Abstract

This study analysed a novel re-liquefaction system integrated with a fuel supply system (FSS) for an LPG carrier to conventional systems. The re-liquefaction system and FSS were installed independently in a conventional LPG carrier, while those systems were combined in the novel system. The condensed LPG in the re-liquefaction system was directly transferred to the FSS without the cooling and expansion process in the novel system. 84,000 m3 LPG carrier equipped with a 10 MW engine at normal continuous rating (NCR) was selected as a target ship. Aspen HYSYS ver.12.1 was employed for process simulation. The results showed that the energy consumption for the novel system was reduced by 38%. The energy for re-liquefaction was decreased because the flow rate recirculated was decreased, and the energy for FSS was reduced as the temperature of the stream supplied to the FSS was relatively high in the novel system. A sensitivity analysis was conducted to investigate the effect of the parameters on the results. The investigated parameters were LPG compositions, seawater temperature, compressor efficiency, and pump efficiency. The energy consumption for the system was significantly different depending on the LPG composition, and the energy consumption was changed by 2.5% for conventional systems and 0.9% for the novel systems with the variation of 4 °C seawater temperature. The energy for the novel system was reduced by 2.8% for conventional systems and 2.3% for the novel systems with the 5% increment of compressor efficiency, whereas pump efficiency had little effect on the results.

1. Introduction

Global warming caused by greenhouse gas (GHG) is one of the critical problems that humanity is facing. GHG emissions from shipping accounted for about 2.89% of global emissions in 2018 [1]. Various solutions were proposed to decrease CO2 emissions from shipping, including the improvement of hull design, the efficiency enhancement of propulsion and power systems, operation optimization like speed reduction, route change, and the use of alternative energy. Alternative energy is considered a practical solution to meet tightened international, national, and local regulations. Alternative energies include liquefied natural gas (LNG), liquefied petroleum gas (LPG), methanol, ethanol, ammonia, hydrogen, biofuels, batteries, solar power, and wind power. Each alternative energy has advantages and disadvantages in terms of fuel price, eco-friendliness, safety, and fuel availability.

Classification societies have intensely studied various alternative fuels to propose an optimal fuel to meet the International Maritime Organization (IMO)’s regulations. Det Norske Veritas∙Germanischer Lloyd (DNVGL) (2018) published the report for the assessment of selected alternative fuels and technologies to provide decision support for investments in ships. It contains an overview of selected alternative fuels including LNG, LPG, methanol, biofuel, and hydrogen as well as emerging technologies such as batteries, fuel cell systems, and wind-assisted propulsion. The guideline paper is dedicated to technical parameters and limitations without considering local market conditions and incentive schemes [2]. DNVGL (2019) published a report for the comparison of alternative marine fuels. The commercial and operational viability of alternative marine fuels were assessed by examining the existing academic and industry literature. They selected six alternative fuels containing methanol, LPG, advanced biodiesel, ammonia, hydrogen, and fully electric, and performed a comparison of 11 key parameters to LNG. The parameters were energy density, technological maturity, local emissions, GHG emissions, energy cost, capital cost, bunkering availability, flammability, toxicity, regulations and guidelines, and global production capacity and locations. They concluded that it is hard to know which of the alternative fuels will become more competitive and available for shipping because there are various uncertainties. Additionally, they claimed that no significant move will happen until 2030 under the current plans and typical development speed of regulations and incentives [3]. The American Bureau of Shipping (ABS) (2019) published a report on low-carbon shipping. They inform the current knowledge on the technologies and issues that could help to reduce greenhouse gas (GHG) emissions from shipping. The solutions for low-carbon shipping were reduced speed, just-in-time shipping, optimizing hull forms, reduced hull friction, and alternative fuels. The alternative fuels described in the report are LNG, LPG, methanol, ammonia, hydrogen, biofuels, synthetic fuels, fuel cells, batteries, solar, and wind power [4]. Lloyd’s Register (LR) (2019) published a report about zero-emission vessels (ZEV) to demonstrate the potential solutions for shipping’s zero-emission transition. They selected seven propulsion options, which are electric, hybrid hydrogen, hydrogen fuel cell, hydrogen + internal combustion engine (ICE), ammonia fuel cell, ammonia + ICE, and biofuel. Five ship types were determined for the investigation. The investigated ship types are a bulk carrier, containership, tanker, cruise, and RoPax. They estimated the lifetime profitability through modelling and analysis. A sensitivity analysis was performed to investigate the effects of ship range, carbon price, and interest rate on ZEV feasibility [5]. ABS (2020) published the report for pathways to sustainable shipping. The paper presents a comprehensive description of the three potential fuel pathways for meeting the IMO goals. Three pathways are (1) light gas pathway, (2) heavy gas and alcohol pathway, and (3) bio/synthetic fuel pathway. They also took into account carbon capture and sequestration, hybrid electric power, direct current (DC) systems, and just-in-time and optimum ship routing. Additionally, they designed future vessels such as liquid biofuel ships, ammonia ships, and hydrogen ships [6]. LR (2020) published a report on the techno-economic assessment of zero-carbon fuels. They investigated 21 zero-emission vessels depending on fuels, including methanol, hydrogen, ammonia, electricity, diesel, and LNG, as well as production methods like natural gas with carbon capture and storage, biomass, and renewable electricity, and propulsion methods such as internal combustion engine and fuel cell. The paper analyses three important aspects of zero-carbon fuels when compared with traditional fossil-based fuels. Three aspects for comparison of zero-carbon fuels are investment readiness, technology readiness, and community readiness. The total cost of operation (TOC) is employed for the assessment of investment readiness. The TOC is a function of the fuel-related voyage costs per year, the capital investment costs due to the new engine and fuel storage system, and the impact on revenue due to additional space requirements. Technology readiness level (TRL) was used for the assessment of technology readiness, which indicates the development of the status of technology on a scale ranging from ‘basic principles observed’ to ‘product and production fully operational’. The community readiness was assessed by estimating the lifecycle emissions. They concluded that there is no most competitive option from today through to 2050. This means that different zero-carbon fuels are more competitive in different decades [7].

