Evaluation of the Hemp Shive (Cannabis sativa L.) Energy Requirements Associated with the Biocomposite Compaction Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Tested Material

2.2. Dividing the Material into Fractions

2.3. Determination of Bulk Density

2.4. Determination of Volumetric Density

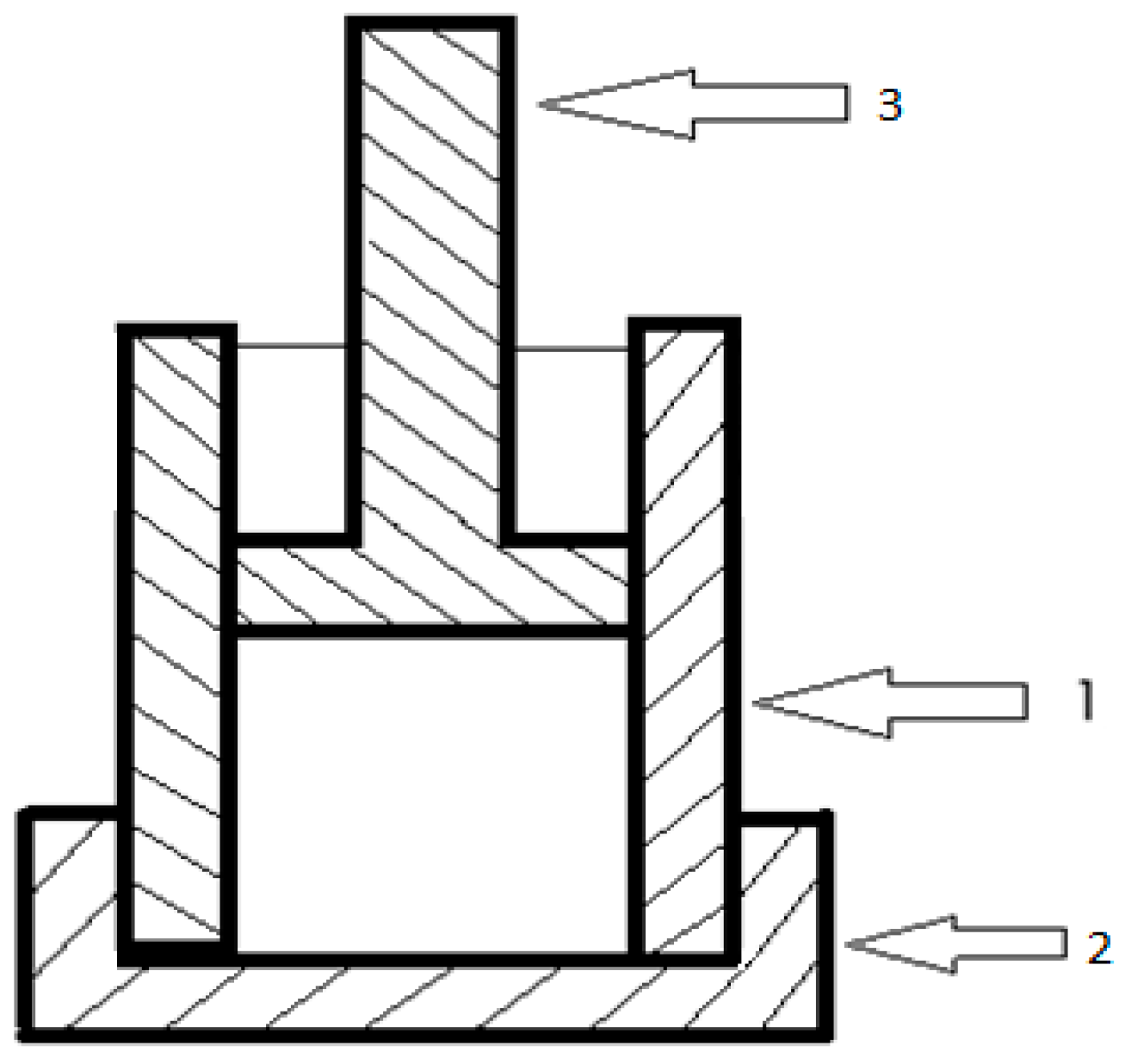

2.5. Construction and Functioning of the Compaction Head

3. Results

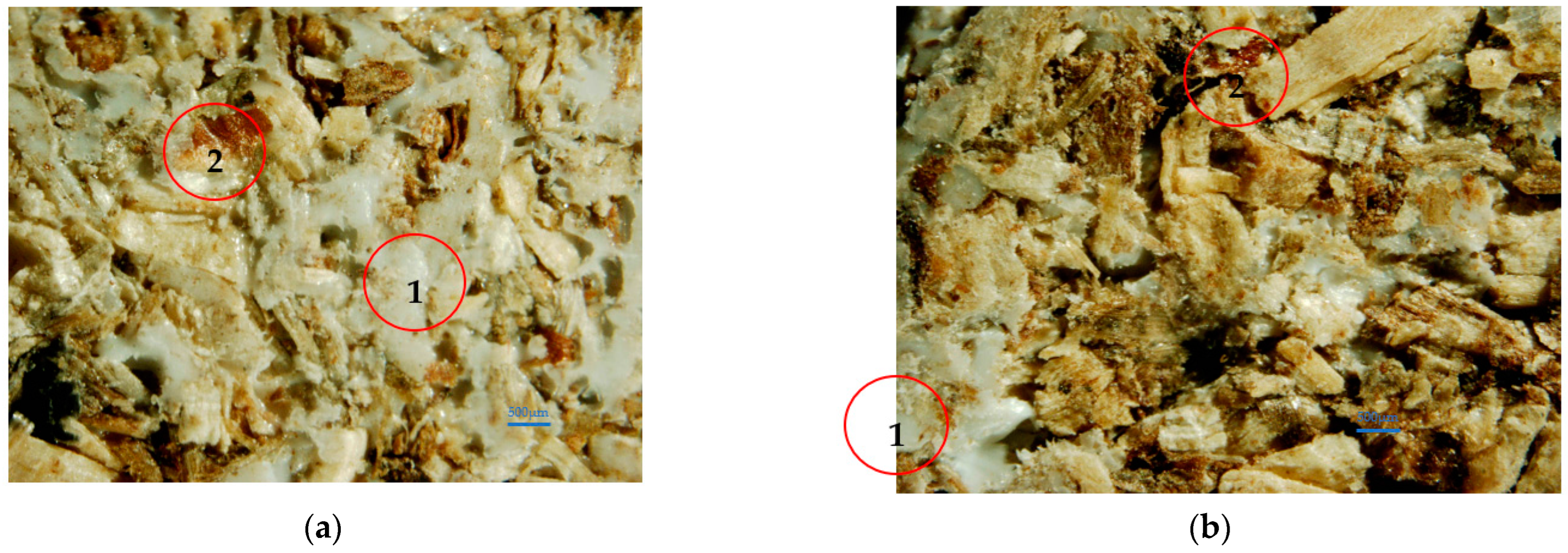

