A General Pattern-Based Design Optimization for Asymmetric Spoke-Type Interior PM Machines

Abstract

1. Introduction

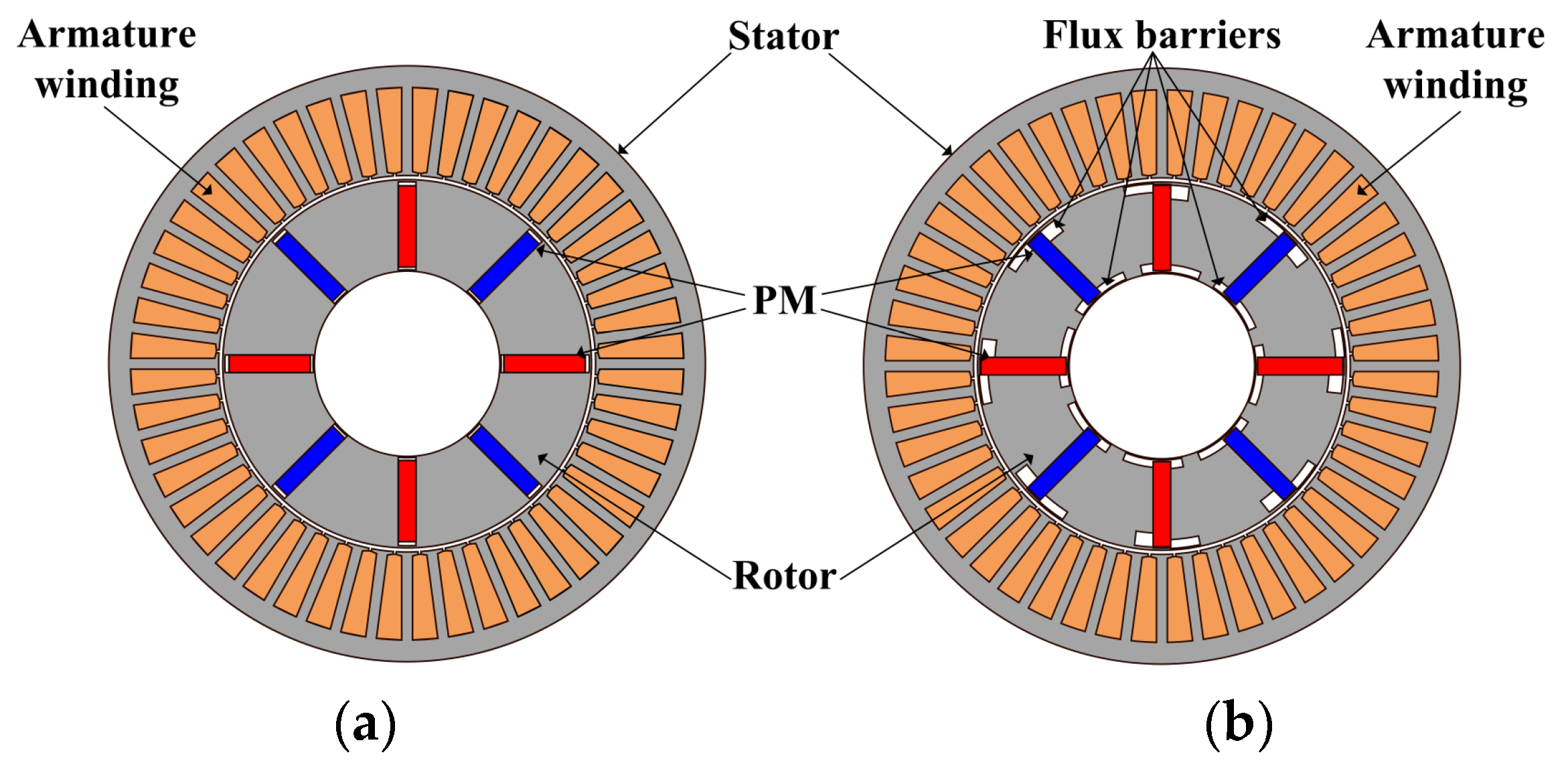

2. Machine Structure and Operation Principle

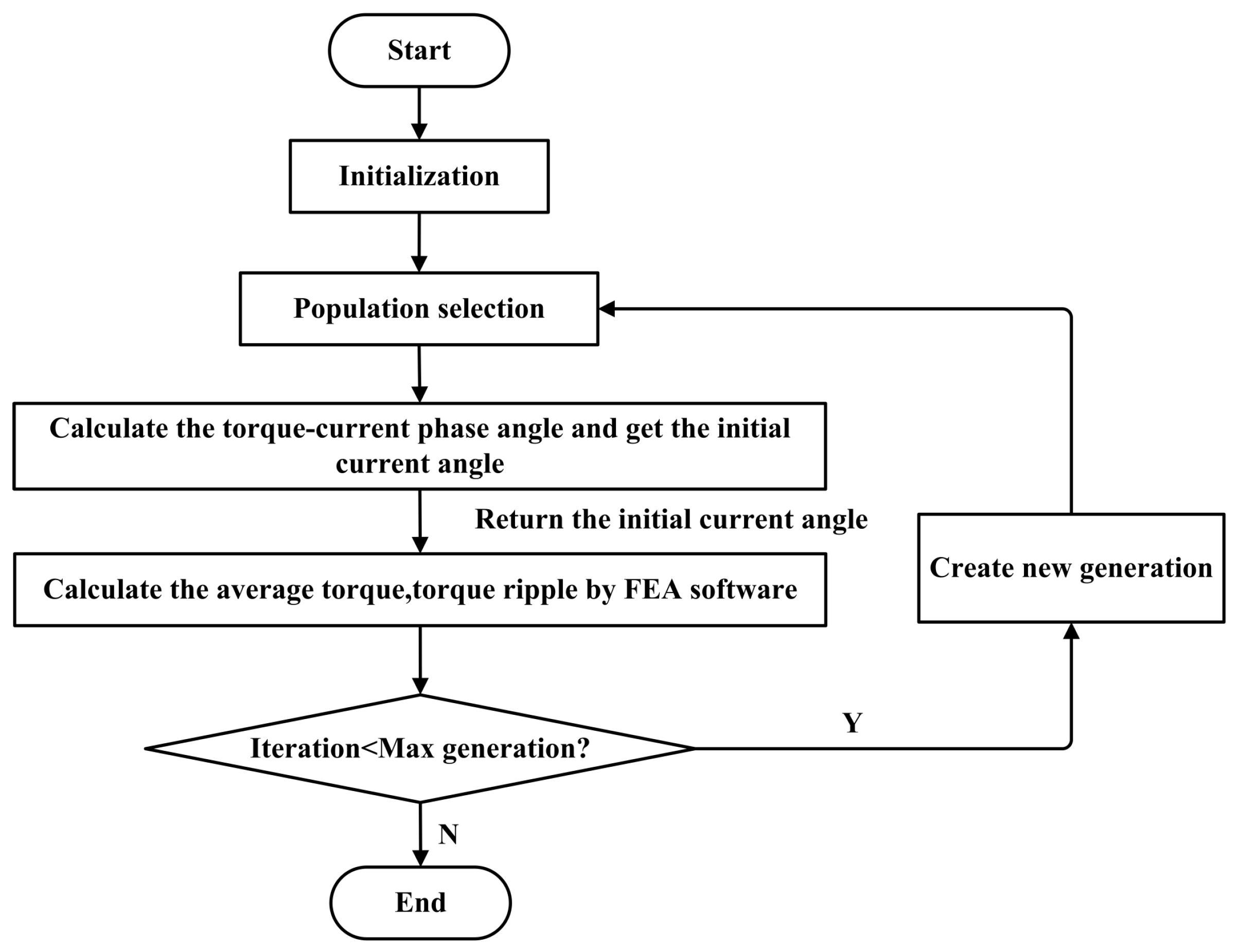

