1. Introduction

The importance of increasing energy efficiency and exploiting renewable energy sources to reduce carbon emissions because of their adverse environmental impact has been a catalyst in the development of organic Rankine cycle (ORC) systems [

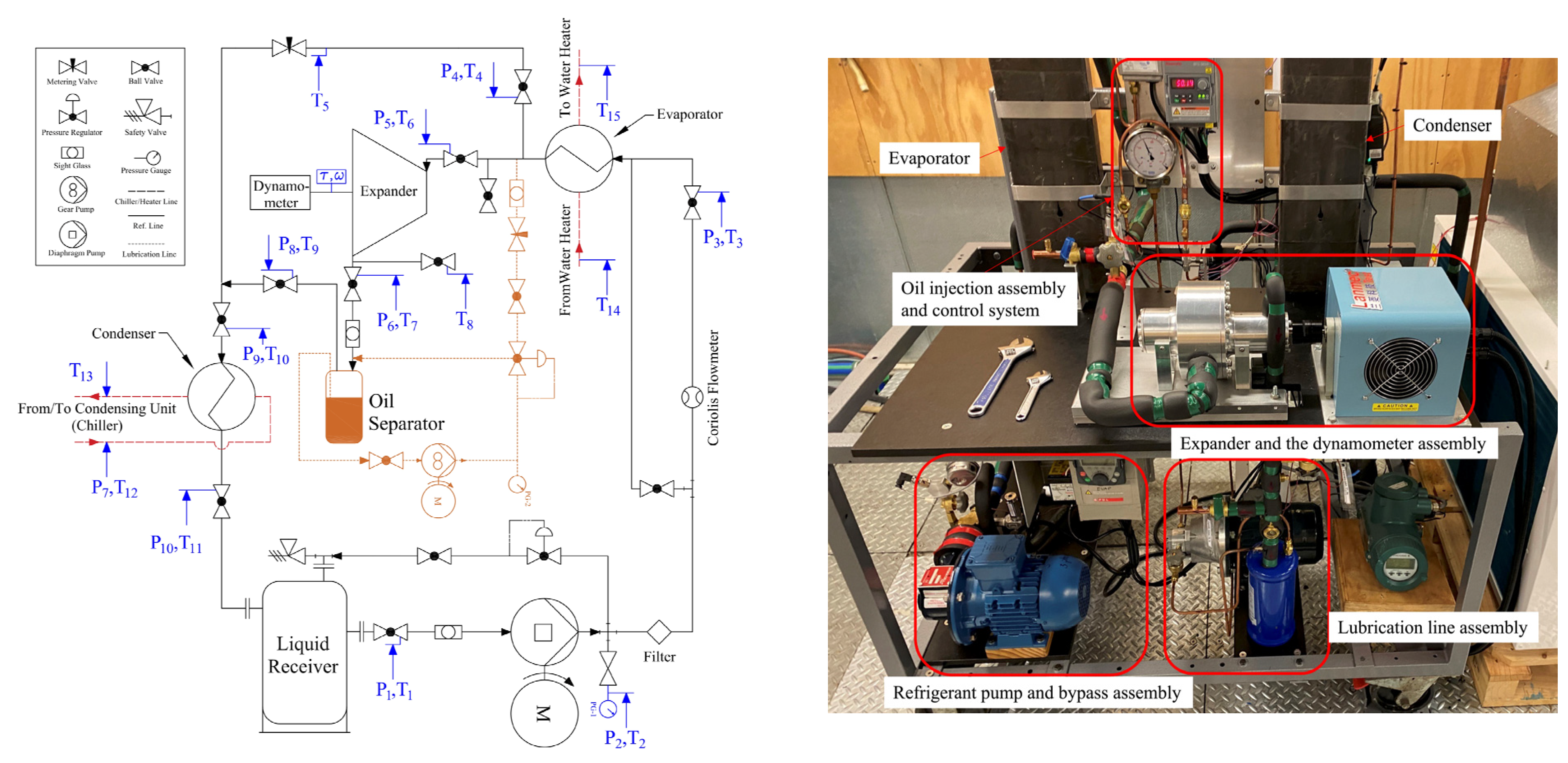

1]. The working principle of ORC systems is analogous to the conventional steam Rankine cycle, but water is replaced with an organic working fluid. The organic fluid is pressurised using pumps and goes through the evaporator, in which the liquid evaporates. Consequently, the high-pressure vapour expands through the expansion device and generates power. Then, the low-pressure vapour enters the condenser, cools down, and turns into the liquid phase before entering the pump. Potential applications of ORC systems mainly comprise renewable energies like geothermal, biomass, solar, and waste heat recovery (WHR) [

2]. WHR using ORC technology has been proven to be a potential solution for increasing the efficiency of the existing systems and converting low to medium-temperature sources (< 400 °C) to power [

3]. According to [

4], the heat from power plants, industrial processes, and exhaust gas from internal combustion engines stands for the most available low to medium-temperature heat sources.

Over the last two decades, extensive research has been carried out on ORCs, proving their promising features like simplicity, compactness, suitability for combined heat and power (CHP) generation, and adaptability to different heat sources. An ORC system works similarly to a conventional steam Rankine power plant but uses a different organic working fluid to overcome water use issues at low temperatures. The low boiling temperature of organic working fluids allows power generation from low-temperature heat sources and condenser operation at pressures higher than atmospheric. Despite the maturity of ORCs for medium to large applications (>100 kWe), efforts are still required to make these systems competitive at micro to small scales (<100 kWe) [

5]. This is particularly due to the technical challenges at smaller scales, such as low Carnot efficiency and turbine design [

6].

