GHG and NH3 Emissions vs. Energy Efficiency of Maize Production Technology: Evidence from Polish Farms; a Further Study

Abstract

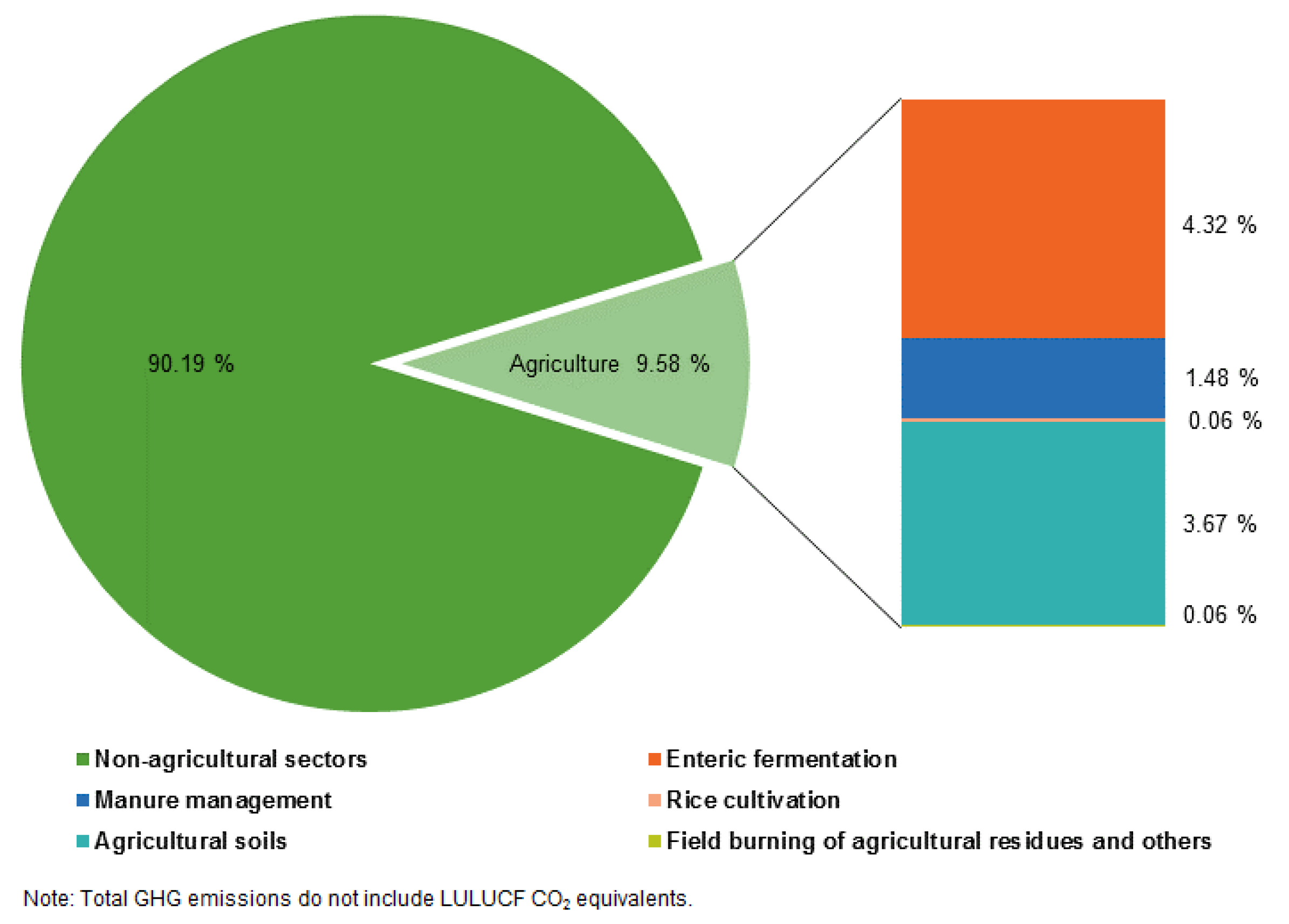

:1. Introduction

2. Methods

2.1. Emissions of N2O and CO2 from the Use of Natural and Inorganic Fertilisers

2.2. Emissions of N2O, CO2 and CH4 from the Fuel Consumption

2.3. Emission of NH3

2.4. Scope of Research

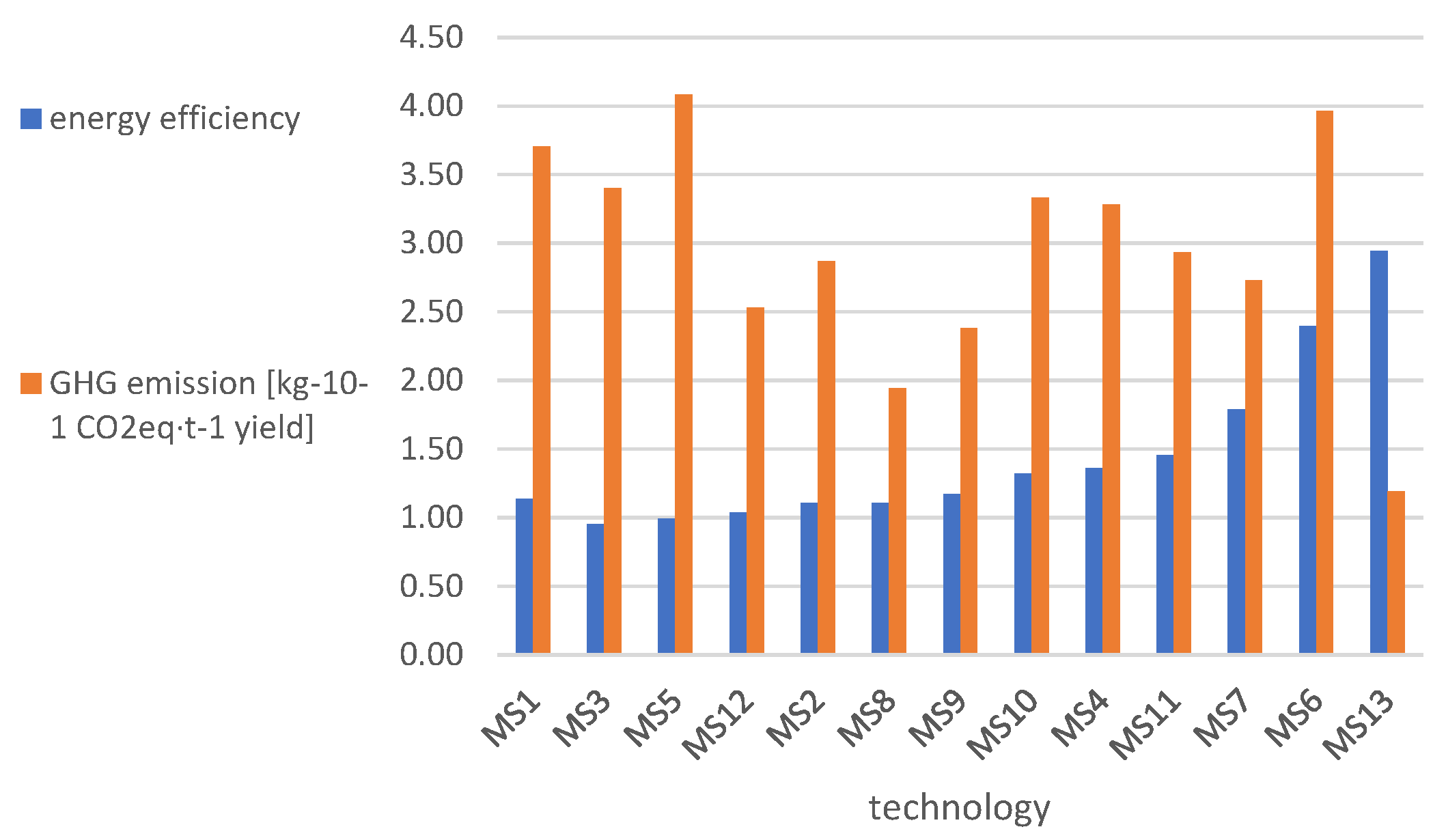

3. Results

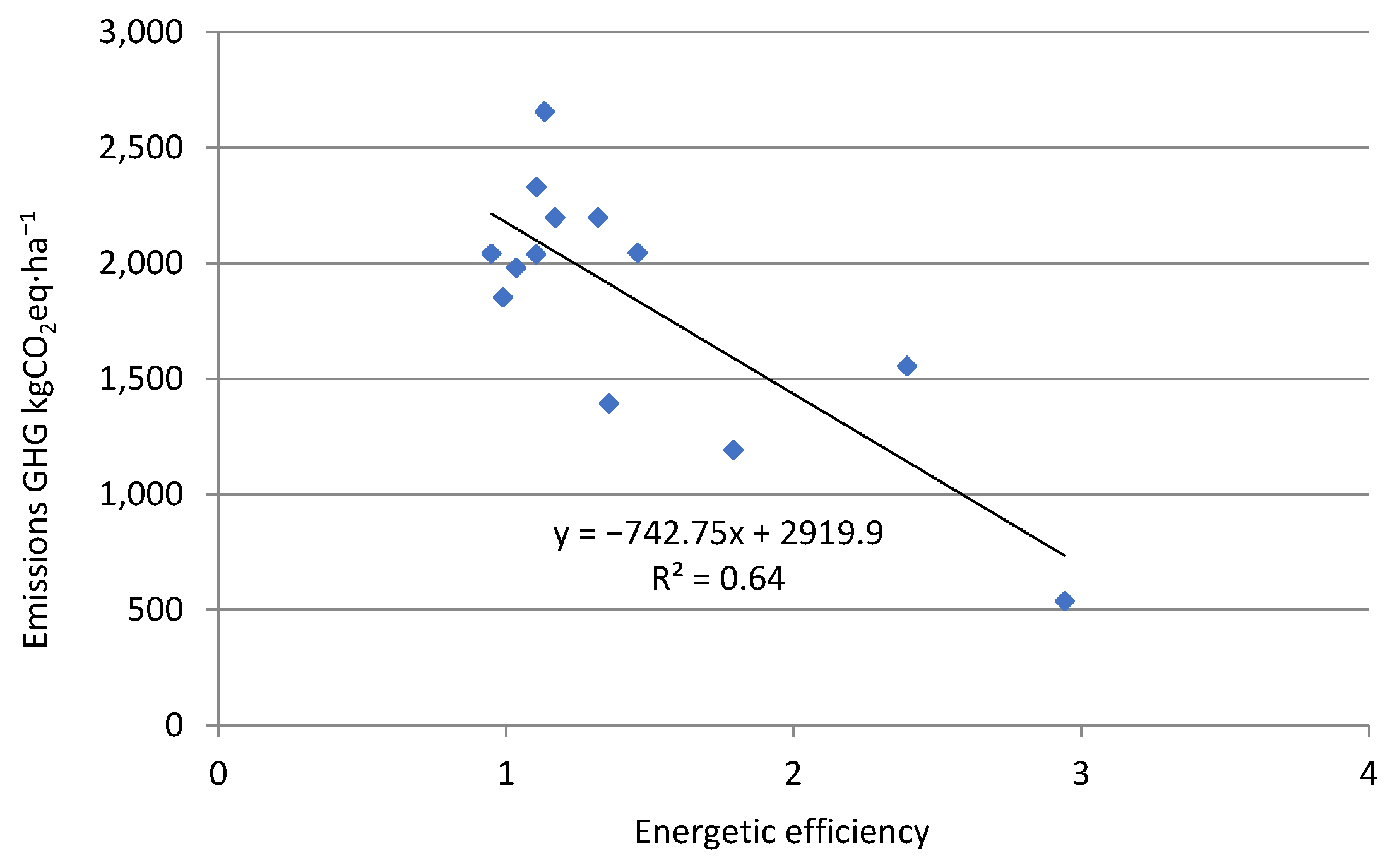

Correlation between Energy Efficiency and the Amount of GHG Emissions across the Silage Maize Cultivation Technologies

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ritchie, H.; Roser, M. CO₂ and Greenhouse Gas Emissions. 2020. Available online: https://ourworldindata.org/co2-and-other-greenhouse-gas-emissions (accessed on 26 August 2021).

- Rzeźnik, W.; Bartkowiak, A.; Jadczyszyn, T.; Mac, J.; Matros, B.; Matyka, M.; Mielcarek, P.; Stekla, J.; Talarczyk, W.; Zbytek, Z.; et al. Różne Aspekty Wykorzystania Biomasy Pofermentacyjnej; Instytut Technologiczno-Przyrodniczy: Kraków, Poland, 2017; ISBN 978-83-65426-30-7. [Google Scholar]

- International Energy Agency. Renewables 2017. Analysis and Forecasts to 2022. Executive Summary. 2017 OECD/IEA 2017. Available online: https://www.iea.org/media/publications/mtrmr/Renewables2017ExecutiveSummary.PDF (accessed on 15 April 2021).

- Energy Information Administration. EIA Projects World Energy Consumption Will Increase 56% by 2040. 2015. Available online: https://www.eia.gov/todayinenergy/detail.php?id=12251 (accessed on 22 June 2021).