3. Design Optimization

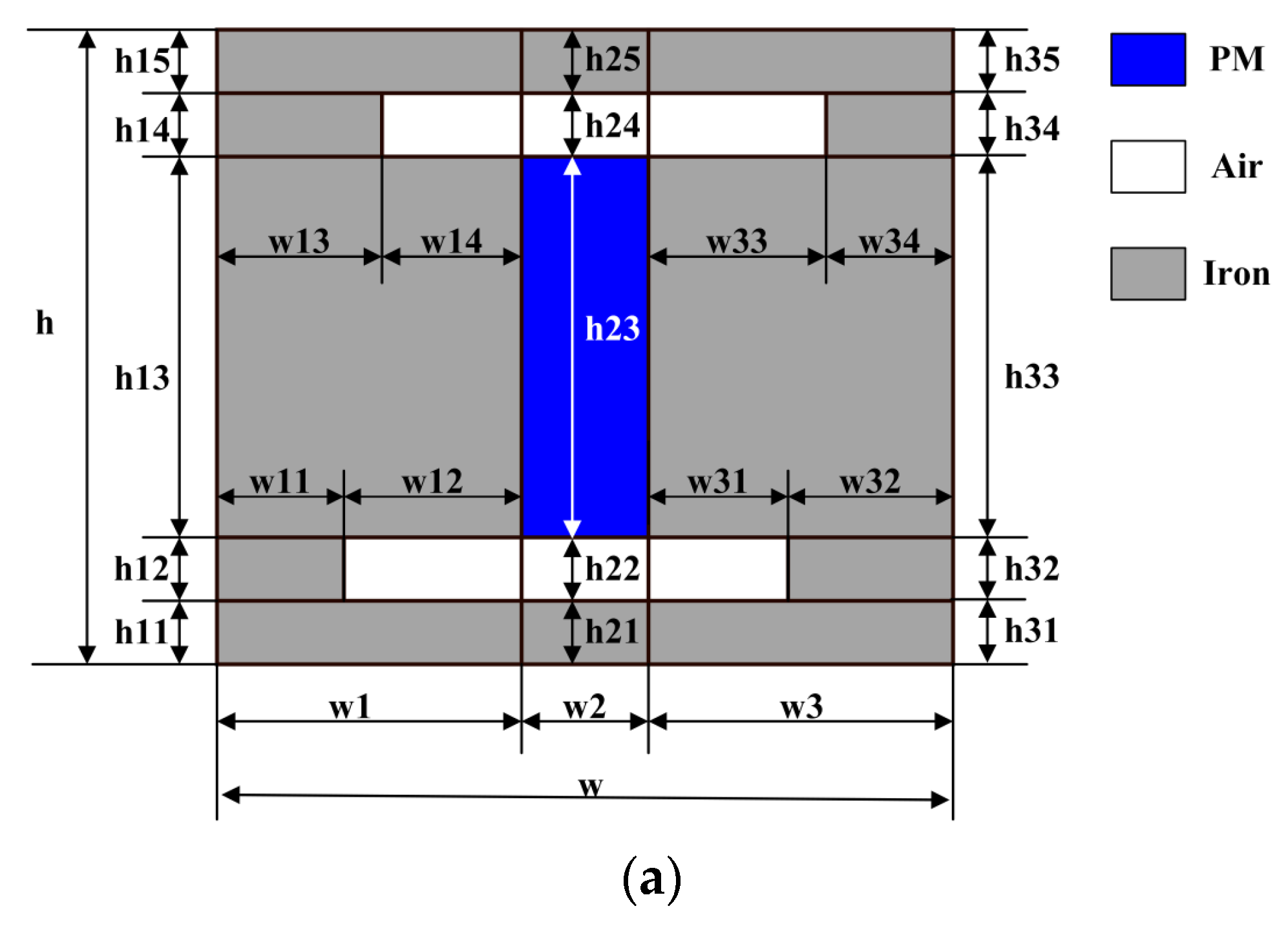

3.1. General Pattern

3.2. Optimization

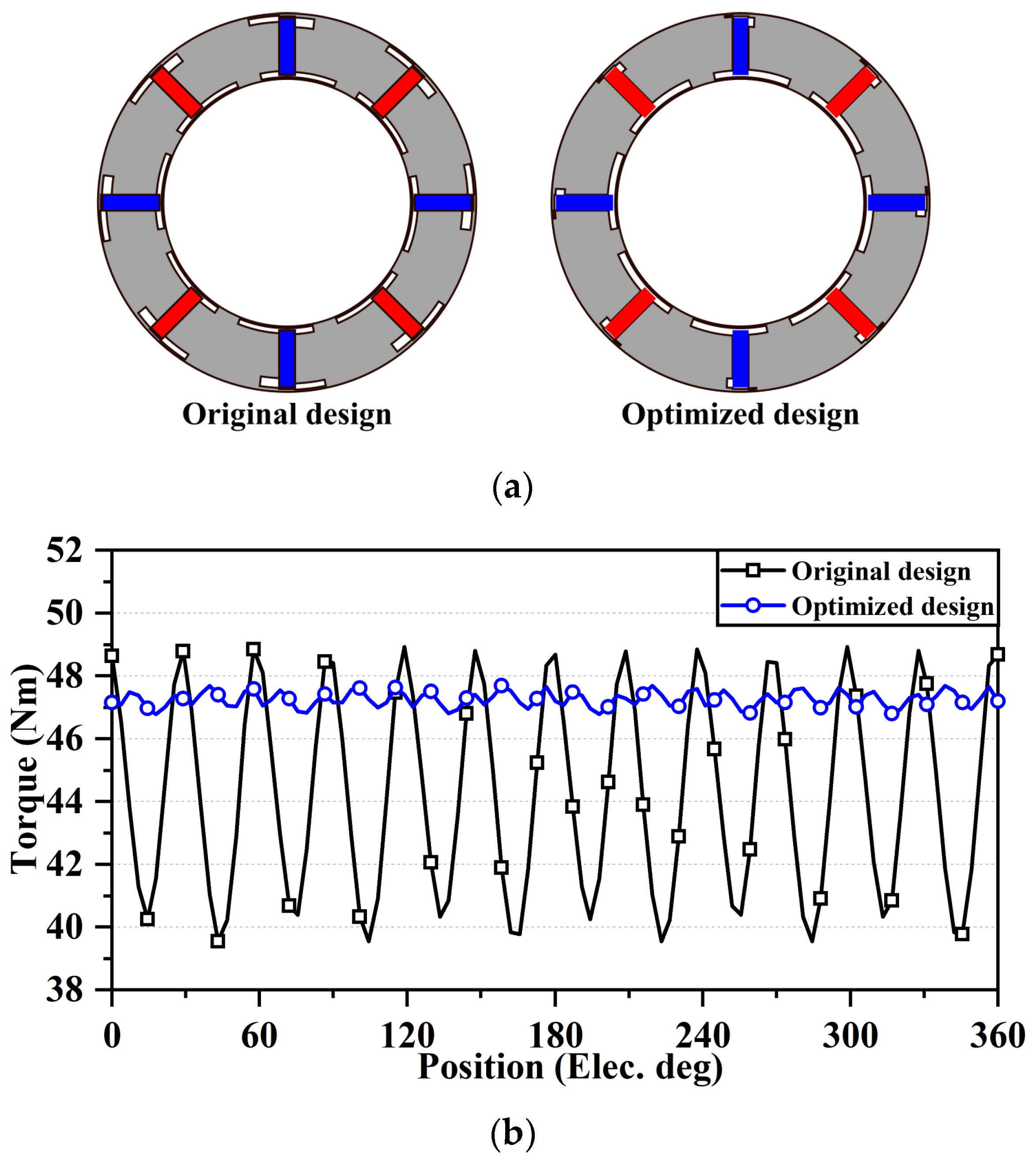

4. Performance Analysis and Comparative Study

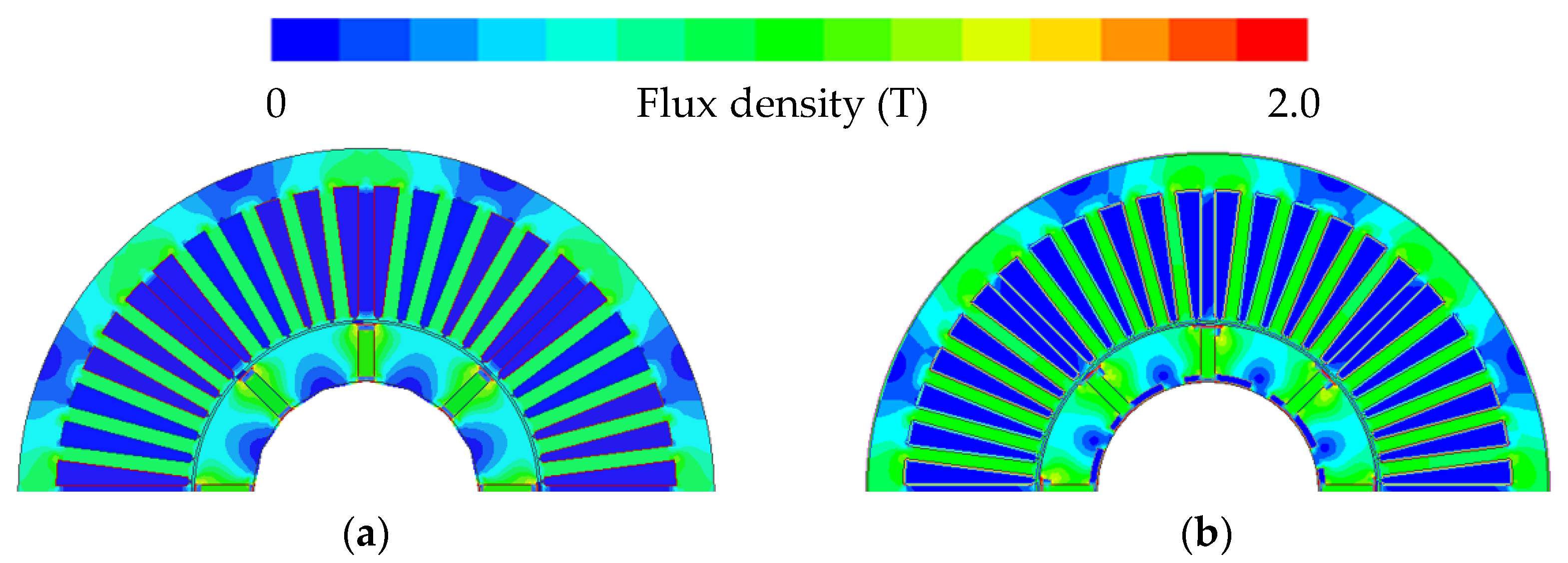

