Evaluation of the Primary Energy and Carbon Dioxide Emissions of a Passive Ventilation System with a Solar Air Heater

Abstract

1. Introduction

2. System and Conditions of Consideration

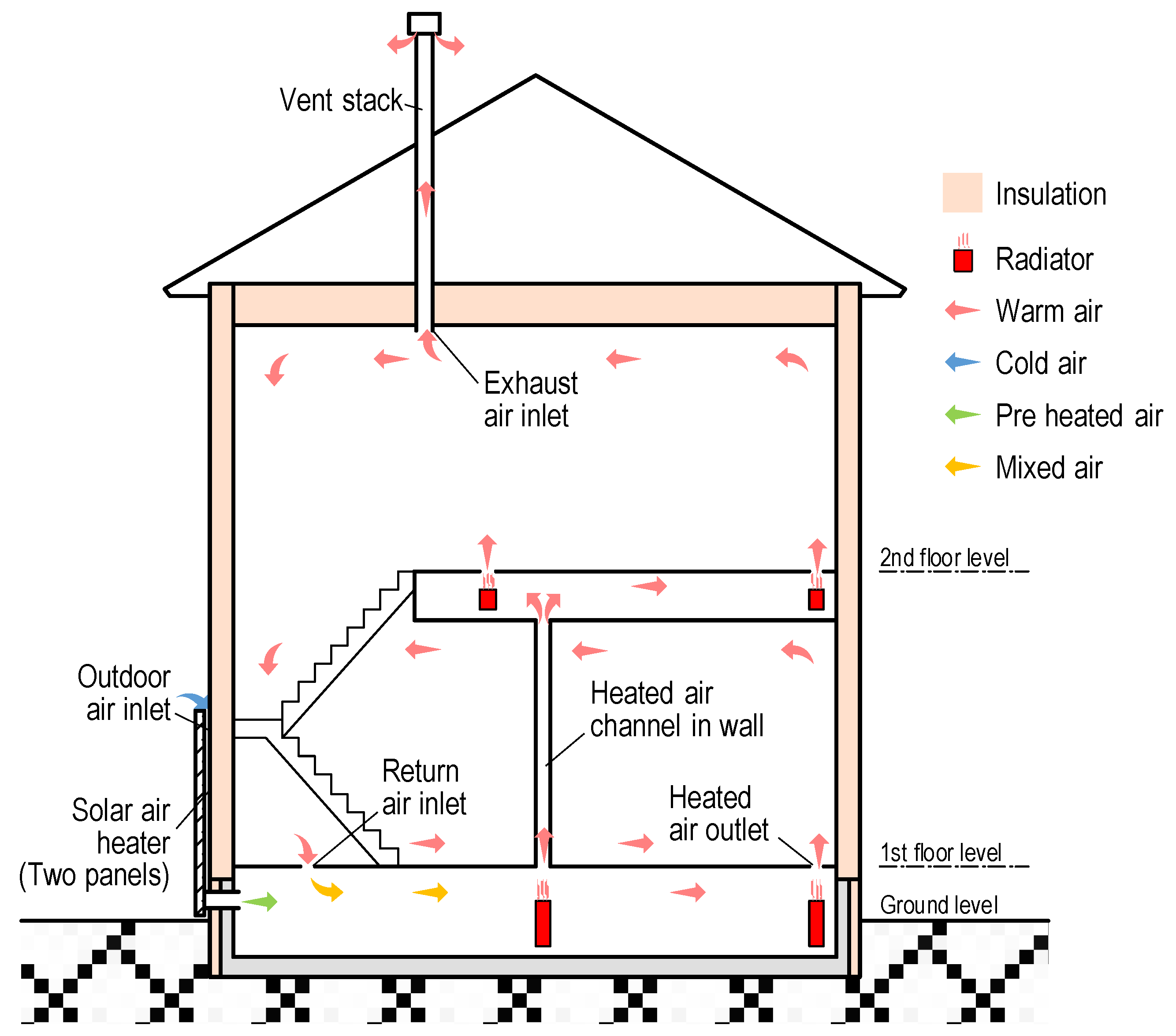

2.1. Passive Ventilation System with a Solar Air Heater

2.2. Comparison System

2.3. Study Zone

2.4. Energy Conversion Factor

2.5. Calculation Method for Ventilation Systems

3. Result

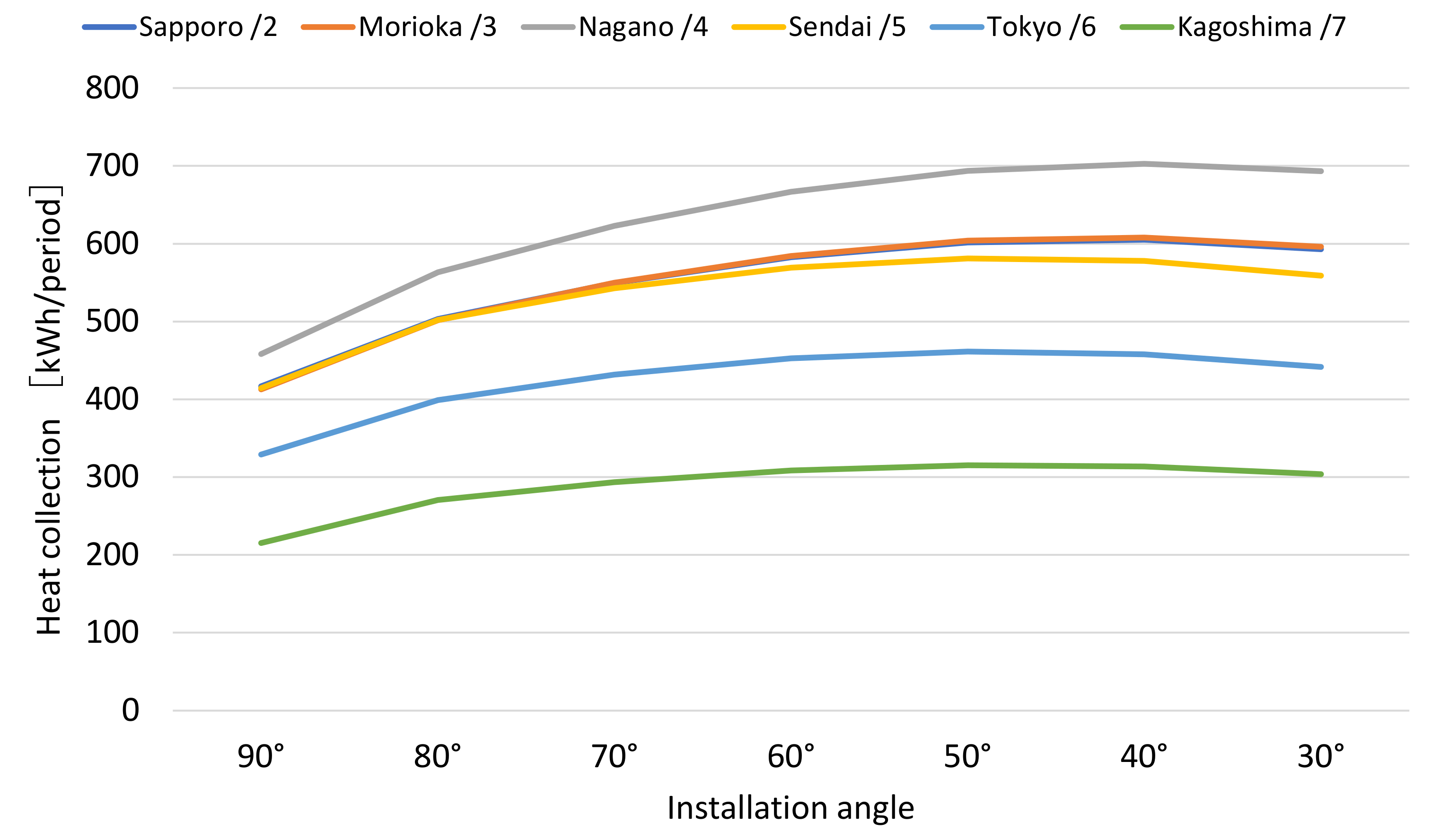

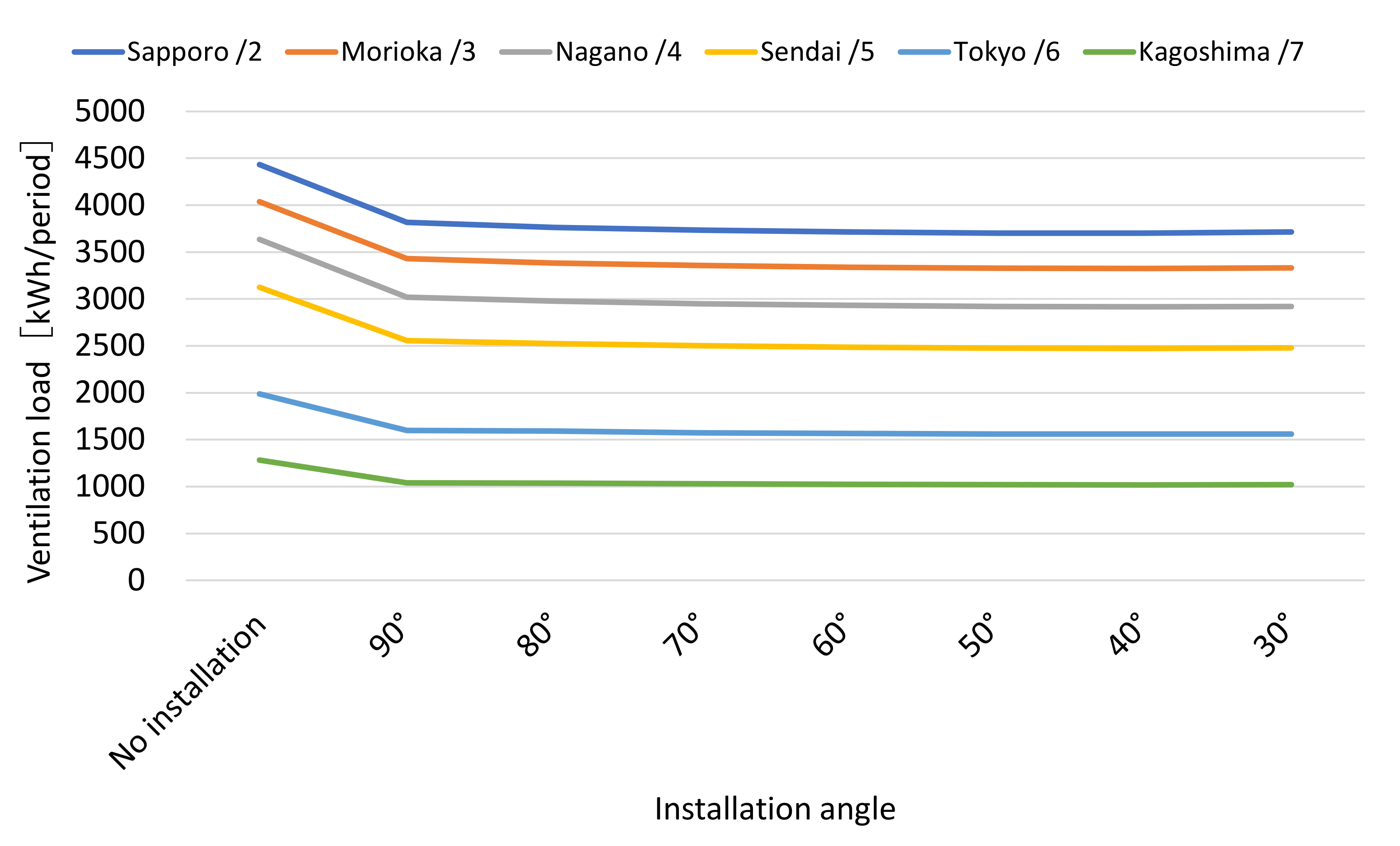

3.1. Consideration of Installation Conditions for the Solar Air Heater

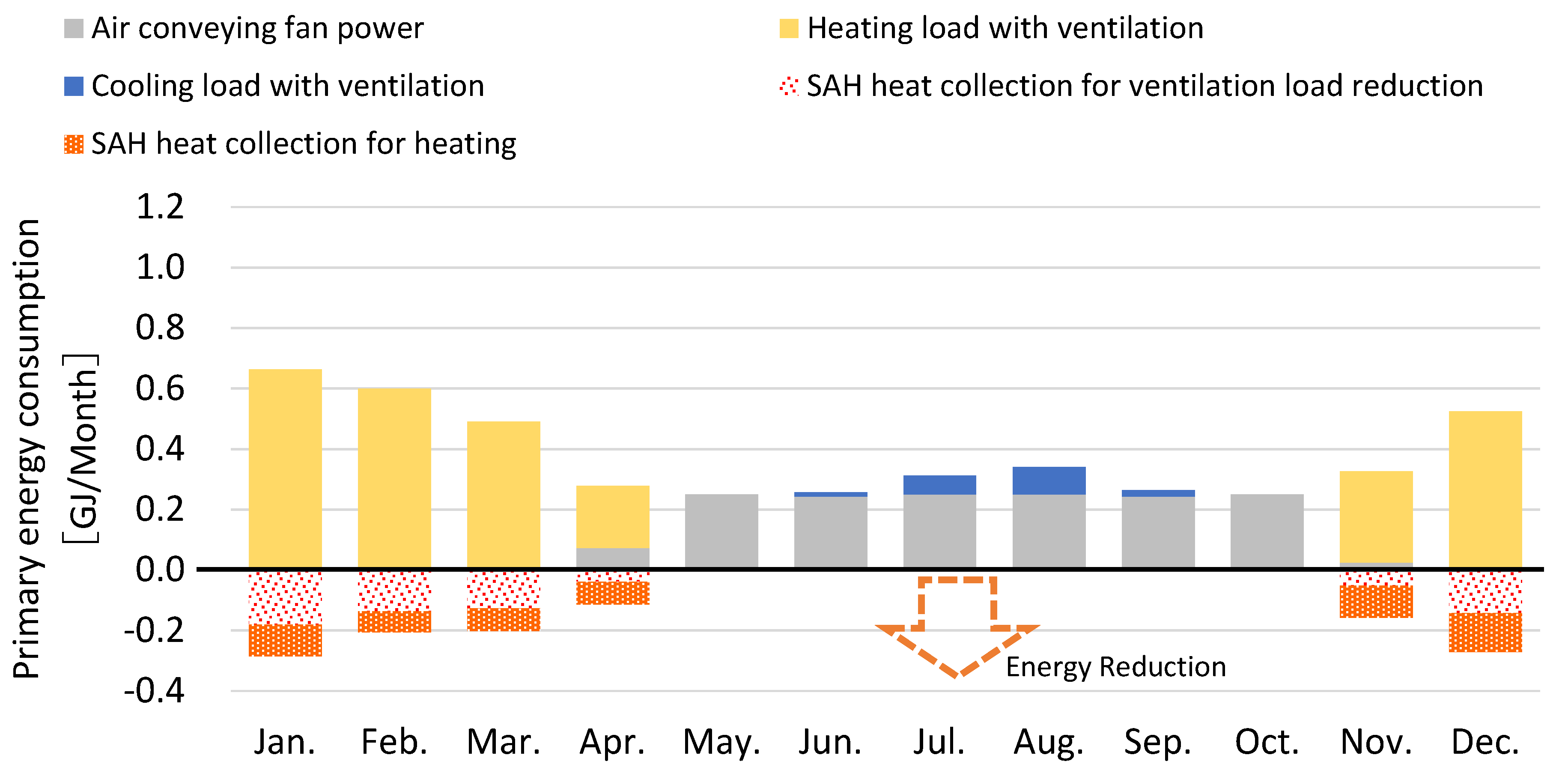

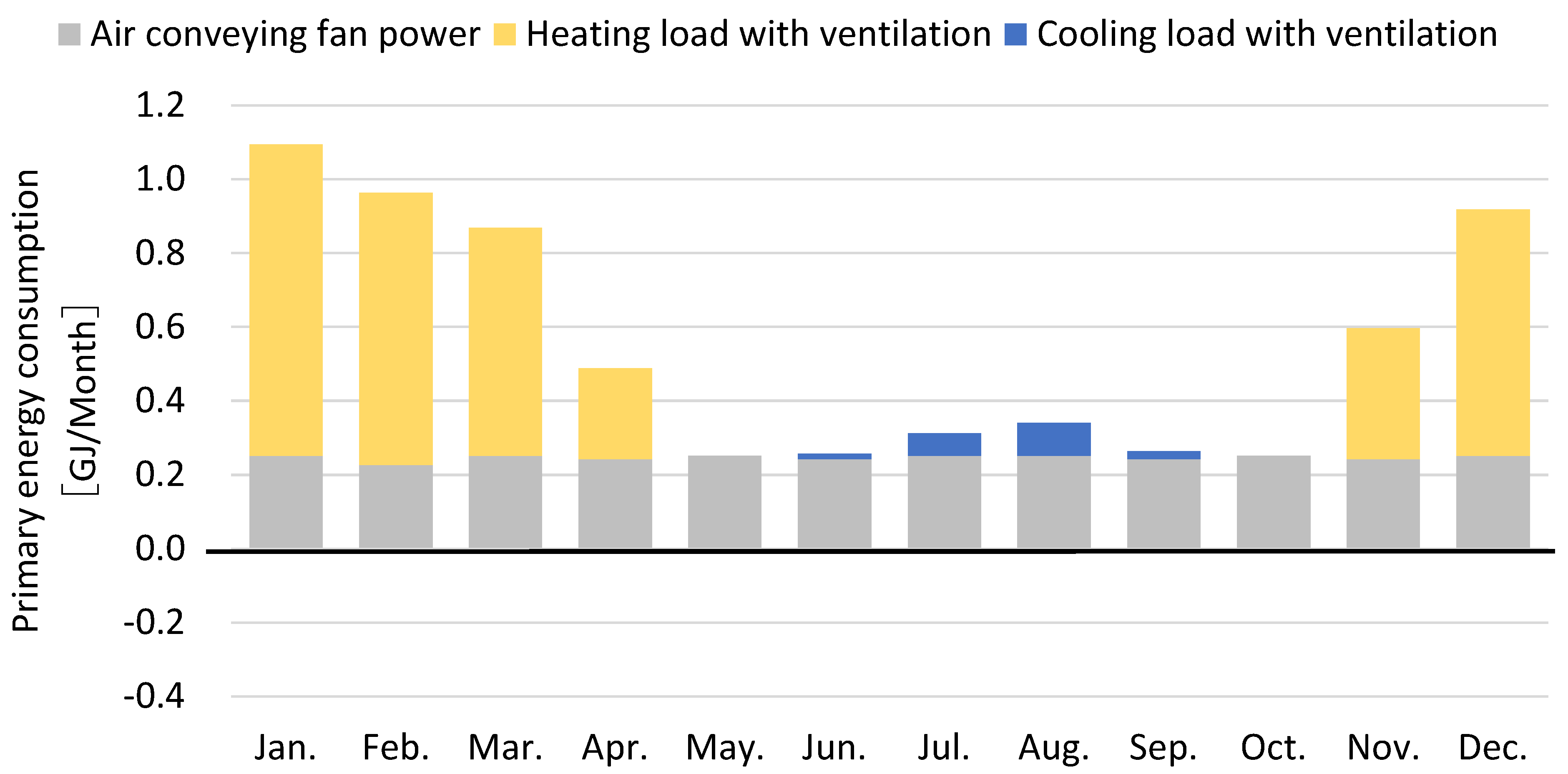

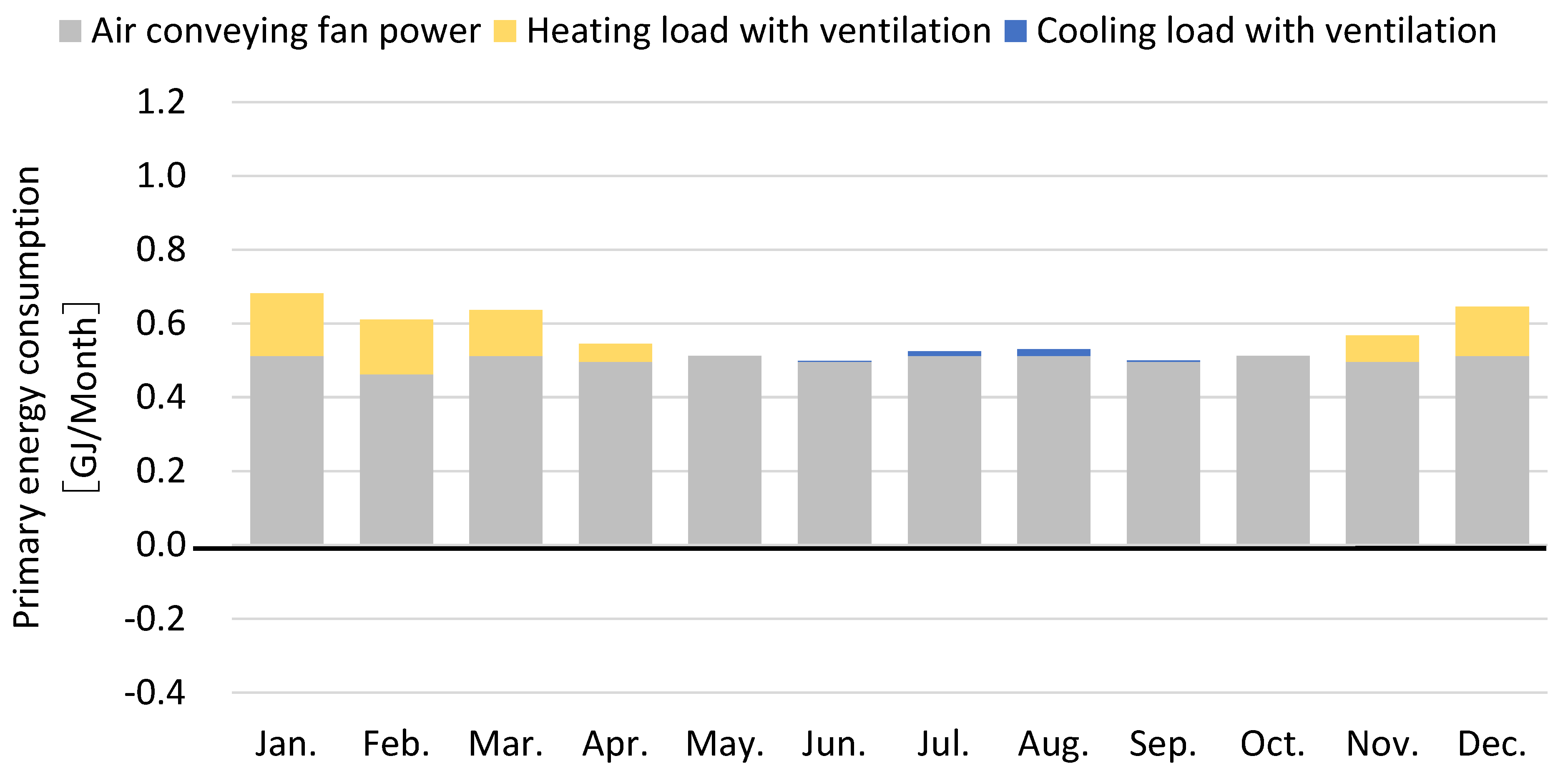

3.2. Evaluation of Primary Energy Consumption by Ventilation System

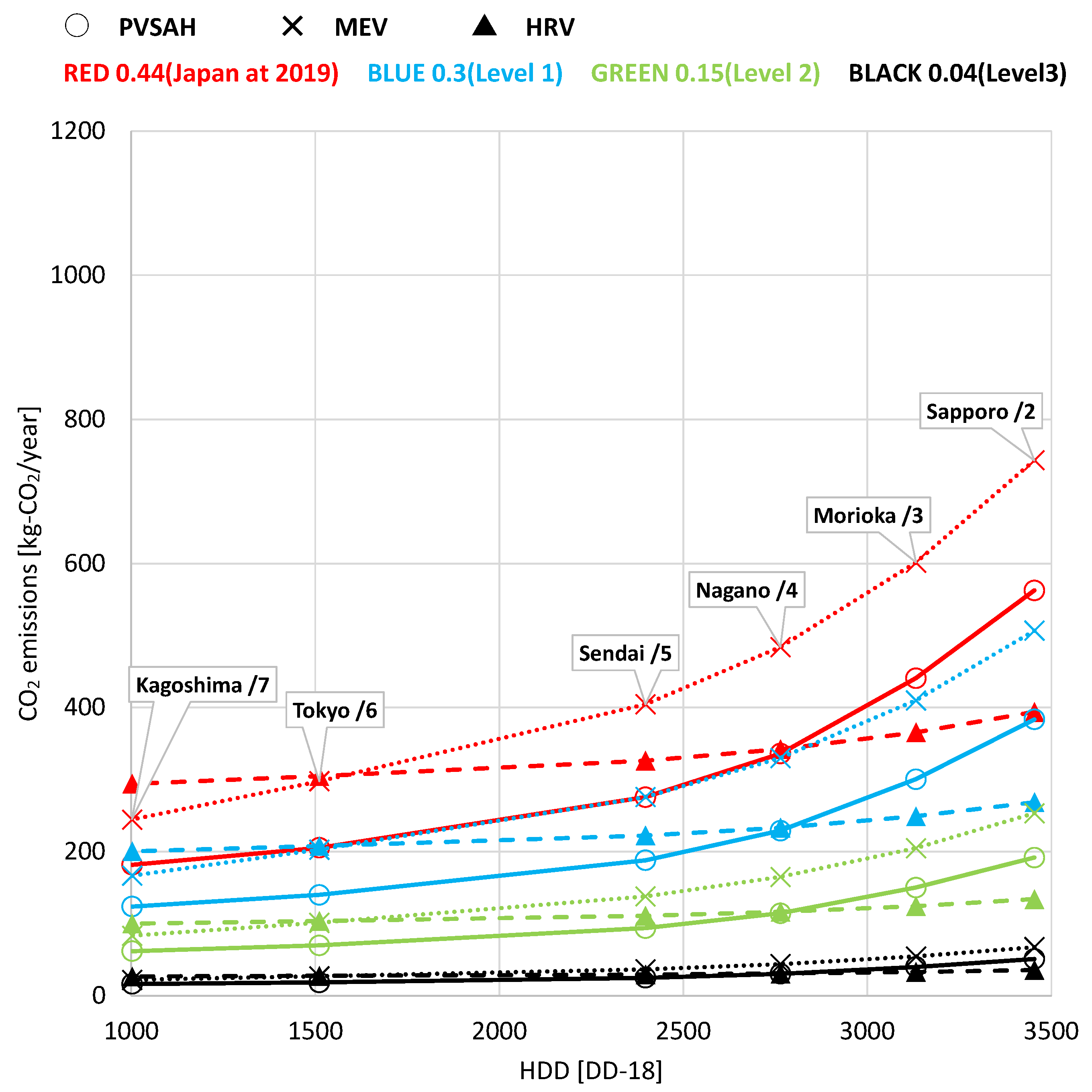

3.3. Comparison of CO2 Emission per System

4. Conclusions

- (1)