3.1. Physical Analysis of Tested Material

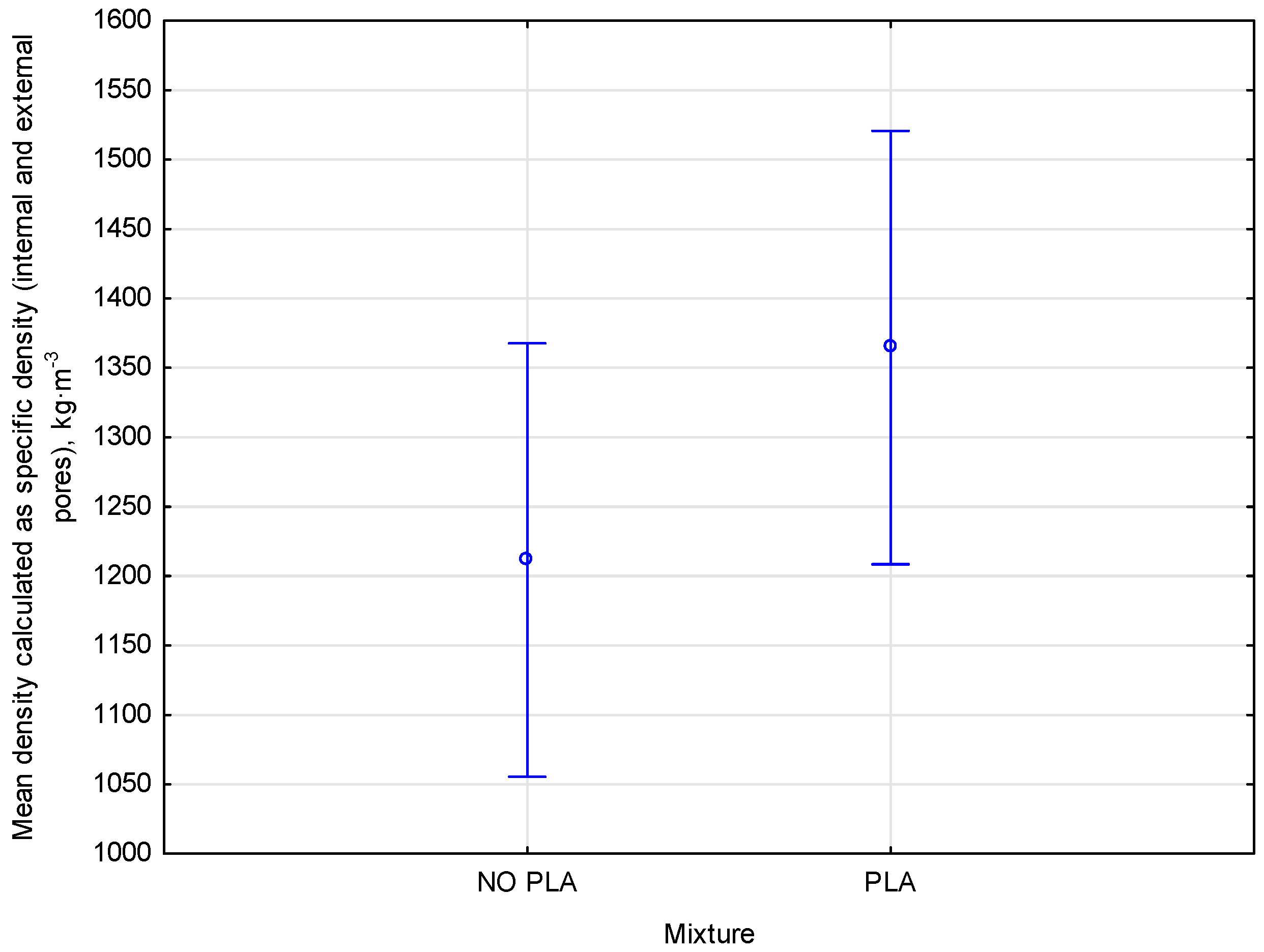

3.2. Comparison of the Density of Shredded Logging Residues

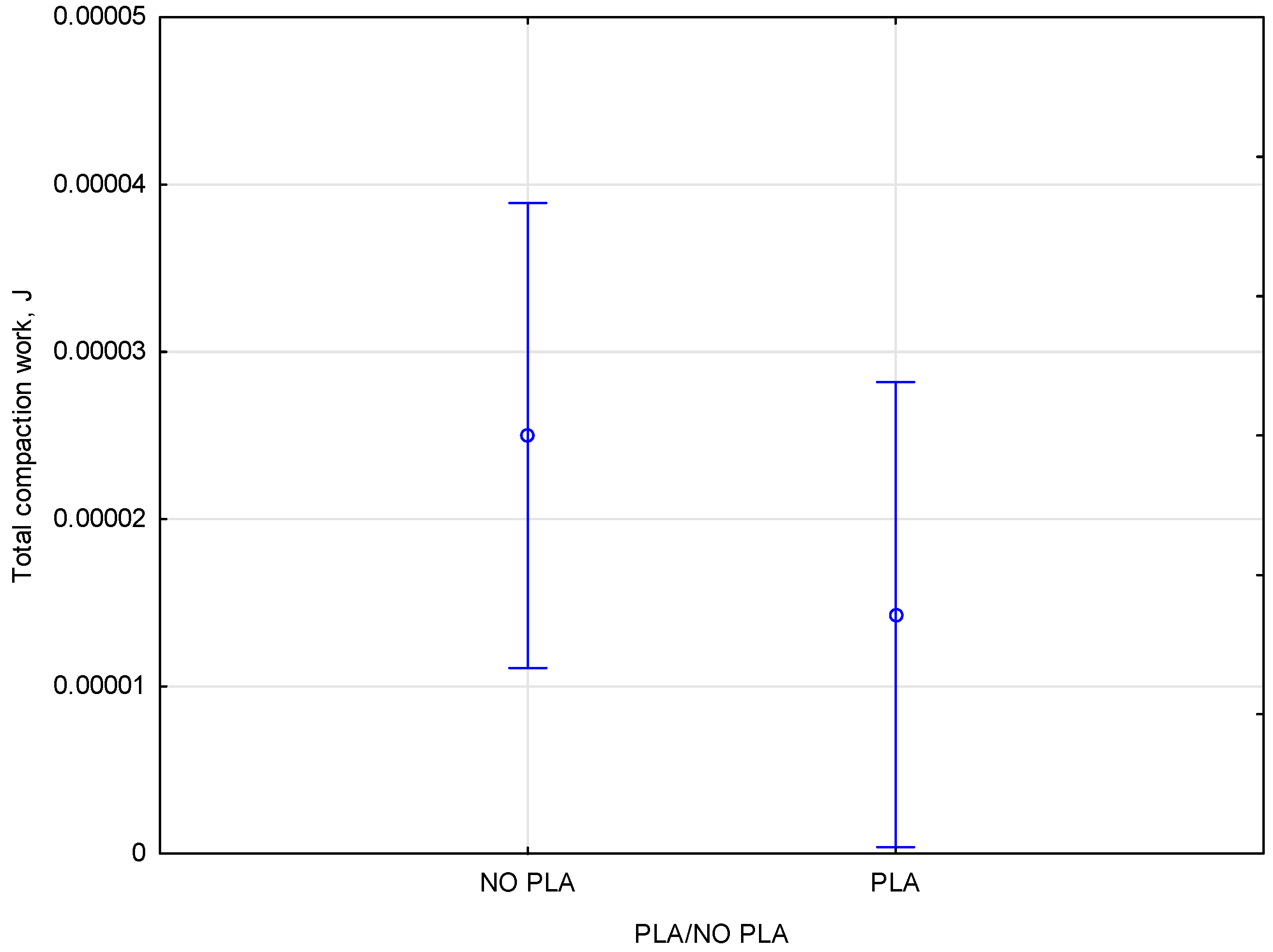

3.3. Analysis of the Compressing Process

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wazir, N.; Zhang, M.; Li, L.; Ji, R.; Li, Y.; Wang, Y.; Ma, Y.; Ullah, R.; Aziz, T.; Cheng, B.; et al. Three-terminal photodetectors based on chemical vapor deposition-grown triangular MoSe2 flakes. FlatChem 2022, 34, 100399. [Google Scholar] [CrossRef]

- Aziz, T.; Mehmood, S.; Haq, F.; Ullah, R.; Khan, F.U.; Ullah, B.; Raheel, M.; Iqbal, M.; Ullah, A. Synthesis and modification of silica-based epoxy nanocomposites with different sol-gel process enhanced thermal and mechanical properties. Appl. Polym. 2021, 138, 51191. [Google Scholar] [CrossRef]

- Stanwix, W.; Alex Sparrow, A. The Hempcrete Book: Designing and Building with Hemp-Lime; Green Books: Dartington, UK, 2014; p. 368. ISBN 9780857841223. [Google Scholar]

- Cherney, J.H.; Small, E. Industrial Hemp in North America: Production, Politics and Potential. Agronomy 2016, 6, 58. [Google Scholar] [CrossRef]

- Fortenbery, T.R.; Mick, T.B. Industrial Hemp: Opportunities and Challenges for Washington’s Hemp Industry; WSU Center for Sustaining Agriculture and Natural Resources: Puyallup, WA, USA, 2014; p. 19. [Google Scholar]