There are many studies to find suitable alternative fuels. Gilbert (2018) performed a life-cycle assessment for low sulphur heavy fuel oil (HFO), marine diesel oil (MDO), LNG, hydrogen + carbon capture and storage (CCS) technology, methanol, renewable hydrogen, soy straight vegetable oil (SVO), rape SVO, soy and rape biodiesel, and bio-LNG [8]. Maja (2020) assessed the feasibility of alternative fuels to reduce CO2 emissions in the Croatian short-sea shipping sector by considering environmental and economic criteria [9]. Xing (2021) conducted a technological review to determine the most promising alternative marine fuels considering the reduction of air pollutant emissions and sustainability [10]. Mallouppas (2021) reviewed the recent literature regarding alternative fuels (nuclear, hydrogen, ammonia methanol), renewable energy sources (biofuels, wind, solar), the maturity of technologies (fuel cells, internal combustion engines) as well as technical and operational strategies to reduce fuel consumption for new and existing ships (slow steaming, cleaning and coating, waste heat recovery, hull, and propeller design) [11]. Ampah (2021) analysed 583 eligible documents published during the last two decades to quantitatively and qualitatively explore the research field of alternative marine fuels [12]. McKinlay (2021) investigated the engineering considerations of three alternative fuels when they were utilized in large-scale international vessels [13]. Maja (2021) conducted a technical, environmental, and economic assessment of alternative fuels for vessels utilized in inland waterway transportation [14]. M¨akitie (2022) investigated the adoption of alternative fuels by Norwegian ship-owners. They surveyed 281 ship-owners in Norway and then analysed the data collected [15]. Atilhan (2021) studied green hydrogen as an alternative fuel for the shipping industry [16].

The use of LPG as a marine fuel is considered one of the promising practical solutions to meet environmental regulations. There are many studies on LPG as a marine fuel. Kjartansson (2011) introduced the LPG characteristic, LPG transportation, and an LPG engine, and studied the feasibility of LPG as a marine fuel in the European and Swedish markets. He concluded that there is sufficient infrastructure for the distribution of LPG, and economic incentive is needed to attract ship owners to invest in LPG-fuelled ships [17]. In the DNVGL (2017) report, an overview of aspects related to LPG was presented as a marine fuel, including production and utilization, engine and tank technology, safety considerations, environmental performance, pricing, and financial feasibility. They mentioned that there will be different optimum fuels among various alternative fuels depending on the different applications and geographic areas (based on the local fuel availability). It was concluded that LPG is an opportunity for cleaner fuel in the future [18]. World LPG Association (WLPGA) (2021) published the report to promote an understanding of the technical possibilities, applications, and market potential of LPG for marine engines. They investigated the market of marine LPG engines and identified the market in which marine engine applications are more promising for LPG as a marine fuel. They covered not only commercial and passenger vessels but also other small crafts. They gave an overview of marine LPG technologies and provided the market outlook for the technologies [19]. Yeo et al. (2022) estimated the annual fuel consumption costs and reduction in air pollutants when ships registered in South Korea use LPG as fuel. The results showed that the annual fuel consumption was reduced by 7.5–10.4% and fuel cost by 8.8–25.9%. The air pollutants such as Sulphur oxides (Sox), and particle matter (PM) could be mostly removed, and CO2 emissions could be reduced by 10–14% compared to conventional fuels. They insisted that it is necessary to promote LPG utilization for marine applications through government policies [20]. There were studies on LPG engines. The utilization of LPG in a direct injection diesel engine with diesel pilot oil for ignition was investigated [21]. The experiments were conducted using a direct injection diesel engine for various LPG/diesel blended fuels [22]. The combustion characteristics and performance of an LPG/diesel blended fuel engine were analysed [23].

The followings are the reasons for the application of LPG to marine fuel. (1) It is a mature technology. The world’s first LPG-fuelled vessel has set sail in 2020. MAN’s dual fuel engine and Wärtsilä’s fuel supply system were employed in the vessel [19]. (2) Air pollutants and CO2 emissions are reduced. When the LPG is used as a marine fuel, SOx, and PM could be mostly removed, and CO2 emissions could be reduced by 10–14% [20]. (3) It has high fuel availability compared to other alternative fuels. LPG has been used for energy in various areas such as the car industry and houses for a long time. Its infrastructure is well established compared to other alternative fuels. (4) LPG supply is surplus. According to WLPGA, the amount of surplus LPG ranges from 15 to 27 million tonnes per year. (5) LPG could be a bridging fuel to ammonia. The materials for ammonia tanks and systems are the same as LPG. The adjustments needed to switch from LPG to ammonia could be minimized.