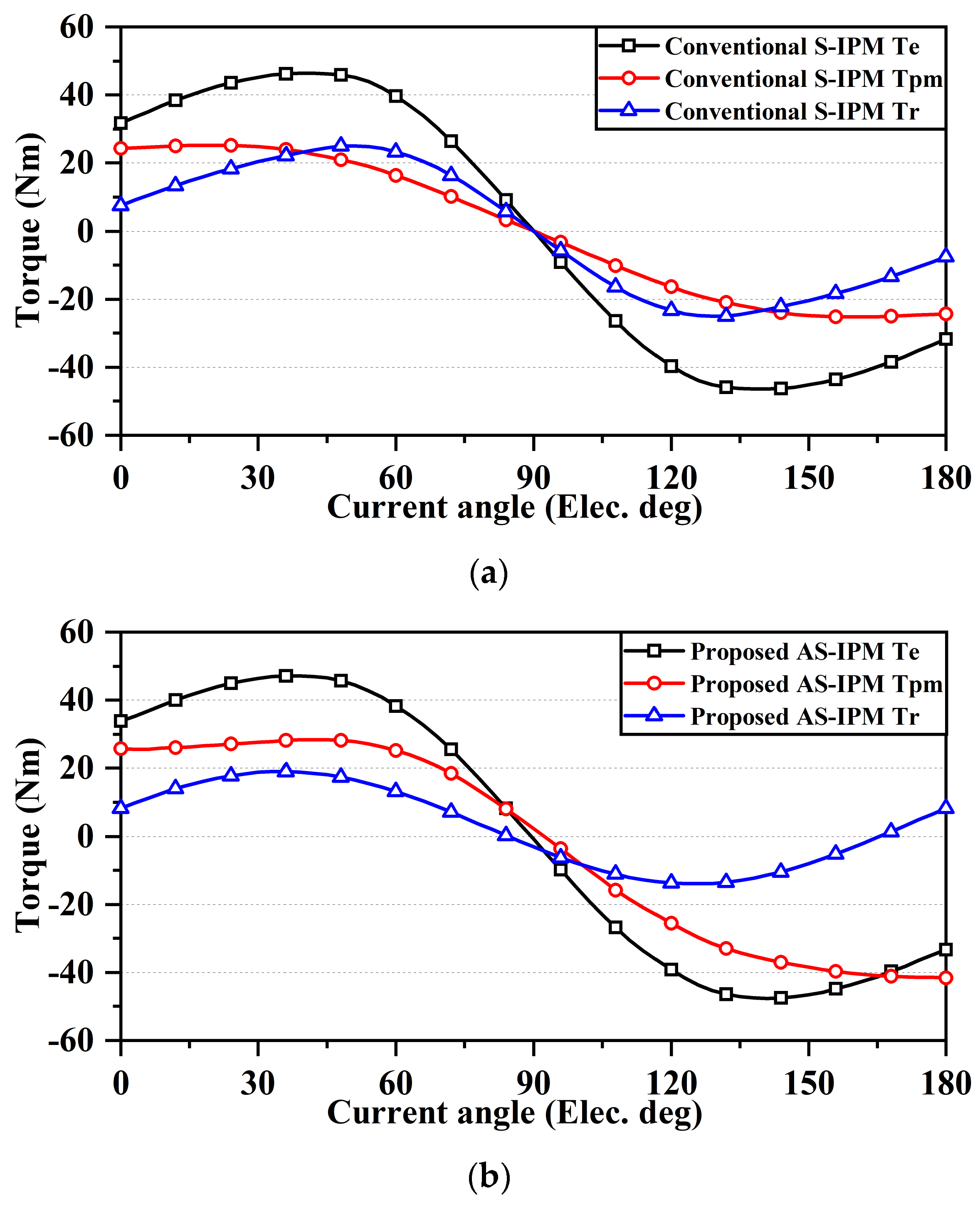

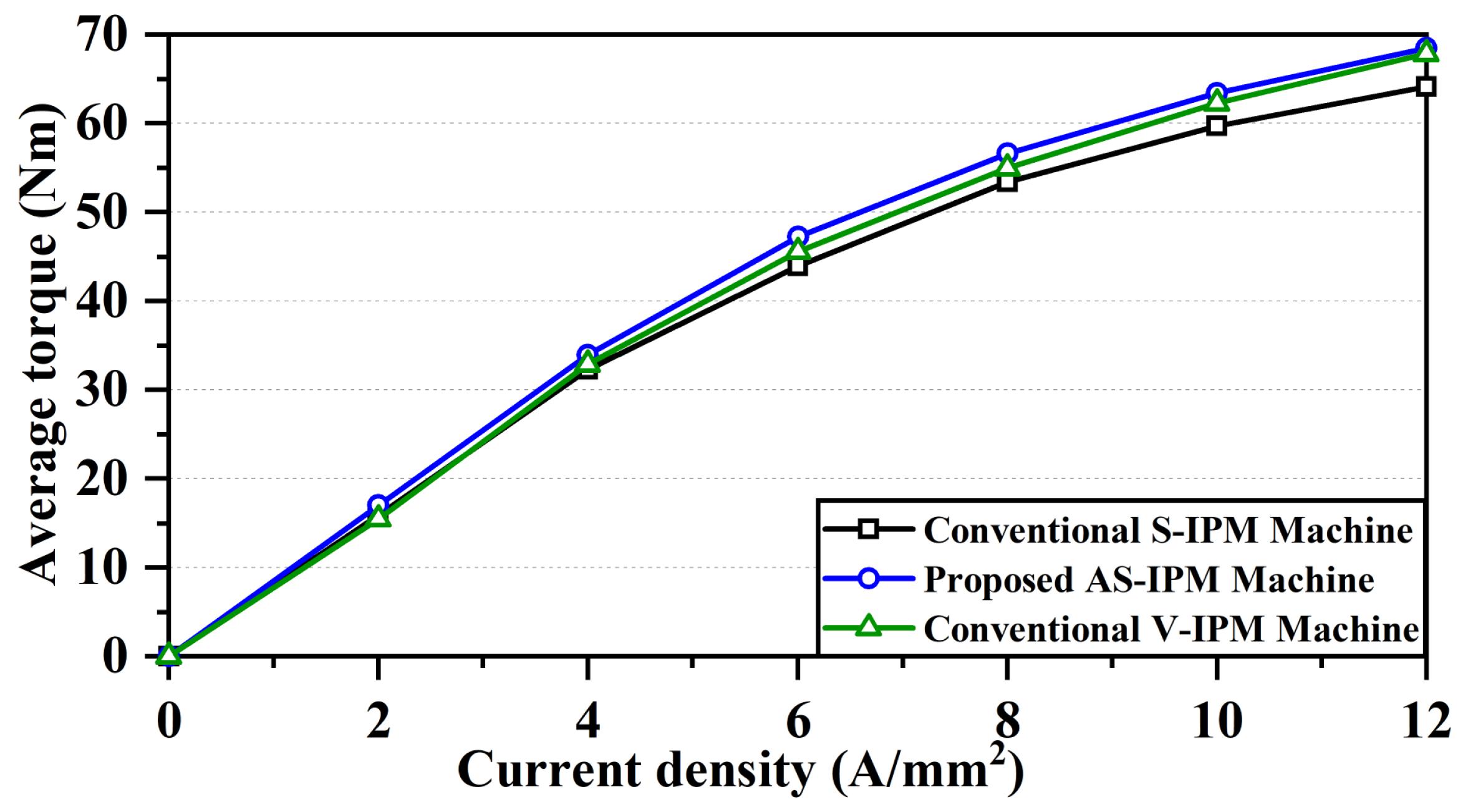

4.1. The Effect of the Asymmetric Flux Barriers on Machine Performance

4.2. Performance Comparison of Conventional and Proposed Machines

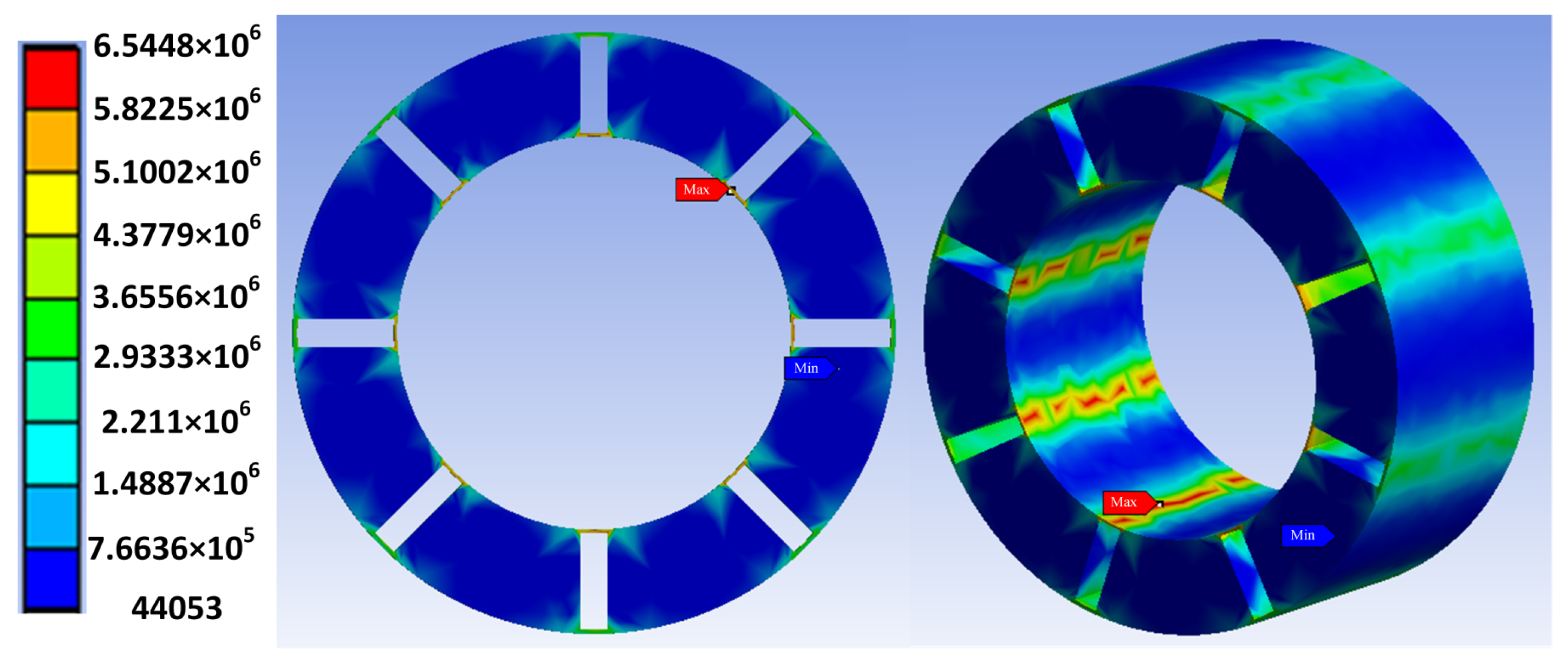

