Medium-Term Effects and Economic Analysis of Biochar Application in Three Mediterranean Crops

(This article belongs to the Section D1: Advanced Energy Materials)

Abstract

1. Introduction

2. Materials and Methods

2.1. Biochar

2.2. Biochar Analysis

2.3. Field Experiments

2.3.1. Biochar Amendment in Corn Crops

2.3.2. Biochar Amendment in Lavandin

2.3.3. Biochar Amendment in Vineyards

2.4. Soil Analysis on Corn

2.5. Statistical Analysis

3. Results

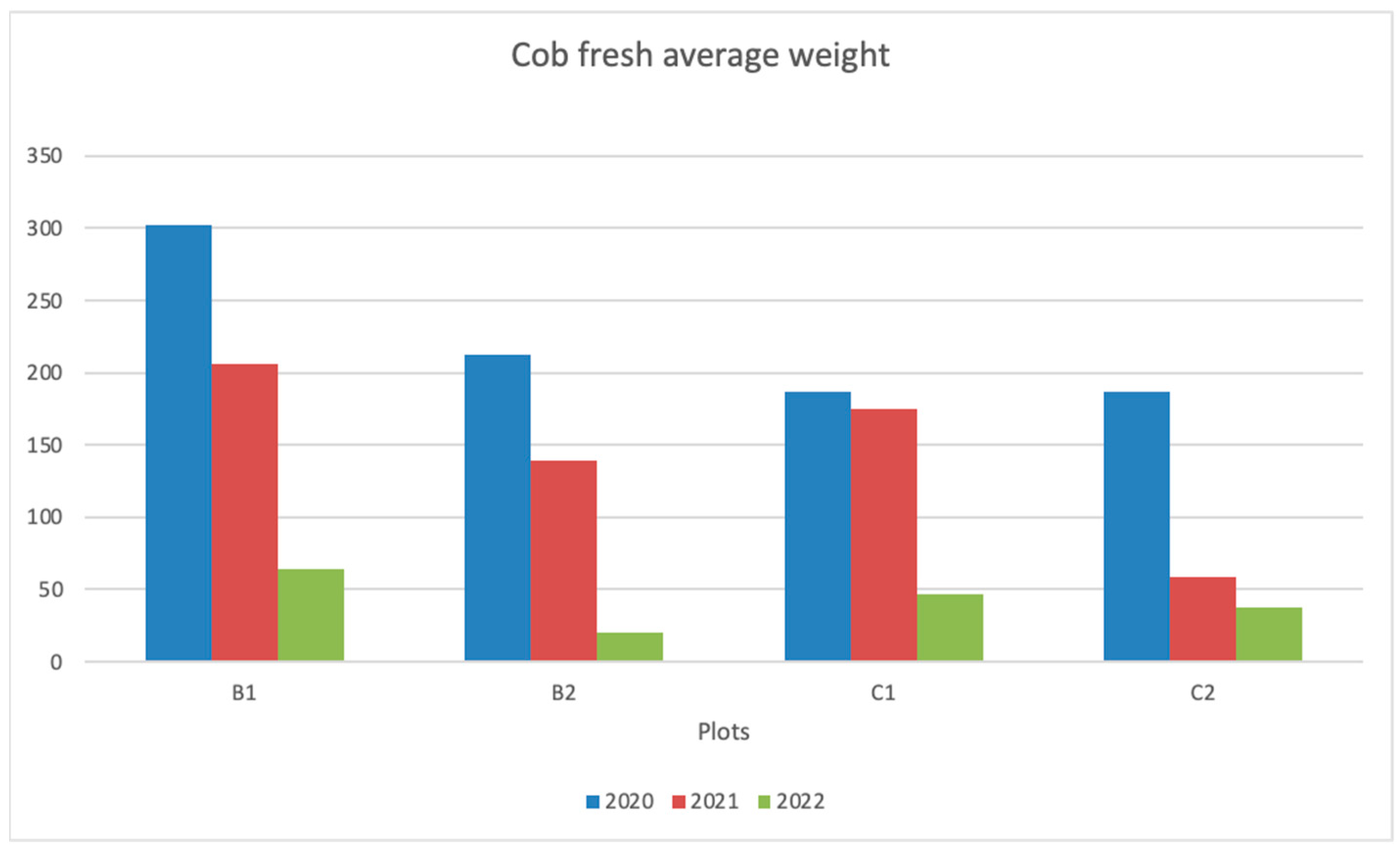

3.1. Fresh Cob Production in 2021 and 2022

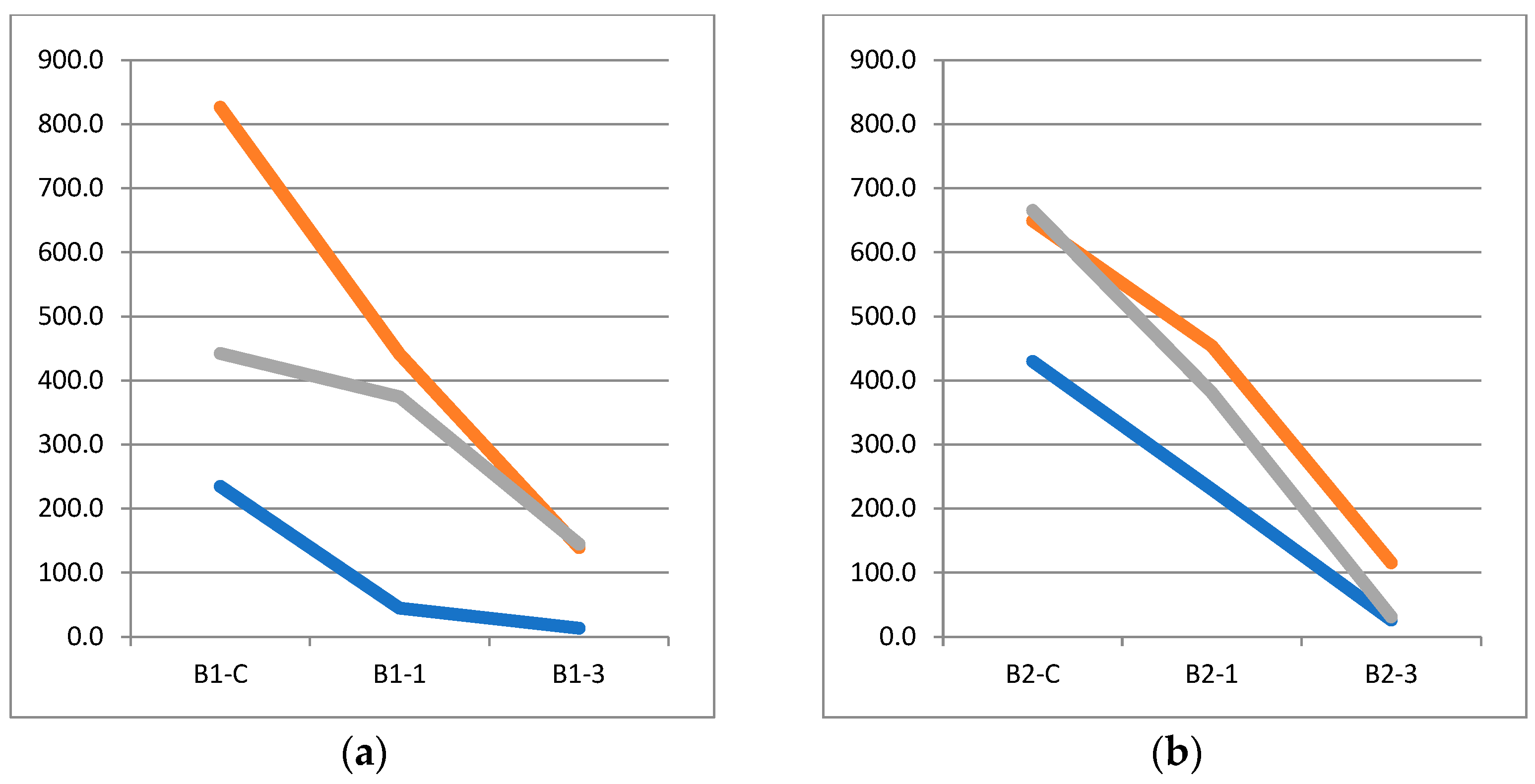

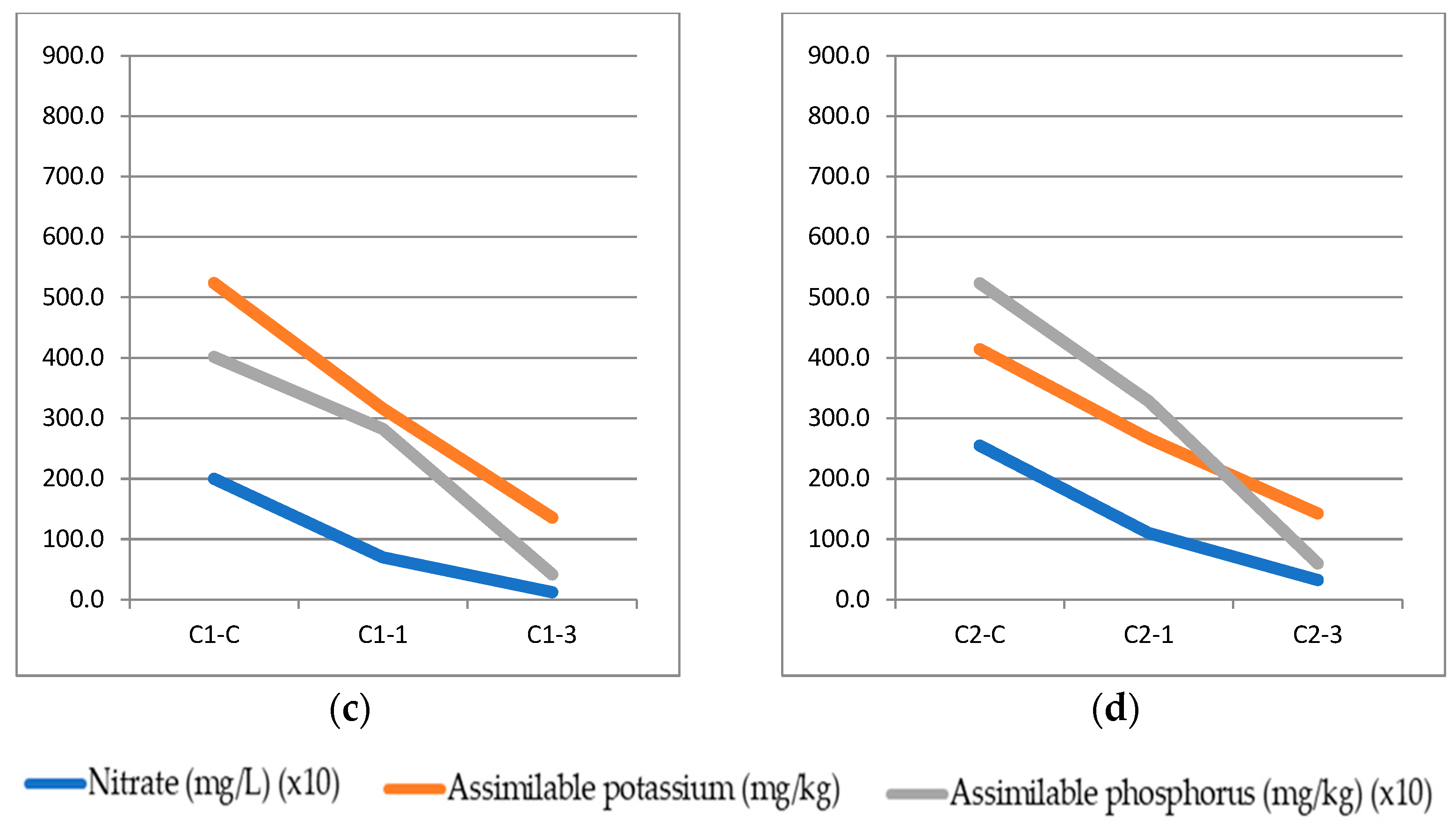

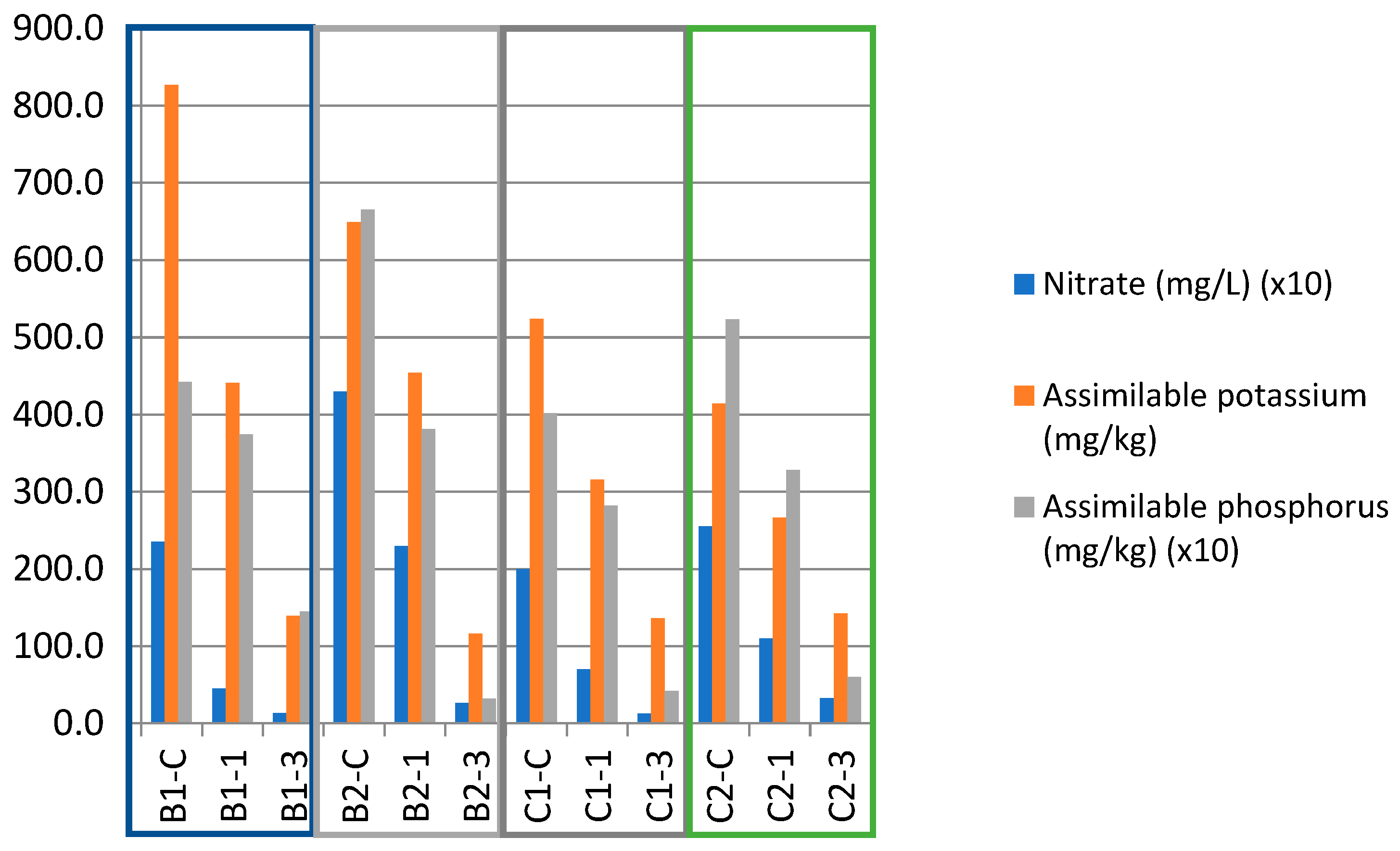

3.2. Soil Analysis

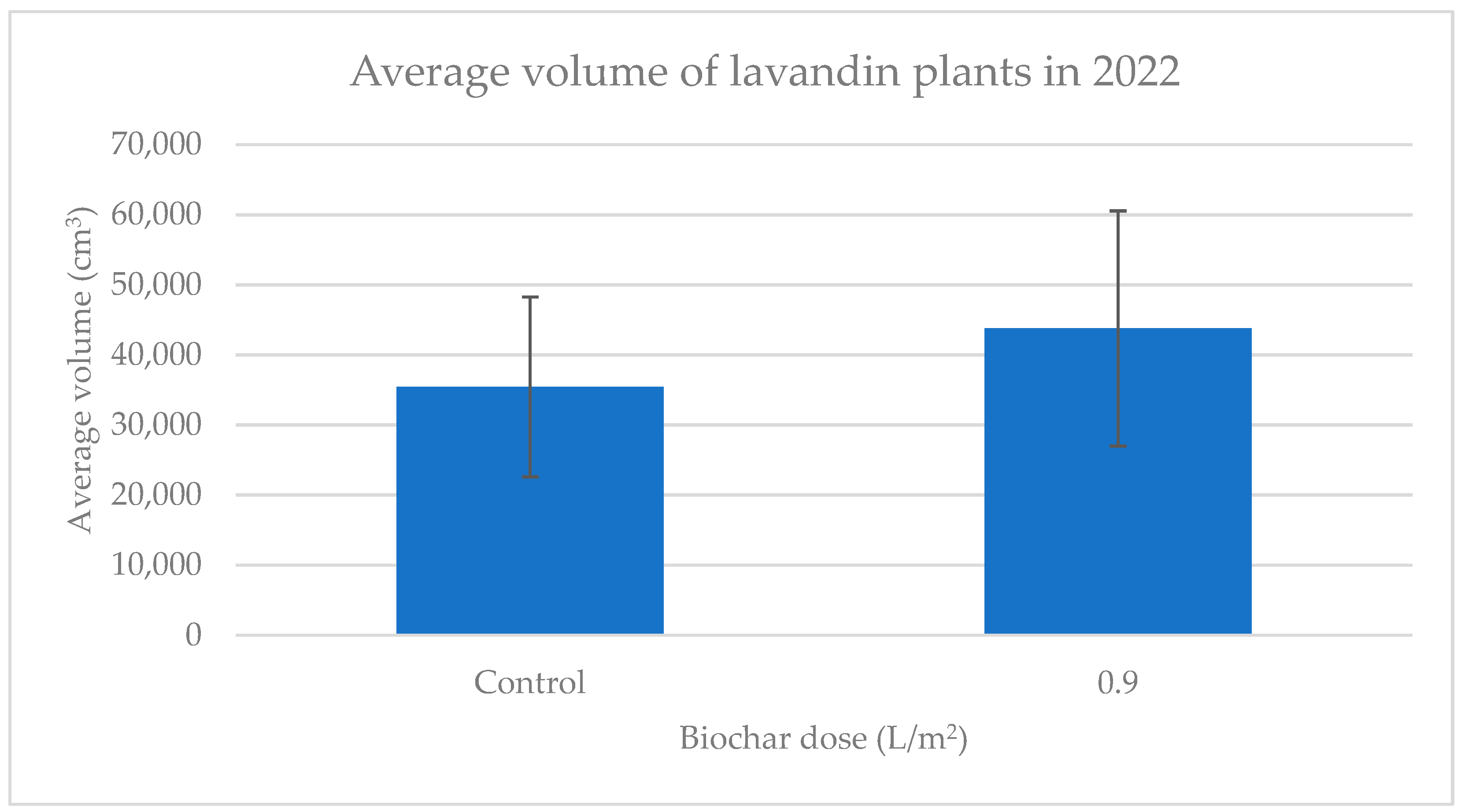

3.3. Effect of Biochar Application on Lavandin

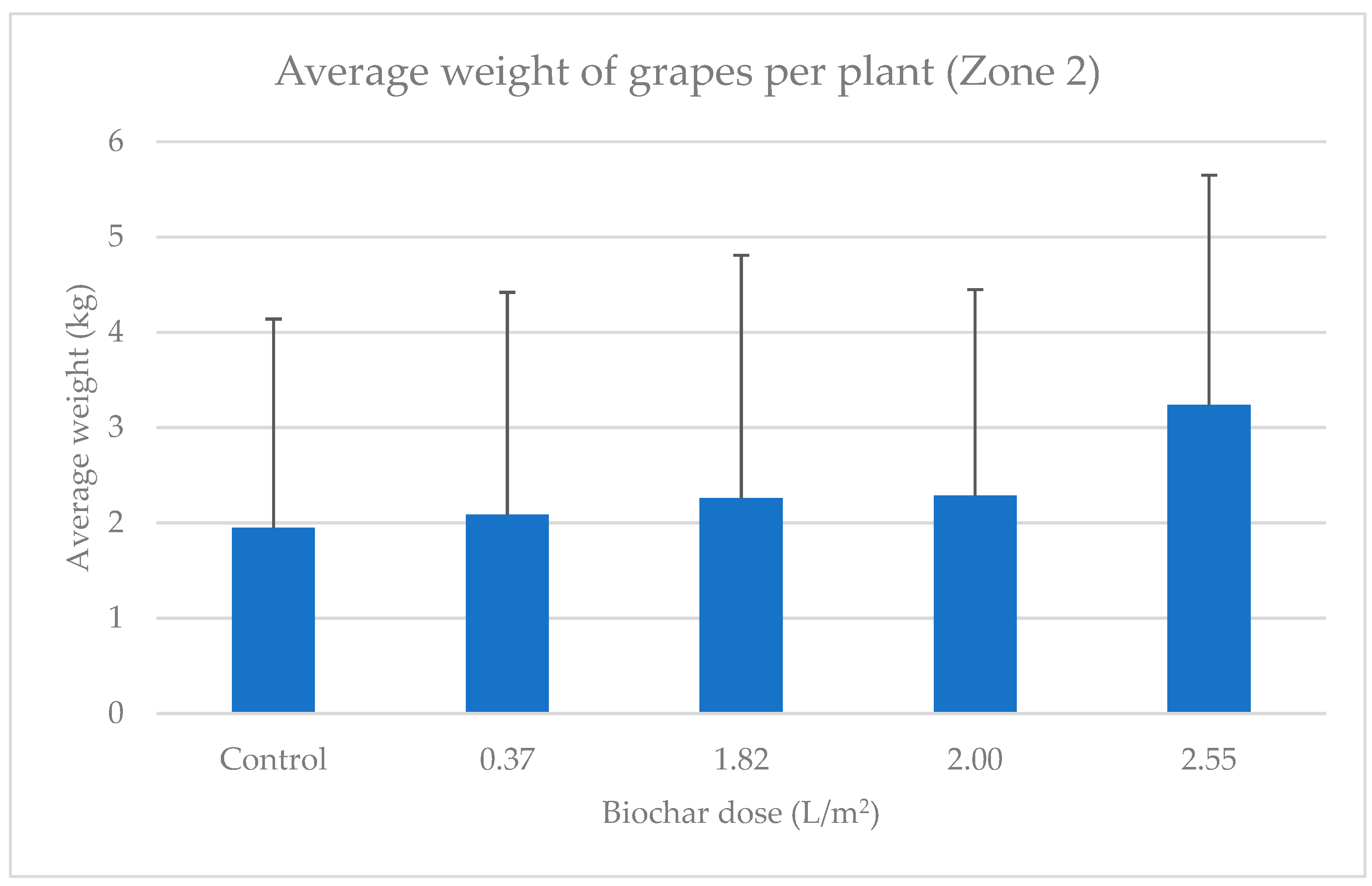

3.4. Effect of Biochar Application on Grapevine in 2021

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAOSTAT Food and Agriculture Data. 2019. Available online: https://www.fao.org/3/ca6030en/ca6030en.pdf (accessed on 15 March 2023).

