Thermo-Chemical Conversion of Microwave Selectively Pre-Treated Biomass Blends

Abstract

:1. Introduction

2. Experimental Equipment and Methods

2.1. Weight Loss Measurements of Blends

2.2. Measurements of the Yield of Volatile Compounds

2.3. Measurements of Combustion Characteristics

2.4. Methodology of Biomass Pre-Treatment

3. Results

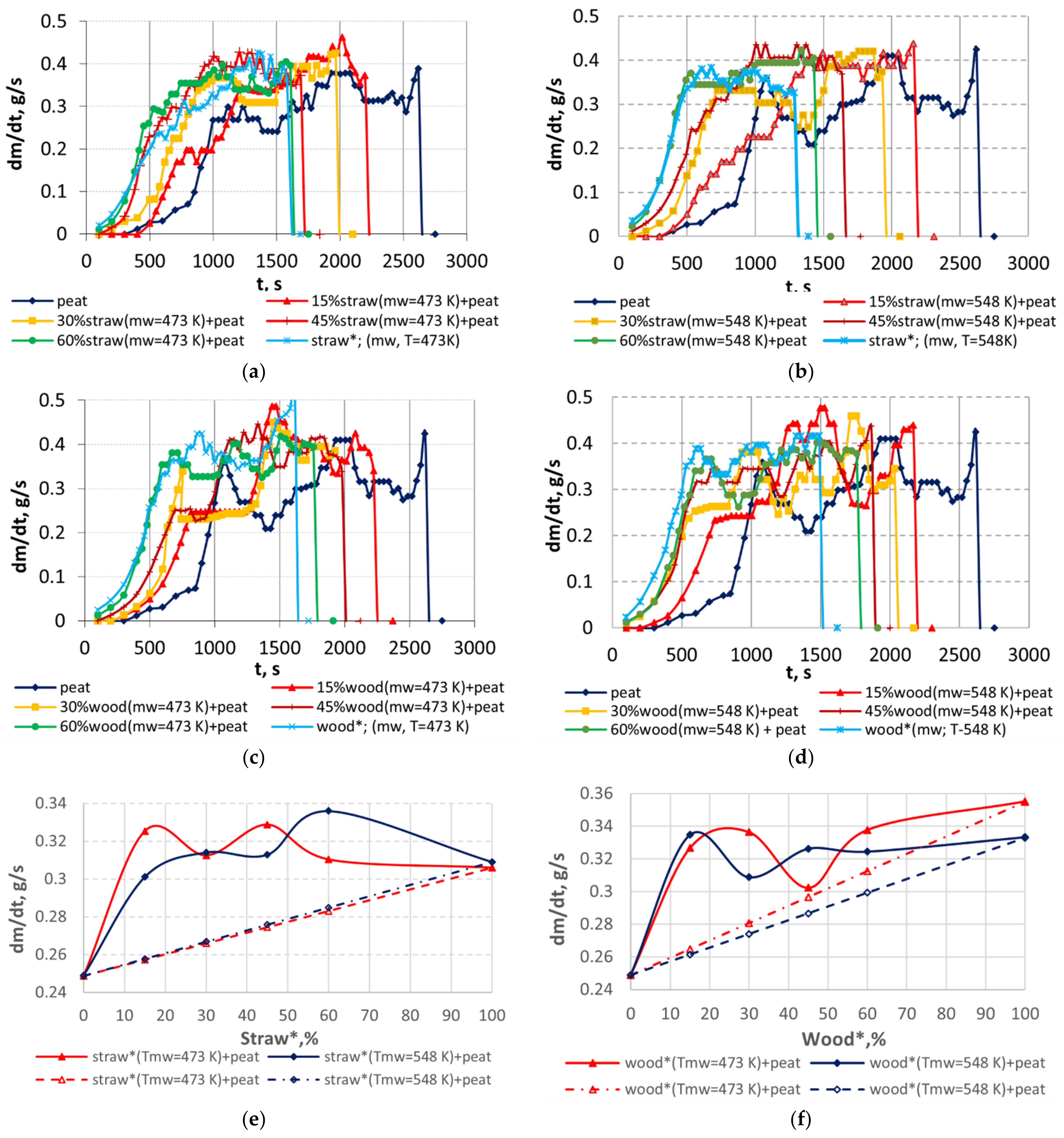

3.1. Thermal Decomposition of Selectively Activated Biomass Blends

