Chopper-Based Control Circuit for BESS Integration in Solar PV Grids

Abstract

1. Introduction

- They are non-dispatchable;

- Uncertainty of generation time;

- Low availability and power quality.

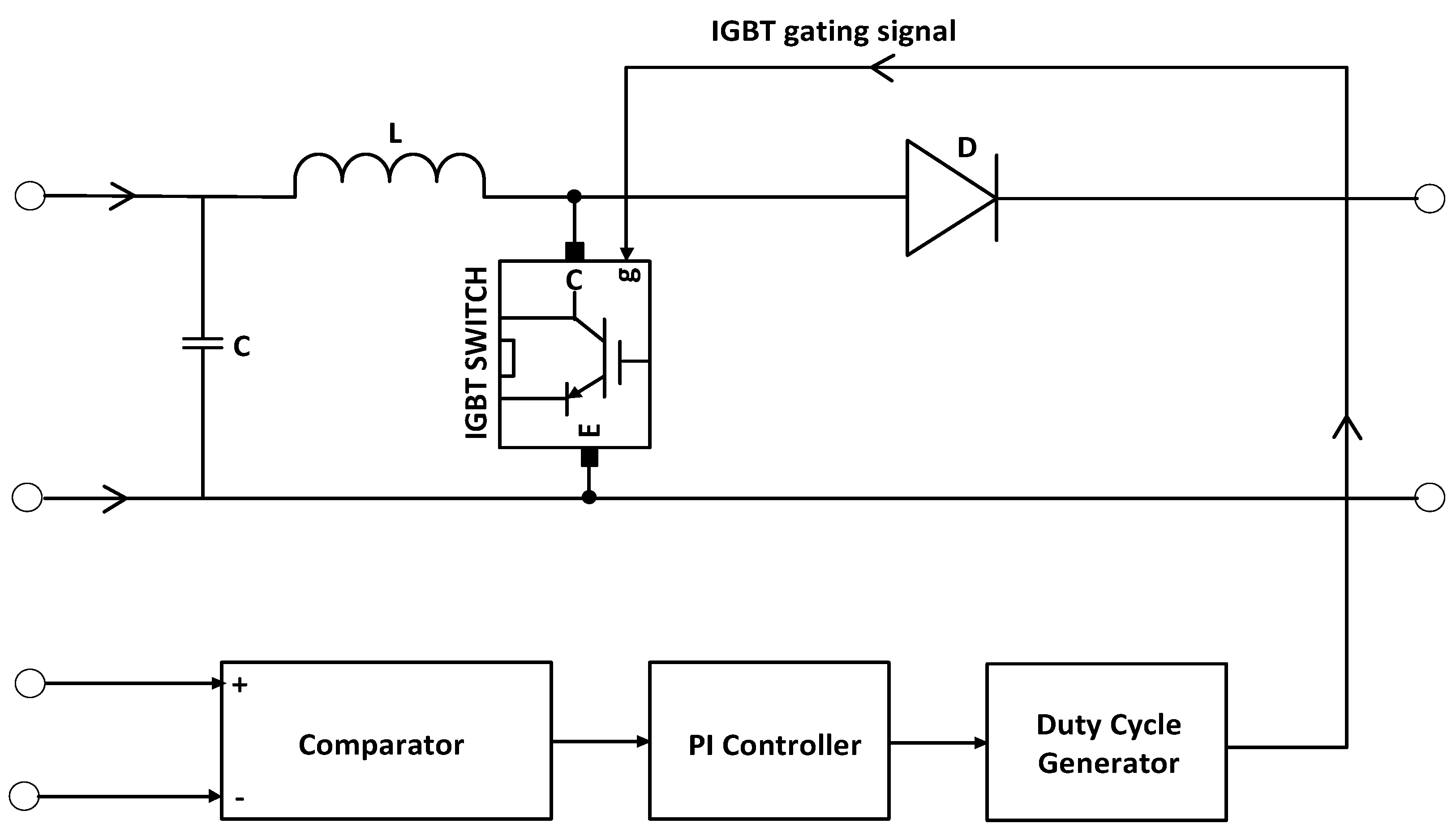

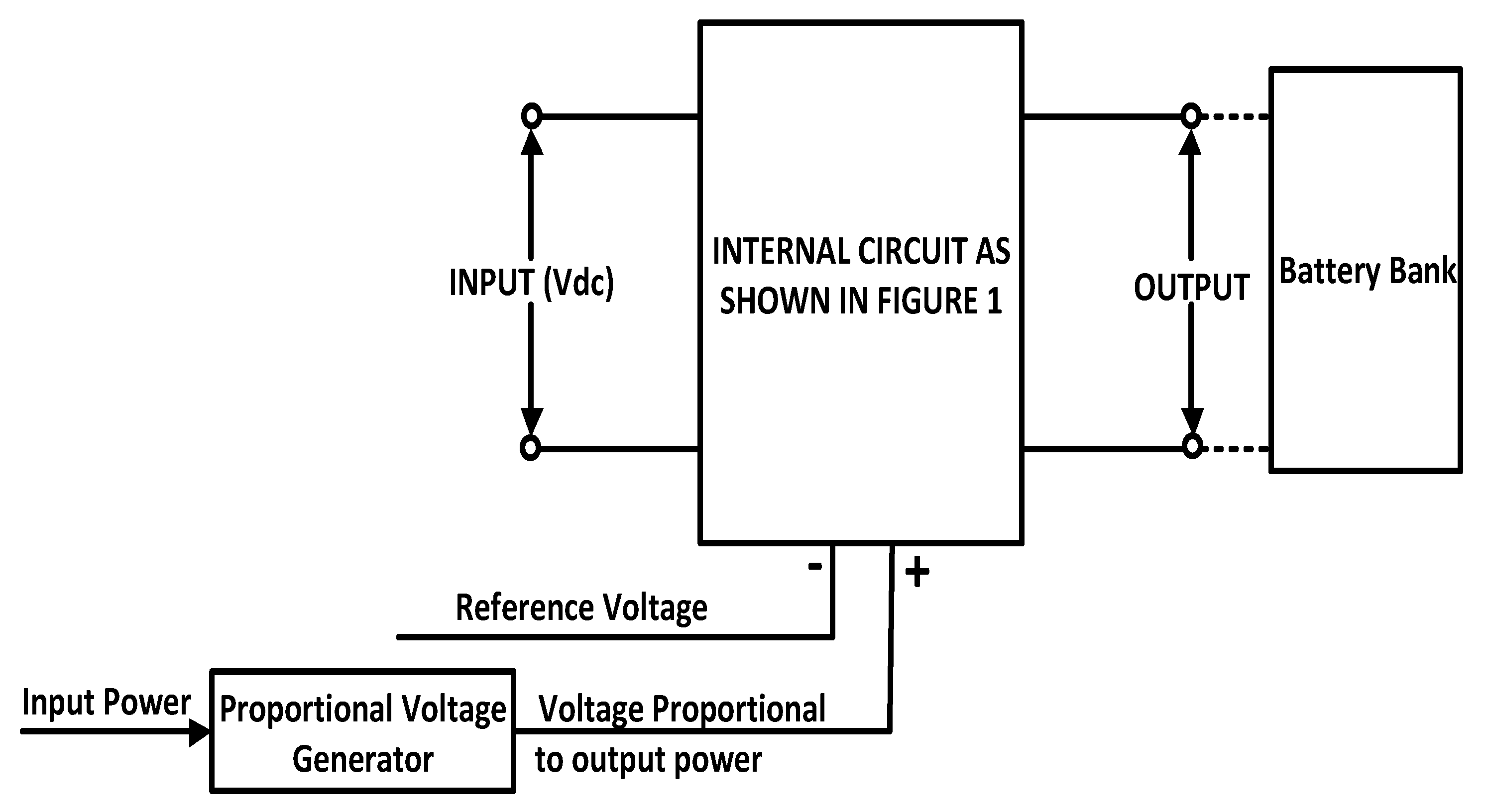

2. Proposed Controller

Operating Range of Controller

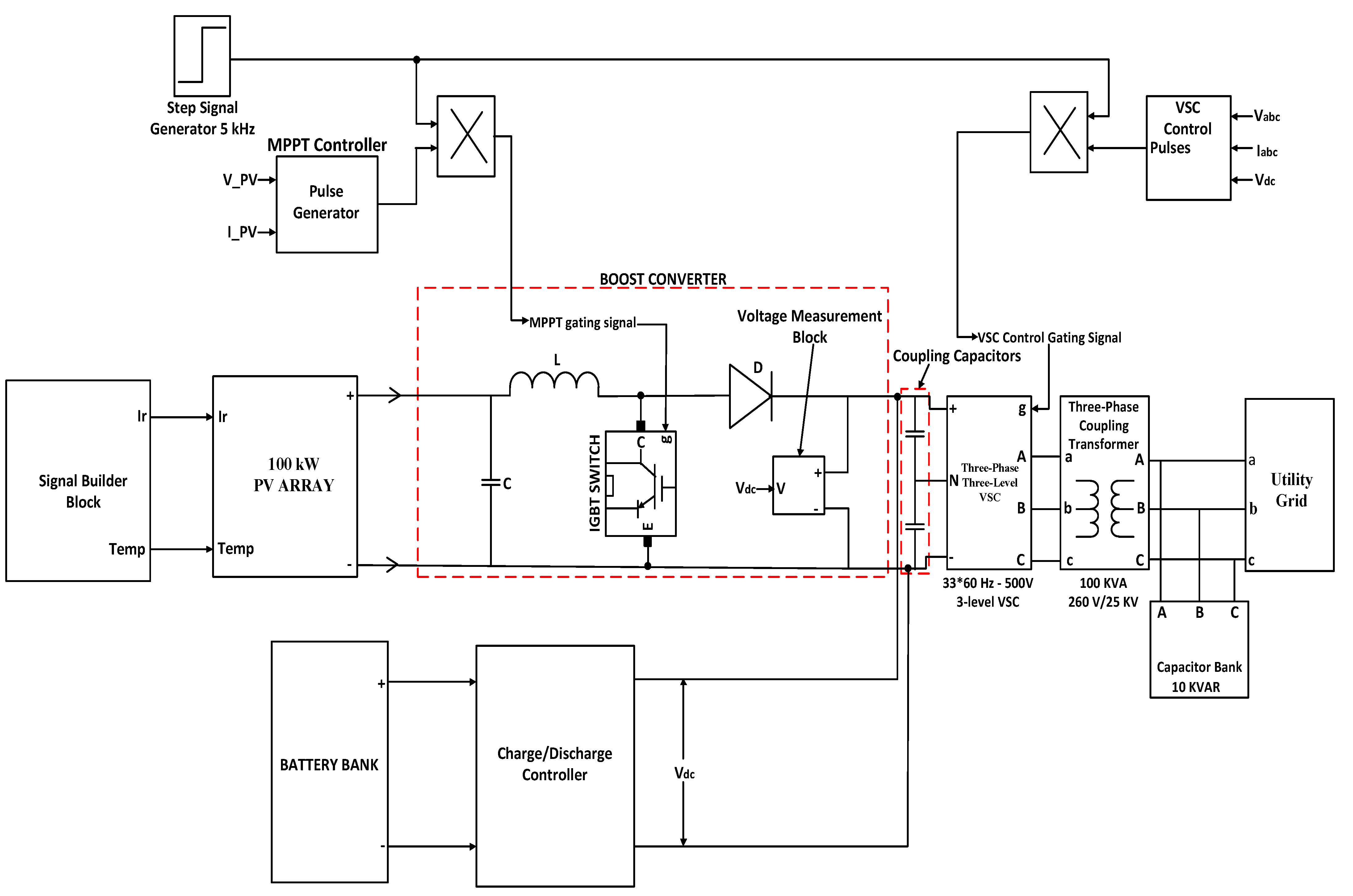

3. Simulation Model of Photovoltaic Grid System with Battery Integration Using a Controller

3.1. Description of Simulation Model and Its Components

- PV Array: Maximum power delivered by the PV array is 100 kW at 1000 W/m2 solar irradiance.

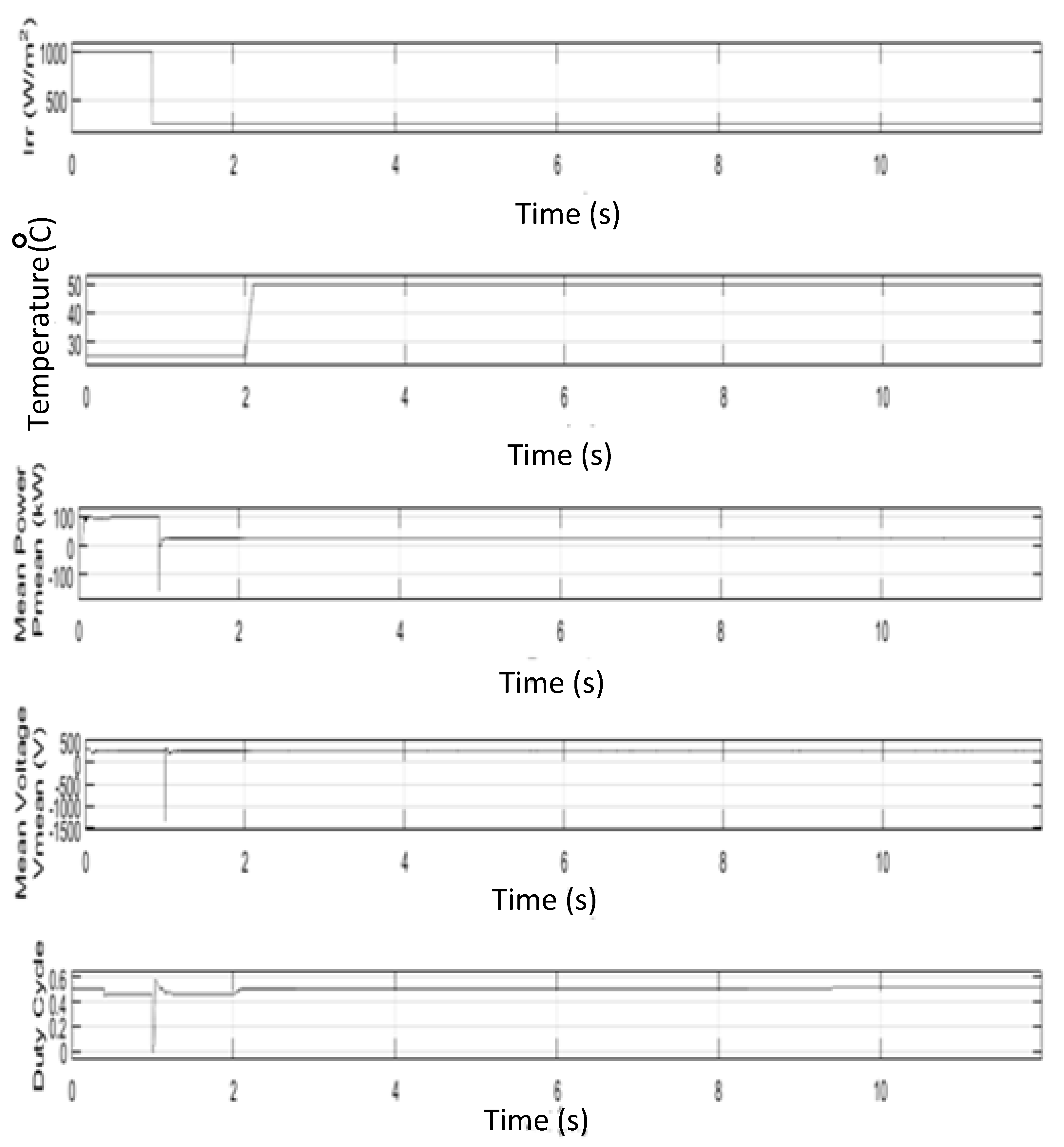

- DC-DC boost converter: At maximum power, PV output voltage was 273 V DC, which increased to 500 V DC by a DC-DC boost converter of 5 kHz. The optimization of the switching duty cycle was performed by a maximum power point tracking (MPPT) controller by using the “Incremental Conductance + Integral Regulator” algorithm. The duty cycle is automatically varied by the MPPT system to provide the voltage required to take out maximum power;

- Three-level three-phase VSC: The simulation circuit and working details of the VSC are presented elsewhere. The output voltage of boost converter was converted from 500 V DC to 260 V AC, and the power factor of unity was maintained by the VSC. VSC uses a switching frequency of 1980 Hz;

- Capacitor bank:VSC harmonics are filtered by DC link capacitors;

- Three-phase coupling transformer: Three-phase coupling transfer of rating 100 kVA 260 V/25 kV was used for stepping-up the VSC output voltage of 260 V AC to 25 kV AC;

- Utility grid: The utility grid consisted of a 25 kV distribution feeder and a 120 kV equivalent transmission system;

- The battery bank and charge/discharge controllers are discussed in separate sections.

