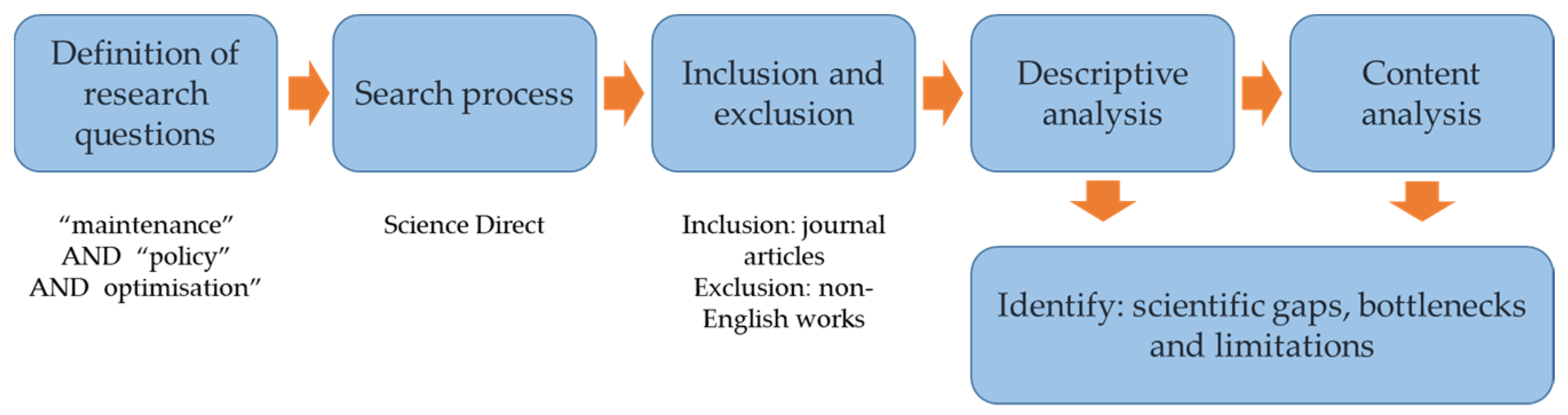

3. Modeling of the Maintenance Optimization Process

Within the frame of this chapter the maintenance model will be divided into two main parts. Within the first part, the general functional model of the maintenance process is described, while in the second part the mathematical model and the solution algorithm of maintenance policy optimization is discussed.