- Prindle, W. National Action Plan for Energy Efficiency 2009. Energy Efficiency as a Low-Cost Resource for Achieving Carbon Emissions Reductions; ICF International Inc.: Fairfax, VA, USA, 2009. [Google Scholar]

- Nadel, S.; Ungar, L. Halfway There: Energy Efficiency Can Cut Energy Use; Report U1907; American Council for an Energy-Efficient Economy: Washington, DC, USA, 2019. [Google Scholar]

- Eurostat. Statistics Explained. 2020. Available online: https://ec.europa.eu/eurostat/statisticsexplained/ (accessed on 21 May 2021).

- Ajanovic, A. Biofuels Versus Food Production: Does Biofuels Production Increase Food Prices? Energy 2011, 36, 2070–2076. [Google Scholar] [CrossRef]

- Stolarski, M.; Szczukowski, S.; Tworkowski, J. Efektywność energetyczna produkcji biomasy wierzby w systemie Eko-Salix. Fragm. Agron. 2011, 28, 62–69. [Google Scholar]

- Tworkowski, J.; Stolarski, M.J.; Szczukowski, S.; Krzyżaniak, M. Energetyczna efektywność produkcji biomasy wierzby systemem Eko-Salix. Zesz. Probl. Postępów Nauk. Rol. 2015, 582, 91–100. [Google Scholar]

- The European Commission. Communication From the Commission to The European Parliament, The Council, The European Economic and Social Committee and The Committee of The Regions. A Roadmap for Moving to a Competitive Low Carbon Economy in 2050 and Greenhouse Gas Emissions in Half by 2050. 2011. Available online: https://www.eea.europa.eu/policy-documents/com-2011-112-a-roadmap (accessed on 26 June 2021).

- Agostini, A.; Battini, F.; Giuntoli, J.; Tabaglio, V.; Padella, M.; Baxter, D.; Marelli, L.; Amaducci, S. Environmentally Sustainable Biogas? The Key Role of Manure Co-Digestion with Energy Crops. Energies 2015, 8, 5234–5265. [Google Scholar] [CrossRef]

