Multi-Parametric Analysis Based on Physico-Chemical Characterization and Biochemical Methane Potential Estimation for the Selection of Industrial Wastes as Co-Substrates in Anaerobic Digestion

Abstract

1. Introduction

2. Materials and Methods

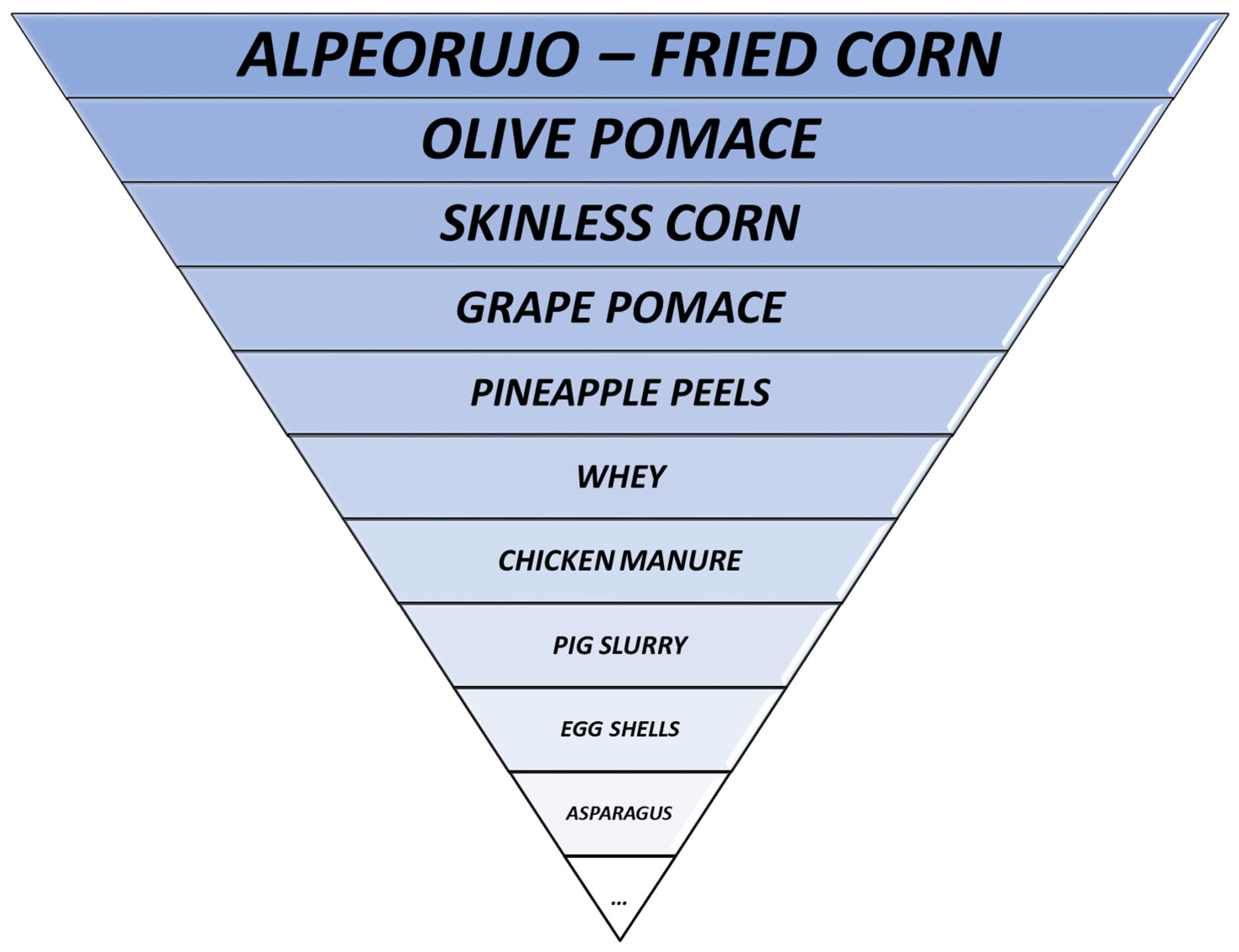

2.1. Pre-Selection of Co-Substrates

2.2. Physico-Chemical Analyses

2.2.1. pH and Conductivity Measurements

2.2.2. Moisture and Ash Content

2.2.3. Elemental Analysis

2.2.4. Biochemical Composition

2.2.5. Estimation of BMP

2.2.6. Selection Matrix

3. Results

3.1. Pre-Selection of Co-Substrates

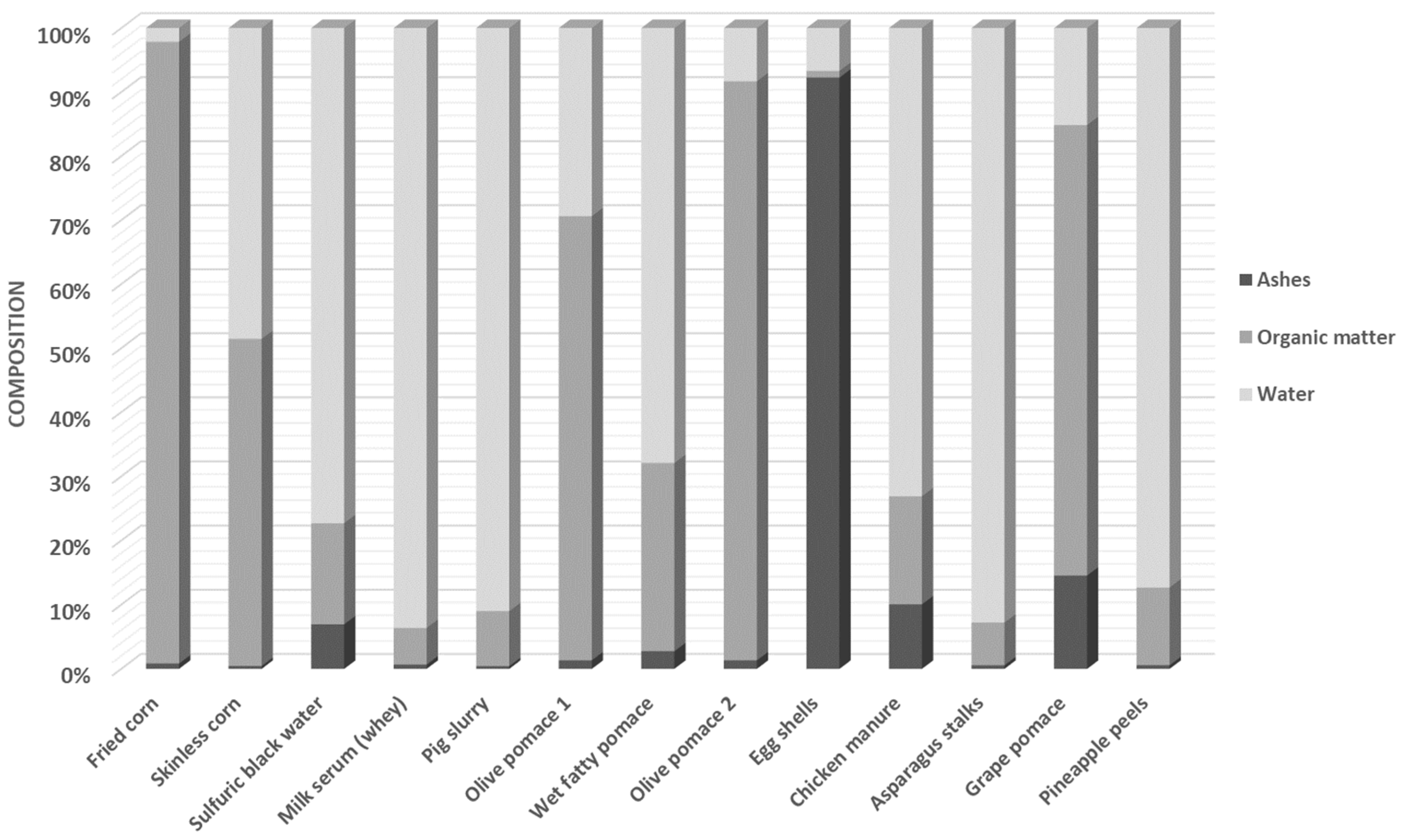

3.2. Physico-Chemical Analyses

3.3. Elemental Analysis

3.4. Biochemical Analysis

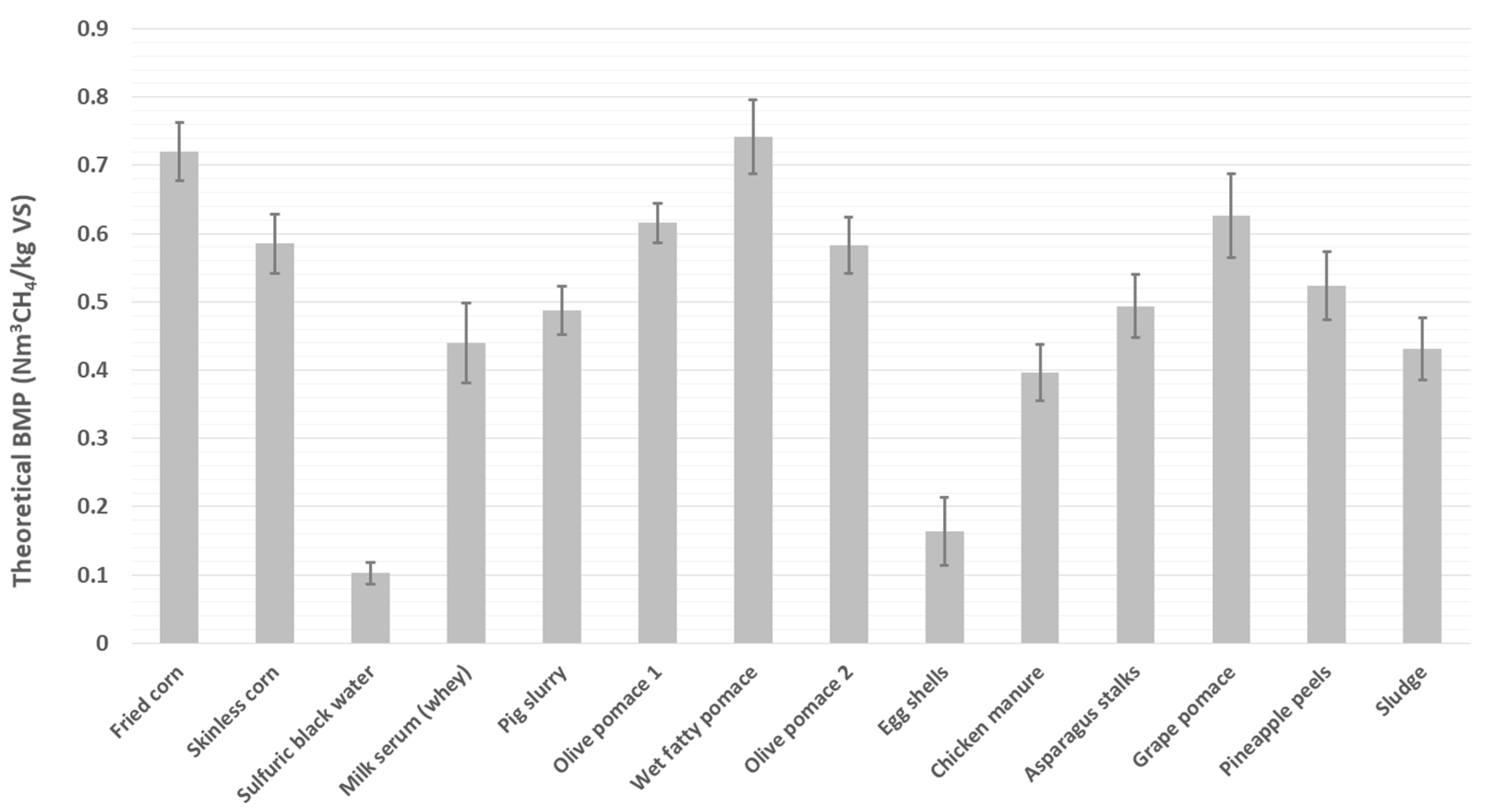

3.5. BMP Estimation

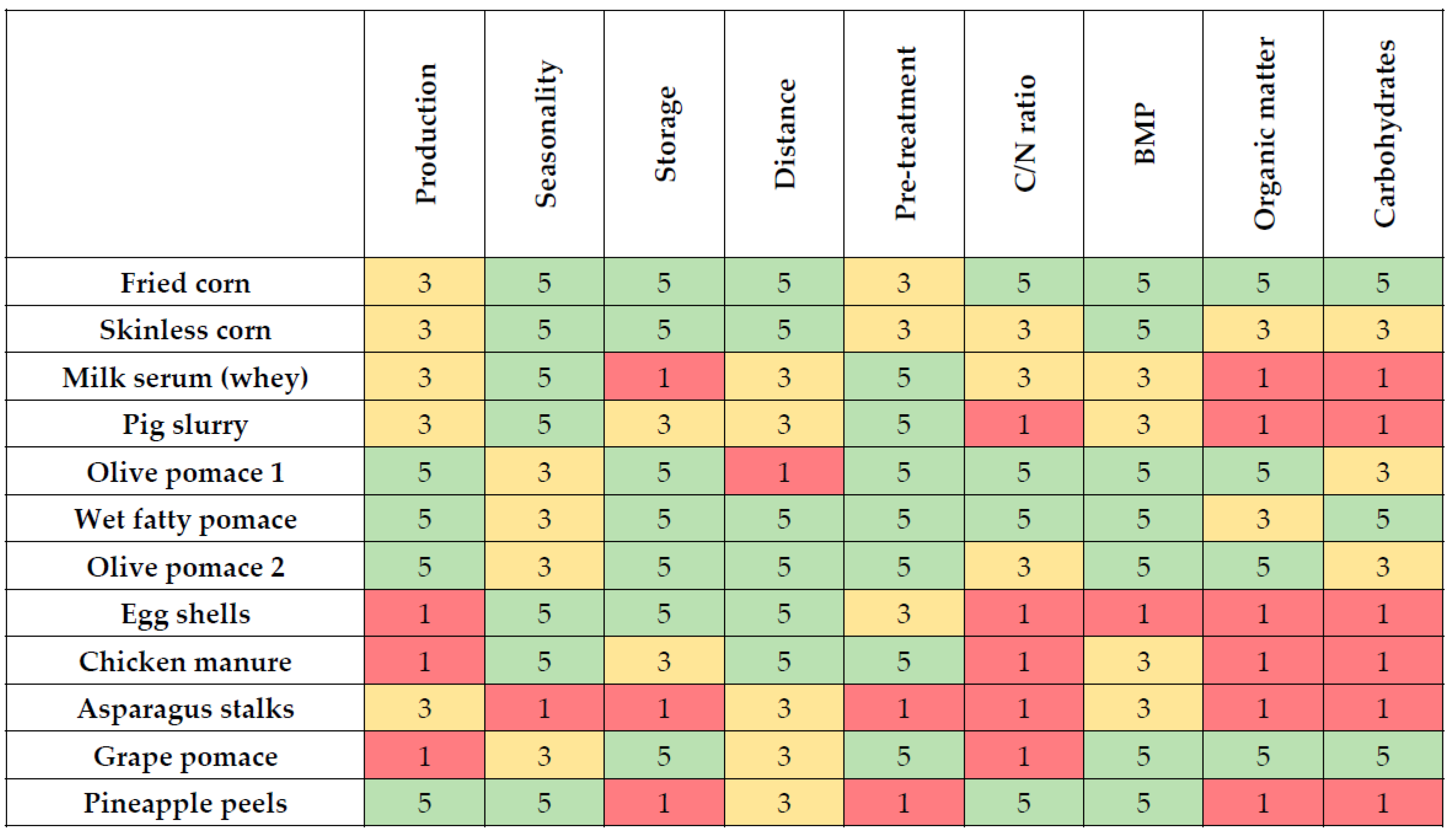

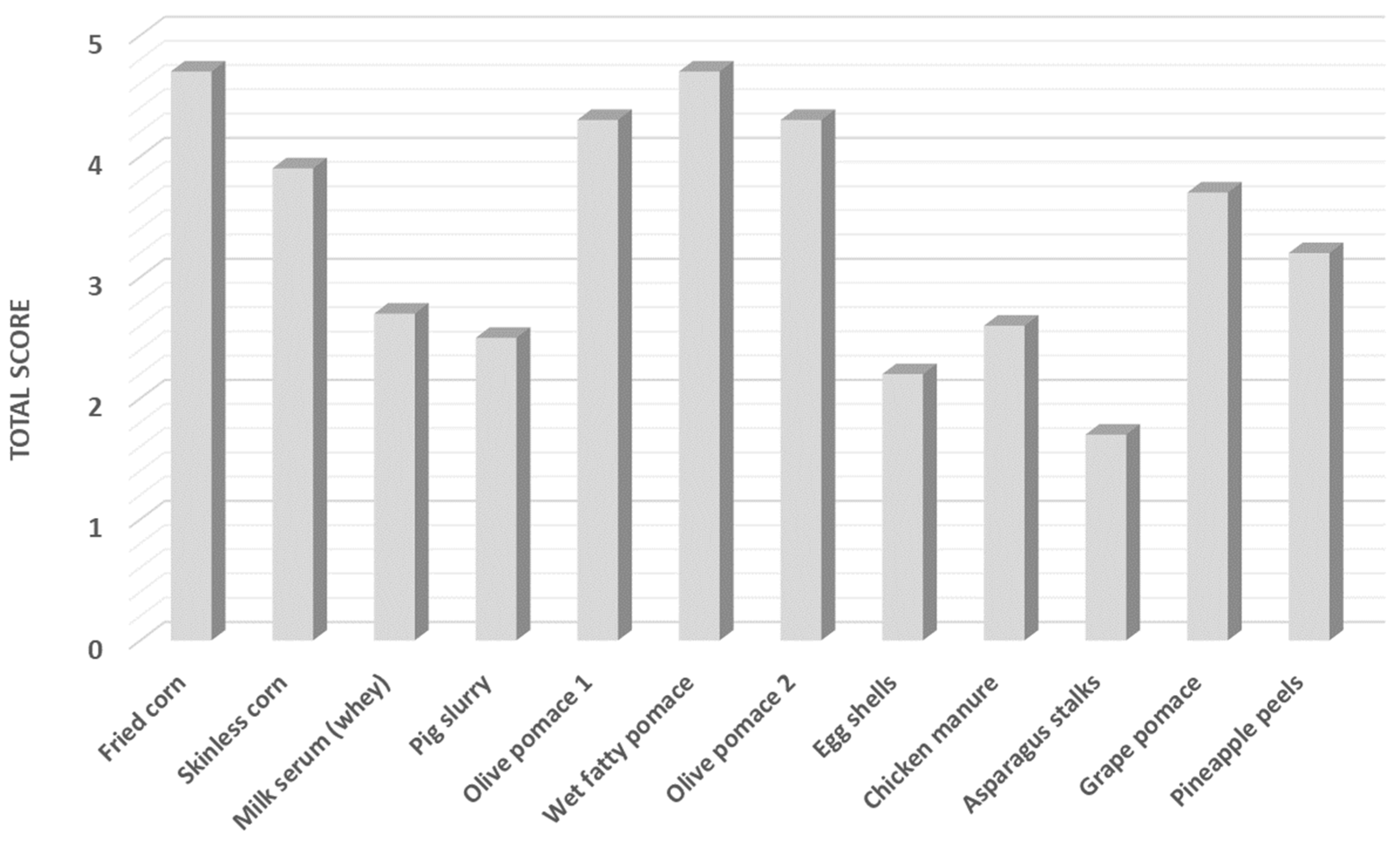

3.6. Multi-Parametric Selection Matrix

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- What a Waste 2.0. A Global Snapshot of Solid Waste Management to 2050. The World Bank (IBRD–IDA). Available online: https://datatopics.worldbank.org/what-a-waste/ (accessed on 26 September 2022).