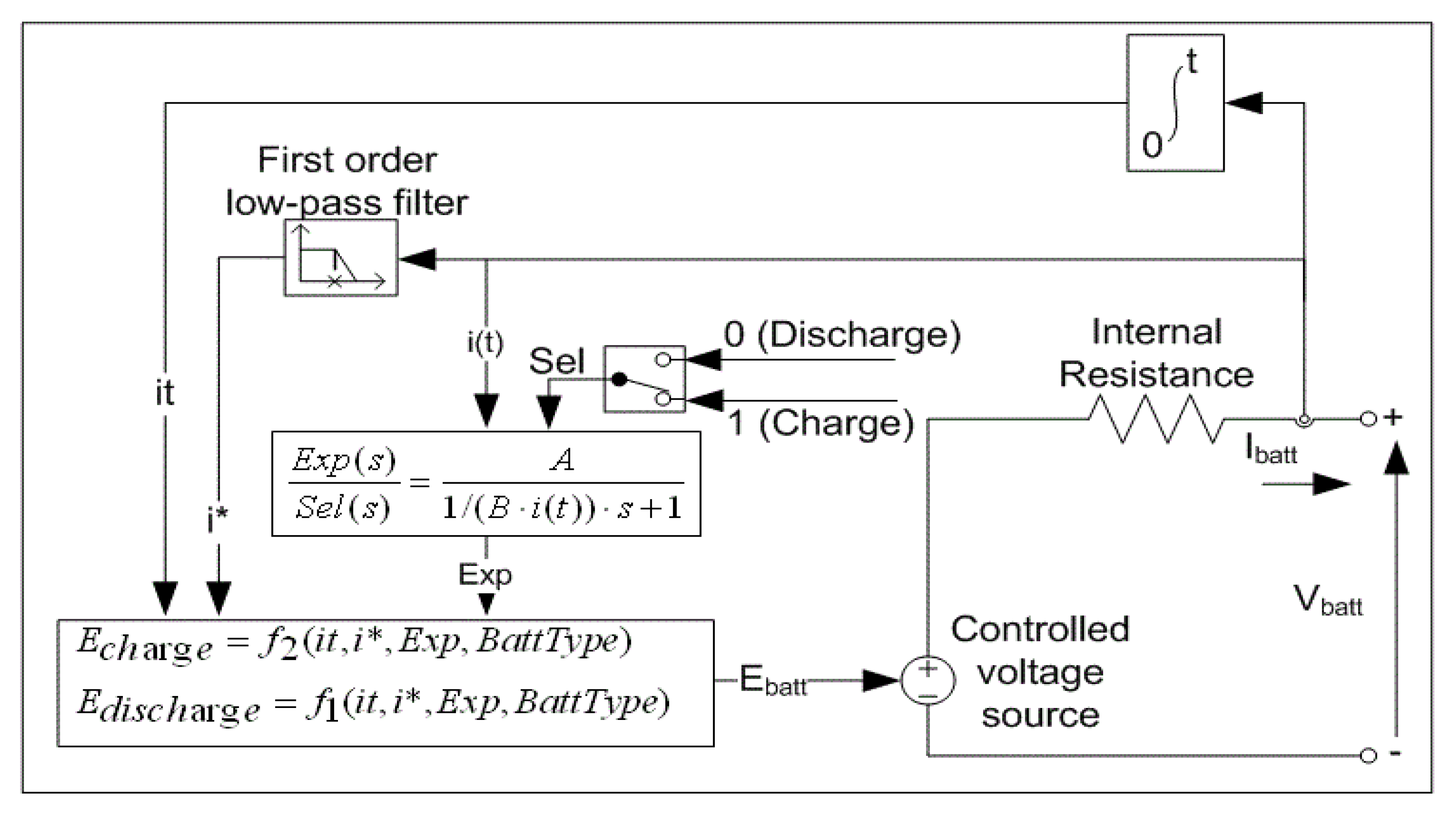

3.2. Battery Bank Description

Reference Equations of the Generic Battery Model

3.3. Charge/Discharge Controller

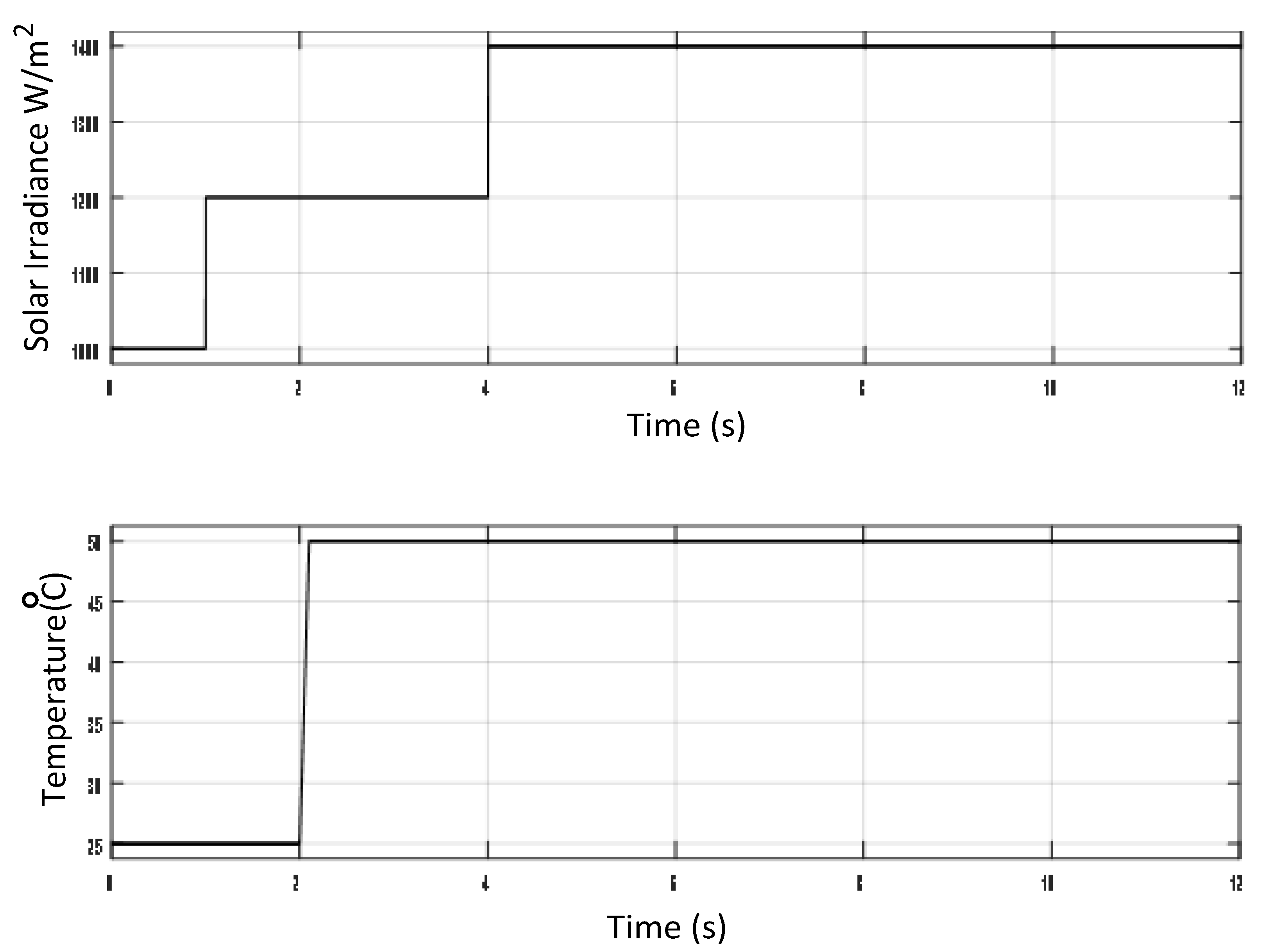

4. Simulation Scenarios

5. Results and Observations

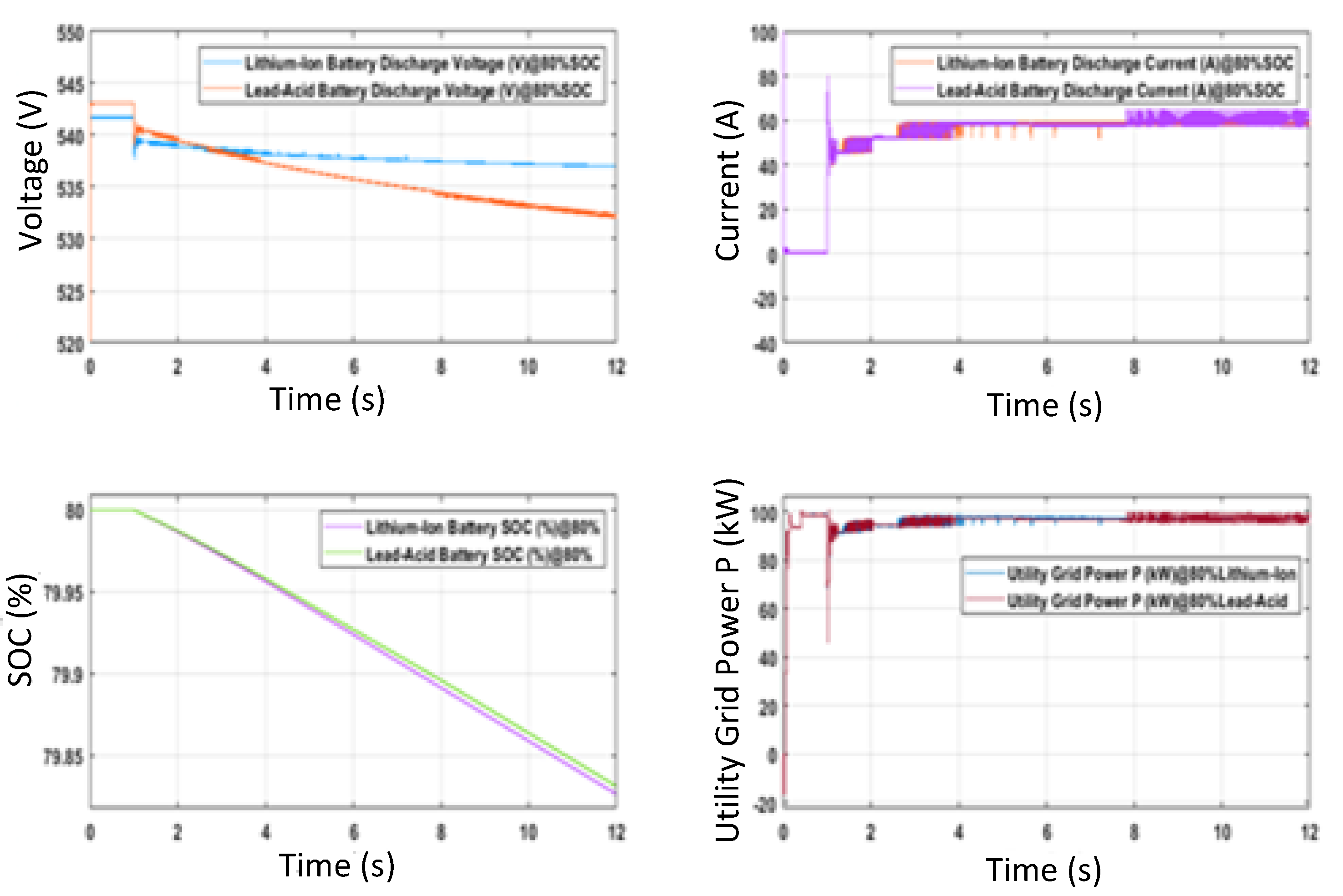

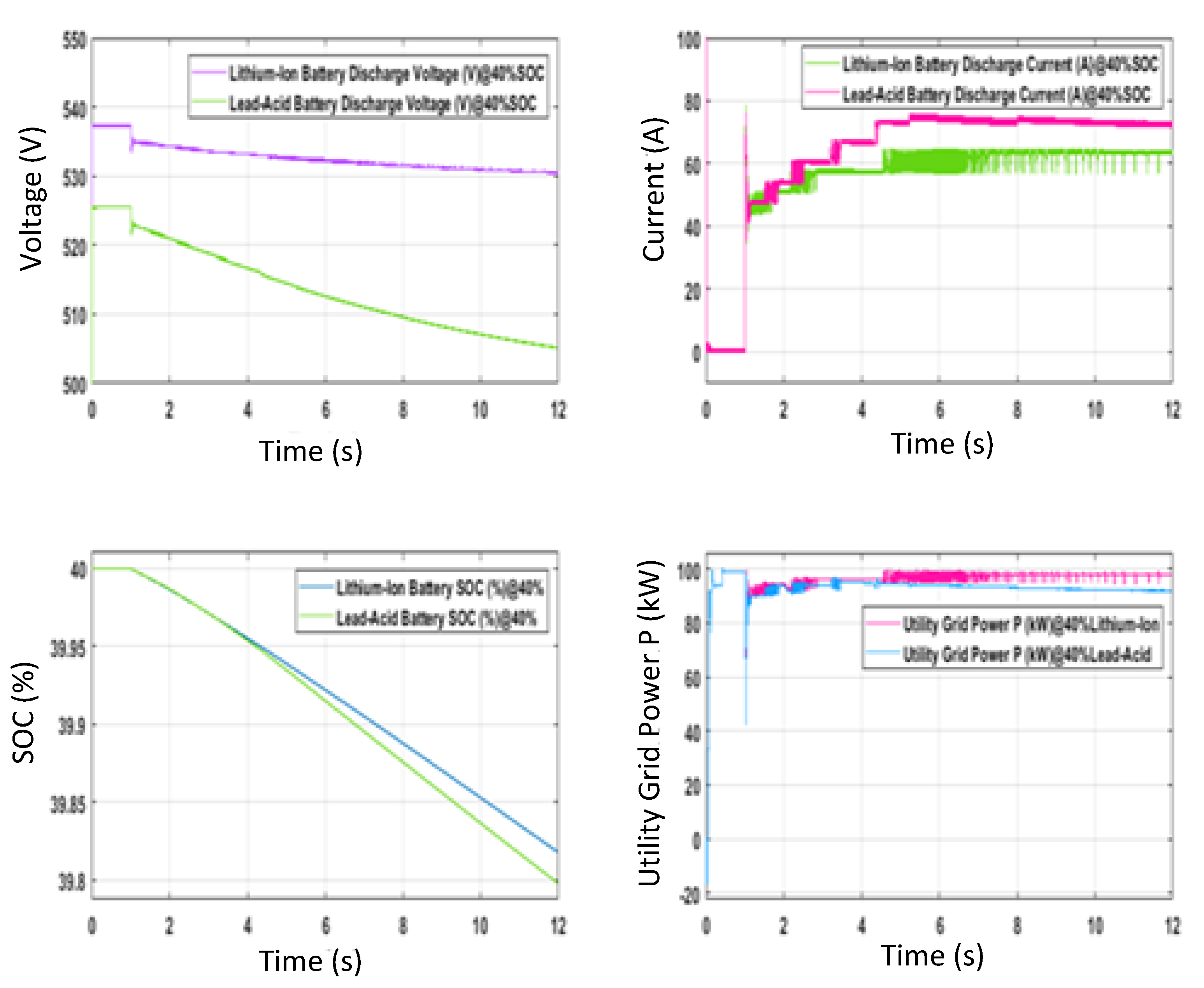

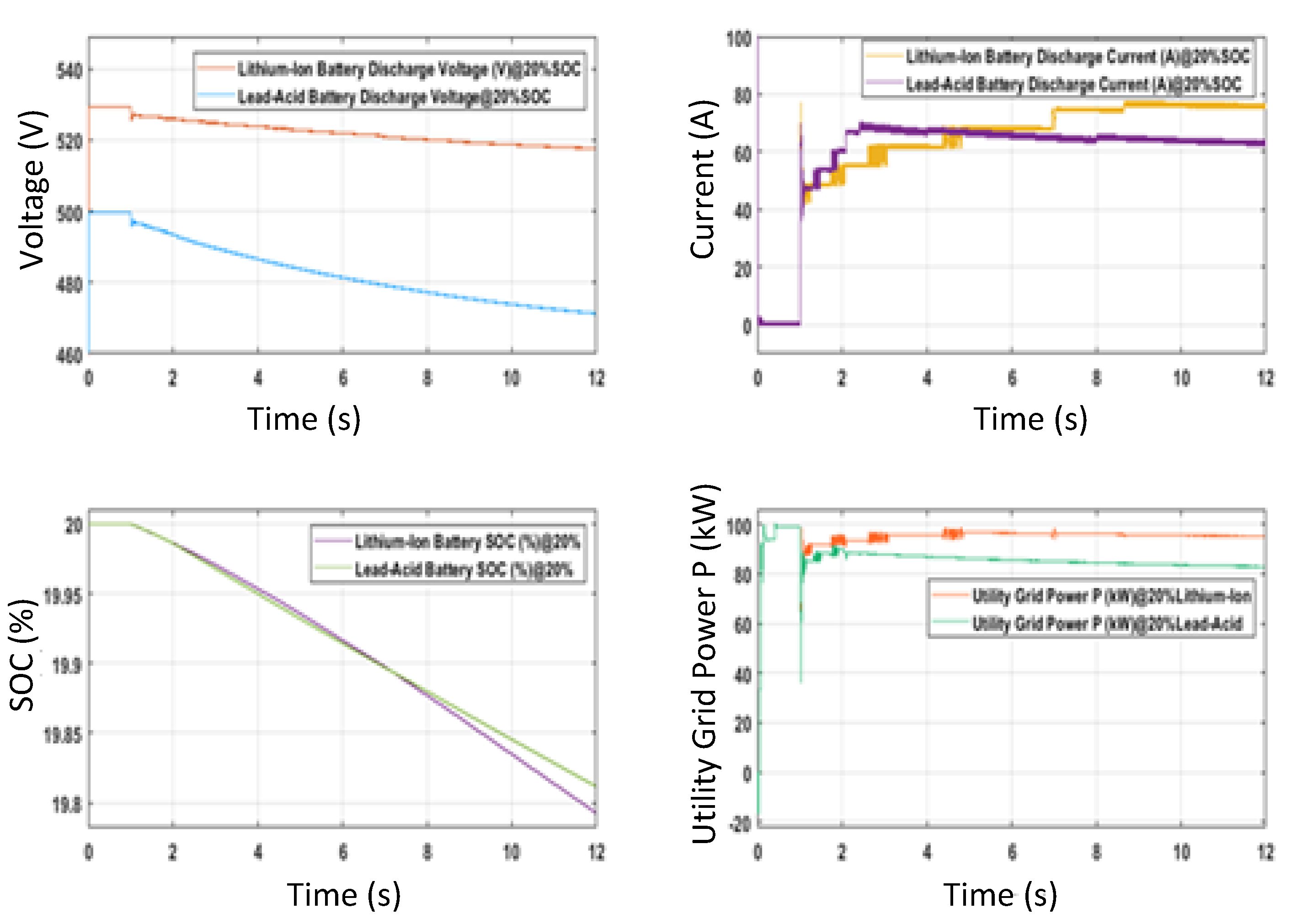

5.1. Scenario 1

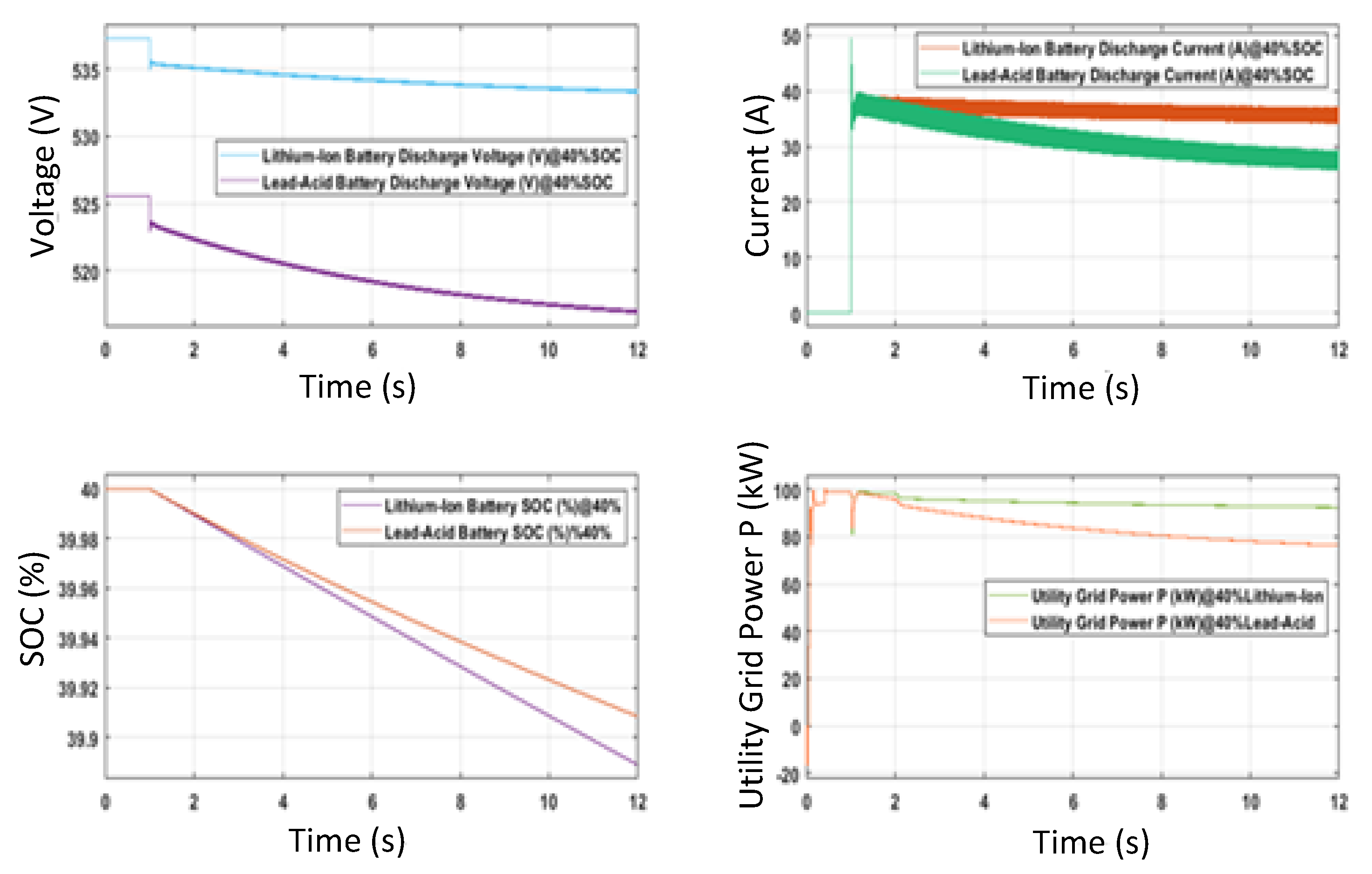

5.1.1. Comparison of Discharging with and without the Controller

5.1.2. Recovery Time of Discharge Controller

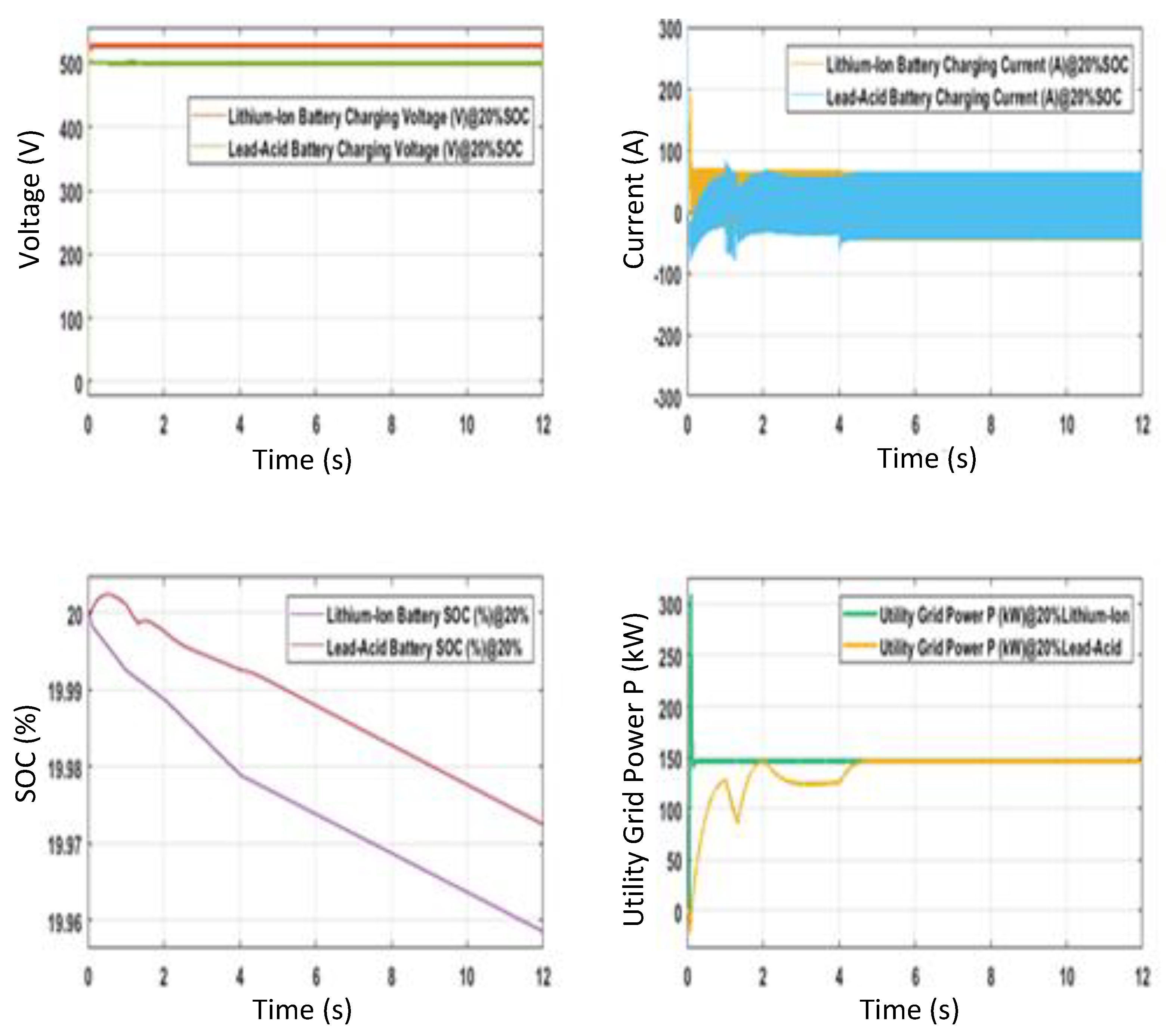

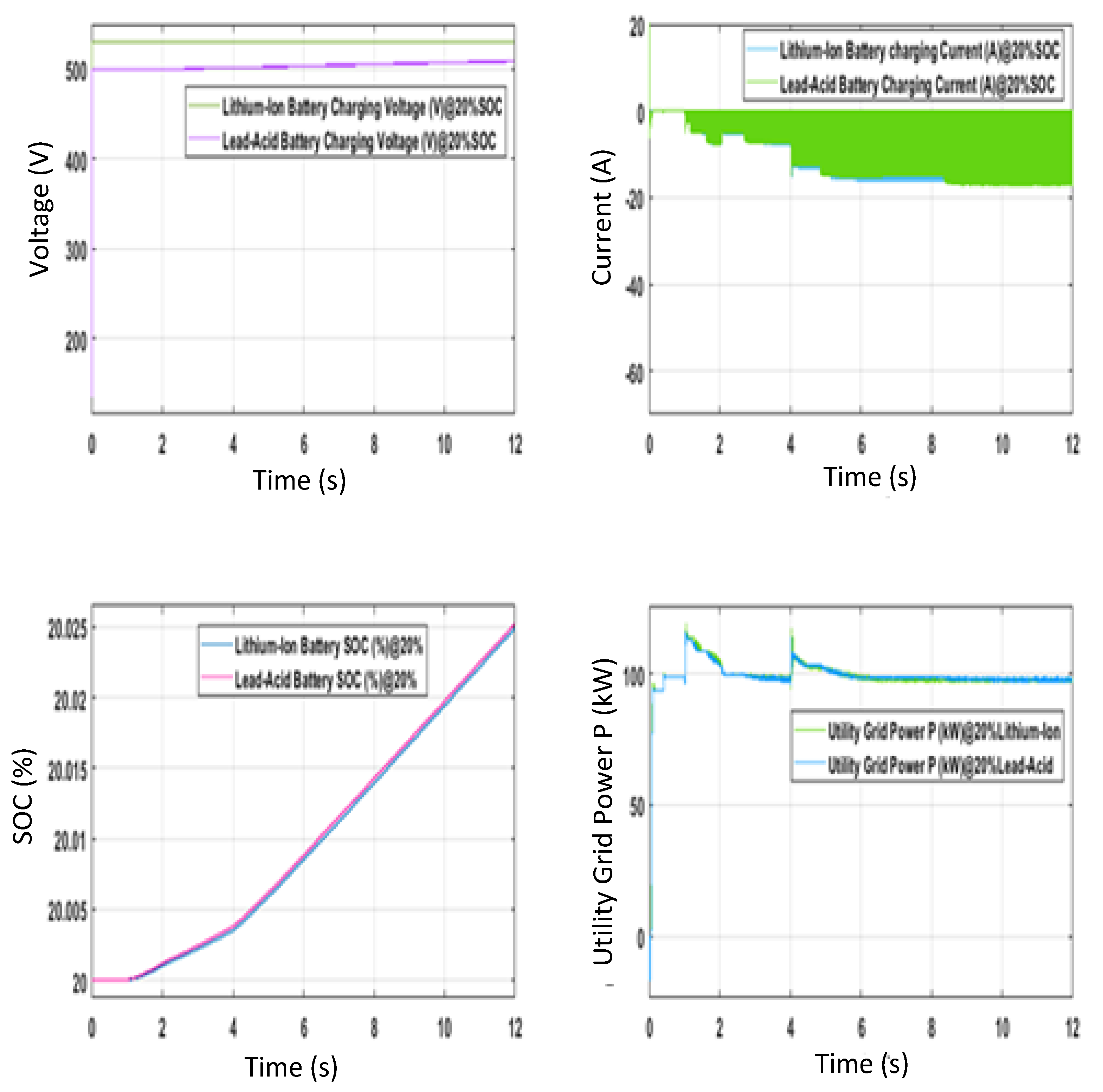

5.2. Scenario 2

5.2.1. Comparison of Charging with and without the Controller

5.2.2. Recovery Time of Charge Controller

5.2.3. Improving the Quality of the Output Power

5.2.4. Performance Range of Controllers

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

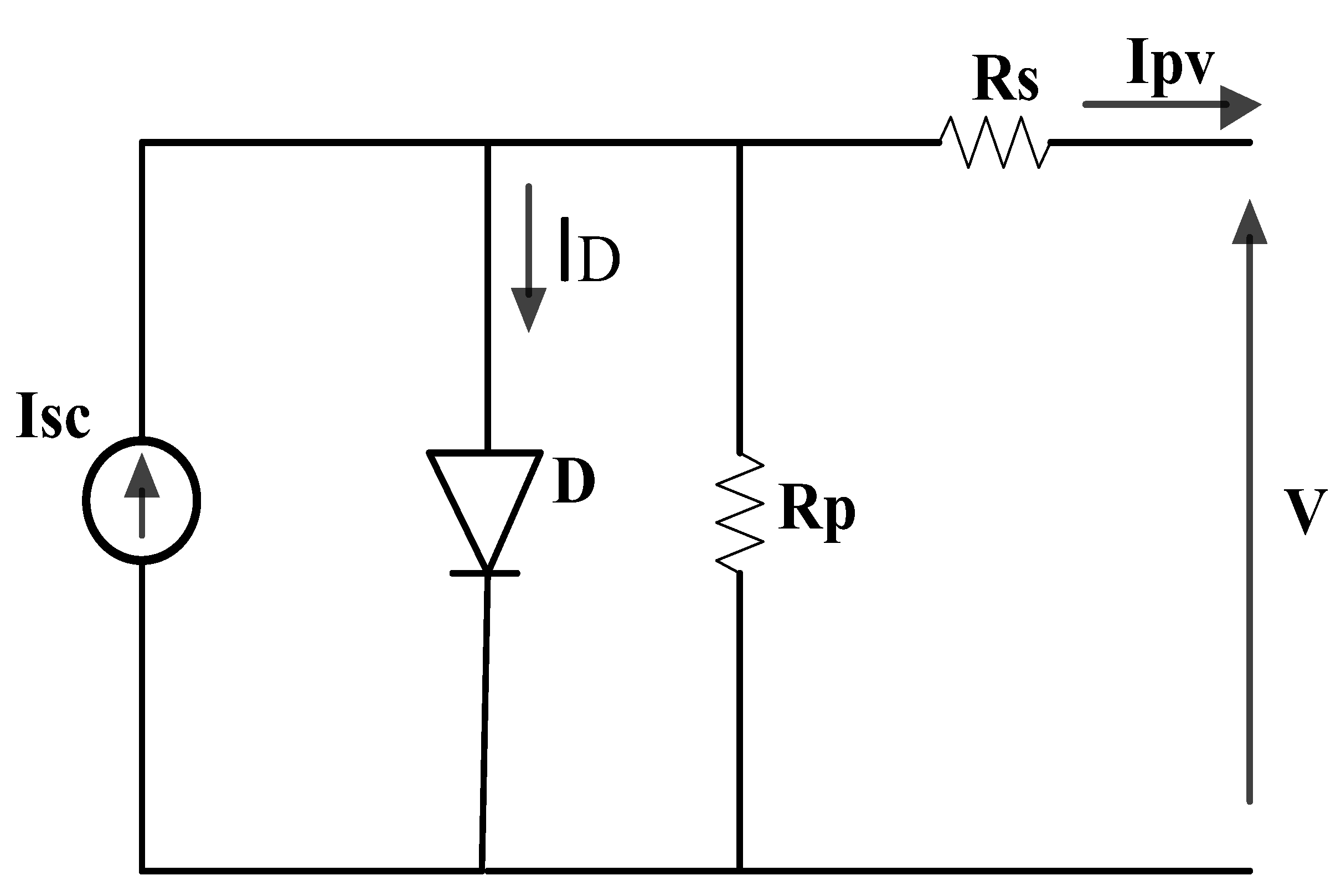

| Ipv | Current in PV cell (A) |

| Vpv | Voltage in PV cell (V) |

| Isc | Short-circuit current of the PV cell (A) |

| I0 | Current at saturation level (A) |

| Ns | Number of series-connected PV cells |

| Np | Number of parallel-connected PV cells |

| Tpn | p-n junction temperature (°C) |

| Bc | Boltzmann constant (J K−1) |

| q | Charge of an electron (C) |

| Rs | PV array series equivalent resistance (Ω) |

| Rp | PV array Parallel equivalent resistance (Ω) |