3.1. Functional Model of Maintenance Policy Optimization

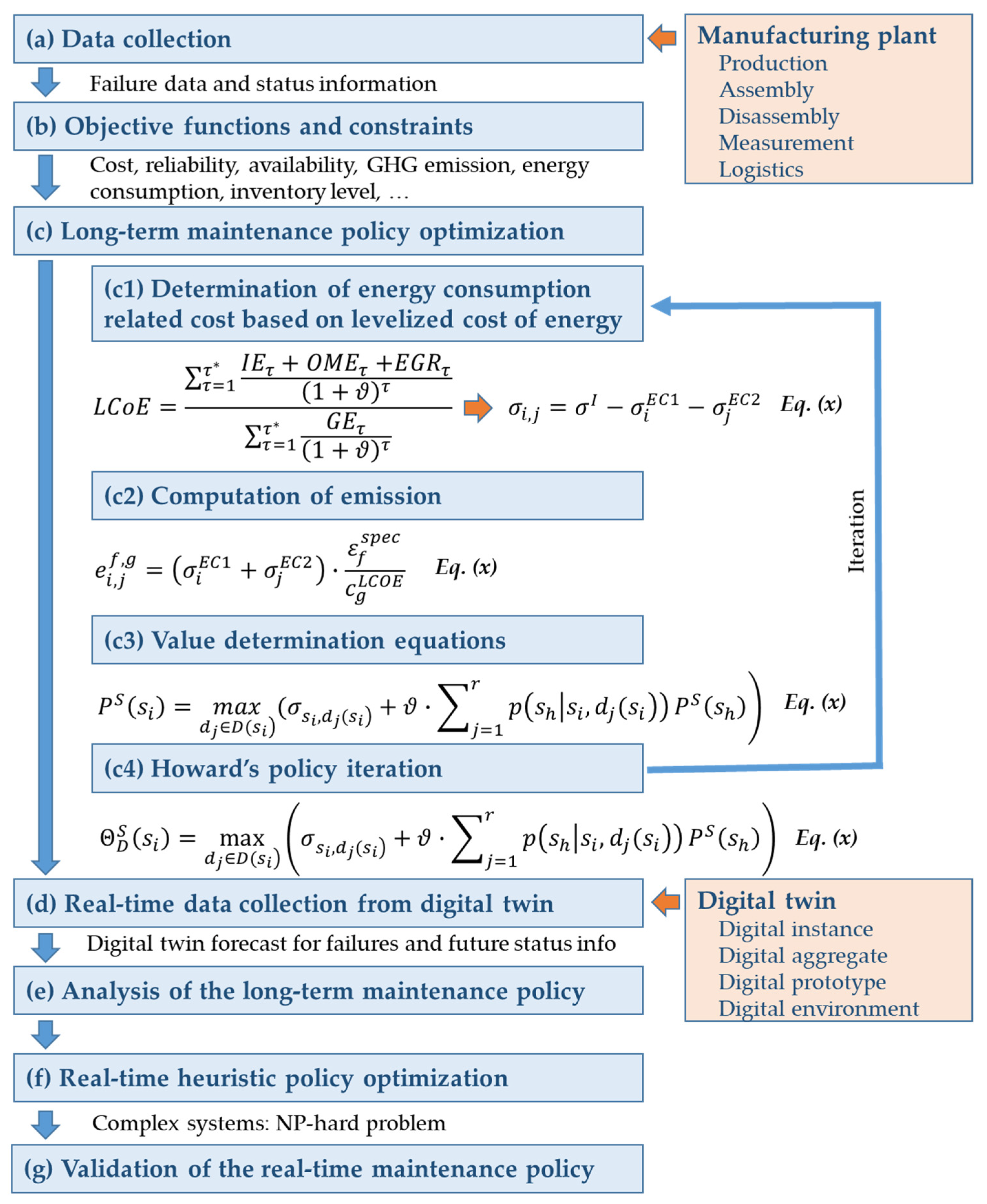

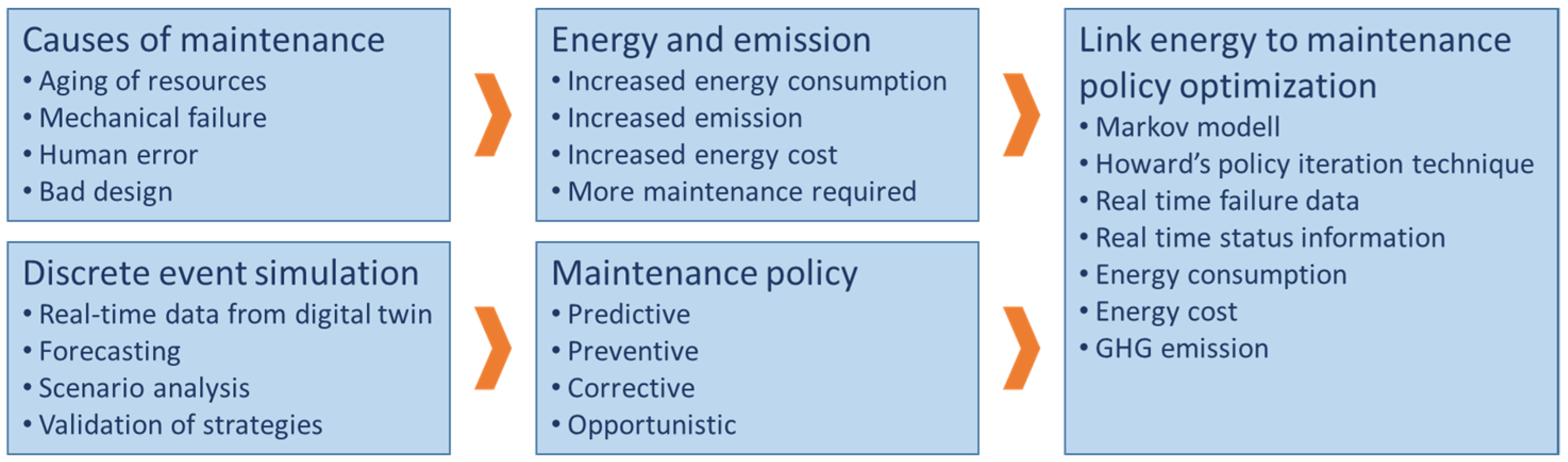

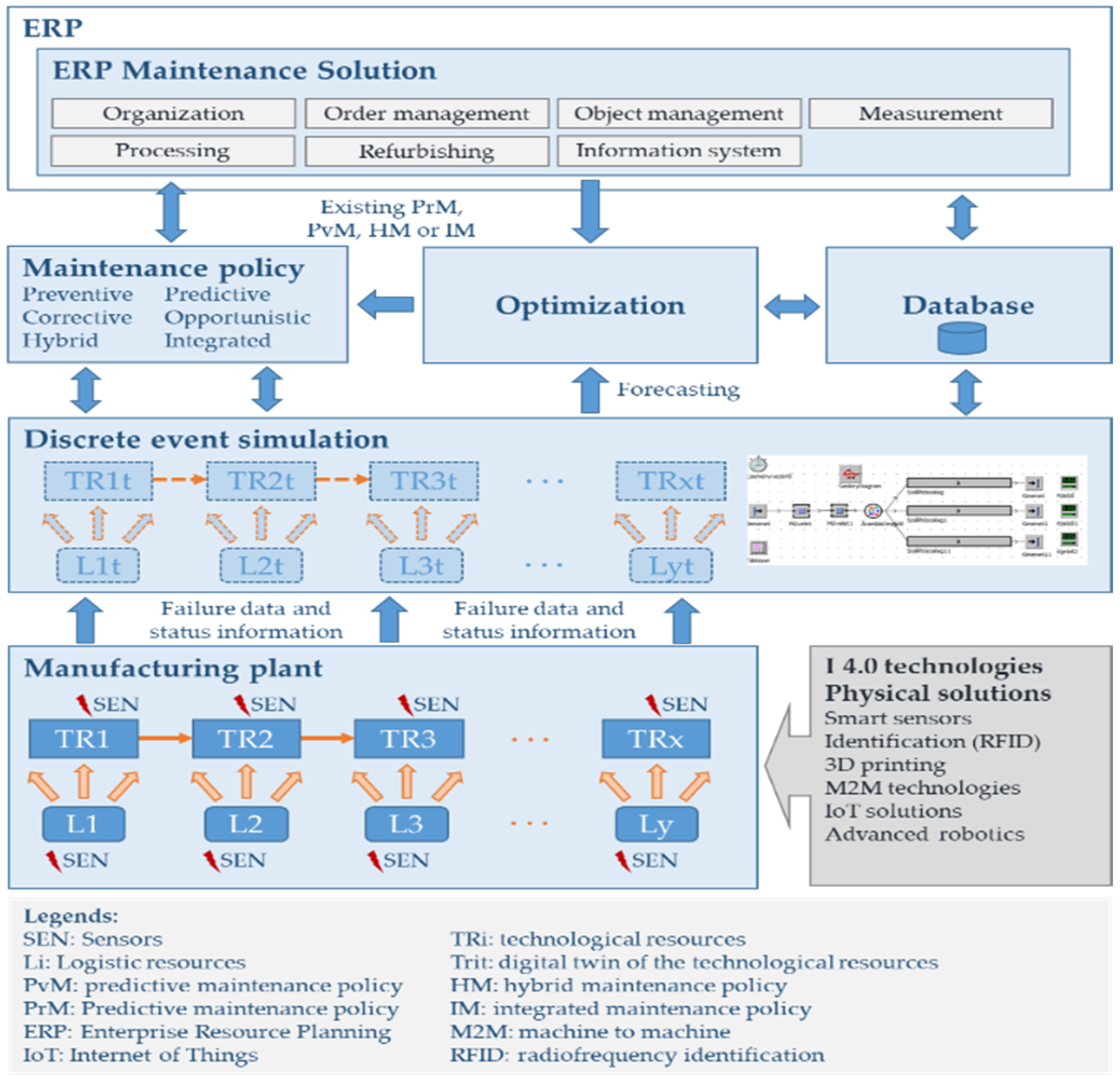

The maintenance module of an ERP system includes the following functions of maintenance related processes: maintenance organization, order management of spare parts and maintenance-related tools and materials, maintenance object management, maintenance measurement and controlling management, maintenance processing, refurbishment processes, and maintenance information system. This maintenance module defines the input parameters, objective functions, and constraints for the maintenance policy. The literature defines four types of maintenance policies: preventive maintenance policy, predictive maintenance policy, corrective maintenance policy, and opportunistic maintenance policy. The combination of these basic maintenance policies leads to the hybrid and integrated maintenance policies. These maintenance policies are defined by an optimization algorithm. In this model, the optimization algorithm includes the well-known Howard’s policy optimization technique, which is combined with energy consumption and greenhouse gas emission calculation.