- European Union Directive 2018/851. European Parliament and Council, 30 de Mayo de 2018. Available online: https://eur-lex.europa.eu/legal-content/ES/TXT/?uri=CELEX%3A32018L0851 (accessed on 26 September 2022).

- Sridhar, A.; Kapoor, A.; Kumar, P.S.; Ponnuchamy, M.; Balasubramanian, S.; Prabhakar, S. Conversion of food waste to energy: A focus on sustainability and life cycle assessment. Fuel 2021, 302, 121069. [Google Scholar] [CrossRef]

- Eurostat Data Browser. Official Website of the European Union. Available online: https://ec.europa.eu/eurostat (accessed on 26 September 2022).

- Plan Nacional Integrado de Energía y Clima: 2021–2030 (PNIEC). 2020. Available online: https://www.miteco.gob.es/es/prensa/pniec.aspx (accessed on 10 January 2023).

- Lima, D.; Appleby, G.; Li, L. A Scoping Review of Options for Increasing Biogas Production from Sewage Sludge: Challenges and Opportunities for Enhancing Energy Self-Sufficiency in Wastewater Treatment Plants. Energies 2023, 16, 2369. [Google Scholar] [CrossRef]

- Maragkaki, A.E.; Fountoulakis, M.; Gypakis, A.; Kyriakou, A.; Lasaridi, K.; Manios, T. Pilot-scale anaerobic co-digestion of sewage sludge with agro-industrial by-products for increased biogas production of existing digesters at wastewater treatment plants. Waste Manag. 2017, 59, 362–370. [Google Scholar] [CrossRef] [PubMed]