| Qd | Ideality factor of diode |

| E | Voltage controlled source (V) |

| Ibat | Battery discharge current (A) |

| Vbat | Battery terminal voltage (V) |

| Vo | Output voltage of boost converter (V) |

| Vi | Input voltage of boost converter (V) |

| D | Duty cycle of boost converter |

| L | Inductance value of boost converter (H) |

| C | Capacitance value of boost converter (F) |

| SOC | Battery state of charge (%) |

| Rbat | Battery variable internal resistance (Ω) |

| Eo | Constant battery voltage (V) |

| K | Resistance of polarization (Ω) |

| Qmax | Capacity of the battery (Ah) |

| Q | Charge in the real battery (Ah) |

| A | The magnitude of the exponential zone (V) |

| B | The inverse time constant of the exponential zone (Ah−1) |

| i* | Filtered current (A) |

| BESS | Battery energy storage system |

| PV | Photovoltaic |

| Exp(s) | Exponential zone dynamics (V) |

| Sel(s) | Battery mode |

| t | Charge or discharge time (s) |

| i | Battery current (A) |

| it | Extracted capacity (Ah) |

| Ebatt | Nonlinear voltage (V) |

References

- Lai, C.S.; Jia, Y.; Lai, L.L.; Xu, Z.; McCulloch, M.D.; Wong, K.P. A comprehensive review on large-scale photovoltaic system with applications of electrical energy storage. Renew. Sustain. Energy Rev. 2017, 78, 439–451. [Google Scholar] [CrossRef]

- Mamatha, G.; Rangasai, D.; Avinash, S.; Naveen, M. Integration of solar PV with the grid. Int. J. Appl. Eng. Res. 2017, 12, 430–434. [Google Scholar]

