Velocity Sensor Fault-Tolerant Controller for Induction Machine Using Intelligent Voting Algorithm

Abstract

:1. Introduction

- The new proposed controller (IBS-DISMC) is introduced to improve the performance of the IM under faulty conditions. Specifically speaking, IBS-DISMC has a fast response, fewer steady-state errors, and a robust performance in the existence of uncertainty.

- The new neural voting algorithm is proposed to avoid setting up a threshold, which is the main limitation of the reported voting algorithms in the literature. Additionally, the proposed voter has a good robustness against parameter variations.

- The fuzzy voter given in [19] is modified to be applicable for diagnosing the failure of a velocity sensor of an induction machine.

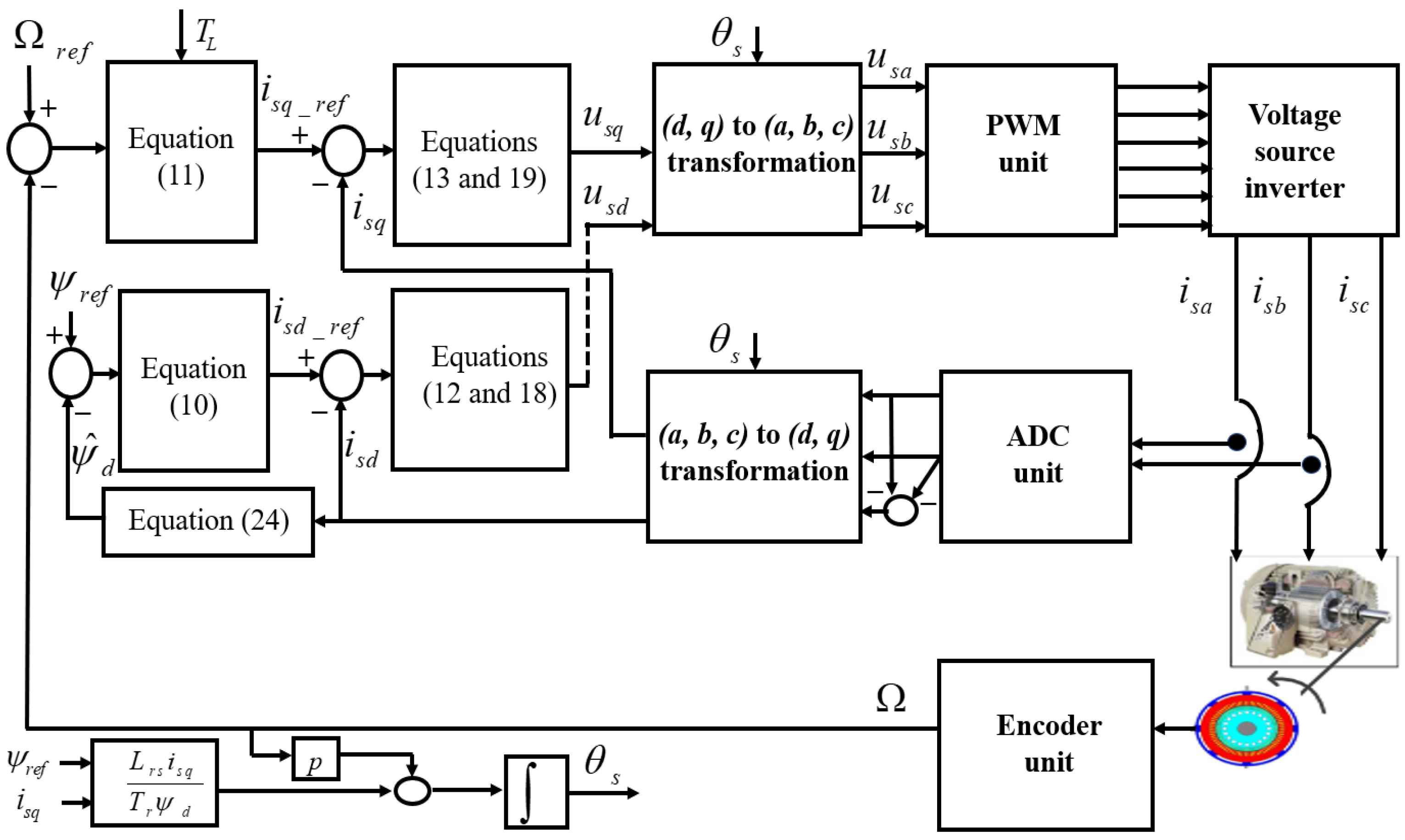

2. Controller Design

2.1. Presentation of the Analytical d-q Model of the Induction Machine

2.2. Suggestion

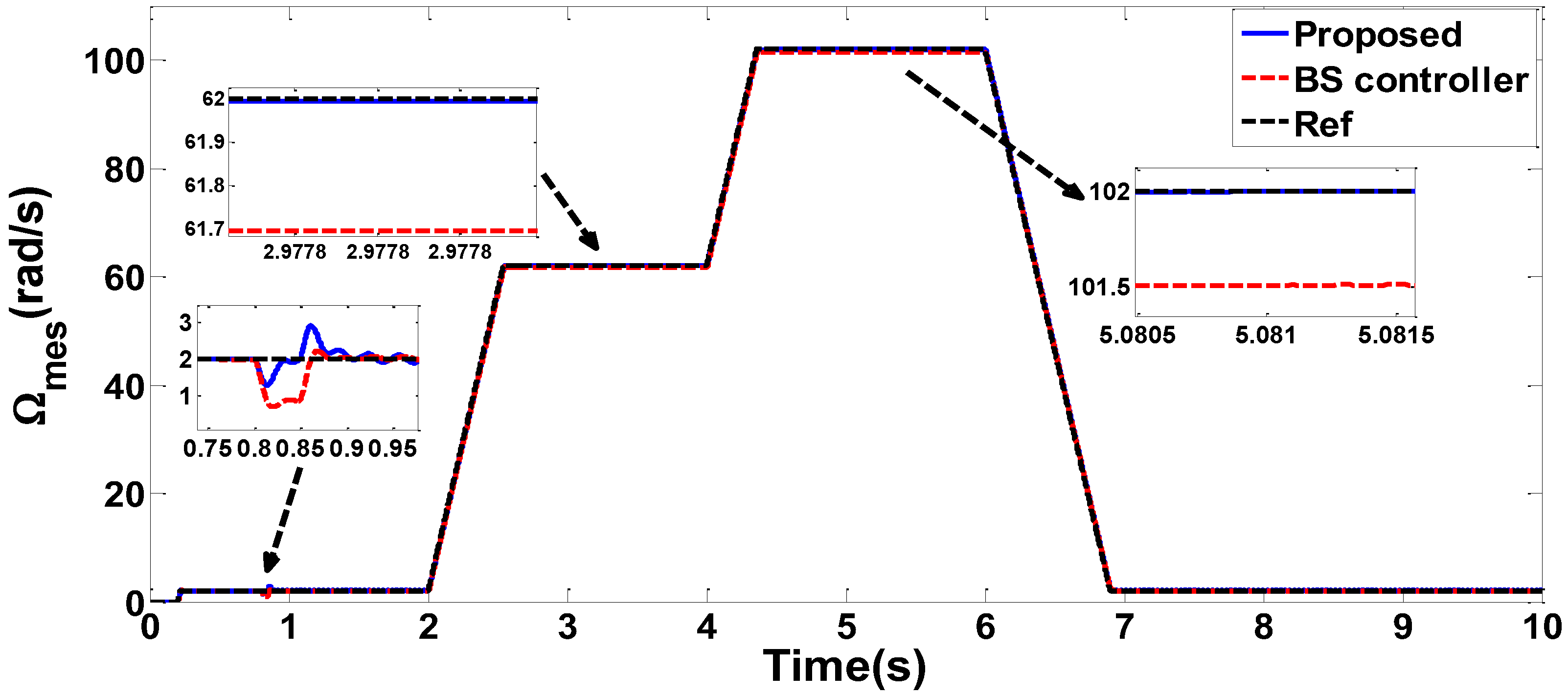

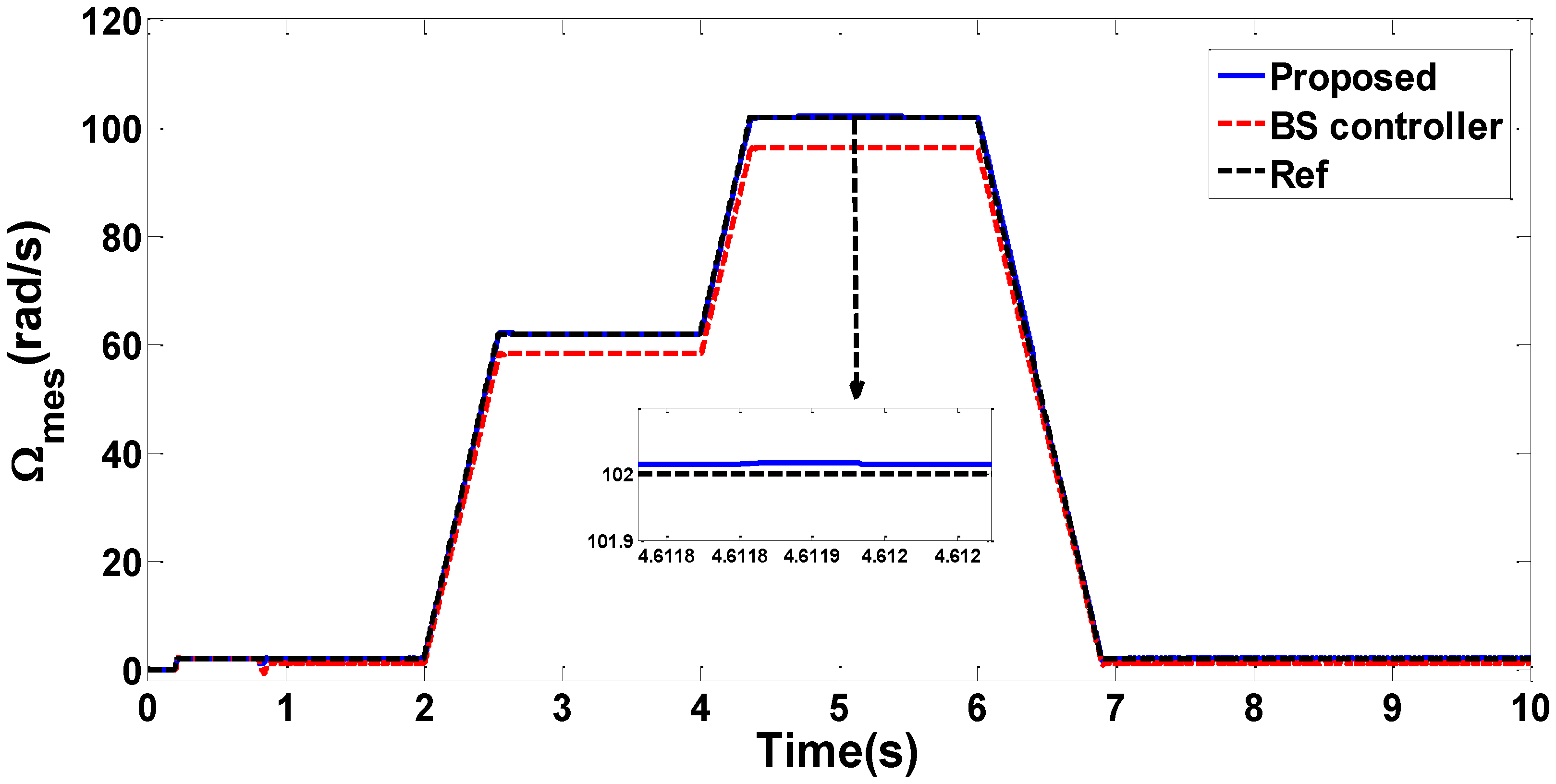

2.3. Integral Back-Stepping Double Integrator Sliding Mode Controller

- and .

2.4. Simulation and Validaton

3. Velocity Observers Design

3.1. Extended Kalman Filter

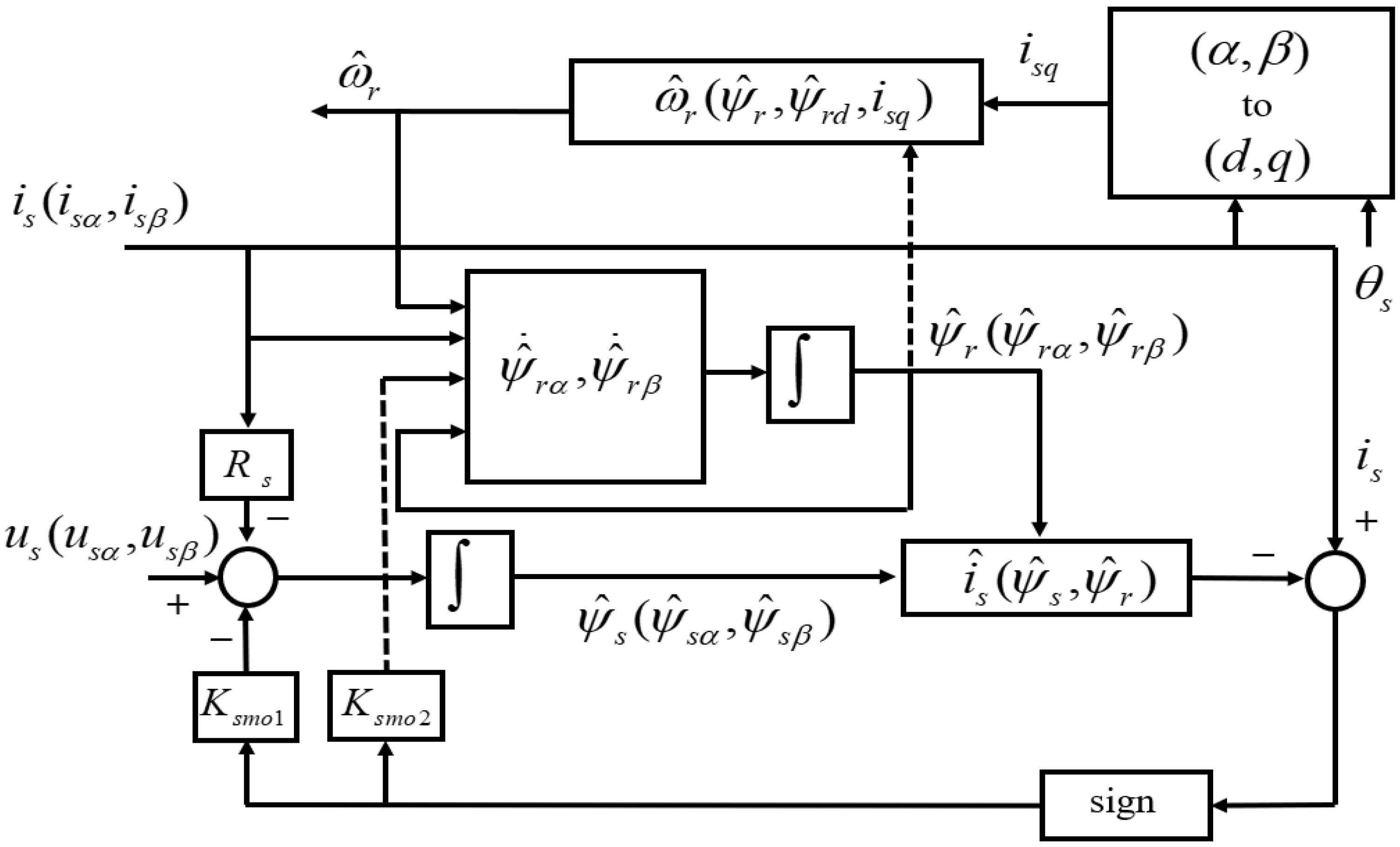

3.2. Sliding Mode Observer

- , , and . and are positive constants.