- Kothari, R.; Pandey, A.K.; Kumar, S.; Tyagi, V.V.; Tyagi, S.K. Different aspects of dry anaerobic digestion for bio-energy: An overview. Renew Sustain. Energy Rev. 2014, 39, 174–195. [Google Scholar] [CrossRef]

- Rafiee, A.; Khalilpour, K.R.; Prest, J.; Skryabin, I. Biogas as an energy vector. Biomass. Bioenergy 2021, 144, 105935. [Google Scholar] [CrossRef]

- Wilinska-Lisowska, A.; Ossowska, M.; Czerwionka, K. The Influence of Co-Fermentation of Agri-Food Waste with Primary Sludge on Biogas Production and Composition of the Liquid Fraction of Digestate. Energies 2021, 14, 1907. [Google Scholar] [CrossRef]

- Ferdes, M.; Paraschiv, G.; Ionescu, M.; Dinc, M.N.; Moiceanu, G.; Zabav, B.S. Anaerobic Co-Digestion: A Way to Potentiate the Synergistic Effect of Multiple Substrates and Microbial Diversity. Energies 2023, 16, 2116. [Google Scholar] [CrossRef]

- Petrovic, A.; Zirngast, K.; Predikaka, T.C.; Simoni, M.; Cucek, L. The advantages of co-digestion of vegetable oil industry by-products and sewage sludge: Biogas production potential, kinetic analysis and digestate valorisation. J. Environ. Manag. 2022, 318, 115566. [Google Scholar] [CrossRef]

