Abstract

The study considers ways to ensure the quality of the functioning of power equipment as one of the directions for ensuring the safety of energy complexes in the period of “green transformation”. Based on the analysis, it is established that for an effective “green” transformation, it is necessary to ensure the energy safety of equipment operation, which is possible by developing effective science-based approaches to technical diagnostics of the state of power systems and individual equipment. The main objective of the study is to develop a Safety Management Model for Life Term Operation of power equipment, which takes into account changes in its condition at different stages of operation and allows for the prediction of further safe operation. The paper proposes an approach to researching the technical condition of power equipment, taking into account the deformations that occur during operation. The results of the calculation of stress intensity coefficients for longitudinal and transverse-postulated cracks in different modes are presented. Based on the calculated and experimentally obtained values, an approach to predicting the operating life of power equipment with regard to changes in technical characteristics is proposed. The results of the calculations showed that by changing the allowable load on the material of the energy equipment to 35 kgf/mm2, the estimated operational lifespan could be extended until 2035, ensuring all necessary safety conditions. It has been proven that with effective management and continuous safety diagnostics, nuclear power plants have the potential to operate beyond their standard design life of up to 30–40 years. This approach allows for the quality and safe operation of power equipment in the context of the transition to sustainable energy.

1. Introduction

Managing the security of energy facilities is an important strategic task for the development of sustainable energy. To ensure the sustainability of energy processes, it is necessary to develop a set of measures and actions that promote the development of energy and technologies while ensuring safety. To achieve a secure shift towards a “green” trajectory, it is essential to create a well-defined implementation plan that considers the resource requirements of the population while accounting for economic, environmental, and social implications. Among the critical resource factors influencing the quality of life, energy needs hold significant importance, and nuclear energy plays a crucial role in meeting these demands. In fact, in 2022, the European Commission recognized nuclear energy as green energy, acknowledging its contribution to the green transformation and the journey towards climate neutrality. However, ensuring energy safety and the secure operation of nuclear power plants and their equipment remains an essential prerequisite.

Ensuring the safe operation of energy facilities, both during their design and beyond their design life, is a crucial socio-economic and environmental undertaking, not only for Ukraine but also for the global energy industry. The significance of nuclear power plant safety during long-term operation (LTO) has escalated due to the growing number of licensees prioritizing assessments for the continued operation of these plants beyond their originally intended design timeframe. By the end of 2014, there were 438 operational nuclear power plants globally, with 225 of them having been in service for more than 30 years. A total of 68.27% of the reactors in the EU have been operational for over 30 years, and 30.8% of them are more than 40 years old, signifying that they have been granted an extended operational life beyond their initial design period, placing them in the category of LTO. As these plants approach the end of their operating licenses, they undergo a comprehensive safety review and ageing assessment of crucial structures, systems, and components. This evaluation is essential to either validate or renew their license to continue operating beyond the originally intended service period [1,2,3,4,5,6]. With some power units in Ukraine reaching or nearing the end of their design life, a significant objective is to extend their lifespan as part of the planned shift towards green energy, while prioritizing safety and dependability. Additionally, nuclear power remains a vital component of many countries’ energy systems, enabling support for the energy sector during the transition to alternative energy sources. Absolutely, achieving safe and sustainable operation of energy complexes, as well as individual elements within them, heavily relies on effective approaches to quality assurance and safety management. These measures are essential for ensuring the reliability, longevity, and overall success of the energy sector’s transition to greener and more sustainable practices.

Thus, today we have some contradictions, namely, for a safe “green” transition and further ensuring the stability of the energy sector, it is necessary to use nuclear energy, which in turn is now considered a “green” energy resource. At the same time, a significant number of nuclear power plants in the world have exhausted or approached their service life, which requires the development of a strategy for a smooth and safe transition to beyond design life and the definition of safety management mechanisms based on comprehensive technical diagnostics for continued operation.

This study aims to present an approach to ensuring energy management for the safety of power equipment operations. In this regard, the paper will analyze the latest research in the field of safety and effective management approaches based on selected articles and studies, which will help researchers and professionals in this field, and propose an energy management model taking into account the technical condition of power equipment. Thus, Section 2 will consider the analysis of approaches to the management of the safe operation of power equipment, after which, Section 3 will consider the management of energy security in the operation of power equipment, and thus, we will end with Section 4 concerning the results and discussions, and finally, with Section 5 referring to the conclusions.

2. Analysis of Approaches to the Management of the Safe Operation of Power Equipment

Green energy plays a crucial role in providing a sustainable source of non-carbon electricity. Safe and reliable operation of the power plant relies on advanced technologies and continuous improvement in management practices. However, owner/operating organizations of power plants are encountering significant challenges to their financial sustainability, especially in competitive electricity markets and with a decreasing or stagnant energy demand. To address these challenges and meet the climate change goals outlined in the Paris Agreement, these organizations are re-evaluating their business models, adopting more robust and resilient approaches, and striving to maintain operational excellence. In recent decades, the energy sector has shown enhanced performance, thanks to the development of effective management models and processes within the green industry [6].

