1. Introduction

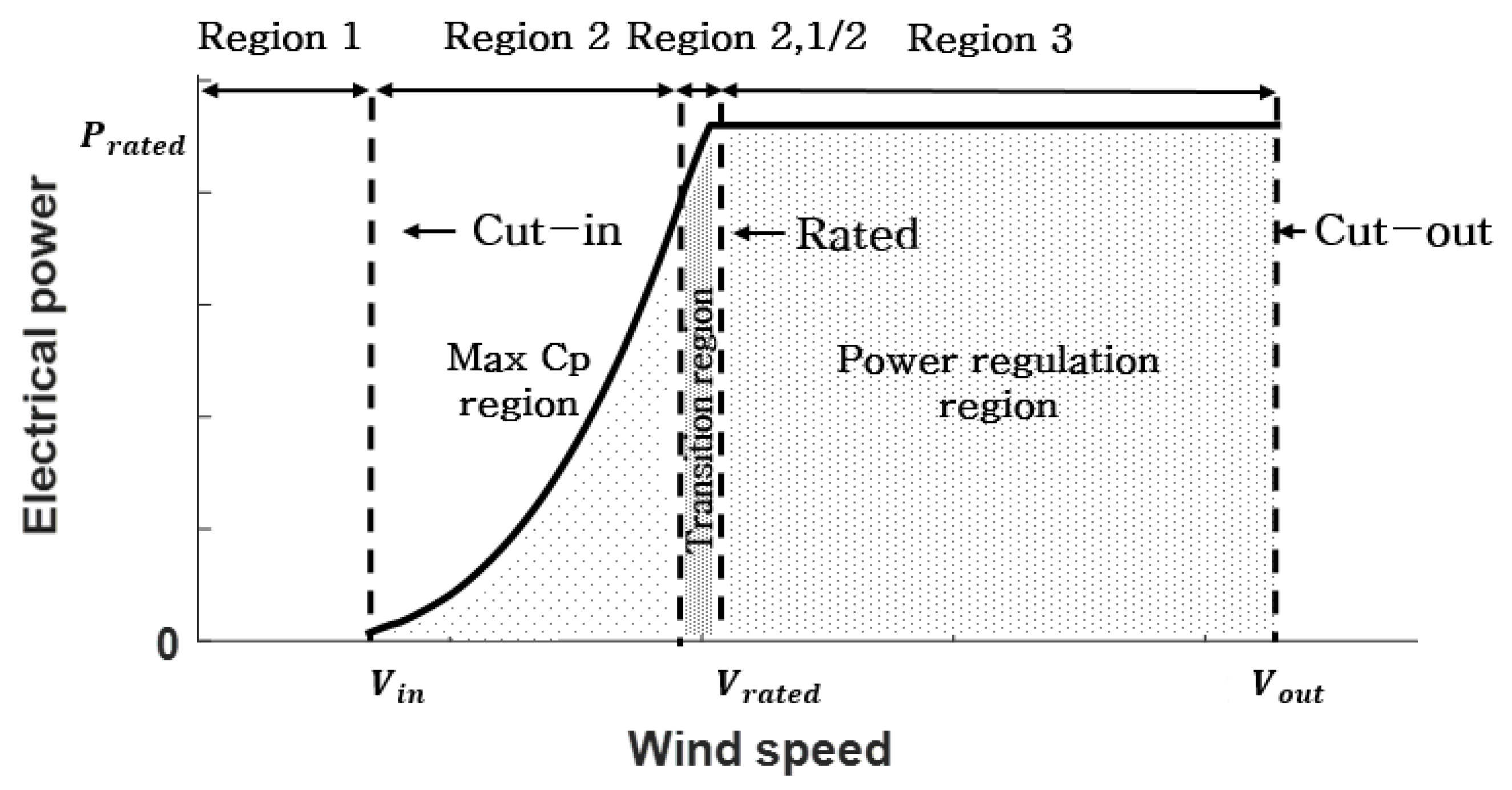

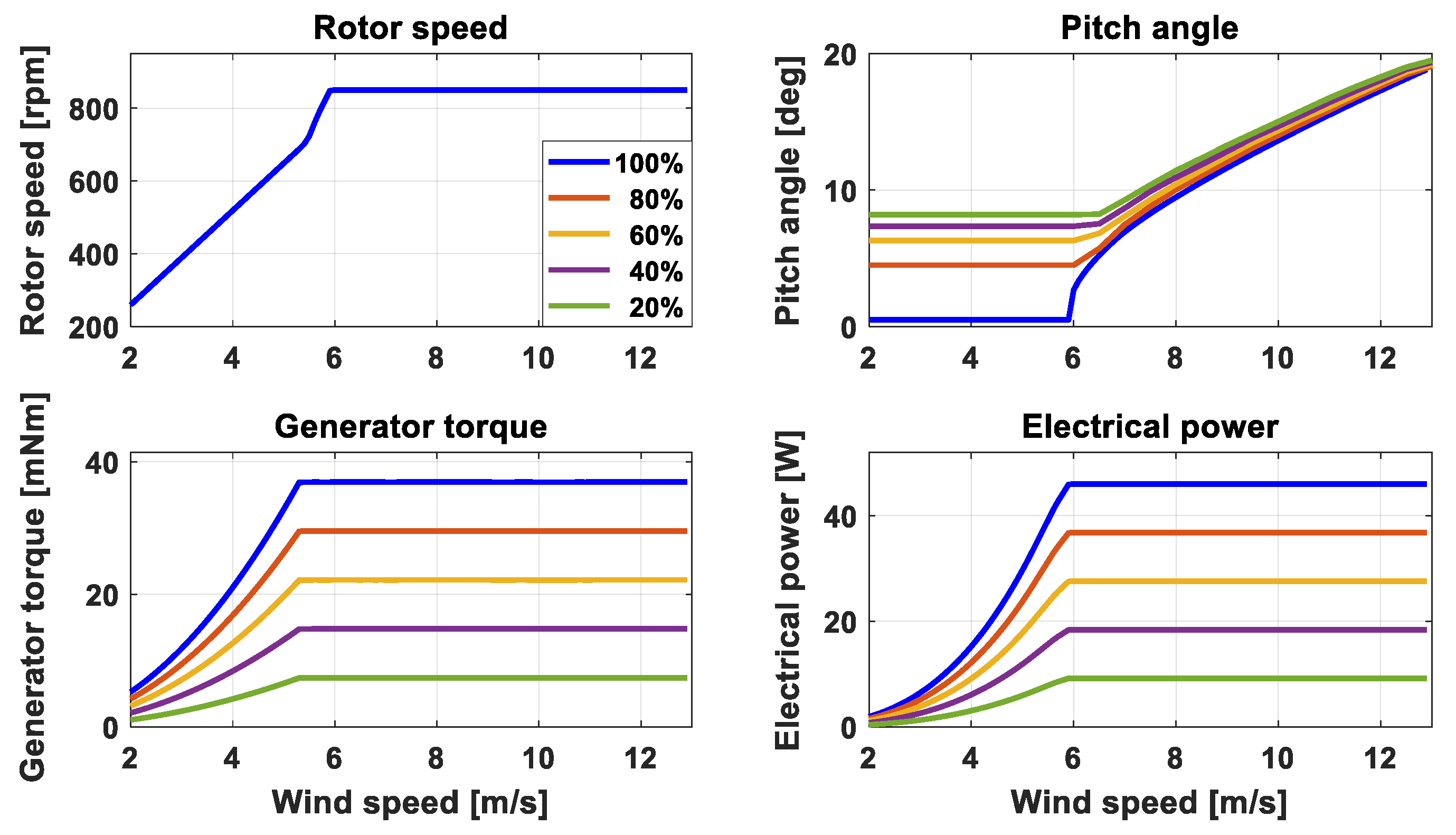

Wind turbine control systems are implemented to allow the wind turbines to operate automatically while responding appropriately to changes in wind speed and direction. In a region with wind speeds lower than the rated wind speed, the generator torque is controlled to ensure that the wind turbine tracks the maximum power points while the blade pitch angle is maintained at the fine pitch angle. In a region with a speed higher than the rated wind speed, the blade pitch angle is controlled to maintain the rated generator speed of the wind turbine, and at the same time, the generator torque is fixed at the rated value or slightly adjusted to maintain the rated power [

1].

