Fault Diagnosis of Transformer Windings Based on Decision Tree and Fully Connected Neural Network

Abstract

1. Introduction

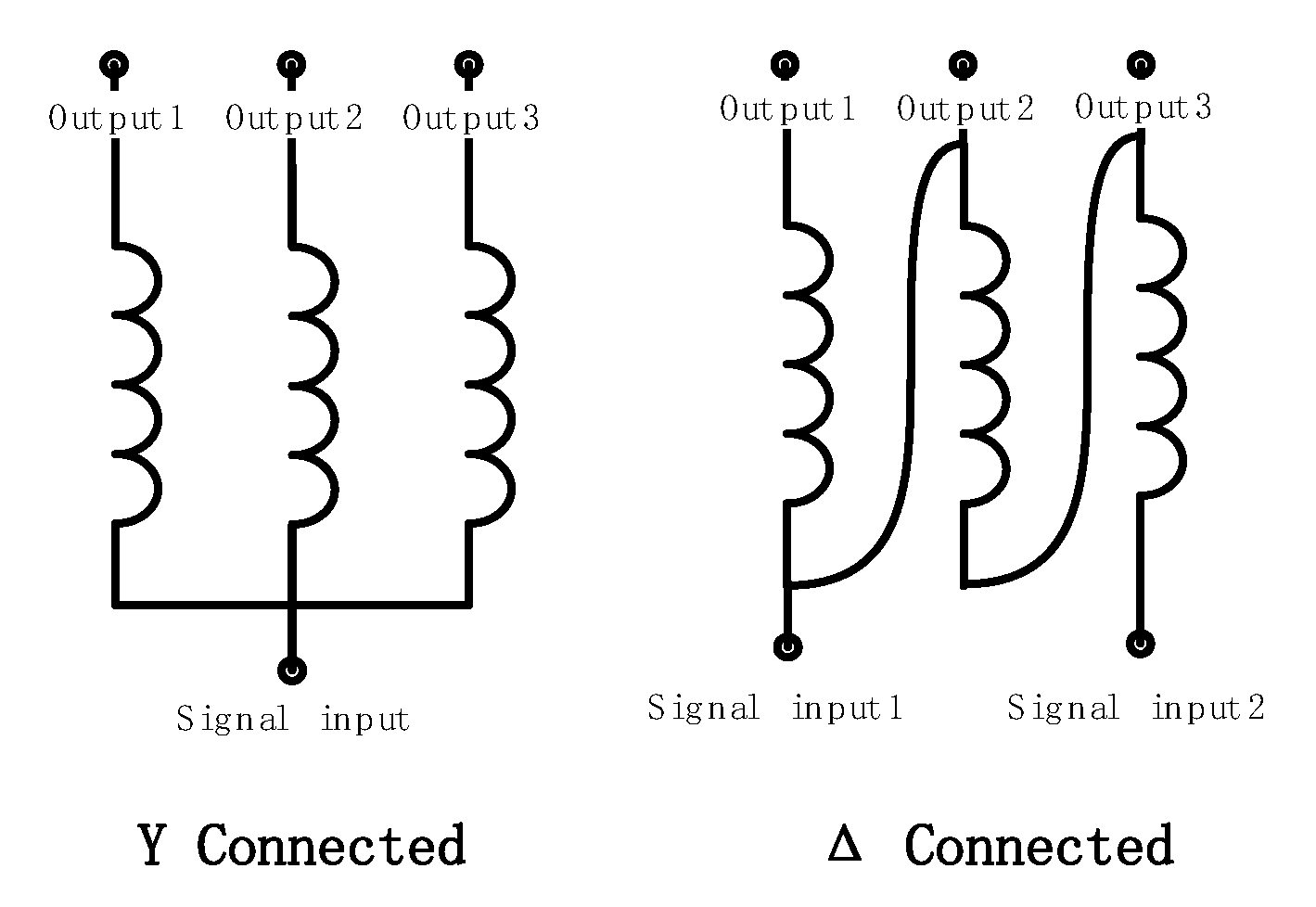

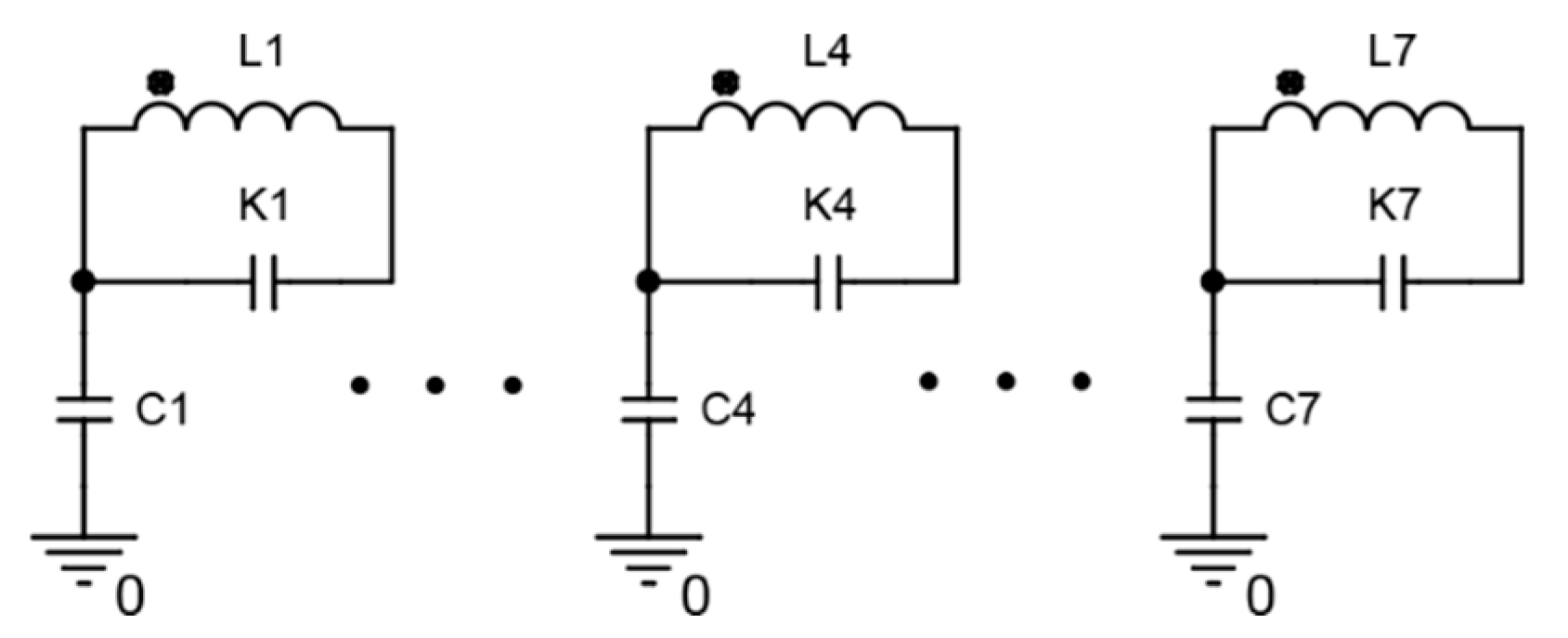

2. Transformer Simulation Model

2.1. Frequency Response Analysis

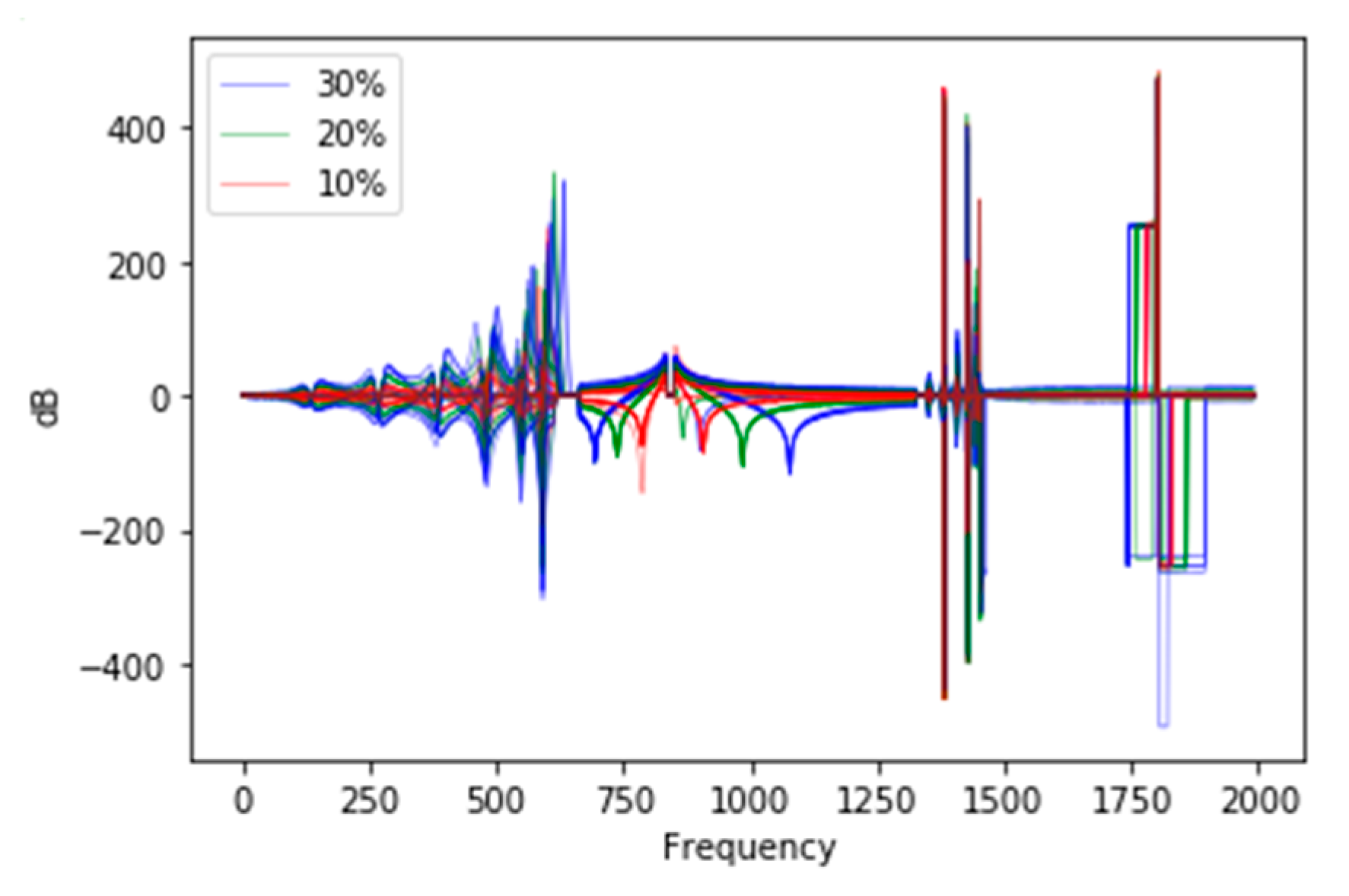

2.2. Frequency Response Analysis

2.3. Frequency Response Analysis

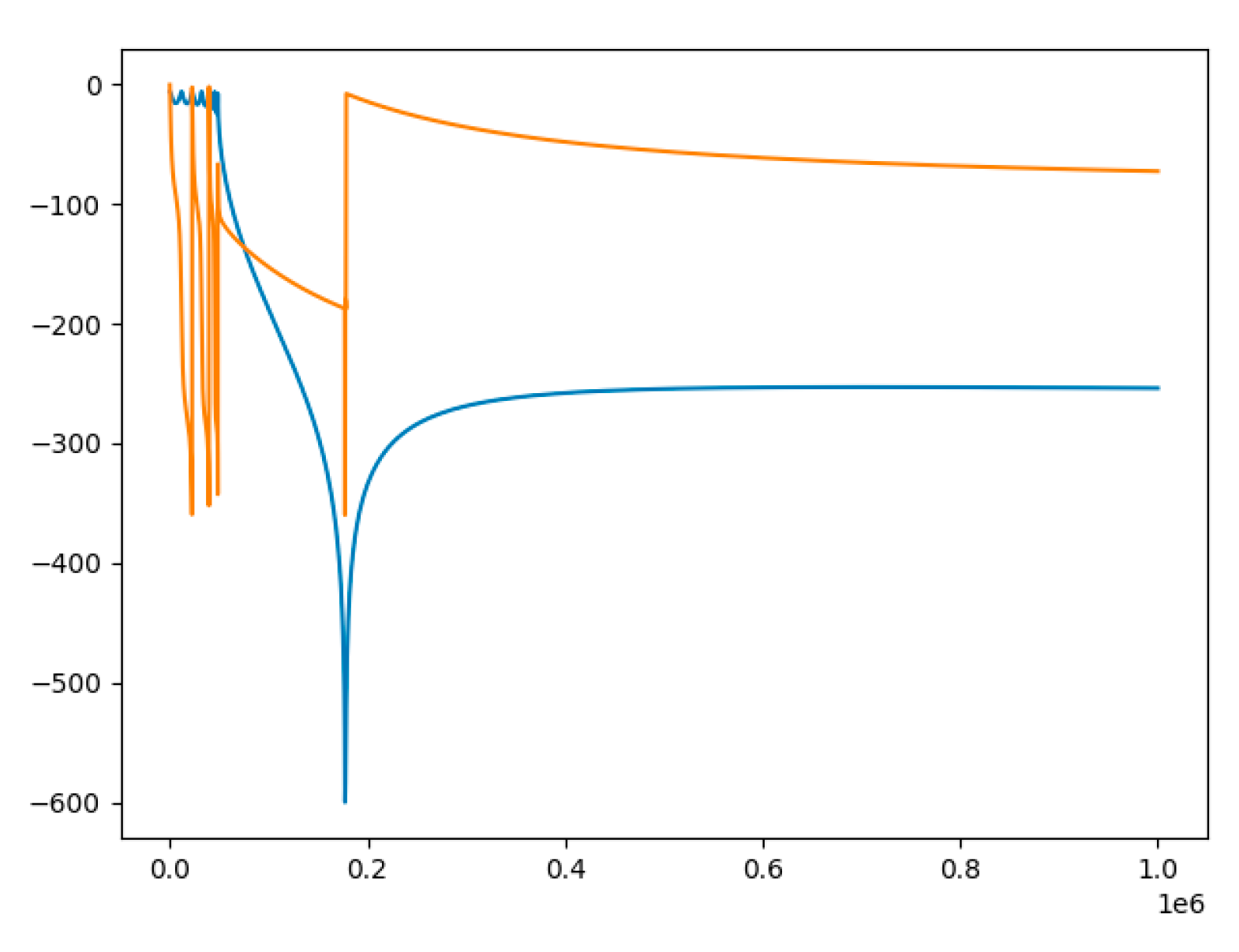

3. Quantification of FRA Signature

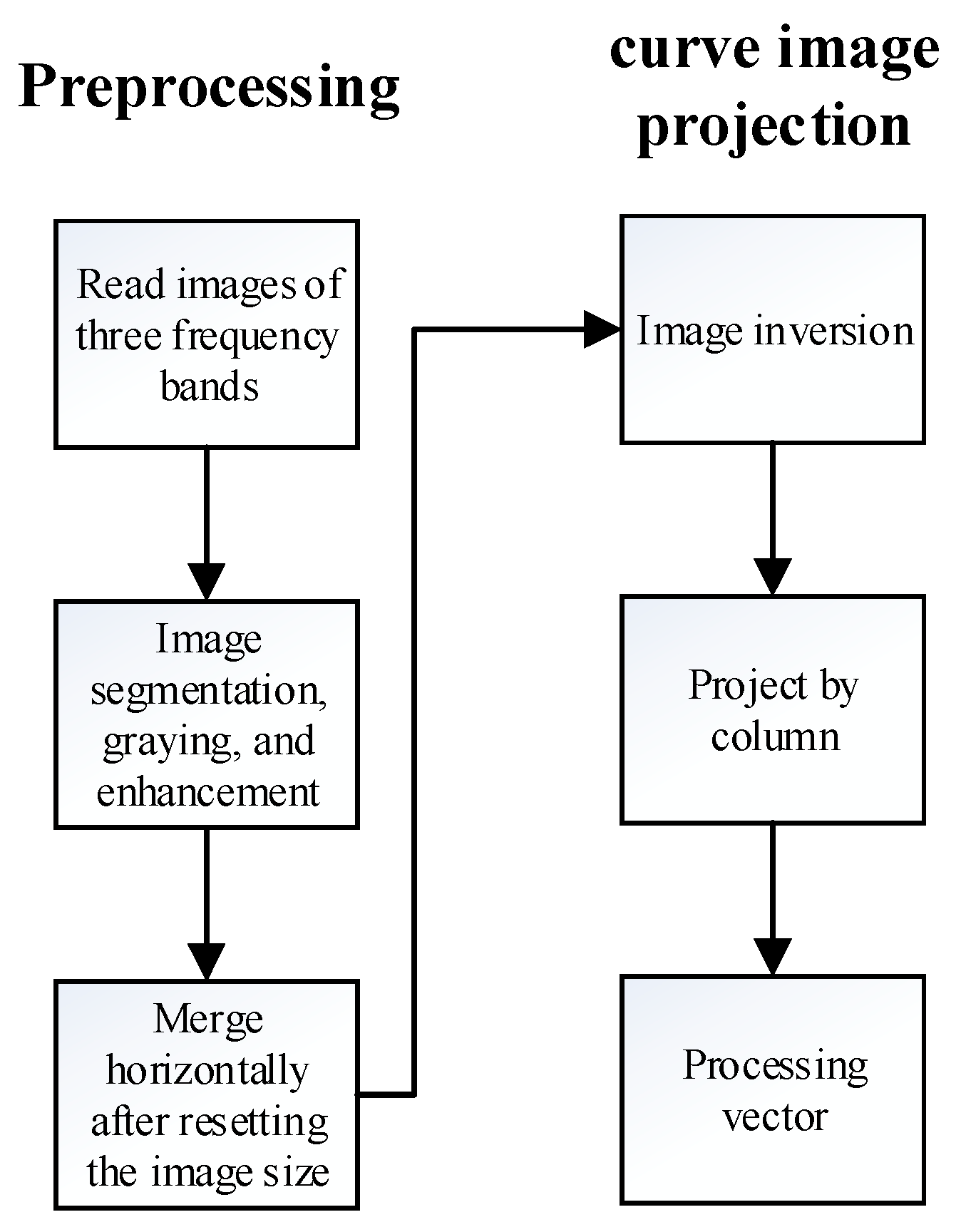

3.1. Preprocessing

3.2. Curve Image Processing

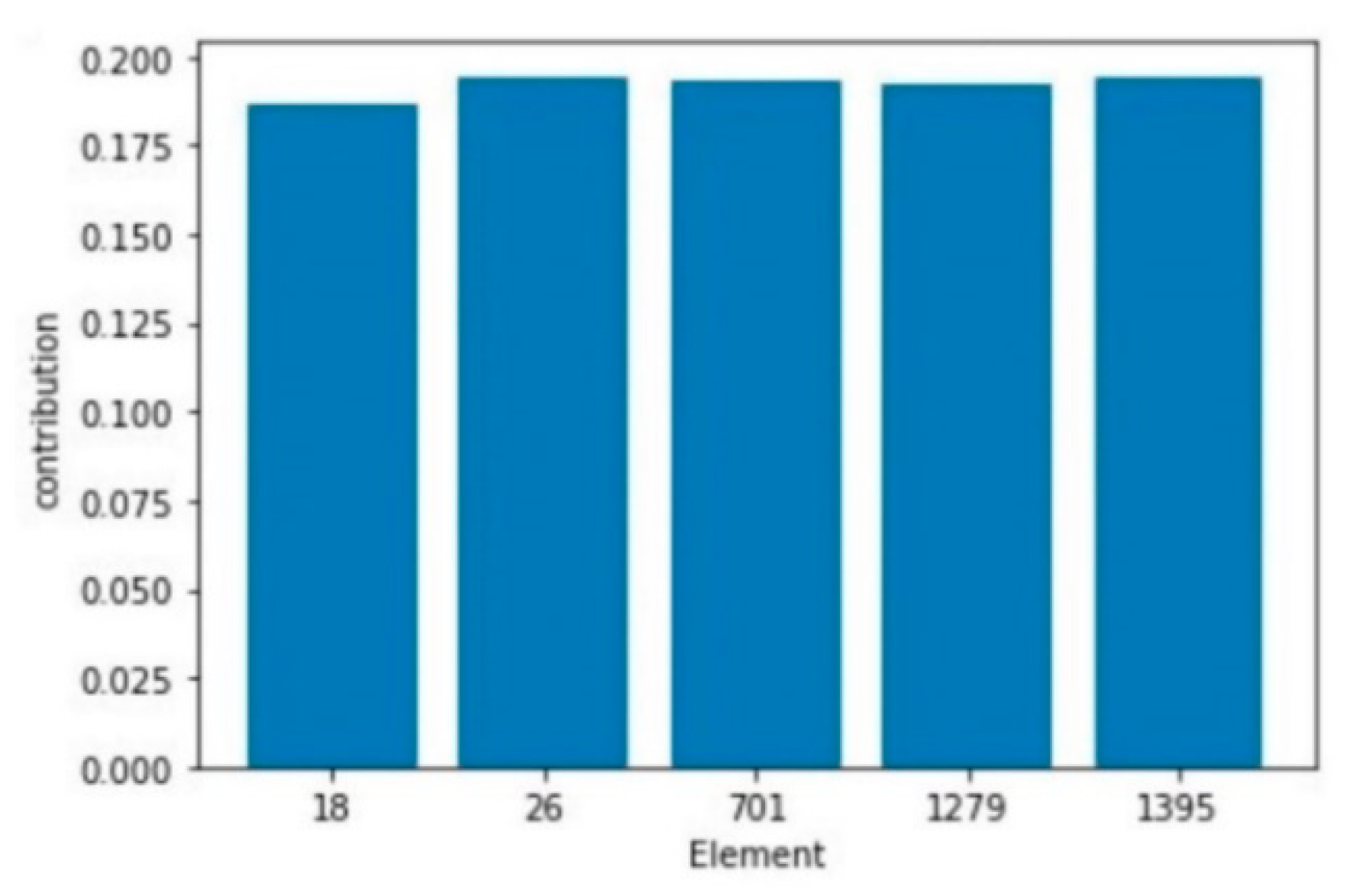

3.3. Feature Vector

4. Fault Diagnosis and Algorithm Comparison

4.1. Fault Type Diagnosis

4.1.1. Decision Tree Classification Model

4.1.2. Model Adjustment

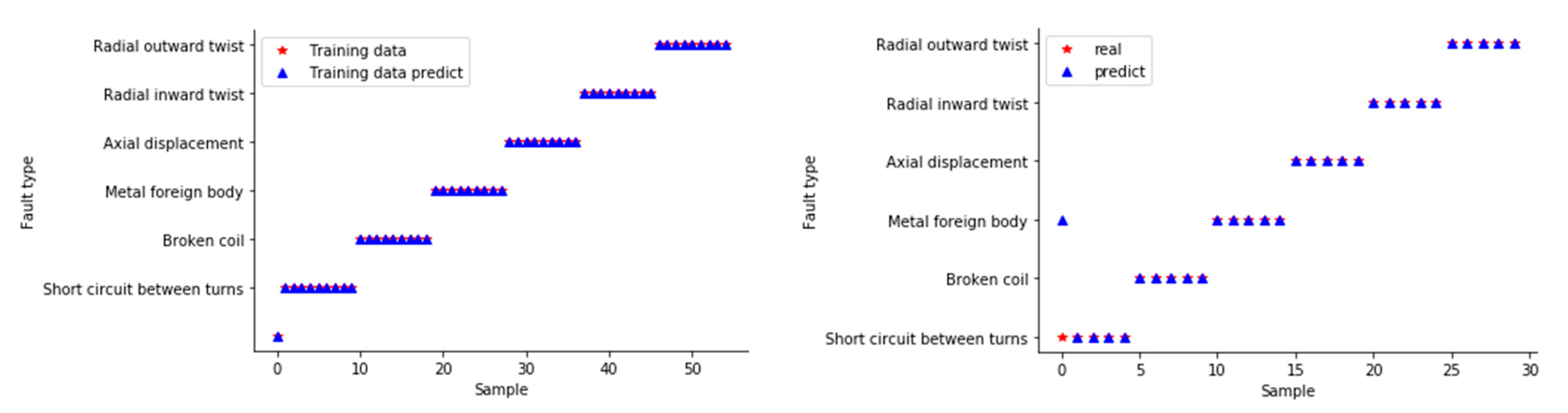

4.1.3. Model Effect

