Abstract

Hybrid systems have gained significant attention among researchers and scientists worldwide due to their ability to integrate solar cells and supercapacitors. Subsequently, this has led to rising demands for green energy, miniaturization and mini-electronic wearable devices. These hybrid devices will lead to sustainable energy becoming viable and fossil-fuel-based sources of energy gradually being replaced. A solar photovoltaic (SPV) system is an electronic device that mainly functions to convert photon energy to electrical energy using a solar power source. It has been widely used in developed countries given that they have advanced photovoltaic (PV) technology that reduces dependence on fossil fuels for energy generation. Furthermore, a supercapacitor is an alternative solution for replacing heavy batteries and it is a system with a prominent high power density and a long life cycle. Its unique properties of high capacitance with low voltage limits lead to this highly in-demand material being incorporated into goods and services that are produced by the electrical and electronics industries. It is another option for grid-based power or large batteries. Since supercapacitors have the ability to store huge amounts of energy, they allow for a novel system that integrates supercapacitors with solar cells in which energy generation and energy storage are combined into one system. This paper explores the common materials that are used for solar cells and supercapacitors, the working mechanisms, the effectiveness of the integrated device and the technical challenges that are encountered when refining this device. Hence, this review serves as a guide for choosing the right materials and methods in order to produce an integrated PV solar cell–energy storage device for various applications.

1. Introduction

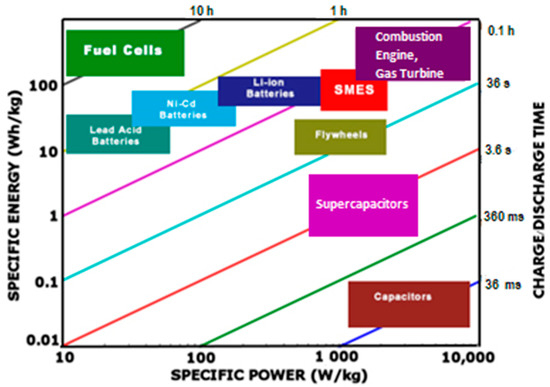

The conventional supercapacitor-charging method using photovoltaic (PV) was originally designed using a solar cell and supercapacitor to operate as two independent units that are connected by wires. Despite being able to simultaneously generate and store energy, the system faces some technical challenges, such as being bulky, inflexible, expensive and, in particular, it loses energy through the external wires connecting the two units [1]. Such disadvantages can be overcome by integrating the supercapacitor and PV cell into one device so that it is compact, flexible, modular and minimizes energy loss, as no wires are required to connect the two units. This invention is in line with the current smart technology that allows for volume minimization, practicality and flexibility such that it can operate in various industries, such as small-scale and large-scale consumer electronics, electric vehicles, smart grids and wearable sensors [2,3,4]. Previously, batteries were used to integrate PV cells, but due to some inadequacies, such as slow charge/discharge capability and short life cycles, supercapacitors are preferred for integration with PV cells. This is attributed to its rapid charging/discharging ability since, first, there is no chemical reaction required, and second, the energy density is reported to be about ten times higher than batteries with the same weight [4,5]. Figure 1 depicts a comparison between batteries, capacitors, supercapacitors and other energy storage devices in terms of specific energy, specific power and the charge/discharge time.

Figure 1.

Ragone plot of the properties of various power sources.

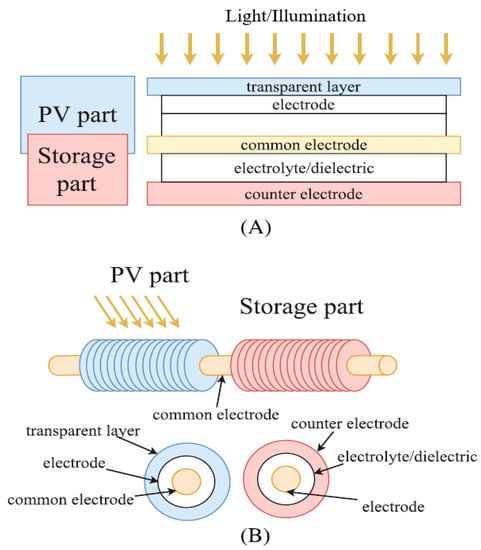

Since the concept of PV cell–supercapacitor integration was introduced in the year 2004, it has sparked interest in many researchers to carry out experimental and simulation work on the fabrication of this device and assess its performance. For instance, a study by [5] integrated hydrogenated amorphous silicon (a-Si/H) solar cells, NiCo2O4 battery supercapacitor hybrids (BSHs) and f light emission diodes (LEDs) into one system. The whole system could work independently with an overall efficiency of 8.1% and the storage efficiency reached 74.24%. These values indicated that the self-driven integrated system was stable for PV conversion and had efficient energy storage. The fundamentals of supercapacitors and solar cells need to be analyzed accordingly before they are integrated into one system in order to achieve high efficiency. Figure 2 below shows the schematic diagram of the integrated device.

Figure 2.

The schematic diagram of (A) planar/monolithic three-electrode system and (B) coaxial fiber parallel system. Reprinted from [6].

A supercapacitor’s performance highly depends on the electrode materials that are used. Hence, investigation on the electrode materials for supercapacitors has been a very important topic in this research area. As technology changes, which it currently does at a rapid rate, consumers greatly rely on energy technology to cater to their electrical/electronic needs. Solar energy is a renewable energy resource and can be harnessed from all parts of the world where the relevant technology is viable. Solar energy is obtained by converting sunlight into electrical energy and it can serve industrial and domestic purposes. An energy storage system is needed to store this electrical energy in order to avoid energy loss during its operation and the supercapacitor comes in handy due to its fast charging/discharging properties alongside its long life cycle. When compared to batteries as energy storage systems, supercapacitors possess higher energy conversion with a low equivalent series resistance; these values have made supercapacitors a very suitable device for energy storage applications for solar cell panels [7].

Adding the energy storage part will increase the thickness of the cell. However, it is still more preferable than combining the two units separately because of the overall compactness and reducing the whole system’s volume. It was established that external connection was often associated with elevated resistances [8], rigid/heavy devices [9] and having a complicated manufacturing process [10]. It is worth noting that the main challenge of developing supercapacitors is increasing their energy and power densities without compromising their long life cycle and fast charging/discharging properties [10,11]. Consequently, the integration of these devices is feasible and could enhance their performance. Table 1 below highlights the overall efficiency and storage efficiency of the PV–storage system integrated devices that were discussed in previous studies. Research on the integrated device from various materials and integration techniques reported storage efficiencies ranging from 20 to 80% and an overall efficiency of up to 8%.

Table 1.

The storage and overall efficiencies of integrated devices that were documented in prior studies.

Storage efficiency is defined as the percentage of maximum energy that is used from a total energy capacity and it can be calculated based on Equation (1):

Meanwhile, the overall efficiency (ηss) of an integrated device can be calculated based on Equation (2) when both efficiencies of the solar cell and energy storage device are provided:

where ηsc is the solar cell efficiency and ηs denotes the energy storage efficiency. Apart from that, the overall or total efficiency of the integrated device can be calculated using Equation (3):

where ηt is the total energy storage of the integrated device, Eoutput denotes the energy output of the supercapacitor, Einput refers to the total incident light energy, S1 represents the surface area of the supercapacitor, Pinput is the illuminated light density, t signifies the photocharging time and S2 is the active area of the hybrid solar cell. What was observed is a huge improvement in the efficiency of the devices ranging from 10% to 80% for the storage efficiency and 1 to 11% for the overall efficiency.

ηss = ηscηs

ηt = Eoutput/Einput = EsS1/(PinputtS2)

It cannot be denied that smart technology is growing at a huge rate due to the rapidly changing nature and high demands of the electronics industry. Since they require great flexibility and portability of energy storage components, many researchers now want to create flexible devices that are aimed toward various applications. For instance, a high-performance hybrid supercapacitor was fabricated using 3D dendritic cell-like nanostructures with Ni-Co layered double hydroxide (LDH) used as the cathode, while the anode was a crumpled leaf-like reduced graphene oxide. The supercapacitor was integrated with a solar cell that harvested the energy and the working potential window obtained from the study was ~1.4–1.8 V. Meanwhile, the power and energy densities of the device at a current density of 0.5 A/g were ~374 W/kg and ~58.4 Wh/kg, respectively. This finding strongly suggested that high energy and power density were achievable when combining these two devices asymmetrically [18]. The supercapacitor demonstrated a superior performance since the coulombic efficiency was approximately 100% [19].

Based on the reviewed studies on this topic, it can be observed that solar cells absorb solar energy and subsequently convert it to electrical energy by using a supercapacitor as the energy transport system. Choosing appropriate active materials for the fabrication of the integrated device is crucial to maximizing the conversion efficiency. In particular, the other parameters that should be paid serious attention are the counter electrodes, conducting polymers, photoactive metal oxides and redox electrolytes given that these materials contribute to high energy conversion efficiency and would subsequently enhance the performance and shelf life of a PV cell integrated supercapacitor. Since the integrated device showed promising results in terms of its efficiencies and flexibility, this sparked great interest amongst researchers worldwide to conduct further analyses when developing solar-cell-integrated supercapacitors with improved properties.

Since improvements in the properties of PV cells and supercapacitors are widely studied and researched, integration of these two components is a novel technique to further enhance the device, particularly in terms of its conversion efficiency and storage capacity. Considering the advantages and disadvantages of PV cells and supercapacitors, these two entities are suitable for integration in order to complement the properties of the energy harvesting and storage system. The integrated device should be designed in such a way that the architecture is practically feasible as an energy generator and storage system [20]. With this in mind, this paper reviews the integration of the relevant materials and the challenges that need to be tackled while working on the fabrication of this device to provide a new technology that is also cost-effective. The research gaps are addressed and future research suggestions are made.