- Zhao, C.; Yan, H.; Liu, Y.; Huang, Y.; Zhang, R.; Chen, C.; Liu, G. Bio-energy conversion performance, biodegradability, and kinetic analysis of different fruit residues during discontinuous anaerobic digestion. Waste Manag. 2016, 52, 295–301. [Google Scholar] [CrossRef]

- Eftaxias, A.; Passa, E.A.; Michailidis, C.; Daoutis, C.; Kantartzis, A.; Diamantis, V. Residual Forest Biomass in Pinus Stands: Accumulation and Biogas Production Potential. Energies 2022, 15, 5233. [Google Scholar] [CrossRef]

- Azarmanesh, R.; Qaretapeh, M.Z.; Zonoozi, M.H.; Ghiasinejad, H.; Zhang, Y. Anaerobic co-digestion of sewage sludge with other organic wastes: A comprehensive review focusing on selection criteria, operational conditions, and microbiology. Chem. Eng. J. Adv. 2023, 14, 100453. [Google Scholar] [CrossRef]

- Song, Y.; Pei, L.; Chen, G.; Mu, L.; Yan, B.; Li, H.; Zhou, T. Recent advancements in strategies to improve anaerobic digestion of perennial energy grasses for enhanced methane production. Sci. Total Environ. 2023, 861, 160552. [Google Scholar] [CrossRef] [PubMed]