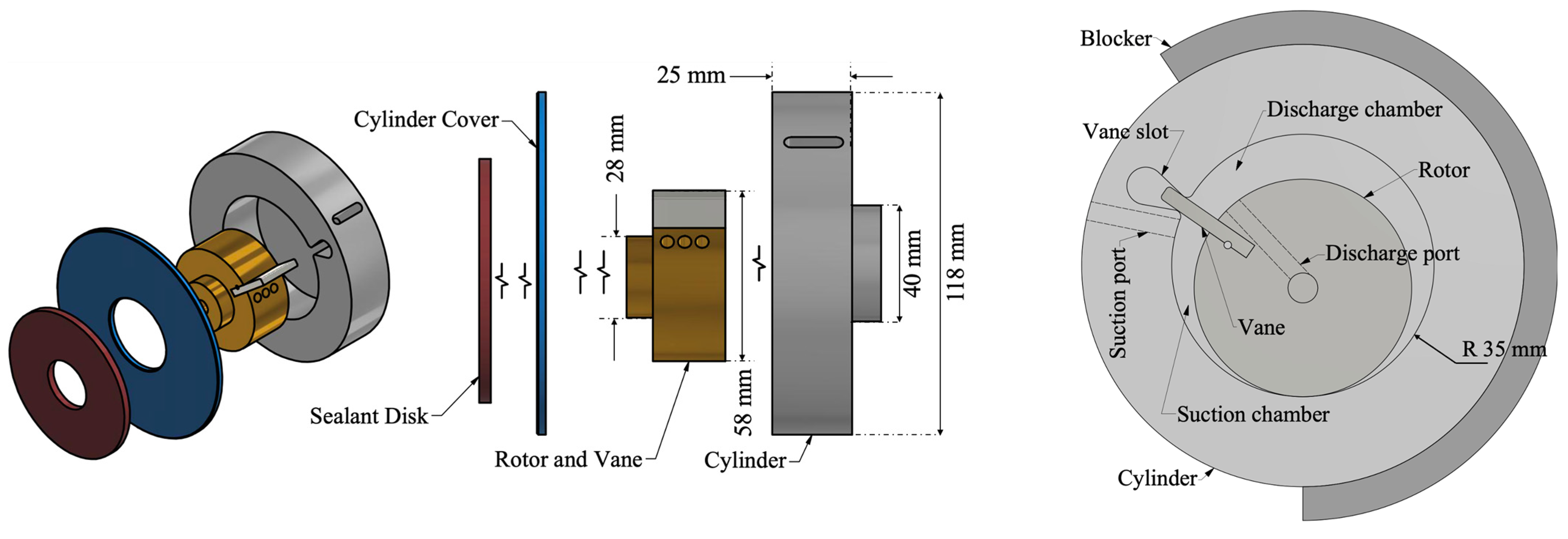

In particular, the expansion device plays a key role in ORC applications as it substantially impacts the efficiency of the system and its overall cost. Expanders are generally categorized into two major types: dynamic machines (turbines) and volumetric machines such as scroll, screw, reciprocating piston, and rotary vane expanders. In a volumetric expander, the high-pressure gas expands and increases the volume of the working chamber and rotates the shaft. At the same time, the kinetic energy drives the impeller and rotates the shaft in a dynamic machine [

7]. Dynamic machines are not usually suited for micro-to-small scales, and volumetric machines are preferred because of their low cost, low maintenance, and reliable operation [

1]. Their main deficiencies are low isentropic efficiency and inherent internal leakages. In addition, the current volumetric expanders are mostly converted from their compressor peers instead of being particularly designed for power generation systems resulting in limited operating temperature and pressure [

8]. Furthermore, they usually bring relatively low power output and mechanical efficiency.

A review of the volumetric expanders for low-grade heat and WHR applications showed that the screw and scroll expanders are more suitable than the vane and piston types [

9]. More precisely, frictional losses and internal leakages account for the main sources of inefficiency in piston and vane expanders. In literature, many studies have investigated the performance of volumetric expanders in ORCs. In particular, Dumont et al. [

8] experimentally studied the performance of four different types of expanders, including scroll, screw, piston and roots, in a small-scale ORC system with R245fa as the working fluid. The authors found that the scroll expander showed the highest isentropic efficiency of up to 76%, followed by the screw expander with 53%. However, they also noted the need for more experimental investigations on different technologies, sizes, and fluids. Most expansion devices studied in ORCs were converted compressors from air-conditioning and refrigeration systems [

10]. In addition, several novel volumetric expanders have been proposed in recent years to reduce the inefficiencies of their conventional peers. For example, Fatigati et al. [

11,

12] theoretically and experimentally investigated the performance of a novel sliding vane rotary expander with a dual intake port which allows the expander to operate at a lower inlet pressure. Giuffrida et al. [

13] studied the performance of a balanced rolling piston expander where no timing mechanisms were required. Krishna et al. [

14] studied a rotating spool expander for ORC applications. Instead, Naseri et al. [

15] studied the performance of a modified revolving vane expander (M-RVE) in a micro-scale ORC system for WHR applications for the first time. Their results showed an isentropic efficiency of up to 42.5% for the M-RVE expander. However, the effect of the expander lubricant on the refrigerant properties was not considered in the isentropic efficiency calculation. Their results also suggested that the highest volumetric efficiency was achieved at high lubricant mass flow rates at similar pressure ratios. The authors concluded that the optimal lubricant mass flow rate must be identified, and the expander tested at higher pressure ratios.

In micro-to-small-scale applications, lubrication plays a vital role in the reliability and performance of a volumetric expander since it helps reduce internal leakages and frictional losses. In practice, the expander oil does not affect the refrigerant pump much since the refrigerant is at the liquid phase only, and the oil circulation rate (

OCR) is typically lower than 5%. Different measures have been implemented for lubricating the volumetric expanders in ORC systems. Biao et al. [

16] investigated two conventional lubricant supply configurations in ORCs. They proposed a new one: (1) a separate lubrication loop where the oil is pumped into the expander suction line and separated before entering the condenser, (2) no external loop where the oil is mixed with the refrigerant and travels through the cycle, and (3) a lubricant oil separator is added between the evaporator and the expander, but oil goes to the condenser too. In the last configuration, the refrigerant-oil mixture is condensed by the condenser after leaving the expander and then pressurized and transported to the evaporator. The high-pressure liquid and vapour enter the oil separator while the vapour travels through the expander, and the extracted lubricant is injected into the bearings and mechanical seals without a pump. The oil separator before the expander showed satisfactory performance for volumetric expanders in ORCs. Zhou et al. [

17] investigated a WHR system for low-temperature flue gas using an ORC system using R123 as the working fluid. A scroll expander with a separate oil circuit with a constant oil flow rate was used to avoid the impact of the lubricant on the heat exchangers’ performance. The results showed the limiting impact of separate oil circuits on the power output due to the pressure drops caused by the additional oil circuit. Jingye et al. [

18] studied the impact of lubrication on the ORC systems in low-temperature WHR applications, where the lubricant oil was mixed with refrigerant in the operating system. Their results showed the significant impact of lubrication on the system performance, which is more sensitive under the lower lubricant oil charges. Recently, some of the authors of the present paper [

19] investigated the impact of the expander lubricant oil on the performances of the main components and especially of the scroll expander of a micro-scale ORC system. In their paper, a mixture of lubricant and refrigerant was travelling within the system components. Their results showed that lubricant oil leads to 5–15% capacity loss in the evaporator and condenser. Furthermore, neglecting the refrigerant-oil mixture properties resulted in overestimating the expander’s mechanical and volumetric efficiency. Dickes [

20] investigated charge-sensitive methods for the off-design performance characterisation of ORC systems. No oil separator was implemented in their study resulting in a fraction of lubricant going through the system. Grebner and Crawford’s model was implemented to model the lubricant-refrigerant thermophysical properties and calibrate the model using the experimental data in the literature. The Grebner and Crawfords’ model [

21] was a 7-coefficient model originally developed to simulate the properties of various mixtures of R134a and R12 with POE and PAG lubricants. The coefficients of the proposed model were calibrated using the experimental data.