- Wanger, T.C.; DeClerck, F.; Garibaldi, L.A.; Ghazoul, J.; Kleijn, D.; Klein, A.-M.; Kremen, C.; Mooney, H.; Perfecto, I.; Powell, L.L. Integrating agroecological production in a robust post-2020 Global Biodiversity Framework. Nat. Ecol. Evol. 2020, 4, 1150–1152. [Google Scholar] [CrossRef] [PubMed]

- Pradhan, A.; Chan, C.; Roul, P.K.; Halbrendt, J.; Sipes, B. Potential of conservation agriculture (CA) for climate change adaptation and food security under rainfed uplands of India: A transdisciplinary approach. Agric. Syst. 2018, 163, 27–35. [Google Scholar] [CrossRef]

- Horrigan, L.; Lawrence, R.S.; Walker, P. How sustainable agriculture can address the environmental and human health harms of industrial agriculture. Environ. Health Perspect. 2002, 110, 445–456. [Google Scholar] [CrossRef] [PubMed]

- Schulz, H.; Dunst, G.; Glaser, B. Positive effects of composted biochar on plant growth and soil fertility. Agron. Sustain. Dev. 2013, 33, 817–827. [Google Scholar] [CrossRef]

- Devereux, R.C.; Sturrock, C.J.; Mooney, S.J. The effects of biochar on soil physical properties and winter wheat growth. Earth Environ. Sci. Trans. R. Soc. Edinb. 2012, 103, 13–18. [Google Scholar] [CrossRef]

- Schulz, H.; Glaser, B. Effects of biochar compared to organic and inorganic fertilizers on soil quality and plant growth in a greenhouse experiment. J. Plant Nutr. Soil Sci. 2012, 175, 410–422. [Google Scholar] [CrossRef]

- Huang, L.; Gu, M. Effects of biochar on container substrate properties and growth of plants—A review. Horticulturae 2019, 5, 14. [Google Scholar] [CrossRef]

- Aguirre, J.L.; Martín, M.T.; González, S.; Peinado, M. Effects and economic sustainability of biochar application on corn production in a mediterranean climate. Molecules 2021, 26, 3313. [Google Scholar] [CrossRef]

- González-Pernas, F.M.; Grajera-Antolín, C.; García-Cámara, O.; González-Lucas, M.; Martín, M.T.; González-Egido, S.; Aguirre, J.L. Effects of biochar on biointensive horticultural crops and its economic viability in the Mediterranean climate. Energies 2022, 15, 3407. [Google Scholar] [CrossRef]