The fuel of an LPG carrier has been also changed from conventional HFO to LPG for cleaner shipping through retrofit or new building [24]. Cargo LPG is used as fuel in an LPG carrier because cargo and fuel are identical substances. When LPG is used as fuel for propulsion and power generation, the pressure and temperature of fuel LPG should be increased from the fuel tank conditions to engine inlet conditions. The pressure and temperature rise needs energy. The energy consumption for the pressure and temperature enhancement should be reduced in the LPG-fuelled LPG carrier for radically cleaner shipping. There were few studies for an LPG-fuelled LPG carrier. Noh et al. (2021) proposed an idea for the gas treatment system on LPG and ammonia carriers, where the fuel supply system was integrated with the re-liquefaction system [25]. Seo et al. (2022) present a concept for a ship prolusion system, ship propulsion method, and propulsion ship using BOG. They considered the fuel mixing from a re-liquefaction system, a fuel tank, and an engine. Although the concept was mainly for an ammonia carrier, it can be also applied to an LPG carrier [26]. Those studies combined a liquefaction system and FSS to reduce energy consumption.

Although there were only a few studies for an LPG-fuelled LPG carrier, these were the ideas or concepts proposal. There was no energy analysis to show how much energy was reduced, and the influences on the changes under various conditions. That is, there was no detailed study for them. The purpose of this study is to analyse the energy consumption of the novel systems (the re-liquefaction system integrated with the fuel supply system) for an LPG-fuelled LPG carrier to a conventional system to improve the efficiency of the carrier. The structure of this paper is as follows. The novel system is described in Section 2 compared to the conventional system. In Section 3, the system modelling is performed for process simulation. The results are presented in Section 4. Finally, the conclusions are presented in Section 5.

2. System Description

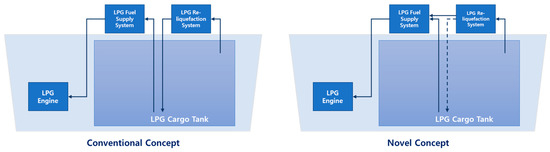

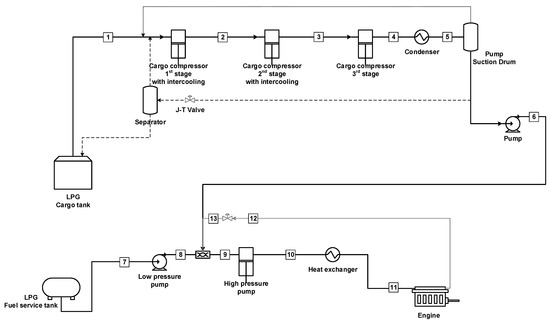

The novel systems proposed in this study are to use LPG from a re-liquefaction system directly. Figure 1 indicates the fuel supply system (FSS) and re-liquefaction system of the conventional LPG-fuelled LPG carrier and the novel systems. FSS supplies the fuel from tanks to an engine after adjusting the flow rate, pressure, and temperature, and the re-liquefaction system liquefies the BOG produced from the cargo tanks. In the case of the conventional LPG-fuelled LPG carrier, the boil-off gas (BOG) generated from the cargo tanks is liquefied by a re-liquefaction system, and then it is returned to the cargo tanks. The fuel for an engine is provided from cargo tanks or separated (independent) fuel tanks. In the novel concept, the liquefied BOG by the re-liquefaction system is directly supplied to the FSS without returning it to the cargo tanks. The LPG supplied from the re-liquefaction system is combined with LPG from the cargo tanks because the amount of the liquefied BOG cannot be enough to meet the engine requirement.

Figure 1.

Configuration of re-liquefaction and fuel supply systems in conventional and novel LPG carrier.

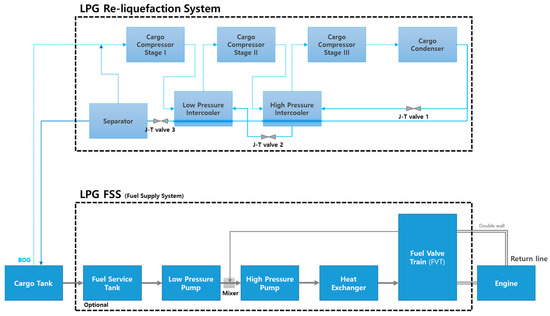

Figure 2 shows the block diagrams of the FSS and re-liquefaction system in the conventional LPG-fuelled LPG carrier. The BOG is compressed and expanded by itself without the external refrigeration system in this re-liquefaction system. Seawater and some chilled BOG after expanding are utilized as a cooling medium for the re-liquefaction. The upper part of Figure 2 is the re-liquefaction system and the lower part is the FSS. The re-liquefaction system consists of a cargo compressor to pressurize the produced BOG, a condenser to condense the pressurized BOG, and intercoolers to cool the BOG in the intermediate stage of the compressor. The pressurized BOG is condensed by the condenser, and then it is expanded by a Joule-Thomson (J-T) valve. Finally, the pressurized BOG is expanded to the pressure of the cargo tank. After expansion, the pressure and temperature are decreased, and some BOG is liquefied. The re-liquefied BOG is injected into the cargo tanks, and the remaining BOG is sent to the inlet of the cargo compressor. The FSS is composed of a fuel service tank for temporary storage, low and high-pressure pumps to increase the pressure, a heat exchanger to adjust the temperature, and the fuel valve train (FVT) for the safe isolation of the engine and the FSS. The LPG from the cargo tanks is supplied to the engine through the fuel service tank, the pumps, the heat exchanger, and the FVT. Some amount of LPG is returned to the FSS after the engine. In the case of LPG engines, only some amount of the fuel that entered the engine was consumed for combustion. The remaining fuel was returned after engine cooling. The returned LPG is recirculated between the LP and HP pumps or the fuel service tank.

Figure 2.

Block diagram of re-liquefaction and fuel supply systems in conventional LPG-fuelled LPG carrier.