- Astals, S.; Batstone, D.J.; Mata-Álvarez, J.; Jensen, P.D. Identification of synergistic impacts during anaerobic co-digestion of organic wastes. Bioresour. Technol. 2014, 169, 421–427. [Google Scholar] [CrossRef] [PubMed]

- Ebner, J.H.; Labatut, R.A.; Lodge, J.S.; Williamson, A.A.; Trabold, T.A. Anaerobic co-digestion of commercial food waste and dairy manure: Characterizing biochemical parameters and synergistic effects. Waste Manag. 2016, 52, 286–294. [Google Scholar] [CrossRef]

- Iocoli, G.A.; Zabaloy, M.C.; Pasdevicelli, G.; Gómez, M.A. Use of biogas digestates obtained by anaerobic digestion and co-digestion as fertilizers: Characterization, soil biological activity and growth dynamic of Lactuca sativa L. Sci. Total Environ. 2019, 647, 11–19. [Google Scholar] [CrossRef]

- Estévez, F. Cosustratos Para la Digestión Anaerobia en EDAR Urbanas: Propuesta de Factores de Idoneidad Para Analizar la Producción de Gas de Digestión y Experimentación en Planta Piloto. Ph.D. Thesis, Universidad de Sevilla, Sevilla, Spain, 2018. Available online: https://hdl.handle.net/11441/80244 (accessed on 18 February 2023).

- Labatut, R.A.; Angenent, L.T.; Scott, N.R. Biochemical methane potential and biodegradability of complex organic substrates. Bioresour. Technol. 2011, 102, 2255–2264. [Google Scholar] [CrossRef]

- Yang, G.; Li, Y.; Zhen, F.; Xu, Y.; Liu, J.; Li, N.; Sun, Y.; Luo, L.; Wang, M.; Zhang, L. Biochemical methane potential prediction for mixed feedstocks of straw and manure in anaerobic co-digestion. Bioresour. Technol. 2021, 326, 124745. [Google Scholar] [CrossRef]

- Koch, K.; Plabst, M.; Schmidt, A.; Helmreich, B.; Drewes, J.E. Co-digestion of food waste in a municipal wastewater treatment plant: Comparison of batch tests and full-scale experiences. Waste Manag. 2016, 47, 28–33. [Google Scholar] [CrossRef]

- Ferrer, P.; Cambra-López, M.; Cerisuelo, A.; Peñaranda, D.S.; Moset, V. The use of agricultural substrates to improve methane yield in anaerobic co-digestion with pig slurry: Effect of substrate type and inclusion level. Waste Manag. 2014, 34, 196–203. [Google Scholar] [CrossRef]

- Roberts, S.; Mathaka, N.; Zeleke, M.A.; Nwaigwe, K.N. Comparative analysis of five kinetic models for prediction of methane yield. J. Inst. Eng. India Ser. A 2023, 104, 335–342. [Google Scholar] [CrossRef]

- McCarty, P.L. Energetics of Organic Matter Degradation; Mitchell, R., Ed.; Water Pollution Microbiology; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1972; pp. 91–118. [Google Scholar]

- Batstone, D.J.; Keller, J.; Newell, R.B.; Newland, M. Modelling anaerobic degradation of complex wastewater. I: Model development. Bioresour. Technol. 2000, 75, 67–74. [Google Scholar] [CrossRef]

- Angelidaki, I.; Ellegaard, L.; Ahring, B.K. A comprehensive model of anaerobic bioconversion of complex substrates to biogas. Biotechnol. Bioeng. 1999, 63, 363–372. [Google Scholar] [CrossRef]

- Nielfa, A.; Cano, R.; Fernández-Polanco, M. Theoretical methane production generated by the co-digestion of organic fraction municipal solid waste and biological sludge. Biotechnol. Rep. 2015, 5, 14–21. [Google Scholar] [CrossRef]

- Achinas, S.; Euverink, G.J.W. Theoretical analysis of biogas potential prediction from agricultural waste. Resour.-Effic. Technol. 2016, 2, 143–147. [Google Scholar] [CrossRef]

- Liu, J.; Zeng, C.; Wang, N.; Shi, J.; Zhang, B.; Liu, C.; Sun, Y. Rapid biochemical methane potential evaluation of anaerobic co-digestion feedstocks based on near infrared spectroscopy and chemometrics. Energies 2021, 14, 1460. [Google Scholar] [CrossRef]

- Xu, Y.; Awasthi, M.K.; Li, P.; Meng, X.; Wang, Z. Comparative analysis of prediction models for methane potential based on spent edible fungus substrate. Bioresour. Technol. 2020, 317, 124052. [Google Scholar] [CrossRef]

- Bekiaris, G.; Triolo, J.M.; Peltre, C.; Pedersen, L.; Jensen, L.S.; Bruun, S. Rapid estimation of the biochemical methane potential of plant biomasses using Fourier transform mid-infrared photoacoustic spectroscopy. Bioresour. Technol. 2015, 197, 475–481. [Google Scholar] [CrossRef]

- Marchetti, R.; Vasmara, C.; Bertin, L.; Flume, F. Conversion of waste cooking oil into biogas: Perspectives and limits. Appl. Microbiol. Biot. 2020, 104, 2833–2856. [Google Scholar] [CrossRef]

- Standard Methods for the Examination of Water and Wastewater, 22nd ed.; American Public Health Association (APHA): Washington, DC, USA, 2022.

- Latha, K.; Velraj, R.; Shanmugam, P.; Sivanesan, S. Mixing strategies of high solids anaerobic co-digestion using food waste with sewage sludge for enhanced biogas production. J. Clean. Prod. 2019, 210, 388–400. [Google Scholar] [CrossRef]

- Babalola, M.A. A multi-criteria decision analysis of waste treatment options for food and biodegradable waste management in Japan. Environments 2015, 2, 471–488. [Google Scholar] [CrossRef]

- Generowicz, A.; Gaska, K.; Hajduga, G. Multi-criteria analysis of the waste management system in a metropolitan area. In Proceedings of the 10th Conference on Interdisciplinary Problems in Environmental Protection and Engineering EKO-DOK 2018, Polanica-Zdroj, Poland, 16–18 April 2018; Volume 44, p. 00043. [Google Scholar] [CrossRef]

- Yazdani, M.; Fomba, S.; Zarate, P. A decision support system for multiple criteria decision making problems. In Proceedings of the 17th International Conference on Group Decision and Negotiation (GDN 2017), Stuttgart, Germany, 14–18 August 2017; Available online: https://hal.science/hal-01914000/document (accessed on 29 March 2023).