The literature review demonstrates the significance of the expander oil entrainment on ORC systems in micro and small scales when the lubricant-refrigerant mixture migrates through the components. To the best of the authors’ knowledge, there is no work in the open literature addressing the impact of the expander lubricant on M-RVEs. Hence, the current study aims at assessing the impact of the expander lubricant on the main components of a micro-scale ORC system by calculating the performance parameters, specifically the isentropic efficiency and the filling factor, considering the lubricant-refrigerant mixture properties instead of the pure refrigerant properties.

Furthermore, the literature is lacking in investigating the individual relation between the lubricant mass flow rate and the expander performance parameters at different operating conditions, such as variations in the filling factor and oil mass flow rate at different expander shaft speeds. In addition, the impact of the variable oil mass flow rate on the performances of the main components of the ORC systems is missed in the literature. Such analysis may suggest a near optimum lubricant/refrigerant mass flow rate ratio through the system (oil circulation rate in the literature and this paper). In addition, the impact of the expander lubricant is more prominent in micro and small-scale ORC systems since their Carnot efficiency is inherently low because of low-temperature heat sources, and any losses in the thermal capacity of the heat exchangers, especially the evaporator, may considerably lower the efficiency of the system. The volume of heat exchangers is significantly larger than the one of the expanders, and a lower amount of oil disperses within them. Therefore, the real impact of the expander oil on other main components would not be seen in their measured performance data but in the calculated performance indicators considering the properties of the lubricant-refrigerant mixture. Hence, the impact of expander oil on the other components is investigated in this work, including the mixture properties, while the same experimental data in oil-free conditions are assumed to be valid. The main novelties of this work are as follows:

The impact of lubricant oil on the M-RVE prototype is investigated in the current study.

An M-RVE prototype is tested with an adjustable oil mass flow rate using an oil separator circuit and in a wider range of working conditions compared to the previous experimental campaign with the same machine.

The impacts of the lubricant oil on the performances of an M-RVE prototype are investigated theoretically and experimentally in terms of shaft power, volumetric efficiency (or filling factor), and isentropic efficiency.

With an adjustable oil mass flow rate, the individual relation between the performance parameters of the expander and the lubricant mass flow rate at different operating conditions is studied.

Considering the opposite impacts of the lubricant oil on the M-RVE volumetric and isentropic efficiencies compared to the evaporator thermal capacity, a near optimum value for the lubricant to the lubricant-refrigerant mixture for the M-RVE prototype in a micro-scale ORC is suggested.

3. Results and Discussion

The impact of the lubricant oil on the performance of the expander in terms of its isentropic and volumetric efficiencies is presented in this section. Following the assumptions described in

Section 2, an estimation of the effect of the lubricant oil on the evaporator is also presented.

3.1. Impact of the Lubricant on the M-RVE Prototype

In this study, a wide range of mass flow rates of the lubricant oil is tested to investigate the impact of lubrication on the

FF, shaft power, and

using the

OCR parameter.

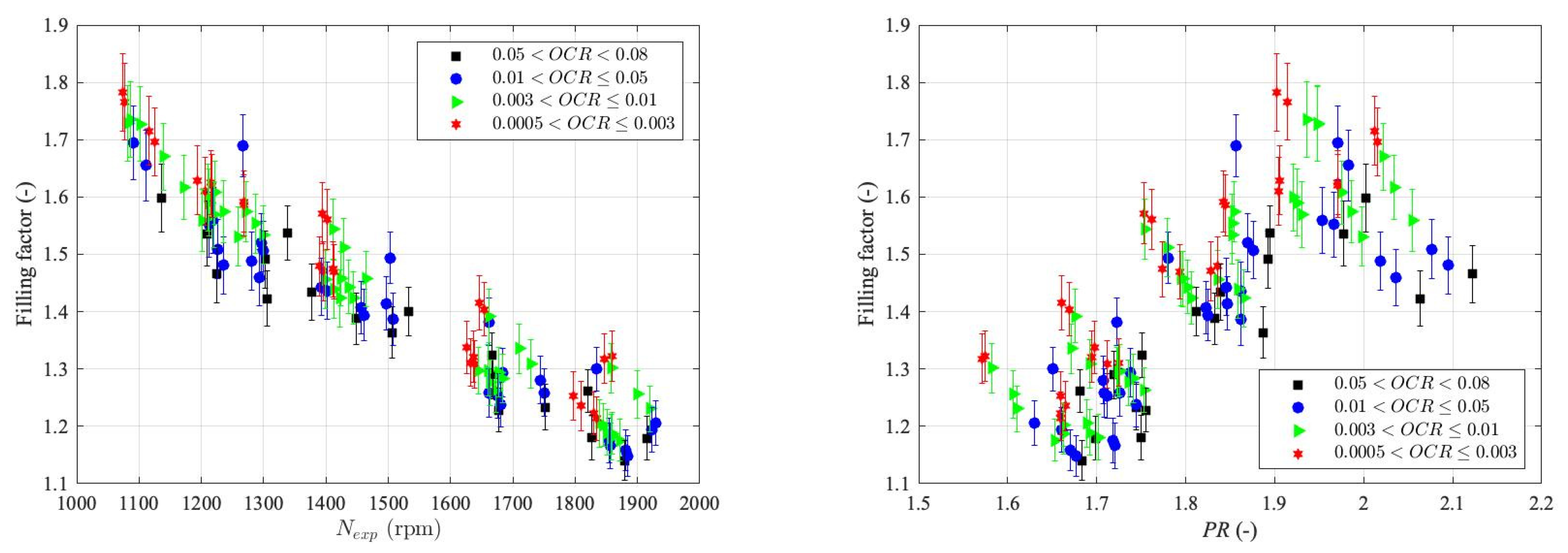

Figure 4 (left) demonstrates the changes in

FF at different shaft speeds for various ranges of

OCRs. Two general trends are observed: (1) the

FF drops as the shaft speed increases due to the lower leakages at the higher shaft speeds; (2) the

FF drops as the

OCR increases at constant shaft speeds, which is due to a better lubrication effect at the internal leakage paths leading to a lower leakage and consequently a lower

FF. In addition, the

FF experienced a moderate drop when the

OCR was increased in a wide range from 0.05% to 8% at constant shaft speeds. However, this drop was negligible for

OCRs higher than 1%.