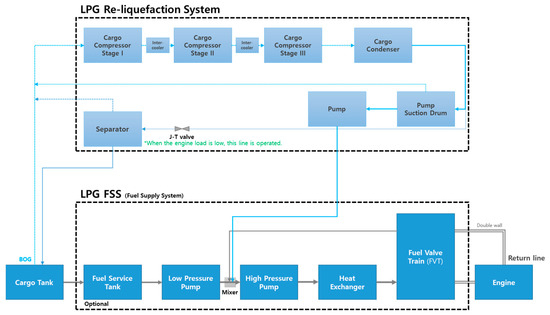

Figure 3 shows the block diagrams of FSS and re-liquefaction system in the novel LPG-fuelled LPG carrier. The FSS is identical to the FSS for the conventional LPG-fuelled LPG carrier, while the re-liquefaction system is simpler than the conventional re-liquefaction system. The novel re-liquefaction system consists of a cargo compressor, a condenser, an intercooler, a pump, and a pump suction drum. The produced BOG is compressed by a cargo compressor(three-stage), and then it is condensed by a condenser using seawater. The condensed BOG is pressurized to a slightly higher pressure than the discharge pressure of the LP pump, and then it is supplied through a pump suction drum between LP and HP pumps. The pump suction drum separates vapor and liquid to prevent the liquid inlet to the pump. The stream from the re-liquefaction system and the stream from the LP pump of the FSS are combined in the mixer to deal with the temperature difference between the streams. The liquefied BOG from the re-liquefaction system to the FSS is provided to the engine through the HP pump, the heat exchanger, and the FVT. When the FSS does not require fuel because the engine has stopped, the produced BOG is compressed and condensed by a condenser, and then it is expanded by the J-T valve. After expansion, vapor and liquid are separated by a separator. The liquefied BOG is sent to the cargo tanks, and the remaining BOG is returned to the compressor.

Figure 3.

Block diagram of re-liquefaction and fuel supply systems in novel LPG-fuelled LPG carrier.

The processes for the re-liquefaction and fuel supply are simplified in the novel systems, and it accompanies the reduction of energy consumption. The generated BOG from cargo tanks is re-liquefied through compression, condensing, and expansion processes, and it is sent to the cargo tank again in the conventional re-liquefaction system. The LPG in the fuel service tank should be pressurized by an LP pump and heated by the heat exchanger to meet the engine requirement in the conventional FSS. However, the condensed BOG is directly sent to the FSS (upstream of the HP pump) without the expansion process in the novel re-liquefaction system. The load for pressurizing by the LP pump and for heating by the heat exchanger could be reduced in the novel FSS because condensed BOG, which has relatively high pressure and temperature, is supplied to the FSS in the novel FSS.

3. Analysis

3.1. Target Vessel

The basic information for the target vessel is indicated in Table 1. The cargo capacity of the carrier was assumed to be 84,000 m3, and the principal dimension is tabulated in Table 1. The service speed was assumed to be 16.5 knots. The MAN B&W 6G60ME-C9.5-LGI(P) was selected for the main engine in the LPG carrier, and the required flow rates at normal continuous rating (NCR) were assumed to be 1474 kg/h for LPG by converting the HFO’s lower heating value (LHV) into LPG LHV consumed in the carrier. This study assumed that auxiliary engines (for electrical power generation) were operated using MDO. The amount of BOG generated from the cargo tank is calculated based on 0.025%/day (BOR).

Table 1.

Basic information of target vessel.

3.2. Design Basis

This study performed the process simulation to analyse the energy consumption of FSS and re-liquefaction systems. Table 2 indicates the values assumed for the process simulation in this study. An Aspen HYSYS v12.1 was utilized for the process simulation, which is widely used in the oil and gas industry [27,28]. Peng-Robinson, which is widely used in LNG and LPG processes, was employed for the equation of state [29,30]. Although the composition of LPG is different with gas fields, the requirement of consumers, and the season, in this study it is assumed to be propane100%. The storage pressure in the cargo tanks is assumed to be 1 bara. The pressure of re-liquefied BOG was also assumed to be 1 bara. The temperature of seawater was assumed to be 32 °C, which is the highest temperature in the IMO codes. The type and efficiency of the cargo compressor were assumed to be reciprocating and 75%, respectively. The efficiencies of the pump to increase the pressure of the condensed BOG were assumed to be 75%. The pressure supplied to the engine was set at 53 bar. The allowed temperature range was 25–45 °C. The types of low-pressure (LP) and high-pressure (HP) pumps were assumed to be centrifugal, and diaphragm, respectively, and those efficiencies were assumed to be 75%.

Table 2.

Values assumed for process simulation.