4.1.4. Analysis of Frequency Response Curve Using Model

4.2. Fault Level Diagnosis

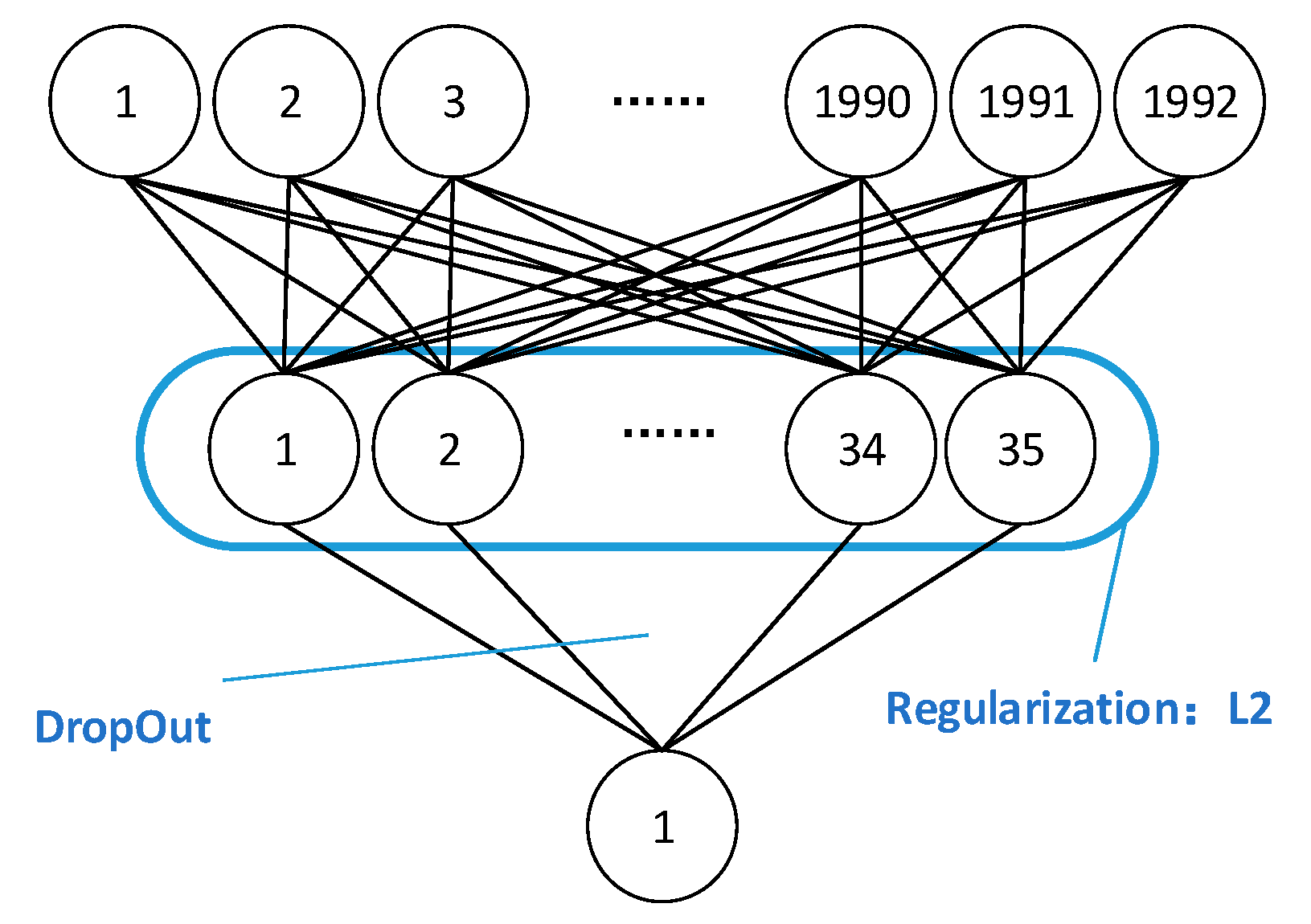

4.2.1. Fully Connected Neural Network

4.2.2. Hyperparameters Setting

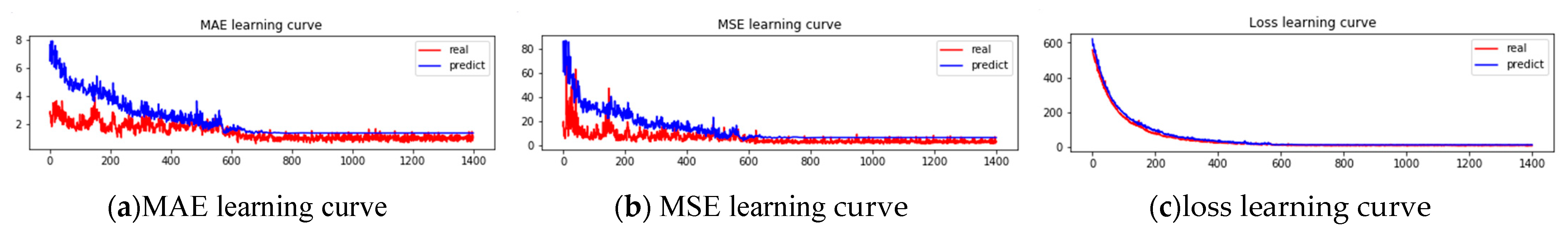

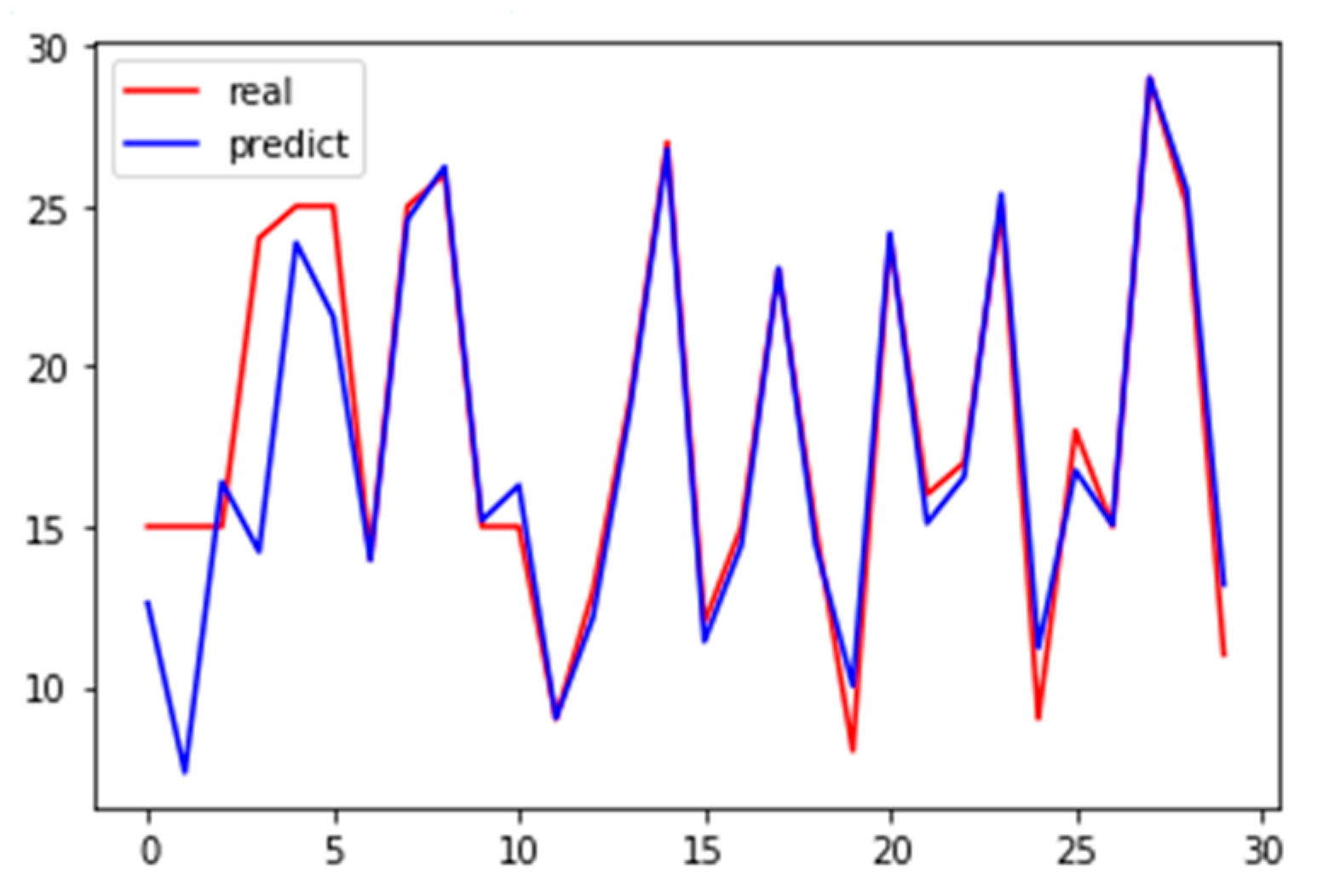

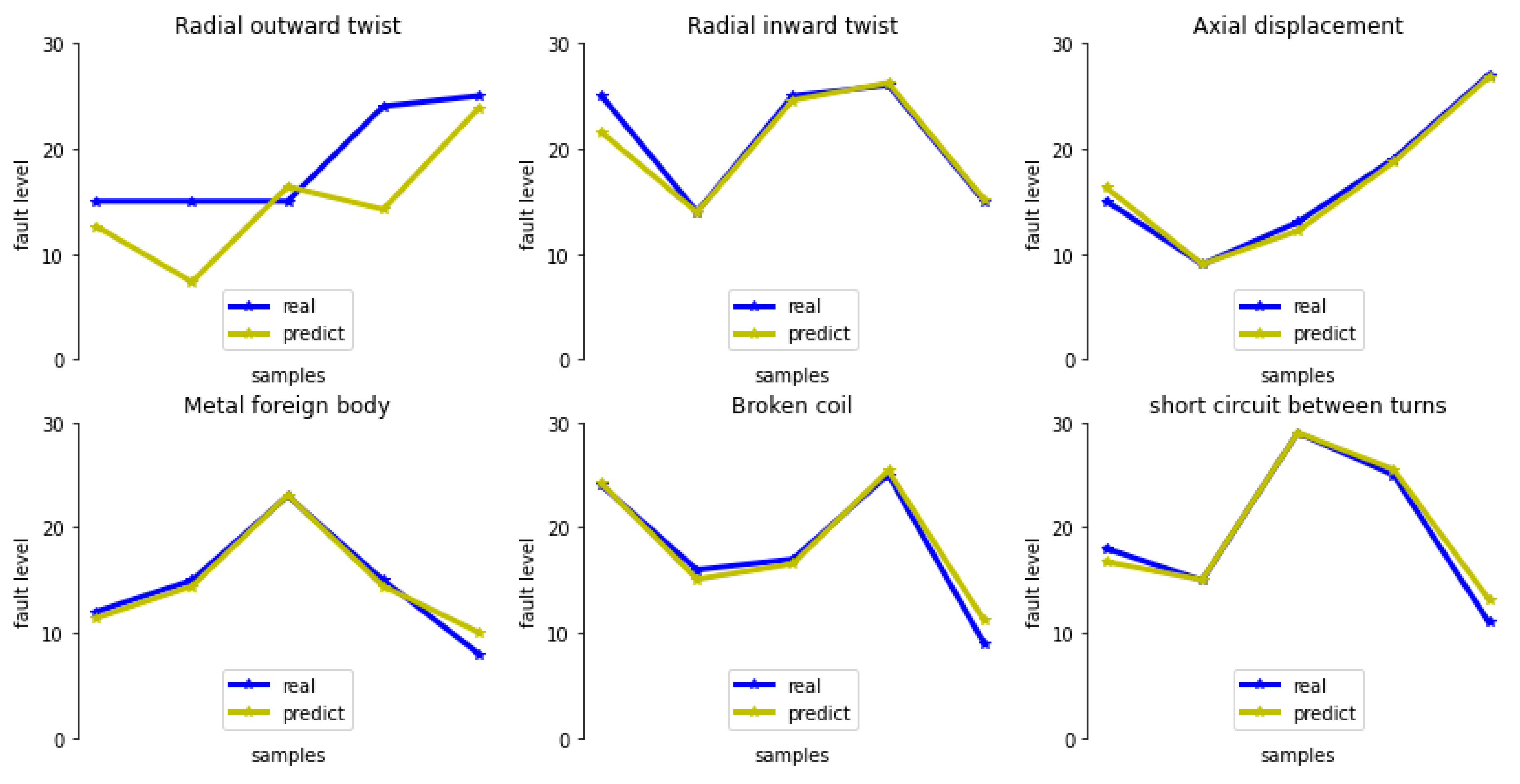

4.2.3. Model Effect and Regressor Explanation

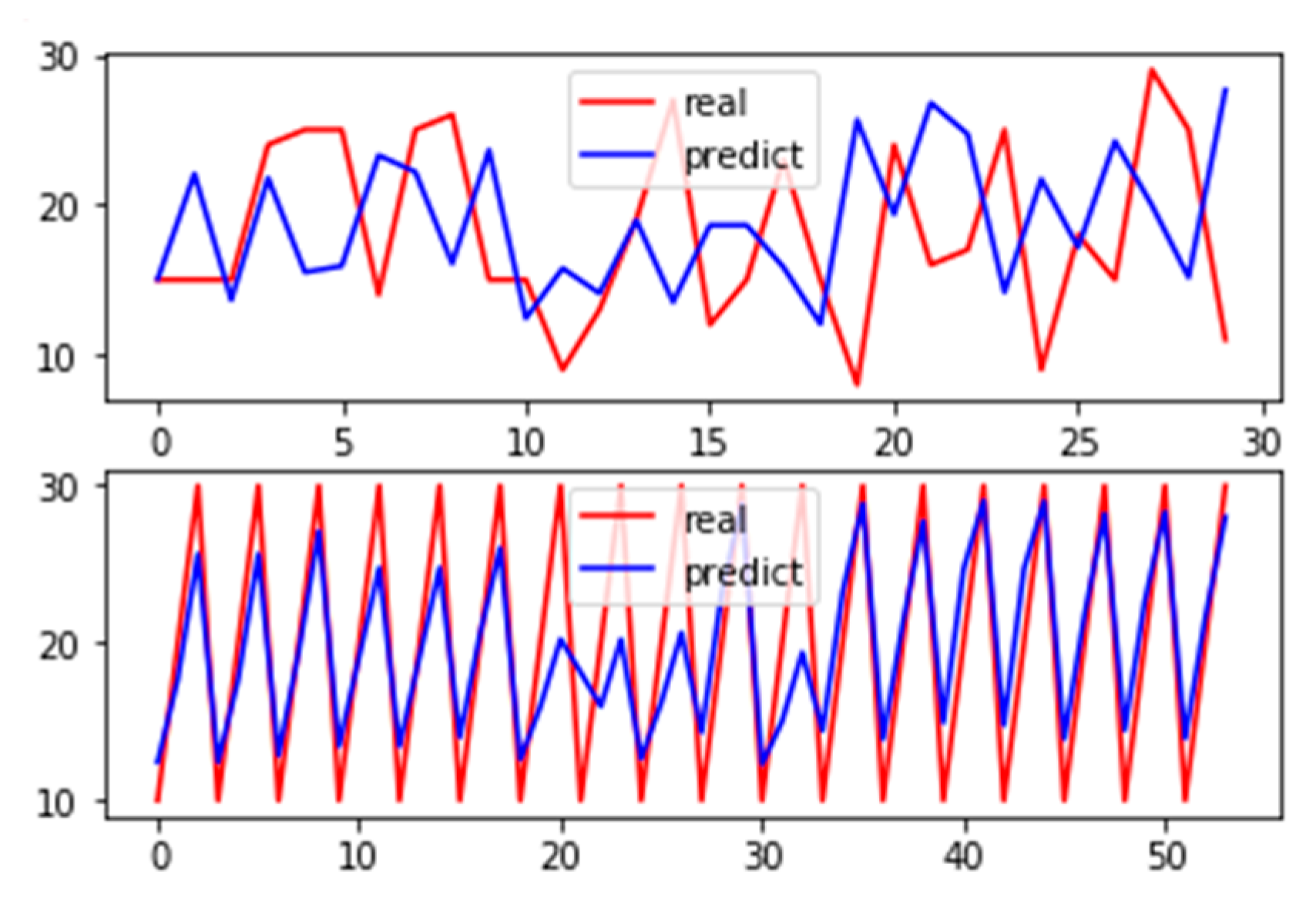

4.3. Algorithm Comparison

4.3.1. Fault Type Diagnosis Comparison

4.3.2. Fault Level Diagnosis Comparison

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Shaban, A.E.; Ibrahim, K.H.; Barakat, T.M. Modeling, Simulation and Classification of Power Transformer Faults Based on FRA Test. In Proceedings of the 2019 21st International Middle East Power Systems Conference (MEPCON), Cairo, Egypt, 17–19 December 2019. [Google Scholar]