- Omran, I.I.; Al-Saati, N.H.; Salman, A.A.; Hashim, K. A new framework for assessing the sustainability of municipal solid waste treatment techniques applying multi-criteria decision analysis. Int. J. Environ. Sci. Technol. 2022. [Google Scholar] [CrossRef]

- Bartkowska, I. Drop in conductivity of sewage sludge in the process of autothermal thermophilic aerobic digestion. J. Ecol. Eng. 2017, 18, 67–75. [Google Scholar] [CrossRef]

- Ponsá, S. Different Indices to Express Biodegradability in Organic Solid Wastes. Application to Full Scale Waste Treatment Plants. Ph.D. Thesis, Universidad Autónoma de Barcelona, Barcelona, Spain, 2010. Available online: https://www.tdx.cat/bitstream/handle/10803/48707/sps1de1.pdf (accessed on 22 February 2023).

- Cheng, J.; Ding, L.; Lin, R.; Yue, L.; Liu, J.; Zhou, J.; Cen, K. Fermentative biohydrogen and biometane co-production from mixture of food waste and sewage sludge: Effects of physiochemical properties and mix ratios on fermentation performance. Appl. Energ. 2016, 184, 1–8. [Google Scholar] [CrossRef]

- Tanimu, M.I.; Ghazi, T.I.M.; Harun, R.M.; Idris, A. Effect of carbon to nitrogen ratio of food waste on biogas methane production in a batch mesophilic anaerobic digester. Int. J. Innov. Manag. Technol. 2014, 5, 116–119. [Google Scholar] [CrossRef]

- Zheng, Y.; Wang, P.; Yang, X.; Lin, P.; Wang, Y.; Cheng, M.; Ren, L. Process Performance and Microbial Communities in Anaerobic Co-digestion of Sewage Sludge and Food Waste with a Lower Range of Carbon/Nitrogen Ratio. Bioenerg. Res. 2022, 15, 1664–1674. [Google Scholar] [CrossRef]

- Xu, F.; Li, Y.; Ge, X.; Yang, L.; Li, Y. Anaerobic digestion of food waste—Challenges and opportunities. Bioresour. Technol. 2018, 247, 1047–1058. [Google Scholar] [CrossRef]

- Messineo, A.; Maniscalco, M.P.; Volpe, R. Biomethane recovery from olive mil residues through anaerobic digestion: A review of the state of the art technology. Sci. Total Environ. 2020, 703, 135508. [Google Scholar] [CrossRef]

- Elalami, D.; Carrere, H.; Monlau, F.; Abdelouahdi, K.; Oukarroum, A.; Barakat, A. Pretreatment and co-digestion of wastewater sludge for biogas production: Recent research advances and trends. Renew Sustain. Energy Rev. 2019, 114, 109287. [Google Scholar] [CrossRef]

- Awe, W.; Lu, J.; Wu, S.; Zhao, Y.; Nzihou, A.; Lyczko, N.; Minh, D.P. Effect of Oil Content on Biogas Production, Process Performance and Stability of Food Waste Anaerobic Digestion Olumide. Waste Biomass. Valori. 2017, 9, 2295–2306. [Google Scholar] [CrossRef]

- Kashi, S.; Satari, B.; Lundin, M.; Horváth, I.S.; Othman, M. Application of a mixture design to identify the effects of substrates ratios and interactions on anaerobic co-digestion of municipal sludge, grease trap waste and meat processing waste. J. Environ. Chem. Eng. 2017, 5, 6156–6164. [Google Scholar] [CrossRef]

- Bintsis, T.; Papademas, P. Sustainable approaches in whey cheese production: A review. Dairy 2023, 4, 249–270. [Google Scholar] [CrossRef]

- Ameziane, H.; Nounah, A.; Khamar, M.; Zouahri, A. Composting olive pomace: Evolution of organic matter and compost quality. Agron. Res. 2020, 18, 5–17. [Google Scholar] [CrossRef]

- El Achkar, J.H.; Lendormi, T.; Hobaika, Z.; Salameh, D.; Louka, N.; Maroun, R.G.; Lanoisellé, J.L. Anaerobic digestion of grape pomace: Biochemical characterization of the fractions and methane production in batch and continuous digesters. Waste Manag. 2016, 50, 275–282. [Google Scholar] [CrossRef]

- Perra, M.; Bacchetta, G.; Muntoni, A.; De Gioannis, G.; Castangia, I.; Rajha, H.N.; Manca, M.L.; Manconi, M. An outlook on modern and sustainable approaches to the management of grape pomace by integrating green processes, biotechnologies and advanced biomedical approaches. J. Funct. Food 2022, 98, 105276. [Google Scholar] [CrossRef]

- Gunaseelan, V.N. Anaerobic digestion of biomass for methane production: A review. Biomass. Bioenergy 1997, 13, 83–114. [Google Scholar] [CrossRef]

- Chalchisa, T.; Dereje, B. From waste to food: Utilization of pineapple peels for vinegar production. Food Process Technol. 2021, 9, 1–5. [Google Scholar] [CrossRef]

- Pellera, F.M.; Gidarakos, E. Effect of substrate to inoculum ratio and inoculum type on the biochemical methane potential of solid agroindustrial waste. J. Environ. Chem. Eng. 2016, 4, 3217–3229. [Google Scholar] [CrossRef]

- The World of Olive Oil. International Olive Council. 2022. Available online: https://www.internationaloliveoil.org/the-world-of-olive-oil/ (accessed on 10 April 2023).

- Avance de la Situación del Mercado del Sector oleícola. Campaña 2020–2021. Ministerio de Agricultura, Pesca y Alimentación. Gobierno de España. 2021. Available online: https://www.mapa.gob.es/es/agricultura/temas/producciones-agricolas/aceite-oliva-y-aceituna-mesa/aceite.aspx (accessed on 10 April 2023).