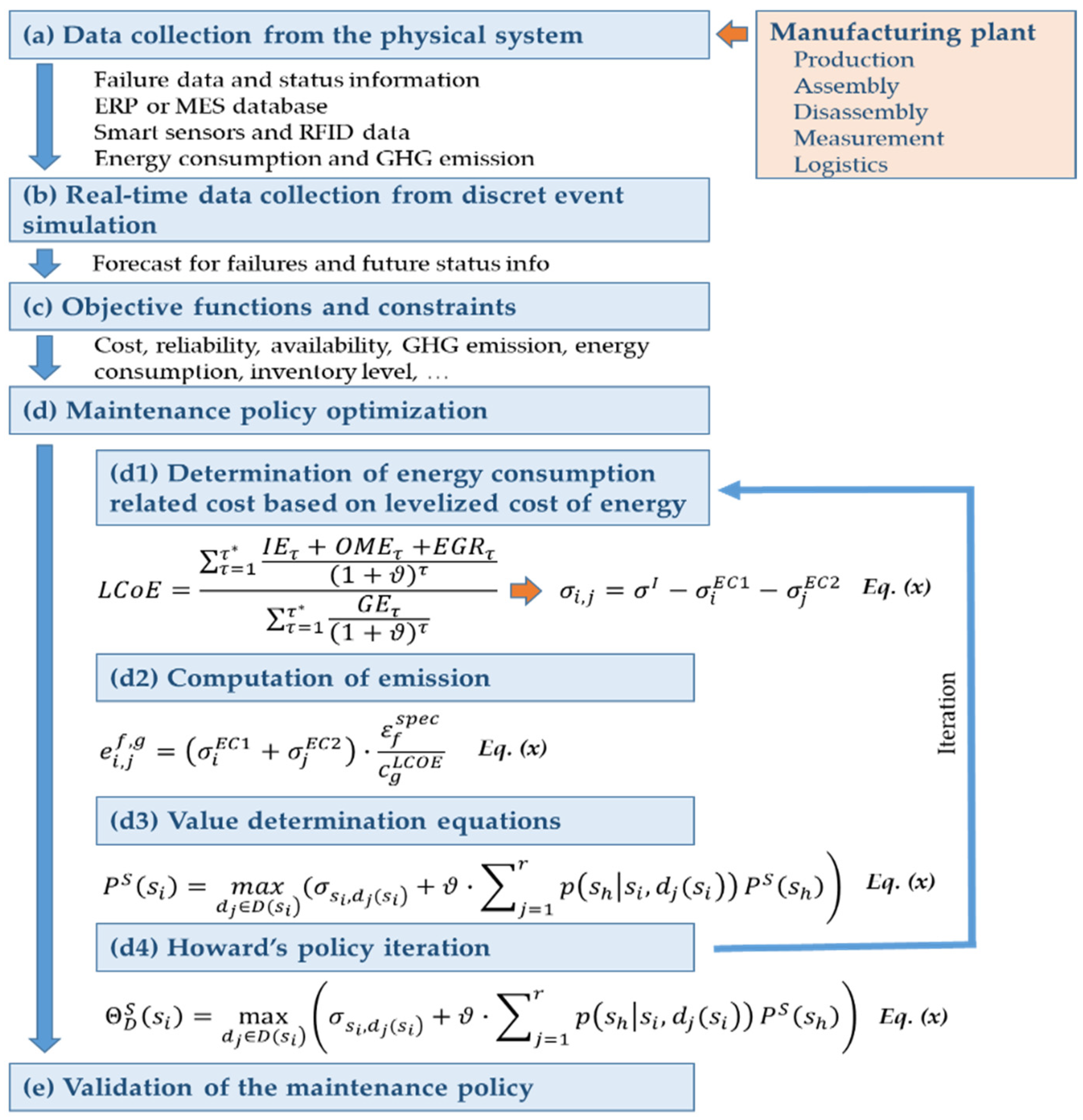

The optimization algorithm is based on the information from the ERP maintenance module, the database of the whole ERP, information from the physical manufacturing and logistics system, and the results of discrete event simulation based on digital twin-information. The functional model of the proposed maintenance optimization is shown in

Figure 5.

The manufacturing plant can be divided into two main parts; the first part is the manufacturing system with technological resources, while the second part is the logistics system including devices and logistics resources for loading and unloading, transporting, storage, packaging, and other material handling operations. The fourth industrial revolution makes it possible to transfer conventional manufacturing systems into cyber-physical systems using Industry 4.0 technologies. In the field of technological resources, the most important I4.0 technologies are smart sensors, identification technologies, machine to machine solutions (M2M), advanced robotics, and IoT solutions. The technological part of the manufacturing plant can include intelligent tools and intelligent products; they can link the physical technological resources to the digital twin model. In the same way, the logistics resources, material handling machines can be linked with smart sensors to the digital twin. The smart sensors send failure data and status information from the physical system to the digital twin and based on these data it is possible to forecast the future failures and status of the whole system. The digital twin solution can integrate process simulation, while big data problems can be solved with three different levels of data processing. These three levels are represented by edge computing, fog computing, and cloud computing.

The digital twin of the manufacturing system is a digital aggregate, which is the integration of digital instances and digital prototypes covered by a digital twin environment. This digital twin can support discrete event simulation with failure data and status information, and the discrete event simulation can forecast the future status of instances. Based on these statuses, it is possible to define the optimal maintenance strategy. In conventional manufacturing systems, maintenance is a part of enterprise resource planning, but it is also possible to integrate the maintenance process into the manufacturing execution system (MES), because maintenance operations are close to the operational level and MES can be directly connected to the maintenance operators. The MES makes the correlation between production and maintenance data stronger [

65].

The primary benefit of the application of energy efficient maintenance policy optimization is a reduction of energy cost. Energy efficiency and environmental performance are linked to each other. In this approach, energy centered maintenance is taken into consideration, but in the literature [

66] there are other types of maintenance approaches (reliability centered maintenance or total productive maintenance).

The reduction of energy consumption of the technological and logistic resources (machine tools and material handling machines) can lead to significant savings in energy costs. Therefore, it is important to find the optimal maintenance policy and maintenance operation schedule. This digital twin-based model makes it possible to perform a maintenance strategy optimization: the maintenance policy optimization is a long-term optimization which is based on Howard’s policy iteration method [

67].

3.2. Mathematical Model and Solution of Maintenance Policy Optimization

Based on the above described functional model, the digital twin-based maintenance policy optimization process has the following main phases: (a) data collection from the physical system and transformation of data to the digital twin; (b) collection of real-time failure data and status information from the digital twin and discrete event simulation scenarios, especially focusing on energy consumption, emissions, and sustainability aspects; (c) definition of objective functions and constraints of the maintenance strategy; (d) optimization of the maintenance policy based on Howard’s policy iteration method and value determination equations. This optimization phase includes the determination of energy consumption related costs based on the levelized cost of energy, while GHG emission can also be calculated based on the different potential electricity generation sources. The optimization process is shown in

Figure 6.

The status of technological and logistics resources can be described as a discrete-time stochastic process; therefore, Markov chains offer suitable representations for the description of this process. The goal of this maintenance policy optimization problem represented by a Markov process is to identify an optimal policy for the decision maker, which can be represented as a set function (see Equation (2)) which specifies the action that the decision maker will choose when the system is in a defined status. A policy is optimal if it minimizes some cumulative function of the random costs, typically the discounted sum over a predefined time window, which can be an infinite time horizon: , where is the cost at time τ when the decision maker follows policy D, and is the discount rate. This Markov decision problem is the infinite-horizon discounted Markov decision problem, which can be solved in many ways: Bellman’s successive approximations method or Howard’s policy iteration.

The benefits of the solution of the mentioned Markov decision process with Howard’s policy iteration techniques for energy consumption are as follows:

the energy consumption and emissions of the resources in the manufacturing system depends on their status; therefore, the iterated policies using Howard’s methodology can lead to decreased energy consumption and emissions;

the energy consumption costs of operation and maintenance influences the discounted profit, therefore Howard’s methodology results in optimal maintenance policies from an energy point of view.

The characteristics of the maintenance policy optimization problem is an assignment problem, where suitable maintenance operations have to be assigned to every status of the system resources. As assumptions, the following are taken into consideration.

In the maintenance model we can define a set of possible states:

where

is state

i of the system and

z is the maximum number of possible states of the system. These states have great impact on the energy efficiency of the manufacturing system, which means that this set of possible states also defines a link between status information, maintenance operations, and energy.

This set includes all potential states of the system and these states can be identified either from the failure data and status information of the physical manufacturing and logistics system or from their digital twin aggregate. In the same way, it is possible to define a decision set, which includes all potential decisions regarding the various states of the system. The decision set includes all suitable maintenance processes:

where

is potential decision

j regarding a maintenance request and

r is the maximum number of possible decisions regarding the maintenance of the whole system. These decisions regarding maintenance operations also form a link to the energy consumption, because it is possible to calculate the energy consumption of all maintenance operations.