- Agostini, A.; Battini, F.; Padella, M.; Giuntoli, J.; Baxter, D.; Marelli, L.; Amaducci, S. Economics of GHG emissions mitigation via biogas production from Sorghum, maize and dairy farm manure digestion in the Po valley. Biomass Bioenergy 2016, 89, 58–66. [Google Scholar] [CrossRef]

- Lovarelli, D.; Falconeb, G.; Orsia, L.; Bacenettia, J. Agricultural small anaerobic digestion plants: Combining economic and environmental assessment. Biomass Bioenergy 2019, 128, 105302. [Google Scholar] [CrossRef]

- Holly, M.A.; Larson, R.A.; Powell, J.M.; Ruark, M.D.; Aguirre-Villegas, H. Greenhouse gas and ammonia emissions from digested and separated dairy manure during storage and after land application. Agric. Ecosyst. Environ. 2017, 239, 410–419. [Google Scholar] [CrossRef]

- Romaniuk, W.; Mazur, K.; Borek, K.; Borusiewicz, A.; Wardal, W.J.; Tabor, S.; Kuboń, M. Biomass Energy Technologies from Innovative Dairy Farming Systems. Processes 2021, 9, 335. [Google Scholar] [CrossRef]

- European Parliament. Directive 2009/28/EC of 23.04.2009 on the Promotion of the Use of Energy from Renewable Sources, Dyrektywa Parlamentu Europejskiego i Rady 2009/28/WE z dnia 23 kwietnia 2009 r. w Sprawie Promowania Stosowania Energii ze Źródeł Odnawialnych Zmieniająca i w Następstwie Uchylająca Dyrektywy 2001/77/WE oraz 2003/30/WE; European Parliament: Brussels, Belgium, 2009. Available online: https://eur-lex.europa.eu/legal-content/PL/ALL/?uri=CELEX%3A32009L0028 (accessed on 26 June 2021).