The safety of power plants depends on the reliability of their equipment, which includes structures, systems, and components. Achieving a high level of equipment reliability requires correct tasking, timely actions, and sufficient resources, which are managed through well-designed processes and programs. In the short term, a key method of ensuring equipment reliability is to predict and identify potential problems before they lead to unexpected equipment failure. Innovations using advanced technologies can complement these efforts by enabling more intensive equipment monitoring, longer trending intervals, and the use of sophisticated analytical algorithms to correlate system parameters and establish criteria for detecting potentially abnormal equipment behavior.

Enhancing the safety of power plant equipment involves advancements in monitoring methods and systems. From the perspective of nuclear reactor safety, research and accident risk assessments demonstrate that adverse events occur at a low rate compared to the overall estimated risk to human life in general. To reduce risks and elevate the safety level of power plant equipment, continuous efforts are required to enhance safety systems, safety management, and human resources [7,8].

Thus, nuclear energy plays a vital role in promoting sustainable economic development and maintaining its reputation as a “green” energy necessitates the active involvement of all stakeholders in ensuring operational safety. As indicated in references [7,8,9,10,11,12], the shift towards a circular, “green” economy is a gradual process, and the energy sector necessitates support and diligent attention to safety at every level and stage of power facility equipment operation.

Numerous studies in the review present equipment reliability models that explicitly incorporate not only baseline reliability but also the impact of aging, maintenance, and testing activities [13,14,15,16].

Ukrainian researchers have extensively investigated the safety aspects of power equipment operation during both its design and extended operational periods, given Ukraine’s robust and advanced nuclear power system. Some research [17,18,19] has addressed the safety concerns related to various aspects of nuclear power plant components and equipment, offering diverse methods and approaches for technical diagnostics and enhancing regulatory support for operational safety. In [20], the authors proposed equipment standardization to distinguish methods and models for evaluating the technical condition of pipeline systems subjected to different types of loads and coolant mediums. Furthermore, papers emphasized the importance of conducting a comprehensive assessment of power equipment, considering its operational characteristics, to predict changes in technical condition and service life beyond the design period.

Ensuring the safe operation of power plant equipment requires a comprehensive approach to assess its quality and technical condition. For instance, for pipelines, researchers have proposed a comprehensive technical diagnosis of energy equipment, which considers structural features, defects, and stress–strain state after a specific period of operation [13,20,21,22]. The studies employ research methods like mathematical modeling, comparison of calculated and experimental results, identifying boundary parameters of the technical condition, predicting service life, and monitoring and controlling the mechanical properties of energy equipment during operation using non-destructive testing methods. They also involve determining the residual resource of metal structures and equipment, considering external factors. The suggested methods and algorithms of technical diagnostics can serve as the foundation for assessing the overall condition of energy equipment. The authors propose an actual analysis of the state of power equipment and the main disadvantage of these methods in comparison with the proposed one is the lack of possibility to make a comprehensive prognostic assessment taking into account possible operational changes.

Developing an effective mechanism to study the operational quality and assess the technical condition of energy equipment beyond its design service life requires the consideration of factors influencing both safety and economic indicators for future operations. Some research [23,24,25,26] explored approaches to optimizing the correlation between safety and economic indicators and criteria in this context.

Studies [27,28,29,30,31] have examined the challenges related to ensuring the safe operation of power plants from various perspectives. In these studies, the authors proposed cutting-edge information and measurement systems, smart technologies, and smart NPP concepts, along with innovative approaches to control system design and reliability assessment. Notably, these authors emphasize the importance of learning from past negative experiences of NPP operation, like the Chernobyl accident and Fukushima, underscoring the need for a robust system to ensure the safe operation of energy facilities.

However, new technologies also bring new risks to the energy industry. Thus, studies [32,33,34] propose Integrated Management of Safety and Security (IMSS) as a necessary means of preventing and preparing for accidents. It considers the risks posed by the development of digitalization and automation in high-risk industries and the resulting growing convergence of risks related to process safety, physical safety, and cyber security, which can lead to serious accidents. The authors of [35] propose an automatic generation control (AGC) for nuclear power plants (NPPs) to ensure the safety of NPP operation. The study is based on the hypothesis that with the development of the energy supply structure towards clean energy, NPPs will be a stabilizer of the power system and an effective advanced AGC strategy is needed, taking into account nuclear safety, relay protection of power units, automation of grid management, the power system stabilizer (PSS), and the speed control system.

Management of safety through the development of various models and approaches for risk assessment is examined in works [36,37,38]. Indeed, for this purpose, authors propose the use of Probabilistic Safety Analysis (PSA) technology, which has emerged as the predominant method worldwide, providing essential support for daily risk management and safety decision-making in nuclear power plants. Absolutely, PSA technology can be utilized to develop an aging PSA model for power plants during the license extension period. This model helps assess the effects of system, structure, and component (SSC) aging on the overall safety of nuclear power plants and verifies whether they still adhere to the original design standards [39,40,41]. By doing so, the extended operation can be ensured to meet the necessary safety requirements. To extend the operation license of a nuclear power plant, it is essential to consider nuclear safety during the extended service life. The goal is to ensure that the safety level of the power unit during the extended service life is at least as high as that of the original design life. Indeed, while PSA technology and other approaches have advanced the evaluation of safety and operational aspects of power equipment, there remain several unresolved issues related to conducting technical diagnostics and ensuring the overall quality and safety of power equipment functioning. These challenges require further research and development to effectively address and enhance the performance and safety of power equipment in various industries.

