) | d | 6.5 ± 0.2 a | 6.1 ± 0.5 ab | 5.4 ± 0.2 b | 5.7 ± 0.1 ab |

| Rm(xmax) | d | 5.0 ± 0.1 a | 4.6 ± 0.5 ab | 4.0 ± 0.1 b | 4.3 ± 0.1 ab |

| Adj. R2 | 0.978 ± 0.003 | 0.968 ± 0.007 | 0.970 ± 0.002 | 0.972 ± 0.002 | |

| Treatment Variant | Specific Energy Demand kWh tVS−1 | Additional Methane Surplus kWh tVS−1 | Energy Balance kWh tVS−1 |

|---|---|---|---|

| CFG | 32.4 | 44.7 | 12.3 |

| BM | 36.2 | 57.6 | 21.4 |

| AG (on the field) | 68.7 | 50.4 | −18.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Heller, R.; Brandhorst, C.; Hülsemann, B.; Lemmer, A.; Oechsner, H. Comparison of Different Mechanical Pretreatment Methods for the Anaerobic Digestion of Landscape Management Grass. Energies 2023, 16, 8091. https://doi.org/10.3390/en16248091

Heller R, Brandhorst C, Hülsemann B, Lemmer A, Oechsner H. Comparison of Different Mechanical Pretreatment Methods for the Anaerobic Digestion of Landscape Management Grass. Energies. 2023; 16(24):8091. https://doi.org/10.3390/en16248091

Chicago/Turabian StyleHeller, René, Christina Brandhorst, Benedikt Hülsemann, Andreas Lemmer, and Hans Oechsner. 2023. "Comparison of Different Mechanical Pretreatment Methods for the Anaerobic Digestion of Landscape Management Grass" Energies 16, no. 24: 8091. https://doi.org/10.3390/en16248091

APA StyleHeller, R., Brandhorst, C., Hülsemann, B., Lemmer, A., & Oechsner, H. (2023). Comparison of Different Mechanical Pretreatment Methods for the Anaerobic Digestion of Landscape Management Grass. Energies, 16(24), 8091. https://doi.org/10.3390/en16248091