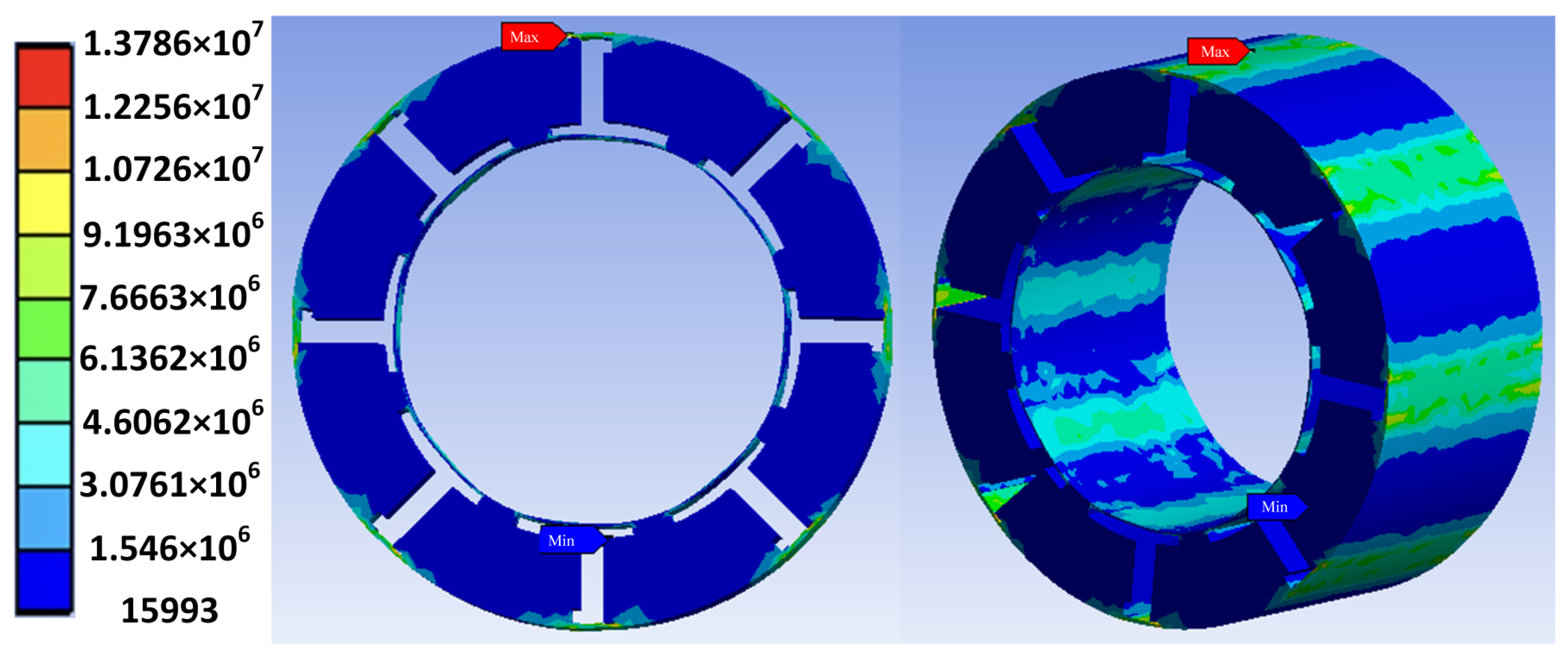

4.3. Mechanical Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chau, K.T.; Chan, C.C.; Liu, C. Overview of permanent-magnet brushless drives for electric and hybrid electric vehicles. IEEE Trans. Ind. Electron. 2008, 55, 2246–2257. [Google Scholar] [CrossRef]

- Azar, Z.; Zhu, Z.Q.; Ombach, G. Investigation of torque-speed characteristics and cogging torque of fractional-slot IPM brushless AC machines having alternate slot openings. IEEE Ind. Appl. 2012, 48, 903–912. [Google Scholar] [CrossRef]

- Niu, S.; Wang, S.; Zhao, X. Overview of stator slot-opening permanent magnet machines. IEEE Trans. Transp. Electrif. 2022, 2, 1561. [Google Scholar] [CrossRef]