Figure 4 (right) demonstrates the changes in

FF at different pressure ratios (

PRs) for different ranges of

OCRs. At a fixed

OCR, the

FF increases with an increase in

PR. This is due to a higher

PR across the leakage paths leading to higher leakages. Moreover, it is observed that higher

PRs are achieved with higher

OCRs. The

FF ranged from 1.1 to 1.8 in this study, where the lowest

FF corresponded to a

PR of 1.7, expander suction temperature of 54 °C, and shaft speed of 1879 rpm.

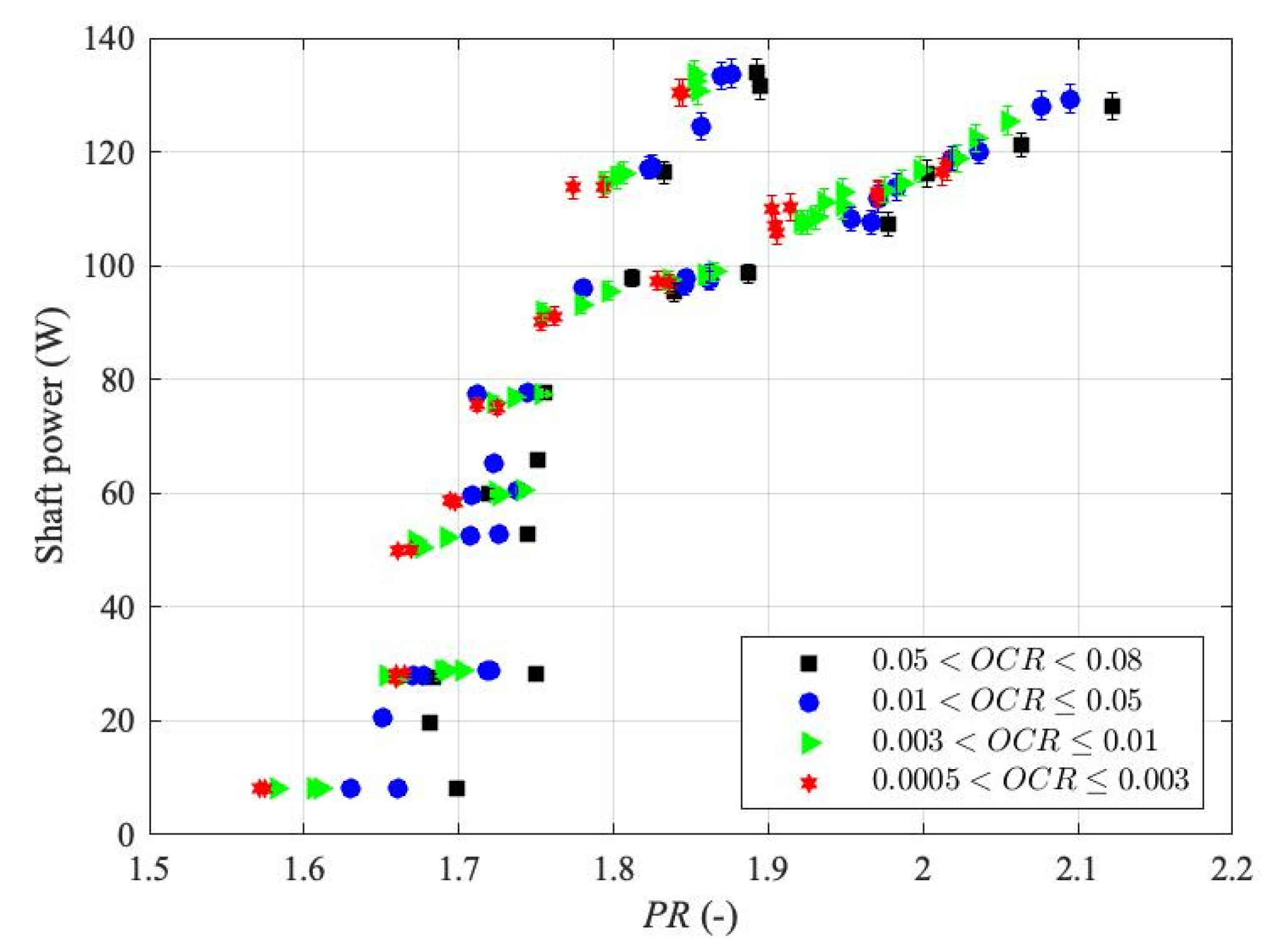

Figure 5 shows the shaft power versus the

PRs at different

OCRs. For the same

OCR, the shaft power increases when

PR increases. This is because a higher body force on the vane leads to higher torque at a similar shaft speed. However, as the

OCR increases, insignificant changes are observed in the power output.

Several parameters are involved in calculating the expander isentropic efficiency considering mixture properties: the expander shaft power, the refrigerant mass flow rate, the mixture enthalpy at the inlet, and the mixture isentropic enthalpy at the outlet. The mixture enthalpy at the expander inlet is calculated using Equation (12). For the mixture isentropic enthalpy at the outlet, Equation (16) is solved to find the isentropic mixture temperature (

) at the expander outlet pressure. Then, the mixture isentropic enthalpy at the expander outlet is calculated using Equation (12) using

.

