Fault Detection for PEM Fuel Cells via Analytical Redundancy: A Critical Review and Prospects

Abstract

1. Introduction

2. The Proton Exchange Membrane Fuel Cells (PEMFC)

2.1. Working Principle of PEMFC

2.2. Major of Faults in PEMFCs

2.2.1. Water Management Faults

2.2.2. Cooling System Faults

2.2.3. Supply System Faults

3. Analytical Redundancy Methods for Fault Detection in PEMFC

3.1. White-Box Methods

3.1.1. Parametric Identification Method

3.1.2. Observer-Based Method

3.1.3. Parity-Space Method

3.2. Black-Box Methods

3.2.1. Neural Network Method

3.2.2. Support Vector Machine Method

3.3. Grey-Box Methods

3.3.1. Fuzzy-Logic Method

3.3.2. Adaptive Neuro-Fuzzy Inference System (ANFIS) Method

4. Summary and Evaluation

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Song, K.; Lan, Y.; Zhang, X.; Jiang, J.; Sun, C.; Yang, G.; Yang, F.; Lan, H. A Review on Interoperability of Wireless Charging Systems for Electric Vehicles. Energies 2023, 16, 1653. [Google Scholar] [CrossRef]

- Noorollahi, Y.; Golshanfard, A.; Aligholian, A.; Mohammadi-Ivatloo, B.; Nielsen, S.; Hajinezhad, A. Sustainable energy system planning for an industrial zone by integrating electric vehicles as energy storage. J. Energy Storage 2020, 30, 101553. [Google Scholar] [CrossRef]

- Gertler, J. Analytical Redundancy Methods in Fault Detection and Isolation-Survey and Synthesis. IFAC Proc. Vol. 1991, 24, 9–21. [Google Scholar] [CrossRef]

- Petrone, R.; Zheng, Z.; Hissel, D.; Péra, M.; Pianese, C.; Sorrentino, M.; Becherif, M.; Yousfi-Steiner, N. A review on model-based diagnosis methodologies for PEMFCs. Int. J. Hydrogen Energy 2013, 38, 7077–7091. [Google Scholar] [CrossRef]

- Jacome, A.; Hissel, D.; Heiries, V.; Gerard, M.; Rosini, S. A Review of Model-Based Prognostic for Proton Exchange Membrane Fuel Cell under Automotive Load Cycling. In Proceedings of the 2019 IEEE Vehicle Power and Propulsion Conference (VPPC), Hanoi, Vietnam, 14–17 October 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Benmouna, A.; Becherif, M.; Depernet, D.; Gustin, F.; Ramadan, H.; Fukuhara, S. Fault diagnosis methods for Proton Exchange Membrane Fuel Cell system. Int. J. Hydrogen Energy 2017, 42, 1534–1543. [Google Scholar] [CrossRef]

- Abid, A.; Khan, M.; Iqbal, J. A review on fault detection and diagnosis techniques: Basics and beyond. Artif. Intell. Rev. 2021, 54, 3639–3664. [Google Scholar] [CrossRef]

- Jouin, M.; Gouriveau, R.; Hissel, D.; Marion-Péra, M.C.; Zerhouni, N. Prognostics and Health Management of PEMFC–State of the art and remaining challenges. Int. J. Hydrogen Energy 2013, 38, 15307–15317. [Google Scholar] [CrossRef]

- Hissel, D.; Pera, M. Diagnostic & health management of fuel cell systems: Issues and solutions. Annu. Rev. Control 2016, 42, 201–211. [Google Scholar] [CrossRef]

- Wang, J.; Yang, B.; Zeng, C.; Chen, Y.; Guo, Z.; Li, D.; Ye, H.; Shao, R.; Shu, H.; Yu, T. Recent advances and summarization of fault diagnosis techniques for proton exchange membrane fuel cell systems: A critical overview. J. Power Sources 2021, 500, 229932. [Google Scholar] [CrossRef]

- Pei, P.; Li, Y.; Xu, H.; Wu, Z. A review on water fault diagnosis of PEMFC associated with the pressure drop. Appl. Energy 2016, 173, 366–385. [Google Scholar] [CrossRef]

- Wang, X.; Ma, Y.; Gao, J.; Li, T.; Jiang, G.; Sun, Z. Review on water management methods for proton exchange membrane fuel cells. Int. J. Hydrogen Energy 2021, 46, 12206–12229. [Google Scholar] [CrossRef]