3. Energy Safety Management of the Power Equipment Operation

The primary document that defines the safe operation of a power unit is the technological regulation for safe operation. It establishes the limits and conditions for the safe operation of the power unit, as well as the requirements and fundamental practices for its safe operation. The regulation also outlines the general procedures for performing safety-related operations at the nuclear power plant.

As an example of technical diagnostics, pipeline systems for various purposes can serve as a crucial element of power equipment. The assessment of their technical condition is of utmost importance for ensuring the safe and efficient operation of the energy facility.

This study is limited to power unit equipment and its components that transport coolant at different stages of operation. The proposed approach can be used in the design, operation within the design life and, most importantly, in ensuring safe operation beyond the design life. This paper does not address the issues of technical diagnostics of the reactor and its equipment.

3.1. Analysis of Factors Affecting the Operational Safety of Power Equipment

The assessment of the technical condition and remaining lifespan of pipelines is carried out as part of control, assessment, prediction, and management of the resource characteristics of the nuclear power plant’s components. This process includes evaluating and predicting the remaining resources of various elements of the nuclear power plant, which ultimately supports the extension of the plant’s operational period.

Correct assessment of the technical condition and safety evaluations of pipeline systems involves a crucial examination of the mechanical properties of pipe metal, particularly its changes during long-term operation compared to normative data. The degradation of mechanical properties can significantly impact the technical condition and safe operation of pipelines, leading to accelerated wear and activating other factors that negatively affect the operational safety of energy equipment. Some of these factors include:

- Increased vulnerability to fatigue and stress-induced failures.

- Reduced material strength and structural integrity, leading to potential leaks or ruptures.

- Elevated susceptibility to corrosion and erosion, which can compromise the integrity of the pipeline.

- Diminished resistance to external forces, such as seismic events or environmental impacts.

- Reduced ability to withstand operational stresses and dynamic loads, increasing the likelihood of unforeseen failures.

- Potential impact on the efficiency and performance of the overall energy system, affecting its reliability and safety.

Therefore, a thorough understanding of the mechanical properties of pipeline metal over time is crucial for ensuring the safe and reliable operation of energy equipment. This knowledge aids in making informed decisions regarding maintenance, repair, and the extension of the equipment’s service life, all contributing to the overall safety of the energy facility.

The primary design loads for pipeline systems include internal or external pressure, product mass and additional loads such as attached equipment, pipe insulation, etc. Other significant loads include reactions from supports and attached pipelines, temperature effects, and vibration-induced loads. There are no standardized methods prescribed for determining design loads, internal forces, displacements, stresses, and deformations of the analyzed elements. The chosen method should account for all design loads in all relevant scenarios and enable the determination of all necessary stress categories.

3.2. Determination of the Stress–Strain State of Equipment Metal

The main challenge in ensuring the safety and longevity of nuclear power plant equipment remains the issues of dynamics and strength. To achieve the primary goal of assessing the remaining service life and extending the operation of pipeline systems in power facilities under dynamic influences, it is crucial to evaluate the resistance to brittle fracture upon crack initiation on the metal surface.

The prediction of the remaining service life is based on a method for determining the stress–strain state of the metal, considering deformations resulting from various loads. The methodology involves assessing the technical condition of the selected equipment based on critical parameters and estimating the remaining service life through measurements and/or determination of the metal’s limit state parameters, accounting for any defects that have arisen or by modeling possible changes.

3.2.1. Determination of the Allowable Stress Intensity

For research purposes, the main circulation pipeline of the South Ukrainian Nuclear Power Plant with a water-cooled water-moderated power reactor WWER-1000 was chosen as an example. The main circulation pipeline is a critical component of the overall energy block system, subject to various types of loads.

The main characteristics of materials used in calculations are the critical stress intensity factor , critical temperature of brittleness , and yield strength .

The condition of crack non-propagation is also considered.

where is the threshold stress intensity factor, which is determined from the equation

The strength condition is met when the stress intensity factor is less than the critical stress intensity factor.

where is the allowable value of the stress intensity factor (MPa∙m1/2).

The index “i” indicates that the allowable values of stress intensity factors are selected differently depending on the operational conditions: i = 1—for normal operating conditions (NOC); i = 2—for hydraulic (pneumatic) testing (HT) and violation of normal operating conditions (VOC); i = 3—for emergency situations (ES).

To account for changes in material properties during operation, the determination of the allowable stress intensity factor is carried out considering the critical temperature of brittleness.

For pearlite steels, high-chromium steels, and their welded joints with a yield strength at 20 °C not exceeding 600 MPa (60 kgf/mm2), the following generalized dependence of the stress intensity factor is used:

The critical temperature of material brittleness is determined using the formula

where is the critical temperature of material brittleness in the initial state; is the shift of the critical temperature of brittleness due to temperature aging; is the shift of the critical temperature of brittleness due to cyclic damage; and is the shift of the critical temperature of brittleness due to the influence of neutron irradiation.