This basic power control of wind turbines can be achieved by either single-input single-output (SISO) or multiple-input multiple-output (MIMO) control, based on the way they deal with inputs and outputs. The PI or PID control, which has been utilized in various fields as a classical SISO control, has been conventionally implemented to control wind turbines. This method consists of two SISO loops, each capable of controlling the blade pitch angle and the generator torque, to generate power with different strategies for different wind speed regions [

1]. SISO control algorithms for wind turbines were further developed to provide new strategies for improving power performance and reducing mechanical load.

Drivetrain dampers are used to reduce the fatigue load of the low-speed shaft caused by the vibrations of the drivetrain torsional mode [

2]. This damper increases the damping ratio of the drive train by calculating the torque command for the generator speed signal through the band pass filter. Tower dampers are known to reduce the vibrations of tower fore-aft mode in the rated power region [

3]. This damper consists of a proportional control loop of the pitch angle relative to the nacelle acceleration signal with the phase compensator to secure phase margins. The tower vibration could also be reduced by torque commands through resonance avoidance strategies [

4]. Peak shaving using additional pitch angles for situations where rotor speed is rapidly increasing can avoid frequent shutdowns of wind turbines due to gusts [

5]. The feed-forward pitch control method using a wind-speed estimator alleviates power fluctuations in the rated power region [

6]. Using artificial neural networks and genetic algorithms helped to address the power tracking problem in the SISO control loop for unpredictable wind uncertainty, improving its performance [

7]. These algorithms are implemented as a feed-forward loop so that the maximum power can be tracked in the conventional PI control loop.

However, because this SISO control is based on a single input, all the effects caused by various wind turbine states cannot be considered simultaneously for control. This is an avoidable constraint on the improvement of the controller performance. Therefore, MIMO control, which can simultaneously take into account various states of wind turbines, was investigated as an alternative allowing for better performance.

By designing an LQR controller using multiple state feedback control methods, simulations demonstrated a reduction in power variation of up to 46% and a 20% reduction in tower load compared to the conventional PI control algorithm [

8]. Studies were also conducted on LQG algorithms with noise-considered state estimators using Kalman filters, and simulations have shown up to a 24% reduction in power variation and a 66% blade load reduction compared to the conventional PI control algorithms [

9]. The MPC method showed a torsional load reduction performance of up to 52% for low-speed shafts through hardware in the loop system when compared to the conventional PI control algorithms [

10]. The control technique for considering the nonlinearity of wind turbines was also studied by applying fuzzy inference techniques to the optimal control algorithms. Up to a 39% power variation reduction and a 13% tower vibration reduction were confirmed through wind tunnel experiments using an LQR control algorithm based on fuzzy logic (LQRF) [

11]. During dynamic simulation, the

control showed a tower and blade fatigue load reduction of up to 8% and 26%, respectively, compared to the conventional PI control algorithms [

12].

Unlike the wind turbine control algorithms, which are used to improve the load and the power of individual wind turbines, control algorithms to increase the total power production of wind farms, and have recently become a topic of interest [

13,

14,

15]. In this case, the upstream wind turbines must be controlled such that they do not to track their own maximum power point, but instead track the power demand from a wind farm controller, which is slightly lower than the maximum power point [

14]. This results in a slight decrease in the power output of the upstream wind turbines, but an increase in the power output of the downstream wind turbines. As the result, an increase in the total power of the wind farm is achieved. This approach is known as active induction control [

15].

For active induction control to be implemented in a real wind farm, the individual wind turbine controller must be modified appropriately regardless of the control types being employed (i.e., SISO or MIMO controllers). The wind turbine controller needs to operate using its original power control when there is no power demand from a wind farm controller, but must track the power demand whenever it occurs. This is known as active power control (APC) or demanded power point tracking (DPPT) control.

Jeong et al. proposed several APC methods [

16]. Through simulations and field tests with a 550 kW wind turbine, a method to obtain rotor speed set-points according to demanded power points was proposed, using the generator torque and blade pitch angle together. A study by Kim et al. used a mode switch to turn on the demanded power point tracking control according to power commands from a wind farm controller [

17]. The proposed algorithm was validated by using a wind tunnel experiment and a field test with a 100 kW wind turbine [

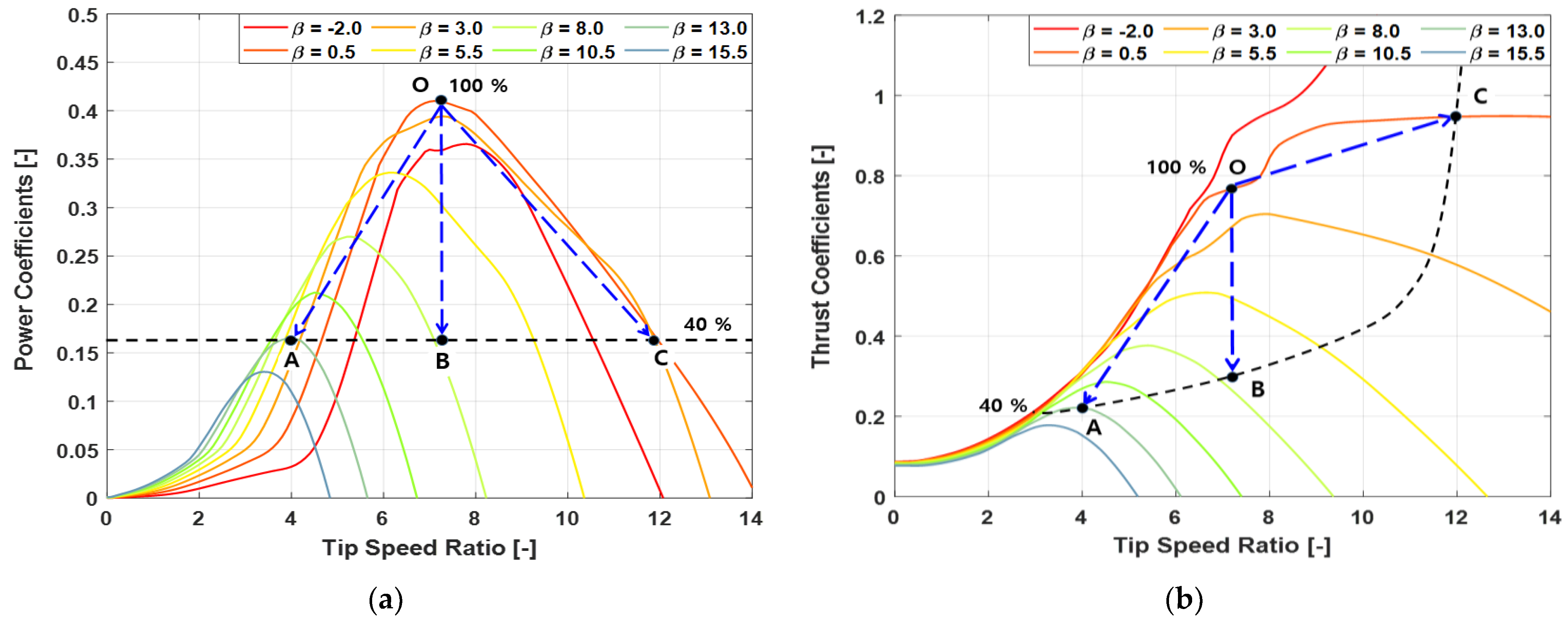

18]. Bottasso et al. considered partialization using a strategy to maintain a constant tip speed ratio (TSR) [

19]. The proposed control algorithm was verified on a motor-generator set simulator, but no experimental verification was performed using wind turbines.

The DPPT algorithms previously proposed in the literature showed promising power tracking capabilities. However, all of them were applicable to the classical SISO control algorithms (PI or PID) of a wind turbine, but cannot be implemented for MIMO control algorithms. Furthermore, although the superior control performance of modern MIMO control algorithms has been demonstrated, no DPPT controls, which can be implemented for MIMO control, were found in the existing literature.