3.3. Model

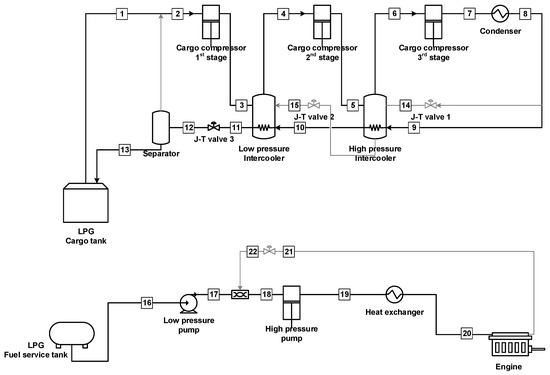

The process flow diagram (PFD) and stream information (pressure, temperature, and flow rate) of the conventional re-liquefaction system with FSS are shown in Figure 4 and Table 3. The BOG produced from the cargo tanks is entered into the re-liquefaction system. The entered BOG is combined with the recirculated BOG, which is not liquefied after the final expansion, and then entered into the first stage compressor. After compression, it is sent to the low-pressure intercooler. The BOG is compressed by the first stage compressor, and the condensed BOG stream is cooled by the cold stream, which is expanded by J-T valve 2 to provide a cooling source, at the low-pressure intercooler. The compressed BOG is sent to second stage compressor. The BOG is compressed by the second stage compressor, and the condensed BOG is cooled by the cold stream, which is expanded by Joule-Thomson (J-T) valve 1, at the high-pressure intercooler. The compressed BOG is sent to the third stage compressor. The compressed BOG is condensed through seawater at a condenser. The condensed BOG is divided into the stream for re-liquefaction and the stream to provide the cooling source. The stream to provide the cooling source is sent to the high-pressure intercooler after expansion by J-T Valve 1. After heat exchange, the vaporized steam is sent to the third stage compressor again, and the remaining stream (not vaporized stream) is sent to the low-pressure intercooler after the second expansion by the J-T valve 2. The stream supplies a cooling source at the low-pressure intercooler, and it is entirely vaporized. The vaporized stream is sent to second stage compressor again. The stream for re-liquefaction after condensing is cooled at the high and low-pressure intercoolers. The stream is expanded by J-T valve 3 for re-liquefaction. The stream after the final expansion is sent to the separator before returning to the first stage compressor and the LPG cargo tank.

Figure 4.

Process flow diagram (PFD) of the conventional re-liquefaction and fuel supply systems.

Table 3.

Stream information of the conventional re-liquefaction system with FSS.

In the FSS, the stream from the fuel tanks is pressurized by the LP pump, and then it is supplied into the HP pump with the recirculated stream from the engine. The HP pump increases the pressure required by the engine. The temperature of the compressed stream is adjusted by a heat exchanger, and then impurities are removed by filters. Finally, it is supplied into the engine through FVT. Some stream supplied into the engine is recirculated without combustion after engine cooling.

The process flow diagram (PFD) and stream information of the novel re-liquefaction system with FSS are shown in Figure 5 and Table 4. The BOG produced from the cargo tanks is entered into the re-liquefaction system. The entered BOG is compressed by three stages of compressor. The compressed BOG by first and second stage compressors can be cooled by seawater depending on its temperature. The entirely compressed BOG by the third stage compressor is condensed by seawater at the condenser. The condensed BOG is supplied to the FSS after pressurizing to the discharge pressure of the LP pump. The condensed BOG from the re-liquefaction system is combined (mixed) with the stream from fuel tanks, and then they are sent to the HP pump. The stream pressurized by the HP pump is supplied to the engine after passing the heat exchanger, filter, and FVT. When the engine load is low and the amount of condensed BOG is greater than the amount required by the engine, the condensed BOG is stored in the pump suction drum. If the pump suction drum is full, the condensed BOG is expanded by the J-T valve. After the expansion, the stream is sent to the separator. The liquefied stream in the separator is transferred to the cargo tank, and the remaining stream (vapor) is recirculated into the stage one compressor.

Figure 5.

Process flow diagram (PFD) of the novel re-liquefaction and fuel supply systems.

Table 4.

Stream information of the novel re-liquefaction system with FSS.

4. Results and Discussion

4.1. Results

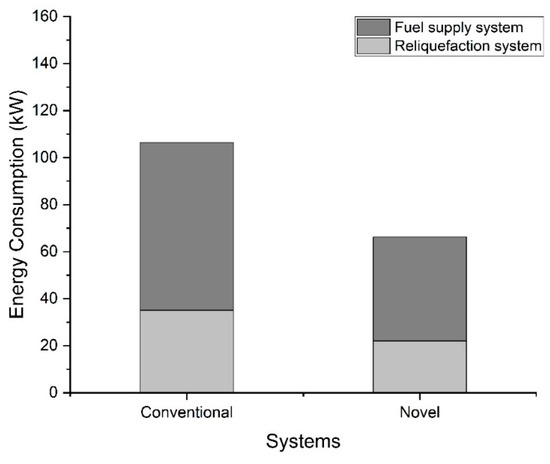

The energy consumption for the novel re-liquefaction system with FSS is 38% lower than the conventional re-liquefaction system with FSS. Figure 6 shows the energy consumption for the conventional and novel re-liquefaction system with FSS. The energy consumption of the re-liquefaction system was reduced by approximately 38%, and that of the FSS was decreased by about 37% for the novel systems compared to the conventional systems. The difference in the energy consumption for the re-liquefaction system was caused by the difference in the flow rate of the compressor. The amount of recycled BOG for compression was significant in the conventional re-liquefaction system because the BOG was not entirely liquefied. During normal operation, there was no recycled BOG in the novel re-liquefaction system because the condensed BOG was entirely sent to the FSS. The difference in the energy consumption for the FSS was caused by the difference in supplying temperature. In the case of the conventional FSS, the energy consumption for heating to meet the engine requirement was substantial because the temperature of the stream from the cargo tanks is relatively low. In contrast, the energy consumption for heating to meet the engine requirement was small in the novel FSS because the temperature of the stream from the re-liquefaction system is relatively high.

Figure 6.

Energy consumption for conventional and novel re-liquefaction and fuel supply systems in LPG carriers.