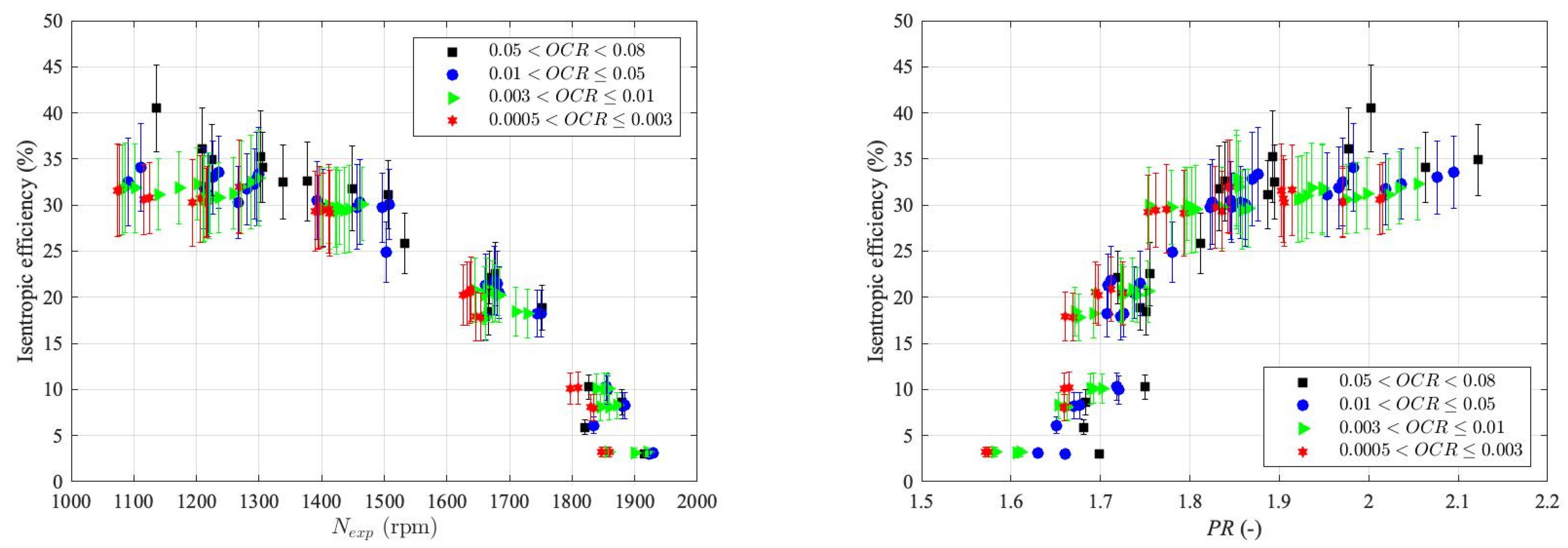

Figure 6 (left) illustrates the changes in the isentropic efficiency by the shaft speed at different

OCRs. The isentropic efficiency drops at higher shaft speeds for similar

OCRs. This is mainly due to the higher frictional loss at higher expander shaft speeds. Looking at the changes in the isentropic efficiency at different

OCRs, it can be observed that although the higher

OCR leads to higher

PRs and improves the

FF, the isentropic efficiency shows insignificant alteration with the change in the

OCR. This is due to a negligible change in the shaft power when increasing

OCR, as shown in

Figure 5.

Figure 6 (right) illustrates the isentropic efficiency by varying the

PR and shaft speed for different

OCRs. The isentropic efficiency increases with

PR until the values are close to the expander

BVR. This is because the higher body force acting on the vane leads to a higher torque value. The isentropic efficiency almost flattens at

PRs higher than the expander

BVR.

In an ideal case, the working fluid undergoes an ideal expansion from the suction pressure at to the discharge pressure at . In a real scenario, the fluid expands from at the suction pressure to an alternative pressure () at . The ratio of the suction pressure to this alternative internal pressure is called the built-in pressure ratio (BPR), which is proportional to the assuming working fluid as an ideal gas with a specific heat ratio of . If the imposed PR by the system is lower than the BPR (which is slightly higher than BVR), the working fluid undergoes an over-expansion.

On the other hand, the PRs higher than the BPR leads to under-expansion of the working fluid. In this study, the refrigerant experiences over-expansion in most cases leading to low isentropic efficiencies. As the PR increases to the BPR, the isentropic efficiency increases and flattens. It should be noted that the isentropic efficiency is expected to drop at PRs higher than the BPR due to the under-expansion losses. However, higher PRs were not achieved in this study due to the capacities and temperature limits of the heat source and sink. The range of the isentropic efficiency is 2.9–41% in this study.

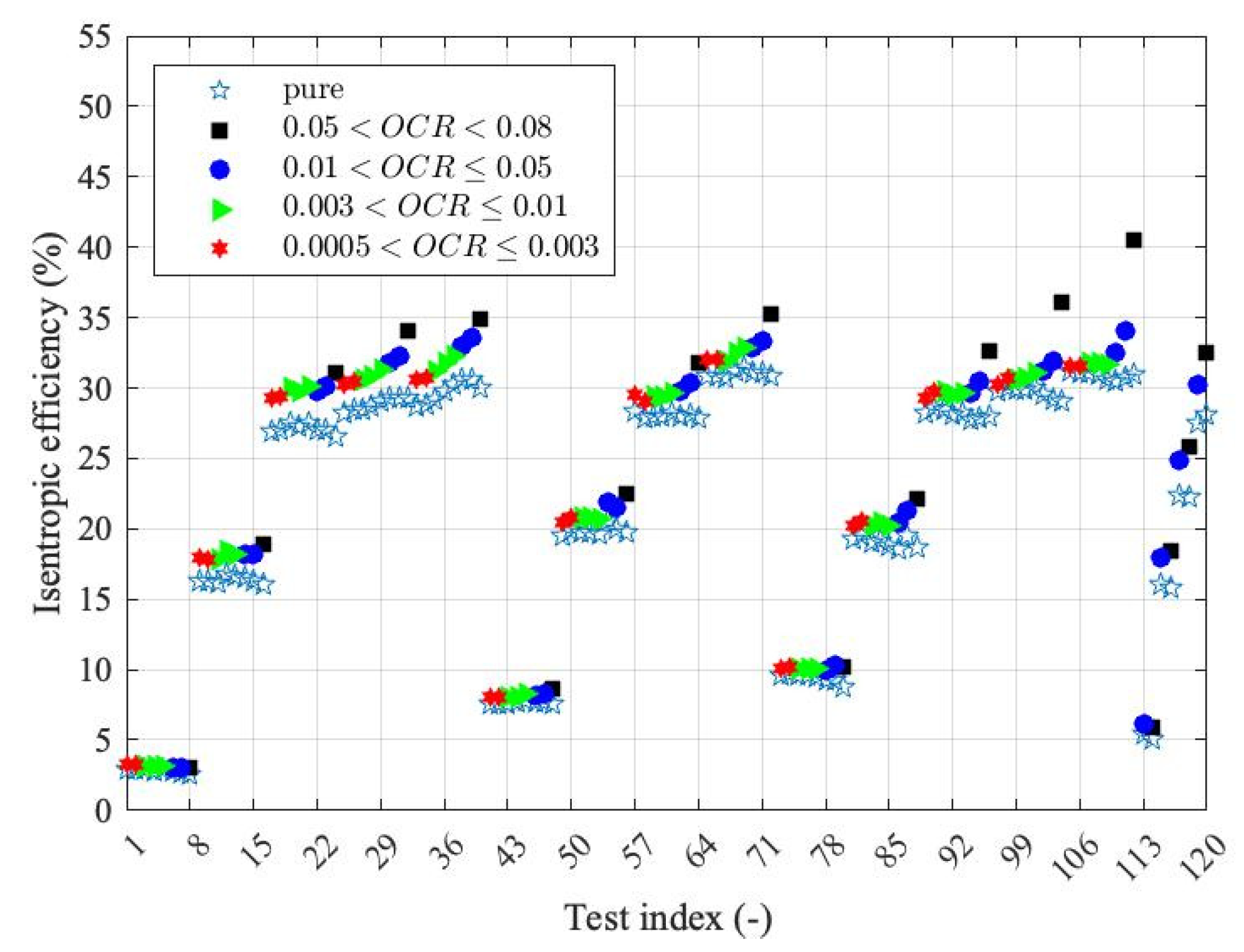

Figure 7 shows the expander isentropic efficiency considering the refrigerant-oil mixture properties compared to the one regarding the pure refrigerant properties. The results suggest that the isentropic efficiency of the refrigerant-oil mixture is calculated higher than the pure refrigerant in all cases. The difference is bigger in higher