3.2.2. Defect Modeling

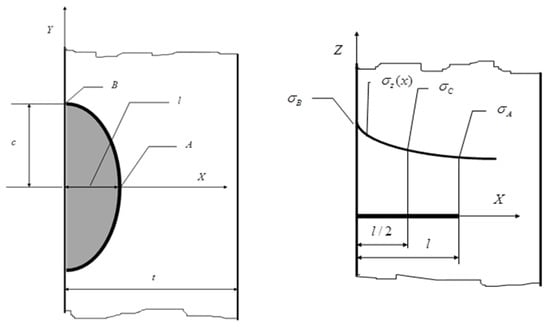

The calculation of the resistance to brittle fracture for defect consideration is performed by modelling a postulated defect on each calculation segment. The defect is modelled as a longitudinal and transverse surface semi-elliptical crack with parameters l/c = 2/3, according to the requirements (Figure 1).

Figure 1.

Surface semi-elliptical crack scheme.

The defect modelling was performed to predict the state of the metal, taking into account possible changes, in the event that actual tests did not reveal any changes or degradation effects in the metal of the power equipment. The actual condition was investigated using non-destructive testing methods in accordance with NPP safety standards and regulations.

The calculation of the stress intensity factor for the elliptical surface cracks (Figure 1) at points A and B is determined by the following formulas:

The crack parameter at point A is denoted as , ; the crack parameter at point B is denoted as , ; is the crack depth in millimeters; is the crack width in millimeters; and for ; for .

In the general case of any stress distribution in the wall of the element, as well as any shape of their application, the depth of the semi-elliptical surface crack is also divided into segments. The number of points at which stresses are specified will be .

The coordinate of each point is determined by the expression

where .

Stresses, which are specified in arbitrary form, are determined for each point : .

The stress values for the points are determined using the following formulas:

where , ,, , for the -th point (), the stress values are determined from Table 1 [42].

Table 1.

Coefficients for calculating crack stress.

For a surface element that has curvature in the direction of the -axis, the coefficients of stress intensity are determined by the ratio (longitudinal crack; radius of curvature in the -axis direction, ):

3.2.3. The Results of Determining the Coefficients of Stress Intensity

Using the proposed methodology, a calculation for the resistance to brittle fracture of the main circulation pipeline elements was performed at various sections.

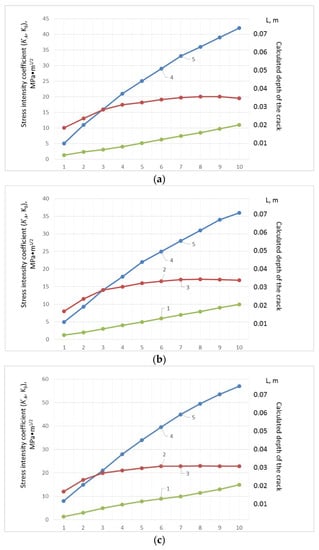

The results of determining the stress intensity coefficients for the longitudinal Y-axis and transverse Z-axis of the conditional crack for normal operating conditions (“NOC”), violation of normal operating conditions (“NOC”) and hydraulic (pneumatic) tests (“HT”) are presented in the form of diagrams in Figure 2.

Figure 2.

The diagram of stress intensity coefficients ( for the Main Circulation Pipeline (MCP): (a) from the Reactor Casing to the Steam Generator for NOC; (b) from the Steam Generator to the Main Circulation Pump for NOC; (c) from the Reactor Casing to the Steam Generator for VOC; and (d) from the Steam Generator to the Main Circulation Pump for VOC. The numbers represent the following: 1  line represents the calculated depth of the crack, 2 and 3 from line

line represents the calculated depth of the crack, 2 and 3 from line  represent the stress intensity coefficient (KA) along the Y-axis at point A, and 4 and 5 from line

represent the stress intensity coefficient (KA) along the Y-axis at point A, and 4 and 5 from line  represent the stress intensity coefficient (KB) along the Z-axis at point B.

represent the stress intensity coefficient (KB) along the Z-axis at point B.

It is worth noting that the permissible stress intensity coefficient .

As can be seen from the graphs (Figure 2), the values of stress intensity factors for the considered operating conditions are three orders of magnitude lower than the stress intensity factors that meet the operational requirements.

The defect modelling and subsequent calculation makes it possible to predict the safe operation of power equipment under certain cyclic loads, or to assess the actual condition of the metal of power equipment and develop recommendations for the service life. This makes it possible to develop a Long-Term Safety Management Model.

4. Results and Discussion

Based on the proposed method of considering the defect resulting from the operation of energy equipment and the corresponding cyclic loads, and using the determined stress intensity coefficients, the estimation of remaining service life and safety prediction for further operation is suggested. Some research [9,13] proposes mathematical models to analyze the changes in the mechanical properties of the metal pipeline, such as , (ultimate tensile strength), (yield strength), ZT (total elongation), AT (reduction of area), KSI (stress intensity coefficients), and others, considering the regularities of metal property changes during operation. These models take into account the geometry of the defect and the accumulation of fatigue damage in equipment and pipelines under different operational loads.