- Aforo de Producción del Olivar de Almazara en Andalucía. Campaña 2020–2021. Consejería de Agricultura, Ganadería, Pesca y Desarrollo Sostenible. Junta de Andalucía. Available online: https://www.juntadeandalucia.es/export/drupaljda/Presentaci%C3%B3n_ACEITUNA%20ACEITE_2020-2021.pdf (accessed on 10 April 2023).

- Hernández, D.; Astudillo, C.A.; Fernández-Palacios, E.; Cataldo, F.; Tenreiro, C.; Gabriel, D. Evolution of physical-chemical parameters, microbial diversity and VOC emissions of olive oil mill waste exposed to ambient conditions in open reservoirs. Waste Manag. 2018, 79, 501–509. [Google Scholar] [CrossRef]

| Waste | Estimated Production Rate | Seasonality | Distance to the WWTP |

|---|---|---|---|

| Fried corn | 1000 kg/d | All year | 12 Km |

| Skinless corn | 2000 kg/d | All year | 12 Km |

| Sulfuric black water | /month | All year | 12 Km |

| Milk serum (whey) | Variable | All year | 7.5 Km |

| Pig slurry | 5000 L/d | All year | 40 Km |

| Olive pomace 1 | Variable | November–March | 52 Km |

| Wet fatty pomace | Variable | November–March | 23 Km |

| Olive pomace 2 | Variable | November–March | 23 Km |

| Egg shells | Unknown | All year | 7.6 Km |

| Chicken manure | Variable | All year | 7.6 Km |

| Asparagus stalks | 1000 kg/d | February–May | 41 Km |

| Grape pomace | 10,000 kg/y | February–April | 28 Km |

| Pineapple peels | 21,000 kg/d | All year | 22 Km |

| Waste | Humidity (%) | Ashes (%) | Organic Matter (%) | TS (%) | VS regarding TS (%) | pH | EC (mS/cm) |

|---|---|---|---|---|---|---|---|

| Fried corn | 2.15 ± 0.24 | 0.84 ± 0.06 | 97.01 ± 0.22 | 97.85 ± 0.24 | 99.14 ± 0.06 | - | - |

| Skinless corn | 48.55 ± 2.62 | 0.45 ± 0.10 | 51.00 ± 2.57 | 51.45 ± 2.62 | 99.13 ± 0.16 | - | - |

| Sulfuric black water | 77.31 ± 4.48 | 6.94 ± 0.13 | 15.76 ± 4.38 | 22.69 ± 4.48 | 69.43 ± 5.79 | 1.30 ± 0.96 | - |

| Milk serum (whey) | 93.62 ± 3.46 | 0.67 ± 0.05 | 5.71 ± 3.47 | 6.38 ± 3.46 | 89.50 ± 7.28 | 6.82 ± 0.07 | 8.16 ± 1.32 |

| Pig slurry | 91.00 ± 1.22 | 0.42 ± 0.05 | 8.58 ± 1.21 | 9.00 ± 1.22 | 95.31 ± 0.70 | 7.68 ± 0.16 | 18.16 ± 4.86 |

| Olive pomace 1 | 29.38 ± 2.26 | 1.33 ± 0.08 | 69.29 ± 2.31 | 70.62 ± 2.26 | 98.12 ± 0.16 | - | - |

| Wet fatty pomace | 67.92 ± 2.44 | 2.75 ± 0.16 | 29.33 ± 2.42 | 32.08 ± 2.44 | 91.43 ± 0.73 | 5.95 ± 0.13 | 20.4 ± 3.14 |

| Olive pomace 2 | 8.33 ± 0.59 | 1.33 ± 0.09 | 90.34 ± 0.68 | 91.67 ± 0.59 | 98.55 ± 0.11 | - | - |

| Egg shells | 6.70 ± 0.63 | 92.27 ± 0.83 | 1.03 ± 0.72 | 93.30 ± 0.63 | 1.11 ± 0.77 | - | - |

| Chicken manure | 73.10 ± 3.94 | 10.05 ± 0.46 | 16.84 ± 4.35 | 26.90 ± 3.94 | 62.63 ± 7.74 | - | - |

| Asparagus stalks | 92.78 ± 2.75 | 0.56 ± 0.08 | 6.66 ± 2.70 | 7.22 ± 2.75 | 92.24 ± 3.53 | - | - |

| Grape pomace | 15.16 ± 0.42 | 14.54 ± 1.61 | 70.30 ± 1.41 | 84.84 ± 0.42 | 82.86 ± 1.86 | - | - |

| Pineapple peels | 87.33 ± 4.07 | 0.57 ± 0.08 | 12.10 ± 4.14 | 12.67 ± 4.07 | 95.50 ± 2.74 | - | - |

| Waste | N (%) | C (%) | H (%) | S (%) | O (%) | C/N Ratio |

|---|---|---|---|---|---|---|

| Fried corn | 1.38 ± 0.05 | 53.81 ± 4.37 | 11.89 ± 0.45 | 0.00 ± 0.00 | 32.08 ± 4.07 | 45.49 ± 4.51 |

| Skinless corn | 1.48 ± 0.13 | 45.04 ± 3.45 | 11.32 ± 0.22 | 0.00 ± 0.00 | 41.71 ± 3.48 | 35.50 ± 3.57 |

| Sulfuric black water | 1.95 ± 0.12 | 13.99 ± 0.47 | 6.79 ± 0.22 | 7.22 ± 3.14 | 63.11 ± 2.31 | 8.37 ± 0.72 |

| Milk serum (whey) | 1.64 ± 0.25 | 38.56 ± 3.56 | 9.33 ± 0.43 | 0.00 ± 0.00 | 49.80 ± 4.18 | 27.43 ± 2.86 |

| Pig slurry | 2.83 ± 0.37 | 42.38 ± 3.05 | 9.36 ± 0.38 | 0.24 ± 0.03 | 44.77 ± 3.28 | 17.47 ± 1.78 |

| Olive pomace 1 | 0.44 ± 0.03 | 49.57 ± 2.95 | 10.09 ± 1.95 | 0.00 ± 0.00 | 38.57 ± 1.14 | 131.44 ± 12.12 |