2. Solar Cells

2.1. Materials for Solar Cells

Photovoltaic technology has evolved over the past few decades to address the challenges of converting solar energy to electricity. The main parameter to be considered for the installation of a PV cell in any device is its conversion efficiency. It is well noted that not all sunlight that reaches the PV panel will be converted into electricity. Hence, some of the parameters of a PV panel, such as the wavelength, recombination of electrons, temperature and light reflection, are crucial for the best possible conversion efficiency [21]. By considering all these parameters, the PV panel would be able to optimally convert solar energy into usable electricity for a wide range of applications. The power that is harvested from PV cells differs according to the region because the variation in solar insolation and seasons during a given year would greatly affect its performance [22]. To date, a wide variety of solar cells with different characteristics have been fabricated, namely, organic solar cells, perovskite solar cells (PSCs), dye-sensitized solar cells (DSSCs), Cu (In, Ga) Se2 (CIGS) solar cells, etc. [7,22,23].

Recently, dye-sensitized solar cells (DSSCs) have been receiving attention, mainly due to their flexibility and cost-effectiveness. A previous study fabricated a flexible printable DSSC/supercapacitor integrated energy device that is flexible, lightweight and portable such that it can be used for a wide range of applications. It possesses a high voltage capacity that could go up to 1.8 V and is environmentally friendly. Outdoor testing was carried out with extreme mechanical loading to test its stability. The results demonstrated that the device achieved stable performance throughout the test [23]. Another researcher developed a flexible supercapacitor by doping graphene onto activated carbon. The supercapacitor that performed as an energy storage system was integrated with DSSC to power an LED. The highest capacitance was obtained by the supercapacitor doped with 0.05 wt.% graphene with a charge/discharge efficiency of 85.29%. A bending test was conducted to analyze any variation in capacitance. The results showed that the capacitance was maintained throughout the test [7].

Meanwhile, Xu and co-workers integrated an MAPbI3-based perovskite solar cell (PSC) and a PPy-based supercapacitor as an energy pack [14]. The voltage of the supercapacitor was set at 0.6 V and the system produced a high output voltage of 1.45 V and an overall output efficiency of 20%. This system provided a continuous output of electric power by using the MAPbI3-based solar cells as an energy source. Another PSC-integrated device was developed by [24]. A semitransparent PSC was integrated with an electrochromic WO3 supercapacitor in a vertically stacked configuration. The power conversion efficiency that was achieved by the PV part was 8.25% and the energy density was 35.9 mW/h. The average power density and areal capacitance were 461.5 mW/m2 and 459.6 F/m2, respectively.

One of the established solar cell devices is made of crystalline silicon, which is still dominating the commercial PV modules in the industry despite its heavy weight, inflexibility and high production cost. Prior research by [25] integrated a commercial polycrystalline silicon device with a supercapacitor, which resulted in an 84% coulombic efficiency. The design demonstrated that the polycrystalline silicon solar cell was capable of charging the supercapacitor under an external load and that a constant current load could be maintained through periods of intermittent illumination, indicating the feasibility of the integration concept. Another type of solar cell that is widely used these days is an organic solar cell (OSC). OSCs have potentially low costs and are suitable for omnipresent distribution. Research by [26] integrated OSCs based on poly(3-hexylthiophene):[6,6]-phenyl-C60-butyric acid methyl ester with Al electrodes and supercapacitors based on graphene ink. The materials were grown on a single substrate using graphene as a common platform. The achieved power conversion efficiency (PCE) was approximately 1.6%, while the Voc was 5 V. The OSC-integrated supercapacitor managed to yield an overall system voltage of up to 4 V.

2.2. Performance of Solar Cells

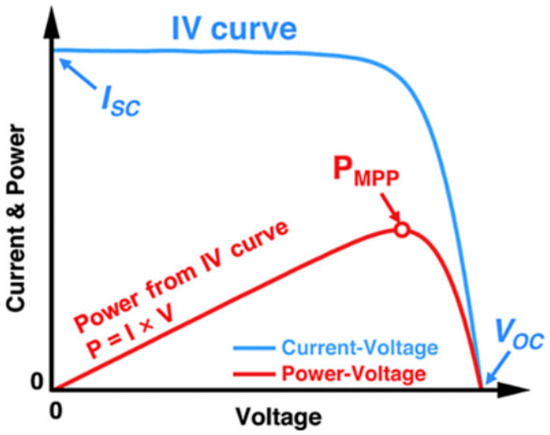

There are four basic parameters that are used to evaluate the performance of solar cells, namely, the short-circuit current (ISC), open-circuit voltage (VOC), fill factor (FF) and PCE. The maximum power point (PMPP) of a solar cell is the point where the solar cell should be operated to obtain the maximum power output, as shown in Figure 3.

Figure 3.

The I–V and power–voltage (P–V) curves of a solar cell. Reprinted with permission from reference [27]. Copyright Elsevier Publishing 2020.

It is essential to work on reducing the solar power cost; this can be done by improving the PCE of solar cells [28,29]. Data from past research showed that single-junction solar cells reached the theoretical limit of PCE and it is quite difficult to be improved further. Therefore, researchers came up with the method of stacking two or more solar cells occupying different band gaps (Eg) and optimized the wavelength absorption range. The findings showed that the theoretical PCE could surpass 50% depending on the number of cells that were stacked [30]. Previous work reported the PCE value to be approximately 40% by developing III-V multi-junction cells. However, the limitation for the use of III-V semiconductor-based tandem devices is due to its high production and material costs, which makes it applicable to only spacecraft and satellites at present [31]. The PCE is the most important parameter for solar cells, other than its efficient preparation technologies and flexible structures. Table 2 summarizes the power conversion efficiency of the various types of solar cells from previous studies.

Table 2.

Power conversion efficiencies of various types of solar cells.

The fabrication of various types of solar cells and the combination of materials showed a significant improvement in their power conversion efficiencies as the technology is advancing and demand from industries keeps increasing. This simultaneously allows researchers to come out with notable techniques and technology to fill the gap for each problem that is faced when building solar cells. To date, substantial growth has been achieved in the development of various types of flexible solar cells, where researchers managed to increase their conversion efficiencies due to technological advancements that are crucial for the development of solar cell integrated devices.

3. Supercapacitor as the Energy Storage Component for an Integrated Device

Supercapacitors are mainly classified into three types, which are electric double-layer capacitors (EDLCs), pseudocapacitors and hybrid capacitors. EDLCs operate by storing the charge at the surface electrode through reversible ion absorption/desorption to form an electrical double-layer capacitance [40]. It was noted that an EDLC can be used as a substitute for rechargeable batteries owing to its capability of fast charging/discharging, especially for a device that necessitates rapid energy harvesting. A pseudocapacitor, on the other hand, operates using fast and reversible redox reactions on or near the electrode surface. The charge passes across the double layer and results in a faradaic current passing through the supercapacitor cell, which is termed pseudocapacitance [41]. Meanwhile, a hybrid capacitor is a combination of a porous carbon electrode and another material, such as a conducting polymer, metal oxides or metal-doped carbons, which are used to enhance the performance of EDLCs and pseudocapacitors [42]. Table 3 summarizes the performance evaluation of different types of supercapacitors. The main challenge regarding supercapacitors is to increase the energy densities while maintaining their long life cycle, high power density and fast charging/discharging. The commercialization of energy storage devices based on hybrid supercapacitors has been a viable option to manufacturers, which highlights the importance of these new materials for a wide range of applications.

Table 3.

Performance parameters for different types of supercapacitors.

Materials for Supercapacitor Electrodes

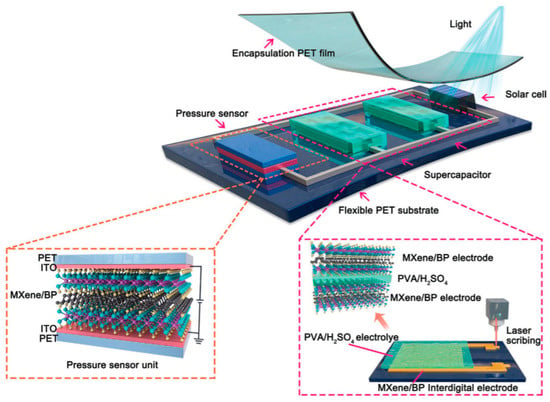

Carbon materials, such as carbon nanotubes (CNT), graphenes and MXenes, have been widely utilized as supercapacitor electrodes due to their high specific area and outstanding conductivity. Generally, CNTs possess a tensile strength of 100–200 GPa [45], electrical conductivity of ~107 S/m and thermal conductivity of ∼2000 W/m·K [46]. A past study by [47] fabricated an all-solid-state integrated device from free-standing and aligned carbon nanotube films. The integrated device exhibited an overall photoelectric conversion and storage efficiency of approximately 5.12% owing to its aligned structure and outstanding electronic property of the film electrode. In addition, the device’s flexibility makes it suitable for a wide range of applications, especially in portable electronic equipment. Another promising finding was obtained by [48] after integrating a DSSC with a supercapacitor by using a CNT film as the common electrode. The authors reported a PCE of 6.1%, a specific capacitance of 48 F/g and a storage efficiency of about 84%. The device is lightweight, flexible and the overall photoelectric conversion and storage efficiencies that were achieved were about 5.12%. Graphene, on the other hand, is synthesized using various methods, such as mechanical exfoliation, chemical exfoliation [49], chemical vapor deposition [50], chemical synthesis [51] and microwave synthesis [52]. Due to its high specific surface area, graphene is found to be more efficient at storing electrostatic charges, thus making it suitable for use in supercapacitor electrodes [53,54]. Even though graphene is considered a new and emerging material, extensive research has been carried out to incorporate graphene into the solar cell–energy storage integrated system. Recently, a DSSC employing a compact and mesoporous titania (TiO2) film as the anode was integrated with a symmetrical supercapacitor utilizing polypyrrole/reduced graphene oxide (PPy/rGO) electrodes as the counter electrode. The specific capacitance of the supercapacitor was 308.1 F/g and the PCE of the DSSC was reported to be 2.4%. The integrated device exhibited a specific capacitance of 124.7 F/g, and a retention percentage of 70.9% was obtained after 50 consecutive charge/discharge cycles [55]. Meanwhile, a new emerging material, namely, MXene, has been extensively studied owing to its tremendous potential for supercapacitor electrodes [56,57]. For instance, prior work by [58] integrated a flexible organic photovoltaic with Ti3C2Tx MXene as the electrode and organic ionogel as the electrolyte. The authors obtained a high power conversion efficiency of 13.6% and a high volumetric capacitance of 502 F/cm3. This simple fabrication method achieved a remarkable storage efficiency of 88%. Another related study developed wearable electronics by integrating an MXene/black phosphorus-based supercapacitor with a solar cell. The detailed schematic diagram of the integrated system is depicted in Figure 4. The developed MXene/BP-based micro-supercapacitor showed a high specific capacitance of 896.87 F/cm3 and an excellent rate performance of 241.2 F/cm3. The system also had long-term cycling stability of 91.74% for 10,000 cycles.