OCRs. Therefore, lubricant oil enhances the expander isentropic efficiency, albeit to a limited extent.

3.2. Impact of the Refrigerant-Oil Mixture on the Evaporator

Although a higher

OCR does not change the isentropic efficiency of the expander significantly, the increased amount of lubricant may impact the evaporator’s performance. When no oil separator loop is implemented, the refrigerant-oil mixture travels through the ORC. As mentioned in

Section 2, the current experimental setup was designed with an oil separator loop to circulate the lubricant just through the expander. Still, it is helpful to predict the effect of different

OCRs on the performance of the evaporator in case simpler configurations are required to reduce the overall cost of the system and to avoid a dedicated oil circuit to reduce the system’s complexity.

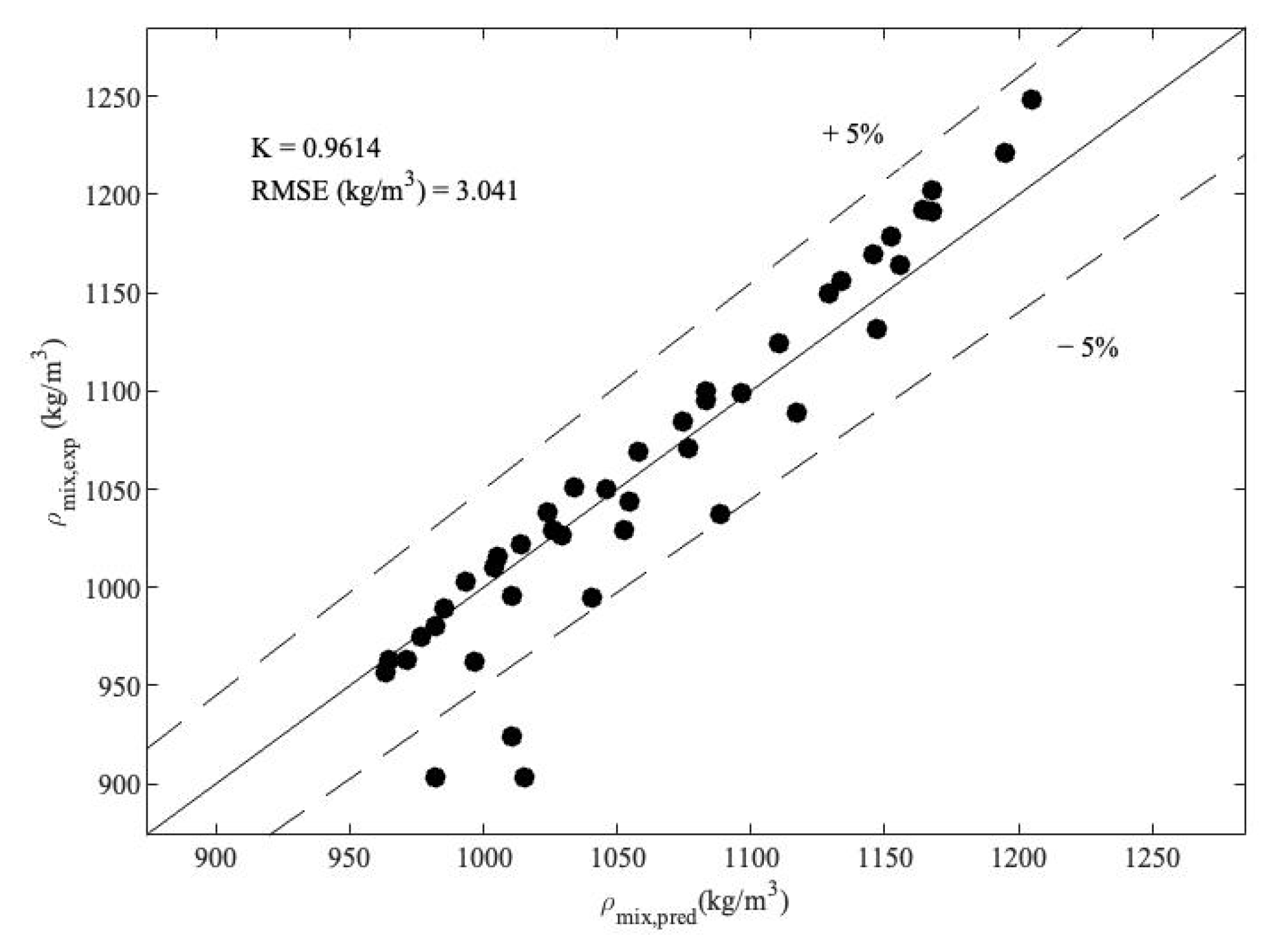

To investigate the impact of the mixture on the performance of the evaporator, it is necessary to calculate the mixture properties, including the refrigerant miscibility, density, and enthalpy, according to the methodology discussed in

Section 2.2.