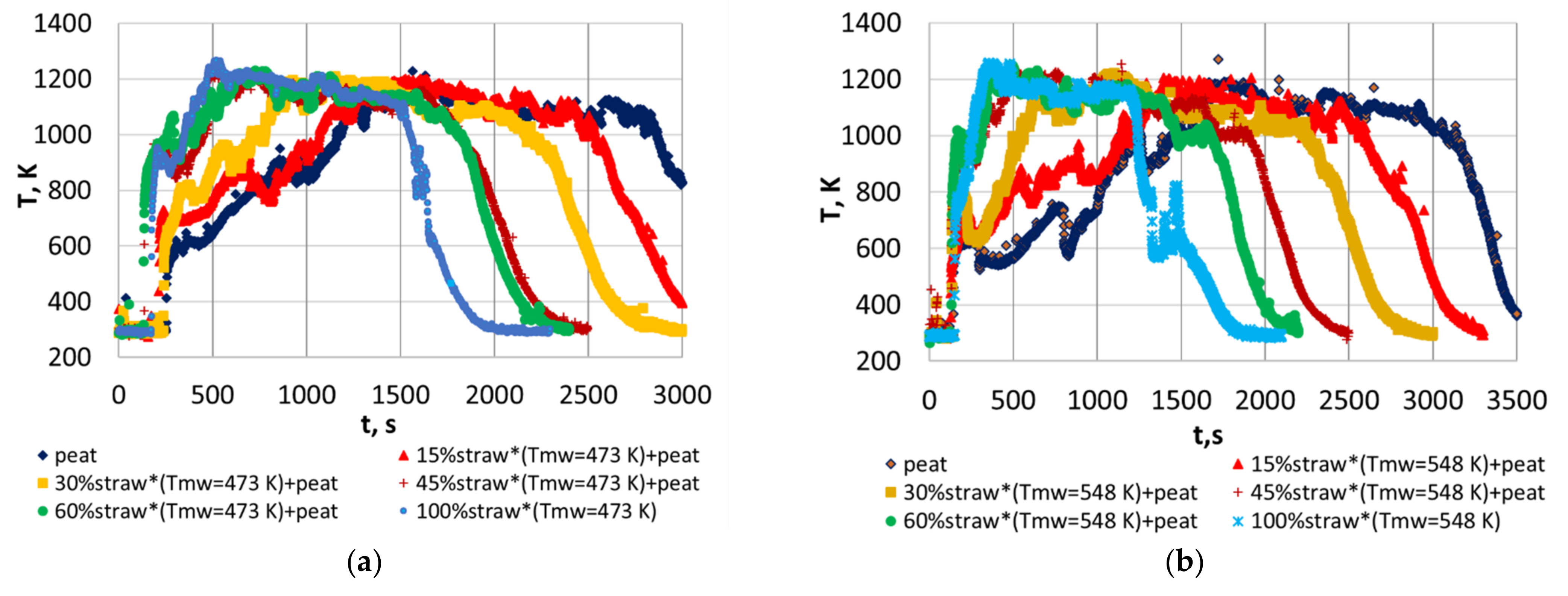

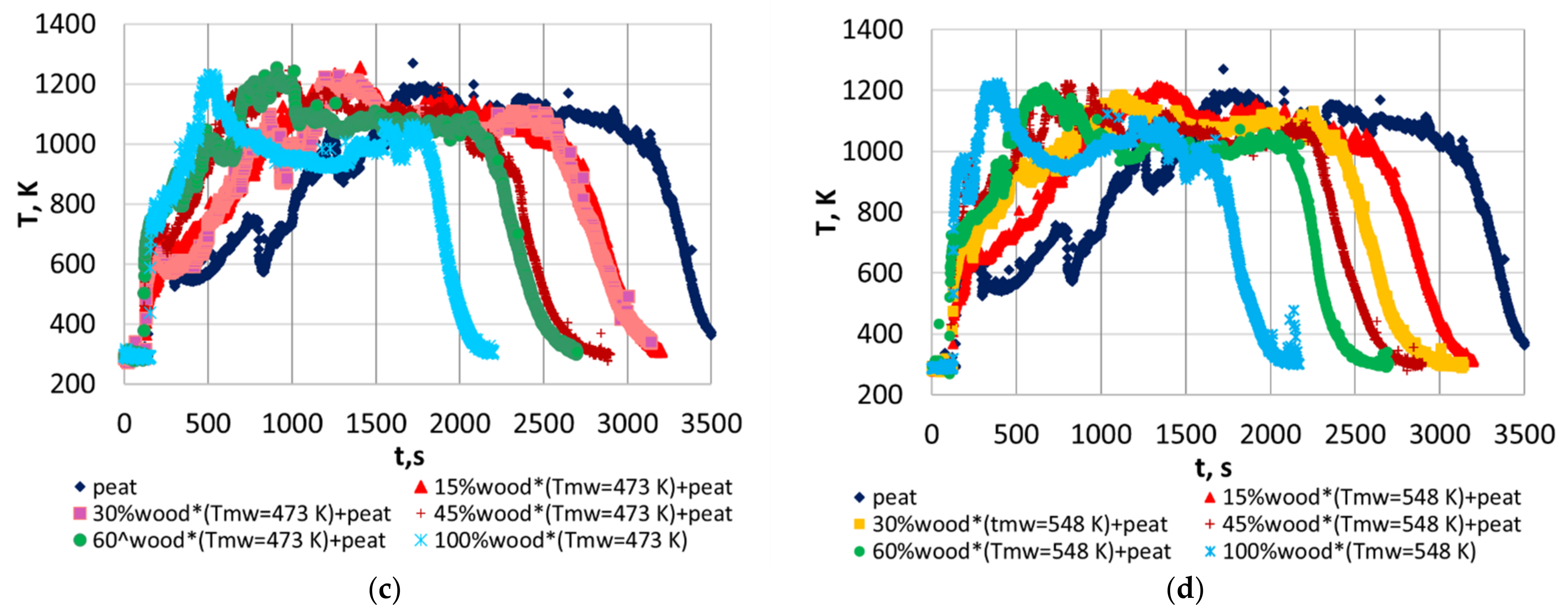

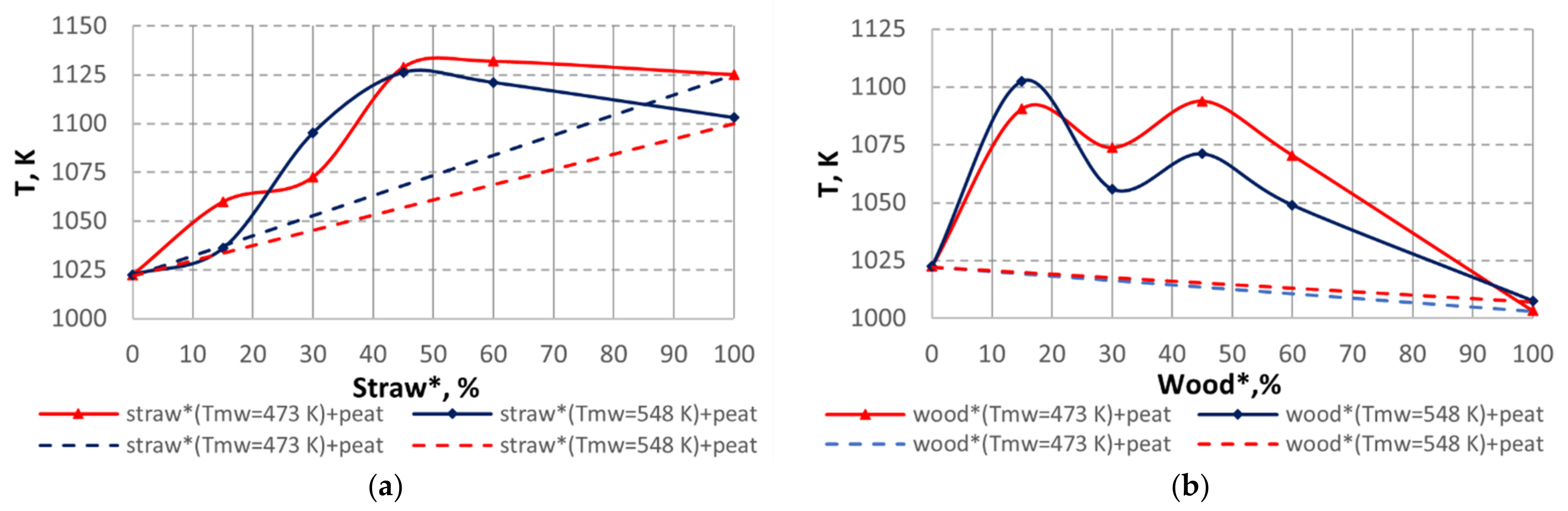

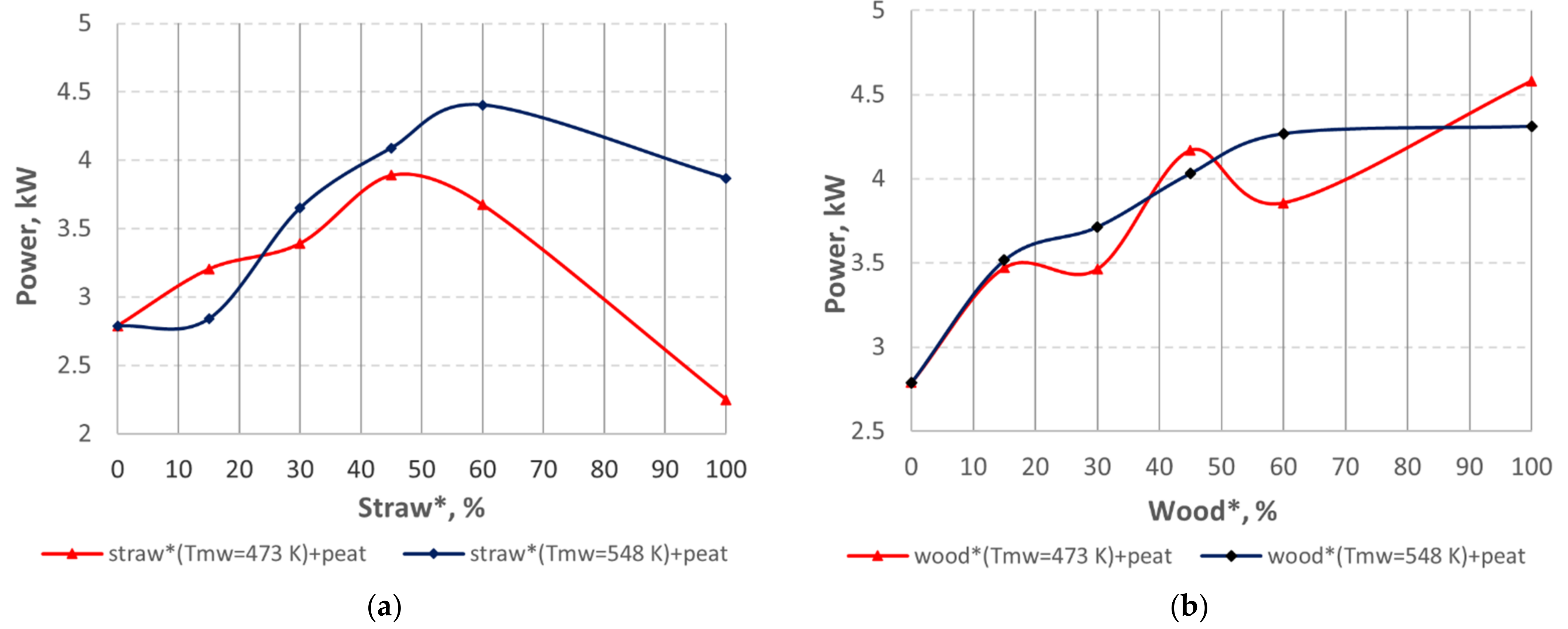

3.2. Combustion Characteristics of Selectively Activated Biomass Blends

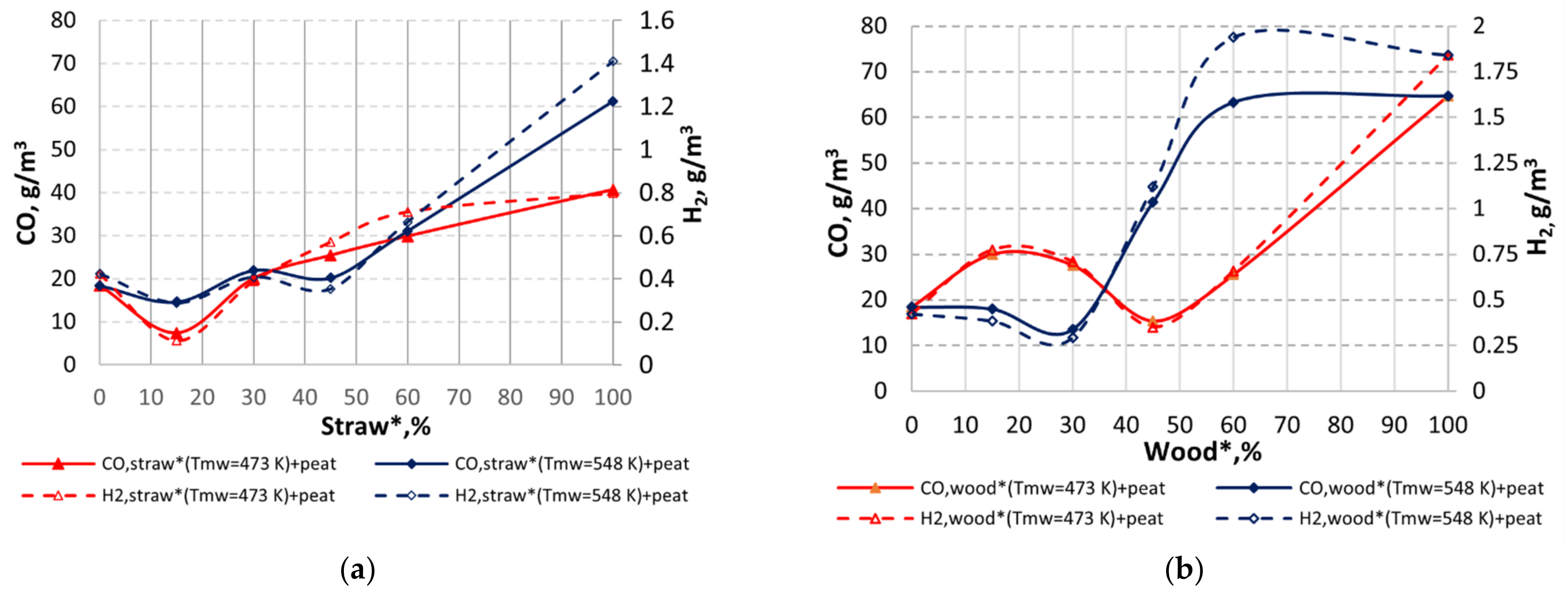

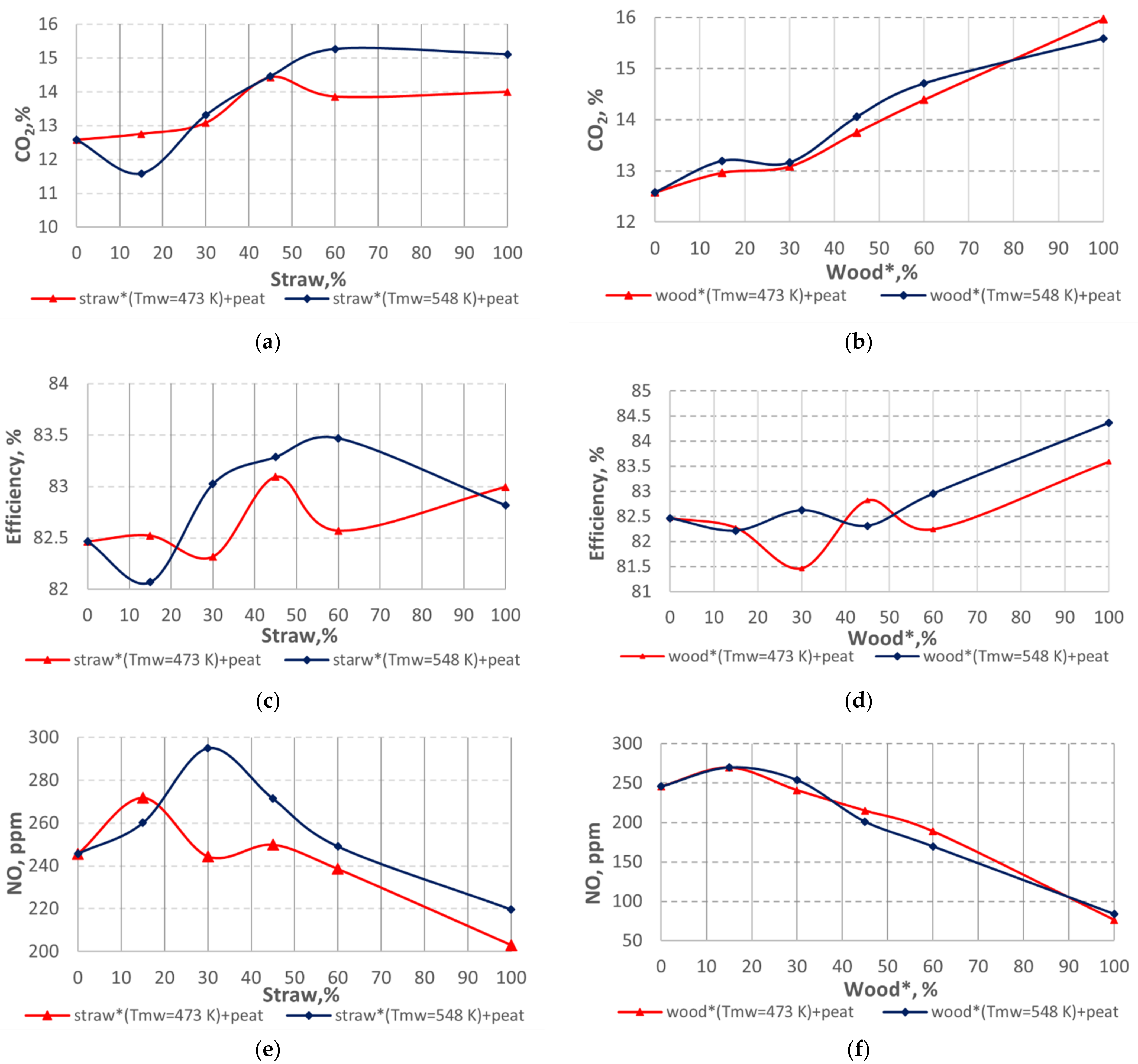

3.3. Effect of Selective MW Pre-Treatment of Blends on the Composition of Emissions

3.4. Numerical Model of Thermo-Chemical Conversion of Pre-Treated Straw Biomass Pellets