- Guan, Y.; Zhu, Z.Q.; Afinowi, I.A.A.; Mipo, J.C.; Farah, P. Comparison between induction machine and interior permanent magnet machine for electric vehicle application. In Proceedings of the 2014 17th International Conference on Electrical Machines and Systems (ICEMS), Hangzhou, China, 1–4 October 2014; pp. 144–150. [Google Scholar]

- Fasolo, A.; Alberti, L.; Bianchi, N. Performance comparison between switching-flux and IPM machines with rare-earth and ferrite PMs. IEEE Trans. Ind. Appl. 2014, 50, 3708–3716. [Google Scholar] [CrossRef]

- Kim, M.; Zhao, F.; Lipo, T.A. Torque density elevation in concentrated winding interior PM synchronous motor with minimized magnet volume. IEEE Trans. Magn. 2013, 49, 3334–3337. [Google Scholar] [CrossRef]

- Wang, A.; Jia, Y.; Soong, W.L. Comparison of five topologies for an interior permanent-magnet machine for a hybrid electric vehicle. IEEE Trans. Magn. 2011, 47, 3606–3609. [Google Scholar] [CrossRef]

- Liu, X.; Chen, H.; Zhao, J.; Belahcen, A. Research on the performances and parameters of interior PMSM used for electric vehicles. IEEE Trans. Ind. Electron. 2016, 63, 3533–3545. [Google Scholar] [CrossRef]

- Zhu, Z.Q.; Xiao, Y. Novel magnetic-field-shifting techniques in asymmetric rotor pole interior PM machines with enhanced torque density. IEEE Trans. Magn. 2022, 58, 1–10. [Google Scholar] [CrossRef]

- Zhao, W.; Zhao, F.; Lipo, T.A.; Kwon, B.-I. Optimal design of a novel V-type interior permanent magnet motor with assisted barriers for the improvement of torque characteristics. IEEE Trans. Magn. 2014, 50, 1–4. [Google Scholar] [CrossRef]

- Xiao, Y.; Zhu, Z.Q.; Chen, J.T.; Wu, D.; Gong, L.M. A novel V-shape interior permanent magnet synchronous machine with asymmetric spoke-type flux barrier. In Proceedings of the 2020 International Conference on Electrical Machines (ICEM), Virtual Conference, 23–26 August 2020; pp. 382–388. [Google Scholar]

- Xu, G.; Liu, G.; Zhao, W.; Chen, Q.; Du, X. Principle of torque-angle approaching in a hybrid rotor permanent-magnet motor. IEEE Trans. Ind. Electron. 2019, 66, 2580–2591. [Google Scholar] [CrossRef]

- Li, Y.; Yang, H.; Lin, H.; Fang, S.; Wang, W. A Novel Magnet-Axis-Shifted Hybrid Permanent Magnet Machine for Electric Vehicle Applications. Energies 2019, 12, 641. [Google Scholar] [CrossRef]

- Zhao, W.; Lipo, T.A.; Kwon, B.-I. Optimal design of a novel asymmetrical rotor structure to obtain torque and efficiency improvement in surface inset PM motors. IEEE Trans. Magn. 2015, 51, 1–4. [Google Scholar]

- Ren, W.; Xu, Q.; Li, Q. Asymmetrical V-Shape rotor configuration of an interior permanent magnet machine for improving torque characteristics. IEEE Trans. Magn. 2015, 51, 1–4. [Google Scholar] [CrossRef]

- Xiao, Y.; Zhao, S.W.; Gong, S. A novel asymmetric interior permanent magnet machine for electric vehicles. Trans. Energy Convers. 2021, 36, 2404–2415. [Google Scholar] [CrossRef]

- Yoon, K.Y.; Hwang, K.Y. Optimal design of spoke-type IPM motor allowing irreversible demagnetization to minimize PM weight. IEEE Access 2021, 9, 65721–65729. [Google Scholar] [CrossRef]

- Bhagubai, P.P.C.; Sarrico, J.G.; Fernandes, J.F.P.; Costa Branco, P.J. Design, multi-objective optimization, and prototyping of a 20 kW 8000 rpm permanent magnet synchronous motor for a competition electric vehicle. Energies 2020, 13, 2465. [Google Scholar] [CrossRef]

- Si, M.; Yang, X.Y.; Zhao, S.W.; Gong, S. Design and analysis of a novel spoke-type permanent magnet synchronous motor. IET Electr. Power Appl. 2016, 10, 571–580. [Google Scholar] [CrossRef]

- Ge, X.; Zhu, Z.Q.; Li, J.; Chen, J. A spoke-type IPM machine with novel alternate airspace barriers and reduction of unipolar leakage flux by step-staggered rotor. IEEE Trans. Ind. Appl. 2016, 52, 4789–4797. [Google Scholar] [CrossRef]

- Liu, W.; Lipo, T.A. Analysis of Consequent Pole Spoke Type Vernier Permanent Magnet Machine With Alternating Flux Barrier Design. IEEE Trans. Ind. Appl. 2018, 54, 5918–5929. [Google Scholar] [CrossRef]

- Li, J.; Wang, K. A novel spoke-type PM machine employing asymmetric modular consequent-pole rotor. IEEE/ASME Trans. Mechatron. 2019, 24, 2182–2192. [Google Scholar] [CrossRef]

- Xiao, Y.; Zhu, Z.Q.; Jewell, G.W.; Chen, J.; Wu, D.; Gong, L. A novel spoke-type asymmetric rotor interior permanent magnet machine. IEEE Trans. Ind. Appl. 2021, 57, 4840–4851. [Google Scholar] [CrossRef]

- Mao, Y.; Zhao, W.; Zhu, S.; Chen, Q.; Ji, J. Vibration investigation of spoke-type PM machine with asymmetric rotor considering modulation effect of stator teeth. IEEE Trans. Ind. Electron. 2021, 68, 9092–9103. [Google Scholar] [CrossRef]