- Ma, T.; Zhang, Z.; Lin, W.; Yang, Y.; Yao, N. A Review on Water Fault Diagnosis of Proton Exchange Membrane Fuel Cell System. J. Electrochem. Energy Convers. Storage 2021, 18, 030801. [Google Scholar] [CrossRef]

- Fouquet, N.; Doulet, C.; Nouillant, C.; Dauphin-Tanguy, G.; Ould-Bouamama, B. Model based PEM fuel cell state-of-health monitoring via ac impedance measurements. J. Power Sources 2006, 159, 905–913. [Google Scholar] [CrossRef]

- Bhattacharya, P.K. Water flooding in the proton exchange membrane fuel cell. Directions 2015, 15, 24–33. [Google Scholar]

- Healy, J.; Hayden, C.; Xie, T.; Olson, K.; Waldo, R.; Brundage, M.; Gasteiger, H.; Abbott, J. Aspects of the Chemical Degradation of PFSA Ionomers used in PEM Fuel Cells. Fuel Cells 2005, 5, 302–308. [Google Scholar] [CrossRef]

- Taniguchi, A.; Akita, T.; Yasuda, K.; Miyazaki, Y. Analysis of degradation in PEMFC caused by cell reversal during air starvation. Int. J. Hydrogen Energy 2008, 33, 2323–2329. [Google Scholar] [CrossRef]

- Pukrushpan, J.; Stefanopoulou, A.; Peng, H. Modeling and control for PEM fuel cell stack system. In Proceedings of the 2002 American Control Conference (IEEE Cat. No.CH37301), Anchorage, AK, USA, 8–10 May 2002; Volume 4, pp. 3117–3122. [Google Scholar] [CrossRef]

- Escobet, T.; Feroldi, D.; de Lira, S.; Puig, V.; Quevedo, J.; Riera, J.; Serra, M. Model-based fault diagnosis in PEM fuel cell systems. J. Power Sources 2009, 192, 216–223. [Google Scholar] [CrossRef]

- Rosich, A.; Sarrate, R.; Nejjari, F. On-line model-based fault detection and isolation for PEM fuel cell stack systems. Appl. Math. Model. 2014, 38, 2744–2757. [Google Scholar] [CrossRef]

- Polverino, P.; Frisk, E.; Jung, D.; Krysander, M.; Pianese, C. Model-based diagnosis through structural analysis and causal computation for automotive polymer electrolyte membrane fuel cell systems. J. Power Sources 2017, 357, 26–40. [Google Scholar] [CrossRef]

- Hernandez, A.; Hissel, D.; Outbib, R. Modeling and Fault Diagnosis of a Polymer Electrolyte Fuel Cell Using Electrical Equivalent Analysis. IEEE Trans. Energy Convers. 2010, 25, 148–160. [Google Scholar] [CrossRef]

- Zeller, A.; Rallières, O.; Régnier, J.; Turpin, C. Diagnosis of a hydrogen/air fuel cell by a statistical model-based method. In Proceedings of the 2010 IEEE Vehicle Power and Propulsion Conference, Lille, France, 1–3 September 2010; pp. 1–6. [Google Scholar] [CrossRef]

- Legros, B.; Thivel, P.X.; Druart, F.; Bultel, Y.; Nogueira, R. Diagnosis and modelling of proton-exchange-membrane fuel cell via electrochemical-impedance-spectroscopy and Acoustic-Emission measurements. In Proceedings of the 2009 8th International Symposium on Advanced Electromechanical Motion Systems & Electric Drives Joint Symposium, Lillie, France, 1–3 July 2009; pp. 1–6. [Google Scholar] [CrossRef]

- Andreasen, S.J.; Vang, J.R.; Kær, S.K. High temperature PEM fuel cell performance characterisation with CO and CO2 using electrochemical impedance spectroscopy. Int. J. Hydrogen Energy 2011, 36, 9815–9830. [Google Scholar] [CrossRef]

- Jullian, G.; Cadet, C.; Rosini, S.; Gérard, M.; Heiries, V.; Bérenguer, C. Fault Detection and Isolation for Proton Exchange Membrane Fuel Cell Using Impedance Measurements and Multiphysics Modeling. Fuel Cells 2020, 20, 558–569. [Google Scholar] [CrossRef]