A few assumptions are made for this analysis: (1) the

OCR truly represents the amount of the oil travelling through the ORC components, i.e., the same measured oil flow rate at the expander inlet travels through the refrigerant pump, evaporator and condenser; (2) when the refrigerant-oil mixture travels through the pump, the volumetric efficiency of the pump at a given pump speed remains the same as the calculated values using the pure refrigerant properties. It is worth mentioning that the amount of lubricant flowing through the system differs from the lubricant oil and refrigerant charge. In this work, the amount of lubricant injected into the expander inlet could be adjusted irrespective of the charge amount. With these assumptions, the mixture mass flow rate through the ORC system can be calculated:

Given the calculated mixture mass flow rate and the enthalpies at the inlet and outlet of the evaporator for the pure and mixed refrigerant, the evaporator thermal power is calculated as the following:

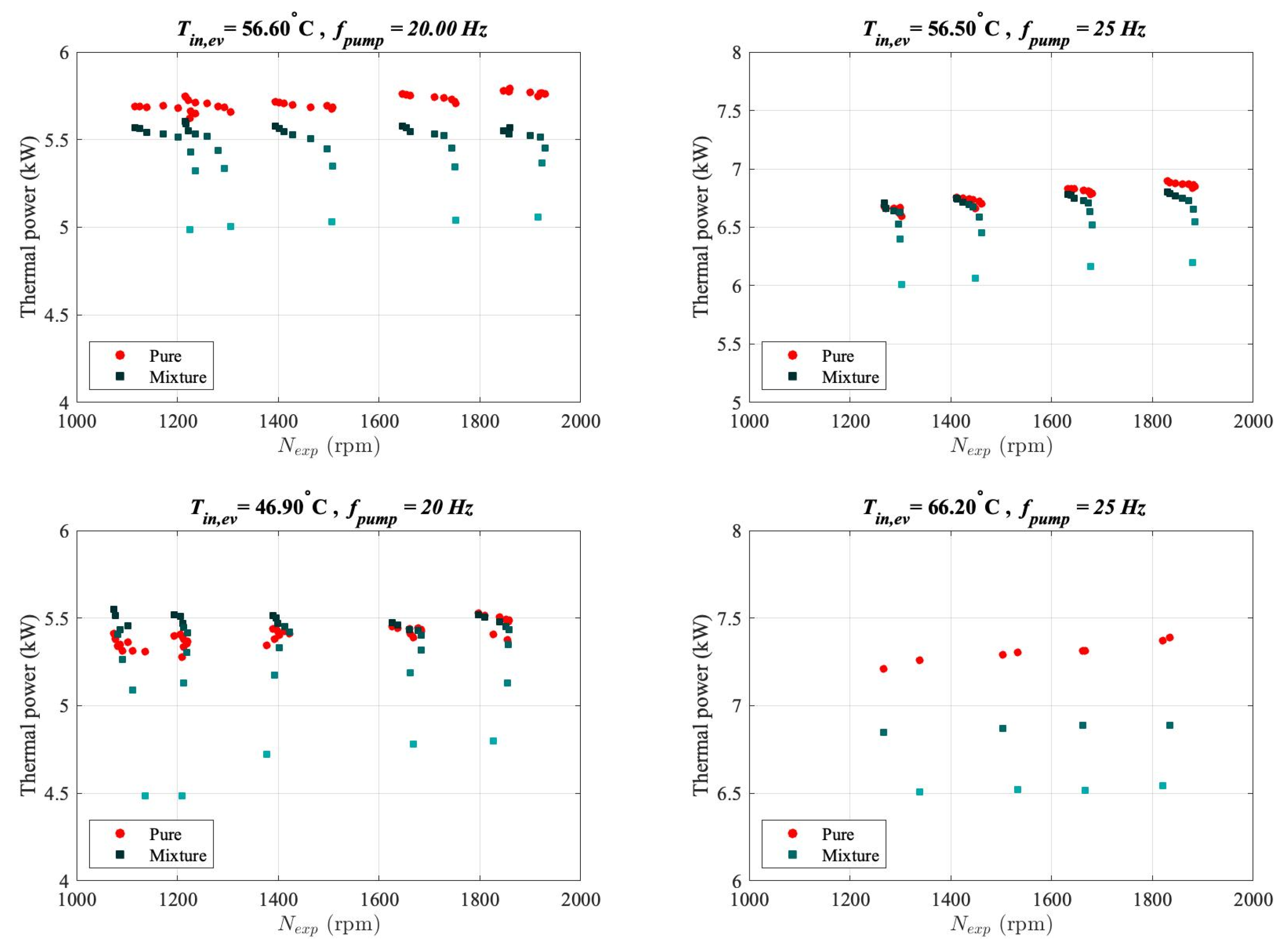

Figure 8 represents the evaporator thermal power by the pure refrigerant and refrigerant-oil mixture in the evaporator at different heat source temperatures, refrigerant mass flow rate, and

OCR (oil mass flow rate) versus the expander shaft speed. The results for each scenario demonstrate a significant drop in the evaporator thermal power as the

OCR increases. To quantify this, the capacity loss for the evaporator is obtained using the following equation [

19], where

is the evaporator thermal power calculated using the pure refrigerant properties.