- Kowalski, K.; Nowak, M. Właściwości fizyczne pozostałości zrębowych w procesie brykietowania (eng. Physical properties of logging residues in the briquetting process). Przegląd Technol. 2021, 114, 23–29. [Google Scholar]

- Samprón, I.; de Diego, L.F.; García-Labiano, F.; Izquierdo, M.T.; Abad, A.; Adánez, J. Biomass Chemical Looping Gasification of pine wood using a synthetic Fe2O3/Al2O3 oxygen carrier in a continuous unit. Bioresour. Technol. 2020, 316, 123908. [Google Scholar] [CrossRef] [PubMed]

- Johnson, M.S.; Wallace, J.G. Genomic and Chemical Diversity of Commercially Available High-CBD Industrial Hemp Accessions. Sec. Genom. Plants Phytoecosyst. 2021, 12, 2021. [Google Scholar] [CrossRef]

- Nowak, A.; Kowalska, K. Optymalna mieszanka frakcji zrębków konopi w procesie brykietowania (eng. Optimal mix of hemp chip fractions in the briquetting process. Energetyka-Rynek-Ceny-Technologie 2022, 28, 45–50. [Google Scholar]

- Spindle, T.R.; Bonn-Miller, M.O.; Vandrey, R. Changing landscape of cannabis: Novel products, formulations, and methods of administration. Curr. Opin. Psychol. 2019, 30, 98–102. [Google Scholar] [CrossRef]

- Chen, C.; Wongso, I.; Putnam, D.; Khir, R.; Pan, Z. Effect of hot air and infrared drying on the retention of cannabidiol and terpenes in industrial hemp (Cannabis sativa L.). Ind. Crops Prod. 2021, 172, 114051. [Google Scholar] [CrossRef]

- Smith, J. Chemical recycling of hemp waste textiles via the ionic liquid based dry-jet-wet spinning technology. Text. Res. J. 2023, 93, 11–12. [Google Scholar]

- Kaiser, C.; Cassady, C.; Matt Ernst, M. September Industrial Hemp Production; University of Kentucky Agricultural Communications Services: Lexington, KY, USA, 2015. [Google Scholar]

- Burczyk, H.; Grabowska, L.; Kołodziej, J.; Strybe, M. Industrial Hemp as a Raw Material for Energy Production. J. Ind. Hemp. 2008, 13, 37–48. [Google Scholar] [CrossRef]

- Zając, A.; Świderski, A. Analiza wartości opałowej i zawartości popiołu konopi siewnych (eng. Analysis of the calorific value and ash content of seed hemp. Inżynieria Rol. 2021, 2, 325–334. [Google Scholar]

- Benfratello, S.; Capitano, C.; Peri, G.; Rizzo, G. Thermal and structural properties of a hemp–lime biocomposite. Constr. Build. Mater. 2013, 48, 745–754. [Google Scholar] [CrossRef]

- Colomer-Romero, V.; Rogiest, D.; García-Manrique, J.A.; Crespo, J.E. Comparison of Mechanical Properties of Hemp-Fibre Biocomposites Fabricated with Biobased and Regular Epoxy Resins. Materials 2020, 13, 5720. [Google Scholar] [CrossRef]

- Leszczyński, M.; Roman, K. Hot-Water Extraction (HWE) Method as Applied to Lignocellulosic Materials from Hemp Stalk. Energies 2023, 16, 4750. [Google Scholar] [CrossRef]

- Suchorab, B.; Roman, K. The PLA content influence selected properties of wood-based composites. Ann. WULS SGGW. For. Wood Technol. 2022, 120, 57–67. [Google Scholar] [CrossRef]

- Da Silveira, P.H.P.M.; Santos, M.C.C.d.; Chaves, Y.S.; Ribeiro, M.P.; Marchi, B.Z.; Monteiro, S.N.; Gomes, A.V.; Tapanes, N.d.L.C.O.; Pereira, P.S.d.C.; Bastos, D.C. Characterization of Thermo-Mechanical and Chemical Properties of Polypropylene/Hemp Fiber Biocomposites: Impact of Maleic Anhydride Compatibilizer and Fiber Content. Polymers 2023, 15, 3271. [Google Scholar] [CrossRef] [PubMed]