- The installation angle of the SAH used in the outdoor air intake area was examined. An angled installation increases heat collection compared with that of a wall installation (90°). For each zone, the maximum heat collection was achieved at installation angles of 40° to 50°. The effect of SAH installation at 90° is 15–20% but changing the angle of installation only improves reduction by a maximum of 2–3%. In addition, the installation of the system on a building at an angle requires consideration of the effects of snow accumulation in cold regions, the effects of typhoons and other strong winds in hot regions, and obstructions caused by the protrusion of the system from the building. Therefore, the study conducted a 90-degree installation on a wall. The results indicated that an angled installation is preferable if conditions permit because it is less expensive, reduces ventilation load by 2–3%, and provides an auxiliary heating effect.

- (2)

- The monthly primary energy consumption of each ventilation system was evaluated in Zone 6 (Tokyo) for heat pump heating and cooling. PVSAH exhibited the highest energy savings because it does not generate air transfer power during the heating season and because of the reduction in ventilation load due to SAH. HRV can reduce ventilation load, but it also generates large air conveying fan power throughout the year, even without heating load. The reduction in ventilation load was a trade-off, which resulted in an energy increase.

- (3)

- The primary energy consumption was evaluated by zone. In the case of heat pump heating with high heating efficiency, PVSAH was superior to HRV in Zone 5 and in the south and displayed the same energy-saving performance in Zone 4. In warmer zones (6–7), HRV was at a disadvantage compared with MEV, with HRV presenting an advantage in colder climates but a disadvantage in warmer climates. However, PVSAH can save more energy than MEV can, even in