- Aljohani, O.; Abu-Siada, A. Application of Digital Image Processing to Detect Short Circuit Turns in Power Transformers using Frequency Response Analysis. IEEE Trans. Ind. Inform. 2016, 12, 2062–2073. [Google Scholar] [CrossRef]

- Aljohani, O.; Abu-Siada, A. Application of digital image processing to detect transformer bushing faults and oil degradation using FRA polar plot signature. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 428–436. [Google Scholar] [CrossRef]

- Juan, C.; Yang, X.-J. Application of Digital Image Processing to Measurement System of Temperature Field in Molten Pool for Laser Remanufacturing. Appl. Laser 2006, 26, 212–220. [Google Scholar]

- Aljohani, O.; Abu-Siada, A. Application of DIP to Detect Power Transformers Axial Displacement and Disk Space Variation Using FRA Polar Plot Signature. IEEE Trans. Ind. Inform. 2017, 13, 1794–1805. [Google Scholar] [CrossRef]

- Abu-Siada, A.; Hashemnia, N.; Islam, S.; Masoum, M.A.S. Understanding power transformer frequency response analysis signatures. IEEE Electr. Insul. Mag. 2013, 29, 48–56. [Google Scholar] [CrossRef]

- Zhao, X.; Yao, C.; Li, C.; Zhang, C.; Dong, S.; Abu-Siada, A.; Liao, R. Experimental evaluation of detecting power transformer internal faults using FRA polar plot and texture analysis. Int. J. Electr. Power Energy Syst. 2019, 108, 1–8. [Google Scholar] [CrossRef]

- Xu, Y.; Gong, Y.-P.; Liu, Y.-W.; Ma, W.-Y.; Zhao, Q.; Wang, W.-H. A block frequency analysis method for frequency response data of transformer windings. Autom. Electr. Power Syst. 2014, 38, 91–97. [Google Scholar]