The transition probabilities represent the constraints of the maintenance policy optimization:

, where

is the transition probability from state

to state

and

The transition probabilities for transition from state

to state

resulting from decision

:

can be calculated. The following constraints can be defined for the transition probability values:

which means that the chosen decision

will not definitely result in the transition probability

from state

to state

, because

will result in a new state of the system and

can be defined as the transition probability from the state resulting from the decision

, from state

to the state

.

Within the frame of the maintenance policy optimization, different objective functions can be taken into consideration: cost, reliability, availability, GHG emission, energy consumption, inventory value, or level of spare parts. In the case of multiple criteria decision making (MCDM), it is possible to involve more than one objective function to be optimized simultaneously. In the case of MCDM, different techniques are used for weighting multiple objectives, the well-known methods are the Churchmann–Ackoff method and the Guilford method. Within the frame of our multi-stage maintenance policy optimization the profit will be used as the objective function of the policy optimization.

In this model, the discounted profit caused by the energy consumption of the manufacturing system and the energy consumption of the maintenance process for an infinite time horizon are taken into consideration. As Winston defines [

68], infinite-horizon probabilistic dynamic programing problems are Markov decision processes, where the profit-based objective function can be defined in the following form:

where

is the expected profit in the initial period if decision

was chosen for status

,

is the expected discounted profit of status

,

is the discounting factor of the profits and

.

The Howard’s policy iteration method is a suitable technique to optimize policies from a value (or cost) determination equation point of view. In this technique, it is possible to calculate a special parameter of the chosen maintenance policy:

where

is a special parameter of the Howard’s policy iteration technique for the state

of the system. If

for

then

is the optimal maintenance policy, otherwise the policy must be changed and a new iteration phase must be computed using value determination equations and the Howard’s policy iteration parameter calculation.

4. Computational Results

This section discusses a scenario analysis, which focuses on the validation of the above-described multi-phase maintenance policy optimization including the long-term optimization based on Howard’s policy iteration techniques. In this scenario, the manufacturing system has five different statuses (excellent, good, average, poor, and bad), and based on these states the set of possible statuses is given as follows:

The decision set of this scenario includes four different level of maintenance policy (no maintenance, level 1, level 2, and level 3):

The status of the system in the next period depends on the status of the current period, therefore it is possible to define the transition probabilities between statuses as a transition matrix of the Markov decision process:

After performing a maintenance process, the transition probabilities from the current status to status E can be calculated as follows:

After performing a maintenance process, the transition probabilities from the current status to status G can be calculated as follows:

After performing a maintenance process, the transition probabilities from the current status to status A can be calculated as follows:

After performing a maintenance process, the transition probabilities from the current status to status P can be calculated as follows:

The profit of the analyzed time window of the manufacturing process is influenced by the income and the costs, including energy consumption (electricity) of manufacturing and maintenance:

where

is the profit of the system in the status of the system

i, while maintenance level

j is performed,

. is the initial income of the manufacturing system,

is the energy consumption of the manufacturing system in the status

i and

. is the energy consumption of the performed maintenance operations of maintenance level

j.

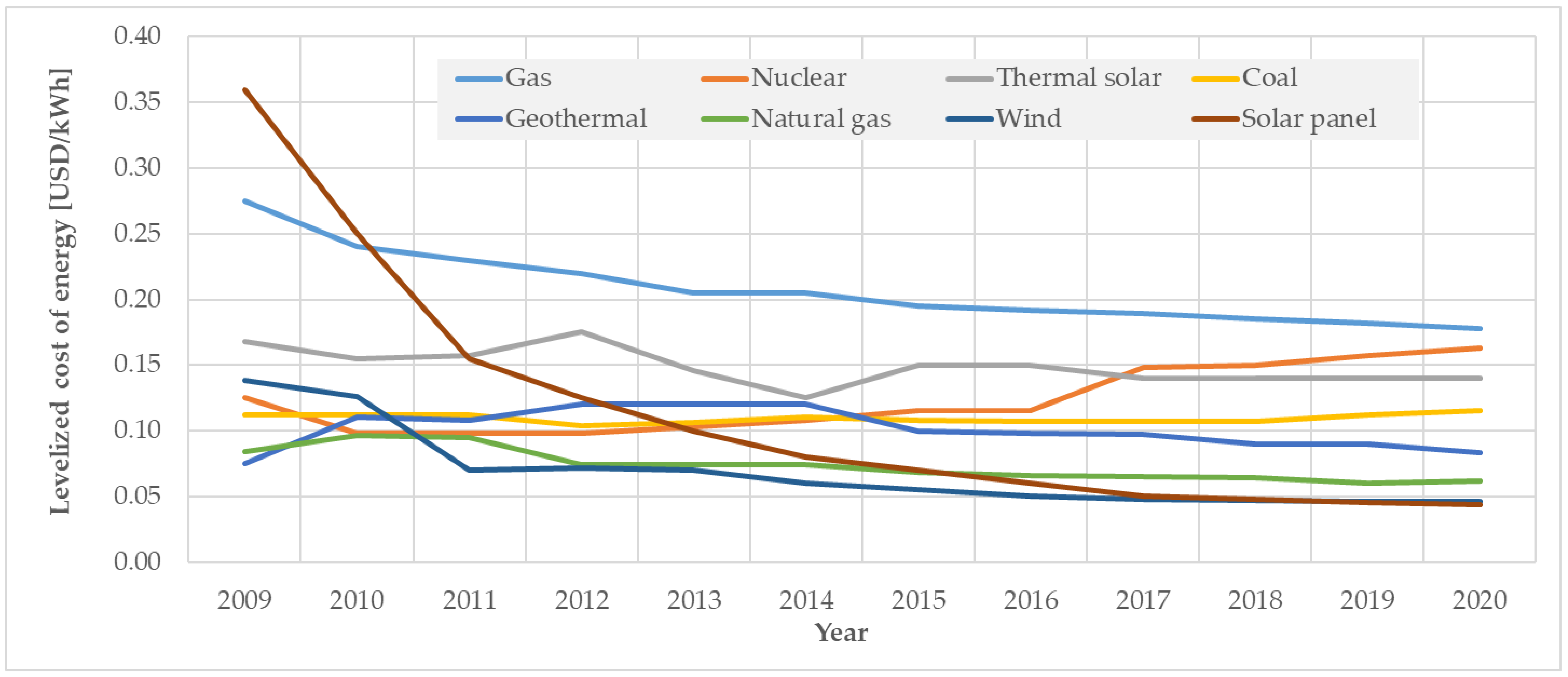

The energy of manufacturing and maintenance operations can be generated from different sources (lignite, coal, oil, natural gas, photovoltaic, biomass, nuclear, water, and wind), and, depending on these energy generation sources, it is possible to calculate both the cost of energy consumption and the virtual emissions of the whole manufacturing process depending on the status of the system and the performed maintenance operations of the chosen maintenance policy. The cost calculation of energy consumption is based on the levelized cost of energy (

Figure 7).

The profit of the system based on the status of the system, the performed maintenance level and the costs caused by the energy consumption of the related maintenance level, and the energy consumption of the manufacturing system in the current status are input parameters of the optimization problem:

For this calculation, the initial energy consumption of manufacturing and maintenance is taken into consideration (

Table 1 and

Table 2).

In this model, the greenhouse gas emissions of various electricity generations sources published by World Nuclear Association are taken into consideration [

69].

Based on the specific GHG emission (

Table 3), the total virtual GHG emission can be calculated based on the status of the manufacturing system and the chosen maintenance policy:

where

is the virtual emission of GHG

f in the case of the state

i of manufacturing system, chosen maintenance policy

j, and electricity generation source

g,

is the specific GHG emission of GHG f,

is the levelized cost of electricity in the case of electricity generation source

g, where

.