Figure 4.

Schematic illustration of MXene/black phosphorus-based self-powered smart sensor system. Reprinted from [59].

The data on studies of traditional materials for supercapacitor electrode materials are widely reported and researchers have come out with more studies on new emerging materials. A summary of conventional and new materials is listed in Table 4.

Table 4.

Traditional and emerging new electrode materials for supercapacitors [47,60,61,62,63,64,65].

4. Integration of Solar Cells and Supercapacitors

Since solar cells and supercapacitors do complement each other, integrating them is done with the intention of removing any disadvantages of both components. Doing so efficiently generates and stores energy with only minimal loss.

4.1. Photo-Assisted Mechanism of a Solar-Cell-Integrated Supercapacitor

A broad range of solar cells, such as perovskite, organic, silicon and dye-sensitized types, can be integrated with either electrical double-layer capacitors, pseudocapacitors or even hybrid supercapacitors. The solar cell and supercapacitor must share the same electrode or substrate in order to be fully integrated and it could be fabricated with two-electrode, three-electrode and four-electrode modes [66]. The integrated device works when the PV panel starts to convert the incident light into electrical energy and excites the electrons to high energy levels. The voltage increases with the presence of light illumination and starts returning to zero when the cell is not illuminated. The efficiency of a PV cell is defined as the amount of electrical power that is produced from the cell upon the absorption of sunlight, which indicates its effectiveness at converting energy from one form to another [37]. Here, the presence of a supercapacitor on the PV panel acts as an energy storage device to store the generated power and, therefore, the voltage of the device will not immediately reach zero but only gradually decrease. Even when light is not present, the delivered power will not be affected since it is already stored in the supercapacitor and would provide a more reliable power output during its application. The power system’s stability is greatly affected by the high fluctuations in the injected power. Therefore, the energy storage system plays an essential role that alleviates these fluctuations and subsequently enhances the system’s power quality [67]. It is worth noting that the bandgap of a PV semiconductor is very important since it indicates the light’s wavelength that can be absorbed and converted into electrical energy. Matching band gaps between PV semiconductors and the light would result in a high conversion efficiency of the PV cell because it can fully employ the available energy in the system [68].

4.2. Integration Configuration

An integrated device can be fabricated using one of a few electrode configurations, such as a planar structure (two-electrode mode and three-electrode mode) and a fiber structure. For a planar structure, the two components are typically connected in series whereby the solar cell is placed at the top to receive light/illumination while a supercapacitor is placed at the bottom of the device [69]. Previous research that fabricated a DSSC-integrated supercapacitor found that the device fabricated with three electrodes resulted in better efficiency compared to the two-electrode mode. This was due to the problems faced by the two-electrode mode system when the electrons from the counter electrode had difficulties crossing the TiO2 layer toward the shared electrode and subsequently resulted in self-discharging of the device [70]. In short, it can be said that the two-electrode system had a higher resistance, which decreased its efficiency. Meanwhile, a three-electrode structure contains an extra electrode to separate the DSSC and supercapacitor. This electrode is called a counter electrode, which functions as a barrier between the solar cell and the supercapacitor. In addition, it also serves as a redox electron transfer surface and as charge storage [6]. Another planar structure of a solar-cell-integrated supercapacitor was developed by [16], where a PEDOT–carbon electrode bridges the supercapacitor and the perovskite solar cell. This device exhibited a maximum overall efficiency of 4.70% with an energy storage efficiency of 73.77%. However, even though planar structures have made rapid progress in the past few years, the rigid connection hinders their applications for portable electronics.

As for the fiber structure, the principle is similar to the planar structure but only differs in the arrangement of the components and is usually classified as coaxial, parallel-like and twisted [66]. In contrast with planar structure, the fiber shape is less efficient and requires complex fabrication but its flexibility and mechanical properties are well-suited for wearable devices that only require low-power applications [71]. Research by [72] fabricated a fiber power integrated system by incorporating a DSSC and supercapacitor, where a stainless steel wire that was coated with polyaniline via anodic deposition was jointly used as the electrode. The system was lightweight, inexpensive, flexible and resulted in an overall energy conversion efficiency of up to 2.1%. Similarly, another study [13] fabricated an all-solid-state fiber-shaped “energy fiber” by integrating a DSSC and an electrochemical capacitor. The system achieved photoelectric conversion and energy storage efficiencies of 2.73% and 75.7%, respectively. This fiber power integrated system is highly flexible, stable and lightweight, making it suitable for various portable electronic devices and weaveable materials.

A prior study by Sonigara and co-workers fabricated a quasi-solid-state DSSC by using a smart thermoreversible water-based polymer gel (poly(ethylene oxide)–poly(propylene oxide)–poly(ethylene oxide) (PEO–PPO–PEO)) electrolyte. The system was highly flexible and possessed self-healing behavior in which its performance recovered close to the initial level when subjected to bending, shrinking or twisting. For instance, the quasi-solid-state DSSC was bent at 90° for 300 cycles but the results showed that its performance could be maintained at a level as high as 94% of the initial level. This aqueous DSSC device provides a new perspective on flexible and wearable solid-state photovoltaic devices [73].

Another type of integration configuration that is being researched is a spring-like architecture that is essential for practical applications, such as electronic textiles, that require flexibility and stretchability. The author and co-workers prepared a fiber-shaped polymer solar cell (PSC) by winding an aligned carbon nanotube sheet onto a spring-like electrode that was attached to an elastic fiber as the substrate. The PSC exhibited superior flexibility and stretchability, which makes it feasible to be woven into the desired application of PSC textile. The energy conversion efficiencies of the PSC varied by less than 10% after being bent 1000 times and under stretching at a strain of above 30%. In addition, the PSC managed to maintain 90% of its initial PCE value after 1000 cycles of bending, which is greater than what is reported for conventional planar PSCs. However, there is a limitation in the overall performance of this spring-like PSC, where the major part of the solar cell was not exposed to sunlight and subsequently reduced its total power output compared to a conventional structure [74].

4.3. Effectiveness of the Integration

Integrated devices are often associated with having higher volumetric and gravimetric energy densities in comparison to a solar power system that was built with separate components. This is due to its more compact structure, less wiring in the system and the sharing of electrodes [6]. What was also reported is that vehicles that are powered by solar cells and/or fuel cells successfully minimized the costs in terms of capital outlay, weight and fuel with the presence of an integrated supercapacitor. Furthermore, Reference [75] revealed that the concept of harvesting electrical energy from a PV cell for powering wireless sensors via integration with supercapacitors is a promising concept. The authors reduced the size of a single PV cell but they could still manage to get an upstream current. Related research by [76] demonstrated that supercapacitors are ideal for medical applications as well, for example, when they are used to power wireless sensors for measuring blood pressure. Other uses are for electrocardiograms and oxygen measurements with the integration of indoor solar cells as an electricity source. Prior research by [77] developed a power system design by incorporating organic solar cells and supercapacitors with a maximum voltage of 1 V. They reported a 43% reduction in internal resistance in comparison with separate devices that were connected by metal wires.

Integrating a solar cell with a supercapacitor was found to be more promising compared to using secondary batteries since it could eliminate the problem of space constraints, is easy to handle and was shown to have better efficiency. It is best suited for such applications that require a short load cycle and high reliability [78]. The most prominent cause of choosing a supercapacitor over batteries for an integrated device is attributed to its high power density, which allows it to provide more energy over a short period [79]. Moreover, batteries are prone to deterioration when there is a high load current for an instantaneous power delivery that elevates the discharge rate and current, unlike a supercapacitor [80].

Some recent works reported improvement in the PCE for an integrated planar perovskite solar cell and supercapacitor. Xu and co-workers [55] prepared a CH3NH3PbI3-based solar cell with a polypyrrole-based supercapacitor and evaluated its performance. The maximum PCE was reported to be 13.6% and the overall storage efficiency was 10% [81]. Another work fabricated an integrated device based on printable perovskite solar cells and a supercapacitor with a PEDOT–carbon cathode and anode. The system delivered a maximum efficiency of 4.70% with a high energy storage efficiency of 73.77%. There is still room to improve the PCE by improving the workability of perovskite solar cells and PEDOT–carbon electrodes [16]. Meanwhile, Zhao and co-workers vertically integrated a perovskite solar cell with a MoO3/Au/MoO3 transparent electrode and electrochromic supercapacitor. They managed to achieve a maximum PCE of 12.54% for the system. The device provided seamless integration of energy harvesting with a storage device, automatic and wide color tunability and enhanced photostability of PSCs. Another work designed PVCS devices for multifunctional smart window applications that are commonly made of glass [24]. With diversified functions and improvements in integrated solar cell devices, various systems were developed in several industries to produce a single device that will eventually replace conventional devices that have restricted performance or only one application. The integration of solar cells with energy storage parts can also diminish the fluctuation of light illumination as the power output source in the device [82].