Taking into account the data on the material of the main circulation pipeline, we will determine the values of permissible stresses for different calculation groups of stress categories.

For the metal of the main circulation pipeline (MCP), with the main material being 10GN2MFA steel:

The normal operating conditions (NOC):

The hydraulic (pneumatic) testing (HT):

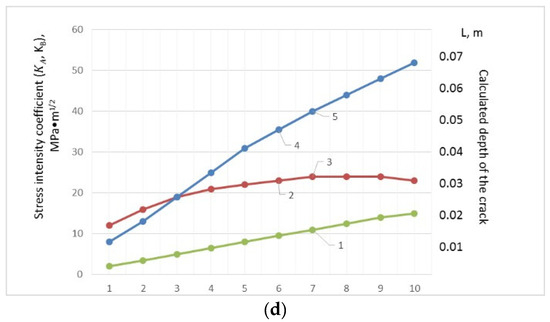

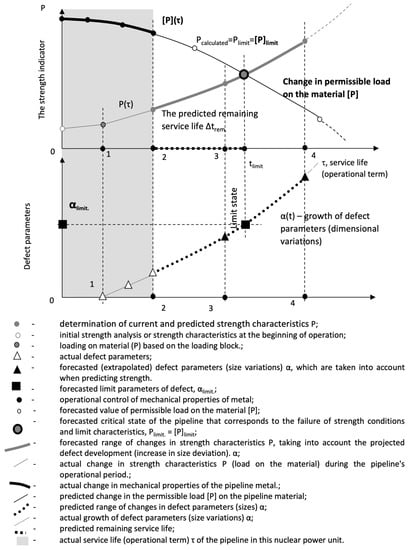

The calculated forecast of the change in the permissible load on the material of the main circulation pipeline (MCP) elements depending on the duration of operation is presented in Figure 3.

Figure 3.

Calculated forecast of the change in permissible load on the material of the main circulation pipeline (MCP) elements.

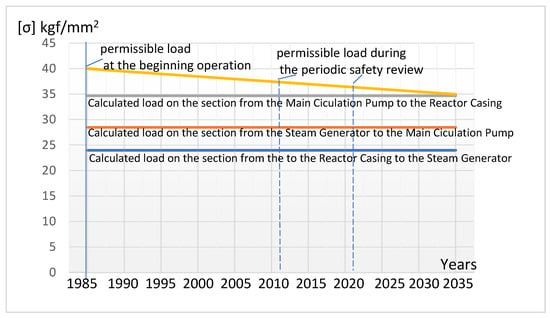

Based on the results of technical diagnostics and calculated predictions of changes in the allowable loads, it can be concluded that the mechanical characteristics of all inspected elements are in agreement with the specified values and meet or exceed the regulatory requirements [43]. The refined forecast of metal changes in the energy equipment under different loads and considering potential defects indicates the possibility of safe operation until 2035. However, it is recommended to plan and carry out metal monitoring and assess changes in allowable loads during the periodic safety review (PSR-2024; PSR-2029) as part of the major overhaul in 2024 and 2029. To achieve this, a safety management scheme is proposed for determining the technical condition and critical parameters of the pipeline metal (energy equipment), aiming at Long-Term Operation (LTO) (Figure 4).

Figure 4.

The Plant Safety Management Model for Life Term Operation Determination.

The Plant Safety Management Model is a system that defines the Life Term Operation of a nuclear power plant. LTO refers to the extension of the operational lifetime of a nuclear power plant beyond its original design life, while ensuring safety and reliability. The LTO process involves conducting comprehensive evaluations, technical diagnostics, and safety assessments to determine whether the plant’s components, including the pipelines, can continue to operate safely and meet the required performance standards [44,45,46,47].

The Plant Safety Management Model includes various aspects, such as probabilistic safety analysis, aging management programs, material property assessments, and defect prediction models. By incorporating these elements, the model can predict the remaining service life of the equipment, including the pipelines, and estimate their future performance considering the effects of aging, degradation, and accumulated fatigue.

The results of the Plant Safety Management Model allow plant operators and regulatory authorities to make informed decisions about the continued safe operation of the nuclear power plant. It also helps in planning maintenance, repair, and replacement activities to ensure the plant’s safe and efficient operation throughout its extended service life.

5. Conclusions

Aging of equipment and corresponding analysis of resource characteristics are important issues in Ukraine and worldwide. Research on the equipment’s maximum service life is driven by a significant portion of equipment that has either reached its designed service life or exceeded it. Forecasting the equipment’s service life, which is the subject of numerous studies, has shown that extending the service life of objects through partial replacement and equipment repair becomes economically and technically feasible. However, to justify extending the operational period, a thorough analysis of factors affecting the safety, functionality, and longevity of the energy equipment is necessary. Specifically, research on specific objects needs to be conducted regarding factors that determine the extent of deformation during prolonged operation. To determine the equipment’s service life and justify the forecast for extending the operational period, data from regular monitoring of the mechanical properties of the base metal during the operational term are required.