- Mao, Y.Z.; Wang, W.; Li, D.M.; Yang, Z.L. Application of Morphological Filtering in Noise Reduction of Partial Discharge of Transformer. Transformer 2014, 51, 32–35. [Google Scholar]

- Sun, Z.; Sun, Z.L.; Wei, J. Research on power transformer fault diagnosis based on decision tree support vector machine algorithm. J. Electr. Eng. 2019, 14, 42–45. [Google Scholar]

- Liu, P.; Zhang, W. A Fault Diagnosis Intelligent Algorithm Based on Improved BP Neural Network. Int. J. Pattern Recognit. Artif. Intell. 2019, 33, 50–56. [Google Scholar] [CrossRef]

- Li, Z.-H.; Xiang, X.; Hu, T.-H.; Abu-Siada, A.; Li, Z.; Xu, Y. An improved digital integral algorithm to enhance the measurement accuracy of Rogowski coil-based electronic transformers. Int. J. Electr. Power Energy Syst. 2020, 118, 105806. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, X.; Deng, Y.; Li, A. An Inspired Machine-Learning Algorithm with a Hybrid Whale Optimization for Power Transformer PHM. Energies 2020, 13, 3143. [Google Scholar] [CrossRef]

- Liu, J.; Zhao, Z.; Tang, C.; Yao, C.; Li, C.; Islam, S. Classifying Transformer Winding Deformation Fault Types and Degrees using FRA based on Support Vector Machine. IEEE Access 2019, 7, 112494–112504. [Google Scholar] [CrossRef]

- Banaszak, S.; Kornatowski, E.; Szoka, W. The Influence of the Window Width on FRA Assessment with Numerical Indices. Energies 2021, 14, 362. [Google Scholar] [CrossRef]

- Duvvury, V.S.B.C.; Pramanik, S. An Attempt to Identify the Faulty Phase in Three-Phase Transformer Windings Using an Advanced FRA Measurement Technique. IEEE Trans. Power Deliv. 2020, 1. [Google Scholar] [CrossRef]

- Zhang, C.; He, Y.; Du, B.; Yuan, L.; Li, B.; Jiang, S. Transformer fault diagnosis method using IoT based monitoring system and ensemble machine learning—ScienceDirect. Future Gener. Comput. Syst. 2020, 108, 533–545. [Google Scholar] [CrossRef]

- Sun, A.; Xu, X.; Liu, H.; Wang, K.; Zhou, X. Transformer Winding Fault Analysis Based on Oscillatory Wave Binarization Image Processing. In Proceedings of the 2020 5th Asia Conference on Power and Electrical Engineering (ACPEE), Chengdu, China, 4–7 June 2020. [Google Scholar]

- Tahir, M.; Tenbohlen, S. FRA lookup charts for the quantitative determination of winding axial displacement fault in power transformers. IET Electr. Power Appl. 2020, 14, 2370–2377. [Google Scholar] [CrossRef]

- Maraaba, L.S.; Twaha, S.; Memon, A.; Al-Hamouz, Z. Recognition of Stator Winding Inter-Turn Fault in Interior-Mount LSPMSM Using Acoustic Signals. Symmetry 2020, 12, 1370. [Google Scholar] [CrossRef]

