District heating (DH) systems are a necessity in northern and central European countries to move forward sustainable energy systems due to in-place infrastructure, which can be further transformed for integration of renewable energy sources (RESs) and thermal energy storage [

1]. In addition, future energy systems require more efficient use of primary energy resources by recovering and utilising unused energy flows [

2]. Therefore, DH networks that connect a great number of buildings in urban areas and provide heat for more than half of the city population have significant potential to integrate these recovered heat flows defined as surplus or waste heat [

3].

Several studies have shown that integration into DH systems is one of the best solutions for waste heat utilisation [

4]. The main reasons are improved efficiency of both the existing heat supply and the waste heat source, lower overall environmental impact due to reduced fuel consumption and avoided thermal flows, and reduced costs from primary energy savings. DH networks can also provide a more flexible heat demand for heat flow utilisation and alignment [

5,

6]. However, when there is no DH network available at an economically sound distance from the energy source, local heat supply solutions can be analysed by applying energy community solutions with local buildings [

7].

1.1. Identification of Waste Heat Sources

The most common waste heat source is industrial objects. Industrial waste heat is divided into three sections based on its temperature—low, medium, and high temperature [

8]. Very high-temperature waste heat (above 400 °C) usually arises from combustion processes. The utilisation potential of such very high-temperature heat flows is the highest as it can be used for power generation [

9]. Waste heat with temperatures from 100 °C to 400 °C is considered medium-temperature waste heat, and it is part of the exhaust processes [

5]. Such temperature levels are suitable for direct integration in DH systems to cover the heat demand. Low-temperature heat or waste heat with a temperature below 100 °C is mostly recovered from cooling processes in industries [

10]. During the last decades, research has focused on the utilisation of ultra-low heat sources because innovative integration strategies and operational changes in existing heating networks are necessary to use these heat flows [

11].

Heat recovery potential from different industries has been a highly researched strategy for reaching primary energy savings [

12,

13,

14]. Jauhara et al. [

15] reviewed the best practices for various waste heat recovery technologies such as recuperators, regenerators, passive air preheaters, regenerative and recuperative burners, plate heat exchangers and economisers in the steel and iron, food, and ceramic industries. In the research conducted by Denarie et al. [

16], industrial waste heat is divided into different temperature levels—high temperature, low temperature, and steam. The authors conclude that in Italy, the main recoverable heat could come from energy production sites and different industrial enterprises. Kasmadakis concluded that the total potential for the implementation of industrial heat pumps (HPs) to recover unused heat flows is 28.37 TWh per year [

17].

Boiler houses and combined heat and power plants are excellent waste heat sources for their high-temperature levels [

18]. The source of waste heat for CHP plants and boiler houses is flue gases. When a flue gas condenser is not used, then the flue gas temperature can be more than 100 °C and therefore can be used directly with a heat exchanger in the DH network. Nevertheless, it is more useful to use a flue gas condenser for heat recovery in boiler houses and CHPs, especially when the used fuel has a high moisture content, for example, woodchips and biomass. In the case of biomass combustion, a flue gas condenser can increase the boiler efficiency by up to 20% (relating to the lowest heating value) depending on the biomass parameters, design of the boiler, and operating conditions [

19].

When a flue gas condenser is used, the leaving flue gases are cooled down to the DH return temperature, which is normally 45–50 °C in the case of a high-temperature DH network. This heat can also be recovered using HPs, as the flue gases can be cooled to 20 °C [

20]. This kind of solution is implemented in Tallinn at the Mustamäe CHP plant, where both a flue gas condenser and flue gas HP are installed to recover even more heat. The profitability of this kind of technical solution depends on the capacity of the boiler. Normally, additional heat recovery of the HP in this case can be 4–5% of the total heat.

One of the possible low-temperature waste heat sources is data centres that generate a remarkable amount of heat from electronic equipment—about 97% of that can be used internally or externally for heat load coverage. It is stated that data centres use about 3% of the world’s energy consumption, and the used energy amount will only increase in the future [

21]. Usually, these centres need constant cooling for proper maintenance, which is an energy-intensive process. Cooling technologies can be supplemented with heat recovery technology to recover the heat generated in these centres and use it internally for space heating or domestic hot water preparation or integrated into the DH network [

22]. In this case, for heat recovery, HPs could be used so that all the excess heat would not be emitted into the atmosphere. In data centres, 30–40% of the used energy is from cooling processes, which is a significant amount of energy consumption and one of the criteria to consider using waste heat [

23]. This energy in data centres in the liquid cooling system is usually at a temperature from 50 to 60 °C but from air cooling systems, it reaches about 25–35 °C [

24]. Another benefit of recovering waste heat, particularly in data centres, is its stable working hours because the cooling system in data centres is needed all the time.