- Brewer, C.E. Biochar Characterization and Engineering; Iowa State University: Ames, IA, USA, 2012; ISBN 126739062X. [Google Scholar] [CrossRef]

- Crombie, K.; Mašek, O.; Sohi, S.P.; Brownsort, P.; Cross, A. The effect of pyrolysis conditions on biochar stability as determined by three methods. GCB Bioenergy 2013, 5, 122–131. [Google Scholar] [CrossRef]

- Břendová, K.; Tlustoš, P.; Száková, J.; Habart, J. Biochar properties from different materials of plant origin. Eur. Chem. Bull. 2012, 1, 535–539. [Google Scholar]

- Li, H.; Dong, X.; da Silva, E.B.; de Oliveira, L.M.; Chen, Y.; Ma, L.Q. Mechanisms of metal sorption by biochars: Biochar characteristics and modifications. Chemosphere 2017, 178, 466–478. [Google Scholar] [CrossRef]

- Zhang, C.; Zeng, G.; Huang, D.; Lai, C.; Chen, M.; Cheng, M.; Tang, W.; Tang, L.; Dong, H.; Huang, B. Biochar for environmental management: Mitigating greenhouse gas emissions, contaminant treatment, and potential negative impacts. Chem. Eng. J. 2019, 373, 902–922. [Google Scholar] [CrossRef]