- Jung, Y.; Park, M.; Lim, M. Asymmetric rotor design of IPMSM for vibration reduction under certain load condition. IEEE Trans. Energy Convers. 2020, 35, 928–937. [Google Scholar] [CrossRef]

- Bi, Y.; Huang, J.; Wu, H.; Fu, W.; Niu, S.; Zhao, X. A general pattern of assisted flux barriers for design optimization of an asymmetric V-shape interior permanent magnet machine. IEEE Trans. Magn. 2022, 58, 1–4. [Google Scholar] [CrossRef]

- Yang, H.; Wang, W.; Lin, H.; Zhu, Z.Q.; Lyu, S.; Niu, S. A novel hybrid-pole interior PM machine with magnet-axis-shifting effect. In Proceedings of the 2019 IEEE International Electric Machines and Drives Conference (IEMDC), San Diego, CA, USA, 1–4 May 2019; pp. 273–279. [Google Scholar]

- Zhao, X.; Niu, S. Design and optimization of a new magnetic-geared pole-changing hybrid excitation machine. IEEE Trans. Ind. Electron. 2017, 64, 9943–9952. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, S.; Niu, S.; Fu, W.; Zhang, X. A novel high-order-harmonic winding design method for vernier reluctance machine with DC coils across two stator teeth. IEEE Trans. Ind. Electron. 2022, 69, 7696–7707. [Google Scholar] [CrossRef]

- Chu, W.Q.; Zhu, Z.Q. Average torque separation in permanent magnet synchronous machines using frozen permeability. IEEE Trans. Magn. 2013, 49, 1202–1210. [Google Scholar] [CrossRef]

- Hwang, H.; Bae, S.; Lee, C. Analysis and design of a hybrid rare-earth-free permanent magnet reluctance machine by frozen permeability method. IEEE Trans. Magn. 2016, 52, 1–4. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| Stator slots | 48 |

| Rotor pole pairs | 4 |

| Stator outer diameter | 220 mm |

| Stack length | 50 mm |

| Air gap length | 0.8 mm |

| Current density | 6 A/mm2 |

| Slot filling factor | 0.5 |

| PM volume | 30 mL |

| PM material | N38EH |

| Rated speed | 1500 rpm |

| Parameters | Unit | Variation Range |

|---|---|---|

| h11, h21, h31 | mm | 0.5–3 |

| h12, h22, h32 | mm | 0.2–5 |

| h23 | mm | 12–17 |

| h13, h33 | mm | 10–18 |

| h14, h24, h34 | mm | 0.2–5 |

| h15, h25, h35 | mm | 0.5–3 |

| w12, w14, w31, w33 | degree | 1–20 |

| w2 | mm | 3–8 |

| Parameters | Conventional S-IPM Machine | Proposed AS-IPM Machine |

|---|---|---|

| Rotor outer diameter (mm) | 108.8 | |

| Rotor inner diameter (mm) | 71.2 | |

| h11 (mm) | / | 0.5 |

| h12(mm) | / | 1.93 |

| h13 (mm) | / | 15.4 |

| h14 (mm) | / | 0.37 |

| h15 (mm) | / | 0.6 |

| h21 (mm) | 0.5 | 0.5 |

| h22 (mm) | 1 | 0.6 |

| h23 (mm) | 15 | 16.4 |

| h24 (mm) | 1.5 | 0.5 |

| h25 (mm) | 0.8 | 0.8 |

| h31 (mm) | / | 0.5 |

| h32 (mm) | / | 2.15 |

| h33 (mm) | / | 12.4 |

| h34 (mm) | / | 2.65 |

| h35 (mm) | / | 1.1 |

| w12 (deg.) | / | 8.3 |

| w14 (deg.) | / | 2.4 |

| w2 (mm) | 5 | 4.57 |

| w31 (deg.) | / | 18.6 |

| w33 (deg.) | / | 1.8 |

| Machine Type | Conventional S-IPM Machine | Conventional V-IPM Machine | Proposed AS-IPM Machine |

|---|---|---|---|

| Average torque | 43.88 Nm | 45.56 Nm | 47.255 Nm |

| Cogging (peak-to-peak) | 0.329 Nm | 0.065 Nm | 0.179 Nm |

| Torque ripple | 10.67% | 5.35% | 1.9% |

| Copper loss | 373.88 W | 373.88 W | 373.88 W |

| Core loss | 149.8 W | 144.4 W | 149.2 W |

| Efficiency | 92.94% | 93.25% | 93.41% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, J.; Fu, W.; Niu, S.; Zhao, X.; Bi, Y.; Qiao, Z. A General Pattern-Based Design Optimization for Asymmetric Spoke-Type Interior PM Machines. Energies 2022, 15, 9385. https://doi.org/10.3390/en15249385

Huang J, Fu W, Niu S, Zhao X, Bi Y, Qiao Z. A General Pattern-Based Design Optimization for Asymmetric Spoke-Type Interior PM Machines. Energies. 2022; 15(24):9385. https://doi.org/10.3390/en15249385

Chicago/Turabian StyleHuang, Jiahui, Weinong Fu, Shuangxia Niu, Xing Zhao, Yanding Bi, and Zhenyang Qiao. 2022. "A General Pattern-Based Design Optimization for Asymmetric Spoke-Type Interior PM Machines" Energies 15, no. 24: 9385. https://doi.org/10.3390/en15249385

APA StyleHuang, J., Fu, W., Niu, S., Zhao, X., Bi, Y., & Qiao, Z. (2022). A General Pattern-Based Design Optimization for Asymmetric Spoke-Type Interior PM Machines. Energies, 15(24), 9385. https://doi.org/10.3390/en15249385