cold regions. Given the impact of maintenance, defrosting, and differences in building airtightness, selecting PVSAH as an energy conservation measure apart from HRV could lead to advantages. In the case of gas heating with low heating efficiency, PVSAH was equal to HRV in Zone 7, while HRV was advantageous in other zones. However, PVSAH saves 20–25% energy compared to MEV, which makes PVSAH an effective energy conservation option apart from HRV. In addition, the value of using PVSAH is expected to increase in the future due to the evolution of energy conservation technology and the possibility that heating efficiency will increase with the renovation of building facilities.

- (4)

- The CO2 emissions of different ventilation systems were compared. In the case of gas heating + heat pump cooling, the change is small, despite the change in the CO2 emission factor of electricity, because the gas combustion energy efficiency of the heating remains the same. Therefore, HRV is significantly more advantageous because heating energy can be significantly reduced. In the case of heat pump cooling and heating, however, HRV poses an advantage in cold climates but a disadvantage in warmer climates because the amount of air conveying fan power does not decrease. HDD 1500 and below: PVSAH > MEV > HRV; HDD 1500 to 2750: PVSAH > HRV > MEV; and HDD 2750 and above: HRV > PVSAH > MEV, in this order. In addition, as the CO2 emission factor decreases, the difference in CO2 emissions between systems decreases. If the difference in emissions becomes smaller, then considering the initial and running (including maintenance and upkeep) costs and the risk of failure of the system is crucial. A simple system configuration with low risks of failure and maintenance, such as PVSAH, may prove advantageous in the future.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| SAH air flow rate | m3/h | |

| Heat collection capacity | W | |

| Air flow rate | m3/h | |

| Ventilation load | W | |

| Equivalent heat capacity | J/K | |

| Heat capacity of air in panel | J/K | |

| Part of the heat capacity of surrounding components | J/K | |

| U-value | W/(m2K) | |

| Area | m2 | |

| Temperature | °C | |

| Amount of solar radiation transmitted into the panel | W/m2 | |

| Time | s | |

| Heat collection efficiency of SAH | - | |

| Heat exchange efficiency | - | |

| Fan power | Wh | |

| Specific fan power | Wh/m3 | |

| front of panel | ||

| back of panel | ||

| hollow layer in the device | ||

| outside air | ||

| indoor air |

References

- Laverge, J.; Janssens, A. Heat recovery ventilation operation traded off against natural and simple exhaust ventilation in Europe by primary energy factor, carbon dioxide emission, household consumer price and exergy. Energy Build. 2012, 50, 315–323. [Google Scholar] [CrossRef]