4.4. Photoelectrochemical Performance of Integrated Device

Photo-powered energy storage devices have made significant progress in recent years owing to their potential applications in smart electronics and their ease of fabrication. The devices are built in planar and flexible/fiber structures that possess multi-axial flexibility and are economically feasible. To date, solar-cell-integrated supercapacitors have shown outstanding overall efficiency with a wide selection of materials. Table 5 highlights the photo-electrochemical properties of past research works on integrated devices.

Table 5.

Photo-electrochemical properties of solar cell–supercapacitor integrated device.

4.5. Power Electronics for Integrated Solar Cells and Supercapacitor

From previous studies [6], it is well understood that there is always a mismatch between solar cells and storage devices, such as supercapacitors. This mismatch between devices due to the technical factors discussed in past research works is of great concern in achieving an improved PCE and storage capacities. Although the voltages of both the solar cell and supercapacitors are comparable, the system efficiency can be improved by incorporating power electronics components in order to control the charging and discharging process of the integrated device. Additionally, the possibility of performing maximum power point tracking (MPPT) is quite common in most solar PV systems in order to improve the efficiency that is not achieved as expected. Many other techniques are being explored by researchers and scientists to include the advantages of power electronics in attaining the targets regarding the effectiveness of integrating solar cell and supercapacitor devices.

Various types of maximum power point tracking (MPPT) technologies were employed to extract the maximum power from a PV array as the I-V and P-V characteristics of the PV array, which change significantly due to variations in insolation and the cell temperature. The technologies for MPPT focus on improving the accuracy and dynamics of the MPPT algorithm and/or on improving the efficiency and reliability of the DC-DC converters that interface PV arrays with a PV-grid-connected inverter [100]. A hybrid PV generation system not only connects to the grid but also stores its excess PV-generated energy/power to a battery/supercapacitor bank that can be used to stabilize the PV output energy or power, respectively. However, a typical PV generation system integrates the discrete components of PV arrays, energy storage devices, a DC-DC converter, a controller and a grid-tied inverter externally using copper cables. The authors of [6] discussed combining PV modules, power electronics and energy storage components in one device. This is similar to micro-inverters with an MPPT for PV modules [101]. However, they are all still on a device level. Batteries that are integrated with PV panels suffer from reduced lifetimes and efficiencies due to increased temperature [102], which can increase the overall cost of the PV-integrated energy storage system. Nevertheless, the supercapacitor can operate at a maximum temperature twice that of a Li-ion battery and at a low temperature of −40 °C [103].

4.6. Possible Applications of the Integrated Device

A solar-cell-integrated energy storage system (capacitors/batteries) is also known as a hybrid solar energy conversion/harvesting storage system [104], photo-rechargeable energy storage system [105,106] and a solar battery [107]. Due to notable evidence regarding its efficiency and eminent reliability, this integrated system has been adopted for various applications, such as low power electronic applications, electrochromic smart windows, self-driven wearable devices, remotely-powered sensors and remote antenna tracking devices. One of the notable applications of this integrated system is wearable electronics, which has significantly shifted consumer electronics by eliminating the necessity to separately carry the devices. This can be found in clothes, watches, glasses and in the skin (to release moisturizer to the skin) [108]. The device could be worn without compromising its comfort, aesthetic or functionality [109]. Wearable electronics in textiles are usually fabricated in a planar structure in order to provide a large area for solar cell energy collection. Other than that, an integrated device can also be used to facilitate intensive care for medical patients; implanted solar-powered wireless sensors are being utilized to monitor the blood pressure and glucose levels of patients [110,111]. Another medical device that is fabricated using the integrated system is the sub-dermal near-flexible solar cell infra-red harvester and storage device for powering medical implants. This device comes in handy as it is very practical for the patients whereby they are not required to undergo further operations for battery replacement. This would subsequently reduce surgical costs and lowers the risk of medical complications [112]. Powering LEDs has also been one of the potential applications of the device for use in emergency medical kits or toolkits [26]. In addition to wearable sensors and medical devices, the integrated system can also be used for electric vehicles whereby solar power can be stored in the energy storage part in order to ensure the smooth running operation of the car in the absence of light.

4.7. Challenges in Integrating Solar Cells and Supercapacitors

4.7.1. Compatibility of Materials

It is important to analyze the compatibility of materials prior to fabricating an integrated device since incompatible materials and structures would result in poor conversion efficiency, storage capacity and diminish the power delivery efficiencies of a PV-integrated supercapacitor. The appropriate selection of PV cell and supercapacitor materials is required to reduce electron recombination and increase its conversion efficiency [113]. In order to ensure the sustainability of the integrated device, both of the components should also not react with one another during redox reactions.

4.7.2. Solar Energy Generation and Storage Capacity Mismatch

When designing the solar cell and supercapacitor, a critical concern involves avoiding the mismatch between the two components whereby the storage capacity should be well fitted with the energy generated from the solar panel [114]. For instance, if the storage capacity is too large but the PV panel only provides a low amount of electrical energy, it would lead to under-sizing of the storage part and subsequently result in poor efficiency [115]. A common situation happens particularly during the afternoon; when the demand is low and solar generation is high, it leads to network overvoltages and increased network losses. Hence, supercapacitors with fast charge/discharge capability and low energy density are more suitable for short-term energy storage purposes. This is another research gap in this field whereby researchers are trying to increase supercapacitors’ energy density for a more efficient system. It is crucial to carefully optimize the parameter matching between solar cells and the supercapacitor, for instance, choosing a photoelectrode with good photoelectrocatalysis activity and charge storage ability in order to efficiently facilitate photocharging [48].

A study by [116] proposed two designs of an energy storage system with PV solar cells to investigate the effects of mismatch between solar generation and demand profiles. They found that the PV generation strategy (PVGS) whereby the energy storage system is charged completely based on the total amount of PV-generated power could provide technical benefits to the system and is more cost-effective. Another important parameter to be considered in tackling the mismatch issue is the lifetime matching between the power conversion (solar cell) and storage system (supercapacitors/batteries). An example is given where a long-lifetime silicon solar cell is integrated with rechargeable batteries with a short life cycle, which will result in an under-utilized silicon solar cell since the integrated system is restricted by the battery part. Therefore, in this case, the silicon solar cell is more suitable to be integrated with a supercapacitor that possesses a longer life cycle to obtain optimal use of the system [117]. On the device level, it is important to ensure the high efficiency of the solar cell while the supercapacitor should be well matched to minimize energy loss by considering the electrode materials, the size of the energy storage parts and the system’s stability.

A conversion and control circuit (CC) in a solar cell acts to manage the flow of charge between the PV and supercapacitor. Previous research inserted a CC into an integrated device that was built for energy harvesting and storage. The integrated circuit is compatible with roll-to-roll manufacturing (R2R) and the newly built system was compared with the conventional integration of PV and supercapacitors whereby the devices were directly connected [80]. It emerged that the incorporation of a CC managed to increase the energy that was harvested by the PV and stored in the supercapacitors. In addition, the CC enhanced the output voltage and simultaneously balance it across the serial connection of supercapacitors. The overall finding showed that incorporating a CC in the system managed to overcome the mismatch problem between a PV cell and a supercapacitor by more than fivefold. This was achieved by balancing the voltages of the supercapacitors.

4.7.3. Leakage of Liquid Electrolyte

Liquid electrolytes are usually employed in the integrated solar cells and supercapacitors to provide a path for the ions to flow but a major concern is the leakages that might occur during the process, which will affect the device’s functionality. Hence, all-solid supercapacitors are more desirable to be used in an integrated device to avoid such issues from occurring, as well as being able to reduce the total cell volume [118]. However, despite its high mechanical strength, the formulation of the electrolyte is also very important in order to ensure that it will not compromise its ionic conductivity, and it must have good compatibility with the supercapacitor electrodes [119]. Another option to solve the problem is by building a highly capable encapsulation for the liquid electrolyte that would act as a barrier to leakages and could simultaneously maintain its power density. These techniques still need more exploration as there is a wide selection of materials for the preparation of solid electrolytes and electrolyte encapsulation. The aim here would be to dramatically increase the ionic conductivity of the electrochemical cells and improve the assembly of the complete integrated device.

4.7.4. Insufficient Data on Long-Term Practical Use of the Integrated Device

The available data from previous research basically focused on the new development of both solar cells and supercapacitors. The published data for experimental work on the integrated devices concentrate on the results that were achieved from the integration, namely, its power conversion efficiency and storage efficiency. However, there is a lack of data on the feasibility of the devices for long-term applications; this is a concern because some devices are greatly affected by aging processes and, consequently, this undermines their overall performance. This is crucial for providing reliable sources in order to completely replace the existing technology with solar cell integrated supercapacitor devices for various electrical power-using fields, such as transportation, domestic appliances and medical technologies. More investigation is needed on the new methods for integrating electrodes and new materials that can prolong the life of the device. Furthermore, advanced materials for the development of the device’s outer casing can be explored in order to protect it from environmental effects during its service.

4.7.5. Levelized Cost of Energy

Technically, it is beyond question that integration would result in enhanced performance of the device, especially when the energy generated from the solar cell will be quickly stored in the supercapacitor and reduce its loss. The supercapacitor integrated into the solar cell compensates for the intermittent power supply from the solar panel when energy is not harvested due to partial shading or the absence of light [120]. This technology is technically viable but at the same time should be cost-effective in the long run. Therefore, LCOE should be paid great attention as it needs to be less expensive than the current LCOE given the issues concerning material, operating, maintenance and replacement costs. A simulation study by [121] showed a decrease in LCOE when integrating a supercapacitor with a DSSC for an energy storage system in the United Arab Emirates from 0.36 to 0.341 USD/kWh. However, there is still limited data on the LCOE for the various types of materials that are used for integrating these two components. For this reason, researchers should focus on lowering the LCOE without compromising the system’s performance.