- Srikanth Goud, B.; Loveswararao, B.; Rami Reddy, C. Essentials for Grid Integration of Hybrid Renewable Energy Systems: A Brief Review. Int. J. Renew. Energy Res. 2020, 10, 813–830. [Google Scholar]

- Guru Prasad, S.; Srikanth, K.S.; Rajanna, B.V. Advanced active power filter performance for grid integrated hybrid renewable power generation systems. Indones. J. Electr. Eng. Comput. Sci. 2018, 11, 60–73. [Google Scholar] [CrossRef]

- Srikanth, M.; Vijay Muni, T.; Vishnu Vardhan, M.; Somesh, D. Design and simulation of PV-wind hybrid energy system. J. Adv. Res. Dyn. Control Syst. 2018, 10, 999–1005. [Google Scholar]

- Rajanna, B.V.; Lalitha, S.V.N.L.; Rao, G.J.; Shrivastava, S.K. Solar photovoltaic generators with MPPT and battery storage in microgrids. Int. J. Power Electron. Drive Syst. (IJPEDS) 2016, 7, 701. [Google Scholar] [CrossRef]

- Kumar, B.P.; Srikanth, M. Photovoltaic—Standalone system with SMES-battery energy storage system cascaded MLI for rural area applications. Int. J. Recent Technol. Eng. 2019, 7, 2064–2068. [Google Scholar]

- Lu, C.; Xu, H.; Pan, X.; Song, J. Optimal Sizing and Control of Battery Energy Storage System for Peak Load Shaving. Energies 2014, 7, 8396–8410. [Google Scholar] [CrossRef]

- Kapoor, A.; Sharma, A. Optimal Charge/Discharge Scheduling of Battery Storage Interconnected with Residential PV System. IEEE Syst. J. 2019, 14, 3825–3835. [Google Scholar] [CrossRef]