Based on the assessment of the technical condition of the main circulation pipeline elements of the South Ukraine Nuclear Power Plant, the following findings regarding the main aging processes of the equipment and pipelines have been established:

- No changes in the shape or dimensions of the construction elements of the inspected components have been detected under the influence of operational loads.

- No metal defects or wall thinning have been observed from the beginning of the operation until the evaluation and reassessment of the service life of the mentioned equipment and pipelines.

A methodology for determining the stress intensity factors to account for possible defects due to operation was proposed. For this purpose, defects were modelled, and stress intensity factors were determined under different operating conditions. Resistance to brittle fracture is considered to be ensured (and the defect is considered stable) if condition (3) is met for the selected design defect in the form of a crack in the considered operating mode. The results of the brittle strength calculation were presented in the form of diagrams (Figure 2), which contain the values of the coefficient stress intensity factor for points A and B for the longitudinal and transverse cracks, as well as the value of the permissible stress intensity factor. As a result of the evaluation of the results of the performed calculation for resistance to brittle fracture, it can be concluded that the condition of brittle strength is met for all considered design zones and operating modes. The permissible stress intensity coefficient and as calculations show, the maximum values of stress intensity coefficient do not exceed .

The results of the calculations for the inspected elements formed the basis for predicting further safe operation. It was found that considering safety factors, the investigated equipment can be operated until 2035, and the values of mechanical characteristics and permissible loads do not exceed the normative limits ([σ] = 20 kgf/mm2 with permissible values [σ]limit = 35 kgf/mm2).

To refine the predicted values, it is recommended to conduct a technical diagnosis of the state of the power equipment in 2024 and 2029 using the proposed plant safety management model for life term operation determination. According to the proposed model, when conducting the periodic safety review, research should take into account changes in the stress–strain state of the equipment metal and strength calculations. In the case when a defect is not detected, modelling of changes and calculation with consideration of possible deformation is proposed.

Further research will be aimed at developing a regulatory methodology for technical diagnostics according to the proposed plant safety management model for life term operation determination, which will include a step-by-step algorithm for conducting research, a methodology for calculating the stress–strain state of power equipment and a methodology for predicting the service life and frequency of the periodic safety review.

Author Contributions

Conceptualization, H.H. and V.K.; methodology, N.S.; software, O.T.; validation, O.T. and D.M.; formal analysis, O.T.; investigation, N.S.; resources, O.T.; data curation, D.M.; writing—original draft preparation, H.H. and V.K.; writing—review and editing, V.K.; visualization, D.M.; supervision, N.S.; project administration, O.S.; funding acquisition, D.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- International Atomic Energy Agency. Regulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power Plants; Safety Reports Series No. 109; IAEA: Vienna, Austria, 2022. [Google Scholar]

- International Atomic Energy Agency. Plant Life Management Models for Long Term Operation of Nuclear Power Plants; IAEA Nuclear Energy Series No. NP-T-3.18; IAEA: Vienna, Austria, 2015. [Google Scholar]

- International Atomic Energy Agency. The Interface Between Safety and Security at Nuclear Power Plants; INSAG Series No. 24; IAEA: Vienna, Austria, 2010. [Google Scholar]

- International Atomic Energy Agency. The Nuclear Safety and Nuclear Security Interface: Approaches and National Experiences; Technical Reports Series No. 1000; IAEA: Vienna, Austria, 2021. [Google Scholar]

- International Atomic Energy Agency. Leadership and Management for Safety; IAEA Safety Standards Series No. GSR Part 2; IAEA: Vienna, Austria, 2016. [Google Scholar]

- Martón, A.; Sánchez, I.; Carlos, S.; Mullor, R.; Martorell, S. Prognosis of wear-out effect on of safety equipment reliability for nuclear power plants long-term safe operation. Reliab. Eng. Syst. Saf. 2023, 233, 109–121. [Google Scholar] [CrossRef]

- International Atomic Energy Agency. Sustaining Operational Excellence at Nuclear Power Plants; IAEA Nuclear Energy Series No. NR-G-3.1; IAEA: Vienna, Austria, 2022. [Google Scholar]

- Bogheiry, A.; Faisal, A.; Sunarno, S. Nuclear energy as environmentally friendly energy and international politics. J. Penelit. Pendidik. Indones. 2022, 8, 488–494. [Google Scholar] [CrossRef]

- Black-Branch, J.L.; Fleck, D. Nuclear Non-Proliferation in International Law—Volume III, Legal Aspects of the Use of Nuclear Energy for Peaceful Purposes; Springer: Berlin/Heidelberg, Germany, 2016; 556p. [Google Scholar] [CrossRef]

- Bobrov Ye, A. Modern Innovations in the Context of the Transition to Circular Economy. Sci. Innov. 2021, 17, 13–23. [Google Scholar] [CrossRef]

- Popović, A.; Radivojević, V. The circular economy: Principles, strategies and goals. Econ. Sustain. Dev. 2022, 6, 45–56. [Google Scholar] [CrossRef]

- Hrinchenko, H.; Trishch, R.; Mykolaiko, V.; Kovtun, O. Qualimetric approaches to assessing sustainable development indicators. E3S Web Conf. 2023, 408, 01013. [Google Scholar] [CrossRef]