- Adams, P.W.R.; McManus, M.C. Characterisation and variability of greenhouse gas emissions from biomethane production via anaerobic digestion of maize. J. Clean. Prod. 2019, 218, 529–542. [Google Scholar] [CrossRef]

- Borek, K.; Romaniuk, W.; Roman, K.; Roman, M.; Kuboń, M. The Analysis of a Prototype Installation for Biogas Production from Chosen Agricultural Substrates. Energies 2021, 14, 2132. [Google Scholar] [CrossRef]

- Roman, K.; Barwicki, J.; Hryniewicz, M.; Szadkowska, D.; Szadkowski, J. Production of Electricity and Heat from Biomass Wastes Using a Converted Aircraft Turbine AI-20. Processes 2021, 9, 364. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change. Guidelines for National Greenhouse Gas Inventories. 2006. Available online: www.ipcc-nggip.iges.or.jp/public/2006gl/vol4.htm (accessed on 23 May 2021).

- Miatkowski, Z.; Turbiak, J.; Burczyk, P.; Myczko, A.; Karłowski, J. Prognozy Zmian Aktywności w Sektorze Rolnictwa Zawierające Informacje Niezbędne do Wyliczenia Szacunkowej Wielkości Emisji Gazów Cieplarnianych; Raport ITP; Instytut Technologiczno-Przyrodniczy: Bydgoszcz, Poland, 2010. [Google Scholar]

- Nyćkowiak, J.; Leśny, J.; Olejnik, J. Ocena bezpośredniej emisji N2O z gleb użytkowanych rolniczo województwa wielkopolskiego w latach 1960–2009 według metodologii IPCC. Woda Sr. Obsz. Wiej. 2012, 4, 203–215. [Google Scholar]

- Internetowy System Aktów Prawnych; Journal of Law. Ustawa z dn. 17 lipca 2009 r. o Systemie Zarządzania Emisjami Gazów Cieplarnianych i Innych Substancji; No 130, item 1070 with Further Amendments, Dz. U. 2009, nr 130, poz. 1070; Internetowy System Aktów Prawnych: Warszawa, Poland, 2009. [Google Scholar]

- Krajowy Ośrodek Bilansowania i Zarządzania Emisjami. Poland’s National Inventory Report 2018. Greenhouse Gas Inventory for 1988–2016. Instytut Ochrony Środowiska—Państwowy Instytut Badawczy, Krajowy Ośrodek Bilansowania i Zarządzania Emisjami: Warszawa, Poland, 2018. [Google Scholar]

- Snyder, C.S.; Bruulsema, T.W.; Jensen, T.L.; Fixen, P.E. Review of greenhouse gas emissions from crop production systems and fertilizer management effects. Agric. Ecosyst. Environ. 2009, 133, 247–266. [Google Scholar] [CrossRef]

- Abalos, D.; Jefrey, S.; Drury, C.F.; Wagner-Riddle, C. Improving fertilizer management in the U.S. and Canada for N2O mitigation: Understanding potential positive and negative side-effects on corn yields. Agric. Ecosyst. Environ. 2016, 221, 214–221. [Google Scholar] [CrossRef]

- Drury, C.F.; Yang, X.; Dan Reynolds, W.; Calder, W.; Oloya, T.O.; Woodley, A.L. Combining Urease and Nitrification Inhibitors with Incorporation Reduces Ammonia and Nitrous Oxide Emissions and Increases Corn Yields. J. Environ. Quality 2017, 46, 939–949. [Google Scholar] [CrossRef] [PubMed]

- Zalega, K. Znaczenie biopaliw i systemu ich certyfikacji–polityka energetyczna i klimatyczna Unii Europejskiej. Kontrola Państwowa 2017, 1, 40. [Google Scholar]

- European Parliament. Directive 98/70/WE, Dyrektywa Parlamentu Europejskiego i Rady 2009/30/WE z dnia 23 kwietnia 2009 r. Zmieniająca Dyrektywę 98/70/WE Odnoszącą się do Specyfikacji Benzyny i Olejów Napędowych oraz Wprowadzającą Mechanizm Monitorowania i Ograniczania Emisji Gazów Cieplarnianych oraz Zmieniającą Dyrektywę Rady 1999/32/WE; European Parliament: Brussels, Belgium, 2009.

- Podkówka, Z.; Podkówka, L. Use of Polish-bread maize hybrid for biogas production. J. Cent. Eur. Agric. 2015, 16, 463–475. [Google Scholar]

- Garcia, A. Corn Silage Production and Utilization. In iGROW Corn: Best Management Practices; Clay, D.E., Clay, S.A., Byamukama, E., Eds.; South Dakota State University: Brookings, SD, USA, 2016. [Google Scholar]

- Główny Urząd Statystyczny. Production of Agricultural and Horticultural Crops in 2019; Główny Urząd Statystyczny: Warsaw, Poland, 2020.