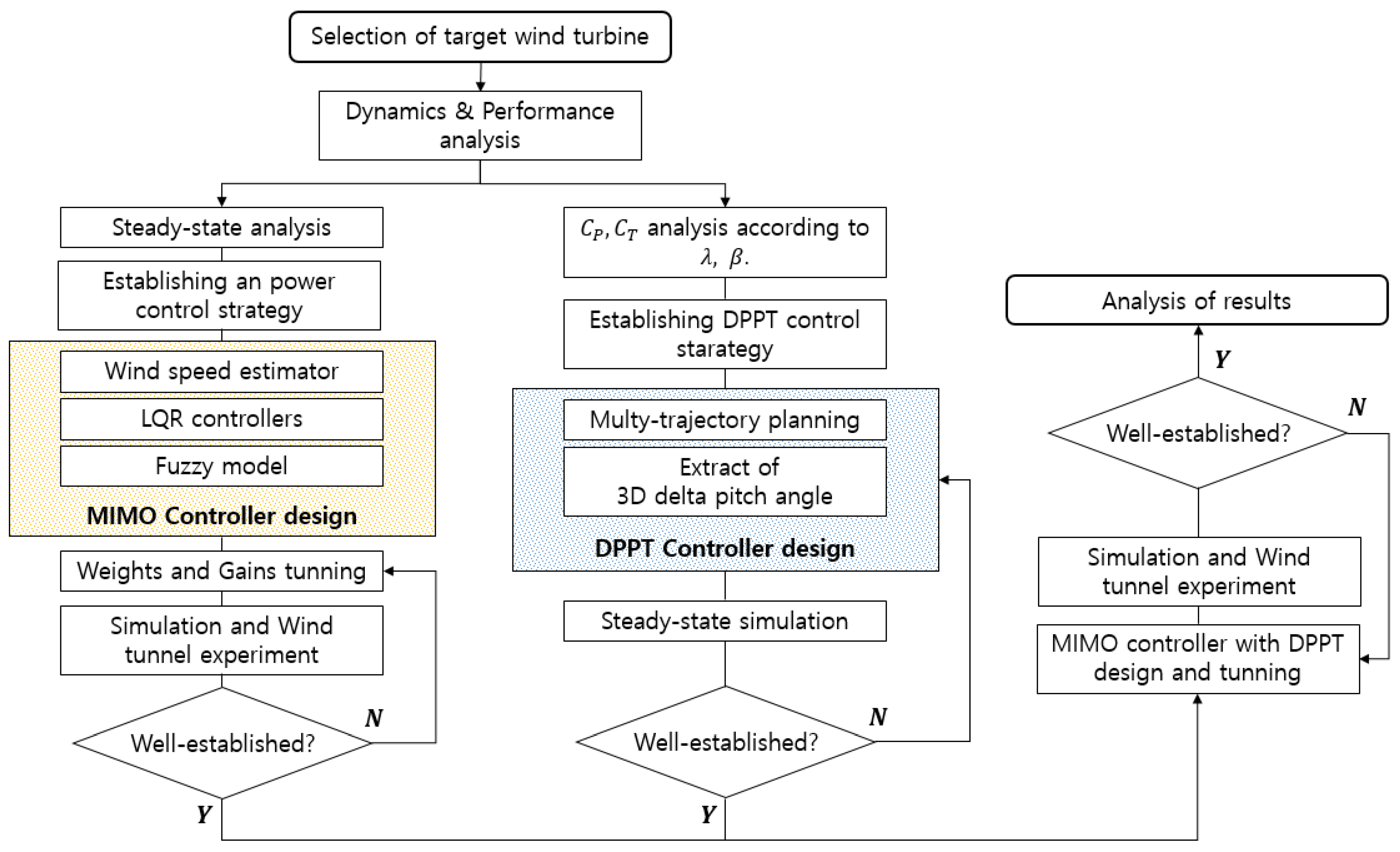

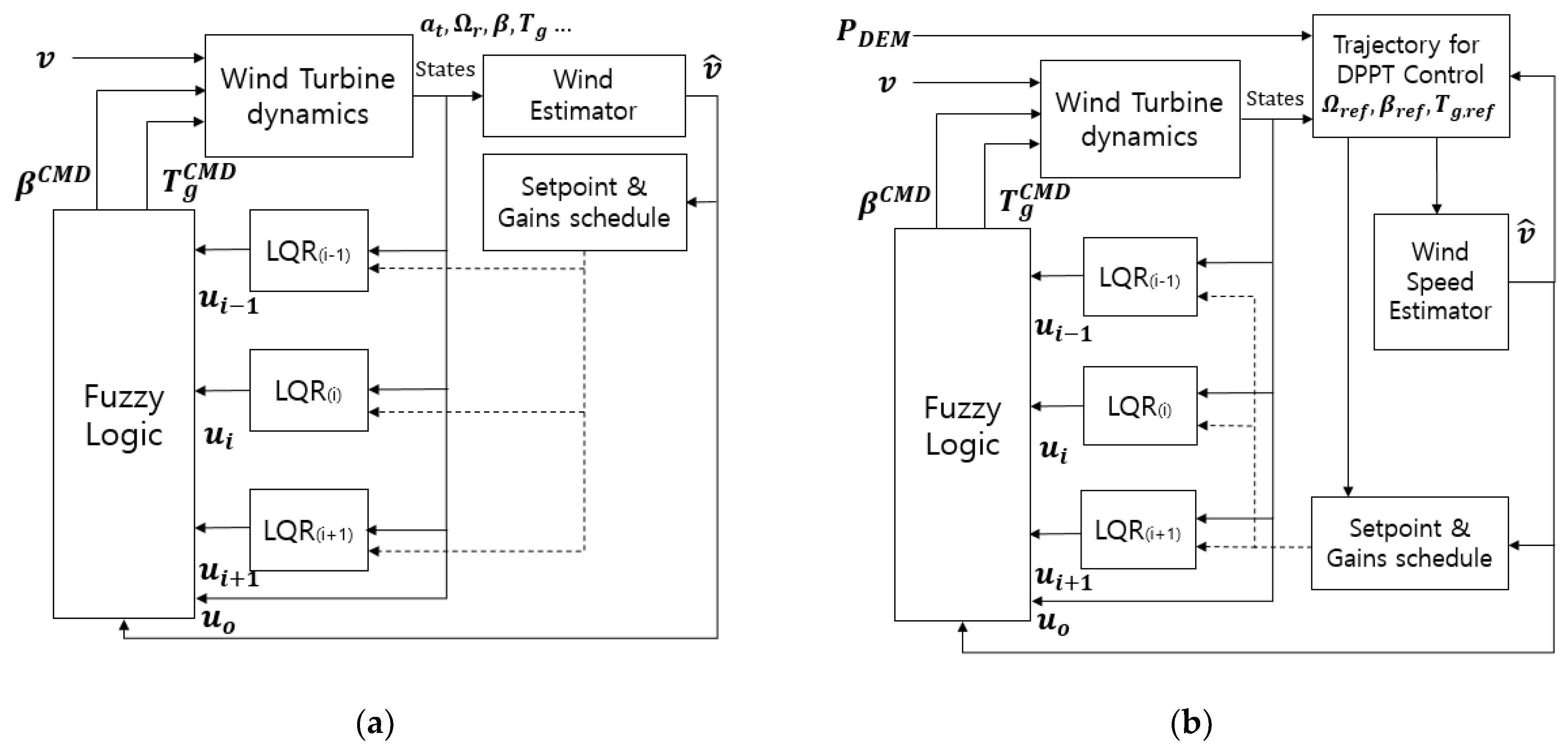

Therefore, the purpose of this study is to design a demanded power point tracking (DPPT) control algorithm for application to an MIMO-type modern control algorithm (LQRF) and to verify its tracking performance through wind tunnel experiments. The proposed DPPT control algorithm for application to an MIMO controller cannot be designed solely using the rotor speed feedback method applied to conventional PI control algorithms. Thus, a suitable DPPT control method was applied to modern control algorithms based on an MIMO that used a multiple reference trajectory method.