5. Conclusions and Future Outlook

This paper summarizes the concept of integrating a solar cell and a supercapacitor, the related material properties and some challenges that are faced when ensuring that a promising device is viable for a broad range of applications. The efficiency of a PV cell is essential for converting the sunlight to electrical power in order to keep the device functioning well and sustaining its energy. In the area of energy storage, adsorption processes in porous carbon are crucial in order for several technologies to use them. Hence, a sound understanding of ion desorption and a charge storage mechanism for supercapacitors is essential if researchers are to ensure that the energy needs can be realized via new technology and applications. Since this integration concept has enhanced the overall performance of the device, it is vital for researchers to carry out a feasibility study on the practicability of this device, especially for long-term usage in various fields. The analysis of the LCOE has proven to be indispensable because inventors and consumers will not only focus on the efficiency of the device but also on cost-effectiveness, which is of equal importance. In addition, the device’s durability is important and must be analyzed. It is well known that aging will lead to some defects in any materials, especially when it is exposed to the outdoor environment. Aging tests must be carried out in order to differentiate the lifespan of this device in relation to a common solar panel, which usually lasts for 25–30 years.

Author Contributions

Conceptualization, N.A.N. and M.N.M.A.; resources, N.A.N. and M.N.M.A.; writing—original draft preparation, N.A.N.; writing—review and editing, M.N.M.A., S.M.N., N.A.H., N.M.L.T., Z.Y. and I.A.; funding acquisition, M.N.M.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by TNB Sdn.Bhd. through the Seeding Fund Research Grant (U-TV-RD-20-10) and the APC was funded by a UNITEN BOLD publication grant (J510050002) through iRMC, Universiti Tenaga Nasional.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Gurung, A.; Qiao, Q. Solar Charging Batteries: Advances, Challenges, and Opportunities. Joule 2018, 2, 1217–1230. [Google Scholar] [CrossRef] [Green Version]

- Salameh, T.; Abdelkareem, M.A.; Olabi, A.G.; Sayed, E.T.; Al-Chaderchi, M.; Rezk, H. Integrated Standalone Hybrid Solar PV, Fuel Cell and Diesel Generator Power System for Battery or Supercapacitor Storage Systems in Khorfakkan, United Arab Emirates. Int. J. Hydrogen Energy 2021, 46, 6014–6027. [Google Scholar] [CrossRef]

- Scalia, A.; Bella, F.; Lamberti, A.; Bianco, S.; Gerbaldi, C.; Tresso, E.; Pirri, C.F. A Flexible and Portable Powerpack by Solid-State Supercapacitor and Dye-Sensitized Solar Cell Integration. J. Power Sources 2017, 359, 311–321. [Google Scholar] [CrossRef]

- Sachin, Q.; Pawar, A.; Patil, D.S.; Shin, J.C. Hexagonal Sheets of Co3O4 and Co3O4-Ag for High-Performance Electrochemical Supercapacitors. J. Ind. Eng. Chem. 2017, 54, 162–173. [Google Scholar]

- Yuan, Y.; Lu, Y.; Jia, B.E.; Tang, H.; Chen, L.; Zeng, Y.J.; Hou, Y.; Zhang, Q.; He, Q.; Jiao, L.; et al. Integrated System of Solar Cells with Hierarchical NiCo2O4 Battery-Supercapacitor Hybrid Devices for Self-Driving Light-Emitting Diodes. Nano-Micro Lett. 2019, 11, 42. [Google Scholar] [CrossRef] [Green Version]

- Vega-Garita, V.; Ramirez-Elizondo, L.; Narayan, N.; Bauer, P. Integrating a Photovoltaic Storage System in One Device: A Critical Review. Prog. Photovolt. Res. Appl. 2019, 27, 346–370. [Google Scholar] [CrossRef] [Green Version]

- Chuang, W.C.; Lee, C.Y.; Wu, T.L.; Ho, C.T.; Kang, Y.Y.; Lee, C.H.; Meen, T.H. Fabrication of Integrated Device Comprising Flexible Dye-Sensitized Solar Cell and Graphene-Doped Supercapacitor. Sens. Mater. 2020, 32, 2077–2087. [Google Scholar] [CrossRef]

- Zhong, Y.; Xia, X.; Mai, W.; Tu, J.; Fan, H.J. Integration of Energy Harvesting and Electrochemical Storage Devices. Adv. Mater. Technol. 2017, 2, 1700182. [Google Scholar] [CrossRef]

- Li, L.; Wu, Z.; Yuan, S.; Zhang, X.B. Advances and Challenges for Flexible Energy Storage and Conversion Devices and Systems. Energy Environ. Sci. 2014, 7, 2101–2122. [Google Scholar] [CrossRef]

- Yu, L.; Chen, G.Z. Supercapatteries as High-Performance Electrochemical Energy Storage Devices. Electrochem. Energy Rev. 2020, 3, 271–285. [Google Scholar] [CrossRef] [Green Version]

- Shen, J.J. Recently-Explored Top Electrode Materials for Transparent Organic Solar Cells. Synth. Met. 2021, 271, 116582. [Google Scholar] [CrossRef]

- Skunik-Nuckowska, M.; Grzejszczyk, K.; Kulesza, P.J.; Yang, L.; Vlachopoulos, N.; Häggman, L.; Johansson, E.; Hagfeldt, A. Integration of Solid-State Dye-Sensitized Solar Cell with Metal Oxide Charge Storage Material into Photoelectrochemical Capacitor. J. Power Sources 2013, 234, 91–99. [Google Scholar] [CrossRef]

- Chen, X.; Sun, H.; Yang, Z.; Guan, G.; Zhang, Z.; Qiu, L.; Peng, H. A Novel “Energy Fiber” by Coaxially Integrating Dye-Sensitized Solar Cell and Electrochemical Capacitor. J. Mater. Chem. A 2014, 2, 1897–1902. [Google Scholar] [CrossRef]

- Xu, X.; Li, S.; Zhang, H.; Shen, Y.; Zakeeruddin, S.M.; Graetzel, M.; Cheng, Y.B.; Wang, M. A Power Pack Based on Organometallic Perovskite Solar Cell and Supercapacitor. ACS Nano 2015, 9, 1782–1787. [Google Scholar] [CrossRef] [PubMed]

- Lechêne, B.P.; Cowell, M.; Pierre, A.; Evans, J.W.; Wright, P.K.; Arias, A.C. Organic Solar Cells and Fully Printed Super-Capacitors Optimized for Indoor Light Energy Harvesting. Nano Energy 2016, 26, 631–640. [Google Scholar] [CrossRef] [Green Version]

- Xu, J.; Ku, Z.; Zhang, Y.; Chao, D.; Fan, H.J. Integrated Photo-Supercapacitor Based on PEDOT Modified Printable Perovskite Solar Cell. Adv. Mater. Technol. 2016, 1, 1600074. [Google Scholar] [CrossRef]

- Liang, J.; Zhu, G.; Lu, Z.; Zhao, P.; Wang, C.; Ma, Y.; Xu, Z.; Wang, Y.; Hu, Y.; Ma, L.; et al. Integrated Perovskite Solar Capacitors with High Energy Conversion Efficiency and Fast Photo-Charging Rate. J. Mater. Chem. A 2018, 6, 2047–2052. [Google Scholar] [CrossRef]

- Shao, H.; Padmanathan, N.; McNulty, D.; O’Dwyer, C.; Razeeb, K.M. Supercapattery Based on Binder-Free Co3(PO4)2·8H2O Multilayer Nano/Microflakes on Nickel Foam. ACS Appl. Mater. Interfaces 2016, 8, 28592–28598. [Google Scholar] [CrossRef] [PubMed]

- Kiran, S.K.; Shukla, S.; Struck, A.; Saxena, S. Surface Enhanced 3D RGO Hybrids and Porous RGO Nano-Networks as High Performance Supercapacitor Electrodes for Integrated Energy Storage Devices. Carbon N. Y. 2020, 158, 527–535. [Google Scholar] [CrossRef]

- Salanne, M.; Rotenberg, B.; Naoi, K.; Kaneko, K.; Taberna, P.L.; Grey, C.P.; Dunn, B.; Simon, P. Efficient Storage Mechanisms for Building Better Supercapacitors. Nat. Energy 2016, 1, 16070. [Google Scholar] [CrossRef]

- Hussain, I.; Tran, H.P.; Jaksik, J.; Moore, J.; Islam, N.; Uddin, M.J. Functional Materials, Device Architecture, and Flexibility of Perovskite Solar Cell. Emergent Mater. 2018, 1, 133–154. [Google Scholar] [CrossRef] [Green Version]

- Ibrahim, I.; Lim, H.N.; Wan, N.W.K.; Huang, N.M.; Lim, S.P.; Busayaporn, W.; Nakajima, H. Plasmonic Silver Sandwich Structured Photoanode and Reflective Counter Electrode Enhancing Power Conversion Efficiency of Dye-Sensitized Solar Cell. Sol. Energy 2021, 215, 403–409. [Google Scholar] [CrossRef]

- Shin, D.H.; Choi, S.H. Recent Studies of Semitransparent Solar Cells. Coatings 2018, 8, 329. [Google Scholar] [CrossRef] [Green Version]

- Zhou, F.; Ren, Z.; Zhao, Y.; Shen, X.; Wang, A.; Li, Y.Y.; Surya, C.; Chai, Y. Perovskite Photovoltachromic Supercapacitor with All-Transparent Electrodes. ACS Nano 2016, 10, 5900–5908. [Google Scholar] [CrossRef] [PubMed]