- Mukherjee, A.; Lal, R. Biochar impacts on soil physical properties and greenhouse gas emissions. Agronomy 2013, 3, 313–339. [Google Scholar] [CrossRef]

- Spokas, K.A.; Reicosky, D.C. Impacts of sixteen different biochars on soil greenhouse gas production. Ann. Environ. Sci. 2009, 3, 179–193. [Google Scholar]

- Li, Y.; Hu, S.; Chen, J.; Müller, K.; Li, Y.; Fu, W.; Lin, Z.; Wang, H. Effects of biochar application in forest ecosystems on soil properties and greenhouse gas emissions: A review. J. Soils Sediments 2018, 18, 546–563. [Google Scholar] [CrossRef]

- Kumar, M.; Xiong, X.; Wan, Z.; Sun, Y.; Tsang, D.C.W.; Gupta, J.; Gao, B.; Cao, X.; Tang, J.; Ok, Y.S. Ball milling as a mechanochemical technology for fabrication of novel biochar nanomaterials. Bioresour. Technol. 2020, 312, 123613. [Google Scholar] [CrossRef]

- Rodriguez-Narvaez, O.M.; Peralta-Hernandez, J.M.; Goonetilleke, A.; Bandala, E.R. Biochar-supported nanomaterials for environmental applications. J. Ind. Eng. Chem. 2019, 78, 21–33. [Google Scholar] [CrossRef]

- Li, S.; Huang, D.; Cheng, M.; Wei, Z.; Du, L.; Wang, G.; Chen, S.; Lei, L.; Chen, Y.; Li, R. Application of sludge biochar nanomaterials in Fenton-like processes: Degradation of organic pollutants, sediment remediation, sludge dewatering. Chemosphere 2022, 307, 135873. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, H.; Cai, L.; Guo, J.; Wang, Y.; Ji, L.; Song, W. Preparation and characterization of macroalgae biochar nanomaterials with highly efficient adsorption and photodegradation ability. Materials 2018, 11, 1709. [Google Scholar] [CrossRef]

- Baltrėnas, P.; Baltrėnaitė, E.; Spudulis, E. Biochar from pine and birch morphology and pore structure change by treatment in biofilter. Water Air Soil Pollut. 2015, 226, 69. [Google Scholar] [CrossRef]

- Deng, S.; Chen, J.; Chang, J. Application of biochar as an innovative substrate in constructed wetlands/biofilters for wastewater treatment: Performance and ecological benefits. J. Clean. Prod. 2021, 293, 126156. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, J.; Feng, Y. The effects of biochar addition on soil physicochemical properties: A review. Catena 2021, 202, 105284. [Google Scholar] [CrossRef]

- Trinh, B.; Werner, D.; Reid, B.J. Application of a full-scale wood gasification biochar as a soil improver to reduce organic pollutant leaching risks. J. Chem. Technol. Biotechnol. 2017, 92, 1928–1937. [Google Scholar] [CrossRef]

- Knicker, H. How does fire affect the nature and stability of soil organic nitrogen and carbon? A review. Biogeochemistry 2007, 85, 91–118. [Google Scholar] [CrossRef]

- Naeem, I.; Masood, N.; Turan, V.; Iqbal, M. Prospective usage of magnesium potassium phosphate cement combined with Bougainvillea alba derived biochar to reduce Pb bioavailability in soil and its uptake by Spinacia oleracea L. Ecotoxicol. Environ. Saf. 2021, 208, 111723. [Google Scholar] [CrossRef]

- Agegnehu, G.; Srivastava, A.K.; Bird, M.I. The role of biochar and biochar-compost in improving soil quality and crop performance: A review. Appl. Soil Ecol. 2017, 119, 156–170. [Google Scholar] [CrossRef]

- Li, X.; Wang, C.; Zhang, J.; Liu, J.; Liu, B.; Chen, G. Preparation and application of magnetic biochar in water treatment: A critical review. Sci. Total Environ. 2020, 711, 134847. [Google Scholar] [CrossRef]

- Lehmann, J.; Gaunt, J.; Rondon, M. Bio-char sequestration in terrestrial ecosystems—A review. Mitig. Adapt. Strateg. Glob. Chang. 2006, 11, 403–427. [Google Scholar] [CrossRef]

- Lehmann, J. Bio-energy in the black. Front. Ecol. Environ. 2007, 5, 381–387. [Google Scholar] [CrossRef]

- Laird, D.A. The charcoal vision: A win–win–win scenario for simultaneously producing bioenergy, permanently sequestering carbon, while improving soil and water quality. Agron. J. 2008, 100, 178–181. [Google Scholar] [CrossRef]

- Sohi, S.P.; Krull, E.; Lopez-Capel, E.; Bol, R. A review of biochar and its use and function in soil. Adv. Agron. 2010, 105, 47–82. [Google Scholar]

- van Zwieten, L.; Kimber, S.; Morris, S.; Chan, K.Y.; Downie, A.; Rust, J.; Joseph, S.; Cowie, A. Effects of biochar from slow pyrolysis of papermill waste on agronomic performance and soil fertility. Plant Soil 2010, 327, 235–246. [Google Scholar] [CrossRef]

- Liang, B.; Lehmann, J.; Solomon, D.; Kinyangi, J.; Grossman, J.; O’Neill, B.; Skjemstad, J.O.; Thies, J.; Luizão, F.J.; Petersen, J. Black carbon increases cation exchange capacity in soils. Soil Sci. Soc. Am. J. 2006, 70, 1719–1730. [Google Scholar] [CrossRef]

- Jin, H. Characterization of Microbial Life Colonizing Biochar and Biochar-Amended Soils. Ph.D. Thesis, Cornell University, Ithaca, NY, USA, 2010. [Google Scholar]

- Riad, G.S.; Youssef, S.M.; El-azm, N.A.I.A.; Ahmed, E.M. Amending Sandy Soil with Biochar or/and Superabsorbent Polymer Mitigates the Adverse Effects of Drought Stress on Green Pea. Egypt. J. Hortic. 2018, 45, 169–183. [Google Scholar] [CrossRef]

- Nadeem, S.M.; Imran, M.; Naveed, M.; Khan, M.Y.; Ahmad, M.; Zahir, Z.A.; David, E. Synergistic use of biochar, compost and plant growth promoting rhizobacteria for enhancing cucumber growth under water deficit conditions. J. Sci. Food Agric. 2017, 97, 5139–5145. [Google Scholar] [CrossRef]

- Artiola, J.F.; Rasmussen, C.; Freitas, R. Effects of a biochar-amended alkaline soil on the growth of romaine lettuce and bermudagrass. Soil Sci. 2012, 177, 561–570. [Google Scholar] [CrossRef]

- Reza, A.; Langeroodi, S.; Campiglia, E.; Mancinelli, R.; Radicetti, E. Scientia Horticulturae Can biochar improve pumpkin productivity and its physiological characteristics under reduced irrigation regimes? Sci. Hortic. 2019, 247, 195–204. [Google Scholar] [CrossRef]