- Jaworski, A. Mechanizacja Uprawy Kukurydzy Paszowej; Małopolski Ośrodek Doradztwa Rolniczego w Karniowicach: Karniowice, Poland, 2012; ISBN 83-60394-03-2. [Google Scholar]

- Forte, A.; Fagnano, M.; Fierro, A. Potential role of compost and green manure amendment to mitigate soil GHGs emissions in Mediterranean drip irrigated maize production systems. J. Environ. Manag. 2017, 192, 68–78. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Czapiewska, G. Consequences of climate change for farming and rural areas. Studia Quat. 2020, 37, 51–56. [Google Scholar]

- Rokochinskiy, A.; Frolenkova, N.; Turcheniuk, V.; Volk, P.; Prykhodko, N.; Tykhenko, R.; Openko, I. The variability of natural and climatic conditions in investment projects in the field of nature management. J. Water Land Dev. 2021, 48, 48–54. [Google Scholar] [CrossRef]

- Michalski, T. Produkcja Wybranych Rolniczych Surowców Energetycznych. Odnawialne Źródła Energii. Rolnicze Surowce Energetyczne; Kołodziej, B., Matyki, M., Eds.; PWRiL Sp. z o.o.: Poznań, Poland, 2012; ISBN 978-83-09-01139-2. [Google Scholar]

- Knox, J.; Daccache, A.; Hess, T.; Haro, D. Meta-analysis of climate impacts and uncertainty on crop yields in Europe. Environ. Res. Lett. 2016, 11, 113004. [Google Scholar] [CrossRef]

- Faber, A.; Jarosz, Z.; Król, A. The Impact of Climate Change on the Efficiency of Nitrogen Use and its Losses. Probl. Rol. Swiat. 2019, 19, 37–46. [Google Scholar]

- EU Nitrogen Expert Panel. Nitrogen Use Efficiency (NUE)—An Indicator for the Utilization of Nitrogen in Agriculture and Food Systems; Wageningen University: Wageningen, The Netherlands, 2015. [Google Scholar]

- Oppeltová, P.; Boráková, J. Monitoring of basic physicochemical parameters in the flow and their possible influence on the quality of the small water source. J. Water Land Dev. 2020, 44, 106–117. [Google Scholar] [CrossRef]

- Krajowy Ośrodek Bilansowania i Zarządzania Emisjami. Krajowy Raport Inwentaryzacyjny 2018; Instytut Ochrony Środowiska—Państwowy Instytut Badawczy. Krajowy Ośrodek Bilansowania i Zarządzania Emisjami: Warszawa, Poland, 2018. [Google Scholar]

- Krajowy Ośrodek Bilansowania i Zarządzania Emisjami. Poland’s National Inventory Report 2017. Greenhouse Gas Inventory for 1988–2015; Instytut Ochrony Środowiska—Państwowy Instytut Badawczy. Krajowy Ośrodek Bilansowania i Zarządzania Emisjami: Warszawa, Poland, 2017. [Google Scholar]

- EMEP/EEA. 3.D Crop Production and Agricultural Soils; tab. 3.2, tab. 3.9; European Environment Agency: Copenhagen, Denmark, 2016.

- Muzalewski, A. Wskaźniki Eksploatacyjno-Ekonomiczne Maszyn i Ciągników Rolniczych w Poradnik PROW. Przepisy Ochrony Środowiska, Normatywy i Wskaźniki Funkcjonujące w Produkcji Rolniczej, 1st ed.; Pruszka, P., Ed.; Centrum Doradztwa Rolniczego w Brwinowie: Kraków, Poland, 2016; ISBN 83-88082-81-7. [Google Scholar]

- Felten, D.; Fröba, N.; Fries, J.; Emmerling, C. Energy balances and greenhouse gasmitigation potentials of bioenergy cropping systems (Miscanthus, rapeseed and maize) based on farming conditions in Western Germany. Renew. Energy 2013, 55, 160–174. [Google Scholar] [CrossRef]

- Radzimirski, S.; Taubert, S. Inwentaryzacja Emisji Wybranych Zanieczyszczeń Sektora Transportu Drogowego w 2008 r; Instytut Transportu Samochodowego, Centrum Ochrony Środowiska: Warszawa, Poland, 2009; Volume 7904. [Google Scholar]

- Internetowy System Aktów Prawnych. Dz. U. 2018 r. Poz. 2527; Rozporządzenie Ministra Środowiska w Sprawie Wykazów Zawierających Informacje i Dane o Zakresie Korzystania ze Środowiska oraz o Wysokości Należnych Opłat; Internetowy System Aktów Prawnych: Warszawa, Poland, 2018.

- Intergovernmental Panel on Climate Change. Climate Change 2007: The Physical Science Basis; Contribution of Working Group I to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; Solomon, S., Qin, D., Manning, M., Chen, Z., Marquis, M., Averyt, K.B., Tignor, M., Miller, H.L., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2007; ISBN 978-0-521-70596-7. [Google Scholar]

- Internetowy System Aktów Prawnych. Dz. U. 2018. Poz. 1339, Rozporządzenie Rady Ministrów z dnia 5 czerwca 2018 r. w Sprawie Przyjęcia „Programu Działań Mających na Celu Zmniejszenie Zanieczyszczenia Wód Azotanami Pochodzącymi ze Źródeł Rolniczych oraz Zapobieganie Dalszemu Zanieczyszczeniu”; Internetowy System Aktów Prawnych: Warszawa, Poland, 2018.