The originality and contribution of this study can be summarized as follows:

The proposed DPPT control algorithm was designed to be applied to a variety of MIMO modern control algorithms, instead of to traditional PI control methods. Previous studies have shown that despite the satisfactory performance of the MIMO-type modern control algorithms, they have not yet been used for studies on the design and validation of DPPT controllers for wind farm control. Therefore, strategies for applying conventional DPPT control techniques to modern MIMO control algorithms that have completely different structures from classical PI control are analyzed herein. The DPPT controller was designed using multiple reference trajectory techniques without mode switches in order to suit MIMO-type modern control algorithms, and was experimentally validated through simulations and wind tunnel experiments. To ensure the validity and suitability of the proposed control algorithm, the proposed DPPT control algorithm was compared with the DPPT control algorithm developed in previous studies, and their control performance was analyzed through simulations. The results of this study are expected to serve as a reference study which will enable wind farm controllers to control individual wind turbines by using MIMO-type modern control algorithms.

This paper consists of six sections.

Section 2 describes the target wind turbine used for verifying the controller.

Section 3 provides a description of the control strategy and the controller design.

Section 4 describes the simulations and wind tunnel experiments performed to validate the proposed control algorithm. The control response to tracking the demanded power from the wind farm controller is confirmed by the time-series data.

Section 5 compares the control performance with other DPPT control algorithms through a dynamic simulation to enhance the validity of the proposed control algorithm. Lastly,

Section 6 describes the conclusions of this study.

4. Controller Validation

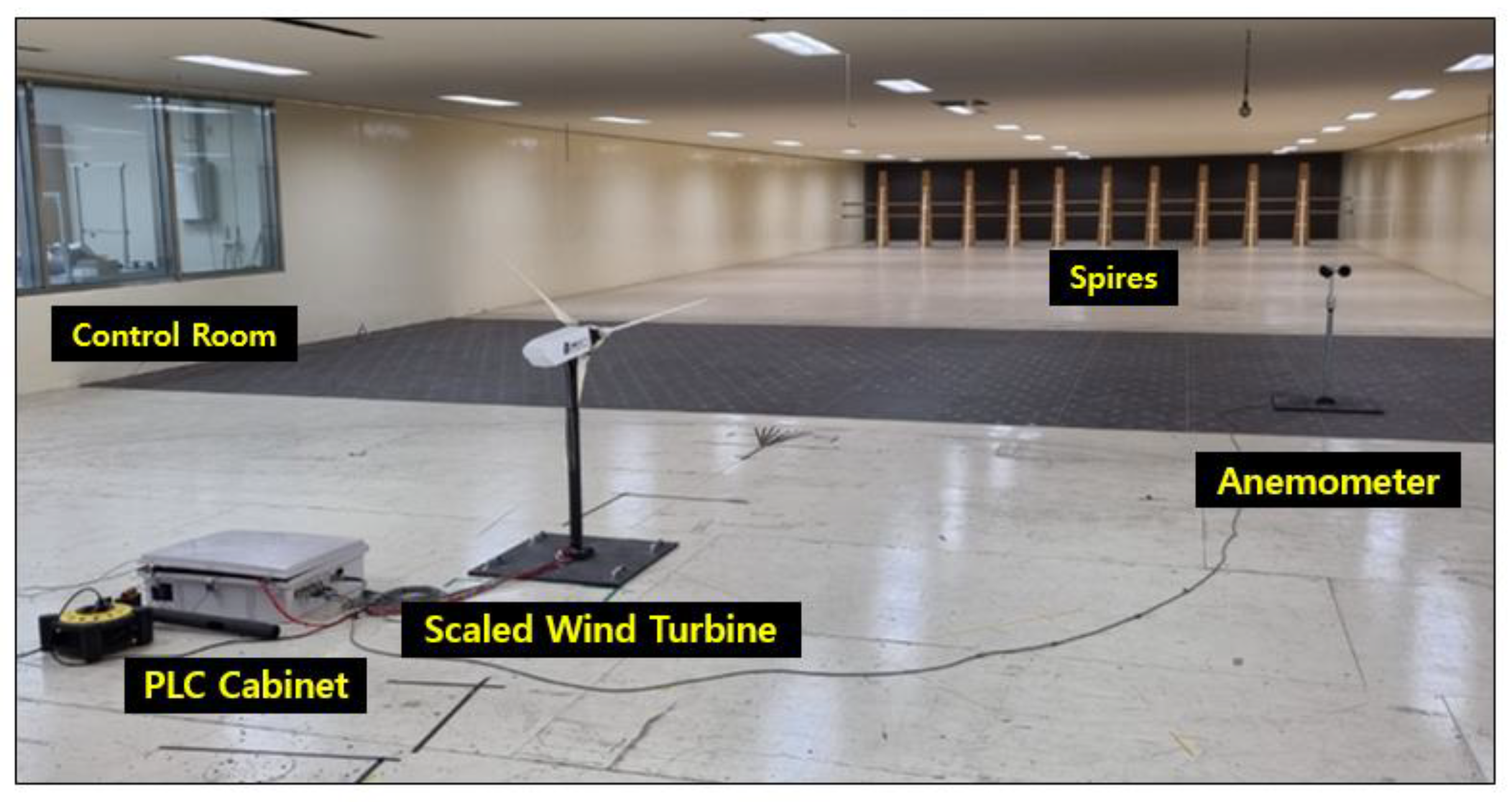

The performance and applicability of the proposed DPPT control algorithm for the MIMO controller (KNUm) were validated by conducting a wind tunnel experiment at a large wind tunnel test center (Jeolla-do, Korea). The wind tunnel is an internal circulation structure wherein the first and second floors are circulated. The experiment was conducted in the wind tunnel on the first floor, a low wind speed test floor. The dimensions of the wind tunnel were 40 × 12 × 2.5 m. The wind tunnel was observed from the control room. The personal computer (PC) in the control room and programmable logic controller (PLC) in the wind tunnel were connected in order to monitor and operate the scaled wind turbine. The C++ code-based controllers were uploaded to the PLC to control the actuators of the scaled wind turbine in real time (250 Hz sampling). The wind conditions were implemented using large blowers and hot-wire anemometers, and a 10% turbulence intensity was implemented using spire structures to perform more realistic wind tunnel experiments. The experiments were conducted by implementing wind conditions in region 2 (4.6 m/s) and region 3 (7.3 m/s) to confirm that the proposed control algorithm tracked the reference trajectory shown in

Table 2.

Figure 9 shows the control experiments performed using a scaled wind turbine inside a wind tunnel.

Furthermore, to validate the proposed control algorithm, the wind tunnel experiments’ results were comparatively analyzed using dynamic simulation results. The dynamic simulations were performed using the DNVGL-bladed commercial program. The C++ code-based controller was extracted into a dynamic link library (DLL) file using Visual Studio. The extracted controller was mounted on a scaled wind turbine numerically modeled using the DNVGL-Bladed program. Average wind speeds of approximately 4.6 and 7.3 m/s, with a turbulence intensity of 10%, were applied to create wind conditions similar to those in the wind tunnel experiments. Since the control systems covered in this study were mechanical controls using pitch and torque actuators, the reactive power was not considered. Therefore, the electrical power from the simulation was assumed to be the active power.