- Dodooa, A.; Gustavsson, L.; Sathrea, R. Primary energy implications of ventilation heat recovery in residential buildings. Energy Build. 2011, 43, 1566–1572. [Google Scholar] [CrossRef]

- Wu, W.; Fang, Z.; Ji, W.; Wang, H. Optimal operation condition division with profit and losses analysis of energy recovery ventilator. Energy Build. 2016, 124, 203–209. [Google Scholar] [CrossRef]

- El Fouiha, Y.; Stabat, P.; Rivièreb, P.; Hoang, P.; Archambault, V. Adequacy of air-to-air heat recovery ventilation system applied in low energy buildings. Energy Build. 2012, 54, 29–39. [Google Scholar] [CrossRef]

- Zhang, J.; Fung, A. Experimental study and analysis of an energy recovery ventilator and the impacts of defrost cycle. Energy Build. 2015, 87, 265–271. [Google Scholar] [CrossRef]

- Zhang, J.; Fung, A. Experimental and numerical investigation of the thermal impact of defrost cycle of residential heat and energy recovery ventilators. Energy Build. 2015, 97, 129–136. [Google Scholar] [CrossRef]

- Fisk, W.; Turiel, I. Residential Air-to-Air Heat Exchangers: Performance, Energy Savings, and Economics. Energy Build. 1983, 5, 197–211. [Google Scholar] [CrossRef]

- Dorer, V.; Breer, D. Residential mechanical ventilation systems: Performance criteria and evaluations. Energy Build. 1998, 27, 247–255. [Google Scholar] [CrossRef]

- Choi, Y.; Song, D.; Seo, D.; Kim, J. Analysis of the variable heat exchange efficiency of heat recovery ventilators and the associated heating energy demand. Energy Build. 2018, 172, 152–158. [Google Scholar] [CrossRef]

- Maier, T.; Krzaczek, M.; Tejchman, J. Comparison of physical performances of the ventilation systems in low-energy residential houses. Energy Build. 2009, 41, 337–353. [Google Scholar] [CrossRef]

- Laverge, J.; Van Den Bossche, N.; Heijmans, N.; Janssens, A. Energy saving potential and repercussions on indoor air quality of demand controlled residential ventilation strategies. Energy Build. 2011, 46, 1497–1503. [Google Scholar] [CrossRef]

- Cho, W.; Song, D.; Hwang, S.; Yun, S. Energy-efficient ventilation with air-cleaning mode and demand control in a multi-residential building. Energy Build. 2015, 90, 6–14. [Google Scholar] [CrossRef]

- Fisk, W.; De Almeida, A. Sensor-based demand-controlled ventilation: A review. Energy Build. 1998, 29, 35–45. [Google Scholar] [CrossRef]

- Guyot, G.; Sherman, M.; Walker, I. Smart ventilation energy and indoor air quality performance in residential buildings: A review. Energy Build. 2018, 165, 416–430. [Google Scholar] [CrossRef]

- Southall, R.G. An assessment of the potential of supply-side ventilation demand control to regulate natural ventilation flow patterns and reduce domestic space heating consumption. Energy Build. 2018, 168, 201–214. [Google Scholar] [CrossRef]

- Turner, W.J.N.; Walker, I.S. Using a ventilation controller to optimise residential passive ventilation for energy and indoor air quality. Build. Environ. 2013, 70, 20–30. [Google Scholar] [CrossRef]

- Jreijiry, D.; Husaunndee, A.; Inard, C. Numerical study of a hybrid ventilation system for single family houses. Sol. Energy 2007, 81, 227–239. [Google Scholar] [CrossRef]

- Matsunaga, J.; Kikuta, K.; Hirakawa, H.; Mizuno, K.; Tajima, M.; Hayashi, M.; Fukushima, A. An Assessment of Heating Load Reduction by Solar Air Heater in a Residential Passive Ventilation System. Energies 2021, 14, 7651. [Google Scholar] [CrossRef]

- Building Research Institute. Technical Information on Energy Consumption Performance of Buildings. (In Japanese). Available online: https://www.kenken.go.jp/becc/index.html (accessed on 28 June 2023).

- Yoshino, H.; Akabayashi, S.; Kato, S.; Ikeda, K.; Sawachi, T.; Adachi, M. Survey on Minimum Ventilation Rate for Residential Buildings on Advanced Countries. AIJ J. Technol. Des. 2004, 19, 189–192. (In Japanese) [Google Scholar] [CrossRef]

- Meteorological Data System Co., Ltd. Expanded AMeDAS Weather Data; Meteorological Data System Co., Ltd.: Kagoshima, Japan, 2010; (In Japanese). Available online: https://www.metds.co.jp/documents/ea/ (accessed on 28 June 2023).