- Robin, C.; Gerard, M.; d’Arbigny, J.; Schott, P.; Jabbour, L.; Bultel, Y. Development and experimental validation of a PEM fuel cell 2D-model to study heterogeneities effects along large-area cell surface. Int. J. Hydrogen Energy 2015, 40, 10211–10230. [Google Scholar] [CrossRef]

- De, S.; Puig, V.; Quevedo, J. PEM Fuel Cell System Robust LPV model-based Fault Diagnosis. In Proceedings of the 20th International Workshop on Principles of Diagnosis, Stockholm, Sweden, 14–17 June 2009. [Google Scholar]

- de Lira, S.; Puig, V.; Quevedo, J. Robust LPV model-based sensor fault diagnosis and estimation for a PEM fuel cell system. In Proceedings of the 2010 Conference on Control and Fault-Tolerant Systems (SysTol), Nice, France, 6–8 October 2010; pp. 819–824. [Google Scholar] [CrossRef]

- de Lira, S.; Puig, V.; Quevedo, J.; Husar, A. LPV observer design for PEM fuel cell system: Application to fault detection. J. Power Sources 2011, 196, 4298–4305. [Google Scholar] [CrossRef]

- Rotondo, D.; Fernandez-Canti, R.M.; Tornil-Sin, S.; Blesa, J.; Puig, V. Robust fault diagnosis of proton exchange membrane fuel cells using a Takagi-Sugeno interval observer approach. Int. J. Hydrogen Energy 2016, 41, 2875–2886. [Google Scholar] [CrossRef]

- Liu, J.; Luo, W.; Yang, X.; Wu, L. Robust Model-Based Fault Diagnosis for PEM Fuel Cell Air-Feed System. IEEE Trans. Ind. Electron. 2016, 63, 3261–3270. [Google Scholar] [CrossRef]

- Bougatef, Z.; Abdelkrim, N.; Aitouche, A.; Abdelkrim, M. Fault detection of a PEMFC system based on delayed LPV observer. Int. J. Hydrogen Energy 2020, 45, 11233–11241. [Google Scholar] [CrossRef]

- Yang, D.; Wang, Y.; Chen, Z. Robust fault diagnosis and fault tolerant control for PEMFC system based on an augmented LPV observer. Int. J. Hydrogen Energy 2020, 45, 13508–13522. [Google Scholar] [CrossRef]

- Kamal, E.; Aitouche, A. Fuzzy observer-based fault tolerant control against sensor faults for proton exchange membrane fuel cells. Int. J. Hydrogen Energy 2020, 45, 11220–11232. [Google Scholar] [CrossRef]

- Yang, Q.; Aitouche, A.; Ould Bouamama, B. Fault detection and isolation of PEM fuel cell system by analytical redundancy. In Proceedings of the 18th Mediterranean Conference on Control & Automation (MED), Marrakech, Morocco, 23–25 June 2010; pp. 1371–1376. [Google Scholar] [CrossRef]

- Aitouche, A.; Yang, Q.; Bouamama, B.O. Fault detection and isolation of PEM fuel cell system based on nonlinear analytical redundancy: An application via parity space approach. Eur. Phys. J. -Appl. Phys. 2011, 54, 23408. [Google Scholar] [CrossRef]

- Steiner, N.Y.; Candusso, D.; Hissel, D.; Moçoteguy, P. Model-based diagnosis for proton exchange membrane fuel cells. Math. Comput. Simul. 2010, 81, 158–170. [Google Scholar] [CrossRef]

- Jemeï, S.; Hissel, D.; Péra, M.; Kauffmann, J. On-board fuel cell power supply modeling on the basis of neural network methodology. J. Power Sources 2003, 124, 479–486. [Google Scholar] [CrossRef]

- Jemei, S.; Hissel, D.; PÉraPera, M.C.; Kauffmann, J.M. A New Modeling Approach of Embedded Fuel-Cell Power Generators Based on Artificial Neural Network. IEEE Trans. Ind. Electron. 2008, 55, 437–447. [Google Scholar] [CrossRef]