- Mehta, G.; Drzal, L.T.; Mohanty, A.K.; Misra, M. Effect of fiber surface treatment on the properties of biocomposites from nonwoven industrial hemp fiber mats and unsaturated polyester resin. Appl. Polim. 2006, 99, 1055–1068. [Google Scholar] [CrossRef]

- Almgren, K.M.; Gamstedt, E.K.; Berthold, F.; Lindström, M. Moisture uptake and hygroexpansion of wood fiber composite materials with polylactide and polypropylene matrix materials. Polym. Compos. 2009, 30, 1809–1816. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef]

- Cheung, H.Y.; Lau, K.T.; Tao, X.M.; Hui, D. A potential material for tissue engineering: Silkworm silk/PLA biocomposite. Compos. Part B Eng. 2008, 39, 1026–1033. [Google Scholar] [CrossRef]

- Wesołowski, M.; Nowakowski, D. Możliwości wykorzystania konopi siewnych do produkcji brykietów opałowych (eng. Possibilities of using hemp seed for the production of fuel briquettes). Probl. Inżynierii Rol. 2018, 4, 39–49. [Google Scholar]

- Kiełbasa, P.; Gałuszka, A. Badania procesu brykietowania pozostałości zrębowych z drzew iglastych (eng. Research on the briquetting process of coniferous logging residues). Inżynieria I Apar. Chem. 2019, 58, 18–19. [Google Scholar]

- Bembenek, M.; Kowalski, Ł.; Kosoń-Schab, A. Research on the Influence of Processing Parameters on the Specific Tensile Strength of FDM Additive Manufactured PET-G and PLA Materials. Polymers 2022, 14, 2446. [Google Scholar] [CrossRef]

- Bednarczyk, P.; Nowak, M.; Mozelewska, K.; Czech, Z. Photocurable Coatings Based on Bio-Renewable Oligomers and Monomers. Materials 2021, 14, 7731. [Google Scholar] [CrossRef] [PubMed]

- PN-EN 15149-1; Wersja Angielska—Biopaliwa Stałe—Oznaczanie Rozkładu Wielkości Ziaren—Cześć 1: Metoda Przesiewania Oscylacyjnego Przy Użyciu Sit o Szczelinie 1 mm Lub Większej (Eng. English Version—Solid Biofuels—Determination of Grain Size Distribution—Part 1: Oscillatory Sieving Method Using Sieves with a Gap of 1 mm or More). Polish Committee for Standardization: Warszawa Poland, 2011; pp. 1–13.

- PN-EN 15149-2; Wersja Angielska—Biopaliwa Stałe—Oznaczanie Rozkładu Wielkości Ziaren—Cześć 2: Metoda Przesiewania Wibracyjnego Przy Użyciu Sit o Szczelinie 3.15 mm Lub Mniejszej (Eng. English Version—Solid Biofuels—Determination of Grain Size Distribution—Part 2: Vibrating Sieving Method Using Sieves with a Gap of 3.15 mm or Less). Polish Committee for Standardization: Warszawa Poland, 2011; pp. 1–13.

- Roman, K. Dobór Parametrów Technicznych Procesu Brykietowania Biomasy Leśnej (eng. Selection of Technical Parameters of the Forestry Biomass Briquetting Process). Ph.D. Thesis, Warsaw University of Life Sciences WULS, Warsaw, Poland, 2017; pp. 1–155. [Google Scholar]

- Starkey, H.; Chenoweth, A.; Johnson, C.; Salem, K.S.; Jameel, H.; Pal, L. Lignin-containing micro/nanofibrillated cellulose to strengthen recycled fibers for lightweight sustainable packaging solutions. Carbohydr. Polym. Technol. Appl. 2021, 2, 100135. [Google Scholar] [CrossRef]