- Pawlak, J. Szacunkowe Zużycie Oleju Napędowego w Rolnictwie w Latach 2010–2015 w Układzie Wojewódzkim. Probl. Inż. Rol. 2017, 2, 55–65. [Google Scholar]

- Wrota Podlasia. Region Description. Available online: https://www.wrotapodlasia.pl/en/gospodarka/coi/Region_Description.html (accessed on 26 August 2021).

- Konieczna, A.; Roman, K.; Roman, M.; Śliwiński, D.; Roman, M. Energy Efficiency of Maize Production Technology: Evidence from Polish Farms. Energies 2021, 14, 170. [Google Scholar] [CrossRef]

- Jacobs, A.; Auburger, S.; Bahrs, E.; Brauer-Siebrecht, W.; Christen, O.; Götze, P.; Koch, H.J.; Rücknagel, J.; Märländer, B. Greenhouse gas emission of biogas production out of silage maize and sugar beet—An assessment along the entire production chain. Appl. Energy 2017, 190, 114–121. [Google Scholar] [CrossRef]

- Camargo, G.T.G.; Ryan, M.R.; Richard, T.L. Energy use and greenhouse gas emissions from crop production using the farm energy analysis tool. Bioscience 2013, 63, 263–273. [Google Scholar] [CrossRef] [Green Version]

- Meyer-Aurich, A.; Schattauer, A.; Hellebrand, H.J.; Klauss, H.; Plöchl, M.; Berg, W. Impact of uncertainties on greenhouse gas mitigation potential of biogas production from agricultural resources. Renew. Energy 2012, 37, 277–284. [Google Scholar] [CrossRef]

- Podkówka, W.; Podkówka, Z. Technologia Kiszenia Biomasy na Cele Paszowe i Biogaz Rolniczy; PWRiL: Warszawa, Poland, 2017; ISBN 978-83-09-01102-6. [Google Scholar]

- Taleghani, A.; Almassi, M.; Ghahderijani, M. Environmental evaluation and optimization of energy use and greenhouse gases mitigation for farm production systems in Mashhad, Iran. Environ. Sci. Pollut. Res. 2020, 27, 35272–35283. [Google Scholar] [CrossRef] [PubMed]

- Gorzelany, J.; Puchalski, C.; Malach, M. Ocena kosztów i nakładów energetycznych w produkcji kukurydzy na ziarno i kiszonkę. Inżynieria Rol. 2020, 8, 135–141. [Google Scholar]

- Jarosz, Z.; Księżak, J.; Faber, A. Assessment of greenhouse gas emissions in systems used in croping maize for bioethanol production. Rocz. Nauk. Stowarzyszenia Ekon. Rol. Agrobiz. 2017, 19, 60–65. [Google Scholar] [CrossRef]

- Miheev, V.V.; Ponomarev, A.G.; Eremin, P.A.; Mikheev, V.S. The Methodology of Modeling and Optimization of Technologies in Crop Production. Agric. Mech. Asia Afr. Lat. Am. 2020, 51, 52–57. [Google Scholar]

- Stošić, M.; Ivezić, V.; Tadić, V. Tillage systems as a function of greenhouse gas (GHG) emission and fuel consumption mitigation. Environ. Sci. Pollut. Res. 2021, 28, 16492–16503. [Google Scholar] [CrossRef] [PubMed]

- Freibauer, A.; Rounsevellb, M.D.A.; Smithc, P.; Verhagen, J. Carbon sequestration in the agricultural soils of Europe. Geoderma 2004, 122, 1–23. [Google Scholar] [CrossRef]

- Jia, Q.; Zhang, H.; Wang, J.; Xiao, X.; Chang, S.; Zhang, C.; Liu, Y.; Hou, F. Planting practices and mulching materials improve maize net ecosystem C budget, global warming potential and production in semi-arid regions. Soil Tillage Res. 2021, 207, 104850. [Google Scholar] [CrossRef]

- Narodowy Program Rozwoju Gospodarki Niskoemisyjnej; Ministerstwo Gospodarki: Warszawa, Poland, 2015.

- Król-Badziak, A.; Pishgar-Komleh, S.H.; Rozakis, S.; Księżak, J. Environmental and socio-economic performance of different tillage systems in maize grain production: Application of Life Cycle Assessment and Multi-Criteria Decision Making. J. Clean. Prod. 2021, 278, 123792. [Google Scholar] [CrossRef]

- Krasuska, E.; Faber, A.; Pudełko, R.; Jarosz, Z.; Borzecka-Walker, M.; Kozyra, J.; Syp, A. Emission saving opportunities for corn cultivation for ethanol in Poland. J. Food Agric. Environ. 2013, 11, 2050–2053. [Google Scholar]

| Source of the Emission | Type of Contamination | |||

|---|---|---|---|---|

| Greenhouse Gases GHG | NH3 | |||

| N2O | CO2 | CH4 | ||

| Natural fertilizers | + | + | ||

| Inorganic fertilizers, including urea | + | + | + | |

| Fuel consumption | + | + | + | |

| Type/Name of the Fertilizer | N Content [%] | The Emission Factor EF | ||

|---|---|---|---|---|

| N2O-N | CO2-C | NH3 [g NH3·kg N−1] | ||

| Ammonium sulphate | 34 | 0.01 | 16 | |

| Ammonium phosphate | 18 | 0.01 | 51 | |

| Ammonium sulfate | 21 | 0.01 | 92 | |

| Calcium nitrate | 15 | 0.01 | 8 | |

| Urea | 46 | 0.01 | 0.2 | 159 |

| Compound fertilizers (NPK) | 0.01 | 67 | ||

| Type/Name of the Fertilizer | N Content [%] | The Emission Factor EF [g NH3·kg N−1] |