- Sisworahardjo, N.; Yalcinoz, T.; El-Sharkh, M.; Alam, M. Neural network model of 100W portable PEM fuel cell and experimental verification. Int. J. Hydrogen Energy 2010, 35, 9104–9109. [Google Scholar] [CrossRef]

- Chang, K.Y. The optimal design for PEMFC modeling based on Taguchi method and genetic algorithm neural networks. Int. J. Hydrogen Energy 2011, 36, 13683–13694. [Google Scholar] [CrossRef]

- Chávez-Ramírez, A.U.; Muñoz-Guerrero, R.; Durón-Torres, S.; Ferraro, M.; Brunaccini, G.; Sergi, F.; Antonucci, V.; Arriaga, L. High power fuel cell simulator based on artificial neural network. Int. J. Hydrogen Energy 2010, 35, 12125–12133. [Google Scholar] [CrossRef]

- Yousfi Steiner, N.; Hissel, D.; Moçotéguy, P.; Candusso, D. Diagnosis of polymer electrolyte fuel cells failure modes (flooding & drying out) by neural networks modeling. Int. J. Hydrogen Energy 2011, 36, 3067–3075. [Google Scholar] [CrossRef]

- Kamal, M.M.; Yu, D. Fault detection and isolation for PEMFC systems under closed-loop control. In Proceedings of the 2012 UKACC International Conference on Control, Cardiff, UK, 3–5 September 2012; pp. 976–981. [Google Scholar] [CrossRef]

- Kamal, M.; Yu, D.; Yu, D. Fault detection and isolation for PEM fuel cell stack with independent RBF model. Eng. Appl. Artif. Intell. 2014, 28, 52–63. [Google Scholar] [CrossRef]

- Sisworahardjo, N.; El-Sharkh, M.; Alam, M. Neural network controller for microturbine power plants. Electr. Power Syst. Res. 2008, 78, 1378–1384. [Google Scholar] [CrossRef]

- Ma, R.; Breaz, E.; Liu, C.; Bai, H.; Briois, P.; Gao, F. Data-driven Prognostics for PEM Fuel Cell Degradation by Long Short-term Memory Network. In Proceedings of the 2018 IEEE Transportation Electrification Conference and Expo (ITEC), Long Beach, CA, USA, 13–15 June 2018; pp. 102–107. [Google Scholar] [CrossRef]

- Wang, F.K.; Cheng, X.-B.; Hsiao, K.C. Stacked long short-term memory model for proton exchange membrane fuel cell systems degradation. J. Power Sources 2020, 448, 227591. [Google Scholar] [CrossRef]

- Zuo, J.; Lv, H.; Zhou, D.; Xue, Q.; Jin, L.; Zhou, W.; Yang, D.; Zhang, C. Deep learning based prognostic framework towards proton exchange membrane fuel cell for automotive application. Appl. Energy 2021, 281, 115937. [Google Scholar] [CrossRef]

- Auria, L.; Moro, R. Support Vector Machines (SVM) as a Technique for Solvency Analysis. SSRN Electron. J. 2008. [Google Scholar] [CrossRef]

- Zhong, Z.D.; Zhu, X.J.; Cao, G.Y. Modeling a PEMFC by a support vector machine. J. Power Sources 2006, 160, 293–298. [Google Scholar] [CrossRef]

- Zhong, Z.D.; Zhu, X.J.; Cao, G.Y.; Shi, J.H. A hybrid multi-variable experimental model for a PEMFC. J. Power Sources 2007, 164, 746–751. [Google Scholar] [CrossRef]

- Li, X.; Cao, G.y.; Zhu, X.j. Modeling and control of PEMFC based on least squares support vector machines. Energy Convers. Manag. 2006, 47, 1032–1050. [Google Scholar] [CrossRef]

- Lu, J.; Zahedi, A. Modelling and control of PEMFC based on support vector machine. In Proceedings of the AUPEC 2011, Brisbane, QLD, Australia, 25–28 September 2011; pp. 1–6. [Google Scholar]

- Li, C.-H.; Zhu, X.-J.; Cao, G.-Y.; Sui, S.; Hu, M.-R. Identification of the Hammerstein model of a PEMFC stack based on least squares support vector machines. J. Power Sources 2008, 175, 303–316. [Google Scholar] [CrossRef]

- Babuška, R. Fuzzy Modeling for Control; International Series in Intelligent Technologies; Springer: Dordrecht, The Netherlands, 2012. [Google Scholar]