- Westover, A.S.; Share, K.; Carter, R.; Cohn, A.P.; Oakes, L.; Pint, C.L. Direct Integration of a Supercapacitor into the Backside of a Silicon Photovoltaic Device. Appl. Phys. Lett. 2014, 104, 10–13. [Google Scholar] [CrossRef]

- Chien, C.T.; Hiralal, P.; Wang, D.Y.; Huang, I.S.; Chen, C.C.; Chen, C.W.; Amaratunga, G.A.J. Graphene-Based Integrated Photovoltaic Energy Harvesting/Storage Device. Small 2015, 11, 2929–2937. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Y.; Wu, Y.; Yang, G.; Mazzarella, L.; Procel-Moya, P.; Tamboli, A.C.; Weber, K.; Boccard, M.; Isabella, O.; et al. High-Efficiency Silicon Heterojunction Solar Cells: Materials, Devices and Applications. Mater. Sci. Eng. R Rep. 2020, 142, 100579. [Google Scholar] [CrossRef]

- Peters, I.M.; Rodriguez Gallegos, C.D.; Sofia, S.E.; Buonassisi, T. The Value of Efficiency in Photovoltaics. Joule 2019, 3, 2732–2747. [Google Scholar] [CrossRef]

- Giannouli, M.; Govatsi, K.; Syrrokostas, G.; Yannopoulos, S.N.; Leftheriotis, G. Factors AFffecting the Power Conversion Efficiency in ZnO DSSCs: Nanowire vs. Nanoparticles. Materials 2018, 11, 411. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alharbi, F.H.; Kais, S. Theoretical Limits of Photovoltaics Efficiency and Possible Improvements by Intuitive Approaches Learned from Photosynthesis and Quantum Coherence. Renew. Sustain. Energy Rev. 2015, 43, 1073–1089. [Google Scholar] [CrossRef] [Green Version]

- Green, M.A.; Dunlop, E.D.; Hohl-Ebinger, J.; Yoshita, M.; Kopidakis, N.; Ho-Baillie, A.W.Y. Solar Cell Efficiency Tables (Version 55). Prog. Photovolt. Res. Appl. 2020, 28, 3–15. [Google Scholar] [CrossRef]

- Nakamura, M.; Tada, K.; Kinoshita, T.; Bessho, T.; Nishiyama, C.; Takenaka, I.; Kimoto, Y.; Higashino, Y.; Sugimoto, H.; Segawa, H. IScience Ll Perovskite/CIGS Spectral Splitting Double. Iscience 2020, 23, 101817. [Google Scholar] [CrossRef] [PubMed]

- Brahmendra Kumar, G.V.; Kaliannan, P.; Padmanaban, S.; Holm-Nielsen, J.B.; Blaabjerg, F. Effective Management System for Solar PV Using Real-Time Data with Hybrid Energy Storage System. Appl. Sci. 2020, 10, 1108. [Google Scholar] [CrossRef] [Green Version]

- Kumar, M.; Raj, A.; Kumar, A.; Anshul, A. An Optimized Lead-Free Formamidinium Sn-Based Perovskite Solar Cell Design for High Power Conversion Efficiency by SCAPS Simulation. Opt. Mater. (Amst) 2020, 108, 110213. [Google Scholar] [CrossRef]

- Sharma, G.D.; Suthar, R.; Pestrikova, A.A.; Nikolaev, A.Y.; Chen, F.C.; Keshtov, M.L. Efficient Ternary Polymer Solar Cells Based Ternary Active Layer Consisting of Conjugated Polymers and Non-Fullerene Acceptors with Power Conversion Efficiency Approaching near to 15.5%. Sol. Energy 2021, 216, 217–224. [Google Scholar] [CrossRef]

- Zhao, L.; Duan, J.; Liu, L.; Wang, J.; Duan, Y.; Vaillant-Roca, L.; Yang, X.; Tang, Q. Boosting Power Conversion Efficiency by Hybrid Triboelectric Nanogenerator/Silicon Tandem Solar Cell toward Rain Energy Harvesting. Nano Energy 2021, 82, 105773. [Google Scholar] [CrossRef]

- Eyderman, S.; John, S. Light-Trapping and Recycling for Extraordinary Power Conversion in Ultra-Thin Gallium-Arsenide Solar Cells. Sci. Rep. 2016, 6, 28303. [Google Scholar] [CrossRef] [PubMed]

- Michael, G.; Zhang, Y.; Nie, J.; Zheng, D.; Hu, G.; Liu, R.; Dan, M.; Li, L.; Zhang, Y. High-Performance Piezo-Phototronic Multijunction Solar Cells Based on Single-Type Two-Dimensional Materials. Nano Energy 2020, 76, 105091. [Google Scholar] [CrossRef]

- Kumar, N.; Rani, J.; Kurchania, R. A Review on Power Conversion Efficiency of Lead Iodide Perovskite-Based Solar Cells. Mater. Today Proc. 2021, 46, 5570–5574. [Google Scholar] [CrossRef]

- Vicentini, R.; Da Silva, L.M.; Cecilio, E.P.; Alves, T.A.; Nunes, W.G.; Zanin, H. How to Measure and Calculate Equivalent Series Resistance of Electric Double-Layer Capacitors. Molecules 2019, 24, 1452. [Google Scholar] [CrossRef] [Green Version]

- Yu, X.; Yun, S.; Yeon, J.S.; Bhattacharya, P.; Wang, L.; Lee, S.W.; Hu, X.; Park, H.S. Emergent Pseudocapacitance of 2D Nanomaterials. Adv. Energy Mater. 2018, 8, 1702930. [Google Scholar] [CrossRef]

- Khan, K.; Tareen, A.K.; Aslam, M.; Mahmood, A.; khan, Q.; Zhang, Y.; Ouyang, Z.; Guo, Z.; Zhang, H. Going Green with Batteries and Supercapacitor: Two Dimensional Materials and Their Nanocomposites Based Energy Storage Applications. Prog. Solid State Chem. 2020, 58, 100254. [Google Scholar] [CrossRef]

- Aziz, S.B.; Hamsan, M.H.; Karim, W.O.; Kadir, M.F.Z.; Brza, M.A.; Abdullah, O.G. High Proton Conducting Polymer Blend Electrolytes Based on Chitosan: Dextran with Constant Specific Capacitance and Energy Density. Biomolecules 2019, 9, 267. [Google Scholar] [CrossRef] [Green Version]

- Denge, N. Study of Hybrid Super-Capacitor. Int. Res. J. Eng. Technol. 2016, 3, 1012–1016. [Google Scholar]

- Takakura, A.; Beppu, K.; Nishihara, T.; Fukui, A.; Kozeki, T.; Namazu, T.; Miyauchi, Y.; Itami, K. Strength of Carbon Nanotubes Depends on Their Chemical Structures. Nat. Commun. 2019, 10, 3040. [Google Scholar] [CrossRef]

- Han, Z.; Fina, A. Thermal Conductivity of Carbon Nanotubes and Their Polymer Nanocomposites: A Review. Prog. Polym. Sci. 2011, 36, 914–944. [Google Scholar] [CrossRef] [Green Version]

- Yang, Z.; Tian, J.; Yin, Z.; Cui, C.; Qian, W.; Wei, F. Carbon Nanotube- and Graphene-Based Nanomaterials and Applications in High-Voltage Supercapacitor: A Review. Carbon N. Y. 2019, 141, 467–480. [Google Scholar] [CrossRef]

- Zeng, Q.; Lai, Y.; Jiang, L.; Liu, F.; Hao, X.; Wang, L.; Green, M.A. Integrated Photorechargeable Energy Storage System: Next-Generation Power Source Driving the Future. Adv. Energy Mater. 2020, 10, 1903930. [Google Scholar] [CrossRef]

- Allen, J.M.; Vincent, T.C.; Richard, K.B. Honeycomb Carbon: A Review of Graphene What Is Graphene ? Chem. Rev. 2010, 110, 132–145. [Google Scholar] [CrossRef] [PubMed]

- Reina, A.; Jia, X.; Ho, J.; Nezich, D.; Son, H.; Bulovic, V.; Dresselhaus, M.S.; Jing, K. Large Area, Few-Layer Graphene Films on Arbitrary Substrates by Chemical Vapor Deposition. Nano Lett. 2009, 9, 30–35. [Google Scholar] [CrossRef]

- Park, S.; Ruoff, R.S. Chemical Methods for the Production of Graphenes. Nat. Nanotechnol. 2009, 4, 217–224. [Google Scholar] [CrossRef] [PubMed]

- Xin, G.; Hwang, W.; Kim, N.; Cho, S.M.; Chae, H. A Graphene Sheet Exfoliated with Microwave Irradiation and Interlinked by Carbon Nanotubes for High-Performance Transparent Flexible Electrodes. Nanotechnology 2010, 21, 405201. [Google Scholar] [CrossRef] [PubMed]

- Wong, S.I.; Sunarso, J.; Wong, B.T.; Lin, H.; Yu, A.; Jia, B. Towards Enhanced Energy Density of Graphene-Based Supercapacitors: Current Status, Approaches, and Future Directions. J. Power Sources 2018, 396, 182–206. [Google Scholar] [CrossRef]

- Shi, X.; Zheng, S.; Wu, Z.S.; Bao, X. Recent Advances of Graphene-Based Materials for High-Performance and New-Concept Supercapacitors. J. Energy Chem. 2018, 27, 25–42. [Google Scholar] [CrossRef] [Green Version]

- Lau, S.C.; Lim, H.N.; Ravoof, T.B.S.A.; Yaacob, M.H.; Grant, D.M.; MacKenzie, R.C.I.; Harrison, I.; Huang, N.M. A Three-Electrode Integrated Photo-Supercapacitor Utilizing Graphene-Based Intermediate Bifunctional Electrode. Electrochim. Acta 2017, 238, 178–184. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, H.B.; Xie, X.; Yang, R.; Liu, Z.; Liu, Y.; Yu, Z.Z. Multifunctional, Superelastic, and Lightweight MXene/Polyimide Aerogels. Small 2018, 14, 1802479. [Google Scholar] [CrossRef] [PubMed]