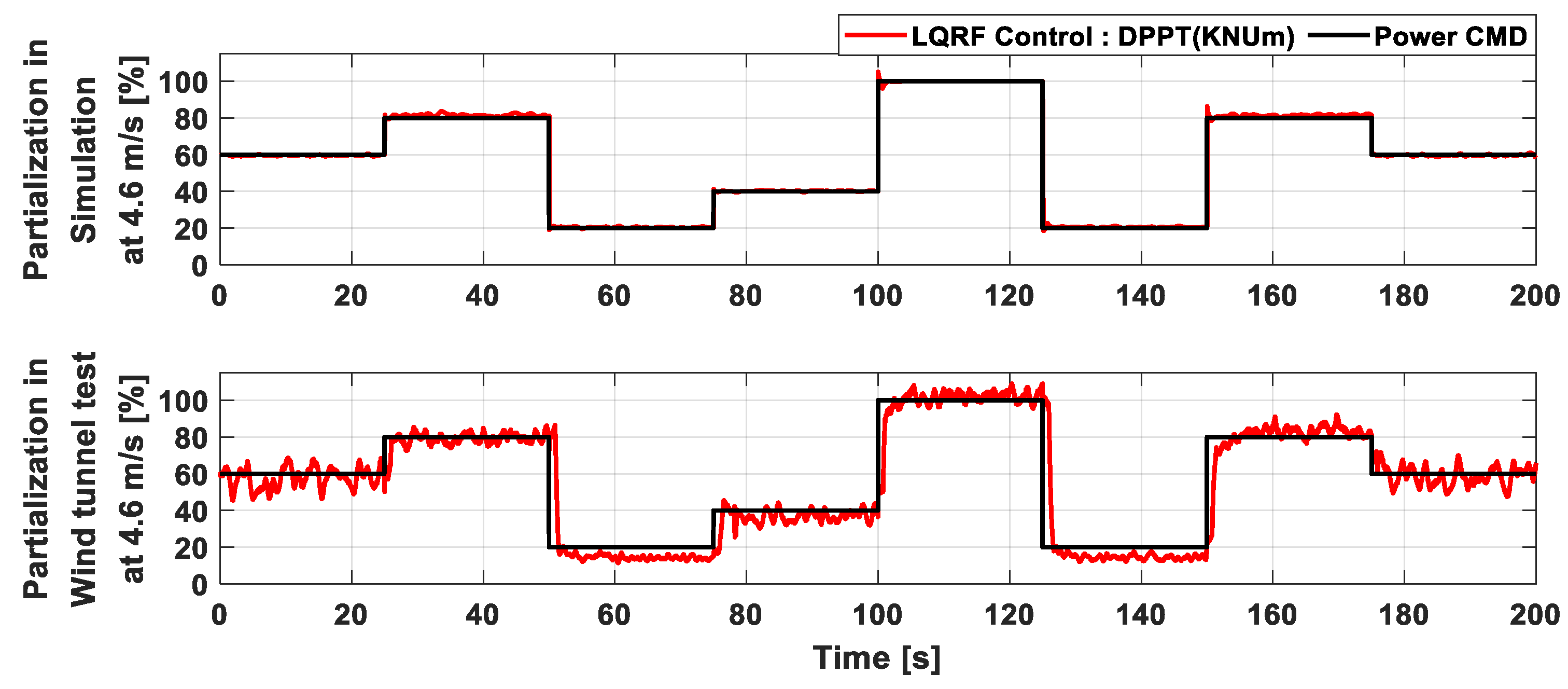

Figure 10 shows the results and of the simulation and the wind tunnel experiment for the proposed DPPT control algorithm for an MIMO controller at an average wind speed of 4.6 m/s. Both the simulation and wind tunnel experiment were implemented in situations wherein 60%-80%-20%-40%-100%-20%-80%-60% power commands were transmitted from the wind farm controller at intervals of 25 s, for a total operation time of 200 s. The sequence of power commands was arbitrarily selected in order to verify the tracking performance of the proposed control algorithm. The windows of the simulation results in

Figure 10 represent wind speed, rotor speed, blade pitch angle, generator torque, and electrical power, respectively.

Figure 10a shows the dynamic simulation results of the proposed control algorithm for an average wind speed of 4.6 m/s. It was confirmed that DPPT control occurred while maintaining the rotor speed according to the DPPT B strategy, as shown in

Figure 4. Additionally, it was confirmed that, as the demanded power decreased, the pitch angle used increased to a value as high as the delta pitch angle in

Figure 5, and the torque became as low as the partialization factor.

Figure 10b shows the results of the wind tunnel experiment with the proposed control algorithm for an average wind speed of 4.6 m/s. In the wind tunnel experiments, the same winds were not re-implemented in the time series, so the experiment was performed twice with the same average wind speed (4.6 m/s) at the same turbulence intensity (10%). However, as in the simulation results, it was confirmed that the same rotor speed level was maintained in accordance with the DPPT B strategy, and the pitch angle and torque control were performed to track the power command. Additionally, high-frequency components were observed for most signals owing to the influence of measurement noise, which was absent in the simulation results.

The power commands and controlled power results are shown in

Figure 11 can be used to closely check the tracking performance of the proposed DPPT control algorithm. The controlled results indicate that the percentage of the power divided by the available power is comparable to the power commands. The simulation and wind tunnel test results indicate that the power commands were well tracked, but the wind tunnel test results showed increased tracking deviation. These differences appear to stem from the measurement noise generated from experiments and the uncertainty in numerical modeling. Additionally, in some cases where the power command is delivered in

Figure 10, the rotor speed decreases slightly. As a result, the power in

Figure 11 also decreases slightly. Since simulations always feature more ideal conditions than those found in experiments, the operating conditions of the wind turbine may differ slightly between the simulations and wind tunnel experiments. However, these differences did not significantly affect the performance of wind turbines, and the overall result is that the power commands from the controller were properly tracked.