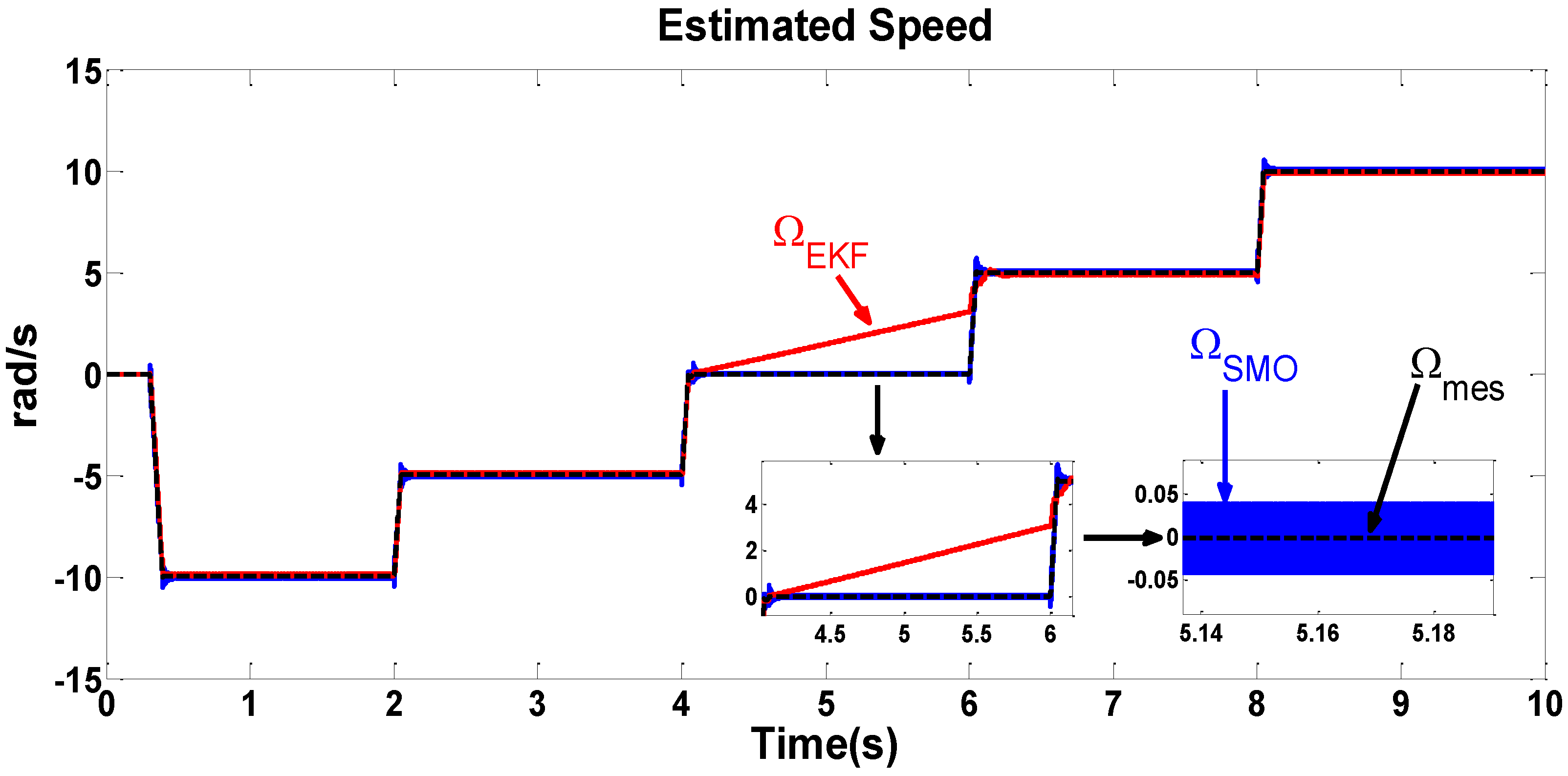

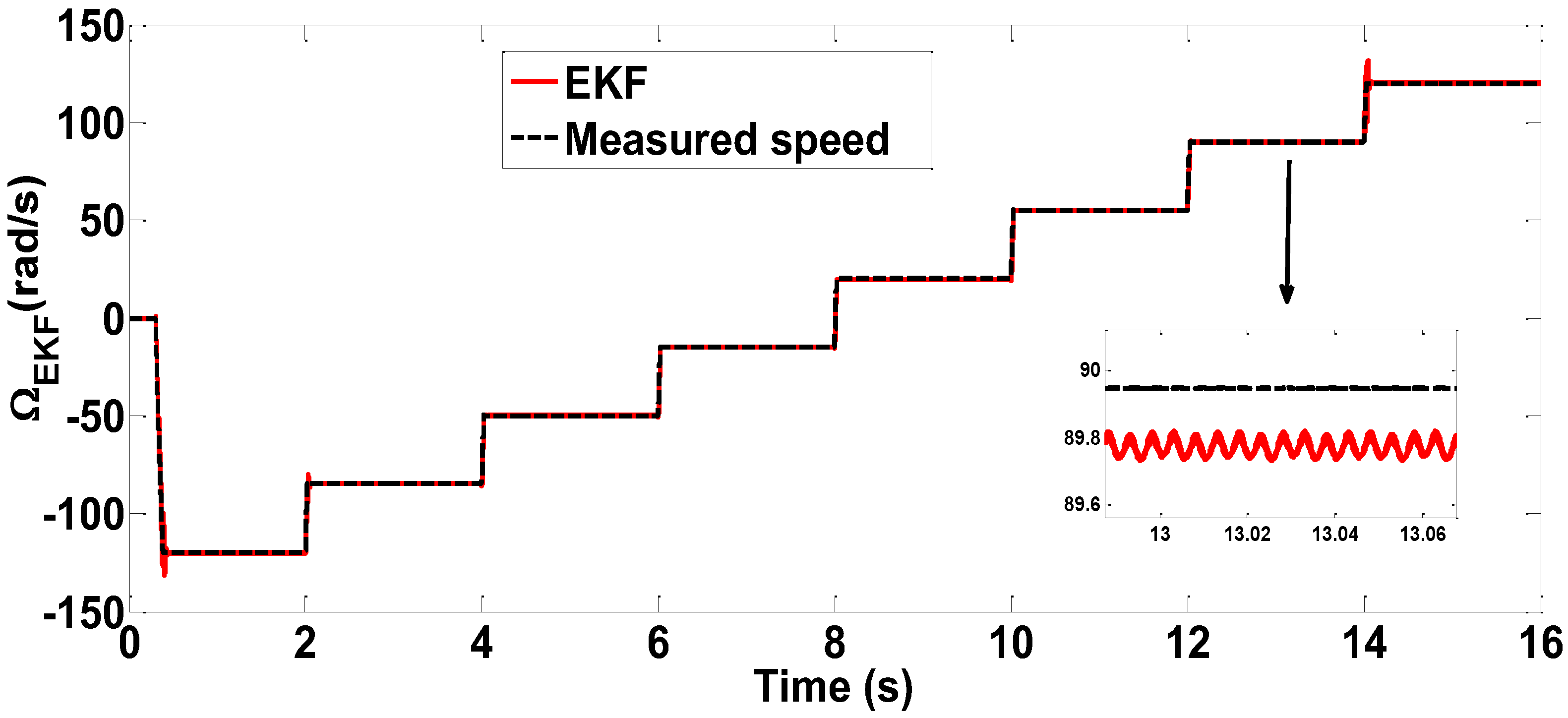

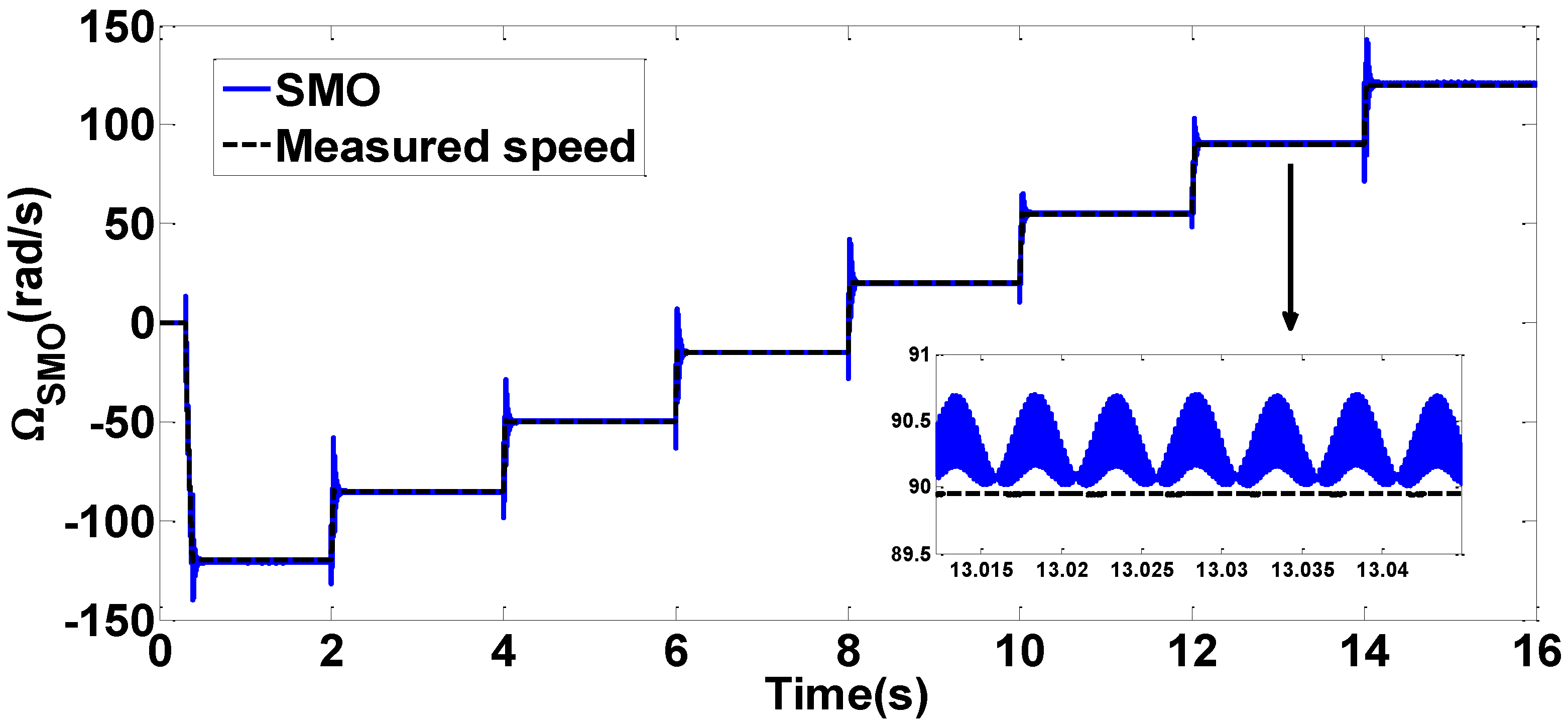

3.3. Simulation and Validation

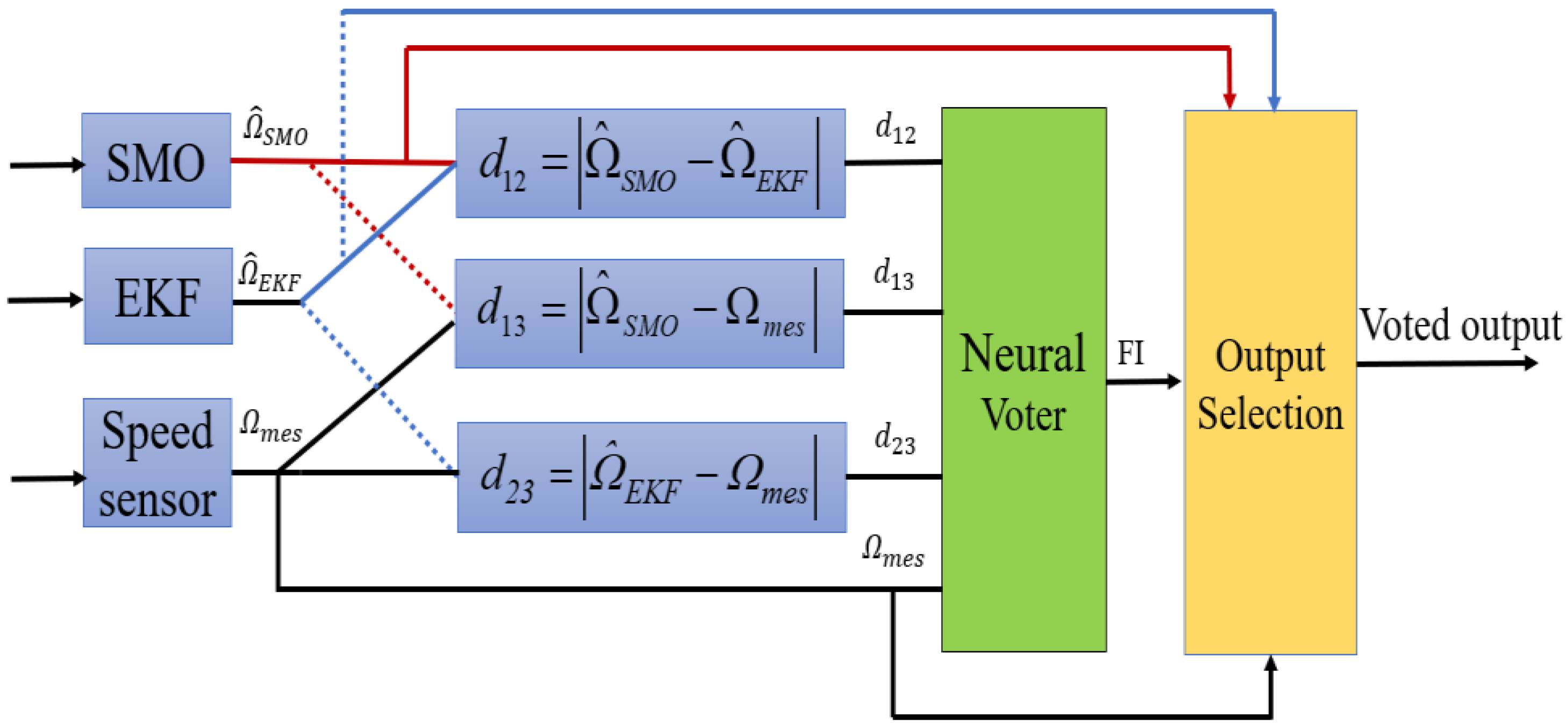