The virtual GHG emission in the case of natural gas electricity generation source is shown in

Table 4. The computational results regarding the virtual emission of other GHGs are in

Table 5,

Table 6,

Table 7,

Table 8 and

Table 9.

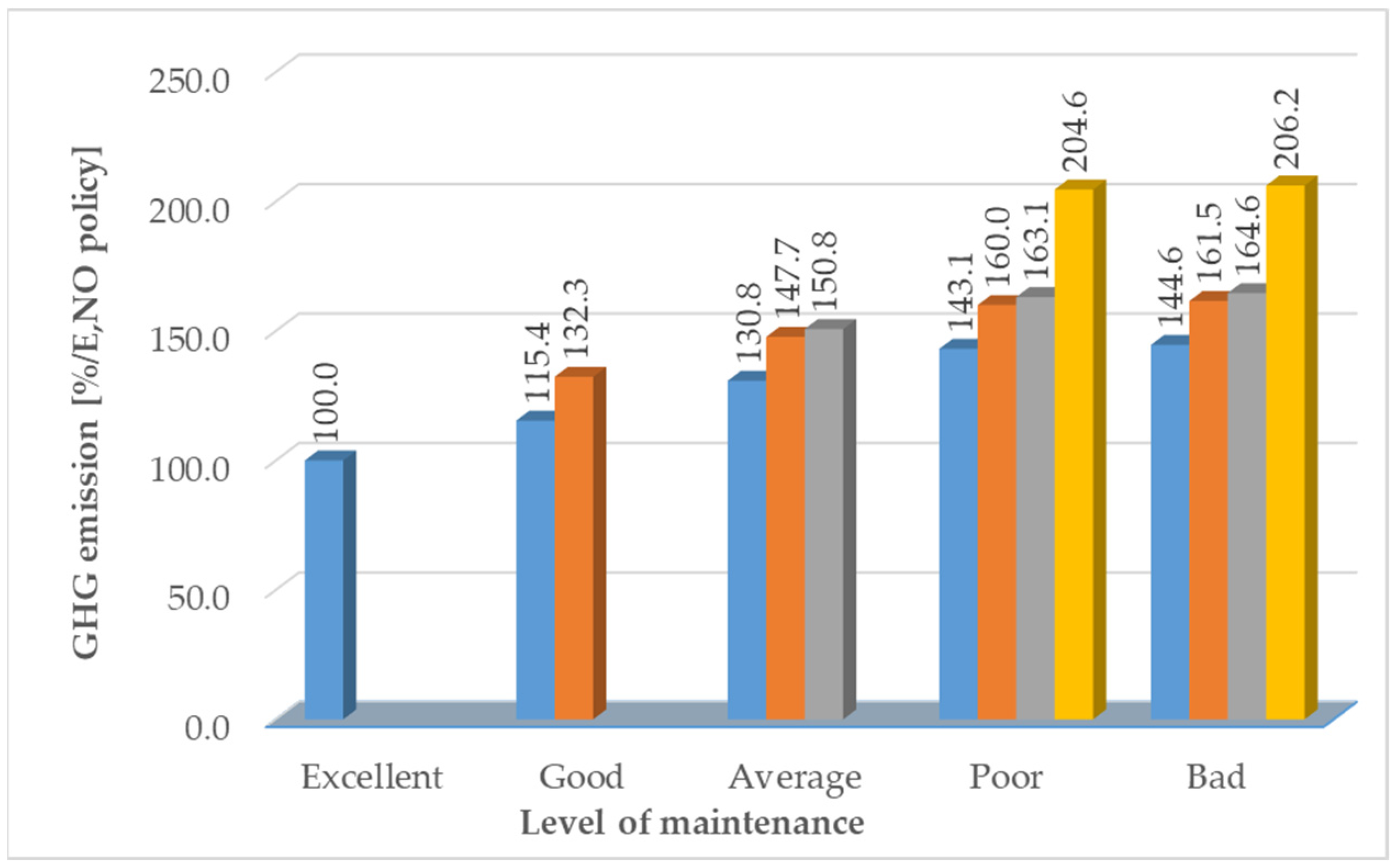

As the above tables show, the GHG emission depends on the status of the systems and the maintenance operations performed. The resulting proportion of GHG emission is shown in

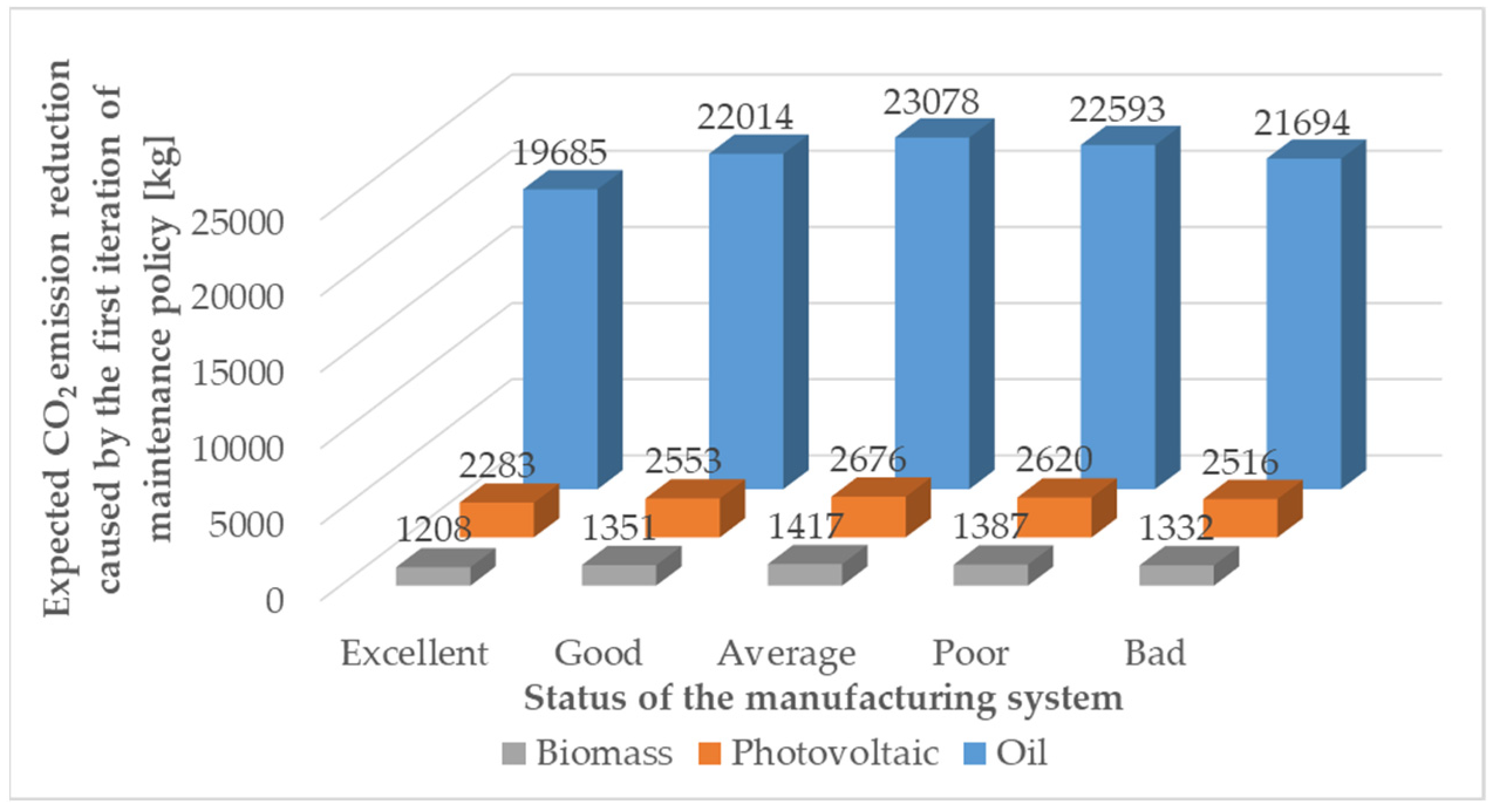

Figure A1. The expected CO

2 emission reduction caused by the first iteration of the maintenance policy [kg] is shown in