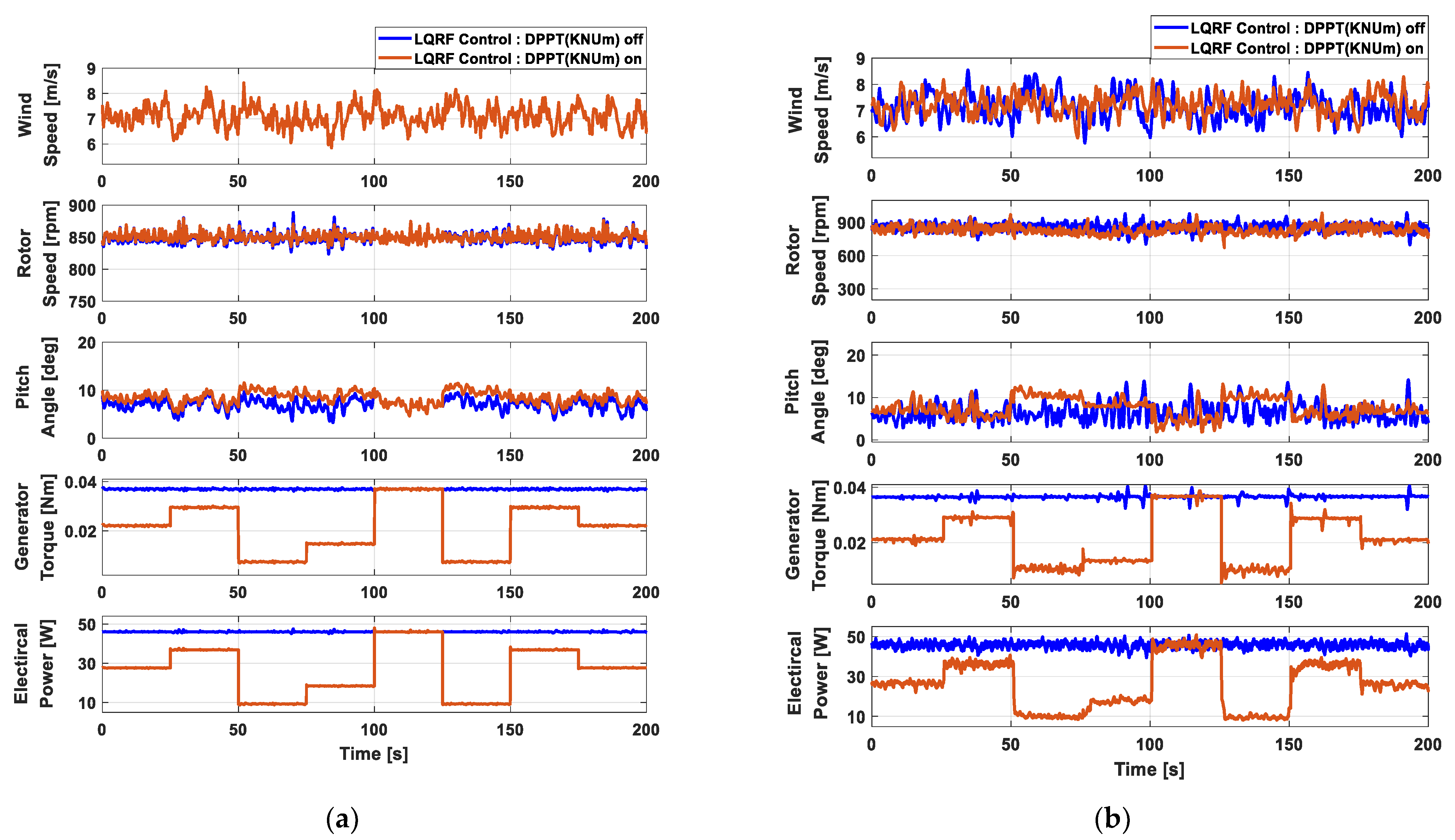

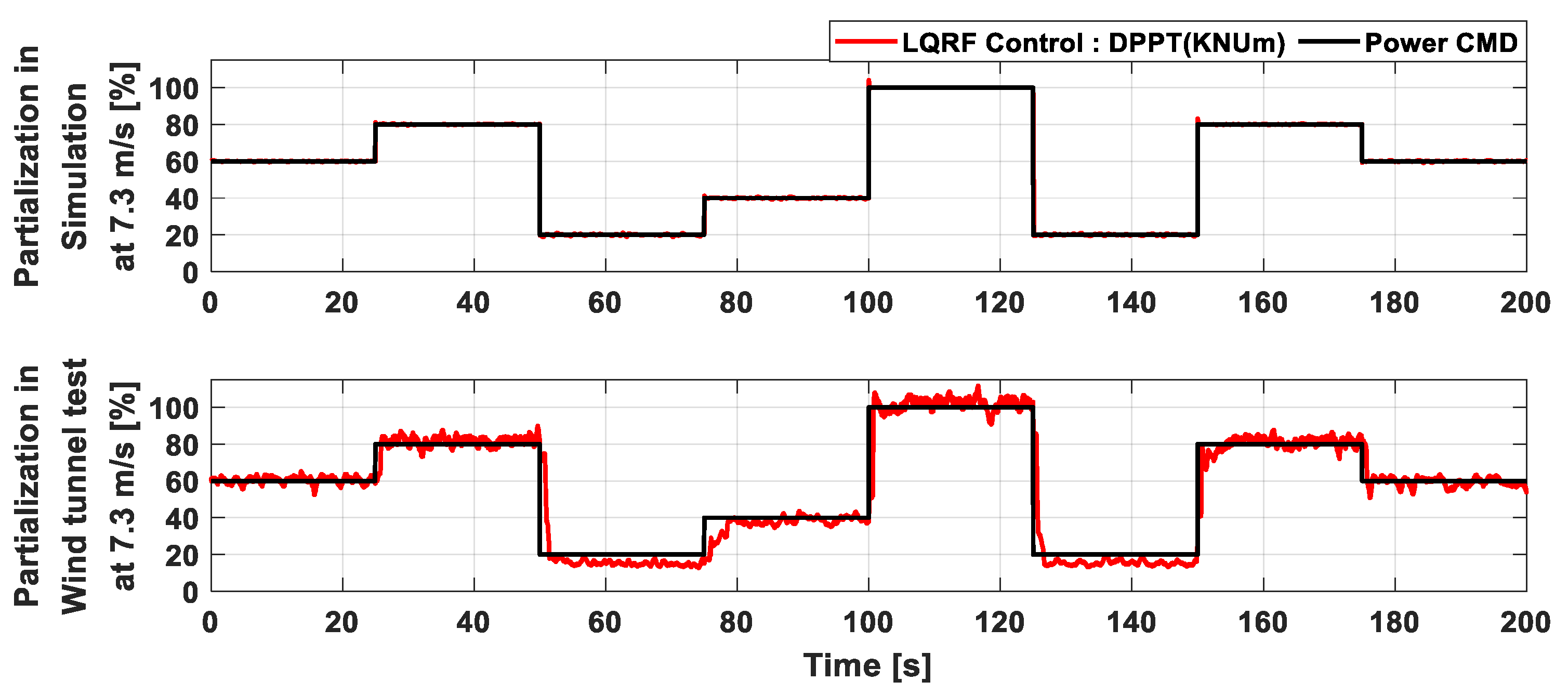

Figure 12 shows the results of the simulation and wind tunnel experiment for the proposed DPPT control algorithm for the MIMO controller at an average wind speed of 7.3 m/s. The same power commands were sent as in the simulation shown in

Figure 10, for a total duration of 200 s.

Figure 12a shows the results of the dynamic simulation of the proposed control algorithm at an average wind speed of 7.3 m/s. The strategic characteristics of the DPPT B strategy shown in

Figure 10a are the same as those shown in

Figure 12a. While maintaining the rotor speed in order to track the demanded power point, it was confirmed that the pitch angle was as high as the delta pitch angle and the torque was as low as the partialization factor.

Figure 12b shows the results of the wind tunnel experiment for the proposed control algorithm at an average wind speed of 7.3 m/s. Similar measurement noise was observed as in

Figure 10b.

Figure 13 is presented to closely check the tracking performance of the proposed control algorithm, which is shown in

Figure 12. Overall, the results in

Figure 12 and

Figure 13 were found to track the power commands more clearly than the results in

Figure 10 and

Figure 11. This difference is due to the strategy of tracking the maximum power point, which minimizes the pitch control in

Figure 10 (region 2). As a result, the overall control performance of the proposed DPPT control algorithm was found to be suitable for all regions.

5. Discussion

In this study, the proposed control algorithm (KNUm) was compared with the previously studied DPPT algorithm (KNU2) for the classical control algorithm, in order to further analyze the improved performance and validity of the proposed control algorithm through a dynamic simulation [

17,

18]. The KNU2 control algorithm was previously validated through wind tunnel experiments using a scaled wind turbine. The KNU2 control algorithm is a DPPT control algorithm based on the DPPT strategy for use as a conventional PI control algorithm, and its validity was authenticated by conducting field tests using a medium wind turbine. Additionally, owing to its ease of accessibility, it can be easily implemented as a valid control algorithm. Therefore, the KNU2 control algorithm was adopted as a target for a comparative validation of the validity and improved control performance of the proposed control algorithm in this study.

Figure 14 shows the block diagram of the classical control algorithm and the classical control-type DPPT control algorithm, which was studied previously.

Figure 14a represents a classic PI control algorithm. Based on the power control strategy shown in

Figure 3, pitch PI control and scheduled torque control are performed by a mode switch action.

Figure 14b shows the addition of the DPPT control algorithm to

Figure 14a. A look-up table was applied in order to output the reference rotor speed as the input of the power command from the wind farm controller. The mode switch and torque control conditions were modified for DPPT control [

17].