- Liu, X.; Wang, H.; Liu, C.; Sun, B.; Zheng, J.; Bian, R.; Drosos, M.; Zhang, X.; Li, L.; Pan, G. Biochar increases maize yield by promoting root growth in the rainfed region. Arch. Agron. Soil Sci. 2020, 67, 1411–1424. [Google Scholar] [CrossRef]

- Khan, I.; Iqbal, B.; Khan, A.A.; Inamullah; Rehman, A.; Fayyaz, A.; Shakoor, A.; Farooq, T.H.; Wang, L.-X. The Interactive Impact of Straw Mulch and Biochar Application Positively Enhanced the Growth Indexes of Maize (Zea mays L.) Crop. Agronomy 2022, 12, 2584. [Google Scholar] [CrossRef]

- Uzoma, K.C.; Inoue, M.; Andry, H.; Fujimaki, H.; Zahoor, A.; Nishihara, E. Effect of cow manure biochar on maize productivity under sandy soil condition. Soil Use Manag. 2011, 27, 205–212. [Google Scholar] [CrossRef]

- Schmidt, H.-P.; Kammann, C.; Niggli, C.; Evangelou, M.W.H.; Mackie, K.A.; Abiven, S. Biochar and biochar-compost as soil amendments to a vineyard soil: Influences on plant growth, nutrient uptake, plant health and grape quality. Agric. Ecosyst. Environ. 2014, 191, 117–123. [Google Scholar] [CrossRef]

- Ubalde, J.M.; Payan, E.; Sort, X.; Rosas, J.G.; Gómez, N. Application of biochar amendments to Mediterranean soils: Effects on vine growth and grape quality. Geophys. Res. Abstr. 2014, 16, 440000. [Google Scholar]

- Genesio, L.; Miglietta, F.; Baronti, S.; Vaccari, F.P. Biochar increases vineyard productivity without affecting grape quality: Results from a four years field experiment in Tuscany. Agric. Ecosyst. Environ. 2015, 201, 20–25. [Google Scholar] [CrossRef]

- Fascella, G.; Mammano, M.M.; D’Angiolillo, F.; Pannico, A.; Rouphael, Y. Coniferous wood biochar as substrate component of two containerized Lavender species: Effects on morpho-physiological traits and nutrients partitioning. Sci. Hortic. 2020, 267, 109356. [Google Scholar] [CrossRef]

- Lehmann, J. A handful of carbon. Nature 2007, 447, 143–144. [Google Scholar] [CrossRef]

- Woolf, D.; Amonette, J.E.; Street-Perrott, F.A.; Lehmann, J.; Joseph, S. Sustainable biochar to mitigate global climate change. Nat. Commun. 2010, 1, 56. [Google Scholar] [CrossRef]

- Llanes, J. IPCC–INFORME DEL PANEL INTERGUBERNAMENTAL SOBRE CAMBIO CLIMÁTICO|Cambio Climático 2022: Mitigación del cambio climático. Rev. Int. Comun. Desarro 2022, 4, 4. [Google Scholar]

- Aguirre, J.L.; Baena, J.; Martín, M.T.; Nozal, L.; González, S.; Manjón, J.L.; Peinado, M. Composition, ageing and herbicidal properties of wood vinegar obtained through fast biomass pyrolysis. Energies 2020, 13, 2418. [Google Scholar] [CrossRef]

- Feng, W.; Yang, F.; Cen, R.; Liu, J.; Qu, Z.; Miao, Q.; Chen, H. Effects of straw biochar application on soil temperature, available nitrogen and growth of corn. J. Environ. Manag. 2021, 277, 111331. [Google Scholar] [CrossRef]

- Iglesias Abad, S.; Alegre Orihuela, J.; Salas Macias, C.; Egüez Moreno, J. Corn yield (Zea mays L.) improves with the use of Eucalyptus biochar. Sci. Agropecu 2018, 9, 25–32. [Google Scholar] [CrossRef]

- Sánchez, A.M.; Orozco, L.E.M.; Villegas, R.G.; Duque, A.S.; Oregel, V.N. Efecto del Biocarbón en la Producción de un Maíz Comercial Bajo Riego en Michoacán. Available online: https://www.researchgate.net/profile/Alexander-Sanchez-Duque/publication/352006775_Efecto_del_biocarbon_en_la_produccion_de_un_maiz_comercial_bajo_riego_en_Michoacan/links/60b55206a6fdcc476bda78b1/Efecto-del-biocarbon-en-la-produccion-de-un-maiz-comercial-bajo-riego-en-Michoacan.pdf (accessed on 15 March 2023).

- Rajkovich, S.; Enders, A.; Hanley, K.; Hyland, C.; Zimmerman, A.R.; Lehmann, J. Corn growth and nitrogen nutrition after additions of biochars with varying properties to a temperate soil. Biol. Fertil. Soils 2012, 48, 271–284. [Google Scholar] [CrossRef]

- Brantley, K.E.; Savin, M.C.; Brye, K.R.; Longer, D.E. Nutrient availability and corn growth in a poultry litter biochar-amended loam soil in a greenhouse experiment. Soil Use Manag. 2016, 32, 279–288. [Google Scholar] [CrossRef]

- Zilberman, D.; Laird, D.; Rainey, C.; Song, J.; Kahn, G. Biochar supply-chain and challenges to commercialization. GCB Bioenergy 2023, 15, 7–23. [Google Scholar] [CrossRef]

- Maroušek, J.; Trakal, L. Techno-economic analysis reveals the untapped potential of wood biochar. Chemosphere 2022, 291, 133000. [Google Scholar] [CrossRef]

- Pesca y Alimentación. (España) Ministerio de Agricultura. Precios Medios Nacionales. 2022. Available online: https://www.mapa.gob.es/es/estadistica/temas/estadisticas-agrarias/economia/precios-medios-nacionales/ (accessed on 16 March 2023).

- Servicio Agronómico Pioneer de Castilla y León. Por qué hoy sigue siendo rentable sembrar maíz en Castilla y León? 2017. Available online: https://www.campocyl.es/portada/por-que-hoy-sigue-siendo-rentable-sembrar-maiz-en-castilla-y-leon/ (accessed on 16 March 2023).

- Filiberto, D.; Gaunt, J. Practicality of Biochar Additions to Enhance Soil and Crop Productivity. Agriculture 2013, 3, 715–725. [Google Scholar] [CrossRef]

- Sendeco2 Precios CO2. 2023. Available online: https://www.sendeco2.com/es/precios-co2 (accessed on 16 March 2023).