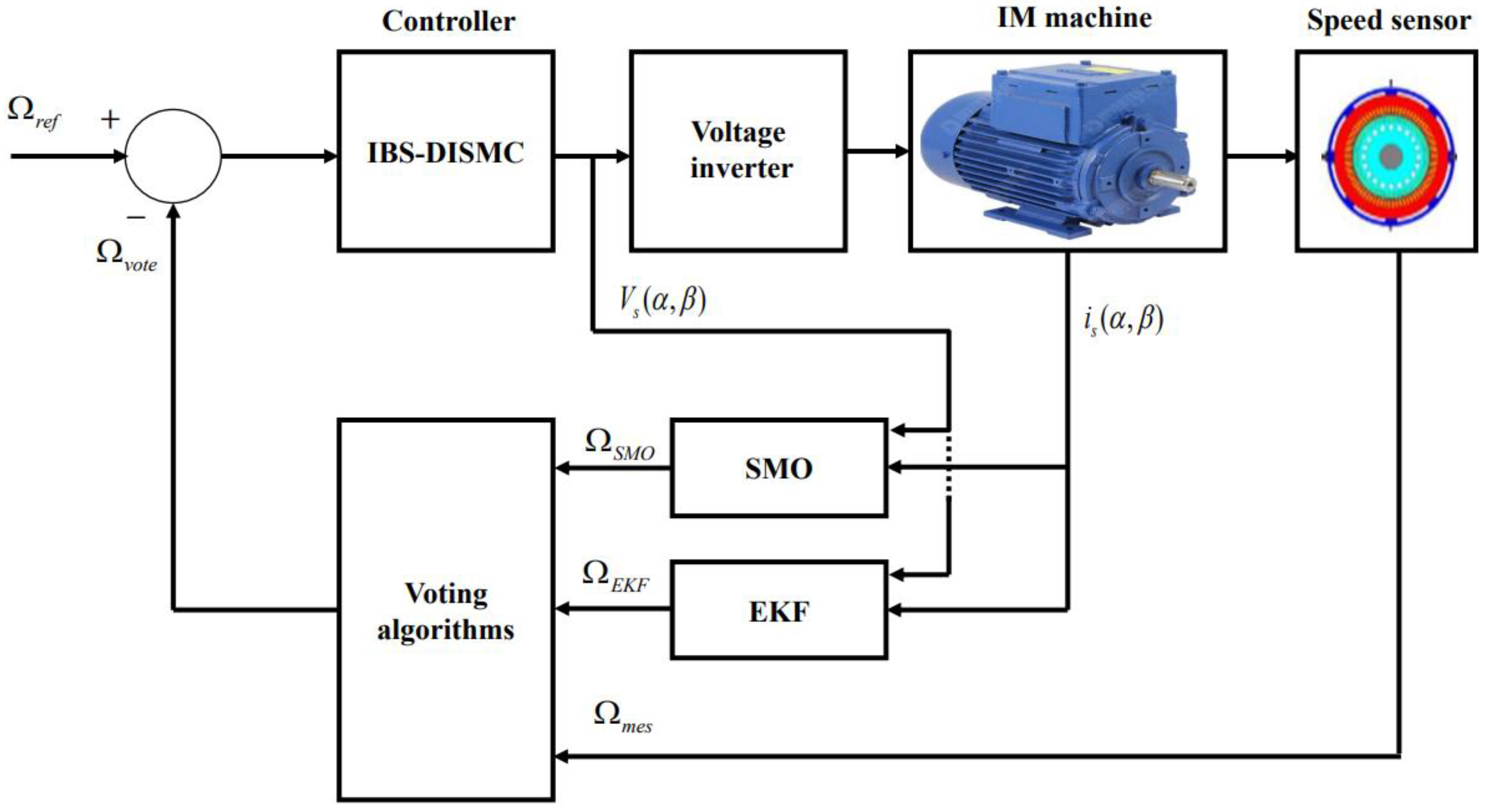

4. Fault-Tolerant Controller

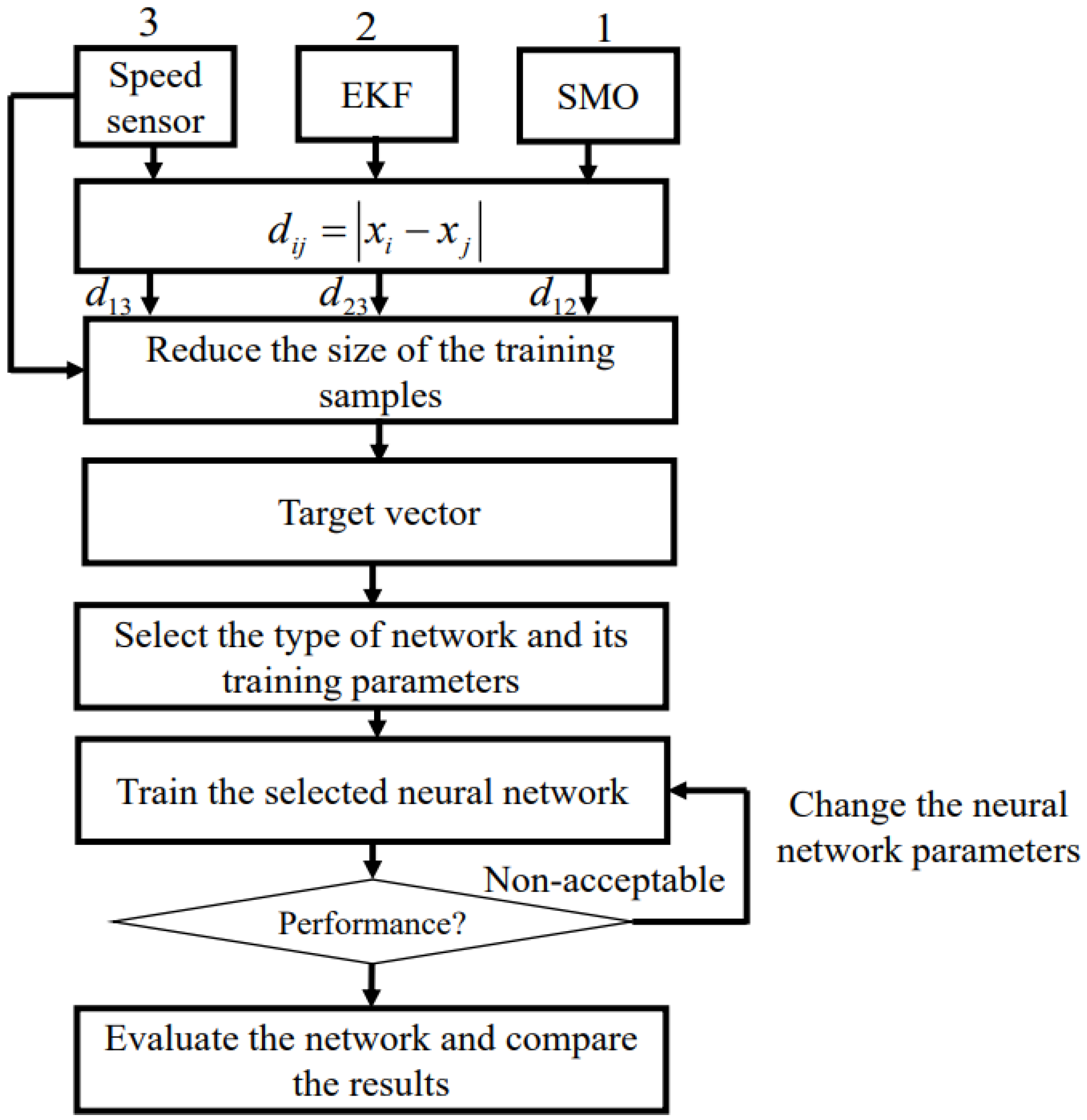

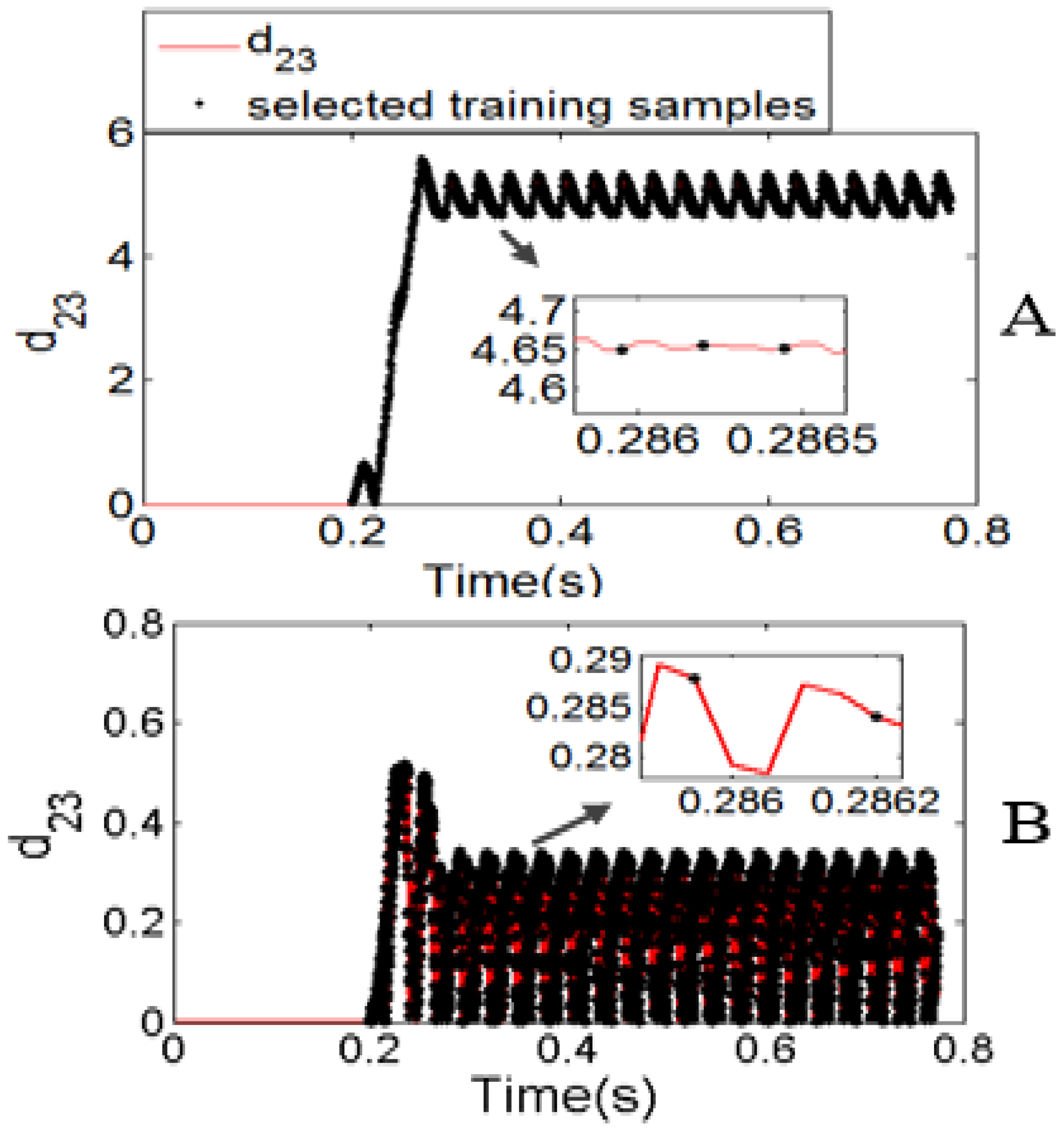

4.1. Neural Voter Algorithm

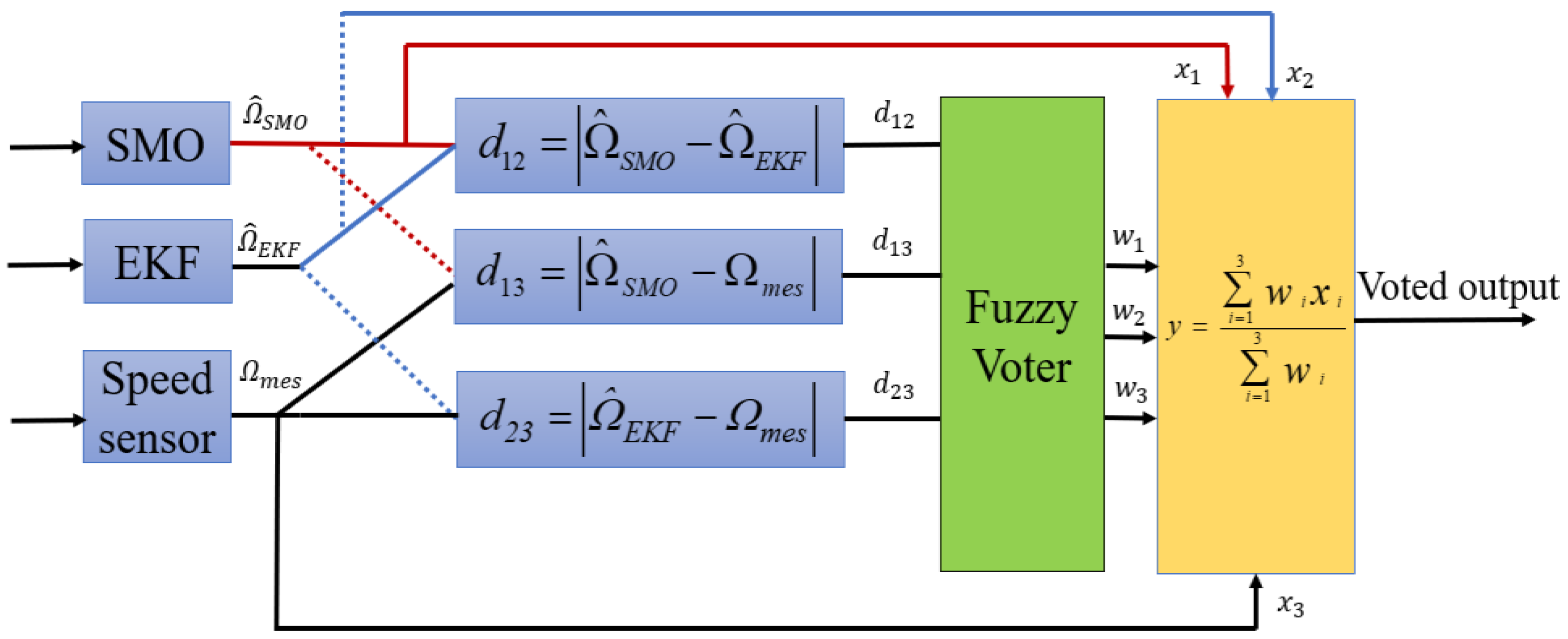