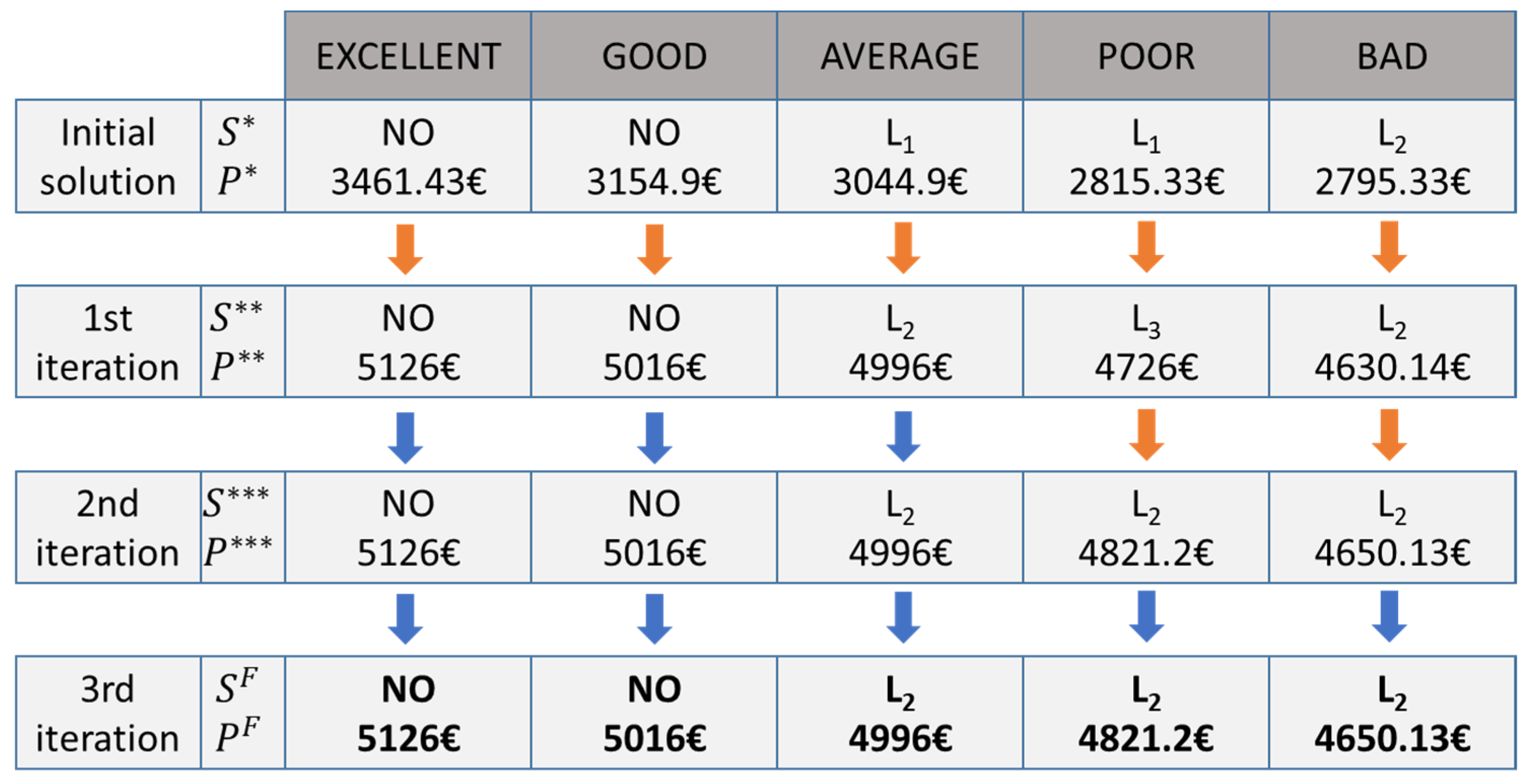

Figure A2. After the initialization of the energy consumption and GHG emission values, the first step is to choose an initial maintenance policy:

which means that in the case of status E and status G no maintenance is performed, in the case of status A and P first level maintenance is performed, and in the case of status B second level maintenance is chosen. The value determination equations (see Equation (5)), and the expected discounted profit for the predefined time-window can be calculated as follows:

Solving these equations, the expected discounted profit for each status in the case of the initial maintenance policy can be determined:

After the solution of value determination equations, the next phase is to apply the Howard’s policy iteration technique, and calculate a

parameter for each

maintenance policy. In the case of status E no maintenance is required, therefore based on Equation (6) it is meaningless to change the maintenance policy for status E:

In the case of status G, the value of

parameter can be computed as follows:

As the solution of Equation (21) shows,

, which means, that there is a better maintenance policy, than the initial policy chosen in the first iteration:

In the case of status A, the value of

parameter can be computed as follows:

As the solution of Equation (23) shows,

, which means, that there is a better maintenance policy for status A of the system, than the

initial policy chosen in the first iteration:

In the case of status P, the value of

parameter can be computed as follows:

As the solution of Equation (25) shows,

, which means, that there is a better maintenance policy for status P of the system, than the

initial policy chosen in the first iteration:

In the case of status B, the value of

parameter can be computed as follows:

As the solution of Equation (27) shows,

, which means, that there is a better maintenance policy for status P of the system than the

initial policy chosen in the first iteration:

After that, the new value determination equations can be defined, and the expected discounted profit can be calculated in the case of

maintenance policy for the predefined time-window:

Solving these equations, the expected profit for each status in the case of the

first iteration of maintenance policy (see Equation (29)) can be given:

Based on the results of the

first iteration, the energy consumption reduction can be determined:

where

is the energy consumption reduction resulting from the first iteration phase in the case of system status

i and electricity generation source

g. Similarly, the GHG emission reduction can also be calculated:

where

is the GHG emission reduction resulting from the first iteration phase in the case of system status

i, electricity generation source

g, and GHG

f.

The computational results of energy consumption reduction and GHG emission reduction after the first iteration phase in the case of natural gas electricity generation source are described in

Table 10.