- Ruz-Cruz, M.A.; Herrera-Franco, P.J.; Flores-Johnson, E.A.; Moreno-Chulim, M.V.; Galera-Manzano, L.M.; Valadez-González, A. Thermal and mechanical properties of PLA-based multiscale cellulosic biocomposites. J. Mater. Res. Technol. 2022, 18, 485–495. [Google Scholar] [CrossRef]

- Kim, D.; Yoo, C.G.; Schwarzc, J.; Dhekneyc, S.; Kozakd, R.; Laufera, C.; Ferriera, D.; Mackaya, S.; Ashcrafta, M.; Williamsa, R.; et al. Effect of lignin-blocking agent on enzyme hydrolysis of acid pretreated hemp waste. RSC Adv. 2021, 11, 22025–22033. [Google Scholar] [CrossRef]

- Anderson-Teixeira, K.J.; Kannenberg, S.A. What drives forest carbon storage? The ramifications of source–sink decoupling. New Phytol. J. 2022, 1, 236. [Google Scholar] [CrossRef]

- PN-EN 15103:2010; Biopaliwa Stałe—Oznaczanie Gęstości Nasypowej (Eng. Solid Biofuels—Determination of Bulk Density). Polish Committee for Standardization: Warszawa Poland, 2011; pp. 1–12.

- Hartmann, H.; Böhm, T.; Daugbjerg Jensen, P.; Temmerman, M.; Rabier, F.; Jirjis, R.; Hersener, J.-L.; Rathbauer, J. Methodsfor Bulk Density Determination of Solid Biofuels. In World Conference and Technology Exhibition on Biomass for Energy, 2nd ed.; Van Swaaij, W.P.M., Fjällström, T., Helm, P., Grassi, A., Eds.; Industry and Climate Protection: Rome, Italy, 2004; pp. 662–665. [Google Scholar]

- Ohijeagbon, I.O.; Adeleke, A.A.; Mustapha, V.T.; Olorunmaiye, J.A.; Okokpujie, I.P.; Ikubanni, P.P. Development and characterization of wood-polypropylene plastic-cement composite board. Case Stud. Constr. Mater. 2020, 13, e00365. [Google Scholar] [CrossRef]

- Niedziółka, I.; Zuchniarz, A. Analiza energetyczna wybranych rodzajów biomasy pochodzenia roślinnego (eng. Energy analysis of selected types of biomass of plant origin). Motrol. Motoryz. I Energetyka Rol. 2006, 8, 232–237. [Google Scholar]

- Wang, Y.; Wu, K.; Sun, Y. Effects of raw material particle size on the briquetting process of rice straw. J. Energy Inst. 2018, 91, 153–162. [Google Scholar] [CrossRef]

- Skonecki, S.; Kulig, R.; Potręć, M. Ciśnieniowe zagęszczanie trocin sosnowych i topolowych—Parametry procesu i jakość aglomeratu (eng. Pressure compaction of pine and poplar sawdust—Process parameters and agglomerate quality). Acta Agrophys. 2011, 18, 149–160. [Google Scholar]

- Kulig, R.; Skonecki, S.; Gawłowski, S.; Zdybel, A.; Łysiak, G. Oddziaływanie ciśnienia na efektywność zagęszczania trocin wybranego drewna miękkiego (eng. Pressure compaction of pine and poplar sawdust—Process parameters and agglomerate quality). Acta Sci. Pol. Tech. Agrar. 2013, 12, 31–40. [Google Scholar]

- Skonecki, S.; Laskowski, J. Wpływ średnicy komory i wilgotności słomy pszennej na parametry zagęszczania (eng. Effect of chamber diameter and moisture content of wheat straw on compaction parameters). Acta Agrophys. 2012, 19, 415–424. [Google Scholar]

| Mixture | Mean Volumetric Density Measured with Water (SD) 1, kg·m−3 | Calculated Value with Conversion Factor (χ), kg·m−3 (SD) 1 | Mean Density Calculated as Specific Density (Internal and External Pores), kg·m−3 |