- Zhang, S.; Hu, Q.; Wang, X.; Wang, X.; Wang, D. Research of transformer optimal design modeling and intelligent algorithm. In Proceedings of the 2011 Chinese Control and Decision Conference (CCDC), Mianyang, China, 23–25 May 2011; pp. 213–218. [Google Scholar]

- Li, Z.; Jiang, W.; Abu-Siada, A.; Li, Z.; Xu, Y.; Liu, S. Research on a Composite Voltage and Current Measurement Device for HVDC Networks. IEEE Trans. Ind. Electron. 2020, 1. [Google Scholar] [CrossRef]

- Ni, J.; Zhao, Z.; Tan, S.; Chen, Y.; Yao, C.; Tang, C. The actual measurement and analysis of transformer winding deformation fault degrees by FRA using mathematical indicators. Electr. Power Syst. Res. 2020, 184, 106324. [Google Scholar] [CrossRef]

- Zhang, C.Y.; Hu, H.; Cheng, H.H.; Liu, Y.P.; Xu, K.; Zhang, P.; Zhou, J.X. Diagnosis method of power transformer winding deformation degree and type based on Euclidean distance analysis. High Volt. Appar. 2020, 56, 224–230. [Google Scholar]

- Cheng, S. The correct application of frequency response correlation coefficient analysis and judgment of winding deformation. High Volt. Appar. 2006, 42, 66–69. [Google Scholar]

- Cheng, H.-H. Transformer Winding Deformation Diagnosis Based on Frequency Response Complex Values and Gray Projection Method. Master’s Thesis, North China Electric Power University, Beijing, China, 2018. [Google Scholar]

- Xie, H.; Chen, J.; Zhang, P. Knowledge acquisition method of power transformer condition assessment based on SMOTE and decision tree algorithm. Electr. Power Autom. Equip. 2019, 40, 137–142. [Google Scholar]

- Menezes, A.G.C.; Almeida, O.M.; Barbosa, F.R. Use of decision tree algorithms to diagnose incipient faults in power transformers. In Proceedings of the 2018 Simposio Brasileiro de Sistemas Eletricos (SBSE), Niteroi, Brazil, 12–16 May 2018; pp. 1–6. [Google Scholar]

- Li, H.; Li, Z.; Hou, H.; Sheng, G.; Jiang, X.; Hu, J. An Intelligent Transformer Warning Model based on Data-driven Bagging Decision Tree. In Proceedings of the 2018 Condition Monitoring and Diagnosis (CMD), Perth, WA, USA, 23–26 September 2018; pp. 1–5. [Google Scholar]

- Admasie, S.; Bukhari, S.B.A.; Gush, T.; Haider, R.; Kim, C.H. Intelligent Islanding Detection of Multi-distributed Generation Using Artificial Neural Network Based on Intrinsic Mode Function Feature. J. Mod. Power Syst. Clean Energy 2020, 8, 511–520. [Google Scholar] [CrossRef]

- Hong, K.; Jin, M.; Huang, H. Transformer winding fault diagnosis using vibration image and deep learning. IEEE Trans. Power Deliv. 2020, 1. [Google Scholar] [CrossRef]

- Qi, M.; Wang, Y.; He, R.-X. Research on Transformer Fault Diagnosis based on Improved Fuzzy Neural Network. J. Chengdu Technol. Univ. 2019, 22, 43–45. [Google Scholar]

- Zhu, N.; Liu, C.; Laine, A.F.; Guo, J. Understanding and Modeling Climate Impacts on Photosynthetic Dynamics with FLUXNET Data and Neural Networks. Energies 2020, 13, 1322. [Google Scholar] [CrossRef]

- Hu, W.; Lu, Z.-X.; Wu, S.-Z.; Zhang, W.; Dong, Y.; Yu, R.; Liu, B. Real-time transient stability assessment in power system based on improved SVM. J. Mod. Power Syst. Clean Energy 2019, 7, 26–37. [Google Scholar] [CrossRef]

| Fault Type | Component | ||

|---|---|---|---|

| C | K | L | |

| Short circuit between turns | / | Increase | Decrease |

| Broken coil | / | / | Increase |

| Metal foreign body | / | Increase | / |

| Axial displacement | Decrease | Decrease | / |

| Radial inward twist | Increase | / | Decrease |

| Radial outward twist | Decrease | / | Increase |

| Type | Location | Level |

|---|---|---|

| Short circuit between turns | Disk 1 | 15% |

| Short circuit between turns | Disk 3 | 15% |

| Short circuit between turns | Disk 4 | 15% |

| …… | ||

| Radial outward twist | Disk 4 | 29% |

| Radial outward twist | Disk 6 | 25% |

| Radial outward twist | Disk 7 | 11% |

| Fault Type | Maximum Predict Deviation/% | Minimum Predict Deviations/% | MAE | MSE |

|---|---|---|---|---|

| Radial outward twist | 9.7833 | 1.1385 | 4.4752 | 32.7039 |

| Radial inward twist | 3.4548 | 0.0578 | 0.8687 | 2.44 |

| Axial displacement | 1.2944 | 0.0076 | 0.53 | 0.5016 |

| Metal foreign body | 2.0251 | 0.0762 | 0.7639 | 1.0183 |

| Broken coil | 2.2046 | 0.1674 | 0.8203 | 1.2079 |

| Short circuit between turns | 2.1844 | 0.0172 | 0.8001 | 1.3177 |

| MAE | MSE | |

|---|---|---|

| Train | 3.5820 | 18.2164 |

| Test | 7.1396 | 72.6370 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Zhang, Y.; Abu-Siada, A.; Chen, X.; Li, Z.; Xu, Y.; Zhang, L.; Tong, Y. Fault Diagnosis of Transformer Windings Based on Decision Tree and Fully Connected Neural Network. Energies 2021, 14, 1531. https://doi.org/10.3390/en14061531

Li Z, Zhang Y, Abu-Siada A, Chen X, Li Z, Xu Y, Zhang L, Tong Y. Fault Diagnosis of Transformer Windings Based on Decision Tree and Fully Connected Neural Network. Energies. 2021; 14(6):1531. https://doi.org/10.3390/en14061531

Chicago/Turabian StyleLi, ZhenHua, Yujie Zhang, Ahmed Abu-Siada, Xingxin Chen, Zhenxing Li, Yanchun Xu, Lei Zhang, and Yue Tong. 2021. "Fault Diagnosis of Transformer Windings Based on Decision Tree and Fully Connected Neural Network" Energies 14, no. 6: 1531. https://doi.org/10.3390/en14061531

APA StyleLi, Z., Zhang, Y., Abu-Siada, A., Chen, X., Li, Z., Xu, Y., Zhang, L., & Tong, Y. (2021). Fault Diagnosis of Transformer Windings Based on Decision Tree and Fully Connected Neural Network. Energies, 14(6), 1531. https://doi.org/10.3390/en14061531