|---|---|---|

| Cattle manure | 0.318 | 0.2500 |

| Manure–pigs | 0.352 | 0.7000 |

| Cattle slurry | 0.383 | 0.1892 |

| Slurry–pigs | 0.373 | 0.5355 |

| Technology No. | Cultivation Area [ha] | Distance from the Farm [km] | Yield [t∙ha−1] | N Content [%] | The Amount of N from Fertilizers [kg∙ha−1] | ||

|---|---|---|---|---|---|---|---|

| Natural | Mineral | Total | |||||

| MS1 | 3.4 | 0,8 | 72 | 323.5 | 207.6 | 173.0 | 380.6 |

| MS2 | 2 | 0.05 | 60 | 184.5 | 174.0 | 131.4 | 305.4 |

| MS3 | 13 | 1.5 | 50 | 152.9 | 112.0 | 181.0 | 293.0 |

| MS4 | 5.07 | 0.5 | 55 | 147.5 | 132.5 | 79.5 | 212.1 |

| MS5 | 3.25 | 0.6 | 65 | 255.0 | 94.6 | 114.6 | 209.2 |

| MS6 | 4.5 | 1 | 80 | 116.2 | 76.0 | 148.4 | 224.4 |

| MS7 | 2 | 2.5 | 50 | 120.0 | 0 | 138.0 | 138.0 |

| MS8 | 3.5 | 2.5 | 70 | 414.9 | 156.8 | 75.6 | 232.4 |

| MS9 | 10 | 2.2 | 67 | 388.5 | 140.0 | 78.2 | 218.2 |

| MS10 | 5 | 1.6 | 75 | 425.6 | 122.5 | 75.4 | 197.9 |

| MS11 | 8 | 2.2 | 75 | 369.0 | 122.5 | 75.4 | 197.9 |

| MS12 | 5 | 1 | 50 | 379.4 | 122.9 | 81.0 | 203.9 |

| MS13 | 3.21 | 1.5 | 45 | 128.9 | 39.9 | 0 | 39.9 |

| Technology No. | Emissions | |||||||

|---|---|---|---|---|---|---|---|---|

| GHG [kg CO2eq·ha−1] | NH3 [kg NH3·ha−1] | |||||||

| Fertilizers | ON Combustion | Total | The Amount of N from Fertilizers [kg∙ha−1] | |||||

| Natural | Mineral | Total | Natural | Mineral | Total | |||

| MS1 | 972.106 | 810.134 | 1782.240 | 875.627 | 2657.868 | 0.059 | 3856.571 | 3856.630 |

| MS2 | 814.817 | 725.327 | 1540.145 | 499.412 | 2039.557 | 0.048 | 15,741.879 | 15,741.926 |

| MS3 | 524.480 | 1104.264 | 1628.744 | 413.930 | 2042.674 | 0.034 | 32,711.643 | 32,711.677 |

| MS4 | 620.686 | 372.412 | 993.098 | 399.353 | 1392.451 | 0.040 | 6470.059 | 6470.099 |

| MS5 | 442.782 | 719.641 | 1162.423 | 690.245 | 1852.667 | 0.025 | 22,134.897 | 22,134.921 |

| MS6 | 355.897 | 885.603 | 1241.500 | 314.595 | 1556.095 | 0.049 | 25,434.429 | 25,434.478 |

| MS7 | 0 | 866.234 | 866.234 | 324.821 | 1191.055 | 0 | 26,643.857 | 26,643.857 |

| MS8 | 734.272 | 474.366 | 1208.638 | 1122.952 | 2331.591 | 0.123 | 14,590.684 | 14,590.807 |

| MS9 | 655.600 | 490.866 | 1146.466 | 1051.518 | 2197.985 | 0.119 | 15,098.186 | 15,098.305 |

| MS10 | 573.650 | 473.541 | 1047.191 | 1152.032 | 2199.223 | 0.104 | 14,565.309 | 14,565.413 |

| MS11 | 573.650 | 473.541 | 1047.191 | 998.824 | 2046.016 | 0.104 | 14,565.309 | 14,565.413 |

| MS12 | 575.322 | 379.311 | 954.634 | 1026.898 | 1981.532 | 0.033 | 6589.929 | 6589.962 |

| MS13 | 186.731 | 0 | 186.731 | 348.946 | 535.677 | 0.012 | 0 | 0.012 |

| Min | 0 | 0 | 186.731 | 314.595 | 535.677 | 0 | 0 | 0.012 |

| Max | 972.106 | 1104.264 | 1 82.240 | 1152.032 | 2657.868 | 0.123 | 32,711.643 | 32,711.677 |

| Mean | 540.769 | 598.096 | 1138.864 | 709.166 | 1848.030 | 0.058 | 15,261.750 | 15,261.808 |

| Standard deviation | 555.344 | 572.851 | 1128.196 | 372.420 | 1500.615 | 0.033 | 2727.008 | 2727.041 |

| Technology No. | Emissions [%] | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| GHG | NH3 | ||||||||