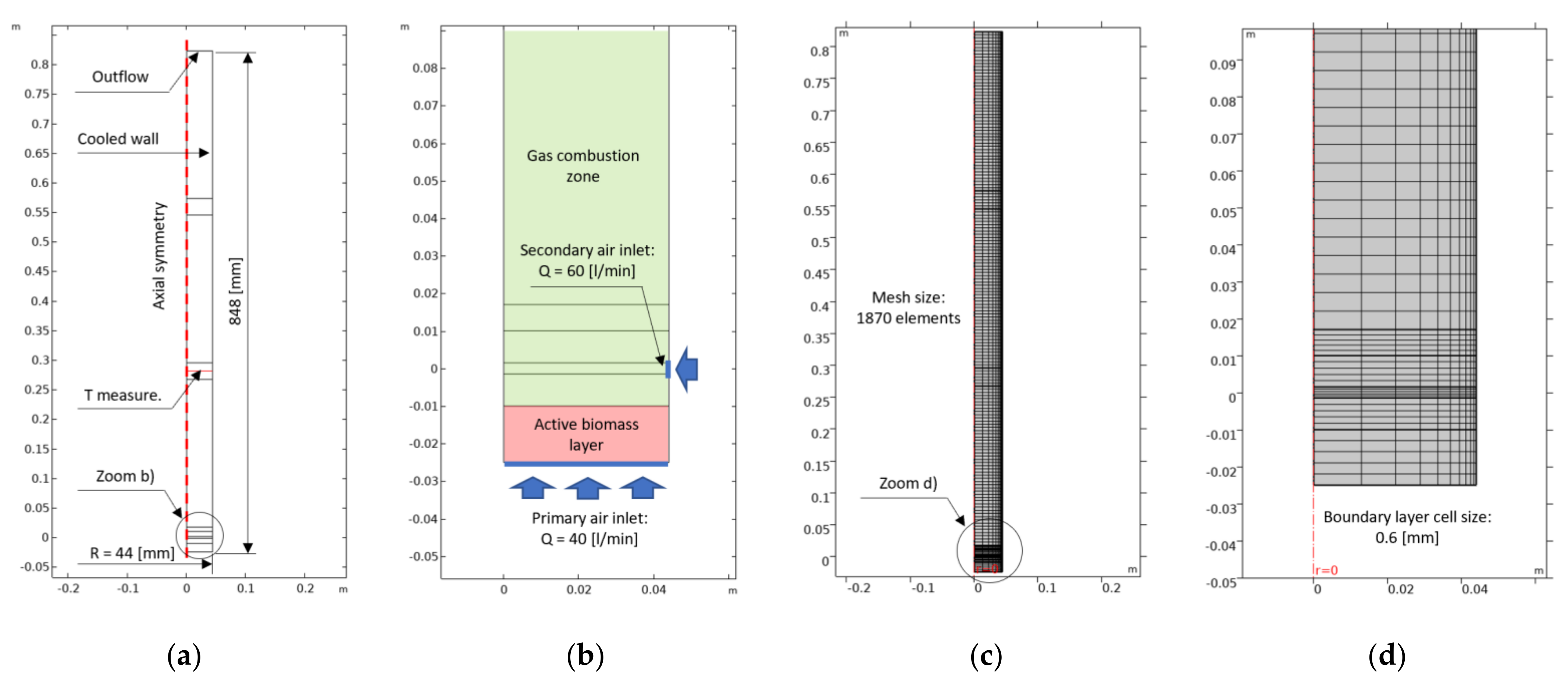

3.4.1. Numerical Model Geometry and Parameters

3.4.2. Modelling MW Pre-Treatment Effect on Thermal Decomposition of Straw Biomass Pellets

3.4.3. Char Oxidation

3.4.4. Release of Moisture

3.4.5. Combustion of Gases

3.4.6. System of Equations for Gas Mixture Modelling

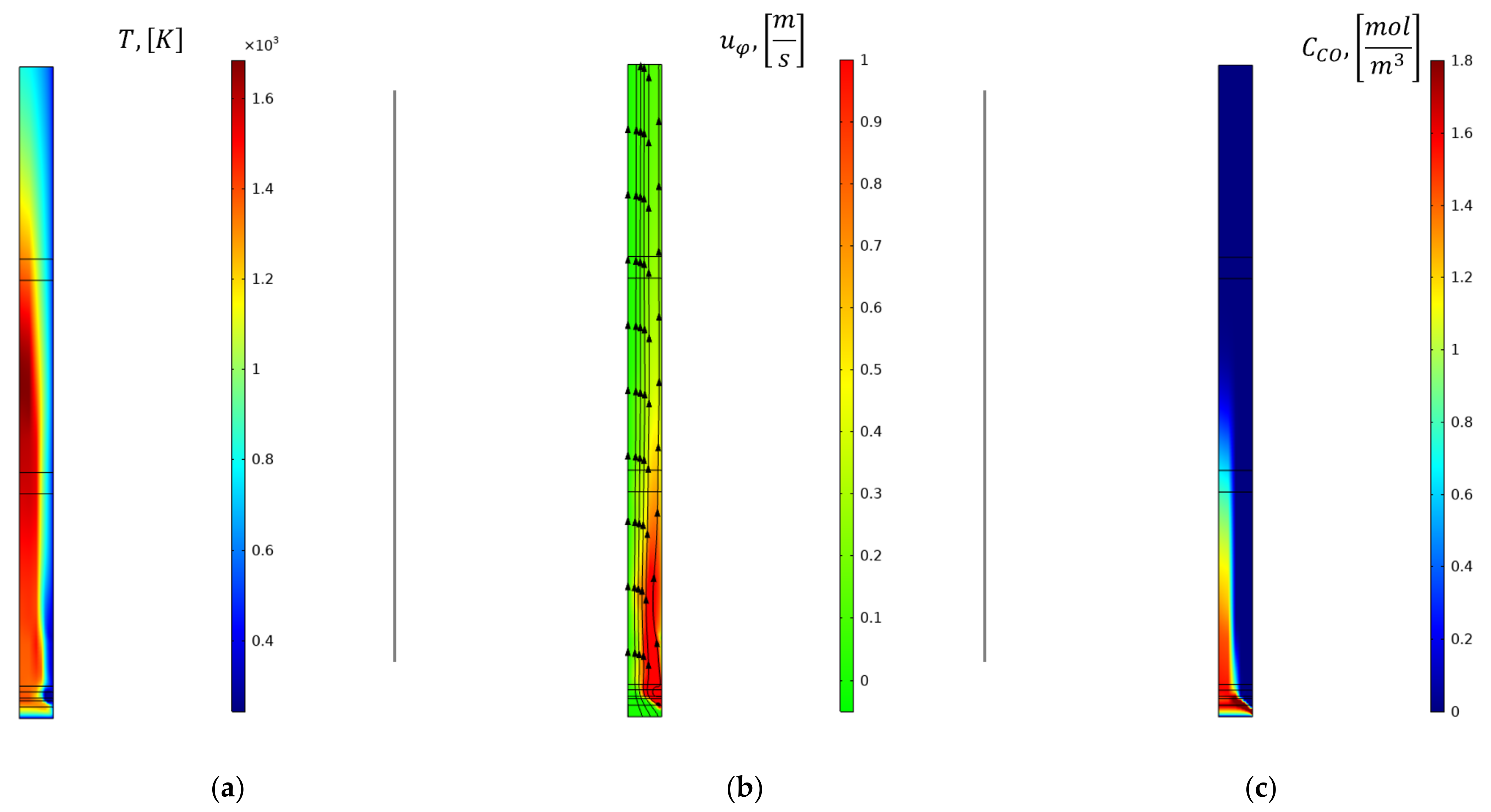

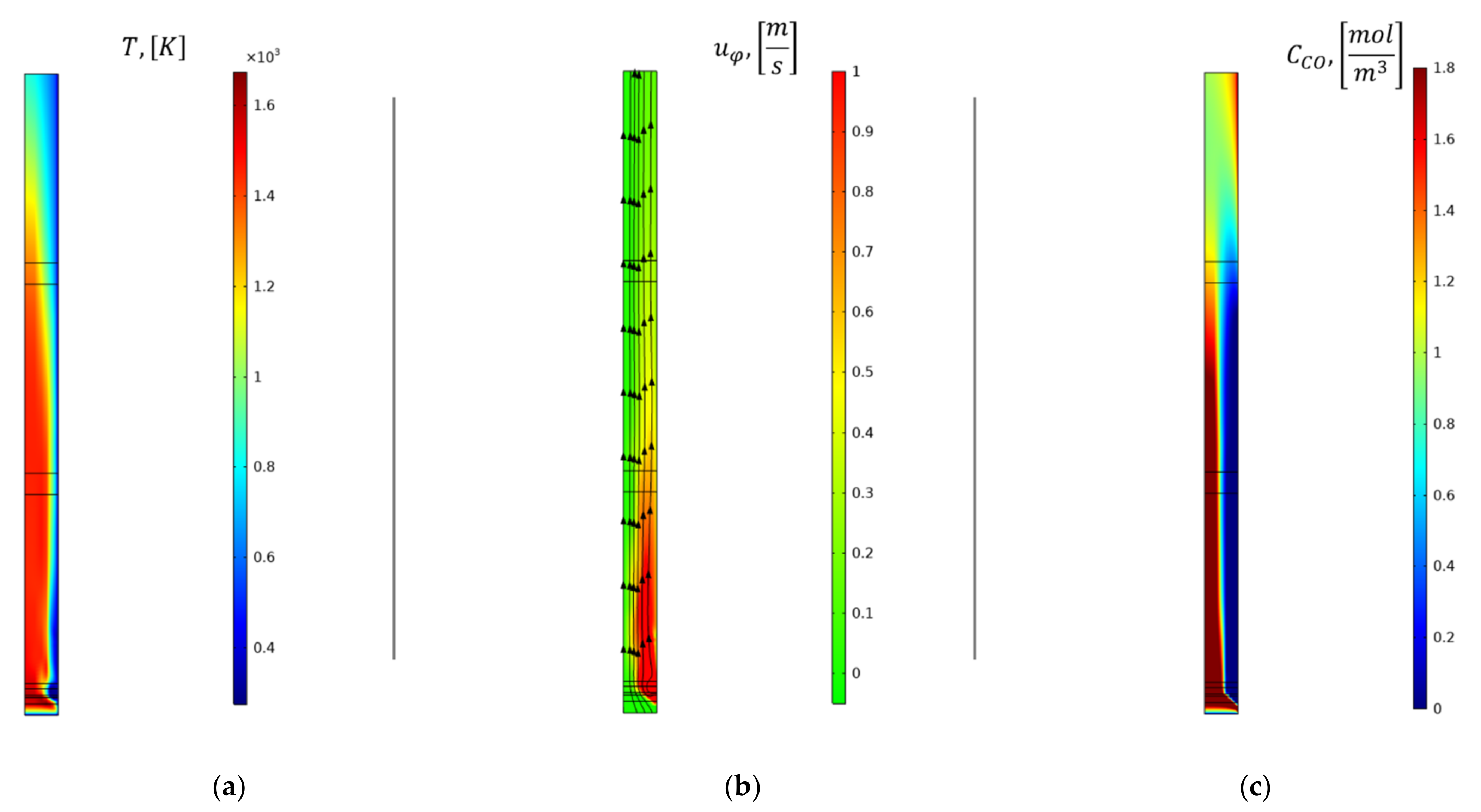

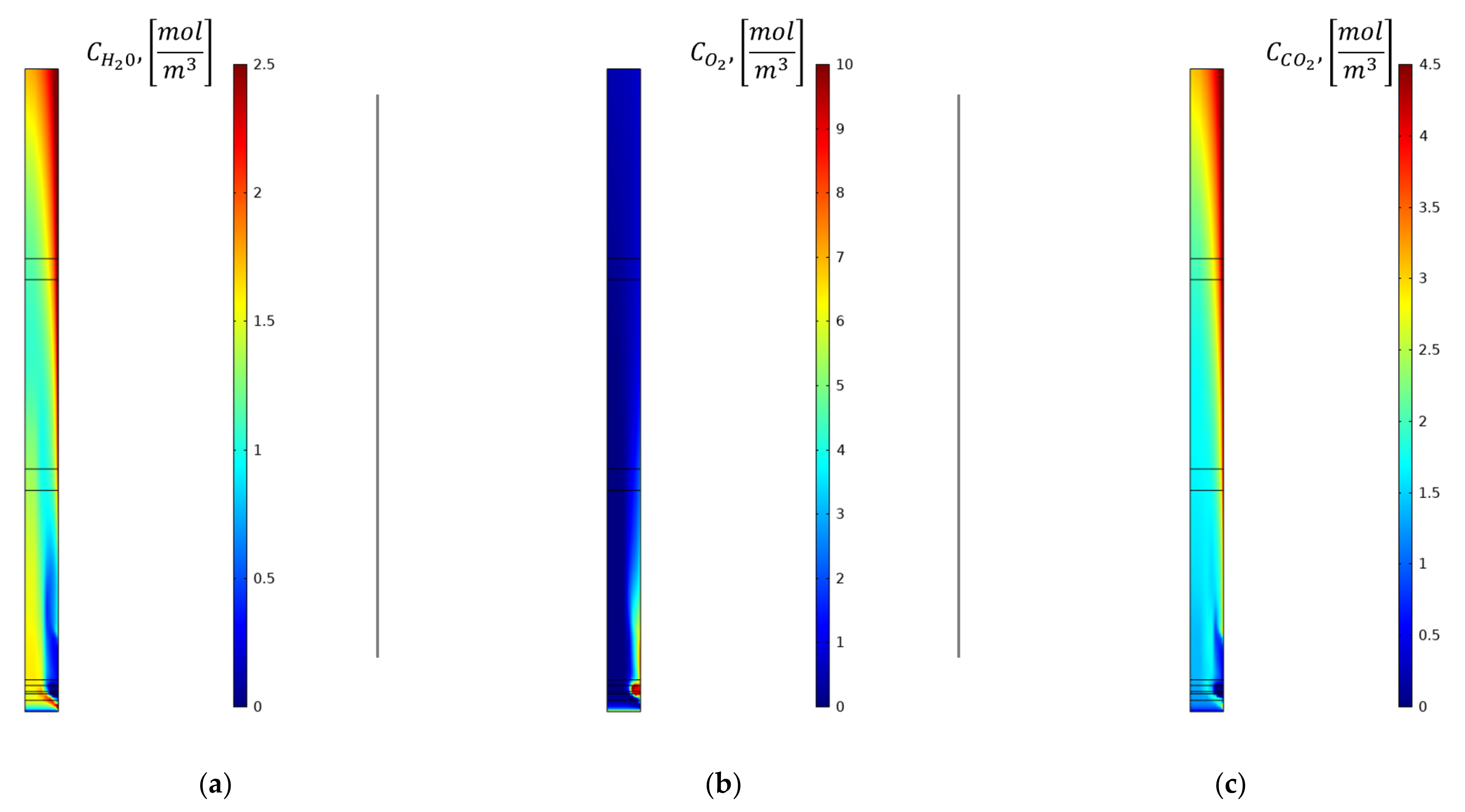