- Hrinchenko, H.; Kupriyanov, O.; Khomenko, V.; Khomenko, S.; Kniazieva, V. An Approach to Ensure Operational Safety for Renewable Energy Equipment. In Green Energy and Technology; Springer: Cham, Switzerland, 2023; pp. 1–17. [Google Scholar] [CrossRef]

- Koval, V.; Arsawan, I.W.E.; Suryantini, N.P.S.; Kovbasenko, S.; Fisunenko, N.; Aloshyna, T. Circular Economy and Sustainability-Oriented Innovation: Conceptual Framework and Energy Future Avenue. Energies 2022, 16, 243. [Google Scholar] [CrossRef]

- Kim, H.; Kim, J.T.; Heo, G. Failure rate updates using condition-based prognostics in probabilistic safety assessments. Reliab. Eng. Syst. Saf. 2018, 175, 225–233. [Google Scholar] [CrossRef]

- Martorell, P.; Martón, I.; Sánchez, A.I.; Martorell, S. Unavailability model for demand-caused failures of safety components addressing degradation by demand-induced stress, maintenance effectiveness and test efficiency. Reliab. Eng. Syst. Saf. 2017, 168, 18–27. [Google Scholar] [CrossRef]

- Hrinchenko, H.; Trisch, R.; Burdeina, V.; Chelysheva, S. Algorithm of technical diagnostics of the complicated damage to the continued resource of the circulation pipeline of the nuclear power plant. Probl. At. Sci. Technol. 2019, 120, 104–110. [Google Scholar] [CrossRef]

- Trishch, R.; Maletska, O.; Hrinchenko, H.; Artiukh, S.; Burdeina, V.; Antonenko, N. Development and validation of measurement techniques according to ISO/IEC 17025:2017. In Proceedings of the 2019 IEEE 8th International Conference on Advanced Optoelectronics and Lasers (CAOL), Sozopol, Bulgaria, 6–8 September 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Hrinchenko, H.; Artiukh, S.; Hrinchenko, V.; Nehodov, S. Unification of technical diagnostic methods of pipeline systems with the purpose of ensuring safe operation. Engineering 2022, 29, 62–69. [Google Scholar] [CrossRef]

- Cancemi, S.; Frano, R. Inverse Heat Conduction Problem in Estimating NPP Pipeline Performance. J. Nucl. Eng. Radiat. Sci. 2022, 8, 034501. [Google Scholar] [CrossRef]

- Dong, F.; Chen, S.; Demachi, K.; Yoshikawa, M.; Seki, A.; Takaya, S. Attention-based time series analysis for data-driven anomaly detection in nuclear power plants. Nucl. Eng. Des. 2023, 404, 112–161. [Google Scholar] [CrossRef]

- Chekurin, V.; Ponomaryov, Y.; Khymko, O. A mathematical model for evaluation the efficiency of gas-main pipelines in transient operational mode. Int. Q. J. 2015, 4, 25–32. [Google Scholar]

- Taler, J.; Weglowski, B.; Sobota, T.; Jaremkiewicz, M.; Taler, D. Inverse Space Marching Method for Determining Temperature and Stress Distributions in Pressure Components. In Developments in Heat Transfer; BoD–Books on Demand: Rijeka, Croatia, 2011; pp. 273–292. [Google Scholar]

- Ahn, J.; Lee, S.J. Deep learning-based procedure compliance check system for nuclear power plant emergency operation. Nucl. Eng. Des. 2020, 370, 110868. [Google Scholar] [CrossRef]

- dos Santos Nicolau, A.; Pinheiro, V.H.C.; Schirru, R.; da Silva, M.D.C.; de Mello, A.S.; de Lima, A.M.M. Deep neural networks for estimation of temperature values for thermal ageing evaluation of nuclear power plant equipment. Prog. Nucl. Energy 2023, 156, 104542. [Google Scholar] [CrossRef]

- Koval, V.; Kryshtal, H.; Udovychenko, V.; Soloviova, O.; Froter, O.; Kokorina, V.; Veretin, L. Review of Mineral Resource Management in a Circular Economy Infrastructure. Min. Min. Depos. 2023, 17, 61–70. [Google Scholar] [CrossRef]

- Králik, J. Actual Problems of the Safety and Reliability of the NPP Structures in Slovakia. Key Eng. Mater. 2017, 738, 261–272. [Google Scholar] [CrossRef]

- Kumar, V.; Mishra, K.C.; Singh, P.; Hati, A.N.; Mamdikar, M.R.; Singh, L.K.; Parida, R.R. Reliability analysis and safety model checking of Safety-Critical and control Systems: A case study of NPP control system. Ann. Nucl. Energy 2022, 166, 108812. [Google Scholar] [CrossRef]

- Ali, A.; Gudarzi, Y.; Abouabdellah, B.; Elzayat, T.; Ali, M.; Saini, G. Smart Nuclear Power Plant (NPP) System, Safety and Security in Nuclear Power Operations. Int. J. Eng. Technol. Res. 2022, 11, 344–351. [Google Scholar]