Using sewage water heat in DH with the help of large-scale HPs is an often-used practice, as sewage water is a very good heat source because its temperatures are high enough for HP integration. Normally, when sewage water first arrives at the water treatment plant, the flow temperatures are between 11 and 15 °C during the winter period and above 15 °C during the summer period, which would be excellent for use as a low-temperature heat source for HPs [

25]. Still, the wastewater treatment process needs sufficient temperatures for the biological treatment process, so waste heat can be used after the treatment process when the flow temperature is around 9–10 °C.

Sewage water waste heat is highly available as water treatment plants are in most major cities and normally, they are not very far from DH networks [

26]. For using treated sewage water as a heat source, the most important parameter in addition to the temperature level is the flow rate, which determines the amount of possible recoverable waste heat. Normally, there are no limiting factors for possible recoverable waste heat by the reservoir where purified sewage is led after treatment. For example, if purified sewage water is led toward the sea after the treatment process, then the purified sewage temperature should be close to the seawater temperature. During the heating period, sewage water temperature is always higher than the seawater temperature, and heat recovery for DH would have a good influence on the marine environment, as the sewage temperature is closer to the seawater temperature.

Although the amount of waste heat from sewage water can be enough to cover a small city’s DH demand, this heat source cannot be the main heat source, as the demand and production curves do not match. Heat production from sewage water is quite constant with short periodical fluctuations, so there is not enough heat for the winter period, and a significant amount is left over during the summer period. This can be solved with thermal energy storage or using auxiliary heat sources.

There are many studies dedicated to other types of waste heat and their potential role in heat supply coverage. Escriva et al. [

27] investigated heat recovery from refrigerated systems in supermarkets and concluded that useful heat recovered in a UK supermarket could range from 28.7% to 43.2%. A relatively small number of studies are dedicated to heat recovery from electric transformers, which could also be used as a heat source for individual heating or integrated into DH networks [

28]. Petrovic et al. [

29]. estimated that the theoretical amount of excess heat from power transformers available for DH in Denmark could reach 0.28 TWh per year.