|---|---|---|---|

| f1 (0 ÷ 2) | 994.89 (5.04) | 616.83 (35.62) | 1377.33 |

| f2 (2 ÷ 4) | 810.65 (2.95) | 502.61 (60.43) | 1122.27 |

| f3 (4 ÷ 6) | 773.81 (17.66) | 479.76 (132.71) | 1071.26 |

| f4 (6 ÷ 8) | 921.20 (4.74) | 571.14 (121.87) | 1275.31 |

| f1 (0 ÷ 2), 50%PLA | 958.05 (3.38) | 593.99 (23.87) | 1326.32 |

| f2 (2 ÷ 4), 50%PLA | 884.35 (1.80) | 548.30 (36.86) | 1224.29 |

| f3 (4 ÷ 6), 50%PLA | 1031.74 (11.48) | 639.68 (86.26) | 1428.34 |

| f4 (6 ÷ 8), 50%PLA | 1068.59 (2.61) | 662.53 (67.03) | 1479.36 |

| Total Work Carried Out under Specified Conditions W(τ, φ) | Determination Coefficient R2 | Displacement l, mm | Total Compaction Work, J |

|---|---|---|---|

| 0.991 | 10.76 | 1.1 × 10−5 | |

| 0.996 | 12.05 | 1.4 × 10−5 | |

| 0.990 | 17.73 | 3.0 × 10−5 | |

| 0.996 | 21.73 | 4.5 × 10−5 | |

| 0.998 | 13.43 | 1.7 × 10−5 | |

| 0.999 | 11.48 | 1.3 × 10−5 | |

| 0.999 | 13.12 | 1.6 × 10−5 | |

| 0.990 | 10.70 | 1.1 × 10−5 |

| Mixture | Mean Volumetric Denisity (SD) 1, kg·m−3 | Mean Density Calculated as Specific Density (Internal and External Pores), kg·m−3 | Mean Density After Compaction (SD) 1, kg·m−3 | Total Compaction Work, J |

|---|---|---|---|---|

| f1 (0 ÷ 2) | 284.26 (1.18) | 1377.33 | 1144.33 (0.84) | 1.1 × 10−5 |

| f2 (2 ÷ 4) | 231.62 (0.68) | 1122.27 | 1101.28 (1.80) | 1.4 × 10−5 |

| f3 (4 ÷ 6) | 221.09 (0.93) | 1071.26 | 1292.40 (1.21) | 3.0 × 10−5 |

| f4 (6 ÷ 8) | 263.20 (0.99) | 1275.31 | 1277.82 (2.52) | 4.5 × 10−5 |

| f1 (0 ÷ 2). 50%PLA | 273.73 1.90 | 1326.32 | 1167.49 (0.42) | 1.7 × 10−5 |

| f2 (2 ÷ 4). 50%PLA | 252.67 (1.11) | 1224.29 | 1117.94 (0.90) | 1.3 × 10−5 |

| f3 (4 ÷ 6). 50%PLA | 294.78 (1.52) | 1428.34 | 1187.55 (0.61) | 1.6 × 10−5 |

| f4 (6 ÷ 8). 50%PLA | 305.31 (1.60) | 1479.36 | 1167.16 (1.26) | 1.1 × 10−5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nowakowski-Pałka, J.; Roman, K. Evaluation of the Hemp Shive (Cannabis sativa L.) Energy Requirements Associated with the Biocomposite Compaction Process. Energies 2023, 16, 6591. https://doi.org/10.3390/en16186591

Nowakowski-Pałka J, Roman K. Evaluation of the Hemp Shive (Cannabis sativa L.) Energy Requirements Associated with the Biocomposite Compaction Process. Energies. 2023; 16(18):6591. https://doi.org/10.3390/en16186591

Chicago/Turabian StyleNowakowski-Pałka, Jakub, and Kamil Roman. 2023. "Evaluation of the Hemp Shive (Cannabis sativa L.) Energy Requirements Associated with the Biocomposite Compaction Process" Energies 16, no. 18: 6591. https://doi.org/10.3390/en16186591

APA StyleNowakowski-Pałka, J., & Roman, K. (2023). Evaluation of the Hemp Shive (Cannabis sativa L.) Energy Requirements Associated with the Biocomposite Compaction Process. Energies, 16(18), 6591. https://doi.org/10.3390/en16186591