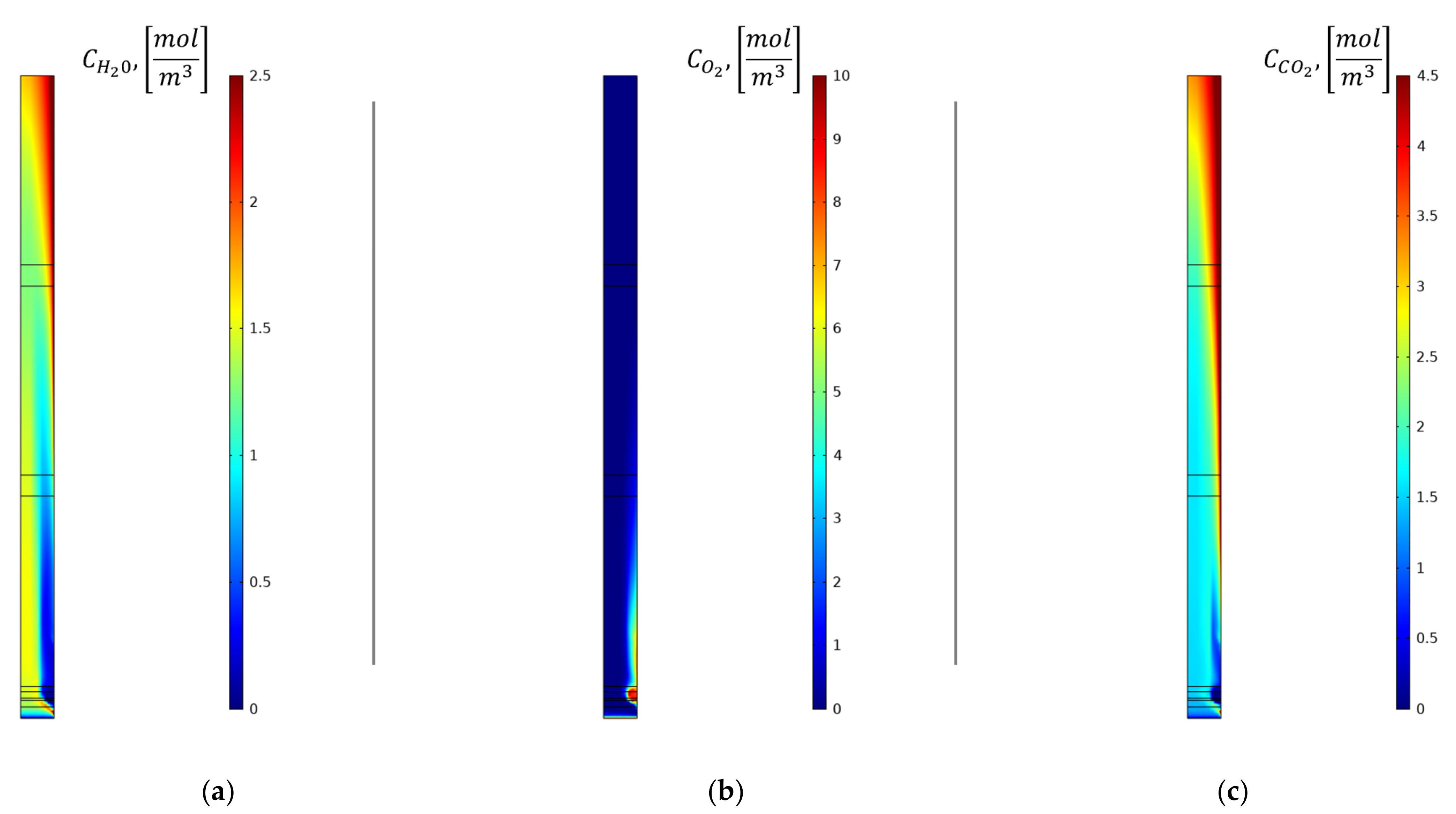

3.4.7. Results of Numerical Modelling

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| microwave pre-treatment temperature, K | |

| weight loss rate, g/s | |

| mass fraction of raw and MW pre-treated pellets in the blend | |

| air-to-fuel ratio | |

| heat (enthalpy) of reaction, kJ/mol or kJ/kg | |

| primary and secondary air flowrates, L/min | |

| velocity, m/s | |

| mass fraction of volatiles, char or other species in biomass | |

| mass fraction moisture and ash in biomass | |

| volume of the active biomass layer, m3 | |

| generation rate of species, kg/(m3 s) | |

| mass density, kg/m3 | |

| pressure, Pa | |

| shear and Reynolds stress tensor, Pa | |

| gravitational acceleration, m/s2 | |

| external force, N/m3 | |

| parameter for stoichiometric oxygen amount | |

| generated heat density, W/m3 | |

| heat capacity, J/(kg·K) | |

| reaction rate, 1/(m3 s·mol) | |

| mass fraction of species in gas reactions | |

| dynamic viscosity of blend, Pa·s | |

| permeability of the biomass pellet bed, m−2 | |

| thermal conductivity of the gas mixture W/(m·K) |

References

- EU Climate Action and the European Green Deal. 2030 Climate Target Plan|Climate Action (europa.eu). Available online: https://ec.europa.eu/clima/eu-action/european-green-deal/2030-climate-target-plan_en (accessed on 16 January 2022).