1.2. Methods Used for Waste Heat Potential Estimation

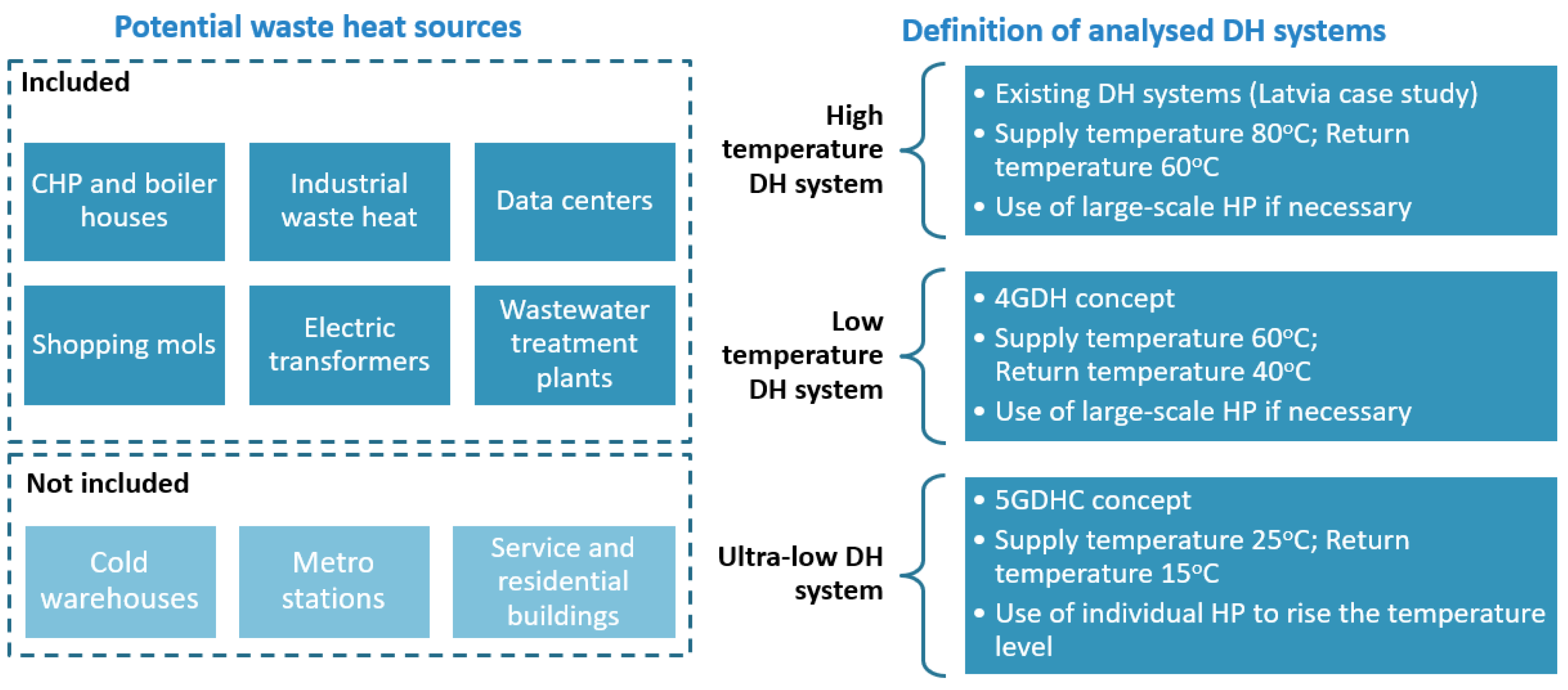

Waste heat integration into the DH system can be divided into indirect and direct integration, which depends on the waste heat temperature and operating temperature of the DH network. Direct waste heat means that it is possible to use it without increasing temperature with a heat exchanger, but when the heat source temperature is too low to use in DH systems, it is necessary to increase the temperature and integrate the heat source indirectly. Therefore, for low-temperature DH systems, HPs are essential elements for the broader integration of waste heat flows [

30].

Previous research mostly used bottom-up (surveys) or top-down (estimation) approaches or a combination of both methods for estimating waste heat potential. The bottom-up approach reckons single case study reports and equalises them as a general result. The top-down approach uses general results through already-calculated waste heat potential factors for quantification of waste heat potential. Furthermore, waste heat potential itself is divided into three categories—theoretical, technical, and economical [

31].