- Donepudi, S.R.; Priyanka, M.V.; Jahnavi, K.; Swathi, M. Optimization of an energy storage device in the photovoltaic system. Int. J. Appl. Eng. Res. 2017, 12, 547–552. [Google Scholar]

- Calero, F.; Canizares, C.A.; Bhattacharya, K. Detailed and Average Battery Energy Storage Model Comparison. In Proceedings of the 2019 IEEE PES Innovative Smart Grid Technologies Europe (ISGT-Europe), Bucharest, Romania, 29 September–2 October 2019; pp. 1–5. [Google Scholar]

- Cho, J.; Jeong, S.; Kim, Y. Commercial and research battery technologies for electrical energy storage applications. Prog. Energy Combust. Sci. 2015, 48, 84–101. [Google Scholar] [CrossRef]

- Rallabandi, V.; Akeyo, O.M.; Jewell, N.; Ionel, D.M. Incorporating Battery Energy Storage Systems Into Multi-MW Grid Connected PV Systems. IEEE Trans. Ind. Appl. 2019, 55, 638–647. [Google Scholar] [CrossRef]

- Muni, T.V.; Lalitha, S.V.N.L. Power management strategy in a solar PV system with battery protection scheme in dc microgrid. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 960–964. [Google Scholar]

- Kumaraswamy, G.; Srinivasa Varma, P.; Chandrasekhar, P. Grid interconnected multi-level inverter-based PV system. J. Adv. Res. Dyn. Control Syst. 2017, 9, 154–160. [Google Scholar]