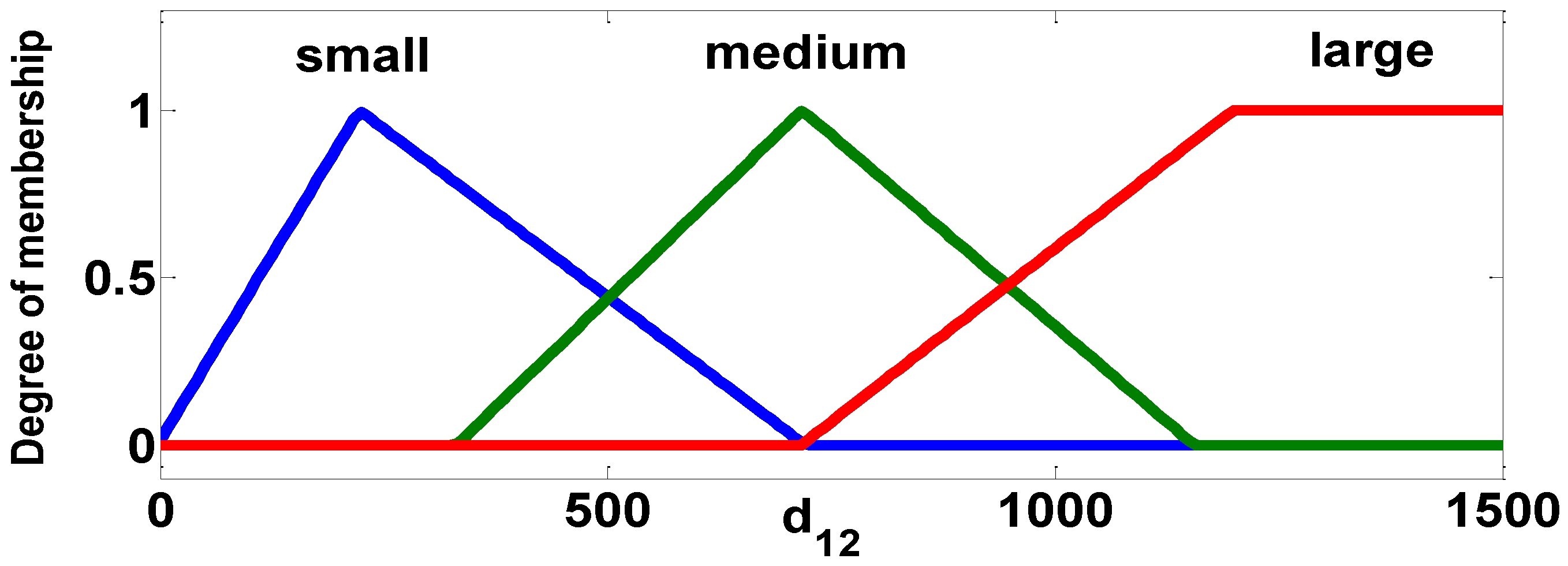

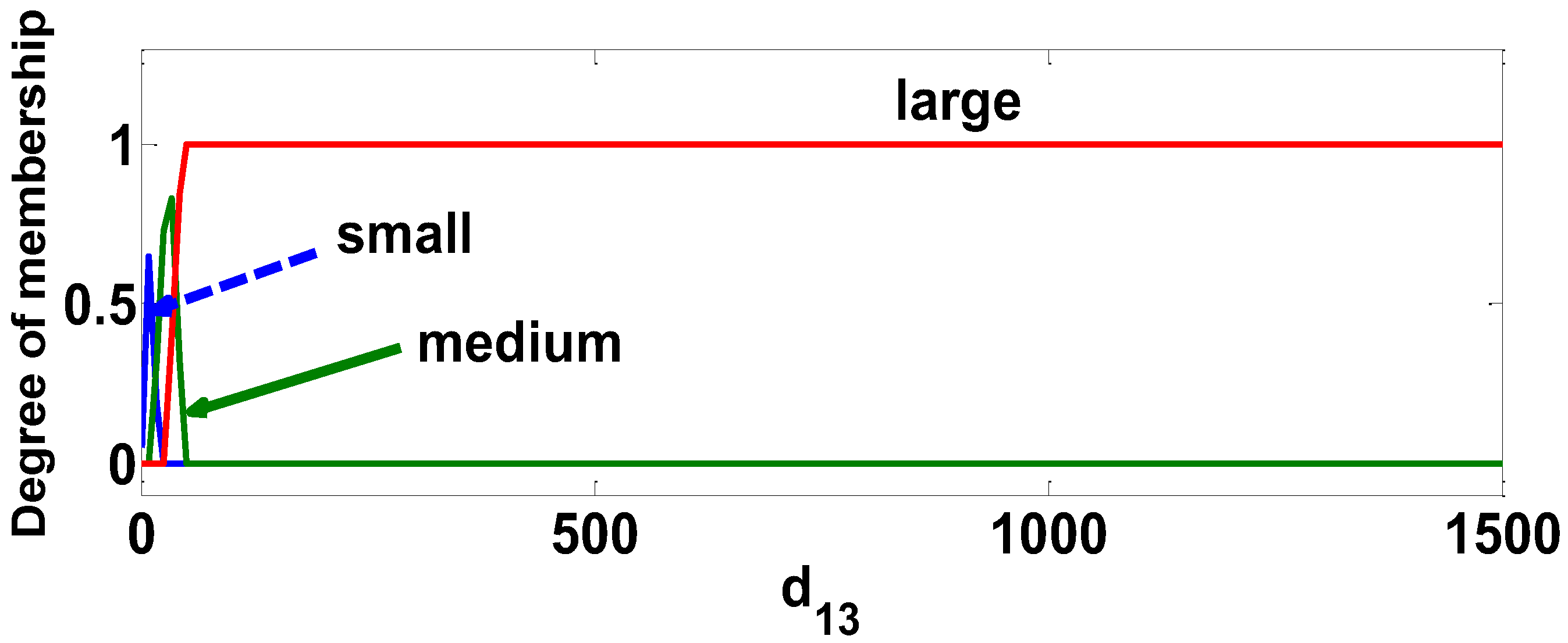

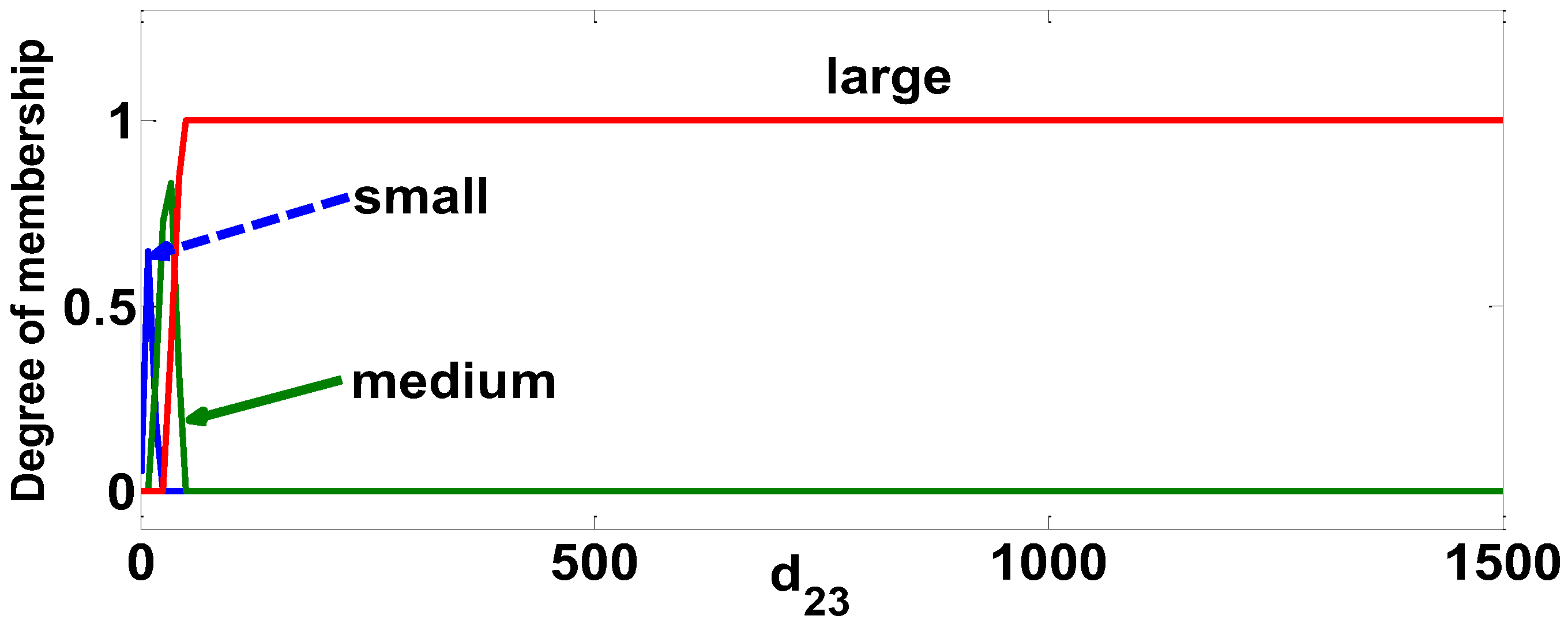

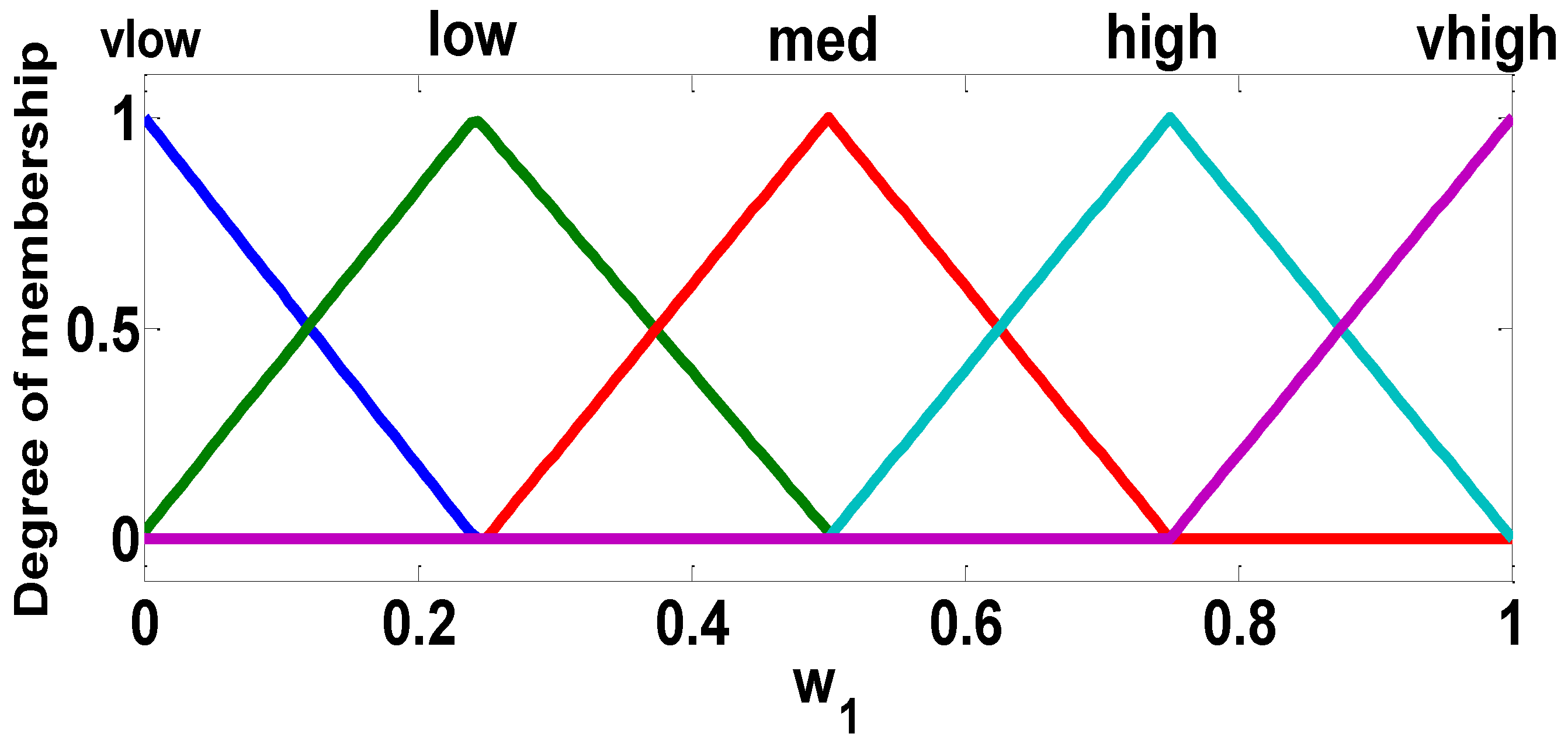

4.2. Fuzzy Voter Algorithm