| Wet fatty pomace | 1.45 ± 0.07 | 54.04 ± 3.54 | 11.82 ± 0.28 | 0.00 ± 0.00 | 29.94 ± 3.83 | 43.48 ± 1.02 |

| Olive pomace 2 | 1.88 ± 0.21 | 48.18 ± 2.79 | 9.75 ± 1.05 | 0.00 ± 0.00 | 38.86 ± 2.54 | 29.90 ± 5.15 |

| Egg shells | 0.68 ± 0.02 | 1.36 ± 0.05 | 0.76 ± 0.03 | 0.00 ± 0.00 | 4.93 ± 0.74 | 2.34 ± 0.09 |

| Chicken manure | 6.91 ± 0.27 | 36.46 ± 2.94 | 6.99 ± 0.37 | 0.10 ± 0.03 | 39.49 ± 2.91 | 6.16 ± 0.70 |

| Asparagus stalks | 3.69 ± 0.27 | 44.68 ± 2.97 | 8.69 ± 0.27 | 0.15 ± 0.04 | 42.23 ± 3.19 | 14.13 ± 1.43 |

| Grape pomace | 4.18 ± 0.31 | 47.42 ± 3.68 | 7.50 ± 0.36 | 0.00 ± 0.00 | 26.36 ± 4.12 | 13.24 ± 1.21 |

| Pineapple peels | 0.90 ± 0.08 | 45.34 ± 3.74 | 9.18 ± 0.29 | 0.00 ± 0.00 | 44.01 ± 3.74 | 58.77 ± 7.27 |

| Sludge | 6.18 ± 0.33 | 42.64 ± 3.11 | 7.61 ± 0.34 | 0.29 ± 0.08 | 42.30 ± 3.07 | 8.05 ± 0.87 |

| Waste | Lipids (%) | Proteins (%) | Carbohydrates (%) | Energetic Value, kcal/100 g |

|---|---|---|---|---|

| Fried corn | 32.45 ± 6.09 | 5.94 ± 0.39 | 58.62 ± 5.79 | 550 ± 41.2 |

| Skinless corn | 1.42 ± 0.14 | 4.16 ± 0.24 | 45.42 ± 4.48 | 211 ± 38.3 |

| Sulfuric black water | -- | -- | -- | -- |

| Milk serum (whey) | 0.01 ± 0.00 | 0.56 ± 0.09 | 5.14 ± 0.30 | 23 ± 4.7 |

| Pig slurry | -- | -- | -- | -- |

| Olive pomace 1 | 2.45 ± 0.21 | 1.93 ± 0.16 | 64.91 ± 7.06 | 289 ± 12.3 |

| Wet fatty pomace | 1.13 ± 0.20 | 2.27 ± 0.34 | 25.92 ± 0.77 | 123 ± 8.8 |

| Olive pomace 2 | -- | -- | -- | -- |

| Egg shells | 2.10 ± 0.16 | 5.84 ± 0.48 | 0.69 ± 0.06 | 45 ± 7.7 |

| Chicken manure | -- | -- | -- | -- |

| Asparagus stalks | 0.09 ± 0.02 | 1.32 ± 0.10 | 5.25 ± 0.20 | 27 ± 5.4 |

| Grape pomace | 0.72 ± 0.05 | 16.14 ± 0.20 | 53.43 ± 1.81 | 285 ± 10.2 |

| Pineapple peels | 0.12 ± 0.04 | 0.59 ± 0.04 | 11.38 ± 0.30 | 49 ± 3.2 |

| Sludge | -- | -- | -- | -- |

| Criterion | Score | Weight | ||

|---|---|---|---|---|

| 1 | 3 | 5 | ||

| Production | Low (<1000 kg/d) | Medium (1000–10,000 kg/d) | High (>10,000 kg/d) | 5% |

| Seasonality | Seasonal generation of waste (<3 months per year) | Seasonal generation of waste (3–9 months per year) | Continuous annual generation (>9 months/per year) | 5% |

| Storage | Not possible | Short periods of time | Long periods of time | 10% |

| Distance to WWTP | >30 km | 15–30 km | <15 km | 10% |

| Pre-treatment | Strong milling and/or chopping | Soft milling and/or chopping | Not required | 10% |

| C/N ratio | <20 or >100 | 20–40 | 40–100 | 20% |

| BMP | <0.2 | 0.2–0.5 | >0.5 | 20% |

| Organic matter | <20% | 20–60% | >60% | 10% |

| Carbohydrates | <20% | 20–50% | >50% | 10% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruiz, L.M.; Fernández, M.; Genaro, A.; Martín-Pascual, J.; Zamorano, M. Multi-Parametric Analysis Based on Physico-Chemical Characterization and Biochemical Methane Potential Estimation for the Selection of Industrial Wastes as Co-Substrates in Anaerobic Digestion. Energies 2023, 16, 5444. https://doi.org/10.3390/en16145444

Ruiz LM, Fernández M, Genaro A, Martín-Pascual J, Zamorano M. Multi-Parametric Analysis Based on Physico-Chemical Characterization and Biochemical Methane Potential Estimation for the Selection of Industrial Wastes as Co-Substrates in Anaerobic Digestion. Energies. 2023; 16(14):5444. https://doi.org/10.3390/en16145444

Chicago/Turabian StyleRuiz, Luz Marina, María Fernández, Ana Genaro, Jaime Martín-Pascual, and Montserrat Zamorano. 2023. "Multi-Parametric Analysis Based on Physico-Chemical Characterization and Biochemical Methane Potential Estimation for the Selection of Industrial Wastes as Co-Substrates in Anaerobic Digestion" Energies 16, no. 14: 5444. https://doi.org/10.3390/en16145444

APA StyleRuiz, L. M., Fernández, M., Genaro, A., Martín-Pascual, J., & Zamorano, M. (2023). Multi-Parametric Analysis Based on Physico-Chemical Characterization and Biochemical Methane Potential Estimation for the Selection of Industrial Wastes as Co-Substrates in Anaerobic Digestion. Energies, 16(14), 5444. https://doi.org/10.3390/en16145444