4.2. Sensitivity Analysis

In this study, a sensitivity analysis was performed to investigate the effects of a variable assumed on the results. The variable analysed was LPG composition. Although the LPG composition was assumed as propane 100% above, it is different with gas fields, the requirement of consumers, and season. Propane 75%/butane 25%, propane 50%/butane 50%, butane 100%, propane 95%/ethane 5%, and propane 90%/ethane 10% were investigated.

4.2.1. LPG Compositions

The pressure compressed for the re-liquefaction was calculated, and the energy consumption was estimated. Table 5 tabulates saturation pressures and assumed final pressures for the conventional and novel systems with LPG compositions when the discharge temperature of the condenser is 38 °C. It was set based on the saturation pressure at 38 °C assuming that the stream temperature can be cooled to 38 °C through 32 °C seawater. The saturation pressure of butane 100% was the lowest, while the pressure of Propane 90%/Ethane 10% was the highest. The assumed final pressure for the novel systems was similar to the corresponding saturation pressure. In contrast, there was a significant difference between the assumed final pressure and the corresponding saturation pressure for the conventional systems. The reason for the difference was that the composition was changed as it was mixed with the returned stream. The returned stream from the vapor part of the vapor/liquid separator mainly consists of light components. Since the mixed stream contains more light components (volatile components), the pressure required for condensation is increased.

Table 5.

Saturation pressures and assumed final pressures of the conventional and novel re-liquefaction and fuel supply systems with LPG compositions (the temperature is 38 °C).

The energy consumption for compression was proportionally increased with the required final pressure. Table 6 indicates the energy consumption for the re-liquefaction system with FSS depending on the various LPG compositions. The energy consumption for the FSS was higher than that for the re-liquefaction. When the stream is composed of only butane (the heaviest component among the LPG components), the required pressure (4.3 bar) for re-liquefaction was the lowest among the proposed cases. If the stream is composed of 10% ethane (the lightest component among the LPG components), the required pressure (16.2 bar) was the highest among the proposed cases. There was a large difference in energy consumption for the FSS depending on the LPG composition. The reason for this is that the temperature in the cargo tanks (atmospheric pressure) is different from the LPG composition. The temperature of the storage tanks at atmospheric pressure was −6.9 °C when the LPG composition was butane 100%, whereas that was −53.6 °C if the LPG composition was Propane 90%/Ethane 10%.

Table 6.

Energy consumption for conventional and novel re-liquefaction and fuel supply systems in LPG carriers with LPG composition.

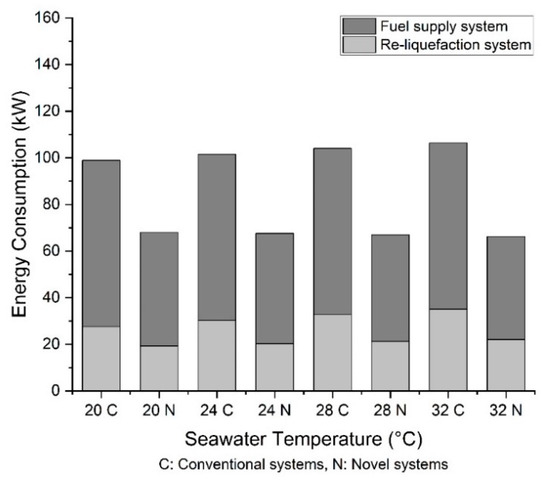

4.2.2. Seawater Temperature

The energy consumption for the conventional and novel systems showed different trends with the rise of seawater temperature. The energy consumption for the conventional system was increased, while that for the novel system was decreased with the increment of seawater temperature as shown in Figure 7. The energy consumption for the conventional system was increased by 2.5% with a 4 °C rise in seawater temperature. In contrast, that was decreased by 0.9% for the novel system. In the case of the conventional system, the pressure required for compression was increased with the rise of seawater temperature because the corresponding saturation pressure was increased. In the case of the novel system, the temperature of the stream supplied to the FSS from the re-liquefaction system was increased with the rise of seawater temperature. The increased temperature of the stream reduced the energy for heating in the FSS. The energy consumption was decreased by the increased temperature of the stream supplied.

Figure 7.

Energy consumption for conventional and novel re-liquefaction and fuel supply systems with seawater temperature.

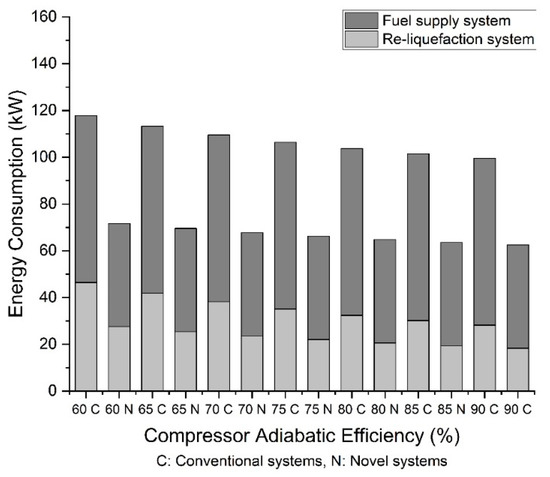

4.2.3. Efficiency of Adiabatic Compressor

The energy consumption for the conventional and novel systems was reduced by the rise of the compressor efficiency as shown in Figure 8. The energy consumption for the conventional system was reduced by 2.8% with the 5% increment of the compressor efficiency, while that for the novel system was 2.3%. More energy was reduced in the conventional system than in the novel system because the flow rate of the conventional system for compression was higher than that of the novel system.

Figure 8.

Energy consumption for conventional and novel re-liquefaction and fuel supply systems with compressor adiabatic efficiency.