- Meyer, S.; Genesio, L.; Vogel, I.; Schmidt, H.-P.; Soja, G.; Someus, E.; Shackley, S.; Verheijen, F.G.A.; Glaser, B. Biochar standardization and legislation harmonization. J. Environ. Eng. Landsc. Manag. 2017, 25, 175–191. [Google Scholar] [CrossRef]

- Gollenbeek, L.; Ehlert, P.; Buisonjeé, F. Perspectives of Ecochar in Europe: Uses and Regulatory Requirements; Wageningen Livestock Research: Wageningen, The Netherlands, 2018. [Google Scholar] [CrossRef]

- Garcia, B.; Alves, O.; Rijo, B.; Lourinho, G.; Nobre, C. Biochar: Production, applications, and market prospects in Portugal. Environments 2022, 9, 95. [Google Scholar] [CrossRef]

- Rashidi, N.A.; Yusup, S. A mini review of biochar synthesis, characterization, and related standardization and legislation. Appl. Biochar Environ. Saf. 2020, 16, 11–26. [Google Scholar] [CrossRef]

- Singh, H.; Northup, B.K.; Rice, C.W.; Prasad, P.V.V. Biochar applications influence soil physical and chemical properties, microbial diversity, and crop productivity: A meta-analysis. Biochar 2022, 4, 8. [Google Scholar] [CrossRef]

- Li, S.; Harris, S.; Anandhi, A.; Chen, G. Predicting biochar properties and functions based on feedstock and pyrolysis temperature: A review and data syntheses. J. Clean. Prod. 2019, 215, 890–902. [Google Scholar] [CrossRef]

- Joseph, S.; Pow, D.; Dawson, K.; Rust, J.; Munroe, P.; Taherymoosavi, S.; Mitchell, D.R.G.; Robb, S.; Solaiman, Z.M. Biochar increases soil organic carbon, avocado yields and economic return over 4 years of cultivation. Sci. Total Environ. 2020, 724, 138153. [Google Scholar] [CrossRef] [PubMed]

- Keey Liew, R.; Loke Show, P.; Su, M.H.; Azwar, E.; Yang, Y.; Sonne, C.; Yek, P.N.Y.; Liew, R.K.; Cheng, C.K.; Show, P.L. Simultaneous removal of toxic ammonia and lettuce cultivation in aquaponic system using microwave pyrolysis biochar. J. Hazard. Mater. 2020, 396, 122610. [Google Scholar]

- Biederman, L.A.; Harpole, W.S. Biochar and its effects on plant productivity and nutrient cycling: A meta-analysis. GCB Bioenergy 2013, 5, 202–214. [Google Scholar] [CrossRef]

- Ronsse, F.; Van Hecke, S.; Dickinson, D.; Prins, W. Production and characterization of slow pyrolysis biochar: Influence of feedstock type and pyrolysis conditions. GCB Bioenergy 2013, 5, 104–115. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, A.; Ji, C.; Joseph, S.; Bian, R.; Li, L.; Pan, G.; Paz-Ferreiro, J. Biochar’s effect on crop productivity and the dependence on experimental conditions—A meta-analysis of literature data. Plant Soil 2013, 373, 583–594. [Google Scholar] [CrossRef]

- Kirkby, C.A.; Richardson, A.E.; Wade, L.J.; Passioura, J.B.; Batten, G.D.; Blanchard, C.; Kirkegaard, J.A. Nutrient availability limits carbon sequestration in arable soils. Soil Biol. Biochem. 2014, 68, 402–409. [Google Scholar] [CrossRef]

- Cleveland, C.C.; Liptzin, D. C: N: P stoichiometry in soil: Is there a “Redfield ratio” for the microbial biomass? Biogeochemistry 2007, 85, 235–252. [Google Scholar] [CrossRef]

- Page, K.L.; Dang, Y.P.; Dalal, R.C. The ability of conservation agriculture to conserve soil organic carbon and the subsequent impact on soil physical, chemical, and biological properties and yield. Front. Sustain. Food Syst. 2020, 4, 31. [Google Scholar] [CrossRef]

- Ontl, T.A.; Schulte, L.A. Soil carbon storage. Nat. Educ. Knowl. 2012, 3, 35. [Google Scholar]

- Fascella, G.; D’Angiolillo, F.; Ruberto, G.; Napoli, E. Agronomic performance, essential oils and hydrodistillation wastewaters of Lavandula angustifolia grown on biochar-based substrates. Ind. Crops Prod. 2020, 154, 112733. [Google Scholar] [CrossRef]

- Egri, D.; Pârvulescu, O.C.; Ion, V.A.; Răducanu, C.E.; Calcan, S.I.; Bădulescu, L.; Madjar, R.; Orbeci, C.; Dobre, T.; Moț, A. Vine Pruning-Derived Biochar for Agronomic Benefits. Agronomy 2022, 12, 2730. [Google Scholar] [CrossRef]

- Rivelli, A.R.; Libutti, A. Effect of biochar and inorganic or organic fertilizer co-application on soil properties, plant growth and nutrient content in Swiss chard. Agronomy 2022, 12, 2089. [Google Scholar] [CrossRef]

- Mackie, K.A.; Marhan, S.; Ditterich, F.; Schmidt, H.P.; Kandeler, E. The effects of biochar and compost amendments on copper immobilization and soil microorganisms in a temperate vineyard. Agric. Ecosyst. Environ. 2015, 201, 58–69. [Google Scholar] [CrossRef]

| Biochar | Wood Vinegar | Bio-Oil | Bio-Bitumen | Syngas | |

|---|---|---|---|---|---|

| Pinewood (B1) | 27.54% | 36.23% | 8.45% | 0.67% | 27.11% |

| Olive stone (B3) | 31.72% | 44.49% | 7.49% | 1.76% | 14.54% |

| Parameter | Unit | Pine (B1) | Pine (B2) | Olive Stone (B3) |

|---|---|---|---|---|

| Moisture | wt.% | 1.55 | 18.3 | 1.33 |

| Dry Matter | wt.% | 98.5 | 81.7 | 98.7 |

| Organic Material | %s.m.s. | 97.5 | 49.5 | 97.7 |

| Organic Carbon | wt.% | 55.5 | 23.5 | 55.9 |

| pH | pH unit | 7.3 | 7.9 | 8.6 |

| Electrical Conductivity (25 °C) | dS/m | 0.144 | 7.540 | 0.508 |

| C/N Ratio | - | 334.55 | 33.05 | 233.99 |

| Humic Acid | wt.% | 2.3 | 4.9 | 0.9 |

| Total Humic Extract | wt.% | 6.7 | 8.3 | 20.3 |

| Fluvic Acid | wt.% | 4.4 | 3.4 | 19.4 |

| Treatment/Cob | Fresh Cob (g) 2021 | Cob Weight (g) by Plot 2021 | Fresh Cob (g) 2022 | Cob Weight (g) by Plot 2022 |