- Hart, J.L.; Hantanasirisakul, K.; Lang, A.C.; Anasori, B.; Pinto, D.; Pivak, Y.; van Omme, J.T.; May, S.J.; Gogotsi, Y.; Taheri, M.L. Control of MXenes’ Electronic Properties through Termination and Intercalation. Nat. Commun. 2019, 10, 522. [Google Scholar] [CrossRef] [Green Version]

- Qin, L.; Jiang, J.; Tao, Q.; Wang, C.; Persson, I.; Fahlman, M.; Persson, P.O.A.; Hou, L.; Rosen, J.; Zhang, F. A Flexible Semitransparent Photovoltaic Supercapacitor Based on Water-Processed MXene Electrodes. J. Mater. Chem. A 2020, 8, 5467–5475. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Wang, L.; Zhao, L.; Wang, K.; Zheng, Y.; Yuan, Z.; Wang, D.; Fu, X.; Shen, G.; Han, W. Flexible Self-Powered Integrated Sensing System with 3D Periodic Ordered Black Phosphorus@MXene Thin-Films. Adv. Mater. 2021, 33, 2007890. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Zhang, Q.; Wang, J.; Huang, X.; Bai, H. A Self-Assembly Route to Porous Polyaniline/Reduced Graphene Oxide Composite Materials with Molecular-Level Uniformity for High-Performance Supercapacitors. Energy Environ. Sci. 2018, 11, 1280–1286. [Google Scholar] [CrossRef]

- Liang, R.; Du, Y.; Xiao, P.; Cheng, J.; Yuan, S.; Chen, Y.; Yuan, J.; Chen, J. Transition Metal Oxide Electrode Materials for Supercapacitors: A Review of Recent Developments. Nanomaterials 2021, 11, 1248. [Google Scholar] [CrossRef] [PubMed]

- Genovese, M.; Lian, K. Polyoxometalates; Elsevier Inc.: Amsterdam, The Netherlands, 2017. [Google Scholar] [CrossRef]

- Makgopa, K.; Bello, A.; Raju, K.; Modibane, K.D.; Hato, M.J. Nanostructured Metal Oxides for Supercapacitor Applications. In Emerging Nanostructured Materials for Energy and Environmental Science; Springer: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

- An, C.; Zhang, Y.; Guo, H.; Wang, Y. Metal Oxide-Based Supercapacitors: Progress and Prospectives. Nanoscale Adv. 2019, 1, 4644–4658. [Google Scholar] [CrossRef] [Green Version]

- Baena-Moncada, A.M.; Quispe-Garrido, V.; Antonio Cerron-Calle, G.; Bazan-Aguilar, A.; Ruiz-Montoya, J.G.; López, E.O. Advances in the Design and Application of Transition Metal Oxide-Based Supercapacitors. Open Chem. 2021, 19, 709–725. [Google Scholar] [CrossRef]

- Sun, Y.; Yan, X. Recent Advances in Dual-Functional Devices Integrating Solar Cells and Supercapacitors. Sol. RRL 2017, 1, 1700002. [Google Scholar] [CrossRef]

- Brahmendra Kumar, G.V.; Anil Kumar, G.; Eswararao, S.; Gehlot, D. Modelling and Control of BESS for Solar Integration for PV Ramp Rate Control. In Proceedings of the 7th 2018 International Conference on Computation of Power, Energy, Information and Communication (ICCPEIC), Chennai, India, 28–29 March 2018; pp. 368–374. [Google Scholar] [CrossRef]

- Li, J.; Aierken, A.; Liu, Y.; Zhuang, Y.; Yang, X.; Mo, J.H.; Fan, R.K.; Chen, Q.Y.; Zhang, X.Y.; Huang, Y.M.; et al. A Brief Review of High Efficiency III-V Solar Cells for Space Application. Front. Phys. 2021, 8, 631925. [Google Scholar] [CrossRef]

- Luo, B.; Ye, D.; Wang, L. Recent Progress on Integrated Energy Conversion and Storage Systems. Adv. Sci. 2017, 4, 1700104. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Miyasaka, T.; Murakami, T.N. The Photocapacitor: An Efficient Self-Charging Capacitor for Direct Storage of Solar Energy. Appl. Phys. Lett. 2004, 85, 3932–3934. [Google Scholar] [CrossRef]

- Cai, X.; Zhang, C.; Zhang, S.; Fang, Y.; Zou, D. Application of Carbon Fibers to Flexible, Miniaturized Wire/Fiber-Shaped Energy Conversion and Storage Devices. J. Mater. Chem. A 2017, 5, 2444–2459. [Google Scholar] [CrossRef]

- Paquin, F.; Rivnay, J.; Salleo, A.; Stingelin, N.; Silva, C. Multi-Phase Semicrystalline Microstructures Drive Exciton Dissociation in Neat Plastic Semiconductors. J. Mater. Chem. C 2015, 3, 10715–10722. [Google Scholar] [CrossRef] [Green Version]

- Sonigara, K.K.; Machhi, H.K.; Vaghasiya, J.V.; Gibaud, A.; Tan, S.C.; Soni, S.S. A Smart Flexible Solid State Photovoltaic Device with Interfacial Cooling Recovery Feature through Thermoreversible Polymer Gel Electrolyte. Small 2018, 14, 1800842. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, Z.; Deng, J.; Zhang, Y.; Guan, G.; Peng, H. Stretchable Polymer Solar Cell Fibers. Small 2015, 11, 675–680. [Google Scholar] [CrossRef]

- Bergonzini, C.; Brunelli, D.; Benini, L. Comparison of Energy Intake Prediction Algorithms for Systems Powered by Photovoltaic Harvesters. Microelectron. J. 2010, 41, 766–777. [Google Scholar] [CrossRef]

- Hande, A.; Polk, T.; Walker, W.; Bhatia, D. Indoor Solar Energy Harvesting for Sensor Network Router Nodes. Microprocess. Microsyst. 2007, 31, 420–432. [Google Scholar] [CrossRef]

- Wee, G.; Salim, T.; Lam, Y.M.; Mhaisalkar, S.G.; Srinivasan, M. Printable Photo-Supercapacitor Using Single-Walled Carbon Nanotubes. Energy Environ. Sci. 2011, 4, 413–416. [Google Scholar] [CrossRef]

- Iro, Z.S.; Subramani, C.; Dash, S.S. A Brief Review on Electrode Materials for Supercapacitor. Int. J. Electrochem. Sci. 2016, 11, 10628–10643. [Google Scholar] [CrossRef]

- Sahin, M.E.; Blaabjerg, F.; Sangwongwanich, A. A Review on Supercapacitor Materials and Developments. Turk. J. Mater. 2020, 5, 10–24. [Google Scholar]

- Mitkowski, W.; Skruch, P. Fractional-Order Models of the Supercapacitors in the Form of RC Ladder Networks. Bull. Pol. Acad. Sci. Tech. Sci. 2013, 61, 581–587. [Google Scholar] [CrossRef]

- Thostenson, J.O.; Li, Z.; Kim, C.H.J.; Ajnsztajn, A.; Parker, C.B.; Liu, J.; Peterchev, A.V.; Glass, J.T.; Goetz, S.M. Integrated Flexible Conversion Circuit between a Flexible Photovoltaic and Supercapacitors for Powering Wearable Sensors. J. Electrochem. Soc. 2018, 165, B3122–B3129. [Google Scholar] [CrossRef]

- Liu, R.; Liu, Y.; Zou, H.; Song, T.; Sun, B. Integrated Solar Capacitors for Energy Conversion and Storage. Nano Res. 2017, 10, 1545–1559. [Google Scholar] [CrossRef]

- Lo, C.W.; Li, C.; Jiang, H. Direct Solar Energy Conversion and Storage through Coupling between Photoelectrochemical and Ferroelectric Effects. AIP Adv. 2011, 1, 042104. [Google Scholar] [CrossRef]

- Zhang, X.; Huang, X.; Li, C.; Jiang, H. Dye-Sensitized Solar Cell with Energy Storage Function through PVDF/ZnO Nanocomposite Counter Electrode. Adv. Mater. 2013, 25, 4093–4096. [Google Scholar] [CrossRef] [PubMed]

- Reddy, G.S.; Anandan, S. Fabrication of Dye Sensitized Solar Cells with Different Anchoring Mode Based Triphenylamine Dyes. Appl. Sol. Energy (Engl. Transl. Geliotekhnika) 2015, 51, 120–128. [Google Scholar] [CrossRef]

- Thimmappa, R.; Paswan, B.; Gaikwad, P.; Devendrachari, M.C.; Makri Nimbegondi Kotresh, H.; Rani Mohan, R.; Pattayil Alias, J.; Thotiyl, M.O. Chemically Chargeable Photo Battery. J. Phys. Chem. C 2015, 119, 14010–14016. [Google Scholar] [CrossRef]

- Paolella, A.; Faure, C.; Bertoni, G.; Marras, S.; Guerfi, A.; Darwiche, A.; Hovington, P.; Commarieu, B.; Wang, Z.; Prato, M.; et al. Light-Assisted Delithiation of Lithium Iron Phosphate Nanocrystals towards Photo-Rechargeable Lithium Ion Batteries. Nat. Commun. 2017, 8, 14643. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Vo, Q.S.; Prokhorov, A.V. Stability Improvement of a Multimachine Power System Connected With a Large-Scale Hybrid Wind-Photovoltaic Farm Using a Supercapacitor. IEEE Trans. Ind. Appl. 2018, 54, 50–60. [Google Scholar] [CrossRef]