After the second solution of the value determination equations, the Howard’s policy iteration techniques can be applied, and the

parameter for each

maintenance policy can be calculated. In the case of status E, no maintenance is required, therefore based on Equation (6) it is meaningless to change the maintenance policy for status E:

In the case of status G, the value of

parameter can be computed as follows:

As the solution of Equation (34) shows,

, which means, that the

first iteration of the maintenance policy for status G is the optimal maintenance policy:

In the case of status A, the value of

parameter can be computed as follows:

As the solution of Equation (36) shows,

, which means, that the

first iteration of the maintenance policy for status A is the optimal maintenance policy:

In the case of status

P, the value of

parameter can be computed as follows:

As the solution of Equation (38) shows,

, which means that there is a better maintenance policy for status P of the system than the

initial policy chosen in the first iteration:

In the case of status

B, the value of

parameter can be computed as follows:

As the solution of Equation (40) shows,

, which means that the

first iteration of the maintenance policy for status

B is the optimal maintenance policy:

After that, the new value determination equations can be defined and the expected discounted profit in the case of

maintenance policy for the predefined time-window can be calculated:

Solving these equations, the expected profit for each status in the case of the

second iteration of the maintenance policy can be determined:

Based on the results of the

second iteration, the energy consumption reduction can be determined:

where

is the energy consumption reduction resulting from the second iteration phase in the case of system status

i and electricity generation source

g. Similarly, the GHG emission reduction can also be calculated:

where

is the GHG emission reduction resulting from the second iteration phase in the case of system status

i, electricity generation source

g, and GHG

f.

The computational results of energy consumption reduction and GHG emission reduction after the second iteration phase in the case of natural gas electricity generation source are described in

Table 11. The computational results of energy consumption and GHG emission reduction in the case of other electricity generation sources are shown in

Table 12 and

Table 13 and

Figure A2After the third solution of the value determination equations, the Howard’s policy iteration techniques can be applied, and the

parameter for each

maintenance policy can be calculated. Based on the condition defined in Equation (4), it is unambiguous that it is no way to improve the maintenance policy and find a better policy for a higher profit, so the optimal maintenance policy for this scenario is the following:

The improvement of the maintenance policy and the resultant discounted profit of the manufacturing system is shown in

Figure 8.

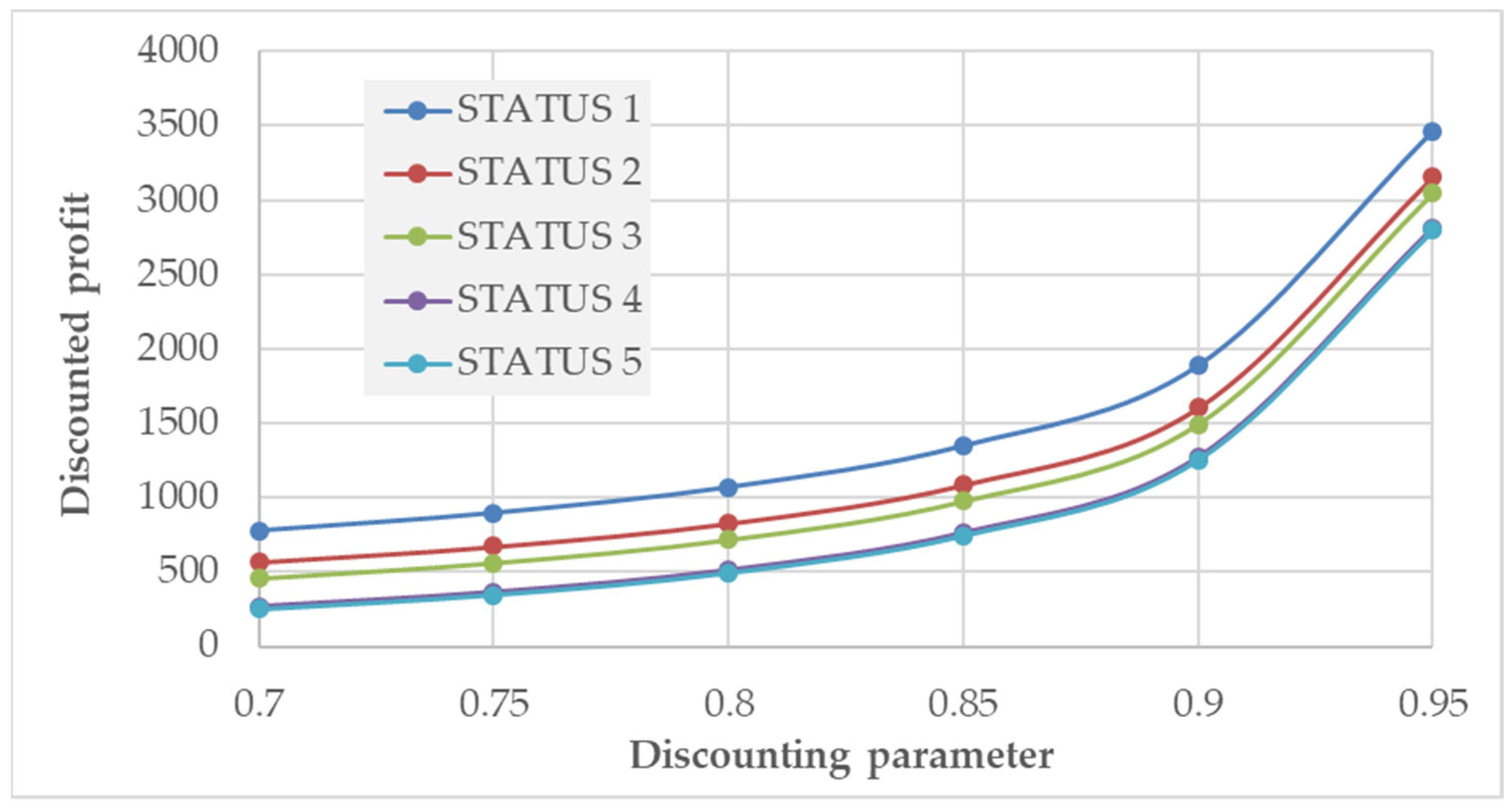

The discounted profit resulting from the optimized maintenance policy is influenced by the parameters of the physical systems and the cost model.

Figure 9 and

Table A3 demonstrate the influence of discounting parameter

on the discounted profit. As

Figure 9 shows, the increased value of the discount parameter leads to an increase in discounted profit.