|---|---|---|---|---|

| B1 | 206.11 ± 186.29 | 13,809.1 | 68.45 ± 64.28 | 3856.90 |

| B2 | 139.12 ± 139.12 | 8347.4 | 20.03 ± 18.02 | 1482.00 |

| C1 | 174.54 ± 156.62 | 9948.9 | 46.40 ± 41.30 | 2784.1 |

| C2 | 136.93 ± 121.66 | 8079.01 | 31.98 ± 37.74 | 1022.91 |

| Groups vs. B1 (%) | Cob 2020 | Cob 2021 | Cob 2022 |

|---|---|---|---|

| B2 | 42.39% | 48.15% | 220.92% |

| C1 | 61.73% | 18.09% | 38.53% |

| C2 | 61.60% | 251.72% | 70.32% |

| Increase in Fresh Weight of Corn by Treatment (vs. B1) | 2020 | 2021 | 2022 |

|---|---|---|---|

| B2 | 81.55% | 65.44% | 160.19% |

| C1 | 73.18% | 38.81% | 38.51% |

| C2 | 119.71% | 70.92% | 277.30% |

| Control | 1st Year | 3rd Year | Control | 1st Year | 3rd Year | Control | 1st Year | 3rd Year | Control | 1st Year | 3rd Year | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| B1 | B1 | B1 | B2 | B2 | B2 | C1 | C1 | C1 | C2 | C2 | C2 | |

| pH | 7.8 | 7.9 | 7.9 | 7.8 | 8.0 | 8.0 | 7.7 | 7.9 | 8.0 | 7.8 | 8.0 | 8.0 |

| Conductivity at 20 °C (μS/cm) | 266.5 | 346.0 | 413.5 | 291.0 | 522.0 | 384.5 | 266.0 | 317.0 | 436.3 | 233.5 | 269.5 | 416.8 |

| NO3/K ratio | 0.8 | 0.2 | 0.1 | 1.0 | 0.8 | 0.3 | 0.8 | 0.6 | 0.1 | 1.3 | 1.0 | 0.3 |

| Ca/Na ratio | 1.6 | 1.0 | 1.1 | 2.5 | 0.8 | 0.9 | 3.3 | 1.0 | 0.8 | 1.2 | 0.9 | 1.0 |

| Ca/Mg ratio | 2.2 | 1.4 | 1.3 | 1.9 | 1.4 | 1.1 | 1.9 | 1.2 | 1.1 | 2.0 | 1.3 | 1.2 |

| K/Mg ratio | 1.3 | 0.4 | 0.1 | 1.0 | 0.4 | 0.1 | 0.8 | 0.2 | 0.1 | 0.8 | 0.3 | 0.1 |

| Exchangeable sodium (meq/100 g soil) | 0.5 | 0.9 | 0.5 | 0.3 | 1.4 | 0.5 | 0.3 | 0.8 | 0.6 | 0.6 | 0.8 | 0.5 |

| Exchangeable potassium (meq/100 g soil) | 2.1 | 1.1 | 0.4 | 1.7 | 1.2 | 0.3 | 1.3 | 0.8 | 0.3 | 1.1 | 0.7 | 0.4 |

| Exchangeable calcium (meq/100 g soil) | 23.2 | 20.1 | 9.7 | 20.6 | 19.7 | 8.6 | 21.4 | 20.4 | 8.6 | 17.8 | 19.8 | 8.5 |

| Exchangeable magnesium (meq/100 g soil) | 5.1 | 6.2 | 3.4 | 4.9 | 6.1 | 3.0 | 4.7 | 6.6 | 2.9 | 4.0 | 6.9 | 3.1 |

| Cation exchange capacity (meq/100 g soil) | 30.9 | 28.3 | 14.0 | 27.5 | 28.4 | 12.5 | 27.7 | 28.6 | 12.4 | 23.5 | 28.3 | 12.4 |

| Assimilable potassium (mg/kg) | 826.8 | 441.3 | 139.4 | 649.4 | 454.0 | 116.0 | 523.8 | 316.0 | 136.0 | 414.4 | 266.4 | 142.7 |

| Assimilable phosphorus (mg/kg) | 44.2 | 37.5 | 14.5 | 66.6 | 38.1 | 3.2 | 40.2 | 28.2 | 4.2 | 52.4 | 32.8 | 6.0 |

| Parameter | Units | IBI-BS | EBC | BQM | ||

|---|---|---|---|---|---|---|

| Basic | Premium | Standard | High Grade | |||

| Organic C | % | ≥10 | - | ≥10 | ||

| H/C | - | ≤0.7 | ≤0.7 | ≤0.7 | ||

| O/C | - | ≤0.4 | - | |||

| Moisture | % | - | ≥30 | ≥20 | ||

| Ash | √ | √ | √ | |||

| EC | mS m−1 | √ | √ | Optional | ||

| Liming | - | √ | - | - | ||

| pH | √ | √ | √ | |||

| PSD | mm | √ | - | √ | ||

| SSA | m2g−1 | - | √ | Optional | ||

| AWC | % | - | √ | Optional | ||

| VM | Optional | √ | - | |||

| Germination | - | Pass/Fail | Optional | - | ||

| Total N | % | √ | √ | √ | ||

| P, K, Mg, Ca | Optional | √ | Total P & K | |||

| PAH | mg kg−1, db | ≤300 | <12 | <4 | <20 | |

| B(a)P | ≤3 | - | - | |||

| PCB | ≤1 | <0.2 | <0.5 | |||

| PCDD/F | ≤17 | <20 | <20 | |||

| As | mg kg−1, db (max.) | 12–100 | - | 100 | 10 | |

| Cd | 1.4–39 | 1.5 | 1 | 39 | 3 | |

| Cr | 64–1200 | 90 | 80 | 100 | 15 | |

| Co | 40–150 | - | - | |||

| Cu | 65–1500 | 100 | 1500 | 40 | ||

| Pb | 70–500 | 150 | 120 | 500 | 60 | |

| Hg | 1–17 | 1 | 17 | 1 | ||

| Mn | - | - | - | 3500 | ||

| Mo | 5–20 | - | 75 | 10 | ||

| Ni | 47–600 | 50 | 30 | 600 | 10 | |

| Se | 2–36 | - | 100 | 5 | ||

| Zn | 200–7000 | 400 | 2800 | 150 | ||

| B | √ | - | - | |||

| Cl | ||||||

| Na | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aguirre, J.L.; González-Egido, S.; González-Lucas, M.; González-Pernas, F.M. Medium-Term Effects and Economic Analysis of Biochar Application in Three Mediterranean Crops. Energies 2023, 16, 4131. https://doi.org/10.3390/en16104131

Aguirre JL, González-Egido S, González-Lucas M, González-Pernas FM. Medium-Term Effects and Economic Analysis of Biochar Application in Three Mediterranean Crops. Energies. 2023; 16(10):4131. https://doi.org/10.3390/en16104131

Chicago/Turabian StyleAguirre, Juan Luis, Sergio González-Egido, María González-Lucas, and Francisco Miguel González-Pernas. 2023. "Medium-Term Effects and Economic Analysis of Biochar Application in Three Mediterranean Crops" Energies 16, no. 10: 4131. https://doi.org/10.3390/en16104131

APA StyleAguirre, J. L., González-Egido, S., González-Lucas, M., & González-Pernas, F. M. (2023). Medium-Term Effects and Economic Analysis of Biochar Application in Three Mediterranean Crops. Energies, 16(10), 4131. https://doi.org/10.3390/en16104131