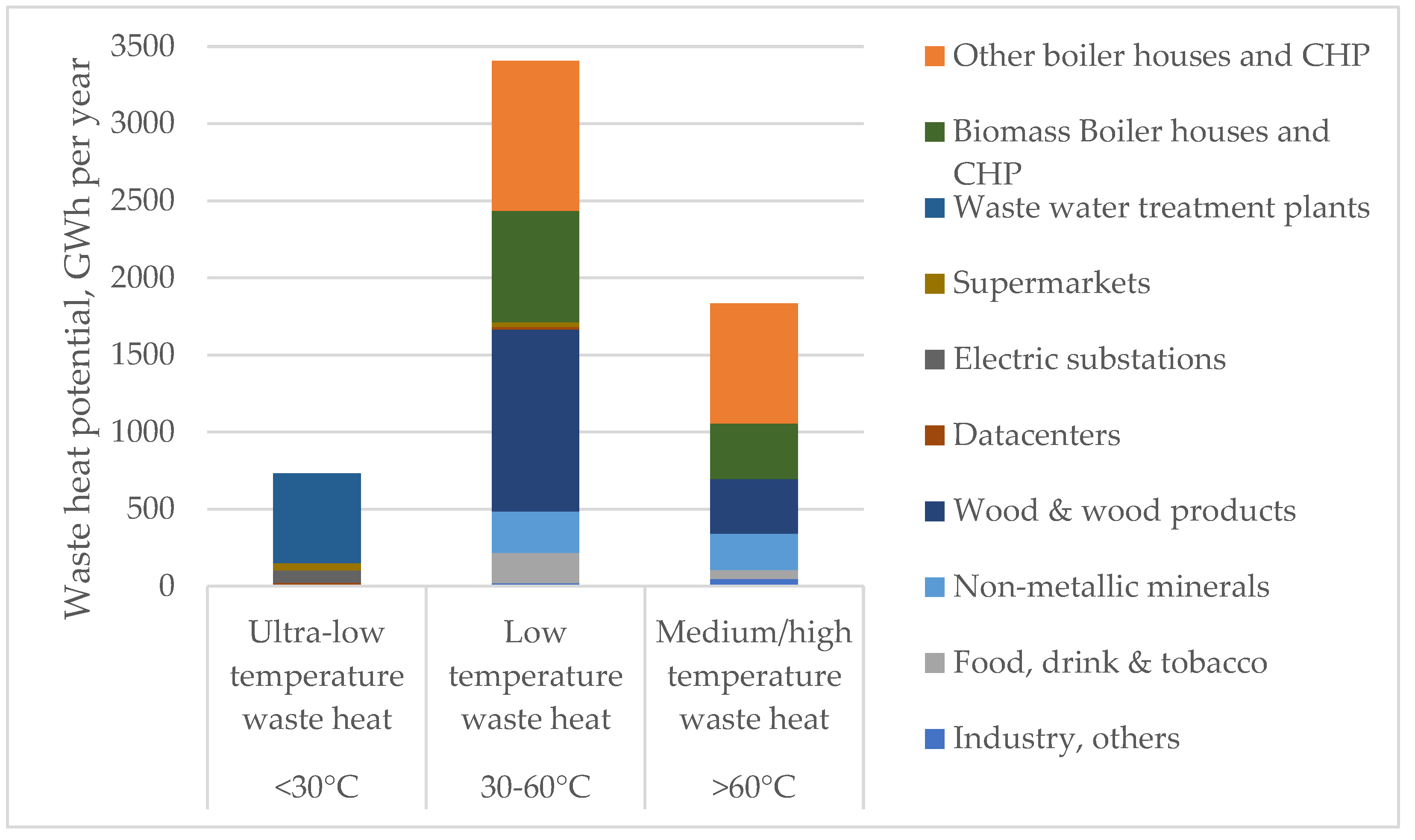

In the study conducted by Forman et al. [

31], global waste heat potential is calculated using the top-down method. In their study, waste heat is part of three types of losses in energy conversion processes—exhaust, effluent, and other losses. The temperature range is also considered. The results show that the largest volume of waste heat is available in low-temperature levels (61% of exhausts and effluents) and most of the waste heat comes from electricity generation.

A study in Taiwan used bottom-up analysis to quantify industrial waste heat potential. In that study, only exhaust flue gas flows are considered [

32]. Based on the calculations, the chemical industry has the largest waste heat potential, accounting for 66.5% of total theoretical waste heat potential and 45.8% of technical potential. Exhaust gases with temperatures between 100 and 150 °C have the highest potential in theoretical calculations.

1.3. Waste Heat Integration into DH Networks

Lower-temperature DH systems will allow for utilising low-temperature waste heat sources since those are the most widely available [

33]. Previous authors have defined four generations of DH systems and an additional ultra-low DH system concept attributed as a type of fourth-generation DH (4GDH) system or a fifth-generation district heating and cooling (5GDHC) system in some studies [

34,

35]. The 4GDH system is based on a broader integration of different RES and operations with a low-temperature heat carrier—about 50–70 °C. It reduces the heating network heat losses, expands the energy efficiency of energy conversion technologies [

36], and makes it easier to use waste heat in DH systems. The 5GDH concept uses a heat carrier with a temperature close to ambient temperature, which is increased individually at each heat consumer using HPs [

37]. The fifth generation [

38] DH system differs from others with its combination of heating and cooling systems. Considering, that this generation DH system is based on using different RES, it gives a lot of flexibility when it comes to heating supply—it is possible to use CHP, HPs, solar energy, electric boilers, and others [

39]. These DH concepts are also considered smart energy systems that interact with power networks for more efficient use of intermittent RES power [

40].

HPs are necessary for low-temperature DH systems and cross-sectoral integration as large electrically powered HPs are used in power-to-heat solutions [

41]. What makes this system effective is that it allows for using more renewable energy instead of using fossil fuel, especially in the heat supply. Using HPs can help to smooth the uncontrollable RES electricity production peaks and therefore to stabilise the electricity price and market. Power-to-heat technologies, together with relatively cheaper thermal energy storage [

42], allow DH systems to accommodate more intermittent renewable energy than alternatives. However, the whole system is more complicated, and there are more operation conditions that need to be considered, for instance, heat storage. In the event of a significant increase in electricity demand due to power-based heat production [

43], additional investments are likely to be required to increase the capacity of the transmission and distribution network. Depending on the waste heat source and previous DH price for consumers, these kinds of investments can still reduce the price for consumers [

43]. To make the investments more attractive to DH companies, investment support could be a good option.