- Chen, H.W.; Hsu, C.Y.; Chen, J.G.; Lee, K.M.; Wang, C.C.; Huang, K.C.; Ho, K.C. Plastic Dye-Sensitized Photo-Supercapacitor Using Electrophoretic Deposition and Compression Methods. J. Power Sources 2010, 195, 6225–6231. [Google Scholar] [CrossRef]

- Li, C.; Islam, M.M.; Moore, J.; Sleppy, J.; Morrison, C.; Konstantinov, K.; Dou, S.X.; Renduchintala, C.; Thomas, J. Wearable Energy-Smart Ribbons for Synchronous Energy Harvest and Storage. Nat. Commun. 2016, 7, 13319. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shi, C.; Dong, H.; Zhu, R.; Li, H.; Sun, Y.; Xu, D.; Zhao, Q.; Yu, D. An “All-in-One” Mesh-Typed Integrated Energy Unit for Both Photoelectric Conversion and Energy Storage in Uniform Electrochemical System. Nano Energy 2015, 13, 670–678. [Google Scholar] [CrossRef]

- Lee, Y.H.; Kim, J.S.; Noh, J.; Lee, I.; Kim, H.J.; Choi, S.; Seo, J.; Jeon, S.; Kim, T.S.; Lee, J.Y.; et al. Wearable Textile Battery Rechargeable by Solar Energy. Nano Lett. 2013, 13, 5753–5761. [Google Scholar] [CrossRef]

- Thekkekara, L.V.; Jia, B.; Zhang, Y.; Qiu, L.; Li, D.; Gu, M. Fabrication and Characterization of Solar Supercapcitors Integrated with a Laser Scribed Graphene Oxide Film. In Proceedings of the Frontiers in Optics 2015, San Jose, CA, USA, 18–22 October 2015; pp. 3–5. [Google Scholar] [CrossRef]

- Lee, F.W.; Ma, C.W.; Lin, Y.H.; Huang, P.C.; Su, Y.L.; Yang, Y.J. A Micromachined Photo-Supercapacitor Integrated with CdS-Sensitized Solar Cells and Buckypaper. Sens. Mater. 2016, 28, 749–756. [Google Scholar] [CrossRef]

- Cohn, A.P.; Erwin, W.R.; Share, K.; Oakes, L.; Westover, A.S.; Carter, R.E.; Bardhan, R.; Pint, C.L. All Silicon Electrode Photocapacitor for Integrated Energy Storage and Conversion. Nano Lett. 2015, 15, 2727–2731. [Google Scholar] [CrossRef]

- Narayanan, R.; Kumar, P.N.; Deepa, M.; Srivastava, A.K. Combining Energy Conversion and Storage: A Solar Powered Supercapacitor. Electrochim. Acta 2015, 178, 113–126. [Google Scholar] [CrossRef]

- Agbo, S.N.; Merdzhanova, T.; Yu, S.; Tempel, H.; Kungl, H.; Eichel, R.A.; Rau, U.; Astakhov, O. Development towards Cell-to-Cell Monolithic Integration of a Thin-Film Solar Cell and Lithium-Ion Accumulator. J. Power Sources 2016, 327, 340–344. [Google Scholar] [CrossRef]

- Um, H.D.; Choi, K.H.; Hwang, I.; Kim, S.H.; Seo, K.; Lee, S.Y. Monolithically Integrated, Photo-Rechargeable Portable Power Sources Based on Miniaturized Si Solar Cells and Printed Solid-State Lithium-Ion Batteries. Energy Environ. Sci. 2017, 10, 931–940. [Google Scholar] [CrossRef]

- Gao, Z.; Bumgardner, C.; Song, N.; Zhang, Y.; Li, J.; Li, X. Cotton-Textile-Enabled Flexible Self-Sustaining Power Packs via Roll-to-Roll Fabrication. Nat. Commun. 2016, 7, 11586. [Google Scholar] [CrossRef] [PubMed]

- Başoʇlu, M.E.; Çakir, B. Comparisons of MPPT Performances of Isolated and Non-Isolated DC-DC Converters by Using a New Approach. Renew. Sustain. Energy Rev. 2016, 60, 1100–1113. [Google Scholar] [CrossRef]

- Watanabe, H.; Itoh, J.I.; Koike, N.; Nagai, S. PV Micro-Inverter Topology Using LLC Resonant Converter. Energies 2019, 12, 3106. [Google Scholar] [CrossRef] [Green Version]

- Palacín, M.R.; De Guibert, A. Batteries: Why Do Batteries Fail? Science 2016, 351, 6273. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Fan, L.; Pham, N.D.; Yao, D.; Wang, T.; Wang, Z.; Wang, H. Self-Charging Flexible Solar Capacitors Based on Integrated Perovskite Solar Cells and Quasi-Solid-State Supercapacitors Fabricated at Low Temperature. J. Power Sources 2020, 479, 229046. [Google Scholar] [CrossRef]

- Vlad, A.; Singh, N.; Galande, C.; Ajayan, P.M. Design Considerations for Unconventional Electrochemical Energy Storage Architectures. Adv. Energy Mater. 2015, 5, 1402115. [Google Scholar] [CrossRef]

- Schmidt, D.; Hager, M.D.; Schubert, U.S. Photo-Rechargeable Electric Energy Storage Systems. Adv. Energy Mater. 2016, 6, 1500369. [Google Scholar] [CrossRef]

- Li, Q.; Liu, Y.; Guo, S.; Zhou, H. Solar Energy Storage in the Rechargeable Batteries. Nano Today 2017, 16, 46–60. [Google Scholar] [CrossRef]

- Yu, L.; Chen, G.Z. Redox Electrode Materials for Supercapatteries. J. Power Sources 2016, 326, 604–612. [Google Scholar] [CrossRef]

- Sarif Ullah Patwary, M.S. Smart Textiles and Nano-Technology: A General Overview. J. Text. Sci. Eng. 2015, 05, 1–7. [Google Scholar] [CrossRef]

- Gong, S.; Cheng, W. Toward Soft Skin-like Wearable and Implantable Energy Devices. Adv. Energy Mater. 2017, 7, 1700648. [Google Scholar] [CrossRef] [Green Version]

- Varma, S.J.; Sambath Kumar, K.; Seal, S.; Rajaraman, S.; Thomas, J. Fiber-Type Solar Cells, Nanogenerators, Batteries, and Supercapacitors for Wearable Applications. Adv. Sci. 2018, 5. [Google Scholar] [CrossRef] [PubMed]

- Khan, Y.; Ostfeld, A.E.; Lochner, C.M.; Pierre, A.; Arias, A.C. Monitoring of Vital Signs with Flexible and Wearable Medical Devices. Adv. Mater. 2016, 28, 4373–4395. [Google Scholar] [CrossRef]

- Zurbuchen, A.; Haeberlin, A.; Bereuter, L.; Wagner, J.; Pfenniger, A.; Omari, S.; Schaerer, J.; Jutzi, F.; Huber, C.; Fuhrer, J.; et al. The Swiss Approach for a Heartbeat-Driven Lead- and Batteryless Pacemaker. Hear. Rhythm 2017, 14, 294–299. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Husain, A.; Zi, W.; Guanzhou, L.; Xinfang, J.; Ertan, A.; Fuqiang, L. An Integrated Solar Cell with Built-In Energy Storage Capability. Electrochim. Acta 2020, 349, 136368. [Google Scholar] [CrossRef]

- Zhai, P.; Lee, H.; Huang, Y.T.; Wei, T.C.; Feng, S.P. Study on the Blocking Effect of a Quantum-Dot TiO2 Compact Layer in Dye-Sensitized Solar Cells with Ionic Liquid Electrolyte under Low-Intensity Illumination. J. Power Sources 2016, 329, 502–509. [Google Scholar] [CrossRef]

- Luo, J.; Yao, X.; Yang, L.; Han, Y.; Chen, L.; Geng, X.; Vattipalli, V.; Dong, Q.; Fan, W.; Wang, D.; et al. Free-Standing Porous Carbon Electrodes Derived from Wood for High-Performance Li-O2 Battery Applications. Nano Res. 2017, 10, 4318–4326. [Google Scholar] [CrossRef]

- Shamshiri, M.; Gan, C.K.; Sardi, J.; Au, M.T.; Tee, W.H. Design of Battery Storage System for Malaysia Low Voltage Distribution Network with the Presence of Residential Solar Photovoltaic System. Energies 2020, 13, 4887. [Google Scholar] [CrossRef]

- Wu, Y.; Li, C.; Tian, Z.; Sun, J. Solar-Driven Integrated Energy Systems: State of the Art and Challenges. J. Power Sources 2020, 478, 228762. [Google Scholar] [CrossRef]

- Zhang, K.; Han, X.; Hu, Z.; Zhang, X.; Tao, Z.; Chen, J. Nanostructured Mn-Based Oxides for Electrochemical Energy Storage and Conversion. Chem. Soc. Rev. 2015, 44, 699–728. [Google Scholar] [CrossRef]

- Dong, P.; Rodrigues, M.F.; Zhang, J.; Borges, R.S.; Kalaga, K.; Reddy, A.L.M.; Silva, G.G.; Ajayan, P.M.; Lou, J. A Fl Exible Solar Cell/Supercapacitor Integrated Energy Device. Nano Energy 2017, 42, 181–186. [Google Scholar] [CrossRef]

- Teo, J.C.; Tan, R.H.G.; Mok, V.H.; Ramachandaramurthy, V.K.; Tan, C. Impact of Partial Shading on the P-V Characteristics and the Maximum Power of a Photovoltaic String. Energies 2018, 11, 1860. [Google Scholar] [CrossRef] [Green Version]

- Salameh, W.; Castelain, C.; Faraj, J.; Murr, R.; El Hage, H.; Khaled, M. Improving the Efficiency of Photovoltaic Panels Using Air Exhausted from HVAC Systems: Thermal Modelling and Parametric Analysis. Case Stud. Therm. Eng. 2021, 25, 100940. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).