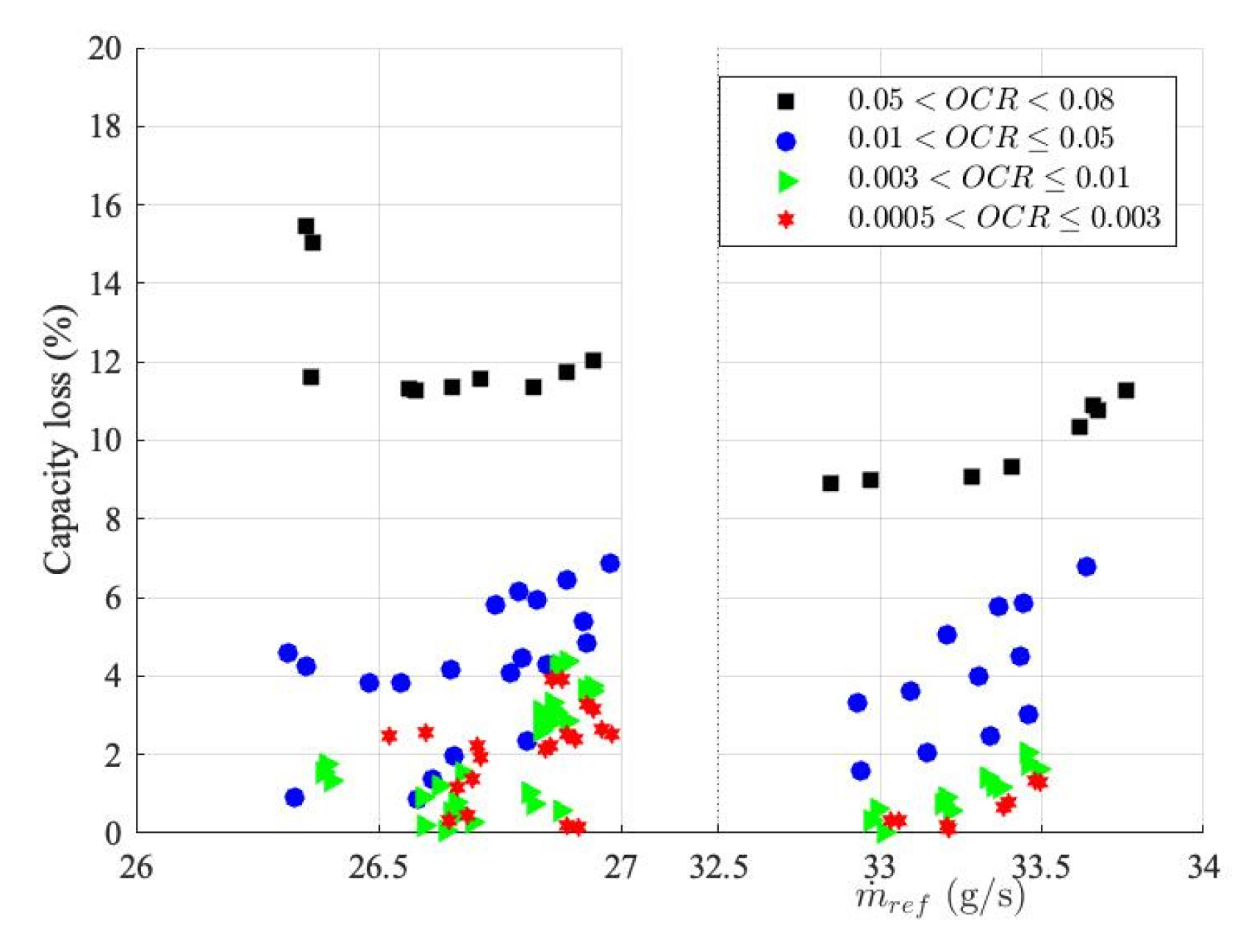

Figure 9 shows the capacity loss at different mass flow rates of the mixture. The impact of the oil on the evaporator capacity loss is significant at higher

OCRs. The minimum capacity loss at

OCRs higher than 5% is 8.8%, while the maximum capacity loss of almost 6.8% is predictable for

OCRs lower than 5%.

The literature does not focus on the impact of the oil on the boiling heat transfer coefficient, as the majority reported a decrease for oil concentrations above 1%, which was drastic for concentrations above 5% [

29]. However, some reported increments in the boiling heat transfer coefficient, such as in [

30,

31], where an increment was observed for concentrations around 3%. The impact of oil on boiling heat transfer coefficient may depend on several parameters like

OCR, refrigerant miscibility, the oil type, the working fluid, the heat flux, the mass flow rate, and the tube or channel geometry. These parameters affect the flow pattern of the boiling flow at the end, which is determinative of the conclusion about the impact of the oil on the evaporator capacity. Nonetheless, the evaporator capacity is penalised in all cases with different

OCRs, as shown in

Figure 9.

Considering the different impacts of the expander oil on the expander and evaporator performance indicator, an almost optimum OCR can be suggested for the M-RVE in ORC systems. At OCRs higher than 1%, changes in the expander FF and the shaft power were negligible, and the expander isentropic efficiency improved considerably with OCR. Considering the significant drop in the evaporator capacity for OCRs of more than 1%, it can be concluded that an OCR of about 1% would be suitable for the M-RVE prototype in micro-scale ORC systems. However, as Equation (1) suggests, the OCR is a function of the oil and refrigerant mass flow rates. It does not represent the mass charge ratio of the lubricant to the refrigerant, and it depends on the internal leakages of the expander. The internal leakages depend on the leakage clearances, working temperature, and the expander shaft speed. For the exact oil and refrigerant charges and at a constant oil mass flow rate, a higher shaft speed results in a lower OCR. Therefore, the OCR is indicative for predicting the near optimum mass charge ratio of the lubricant to refrigerant at the design shaft speed and for specific refrigerant, lubricant, and expander types. A more holistic conclusion requires further experimental studies to observe the impact of these parameters on the near-optimum OCR and the associated mass charge ratio of the lubricant to the refrigerant.

4. Conclusions

In this study, an M-RVE prototype was tested in a micro-scale ORC test rig with an adjustable oil mass flow rate. The impacts of the lubricant oil on the performances of the M-RVE prototype were investigated in terms of expander FF, shaft power, and isentropic efficiency within a wide range of OCRs. The ORC system presented in this study only had an oil separator loop circulating the oil through the expander. Hence, the impact of the oil on the performance of the evaporator, which significantly affects the overall efficiency of the ORC system, could not be studied experimentally. Nevertheless, at the micro-to-small scale, a dedicated oil circuit introduces further complexity to the system with potentially limited benefits to its performance.

As the main impact of oil on the evaporator is due to misinterpretation of the performance indicators due to low OCRs in practice, the refrigerant-oil mixture properties are used to investigate the evaporator capacity loss. Considering the opposite impact of the lubricant oil on the M-RVE volumetric and isentropic efficiencies and the evaporator thermal power, a compromised value for the OCR is suggested for micro-scale ORC systems. The main findings of this study are summarised in the following:

The OCR being altered within a wide range from 0.05% to 8% for constant shaft speeds, the FF demonstrates an insignificant drop for OCRs higher than 1%.

It is observed that higher PRs are achieved at higher OCRs. Meanwhile, the shaft power shows a negligible change with the OCR.

Although a higher OCR improves the FF, the isentropic efficiency shows insignificant alteration with the change in the OCR.

The isentropic efficiency of the refrigerant-oil mixture is higher than pure refrigerant for all scenarios, while this difference increases with increasing the OCR.

The evaporator thermal power calculated at different scenarios for pure and refrigerant-oil mixtures dropped significantly as the OCR increased.

The minimum evaporator capacity loss at OCRs higher than 5% is 8.8%, while the maximum capacity loss of almost 6.8% is observed for OCRs lower than 5%.

Therefore, due to the negligible changes in the FF, the shaft power, and the isentropic efficiency, and the large drop in the evaporator thermal power for OCRs of more than 1%, this value presents an approximate optimal OCR for the studied M-RVE prototype in the micro-scale ORC rig.

In addition, this study provides indications to consider a more realistic design target for volumetric expanders with the lubrication requirement corresponding to the OCR ≤ 1% instead of dry machines for micro-to-small scale ORC systems. Notably, OCR does not represent the mass charge ratio of the lubricant to the refrigerant, which is one of the boundary conditions defining the ORC systems. OCR can indicate the near-optimum mass charge ratio of the lubricant to the refrigerant. Despite this work suggests a near optimum OCR of 1% for the studied MRVE working with R134a and POE mixture, a holistic conclusion about the near optimum OCRs for volumetric expanders and the associated near optimum mass charge ratio of the lubricant to refrigerant requires further studies with other types of volumetric expanders, working fluids, and lubricants.