- Wang, S.C.; Ye, W.P.; Bai, T. Research and Application of FPGA V&V Technology in NPP Safety I&C System. In Nuclear Power Plants: Innovative Technologies for Instrumentation and Control Systems: The Fifth International Symposium on Software Reliability, Industrial Safety, Cyber Security and Physical Protection of Nuclear Power Plant (ISNPP) 5; Springer: Singapore, 2021. [Google Scholar] [CrossRef]

- Potanina, T.; Yefimov, O.; Harkusha, T.; Yesypenko, T. Application of Interval Analysis Methods for NPP Power Units Safety and Reliability Assessment. Nucl. Radiat. Saf. 2018, 3, 23–29. [Google Scholar] [CrossRef]

- Ylönen, M.; Björkman, K. Integrated management of safety and security (IMSS) in the nuclear industry—Organizational culture perspective. Saf. Sci. 2023, 166, 106236. [Google Scholar] [CrossRef]

- Ylönen, M.; Tugnoli, A.; Oliva, G.; Heikkilä, J.; Nissilä, M.; Iaiani, M.; Cozzani, V.; Setola, R.; Assenza, G.; van der Beek, D.; et al. Integrated management of safety and security in Seveso sites—Sociotechnical perspectives. Saf. Sci. 2022, 151, 105741. [Google Scholar] [CrossRef]

- Ylönen, M.; Aven, T. A new perspective for the integration of intelligence and risk management in a customs and border control context. J. Risk Res. 2023, 26, 433–449. [Google Scholar] [CrossRef]

- Chuanxiang, J.; Yuntao, Z. Improvement and Realization of AGC Strategy in Nuclear Power Plants. In Proceedings of the 23rd Pacific Basin Nuclear Conference; Volume 2. Springer Proceedings in Physics; Liu, C., Ed.; Springer: Singapore, 2023; Volume 284. [Google Scholar] [CrossRef]

- XYu, X.; Wang, Z. Application of PSA Technology in Safe Operation of Nuclear Power Plant. In Proceedings of the 2023 5th Asia Energy and Electrical Engineering Symposium (AEEES), Chengdu, China, 23–26 March 2023; pp. 495–500. [Google Scholar] [CrossRef]

- Wang, H.; Li, Q. Study on PSA method applied to SSC aging sensitive screening and classification in nuclear power plant. IOP Conf. Ser. Earth Environ. Sci. 2023, 1171, 012002. [Google Scholar] [CrossRef]

- Yu, X.; Yang, Z. Application of PSA Technology in Technical Requirements Optimization of Nuclear Power Plant. In Proceedings of the 4th International Conference on System Reliability and Safety Engineering (SRSE), Guangzhou, China, 15–18 December 2022; pp. 133–138. [Google Scholar] [CrossRef]

- Dienstbier, J.; Hustak, S.; Rydl, A. Level 2 PSA for the VVER 440/213 Dukovany Nuclear Power Plant. In Probabilistic Safety Assessment and Management; Spitzer, C., Schmocker, U., Dang, V.N., Eds.; Springer: London, UK, 2004. [Google Scholar] [CrossRef]

- Latysheva, O.; Rovenska, V.; Smyrnova, I.; Nitsenko, V.; Balezentis, T.; Streimikiene, D. Management of the Sustainable Development of Machine-Building Enterprises: A Sustainable Development Space Approach. J. Enterp. Inf. Manag. 2021, 34, 328–342. [Google Scholar] [CrossRef]

- Sribna, Y.; Skakovska, S.; Paniuk, T.; Hrytsiuk, I. The Economics of Technology Transfer in the Environmental Safety of Enterprises for the Energy Transition. Econ. Ecol. Socium 2023, 7, 84–96. [Google Scholar] [CrossRef]

- Pakhalovych, M.; Kiporenko, G. Improvement of the methodology for calculating the resistance to brittle fracture of pipelines of the South Ukrainian. Inf. Process. Syst. 2016, 7, 181–184. [Google Scholar]

- Carnevale, M.; Wang, F.; Parry, A.B.; Green, J.S.; di Mare, L. Fan Similarity Model for the Fan–Intake Interaction Problem. J. Eng. Gas Turbine. Power 2018, 140, 051202. [Google Scholar] [CrossRef]

- Capuano, A.; Spano, M.; Musa, A.; Toscano, G.; Misul, D.A. Development of an Adaptive Model Predictive Control for Platooning Safety in Battery Electric Vehicles. Energies 2021, 14, 5291. [Google Scholar] [CrossRef]

- Vita, G.; Salvadori, S.; Sarkić-Glumac, A.; Misul, D.A. On the Potential Yield of Wind Turbines on High-Rise Buildings. E3S Web Conf. 2021, 238, 01004. [Google Scholar] [CrossRef]

- Shkola, V.; Prokopenko, O.; Stoyka, A.; Nersesov, V.; Sapiński, A. Green Project Assessment within the Advanced Innovative Development Concept. Estud. Econ. Apl. 2021, 39, 1–15. [Google Scholar] [CrossRef]

- Zvoncek, P.; Nusbaumer, O.; Torri, A. Development of a Fully-Coupled, All States, All Hazards Level 2 PSA at Leibstadt Nuclear Power Plant. Nucl. Eng. Technol. 2017, 49, 426–433. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).