| Fertilizers | Fertilizers | ON Combustion | Total | Fertilizers | |||||

| Natural | Mineral | Total | Natural | Mineral | Total | ||||

| MS1 | 54.5 | 45.5 | 100 | 67.1 | 32.9 | 100 | 0.002 | 99.998 | 100 |

| MS2 | 52.9 | 47.1 | 100 | 75.5 | 24.5 | 100 | 0 | 100 | 100 |

| MS3 | 32.2 | 67.8 | 100 | 79.7 | 20.3 | 100 | 0 | 100 | 100 |

| MS4 | 62.5 | 37.5 | 100 | 71.3 | 28.7 | 100 | 0.001 | 99.999 | 100 |

| MS5 | 38.1 | 61.9 | 100 | 62.7 | 37.3 | 100 | 0 | 100 | 100 |

| MS6 | 28.7 | 71.3 | 100 | 79.8 | 20.2 | 100 | 0 | 100 | 100 |

| MS7 | 0 | 100 | 100 | 72.7 | 27.3 | 100 | 0 | 100 | 100 |

| MS8 | 60.8 | 39.2 | 100 | 51.8 | 48.2 | 100 | 0.001 | 99.999 | 100 |

| MS9 | 57.2 | 42.8 | 100 | 52.2 | 47.8 | 100 | 0.001 | 99.999 | 100 |

| MS10 | 54.8 | 45.2 | 100 | 47.6 | 52.4 | 100 | 0.001 | 99.999 | 100 |

| MS11 | 54.8 | 45.2 | 100 | 51.2 | 48.8 | 100 | 0.001 | 99.999 | 100 |

| MS12 | 60.3 | 39.7 | 100 | 48.2 | 51.8 | 100 | 0.001 | 99.999 | 100 |

| MS13 | 100 | 0 | 100 | 34.9 | 65.1 | 100 | 100 | 0 | 100 |

| Min | 0 | 0 | 34.9 | 20.2 | 0 | 0 | |||

| Max | 100 | 100 | 79.8 | 65.1 | 100 | 100 | |||

| Mean | 50.5 | 49.5 | 61.1 | 38.9 | 7.693 | 92.307 | |||

| Technology No. | Emissions | |||||||

|---|---|---|---|---|---|---|---|---|

| GHG [kg CO2eq·t−1 of Yield] | NH3 [kg NH3·t−1 of Yield] | |||||||

| Fertilizers | ON Combustion | Total | Fertilizers | |||||

| Natural | Mineral | Total | Natural | Mineral | Total | |||

| MS1 | 13.547 | 11.289 | 24.836 | 12.202 | 37.038 | 0.001 | 53.743 | 53.743 |

| MS2 | 13.580 | 12.089 | 25.669 | 8.324 | 33.993 | 0.001 | 262.365 | 262.365 |

| MS3 | 10.490 | 22.085 | 32.575 | 8.279 | 40.853 | 0.001 | 654.233 | 654.234 |

| MS4 | 11.285 | 6.771 | 18.056 | 7.261 | 25.317 | 0.001 | 117.637 | 117.638 |

| MS5 | 6.852 | 11.137 | 17.989 | 10.682 | 28.670 | 0 | 342.539 | 342.540 |

| MS6 | 4.449 | 11.070 | 15.519 | 3.932 | 19.451 | 0.001 | 317.930 | 317.931 |

| MS7 | 0 | 17.325 | 17.325 | 6.496 | 23.821 | 0 | 532.877 | 532.877 |

| MS8 | 10.490 | 6.777 | 17.266 | 16.042 | 33.308 | 0.002 | 208.438 | 208.440 |

| MS9 | 9.785 | 7.326 | 17.111 | 15.694 | 32.806 | 0.002 | 225.346 | 225.348 |

| MS10 | 7.649 | 6.314 | 13.963 | 15.360 | 29.323 | 0.001 | 194.204 | 194.206 |

| MS11 | 7.649 | 6.314 | 13.963 | 13.318 | 27.280 | 0.001 | 194.204 | 194.206 |

| MS12 | 11.506 | 7.586 | 19.093 | 20.538 | 39.631 | 0.001 | 131.799 | 131.799 |

| MS13 | 4.150 | 0 | 4.150 | 7.754 | 11.904 | 0 | 0 | 0 |

| Min | 0 | 0 | 4.150 | 3.932 | 11.904 | 0 | 0 | 0 |

| Max | 13.580 | 22.085 | 32.575 | 20.538 | 40.853 | 0.002 | 654.233 | 654.234 |

| Mean | 8.572 | 9.699 | 18.270 | 11.222 | 29.492 | 0.001 | 248.870 | 248.871 |

| Standard deviation | 6.645 | 7.983 | 14.628 | 3.145 | 17.773 | 0.000 | 38.002 | 38.002 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Konieczna, A.; Roman, K.; Borek, K.; Grzegorzewska, E. GHG and NH3 Emissions vs. Energy Efficiency of Maize Production Technology: Evidence from Polish Farms; a Further Study. Energies 2021, 14, 5574. https://doi.org/10.3390/en14175574

Konieczna A, Roman K, Borek K, Grzegorzewska E. GHG and NH3 Emissions vs. Energy Efficiency of Maize Production Technology: Evidence from Polish Farms; a Further Study. Energies. 2021; 14(17):5574. https://doi.org/10.3390/en14175574

Chicago/Turabian StyleKonieczna, Anita, Kamil Roman, Kinga Borek, and Emilia Grzegorzewska. 2021. "GHG and NH3 Emissions vs. Energy Efficiency of Maize Production Technology: Evidence from Polish Farms; a Further Study" Energies 14, no. 17: 5574. https://doi.org/10.3390/en14175574

APA StyleKonieczna, A., Roman, K., Borek, K., & Grzegorzewska, E. (2021). GHG and NH3 Emissions vs. Energy Efficiency of Maize Production Technology: Evidence from Polish Farms; a Further Study. Energies, 14(17), 5574. https://doi.org/10.3390/en14175574