4.3. Fault-Tolerant Control Structure

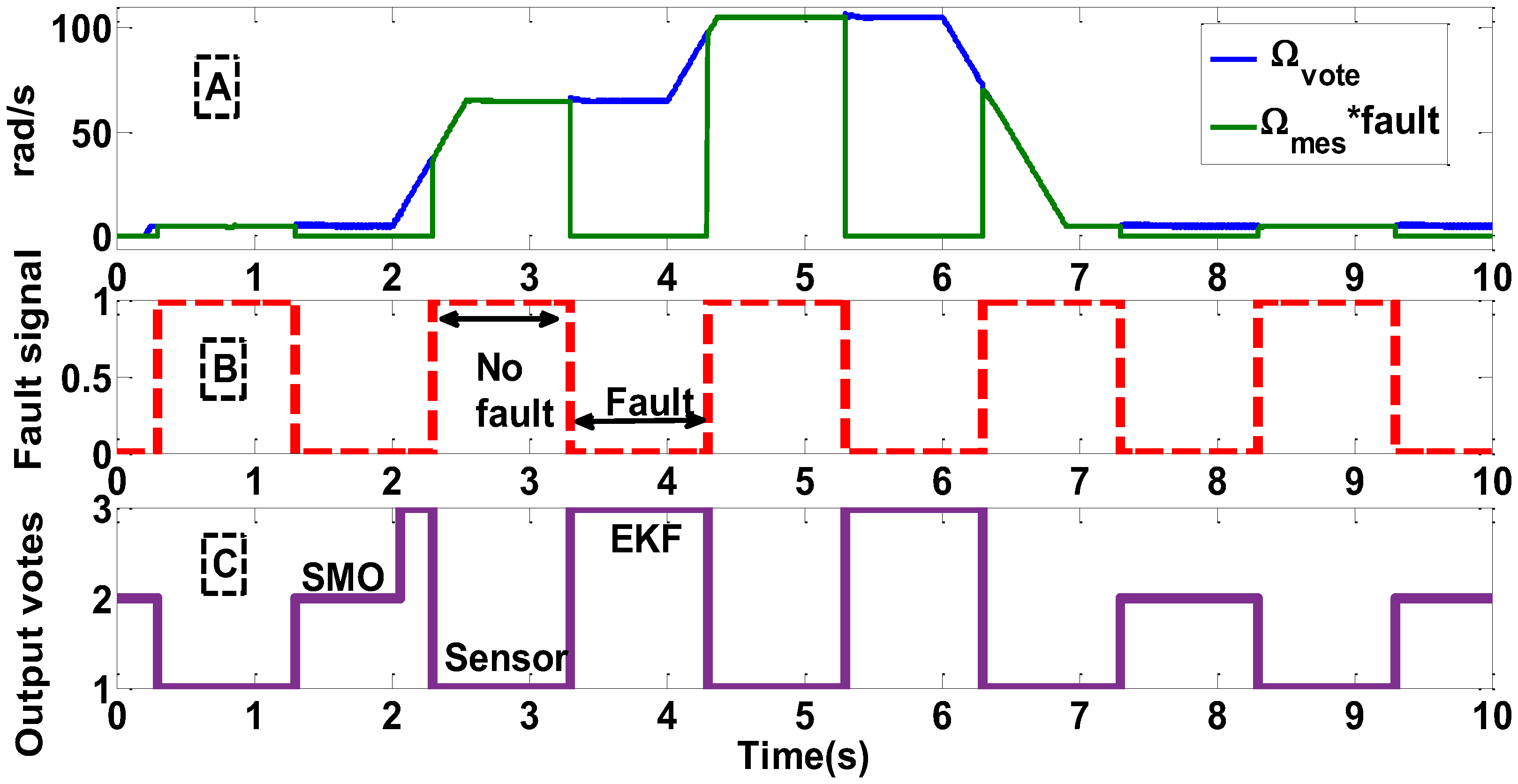

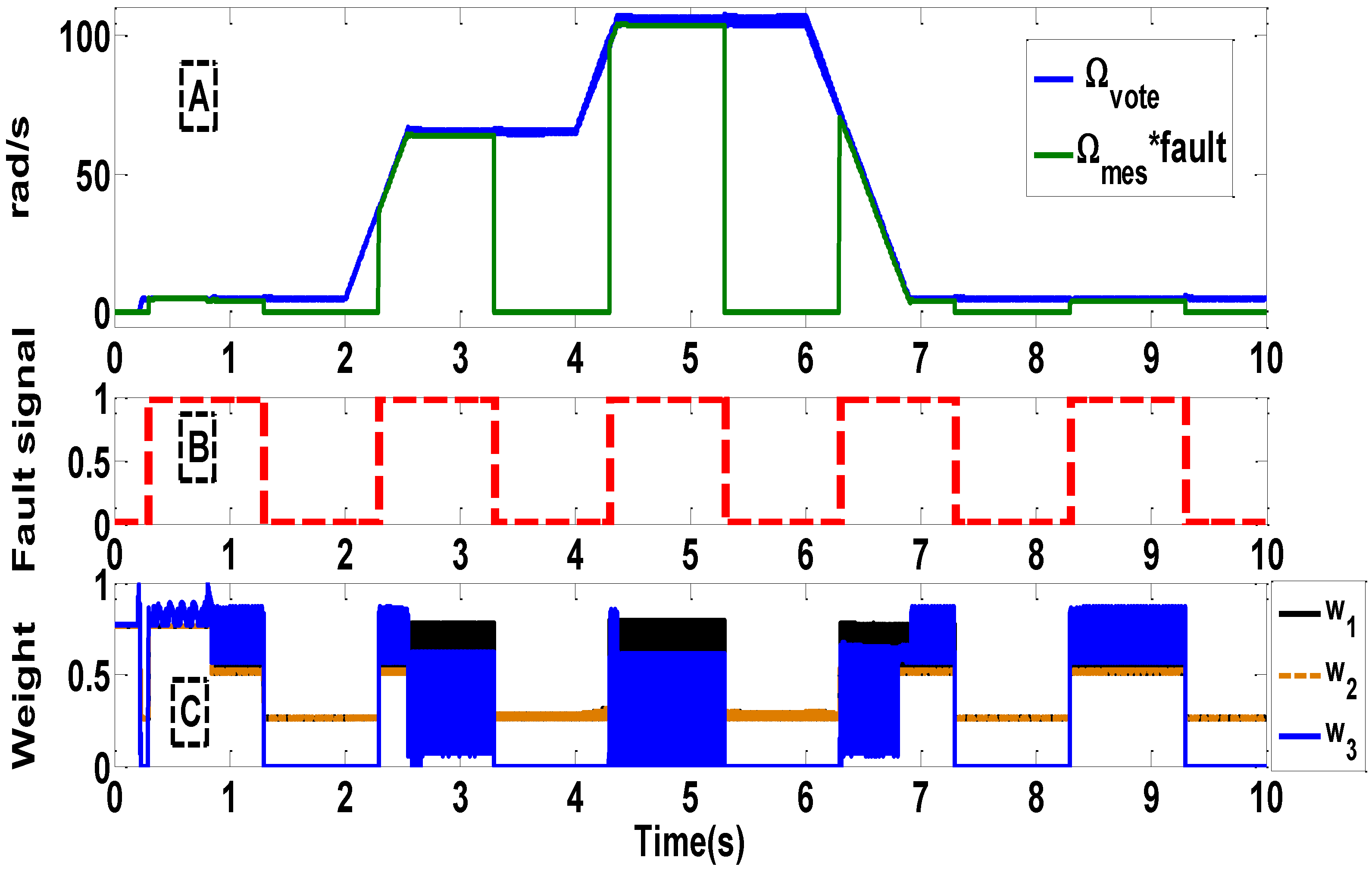

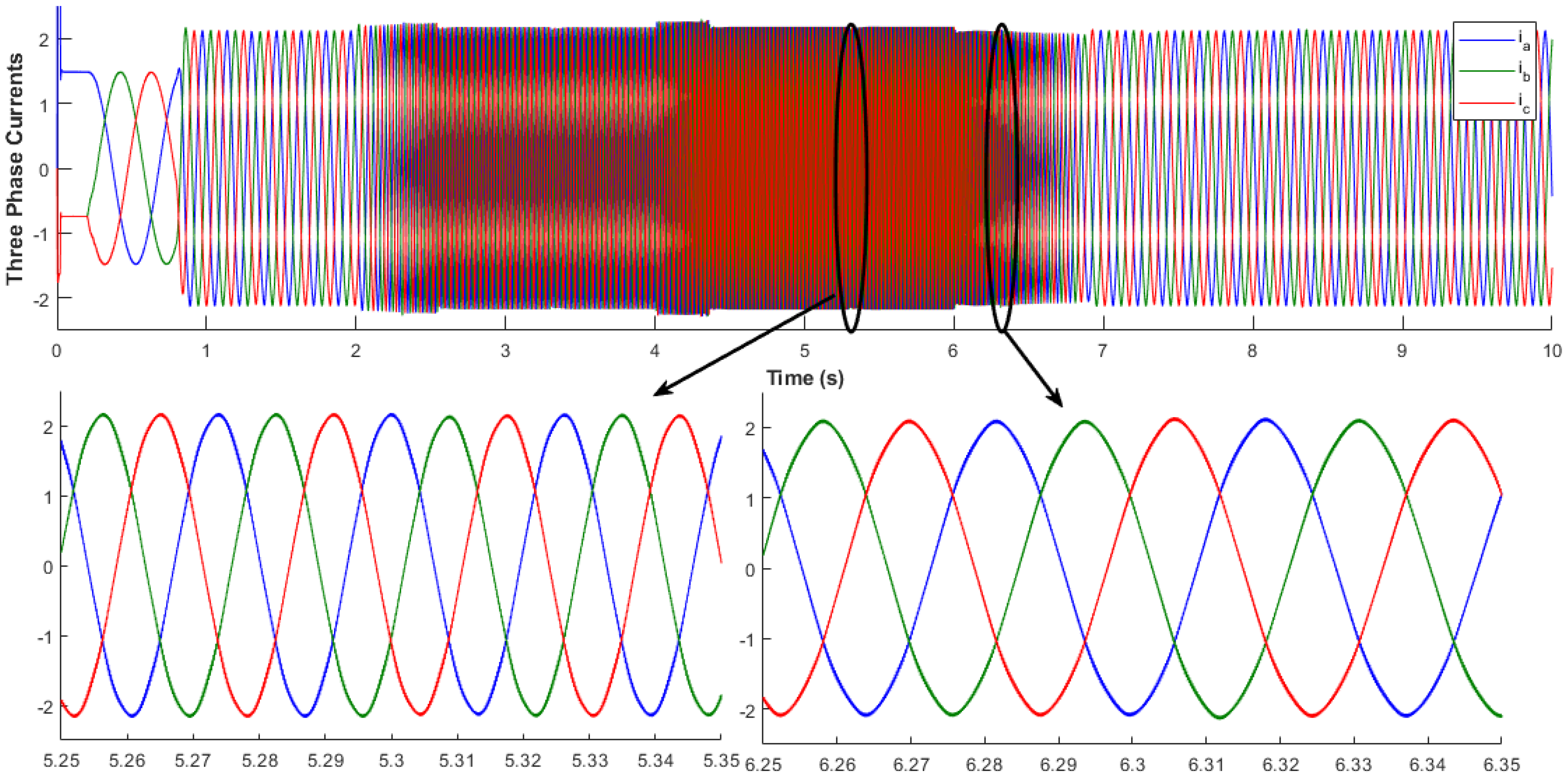

4.4. Simulation and Validation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Akrad, A.; Hilairet, M.; Diallo, D. Design of a Fault-Tolerant Controller Based on Observers for a PMSM Drive. IEEE Trans. Ind. Electron. 2011, 58, 1416–1427. [Google Scholar] [CrossRef]