- The Society of Heating, Air-Conditioning and Sanitary Engineers of Japan. SHASE-S112-2019, Simplified Calculation Methods of Cooling and Heating Loads; The Society of Heating, Air-Conditioning and Sanitary Engineers of Japan: Tokyo, Japan, 2019. (In Japanese) [Google Scholar]

- National Institute for Land and Infrastructure Management; MLIT; Building Research Institute. Incorporated Administrative Agency: Design Guidelines for Low Energy Housing with Validated Effectiveness: Mild Climate Region Edition; IBEC: Tokyo, Japan, 2015. (In Japanese) [Google Scholar]

- International Energy Agency. Annual GHG Emission Factors for World Countries from Electricity and Heat Generation, Data and Statistics 2019; International Energy Agency: Paris, France, 2019. [Google Scholar]

| System | Specific Fan Power | Air Change per Hour | Heat Exchange Efficiency | Heat Collection Efficiency of SAH | |

|---|---|---|---|---|---|

| Wh/m3 | h−1 | - | - | ||

| Mechanical Exhaust Ventilation System | 0.24 | 0.5 | - | - | |

| Passive Ventilation System with a Solar Air Heater | Heating period | 0.00 | 0.5 | - | 0.6 1 (Rated efficiencies) |

| Non-heating period | 0.24 | 0.5 | - | - | |

| Heat Recovery Ventilation System | 0.49 | 0.5 | 0.8 | - | |

| City | Zone | North Latitude | Heating Degree-Day (HDD18-18) | Maximum Air Temperature (°C) | Annual Snowfall (cm) | Annual Amount of Solar Radiation (MJ/m2) | Heating Period | Heating APF | Gas Boiler Efficiency |

|---|---|---|---|---|---|---|---|---|---|

| East Longitude | Minimum Air Temperature (°C) | Cooling Period | Cooling APF | ||||||

| Sapporo | 2 | 43°03′51″ | 4499~3500 | 32 | 479 | 4436 | 9/26~6/4 | 3.2 | 0.87 |

| 141°20′49″ | −11.4 | 7/15~8/31 | 6.6 | ||||||

| Morioka | 3 | 39°42′13″ | 3499~3000 | 31.9 | 209 | 4538 | 9/30~5/31 | 3.8 | |

| 141°09′09″ | −12.2 | 7/10~8/31 | 6.6 | ||||||

| Nagano | 4 | 36°39′05″ | 2999~2500 | 35.7 | 163 | 5354 | 10/1~5/30 | 4.6 | |

| 138°10′52″ | −8.2 | 7/10~8/31 | 6.4 | ||||||

| Sendai | 5 | 38°16′08″ | 2499~2000 | 35.4 | 59 | 4495 | 10/10~5/15 | 5.1 | |

| 140°52′19″ | −4.2 | 7/6~8/31 | 5.7 | ||||||

| Tokyo | 6 | 35°41′22″ | 1999~1500 | 35.2 | 8 | 4713 | 11/4~4/21 | 5.6 | |

| 139°41′30″ | −0.5 | 5/30~9/23 | 6.2 | ||||||

| Kagoshima | 7 | 31°33′37″ | 1499~500 | 34.6 | 2 | 5223 | 11/26~3/27 | 5.7 | |

| 130°33′29″ | −0.3 | 5/15~10/13 | 6.3 |

| Energy Type | Conversion Factor per Unit | Calorific Value per Unit |

|---|---|---|

| Electricity | 9.76 MJ/kWh | 1.000 kWh/kWh |

| Gas | 45.00 MJ/m3 | 12.083 kWh/m3 |

| Level | Japan in 2019 | Level 1 | Level 2 | Level 3 |

|---|---|---|---|---|

| Electricity CO2 emission factor [kg-CO2/kWh] | 0.44 | 0.3 | 0.15 | 0.04 |

| Gas CO2 emission factor [kg-CO2/m3] | 2.21 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matsunaga, J.; Kikuta, K.; Hirakawa, H.; Hayashi, M.; Fukushima, A. Evaluation of the Primary Energy and Carbon Dioxide Emissions of a Passive Ventilation System with a Solar Air Heater. Energies 2023, 16, 5535. https://doi.org/10.3390/en16145535

Matsunaga J, Kikuta K, Hirakawa H, Hayashi M, Fukushima A. Evaluation of the Primary Energy and Carbon Dioxide Emissions of a Passive Ventilation System with a Solar Air Heater. Energies. 2023; 16(14):5535. https://doi.org/10.3390/en16145535

Chicago/Turabian StyleMatsunaga, Junichiro, Koki Kikuta, Hideki Hirakawa, Motoya Hayashi, and Akira Fukushima. 2023. "Evaluation of the Primary Energy and Carbon Dioxide Emissions of a Passive Ventilation System with a Solar Air Heater" Energies 16, no. 14: 5535. https://doi.org/10.3390/en16145535

APA StyleMatsunaga, J., Kikuta, K., Hirakawa, H., Hayashi, M., & Fukushima, A. (2023). Evaluation of the Primary Energy and Carbon Dioxide Emissions of a Passive Ventilation System with a Solar Air Heater. Energies, 16(14), 5535. https://doi.org/10.3390/en16145535