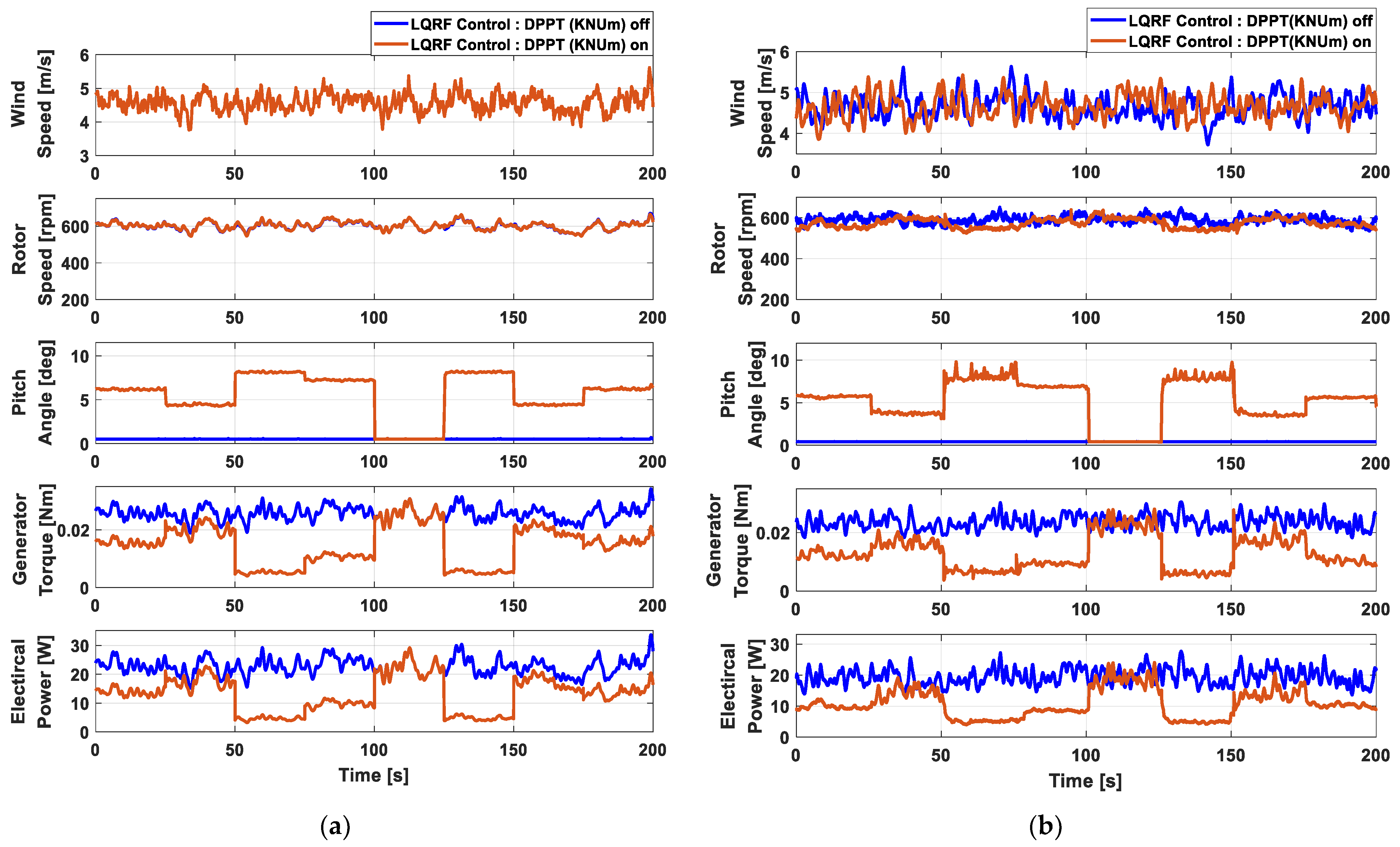

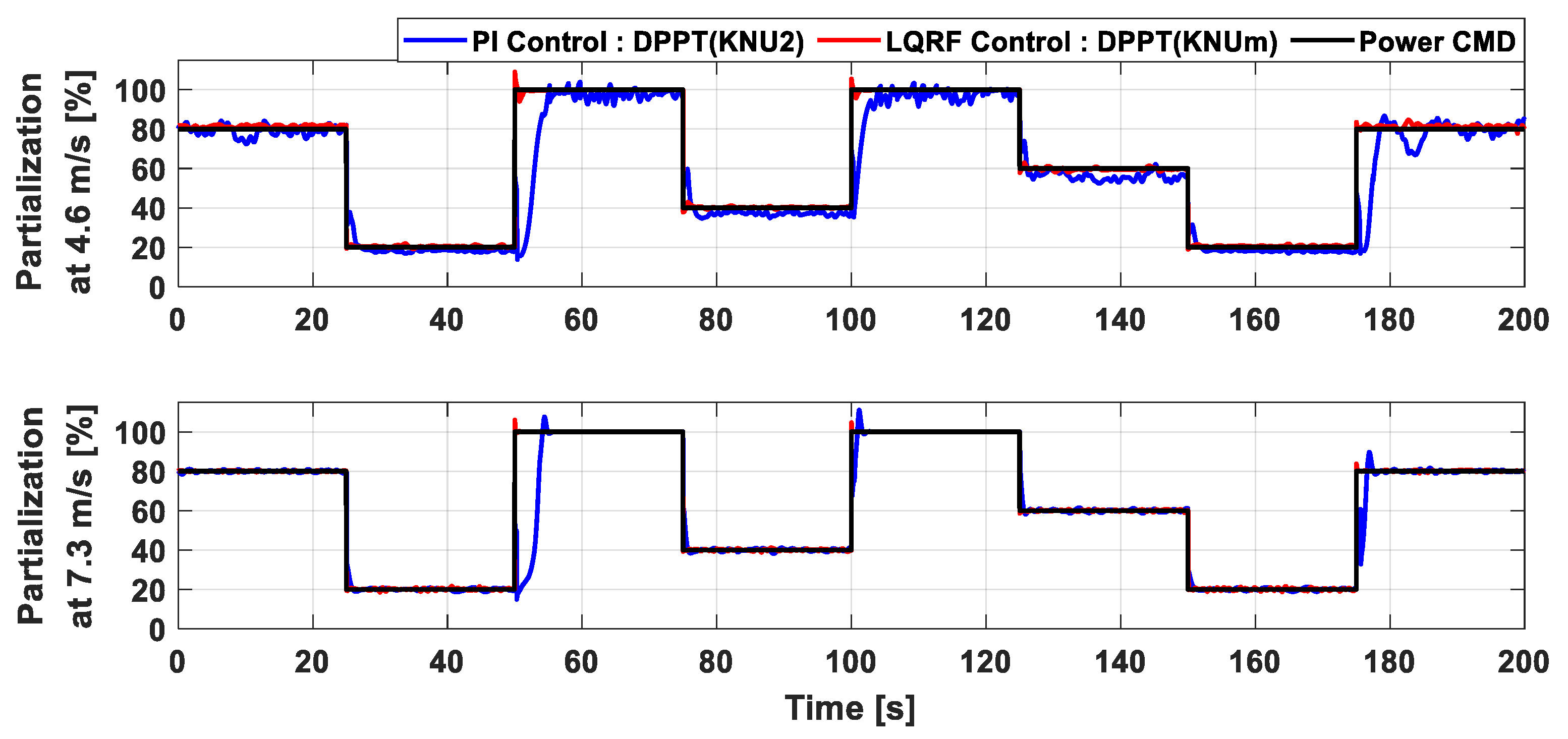

Figure 15 shows the comparative results of the dynamic simulation using the DPPT controller with the classical control algorithm (KNU2) and the modern control algorithms (KNUm) at mean wind speeds of 4.6 and 7.3 m/s. The simulation was implemented by transmitting 80%-20%-100%-40%-100%-60%-20%-80% power commands from the wind farm controller at intervals of 25 s. The sequence of power commands was arbitrarily re-selected to verify the tracking performance of the designed control algorithms.

Figure 15a shows the simulation results obtained under a turbulence intensity of 10% and an average wind speed of 4.6 m/s. The DPPT control algorithms of the PI and LQRF controllers were compared using the simulation results, depending on the transmission of power commands from the wind farm controller. It was confirmed that the pitch angles were used more when using the KNU2 controller with the DPPT A strategy than when using the KNUm controller with the DPPT B strategy, as shown in

Figure 4. As a result, at approximately 50, 100, and 175 s, the time required to track the required power command slowed down each time the power command changed, due to the rotor speed slowing down or increasing rapidly. Furthermore, because the rotor speed was reduced by the use of several pitch angles when using the KNU2 controller, it was confirmed that a lower torque was required in order to track the power commands.

Figure 15b shows the simulation results under a wind turbulence intensity of 10% and an average wind speed of 7.3 m/s. Overall, the characteristics according to the DPPT strategy were similar to those shown in

Figure 15a, but were found to be more pronounced. As illustrated in

Figure 12, this occurs because the available power in region 3 becomes constant at the rated power, resulting in pitch control to control it.