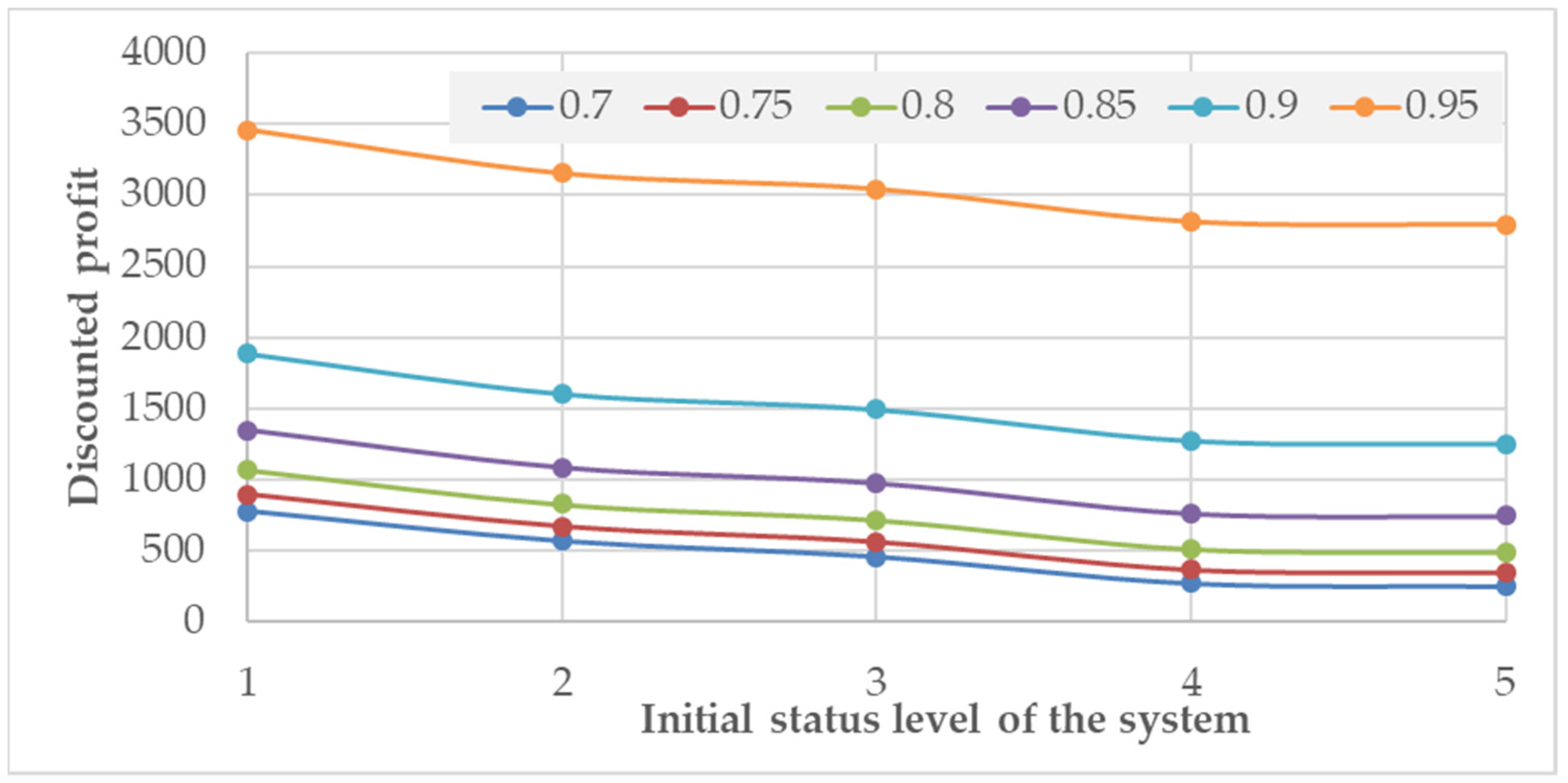

The discounted profit depends on the initial status level of the system.

Figure 10 demonstrates the influence of initial status level of the system on the discounted profit. As

Figure 10 shows, the better status level causes higher discounted profit and the increased

value also increases the discounted profit for all initial system statuses.

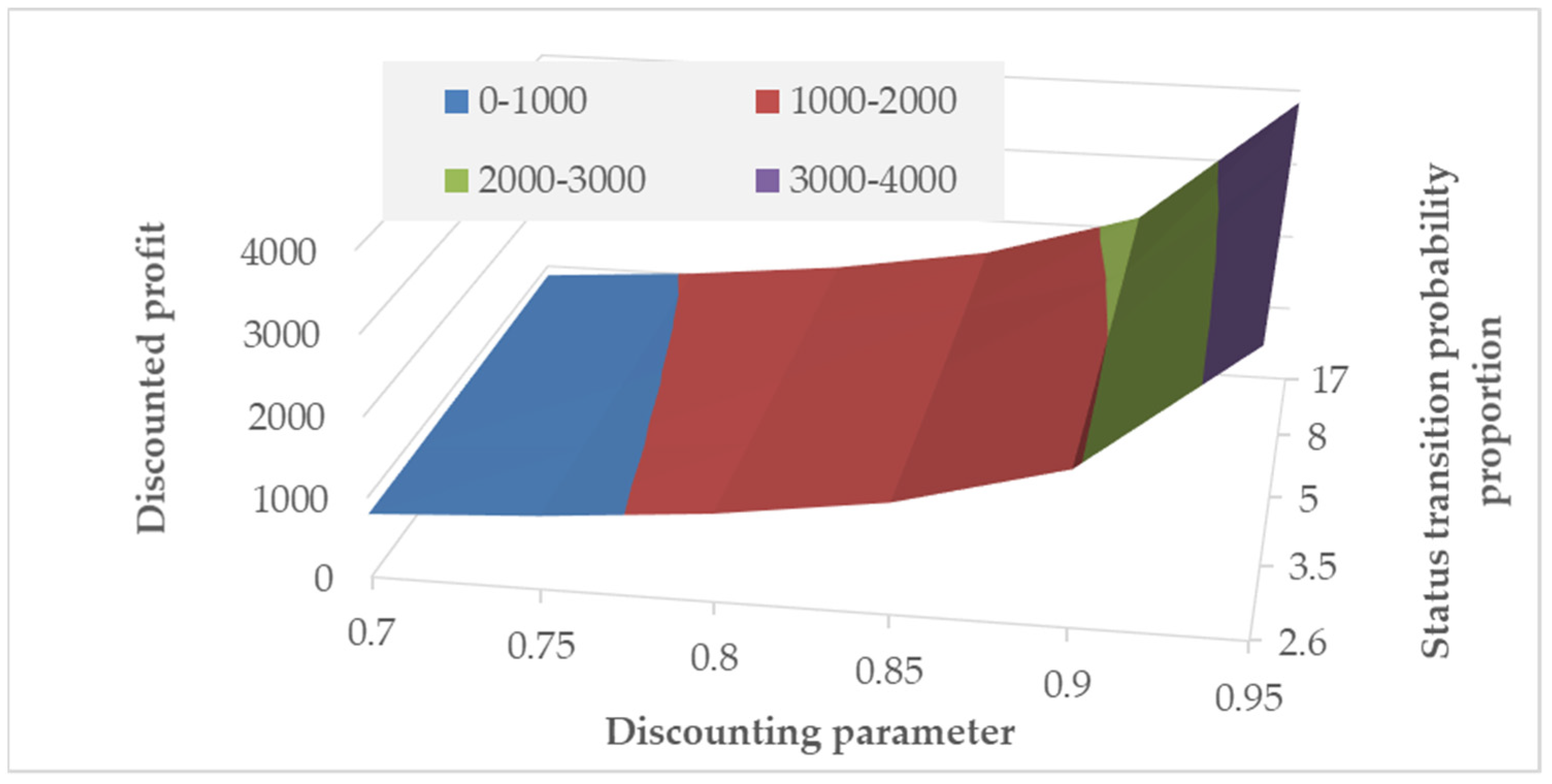

The impact of the initial system status and the

discount parameter on the discounted profit is shown in

Figure 11 and

Table A4. The sensitivity analysis shows that optimal maintenance policy is influenced by the parameters of the technological system and the corresponding cost model represented by the

discount parameter.

The discount parameter does not influence the optimal maintenance policy, but it has a great impact on the discounted profit, because energy costs have to be taken into consideration as discounted costs. The above-described scenario validates the digital twin-based maintenance policy optimization and justifies the maintenance policy in both conventional and cyber-physical manufacturing systems. Services must be optimized in order to increase performance and ensure that all technological and logistics resources can operate at 100% efficiency at all times. To summarize, the proposed Howard’s policy iteration technique-based optimization model makes it possible to analyze the impact of maintenance policy on the performance parameters of technological and logistics processes and decrease the energy consumption and the related discounted costs.

As the findings of the literature review show, the articles that addressed the maintenance policy optimization are focusing on conventional production environments, but none of the articles aimed to identify the potential in a cyber-physical production environment, where Industry 4.0 technologies can increase the impact of the maintenance policy optimization. The comparison of our results with those from other studies shows that the optimization of maintenance policies in cyber-physical environments still requires more attention and research.