- Tousizadeh, M.; Che, H.S.; Selvaraj, J.; Rahim, N.A.; Ooi, B.T. Performance Comparison of Fault-Tolerant Three-Phase Induction Motor Drives Considering Current and Voltage Limits. IEEE Trans. Ind. Electron. 2019, 66, 2639–2648. [Google Scholar] [CrossRef]

- Fekih, A.; Mobayen, S.; Chen, C.C. Adaptive robust fault-tolerant control design for wind turbines subject to pitch actuator faults. Energies 2021, 16, 1791. [Google Scholar] [CrossRef]

- Rotondo, D. Background on Fault Tolerant Control. In Advances in Gain-Scheduling and Fault Tolerant Control Techniques; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Amin, A.; Hasan, K. A review of fault tolerant control systems: Advancement and applications. Measurement 2019, 143, 58–68. [Google Scholar] [CrossRef]

- Hasan, M.; Haris, M.; Qin, S. Fault-tolerant spacecraft attitude control: A critical assessment. Prog. Aerosp. Sci. 2022, 130, 100806. [Google Scholar] [CrossRef]

- Raisemche, A.; Boukhnifer, M.; Larouci, C.; Diallo, D. Two active fault-tolerant control schemes of induction-motor drive in EV or HEV. IEEE Trans. Veh. Technol. 2014, 63, 19–29. [Google Scholar] [CrossRef]

- Garramiola, F.; Olmo, J.D.; Poza, J.; Madina, P.; Almandoz, G. Integral Sensor Fault Detection and Isolation for Railway Traction Drive. Sensors 2018, 18, 1543. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Berzoy, A.; Mohammed, O.A.; Restrepo, J. Analysis of the Impact of Stator Inter-Turn Short-Circuit Faults on Induction Machines driven by Direct Torque Control. IEEE Trans. Energy Convers. 2018, 33, 1463–1474. [Google Scholar] [CrossRef]

- Hajary, S.A.; Kianinezhad, R.; Seifossadat, S.G.; Mortazavi, S.S.; Saffarian, A. Detection and Localization of Open-phase Fault in Three Phase Induction Motor Drives using Second Order Rotational Park Transformation. IEEE Trans. Power Electron. 2019, 34, 11241–11252. [Google Scholar] [CrossRef]

- Najafabadi, T.A.; Salmasi, F.R.; Jabehdar-Maralani, P. Detection and isolation of speed-, DC-link voltage-, and current-sensor faults based on an adaptive observer in induction-motor drives. IEEE Trans. Ind. Electron. 2011, 58, 1662–1672. [Google Scholar] [CrossRef]

- Morel, C.; Akrad, A.; Sehab, R.; Azib, T.; Larouci, C. Open-Circuit Fault-Tolerant Strategy for Interleaved Boost Converters via Filippov Method. Energies 2022, 15, 352. [Google Scholar] [CrossRef]

- Alyoussef, F.; Akrad, A. Speed Sensor Fault-Tolerant Controller for Induction Motor Using New Minimum Probability Voter Based on Signal Strength. In Proceedings of the 2019 International Conference on Applied Automation and Industrial Diagnostics (ICAAID), Elazig, Turkey, 25–27 September 2019. [Google Scholar]

- Yu, Y.; Wang, Z.; Xu, D.; Zhou, T.; Xu, R. Speed and Current Sensor Fault Detection and Isolation Based on Adaptive Observers for IM Drives. J. Power Electron. 2014, 14, 967–979. [Google Scholar] [CrossRef]

- Tabbache, B.; Benbouzid, M.; Kheloui, A. On the Transition Improvement of EV or HEV Induction Motor Propulsion Sensor Fault-Tolerant Controller. In Proceedings of the IEEE Vehicle Power and Propulsion Conference, Lille, France, 1–3 September 2010. [Google Scholar]

- Chakraborty, C.; Verma, V. Speed and current sensor fault detection and isolation technique for induction motor drive using axes transformation. IEEE Trans. Ind. Electron. 2015, 62, 1943–1954. [Google Scholar] [CrossRef]

- Choi, C.; Lee, K.; Lee, W. Observer-based phase-shift fault detection using adaptive threshold for rotor position sensor of permanent-magnet synchronous machine drives in electromechanical brake. IEEE Trans. Ind. Electron. 2015, 62, 1964–1974. [Google Scholar] [CrossRef]

- Lorczak, P.R.; Caglayan, A.K.; Eckhardt, D.E. A theoretical investigation of generalized voters for redundant systems. In Proceedings of the Nineteenth International Symposium on Fault-Tolerant Computing, Chicago, IL, USA, 21–23 June 1989. [Google Scholar]

- Latif-Shabgahi, G.; Hirst, A.J. A fuzzy voting scheme for hardware and software fault tolerant systems. Fuzzy Sets Syst. 2005, 150, 579–598. [Google Scholar] [CrossRef]

- Leung, Y.W. Maximum Likelihood Voting for Fault-Tolerant Software with Finite Output-Space. IEEE Trans. Reliab. 1995, 44, 419–427. [Google Scholar] [CrossRef]

- Raisemche, A.; Boukhnifer, M.; Diallo, D. New fault-tolerant control architectures based on voting algorithms for electric vehicle induction motor drive. Trans. Inst. Meas. Control. 2016, 38, 1120–1135. [Google Scholar] [CrossRef]

- Lin, F.J.; Wai, R.J.; Chou, W.D.; Hsu, S.P. Adaptive backstepping control using recurrent neural network for linear induction motor drive. IEEE Trans. Ind. Electron. 2002, 49, 134–146. [Google Scholar]

- Soto, R.; Yeung, K.S. Sliding-mode control of an induction motor without flux measurement. IEEE Trans. Ind. Appl. 1995, 31, 744–751. [Google Scholar] [CrossRef]

- Jia, Z.; Yu, J.; Mei, Y. Integral backstepping sliding mode control for quadrotor helicopter under external uncertain disturbances. Aerosp. Sci. Technol. 2017, 68, 299–307. [Google Scholar] [CrossRef]

- Adhikary, N.; Mahanta, M. Integral backstepping sliding mode control for underactuated systems: Swing-up and stabilization of the Cart-Pendulum System. ISA Trans. 2013, 52, 870–880. [Google Scholar] [CrossRef] [PubMed]

- Qureshi, M.A.; Ahmad, I.; Munir, M.F. Double integral sliding mode control of continuous gain four quadrant quasi-z-source converter. IEEE Access 2018, 6, 77785–77795. [Google Scholar] [CrossRef]

- Pradhan, R.; Subuddhi, B. Double Integral Sliding Mode MPPT Control of a Photovoltaic System. IEEE Trans. Control. Syst. Technol. 2016, 24, 285–292. [Google Scholar] [CrossRef]

- Vas, P. Sensorless Vector and Direct Torque Control; Oxford University Press: London, UK, 1998. [Google Scholar]

- Hilairet, M.; Auger, F.; Berthelot, E. Speed and rotor flux estimation of induction machines using a two-stage extended Kalman filter. Automatica 2009, 45, 1819–1827. [Google Scholar] [CrossRef]

- Lascu, C.; Boldea, I.; Blaabjerg, F. A class of speed-sensorless sliding-mode observers for high-performance induction motor drives. IEEE Trans. Ind. Electron. 2009, 56, 3394–3403. [Google Scholar] [CrossRef]

- Yang, J.; Zhu, F.; Wang, X.; Bu, X. Robust sliding-mode observer-based sensor fault estimation, actuator fault detection and isolation for uncertain nonlinear systems. Int. J. Control Autom. Syst. 2015, 13, 1037–1046. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| Rated output power | Pn = 1.2 kW |

| Rated speed | N = 1440 tr/min |

| Rated voltage | Vn = 220 V |

| Rated current | In = 6 A |

| Stator resistance | Rs = 1.8 Ω |

| Rotor resistance | Rr = 1.3 Ω |

| Stator inductances | Lls = 0.142 mH |

| Rotor inductances | Llr = 0.076 mH |

| Number of pole pairs | p = 2 |

| Inertia load | J = 0.012 kg·m2 |

| Viscous coefficient | f = 0.004 Nm/s |

| Item | Parameters |

|---|---|

| BS Controller | , , , |

| IBS-DISMC | , , , , , , and |

| EKF | |

| SMO | and |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alyoussef, F.; Akrad, A.; Sehab, R.; Morel, C.; Kaya, I. Velocity Sensor Fault-Tolerant Controller for Induction Machine Using Intelligent Voting Algorithm. Energies 2022, 15, 3084. https://doi.org/10.3390/en15093084

Alyoussef F, Akrad A, Sehab R, Morel C, Kaya I. Velocity Sensor Fault-Tolerant Controller for Induction Machine Using Intelligent Voting Algorithm. Energies. 2022; 15(9):3084. https://doi.org/10.3390/en15093084

Chicago/Turabian StyleAlyoussef, Fadi, Ahmad Akrad, Rabia Sehab, Cristina Morel, and Ibrahim Kaya. 2022. "Velocity Sensor Fault-Tolerant Controller for Induction Machine Using Intelligent Voting Algorithm" Energies 15, no. 9: 3084. https://doi.org/10.3390/en15093084

APA StyleAlyoussef, F., Akrad, A., Sehab, R., Morel, C., & Kaya, I. (2022). Velocity Sensor Fault-Tolerant Controller for Induction Machine Using Intelligent Voting Algorithm. Energies, 15(9), 3084. https://doi.org/10.3390/en15093084