The numerical comparison results of the simulation are given in

Table 3. To understand the structural stability of wind turbines and the state of stable power production, the mean and standard deviation for the rotor speed and power, and tower fore-aft vibration, were selected as the indicators for evaluating the performance of the proposed controller. Compared to the PI control in the situation where the DPPT was off, torque and pitch control were performed by the LQRF algorithm whenever the deviation was likely to be severe, considering the rotor speed and tower vibration deviation. As a result, the rotor speed deviation was reduced by 23.44%, the power deviation by 41.83%, and the tower vibration by 17.24% at an average wind speed of 7.3 m/s. At an average wind speed of 4.6 m/s, not only is it important to reduce the standard deviation, but also to track the maximum power point by the power strategy, so the effect of reducing the deviation was less than at an average wind speed of 7.3 m/s. In the situation where the DPPT was on, the mean rotor speed and tower vibration increased owing to the use of a smaller pitch angle by the KNUm strategy compared to the KNU2 strategy. On the other hand, the standard deviation of the rotor speed and the tower vibration was reduced due to the control performance of the LQRF control and the KNUm strategy of maintaining the same rotor speed level according to the demanded power command.

The power commands and controlled power results in

Figure 15 are shown in

Figure 16 to compare the tracking performance of the two DPPT control algorithms. The tracking performance of the two control algorithms was found to be better in region 3 (7.3 m/s) than in region 2 (4.6 m/s), similar to the result in

Figure 13. Although the KNUm control algorithm used a lower pitch angle than KNU2, it maintained a constant rotor speed, increasing the stability of the control system relative to the rotor speed. As a result, the control performance and suitability of the proposed DPPT control algorithm were acceptable.

Table 4 shows a quantitative comparison of the tracking performance of the two DPPT control algorithms for the demanded power in

Figure 16. The tracking performance was evaluated using the mean absolute error (MAE) and the mean square error (MSE) for the demanded power command. Overall, the KNUm controller had a lower error than the KNU2 controller. In region 2, the difference was up to approximately 4.3% for the MAE and up to approximately 10.4% for the MSE. In region 3, the difference was up to approximately 1.8% for the MAE and up to approximately 8.8% for the MSE.

6. Conclusions

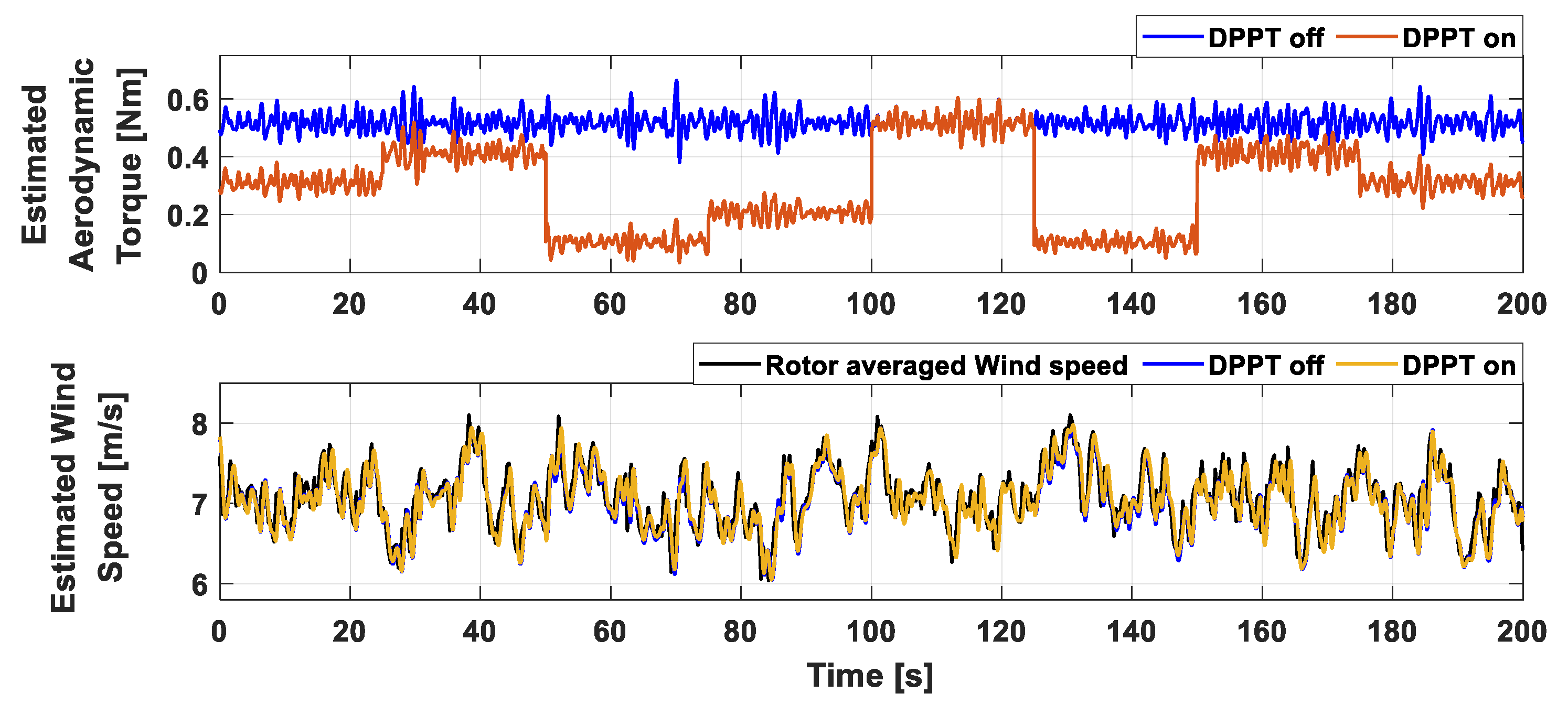

In this study, a DPPT controller was designed for use with a MIMO-type modern control algorithm. The proposed DPPT control algorithm was implemented without mode switches by using multiple reference trajectory. The LQRF control algorithm using wind speed estimators was selected as the target MIMO-type modern control algorithm. The validity of the use of wind-speed estimators for the DPPT algorithms was examined. Although low aerodynamic torque occurred due to DPPT control action, the normal wind speed was maintained because of the reduced torque coefficient stemming from the pitch angle use.

Dynamic simulations and wind tunnel experiments were performed using a scaled wind turbine to validate the proposed control algorithm. Average wind speeds of 4.6 m/s and 7.3 m/s, corresponding to region 2 and region 3, were applied with a turbulence intensity of 10%. Overall, the tracking performance in region 3 was superior to that in region 2, which was attributed to differences in pitch control between the regions based on different power control strategies. In the wind tunnel experiments, variations tended to increase more than in the simulations because of measurement noise and uncertainty problems in numerical modeling. However, both sets of results showed satisfactory tracking performance for demand power commands from the wind farm controllers.

The control performance of the proposed DPPT control algorithm (KNUm) for the MIMO controller was compared with the performance of a previously studied classical control-type DPPT control algorithm (KNU2) through dynamic simulations. KNU2 control algorithms used strategies that produced significant wake deficit effects, although they tended to increase their tracking response time due to the rapid change in rotor speed caused by the use of large pitch angles. The KNUm control algorithm used relatively small pitch angles, but the rotational speed level was preserved. That is, by ensuring the stability of the LQRF control algorithm, rapid tracking response times were achieved and the transient response of the pitch angle was reduced. Specifically, the proposed DPPT control algorithm was confirmed to be suitable for operating the MIMO-type control algorithm.

Overall, this study conducted dynamic simulations and wind tunnel experiments to authenticate the validity, applicability, and tracking performance of the proposed KNUm control algorithm. However, a compromise or optimization problem remains when trying to simultaneously optimize the wake reduction performance and the stability of the control system. Therefore, further studies should be conducted on how to optimize the reference trajectory for power commands. Optimization problems may be studied in conjunction with wind farm control algorithms using machine learning techniques and aerodynamic data from the target wind turbines. Additionally, a study on the control of wind farms using various MIMO-type modern control algorithms could be conducted based on the work presented in this study.