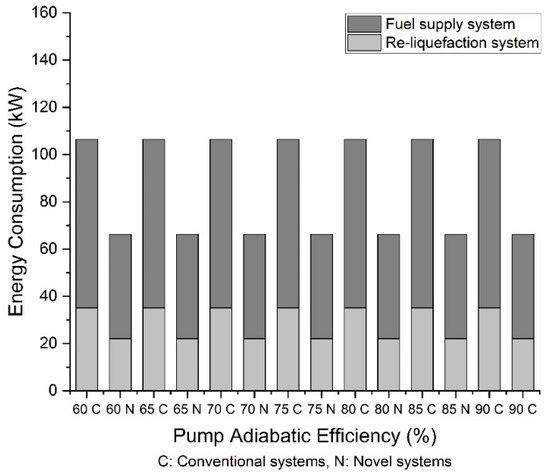

4.2.4. Efficiency of Adiabatic Pump

The energy consumption for the conventional and novel systems hardly changed with the increment of pump efficiency as shown in Figure 9. Since the energies required by the pumps in the systems represent only a small part of the total energy, there was only a slight change in the energy consumption for the conventional and novel systems.

Figure 9.

Energy consumption for conventional and novel re-liquefaction and fuel supply systems with pump adiabatic efficiencies.

5. Conclusions

The novel system combining the re-liquefaction system and the FSS was analysed to enhance the efficiency of the LPG carrier. The novel systems were relatively simple because they combined the traditionally separated re-liquefaction system and FSS. The processes in the conventional re-liquefaction system consist of compression, condensing, and expansion processes, but the condensed BOG is sent directly to the FSS without the expansion process in the novel re-liquefaction system. The load for pressurizing and heating is reduced in the novel FSS, because the pressure and temperature of the condensed BOG are relatively close to the engine requirement compared to the LPG in the cargo tanks. The process simulation was performed by Aspen HYSYS ver. 12.1 to analyse energy consumption. When the novel system was applied, energy consumption was reduced by 38%. The recirculated flow rate was significant in the conventional re-liquefaction system, while it was reduced in the novel system. The decreased flow rate reduced the energy consumption in the novel system. Additionally, the temperature of the stream supplied to the FSS was relatively low in the conventional system, whereas it was comparatively high in the novel system. The increased temperature of the stream entering the FSS reduced the required heating energy for the novel system. The low-temperature LPG was directly supplied to the FSS in the conventional system, while the relatively high-temperature LPG was supplied to the FSS in the novel system. The effect of the assumed parameter in this study was investigated through sensitivity analysis. The analysed parameters were LPG composition, seawater temperature, compressor efficiency, and pump efficiency. The LPG composition significantly influenced the results. When the LPG composition was butane 100%, the system required the least energy among the investigated LPG composition. In contrast, the system needed the most energy if the LPG composition was propane 90% and ethane 10%. The energy consumption was changed by 2.5% for conventional systems and 0.9% for the novel systems with the 4 °C change of seawater temperature, and it was reduced by 2.8% for conventional systems and 2.3% for the novel systems with the 5% enhancement of compressor efficiency. The pump efficiency had little effect on the results. Although many additional studies are required to commercialize the novel system, it will help to increase the efficiency of LPG carriers.

Author Contributions

Conceptualization, methodology, and writing—original draft preparation, Y.S.; review, J.K. and J.L.; software, E.P.; data curation, M.C.; project administration, S.H. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by a grant from National R&D Project “Development of low flash point fuel injection system for hazardous emission reduction from small and middle class ships” funded by the Ministry of Trade, Industry and Energy (20013146). This research was also supported by Korea Research Institute of Ships and Ocean Engineering, a grant from Endowment Project of “Development of Evaluation Model for Hydrogen Offshore Supply Chain and Test Technologies for Hydrogen Equipment” funded by the Ministry of Oceans and Fisheries (PES4340).

Data Availability Statement

The data presented in this study are available in this article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- International Maritime Organization (IMO). Fourth IMO Greenhouse Gas Study: Executive Summary; IMO: London, UK, 2021. [Google Scholar]

- DNV GL—Maritime. Assessment of Selected Ternative Fuels and Technologies; DNV: Hamburg, Germany, 2018. [Google Scholar]

- Ryste, J.A.; Wold, M.; Sverud, T. Comparison of Alternative Marine Fuels; SEA-LNG: Høvik, Norway, 2019. [Google Scholar]

- American Bureau of Shipping (ABS). Setting the Course to Low Carbon Shipping; Spring: Houston, TX, USA, 2019. [Google Scholar]

- Lloyd’s Register. UMAS Zero-Emission Vessels 2030. How Do We Get There? Lloyd’s Register: London, UK, 2018. [Google Scholar]

- American Bureau of Shipping (ABS). Setting the Course to Low Carbon Shipping—Pathways to Sustainable Shipping; Spring: Houston, TX, USA, 2020. [Google Scholar]

- Lloyd’s Register. UMAS Techno-Economic Assessment of Zero-Carbon Fuels; Lloyd’s Register: London, UK, 2020. [Google Scholar]

- Gilbert, P.; Walsh, C.; Traut, M.; Kesieme, U.; Pazouki, K.; Murphy, A. Assessment of full life-cycle air emissions of alternative shipping fuels. J. Clean. Prod. 2018, 172, 855–866. [Google Scholar] [CrossRef]

- Perčić, M.; Vladimir, N.; Fan, A. Life-cycle cost assessment of alternative marine fuels to reduce the carbon footprint in short-sea shipping: A case study of Croatia. Appl. Energy 2020, 279, 115848. [Google Scholar] [CrossRef]