- Ramesh, V.; Latha, Y.K. Performance improvement of grid-connected PV system using new converter topologies. In Proceedings of the 2017 2nd IEEE International Conference on Electrical, Computer and Communication Technologies, ICECCT, Coimbatore, India, 22–24 February 2017. [Google Scholar]

- Luo, X.; Wang, J.; Dooner, M.; Clarke, J. Overview of current development in electrical energy storage technologies and the application potential in power system operation. Appl. Energy 2015, 137, 511–536. [Google Scholar] [CrossRef]

- Cedric, C.; Adnan, S.; Ahmed, A.-D.; Muyeen, S.M.; Adnan, S. Modeling and analysis of battery performance for renewable energy application. In Proceedings of the 2013 15th European Conference on Power Electronics and Applications (EPE), Lille, France, 3–5 September 2013; p. 110. [Google Scholar]

- Vijay Muni, T.; Lalitha, S.V.N.L. Implementation of control strategies for optimum utilization of solar photovoltaic system with energy storage systems. Int. J. Renew. Energy Res. 2020, 10, 716–726. [Google Scholar]

- Darabi, A.; Hosseina, M.; Gholami, H.; Khakzad, M. Modeling and Simulation of Lead- Acid Storage Batteries within Photovoltaic Power Systems. Int. J. Emerg. Technol. Adv. Eng. 2013, 18, 2250–2459. [Google Scholar]

- Keshan, H.; Thornburg, J.; Ustun, T. Comparison of lead-acid and lithium ion batteries for stationary storage in off-grid energy systems. In Proceedings of the 4th IET Clean Energy and Technology Conference (CEAT 2016), Kuala Lumpur, Malaysia, 14–15 November 2016; pp. 1–7. [Google Scholar]