- Hissel, D.; Candusso, D.; Harel, F. Fuzzy-clustering durability diagnosis of polymer electrolyte fuel cells dedicated to transportation applications. IEEE Trans. Veh. Technol. 2007, 56, 2414–2420. [Google Scholar] [CrossRef]

- Zheng, Z.; Petrone, R.; Péra, M.C.; Hissel, D.; Béchérif, M.; Pianese, C.; Yousfi Steiner, N.; Sorrentino, M. A review on non-model based diagnosis methodologies for PEM fuel cell stacks and systems. Int. J. Hydrogen Energy 2013, 38, 8914–8926. [Google Scholar] [CrossRef]

- Hissel, D.; Marion-Péra, M.C.; Kauffmann, J. Diagnosis of automotive fuel cell power generators. J. Power Sources 2004, 128, 239–246. [Google Scholar] [CrossRef]

- Fennie, C.; Reisner, D.; Barbetta, J.; Singh, P. Fuzzy Logic-Based State-of-Health Determination of PEM Fuel Cells. In Proceedings of the Electric Vehicle Symposium and Exhibition, Nanjing, China, 25–28 June 2001. [Google Scholar]

- Zheng, Z.; Péra, M.C.; Hissel, D.; Becherif, M.; Agbli, K.S.; Li, Y. A double-fuzzy diagnostic methodology dedicated to online fault diagnosis of proton exchange membrane fuel cell stacks. J. Power Sources 2014, 271, 570–581. [Google Scholar] [CrossRef]

- Kishor, N.; Mohanty, S. Fuzzy modeling of fuel cell based on mutual information between variables. Int. J. Hydrogen Energy 2010, 35, 3620–3631. [Google Scholar] [CrossRef]

- Sun, T.; Yan, S.-J.; Cao, G.-Y.; Zhu, X.-J. Modelling and control PEMFC using fuzzy neural networks. J. Zhejiang Univ.-Sci. A 2005, 6, 1084–1089. [Google Scholar]

- Vural, Y.; Ingham, D.B.; Pourkashanian, M. Performance prediction of a proton exchange membrane fuel cell using the ANFIS model. Int. J. Hydrogen Energy 2009, 34, 9181–9187. [Google Scholar] [CrossRef]

- Asghari, S.; Mokmeli, A.; Samavati, M. Study of PEM fuel cell performance by electrochemical impedance spectroscopy. Int. J. Hydrogen Energy 2010, 35, 9283–9290. [Google Scholar] [CrossRef]