- Bui, H.-H.; Tran, K.-Q.; Chen, W.-H. Pyrolysis of microalgae residues—A Kinetic study. Bioresour. Technol. 2015, 199, 362–366. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.H.; Lin, B.J.; Lin, Y.Y.; Chu, Y.S.; Ubando, A.T.; Show, P.L.; Ongh, H.C.; Chang, J.S.; Ho, S.H.; Culaba, A.B.; et al. Progress in biomass torrefaction: Principles, applications and challenges. Prog. Energy Combust. Sci. 2021, 82, 10087. [Google Scholar] [CrossRef]

- Vassilev, S.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An overview of the chemical composition of biomass. Fuel 2010, 89, 913–933. [Google Scholar] [CrossRef]

- Mocraoui, S. Introduction to Biomass Energy Conversion. 2015. Available online: https://set.ksu.edu.sa/sites/set.ksu.edu.sa/files/imce_images/third_series_by_dr-_salim.pdf (accessed on 16 January 2022).

- Van der Stelt, M.J.C. Chemistry and Reaction Kinetics of Biowaste Torrefaction. Ph.D. Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 2011; p. 245. [Google Scholar] [CrossRef]

- Mamvura, T.A.; Danha, G. Biomass torrefaction as an emerging technology to aid in energy production. Heliyon 2020, 6, 503–531. [Google Scholar] [CrossRef]

- Chen, W.H.; Peng, J.; Bi, X.T. A state of the art review of biomass torrefaction, densification and applications. Renew. Sustain. Energy Rev. 2015, 44, 847–866. [Google Scholar] [CrossRef]

- Basu, P.; Sadhukhan, A.K.; Gupta, P.; Rao, S.; Dhungana, A.; Acharya, B. An experimental and theoretical investigation on torrefaction of a large wet wood particle. Bioresour. Technol. 2014, 159, 215–222. [Google Scholar] [CrossRef]

- Barskov, S.; Zappi, M.; Buchireddy, P.; Dufreche, S.; Guillory, J.; Gang, D.; Hernandez, R.; Bajpai, R.; Baudier, J.; Cooper, R.; et al. Torrefaction of biomass: A review of production methods for biocoal from cultured and waste lignocellulosic feedstocks. Renew. Energy 2019, 142, 624–642. [Google Scholar] [CrossRef]

- Technology Status and Commercialisation, Applications for Torrefied Biomass and Its Role in Logistics and Trade Webinar. Available online: www.ieabioenergy.com (accessed on 16 January 2022).

- Plans for New Bio-Coal Plant in Estonia, HD Forest. 2018. Available online: https://www.hdforest.com/news/plans-for-new-bio-coal-plant-in-estonia (accessed on 16 January 2022).

- Thrän, D.; Witt, J.; Schaubach, K.; Kiel, J.; Carbo, M.; Maier, J.; Ndibe, C.; Koppejan, J.; Alakangas, E.; Majer, S.; et al. Moving torrefaction towards market introduction. Technical improvements and economic-environmental assessment along the overall torrefaction supply chain through the SECTOR project. Biomass Bioenergy 2016, 89, 184–200. [Google Scholar] [CrossRef] [Green Version]

- Huang, Y.-F.; Chiueh, P.-T.; Kuan, W.-H.; Lo, S.-L. Effects of lignocellulosic composition and microwave poer level on the gaseous product of microwave pyrolysis. Energy 2015, 89, 974–981. [Google Scholar] [CrossRef]

- Huang, Y.-F.; Chiueh, P.-T.; Lo, S.-L. A review on microwave pyrolysis of lignocellulosic biomass. Sustain. Environ. Res. 2016, 26, 103–109. [Google Scholar] [CrossRef] [Green Version]

- Kostas, E.T.; Beneroso, D.; Robinson, J.P. The application of microwave heating in bioenergy: A review on the microwave pre-treatment and upgrading technologies for biomass. Renew. Sustain. Energy Rev. 2017, 77, 12–27. [Google Scholar] [CrossRef] [Green Version]

- Arshanitsa, A.; Akishin, Y.; Zile, E.; Dizhbite, T.; Solodovnik, V.; Telysheva, G. Microwave treatment combined with conventional heating of plant biomass pellets in a rotated reactor as a high rate process for solid biofuel manufacture. Renew. Energy 2016, 91, 386–396. [Google Scholar] [CrossRef]

- Andersone, A.; Arshanitsa, A.; Akishin, Y.; Semenischev, A.; Telysheva, G. Microwave assisted torrefaction of plant biomass of different origin with focus on the solid products valorisation for energy and byond. Chem. Eng. Trans. 2021, 86, 109–114. [Google Scholar]

- Arshanitsa, A.; Dizhbite, T.; Bikovens, O.; Pavlovich, G.; Andersone, A.; Telysheva, G. Effects of Microwave Treatment on the Chemical Structure of Lignocarbohydrate Matrix of Softwood and Hardwood. Energy Fuels 2016, 30, 457–464. [Google Scholar] [CrossRef]

- Lauberts, M.; Lauberte, L.; Arshanitsa, A.; Dizhbite, T.; Dobele, G.; Bikovens, O.; Telysheva, G. Structural transformations of wood and cereal biomass components induced by microwave assisted torrefaction with emphasis on extractable value chemicals obtaining. J. Anal. Appl. Pyrolysis 2018, 134, 1–11. [Google Scholar] [CrossRef]

- Hupa, M. Interaction of fuels in co-firing in FBC. Fuel 2005, 84, 1312–1319. [Google Scholar] [CrossRef]

- Quan, C.; Gao, N. Co-pyrolysis of coal: A review of effects of co-pyrolysis parameters, products properties, and synergistic mechanisms. Appl. Biotechnol. Prod. Biomass Based Fuels 2016, 2016, 6197867. [Google Scholar] [CrossRef] [Green Version]

- Oladejo, J.; Shi, K.; Meng, Y.; Adegbite, S.; Wu, T. Biomass constituents’ interactions with coal during co-firing. Energy Procedia 2019, 158, 1640–1645. [Google Scholar] [CrossRef]

- Xue, J.; Ceylan, S.; Goldfarb, L. Synergism among biomass building blocks? Evolved gas and kinetics analysis of starch and cellulose pyrolysis. Thermochim. Acta 2015, 618, 36–47. [Google Scholar] [CrossRef]