- Moncecchi, M.; Brivio, C.; Corigliano, S.; Cortazzi, A.; Merlo, M. Battery modeling for microgrid design: A comparison between lithium-ion and lead acid technologies. In Proceedings of the 2018 International Symposium on Power Electronics, Electrical Drives, Automation and Motion (SPEEDAM), Amalfi, Italy, 20–22 June 2018; pp. 1215–1220. [Google Scholar]

- Chatzinikolaou, E.; Rogers, D.J. A Comparison of Grid-Connected Battery Energy Storage System Designs. IEEE Trans. Power Electron. 2016, 32, 6913–6923. [Google Scholar] [CrossRef]

- Soares dos Santos, G.; José Grandinetti, F.; Augusto Rocha Alves, R.; de Queiróz Lamas, W. Design and Simulation of an Energy Storage System with Batteries Lead Acid and Lithium-Ion for an Electric Vehicle: Battery vs. Conduction Cycle Efficiency Analysis. IEEE Latin Am. Trans. 2020, 18, 1345–1352. [Google Scholar] [CrossRef]

- Poullikkas, A. A comparative overview of large-scale battery systems for electricity storage. Renew. Sustain. Energy Rev. 2013, 27, 778–788. [Google Scholar] [CrossRef]

- Suraj, G.O.; Narasimha Raju, K.; Trivedi, N. Comparative analysis of Li-Ion battery charging with different rectifier topologies. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 420–424. [Google Scholar]

- Kularatna, N. Dynamics and Modeling of Rechargeable Batteries: What electrochemists? Work tells the electronic engineers. IEEE Power Electron. Mag. 2014, 1, 23–33. [Google Scholar] [CrossRef]

- Chen, M.; Rincon-Mora, G.A. Accurate electrical battery model capable of predicting runtime and i-v performance. IEEE Trans. Energy Convers. 2006, 21, 504–511. [Google Scholar] [CrossRef]

- Akbar, N.; Islam, M.; Ahmed, S.S.; Al Hye, A. Dynamic model of battery charging. In Proceedings of the TENCON 2015—2015 IEEE Region 10 Conference, Macao, 1–4 November 2015; pp. 1–4. [Google Scholar]

- Yao, L.W.; Aziz, J.A.; Kong, P.Y.; Idris, N.Y.N. Modeling of Lithium-Ion Battery Using MATLAB/Simulink. IEEE 2013, 1729–1734. [Google Scholar]

- Rajanna, B.V.; Kumar, M.K. Comparison of one and two time constant models for lithium-ion battery. Int. J. Electr. Comput. Eng. (IJECE) 2020, 10, 670–680. [Google Scholar] [CrossRef]

- Stevanatto, L.C.; Tairov, S.; Brusamarello, V.J. Parameter Identification and Analysis of Uncertainties in Measurements of Lead–Acid Batteries. IEEE Trans. Instrum. Meas. 2013, 63, 761–768. [Google Scholar] [CrossRef]

- Schweighofer, B.; Recheis, M.; Gallien, T.; Wegleiter, H. Fast and accurate battery model including temperature dependency. In Proceedings of the Industrial Electronics Society, IECON 2013—39th Annual Conference of the IEEE, Vienna, Austria, 10–13 November 2013; pp. 6740–6745. [Google Scholar]

- Sparacino, A.R.; Reed, G.F.; Kerestes, R.J.; Grainger, B.M.; Smith, Z.T. Survey of battery energy storage systems and modeling techniques. In Proceedings of the 2012 IEEE Power and Energy Society General Meeting, SanDiego, CA, USA, 22–26 July 2012; pp. 1–8. [Google Scholar]

- Rajanna, B.V.; Kumar, M.K. Dynamic model development for a lead-acid storage battery. Indones. J. Electr. Eng. Comput. Sci. 2019, 15, 609–619. [Google Scholar] [CrossRef]

- Guasch, D.; Silvestre, S. Dynamic battery model for photovoltaic applications. Prog. Photovolt. Res. Appl. 2003, 11, 193–206. [Google Scholar] [CrossRef]

- Rodrigues, E.M.G.; Godina, R.; Osorio, G.J.; Lujano-Rojas, J.M.; Matias, J.C.O.; Catalao, J.P.S. Comparison of battery models for energy storage applications on insular grids. In Proceedings of the 2015 Australasian Universities Power Engineering Conference (AUPEC), Wollongong, NSW, Australia, 27–30 September 2015; pp. 1–6. [Google Scholar]

- Rosewater, D.M.; Copp, D.A.; Nguyen, T.A.; Byrne, R.H.; Santoso, S. Battery Energy Storage Models for Optimal Control. IEEE Access 2019, 7, 178357–178391. [Google Scholar] [CrossRef]

- Ravi Kumar, K.S.; Mohanta, D.K.; Sastry, V.V.; Rajesh, D.; Sekhar, O.C.; Varma, M.P.C. Design and fabrication of coulomb counter for estimation of SOC of battery. In Proceedings of the IEEE International Conference on Power Electronics, Drives and Energy Systems, PEDES 2016, Trivandrum, India, 14–16 December 2016; pp. 1–6. [Google Scholar]

- Tremblay, O.; Dessaint, L.-A.; Dekkiche, A. A Generic Battery Model for the Dynamic Simulation of Hybrid Electric Vehicles. In Proceedings of the IEEE Vehicle Power and Propulsion Conference, Gijón, Spain, 25–28 October 2007; pp. 284–289. [Google Scholar]

- Wang, W.; Mu, J. State of Charge Estimation for Lithium-Ion Battery in Electric Vehicle Based on Kalman Filter Considering Model Error. IEEE Access 2019, 7, 29223–29235. [Google Scholar] [CrossRef]

- How, D.N.T.; Hannan, M.A.; Lipu, M.S.H.; Ker, P.J. State of Charge Estimation for Lithium-Ion Batteries Using Model-Based and Data-Driven Methods: A Review. IEEE Access 2019, 7, 136116–136136. [Google Scholar] [CrossRef]

| PV Array Ratings 330 Sun Power Modules (SPR-305E-WHT-D) | Remarks | |

| Rating of PV Array | 100 kW | Number of strings in parallel × Number of modules per string × power per module = 66 × 5 × 305.2 W = 100.7 kW, approximately. |

| Utility Grid Demand | 100 kW | |

| PV Module Power | 305 W | Voltage at maximum power Vmp × Current at maximum power Imp = 54.7 V × 5.58 A = 305.2 W, approximately. |

| Number of modules | 330 | |

| Short-Circuit Current (Isc) of PV cell | 5.96 A | |

| Open-Circuit Voltage (Voc) of PV cell | 64.2 V | |

| Voltage at maximum power Vmp | 54.7 V | |

| Current at maximum power Imp | 5.58 A | |

| Number of series connected PV Cells | 96 per module | |

| Number of strings in parallel | 66 | |

| Number of modules per string | 5 | |

| Battery Ratings | Value | Remarks |

|---|---|---|

| Number of Batteries Connected in Parallel | 4 | |

| Type of Battery Used | Lead-Acid or Lithium-Ion | |

| Nominal Voltage of Lead-Acid Battery | 535 V | |

| Nominal Voltage of Lithium-Ion Battery | 500 V | |

| Fully Charged Voltage of Batteries | 582.5 V | |

| Ah Rating of Each Battery | 100 Ah | |

| Power Rating of Battery Bank | 100 kW | |

| DC Link Voltage, Vdc | 500 V | |

| Total Current Delivered by the Cattery Bank | 200 A | |

| Current Delivered by Each Battery | 50 A | |

| Battery Bank Back-Up Time | 2 h |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rajanna, B.V.; Kumar, M.K. Chopper-Based Control Circuit for BESS Integration in Solar PV Grids. Energies 2021, 14, 1530. https://doi.org/10.3390/en14061530

Rajanna BV, Kumar MK. Chopper-Based Control Circuit for BESS Integration in Solar PV Grids. Energies. 2021; 14(6):1530. https://doi.org/10.3390/en14061530

Chicago/Turabian StyleRajanna, B. V., and Malligunta Kiran Kumar. 2021. "Chopper-Based Control Circuit for BESS Integration in Solar PV Grids" Energies 14, no. 6: 1530. https://doi.org/10.3390/en14061530

APA StyleRajanna, B. V., & Kumar, M. K. (2021). Chopper-Based Control Circuit for BESS Integration in Solar PV Grids. Energies, 14(6), 1530. https://doi.org/10.3390/en14061530