- Xing, H.; Stuart, C.; Spence, S.; Chen, H. Alternative fuel options for low carbon maritime transportation: Pathways to 2050. J. Clean. Prod. 2021, 297, 126651. [Google Scholar] [CrossRef]

- Mallouppas, G.; Yfantis, E.A. Decarbonization in Shipping industry: A review of research, technology development, and innovation proposals. J. Mar. Sci. Eng. 2021, 9, 415. [Google Scholar] [CrossRef]

- Ampah, J.D.; Yusuf, A.A.; Afrane, S.; Jin, C.; Liu, H. Reviewing two decades of cleaner alternative marine fuels: Towards IMO’s decarbonization of the maritime transport sector. J. Clean. Prod. 2021, 320, 128871. [Google Scholar] [CrossRef]

- McKinlay, C.J.; Turnock, S.R.; Hudson, D.A. Route to zero emission shipping: Hydrogen, ammonia or methanol? Int. J. Hydrogen Energy 2021, 46, 28282–28297. [Google Scholar] [CrossRef]

- Perčić, M.; Vladimir, N.; Fan, A. Techno-economic assessment of alternative marine fuels for inland shipping in Croatia. Renew. Sustain. Energy Rev. 2021, 148, 111363. [Google Scholar] [CrossRef]

- Mäkitie, T.; Steen, M.; Saether, E.A.; Bjørgum, Ø.; Poulsen, R.T. Norwegian ship-owners’ adoption of alternative fuels. Energy Policy 2022, 163, 112869. [Google Scholar] [CrossRef]

- Atilhan, S.; Park, S.; El-Halwagi, M.M.; Atilhan, M.; Moore, M.; Nielsen, R.B. Green hydrogen as an alternative fuel for the shipping industry. Curr. Opin. Chem. Eng. 2021, 31, 100668. [Google Scholar] [CrossRef]

- Kjartansson, S. A Feasibility Study on LPG as Marine Fuel; DNV: Hamburg, Germany, 2011; p. 48. [Google Scholar]

- Brinks, H.W.; Chryssakis, C. LPG as A Marine Fuel; DNV: Hamburg, Germany, 2017. [Google Scholar]

- Crafts, R.; Boats, O. LPG for marine engines. In The Marine Alternative Fuel Commercial, Passenger, Offshore Boats/Ships, Recreational Crafts and Other Boats; WLPGA: Neuilly-sur-Seine, France, 2021; p. 144. [Google Scholar]

- Yeo, S.J.; Kim, J.; Lee, W.J. Potential economic and environmental advantages of liquid petroleum gas as a marine fuel through analysis of registered ships in South Korea. J. Clean. Prod. 2022, 330, 129955. [Google Scholar] [CrossRef]

- Qi, D.H.; Chen, B.; Zhang, D. Combustion and Exhaust Emissions Characteristics of a Dual-Fuel Compression Ignition Engine Operated with Diesel Fuel and Liquefied Petroleum Gas. J. Energy Eng. 2016, 142, 04016017. [Google Scholar] [CrossRef]

- Donghui, Q.; Longbao, Z.; Shenghua, L. Experimental studies on the combustion characteristics and performance of a naturally aspirated, direct injection engine fuelled with a liquid petroleum gas/diesel blend. J. Automob. Eng. 2005, 219, 253–261. [Google Scholar] [CrossRef]

- Qi, D.H.; Bian, Y.Z.H.; Ma, Z.H.Y.; Zhang, C.H.H.; Liu, S.H.Q. Combustion and exhaust emission characteristics of a compression ignition engine using liquefied petroleum gas—Diesel blended fuel. Energy Convers. Manag. 2007, 48, 500–509. [Google Scholar] [CrossRef]

- Deng, L. LPG Carriers Stepping Up to the Decarbonization Challenge; DNV: Hamburg, Germany, 2021. [Google Scholar]

- Noh, Y. Gas Treatment System and Ship Having the Same 2020. Available online: http://engpat.kipris.or.kr/engpat/biblioa.do?method=biblioFrame&start=biblio&link=N&rvtExtend=N (accessed on 6 December 2022).

- Seo, Y. Ship Propulsion System, Ship Propulsion Method and Propulsion Ship Using Bog 2021. Available online: http://engpat.kipris.or.kr/engpat/biblioa.do?method=biblioFrame&start=biblio&link=N&rvtExtend=N (accessed on 6 December 2022).

- Pina, A.; Ferrão, P.; Fournier, J.; Lacarrière, B.; Corre, O. Le Exergetic analysis of an LPG production plant using HYSYS software The analysis Exergetic production Assessing the feasibility of using. Energy Procedia 2019, 157, 1385–1390. [Google Scholar] [CrossRef]

- Jalal, H.; Abuyahya, S.; Pal, P.; Banat, F. Sweetening lique fi ed petroleum gas (LPG): Parametric sensitivity analysis using Aspen HYSYS. J. Nat. Gas Sci. Eng. 2015, 26, 1011–1017. [Google Scholar] [CrossRef]

- Uwitonze, H.; Han, S.; Jangryeok, C.; Suk, K. Design process of LNG heavy hydrocarbons fractionation: Low LNG temperature recovery. Chem. Eng. Process. Process Intensif. 2014, 85, 187–195. [Google Scholar] [CrossRef]

- Waqar, M.; Ishaq, H.; Rukh, S. Energetically enhanced natural gas liquefaction process with CO2 precooling. Energy Convers. Manag. X 2022, 14, 100200. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).