- Wu, Z.; Wang, S.; Zhao, J.; Meng, H. Synergistic effect on thermal behavior during co-pyrolysis of lignocellulosic biomass model components blend with bituminous coal. Bioresour. Technol. 2014, 169, 220–228. [Google Scholar] [CrossRef]

- Vuppaladadiyam, A.K.; Antunes, E.; Sanchez, P.B.; Duan, H.; Zhao, M. Influence of microalgae on synergism during co-pyrolysis with organic waste biomass: A thermogravimetric and kinetic analysis. Renew. Energy 2021, 167, 42–55. [Google Scholar] [CrossRef]

- Oyedun, O.; Gebreegziabher, T.; Hui, C.-W. Co-pyrolysis of biomass and plastics waste. Chem. Eng. Trans. 2013, 35, 883–888. [Google Scholar]

- Lanigan, B. Microwave Processing of Lignocellulosic Biomass for Production of Fuels. Ph.D. Thesis, University of York, New York, NY, USA, 2010. [Google Scholar]

- Goldšteins, L.; Valdmanis, R.; Zaķe, M.; Arshanitsa, A.; Andersone, A. Thermal Decomposition and Combustion of Microwave Pre-Treated Biomass Pellets. Processes 2021, 9, 429. [Google Scholar] [CrossRef]

- Goldsteins, L.; Valdmanis, R.; Zake, M. Activated combustion of biomass blends by microwave pre-treatment of straw. Eng. Rural. Dev. 2021, 20, 152–156. [Google Scholar] [CrossRef]

- Barmina, I.; Goldsteins, L.; Valdmanis, R.; Zake, M. Improvement of biomass gasification/combustion characteristics using the microwave pre-treatment of biomass pellets. Combust. Eng. Technol. 2021, 44, 2018–2025. [Google Scholar] [CrossRef]

- Larina, O.M.; Sinelshchikov, V.A.; Sytchev, G.A. Comparison of thermal conversion methods of different biomass types into gaseous fuel. J. Phys. Conf. Ser. 2016, 774, 1–7. [Google Scholar] [CrossRef]

- Fatehi, H. Numerical Simulation of Combustion and Gasification of Biomass Particles. Ph.D. Thesis, Division of Fluid Mechanics, Department of Energy Sciences Faculty of Engineering LTH, Lund University, Lund, Sweden, 2014; p. 90. [Google Scholar]

- Arshanitsa, A.; Andersone, A.; Telysheva, G. Non-isothermal thermal analysis of different originated lignocellulosic biomass, non-treated and torrified by microwave treatment. Eng. Rural Dev. 2021, 20, 424–430. [Google Scholar]

- Yang, H.; Yan, R.; Chen, H.; Lee, D.H.; Zheng, C. Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 2007, 86, 1781–1788. [Google Scholar] [CrossRef]

- Haushfar, E.; Levas, T.; Skreiberg, O. Experimental investigation on NOx reduction by primary measures in biomass combustion: Straw, peat, sewage sludge, forest residues and wood pellets. Energies 2012, 5, 270–290. [Google Scholar] [CrossRef] [Green Version]

- Koufopanos, C.A.; Papayannakos, N.; Maschio, G.; Lucchesi, A. Modelling of the Pyrolysis of Biomass Particles. Studies on Kinetics, Thermal and Heat Transfer Effects. Can. J. Chem. Eng. 1991, 69, 907–915. [Google Scholar] [CrossRef]

- Zhou, H.; Jensen, A.D.; Glarborg, P.; Jensen, P.A.; Kavaliauskas, A. Numerical modelling of straw combustion in a fixed bed. Fuel 2005, 84, 389–403. [Google Scholar] [CrossRef]

- Miltner, M.; Makaruk, A.; Harasek, M.; Friedl, A. Computational fluid dynamic simulation of a solid biomass combustor: Modelling approaches. Clean Technol. Environ. Policy 2008, 10, 165–174. [Google Scholar] [CrossRef]

- Pedersen, K. The Product Ratio of CO/CO2 in the Oxidation of Biomass Char. Master’s Thesis, Technical University of Denmark, Lyngby, Denmark, 2003. [Google Scholar]

- Magnussen, B.F.; Hjertager, B.H. On mathematical modelling of turbulent combustion with special emphasis on soot formation and combustion. Symp. Combust. 1977, 16, 719–729. [Google Scholar] [CrossRef]

- Richardson, J.F.; Harker, J.H.; Backhurst, J.R. CHAPTER 4—Flow of fluids through granular beds and packed columns. In Chemical Engineering, 5th ed.; Richardson, J.F., Harker, J.H., Backhurst, J.R., Eds.; Butterworth-Heinemann: Oxford, UK, 2002; Volume 2, pp. 191–236. [Google Scholar]

| Tmw, K | Moist.% | Ash,% | Vol,% | Char,% | dm/dt, g/s |

|---|---|---|---|---|---|

| - | 10 | 5 | 75.9 | 24.1 | 0.3 |

| 473 | 2 | 5 | 72.2 | 27.8 | 0.39 |

| 523 | 2 | 7.5 | 64.3 | 35.7 | 0.38 |

| 548 | 2 | 8.751 | 49.151 | 50.851 | 0.37 |

| 573 | 2 | 13.75 | 34 | 66 | 0.42 |

| TMW, K | Q, kW | T, K | Mass Fraction at Outlet: | |||||

|---|---|---|---|---|---|---|---|---|

| CO | CO2 | H2 | O2 | N2 | H2O | |||

| - | 3.77 | 1042 | 0.0% | 30.1% | 0.0% | 3.4% | 59.6% | 7.0% |

| 473 | 4.50 | 1153 | 6.1% | 33.1% | 0.0% | 1.6% | 52.2% | 7.0% |

| 523 | 4.55 | 1155 | 6.8% | 33.0% | 0.0% | 2.4% | 51.9% | 5.9% |

| 548 | 4.79 | 1184 | 9.2% | 33.5% | 0.0% | 4.9% | 48.0% | 4.4% |

| 573 | 5.32 | 1225 | 14.3% | 35.3% | 0.0% | 9.6% | 37.4% | 3.4% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Goldšteins, L.; Dzenis, M.G.; Valdmanis, R.; Zaķe, M.; Arshanitsa, A. Thermo-Chemical Conversion of Microwave Selectively Pre-Treated Biomass Blends. Energies 2022, 15, 755. https://doi.org/10.3390/en15030755

Goldšteins L, Dzenis MG, Valdmanis R, Zaķe M, Arshanitsa A. Thermo-Chemical Conversion of Microwave Selectively Pre-Treated Biomass Blends. Energies. 2022; 15(3):755. https://doi.org/10.3390/en15030755

Chicago/Turabian StyleGoldšteins, Linards, Māris Gunārs Dzenis, Raimonds Valdmanis, Maija Zaķe, and Alexandr Arshanitsa. 2022. "Thermo-Chemical Conversion of Microwave Selectively Pre-Treated Biomass Blends" Energies 15, no. 3: 755. https://doi.org/10.3390/en15030755

APA StyleGoldšteins, L., Dzenis, M. G., Valdmanis, R., Zaķe, M., & Arshanitsa, A. (2022). Thermo-Chemical Conversion of Microwave Selectively Pre-Treated Biomass Blends. Energies, 15(3), 755. https://doi.org/10.3390/en15030755