1.4. Aim and Scope of This Study

While previous research has explored waste heat potential and the feasibility of heat load coverage, a research gap remains in understanding the conditions necessary for the broader utilisation of waste heat flows, particularly in the context of evolving fourth- and fifth-generation district heating (4GDH and 5GDH) systems and their integration into smart energy systems. Further studies on waste heat’s role among different heat supply systems and its potential impact on existing heat supply are necessary. The innovation of this study lies in its pursuit of bridging this gap. The research sets out to explore waste heat’s evolving role among various heat supply systems and its potential impact on existing heat supply structures.

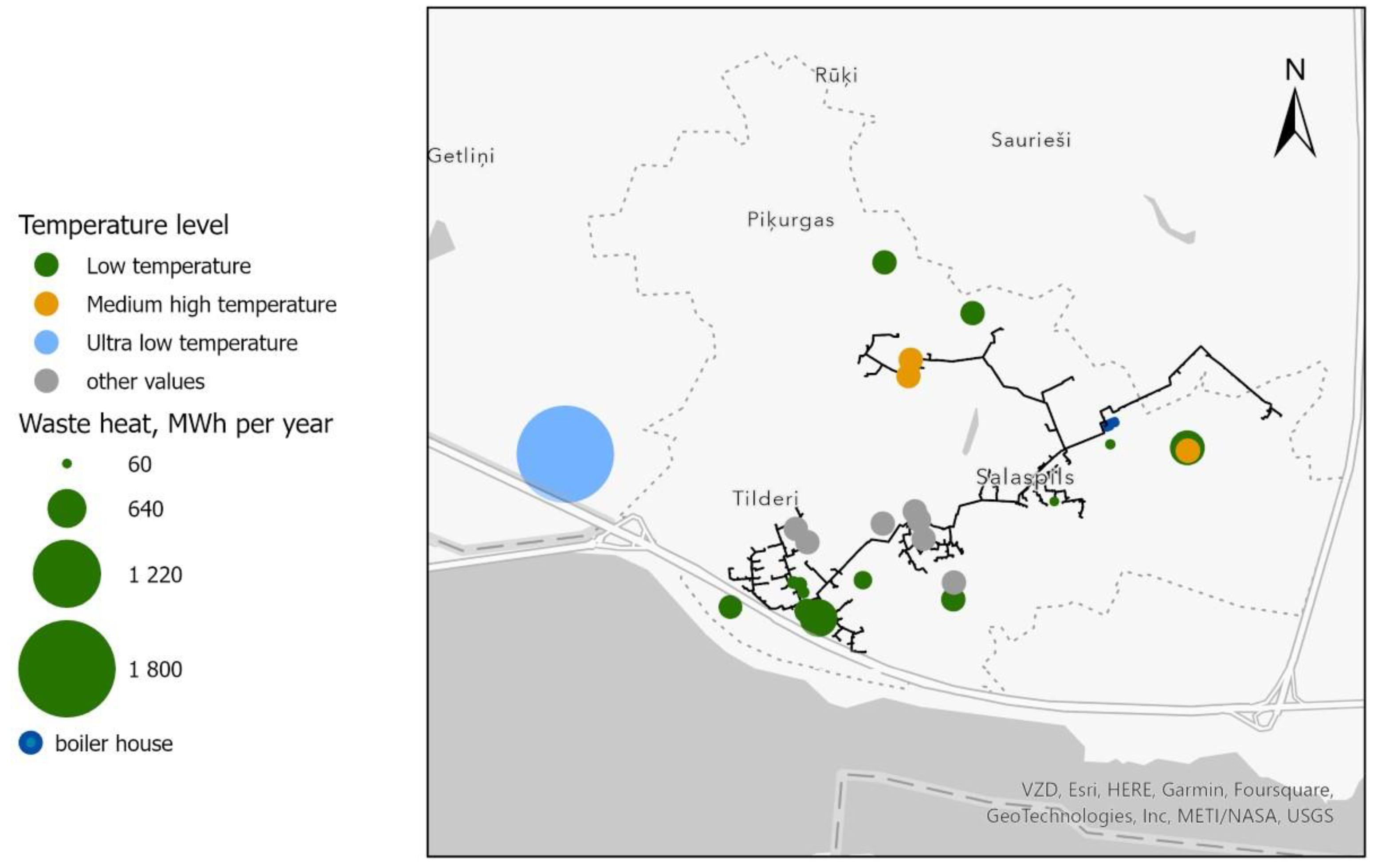