| Classes | Sub-Classes | Benefits/Advantages | Limitations/Drawbacks |

|---|---|---|---|

| White-box | Parametric identification |

|

|

| Observer-based |

|

| |

| Parity space |

|

| |

| Black-box | Neural network |

|

|

| Support vector machine |

|

| |

| Grey-box | Fuzzy logic |

|

|

| ANFIS |

|

|

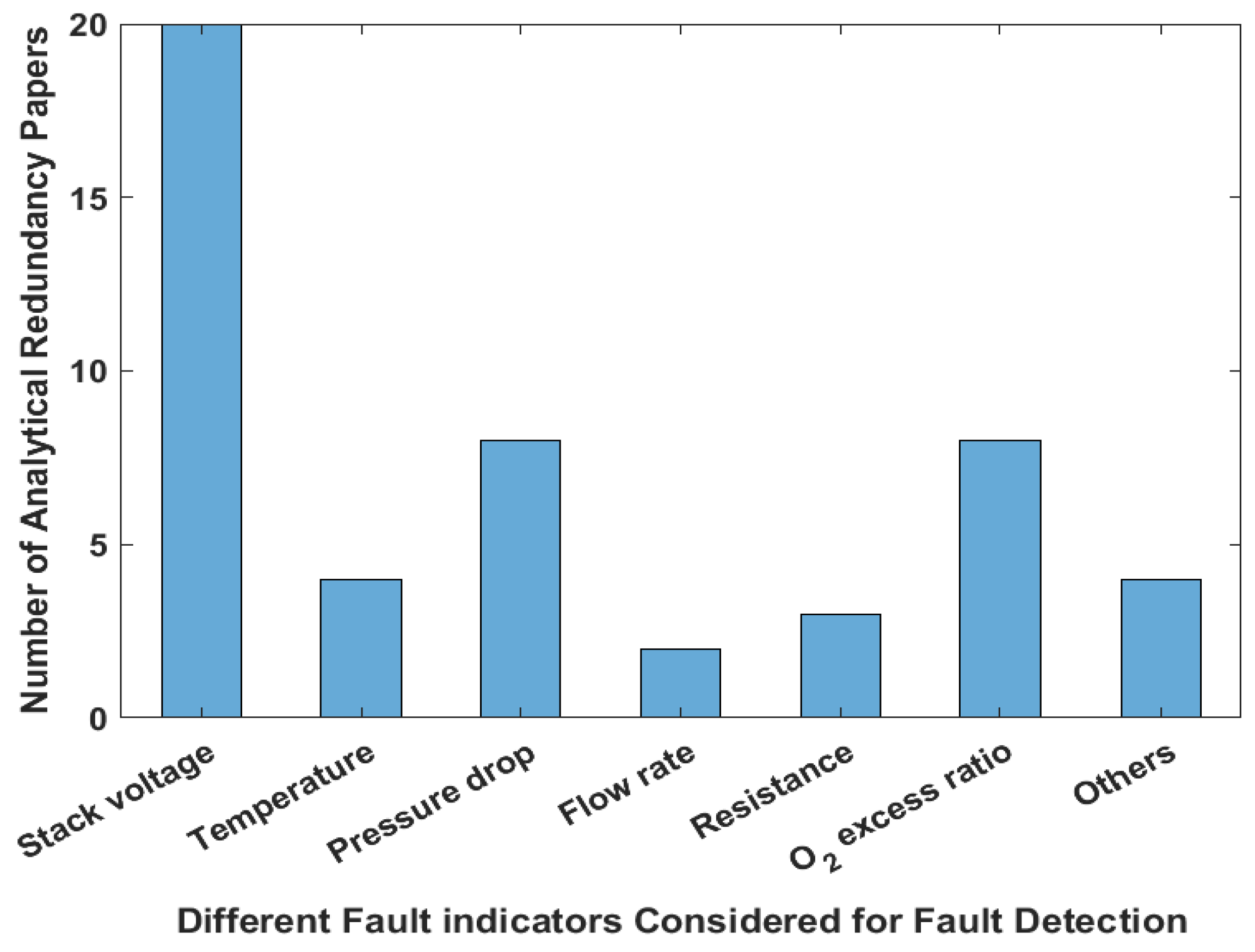

| Methods/Indicators | Stack Voltage | Temperature | Pressure Drop | Flow Rate | Resistance | O2 Excess Ratio | Others |

|---|---|---|---|---|---|---|---|

| Parametric identification | [18,19,22,23,26,66] | [22] | [22] | [14,24,25] | |||

| Observer-based | [28,29,30] | [29] | [28,29,31] | [28,29,30,32] | [30,31] | ||

| Parity space | [37] | [37] | |||||

| Neural networks | [38,39,40,41,42,43,44] | [43] | [38,44] | [41] | [45,46] | [41] | |

| Support vector machine | [52,53] | [56] | [56] | [54,55] | |||

| Fuzzy logic | [63] | ||||||

| ANFIS | [65] | [64] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sani, M.; Piffard, M.; Heiries, V. Fault Detection for PEM Fuel Cells via Analytical Redundancy: A Critical Review and Prospects. Energies 2023, 16, 5446. https://doi.org/10.3390/en16145446

Sani M, Piffard M, Heiries V. Fault Detection for PEM Fuel Cells via Analytical Redundancy: A Critical Review and Prospects. Energies. 2023; 16(14):5446. https://doi.org/10.3390/en16145446

Chicago/Turabian StyleSani, Mukhtar, Maxime Piffard, and Vincent Heiries. 2023. "Fault Detection for PEM Fuel Cells via Analytical Redundancy: A Critical Review and Prospects" Energies 16, no. 14: 5446. https://doi.org/10.3390/en16145446

APA StyleSani, M., Piffard, M., & Heiries, V. (2023). Fault Detection for PEM Fuel Cells via Analytical Redundancy: A Critical Review and Prospects. Energies, 16(14), 5446. https://doi.org/10.3390/en16145446