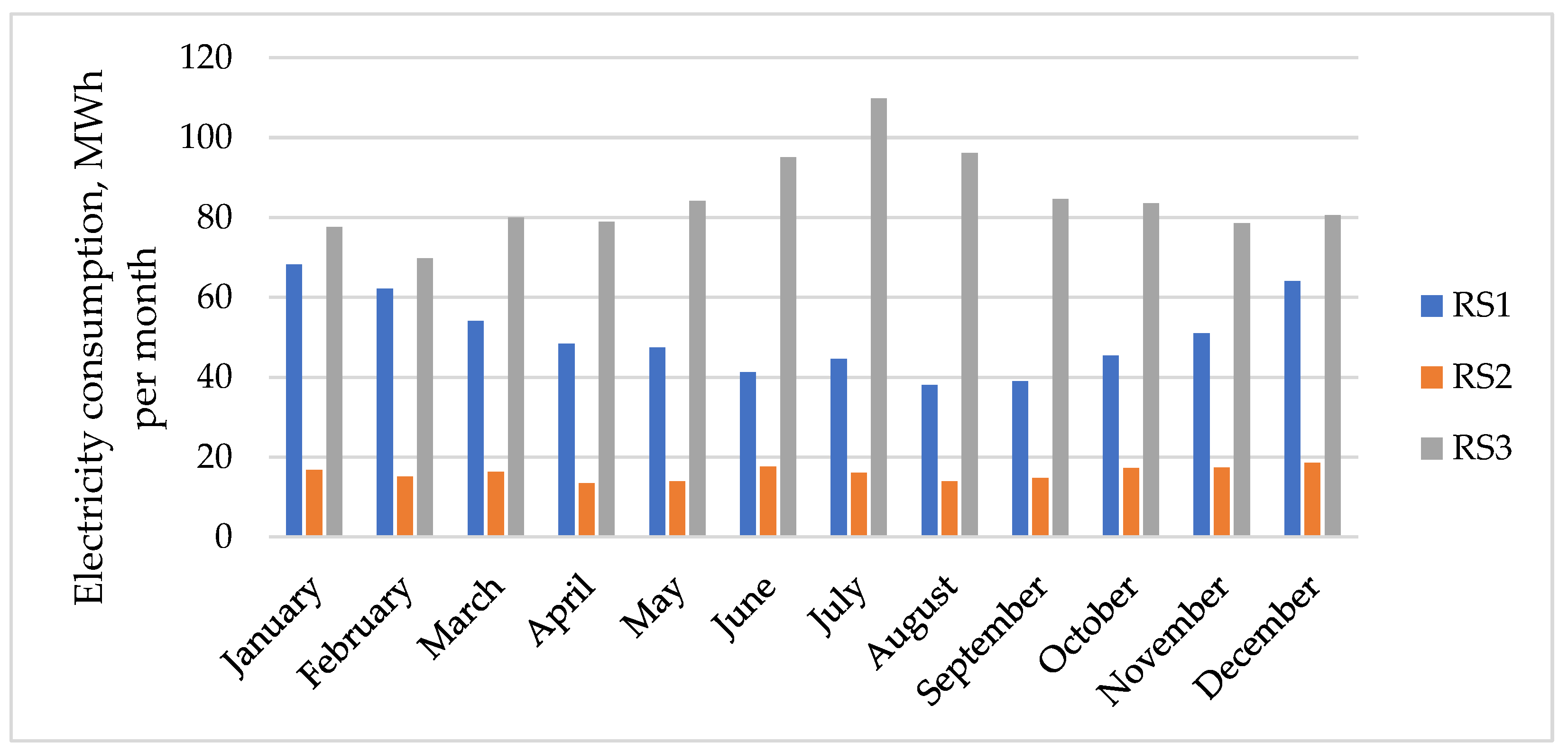

Potential waste heat sources are valorised within this study using in-depth national potential assessment and technical simulation. In addition, a local scale waste heat assessment is provided to analyse the potential impact on the existing RES heat supply technologies. This localised analysis is crucial for understanding how waste heat utilisation can complement or potentially impact existing RES systems at the DH system level.

Therefore, this study includes multi-scale analyses by investigating waste heat valorisation for utilisation in DH systems in local and national contexts. Using this approach, the authors aim to provide a comprehensive framework for understanding the potential of waste heat utilisation, not only as an energy source but as a critical component of the evolving energy landscape.